Patents

Literature

33 results about "Double plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

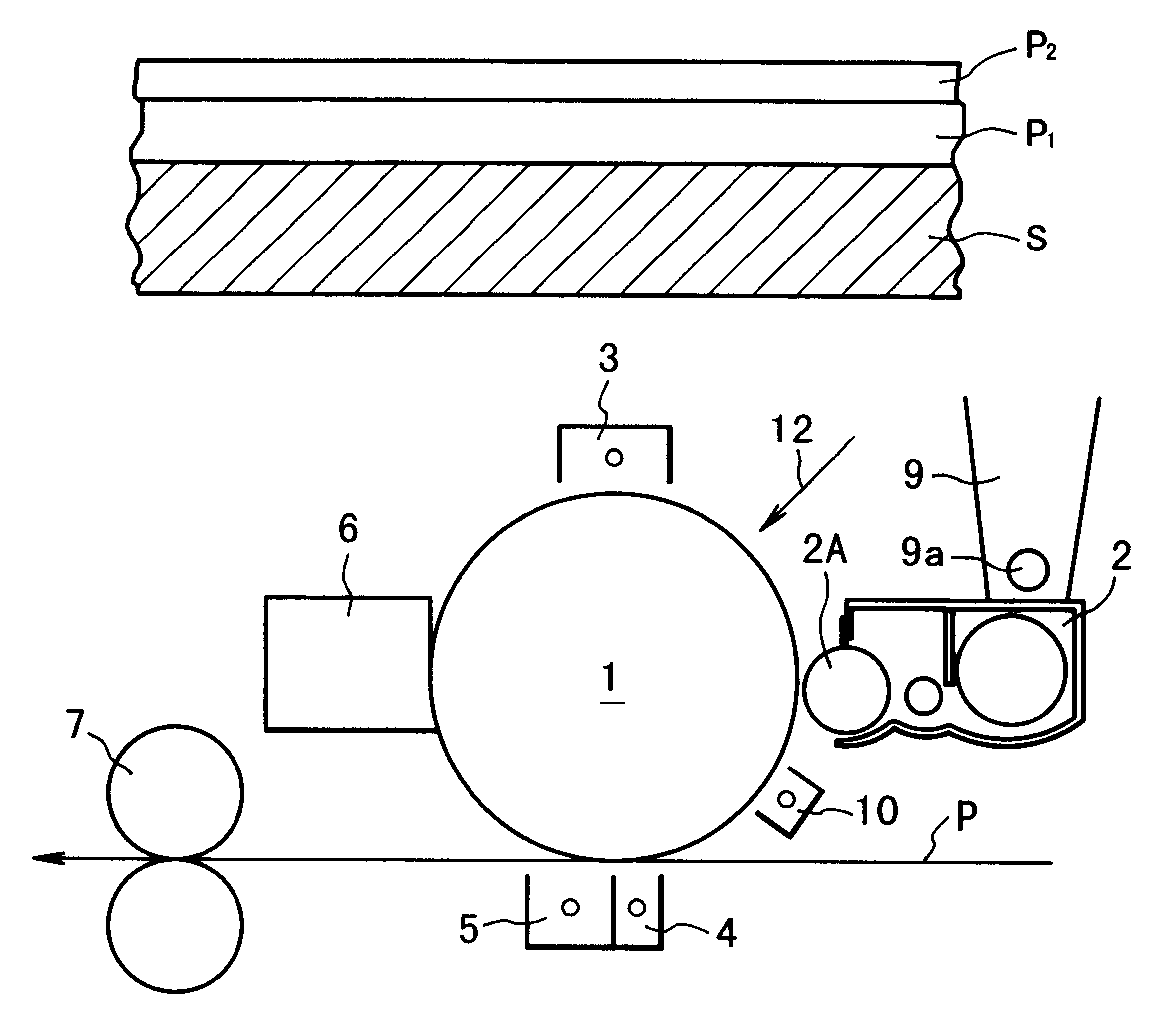

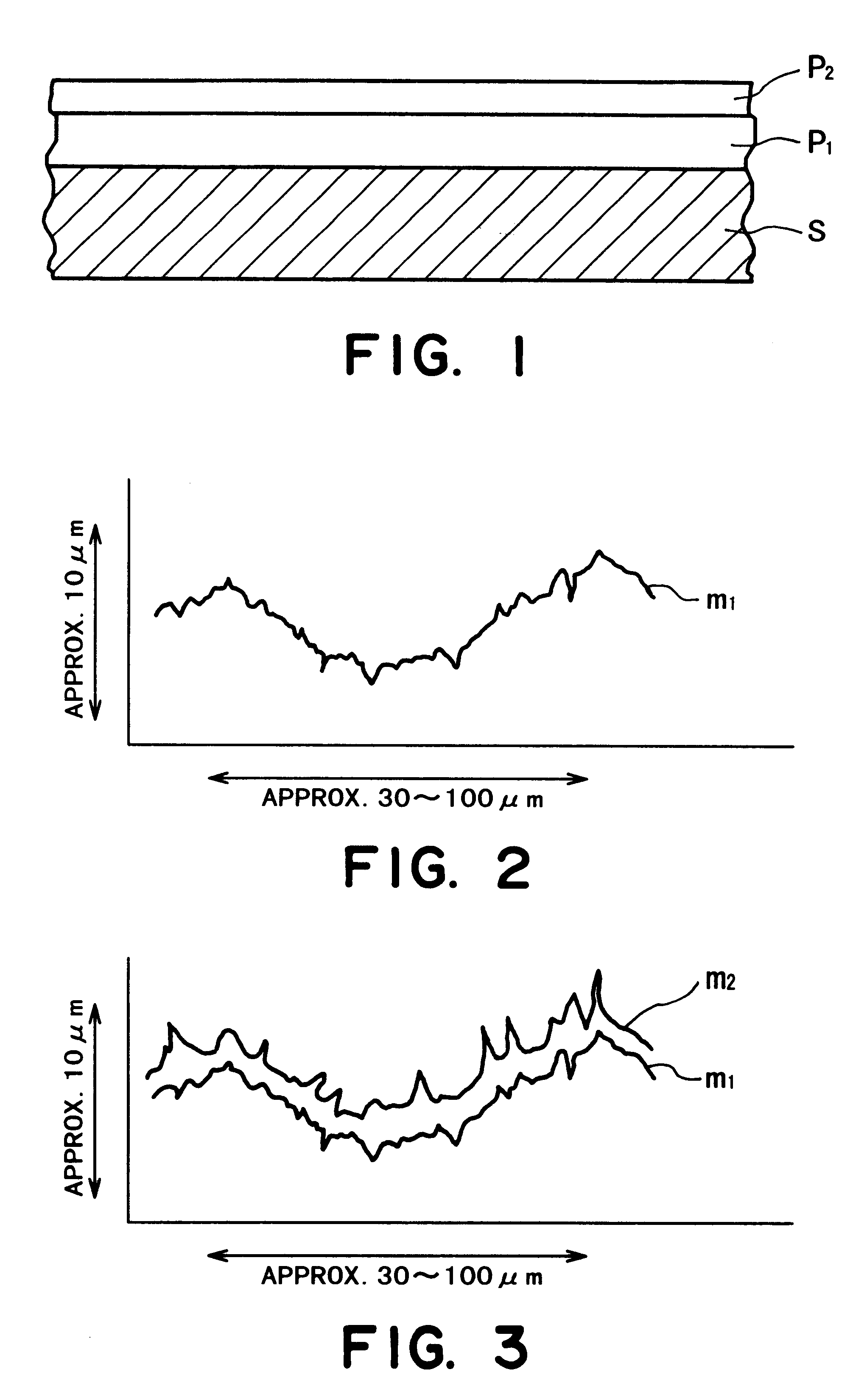

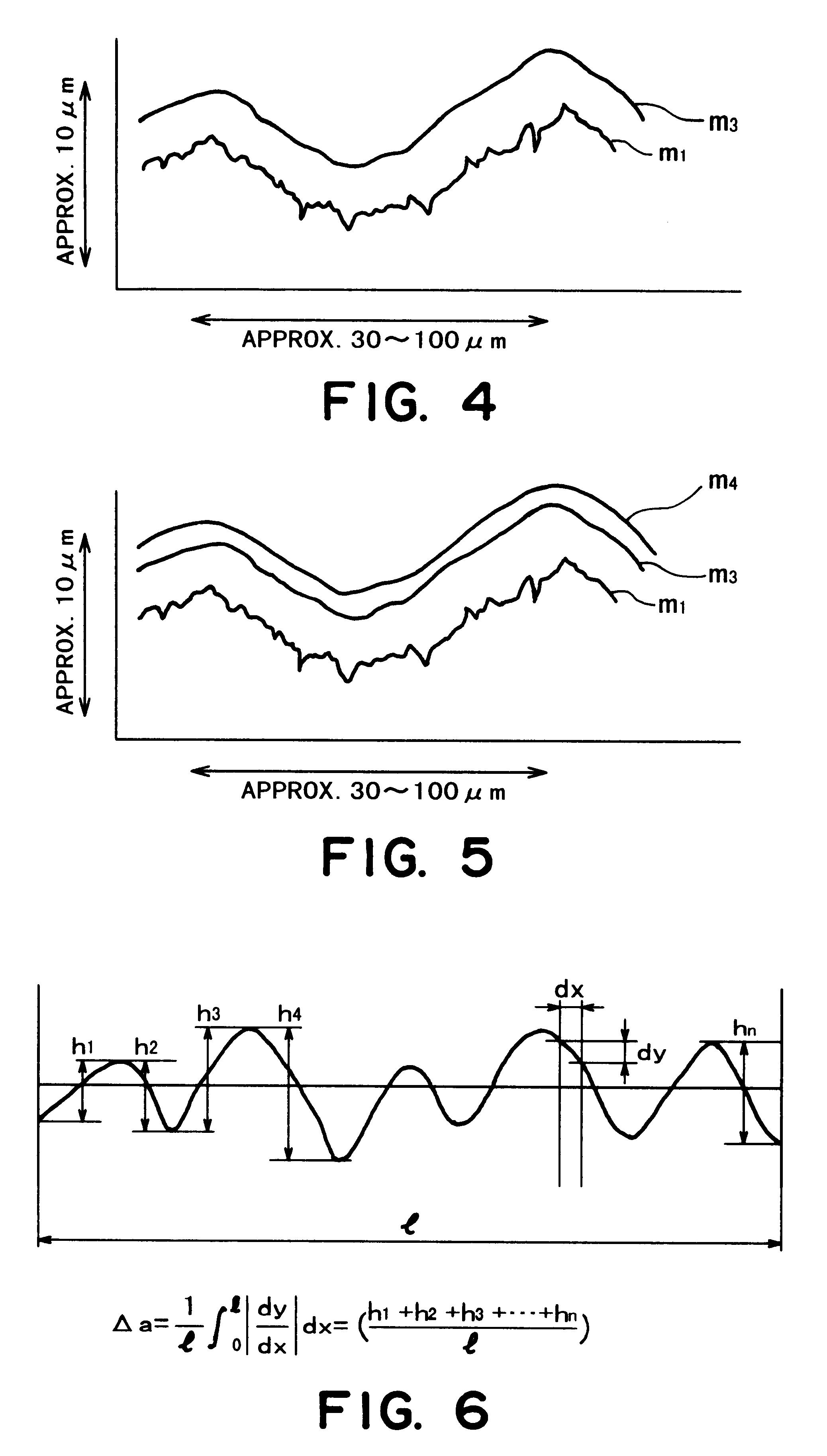

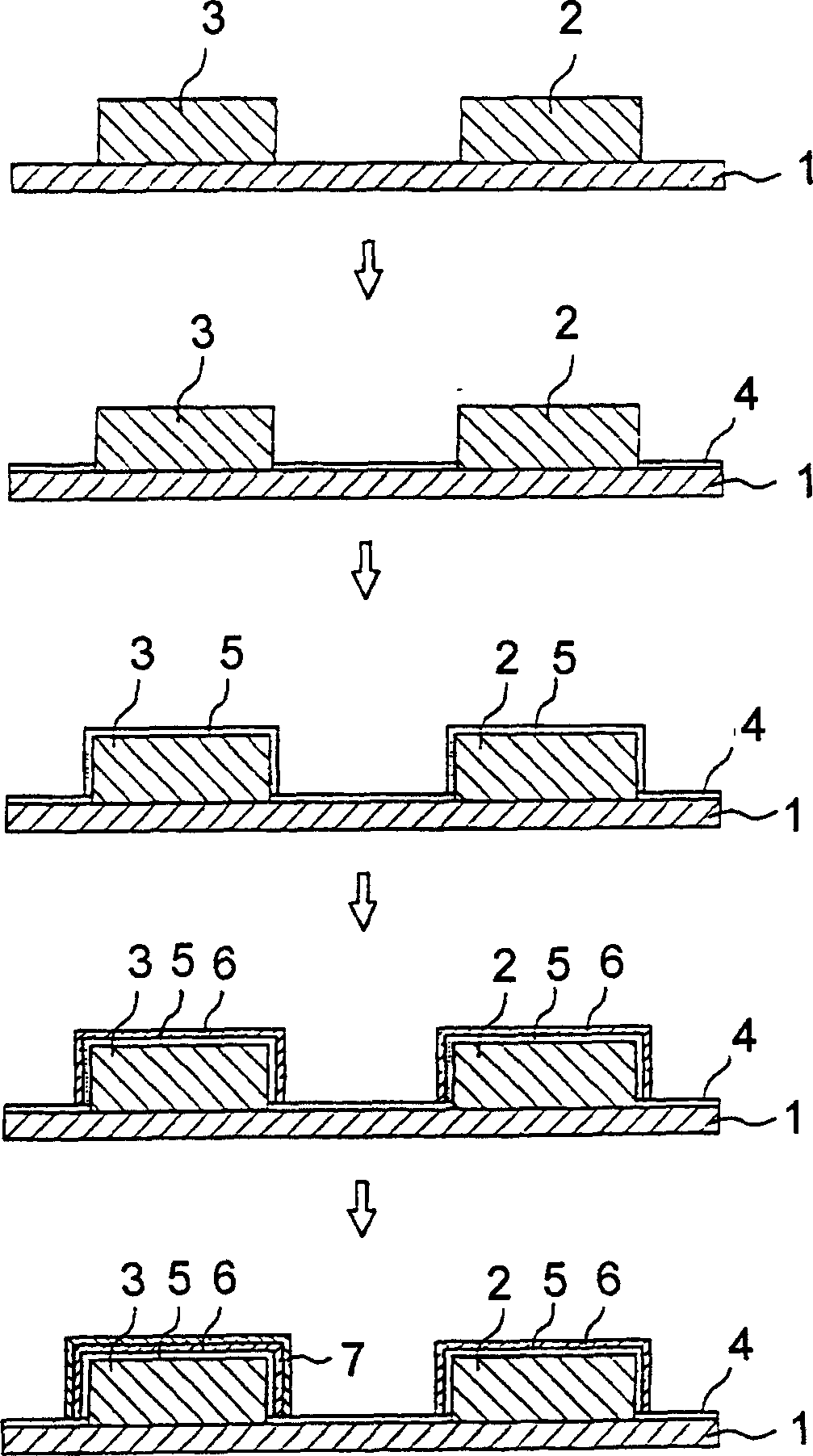

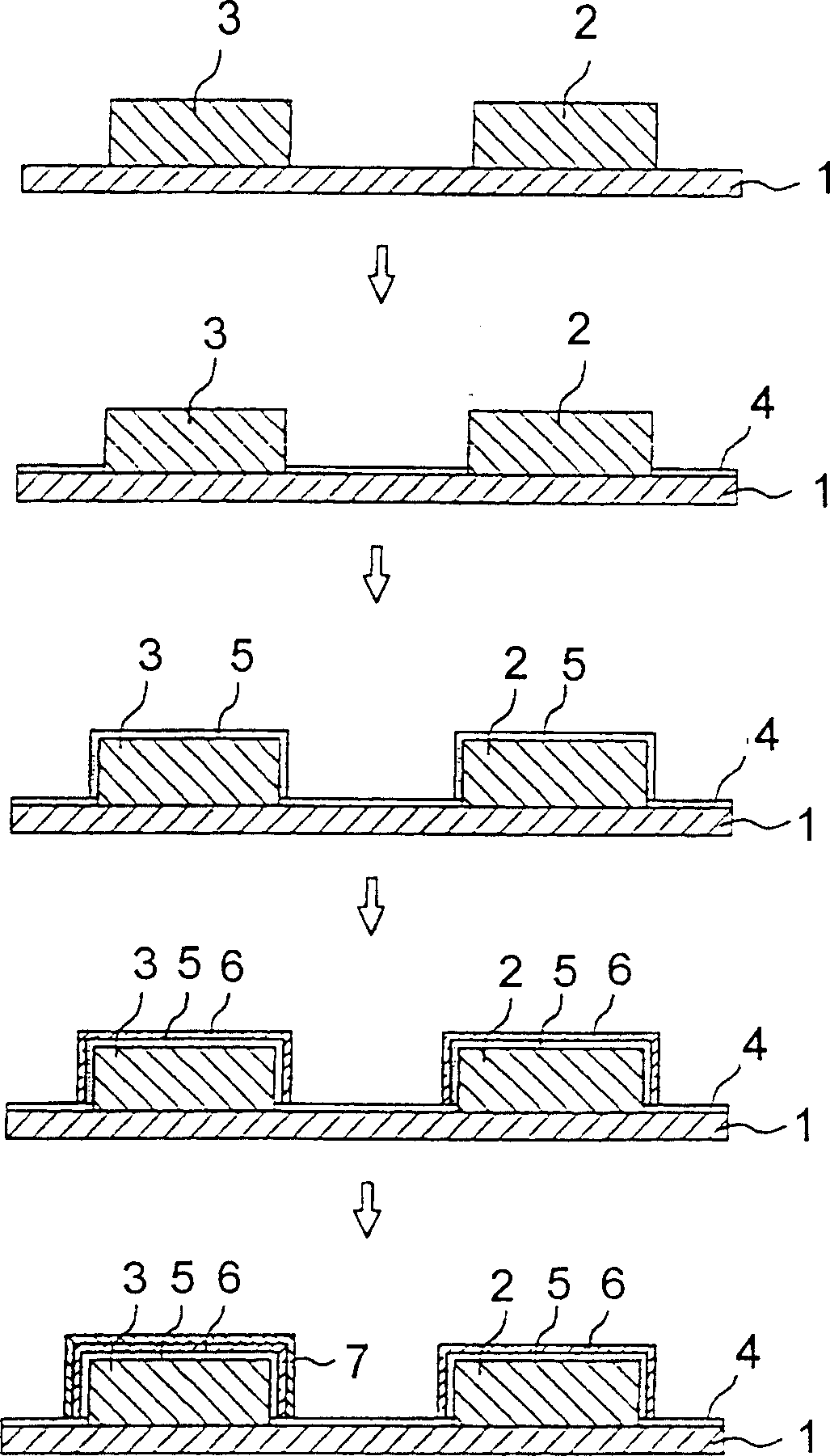

Developer-carrying member, and developing device and image forming apparatus including the member

InactiveUS6201942B1High accuracy of surface roughnessHigh hardnessShaft and bearingsElectrographic process apparatusWear resistantEngineering

A developer-carrying member to be installed in an electrophotographic developing device for carrying and conveying a developer along a surface thereof, is formed of a substrate, and an intermediate electroless plating layer and an electroplating layer disposed in this order on the substrate. As a result of the electroless and electro double plating layer structure, the developer-carrying member is provided with a wear-resistant surface which has an appropriate degree of roughness suitable for conveying the developer thereon and is yet free from minute projections and cracks undesirable from the viewpoint of continuous image forming performances.

Owner:CANON KK +1

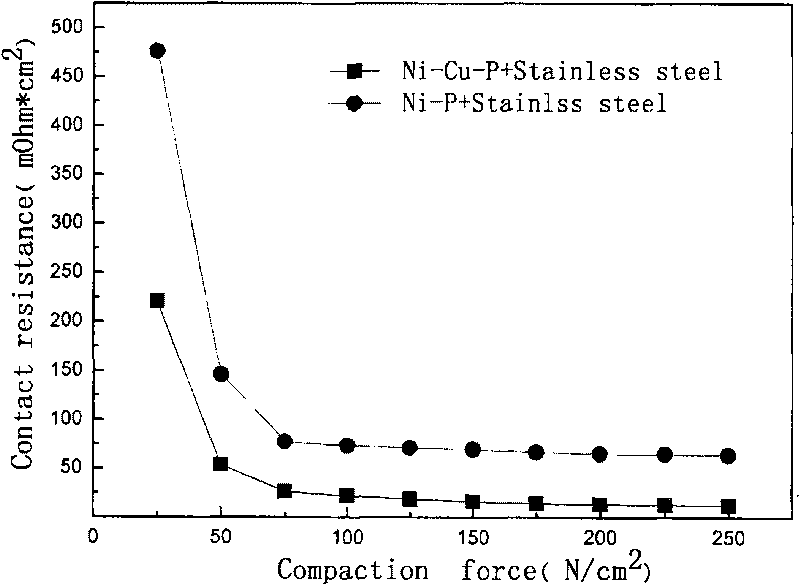

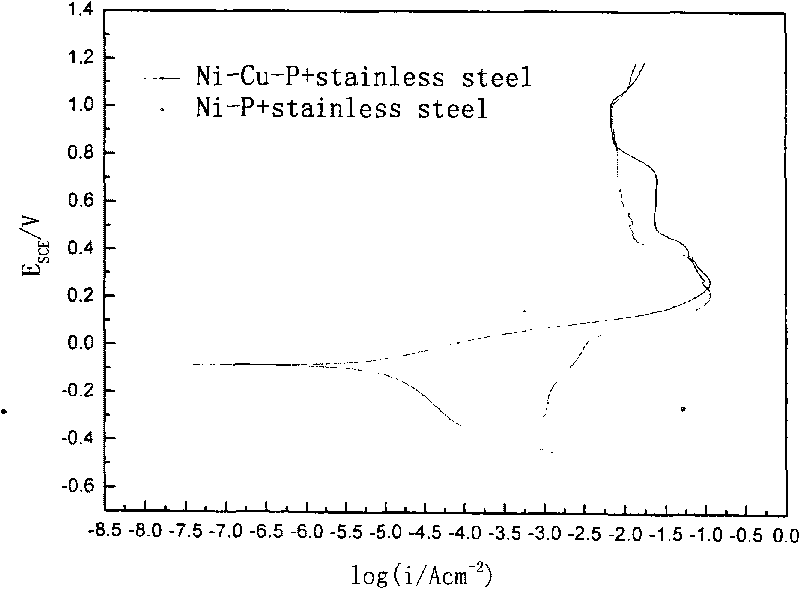

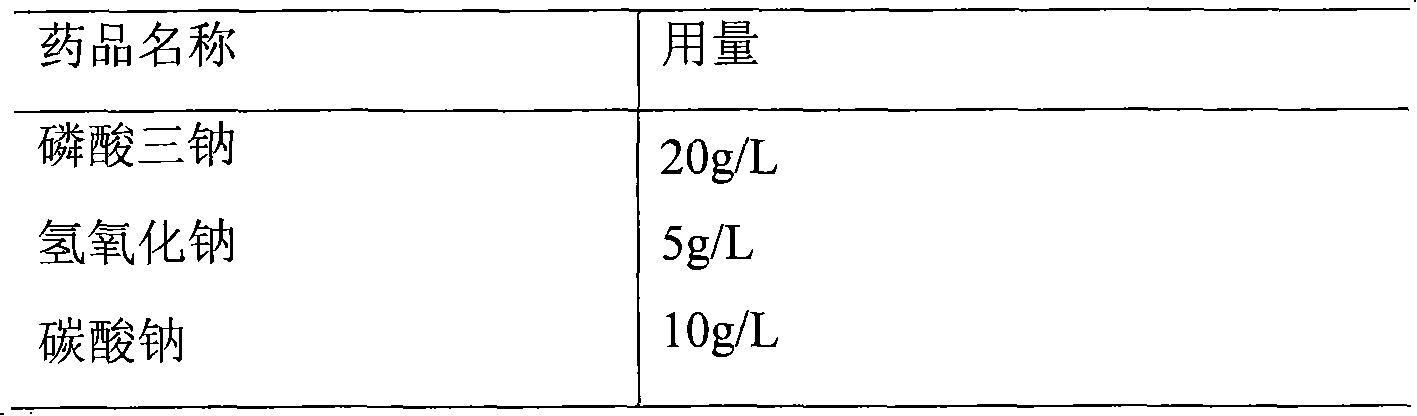

Proton exchange membrane fuel cell stainless steel bipolar plate and modification method thereof

InactiveCN101710620AImprove corrosion resistanceLow priceCell electrodesLiquid/solution decomposition chemical coatingElectrical resistance and conductanceElectroless deposition

The invention relates to an improvement on a surface property of a proton exchange membrane fuel cell metal bipolar plate, which is characterized in that: a substrate surface is plated with a nickel layer and a Ni-Cu-P double-plating layer, wherein Ni-Cu-P adopts electroless deposition. The improvement not only greatly reduces contact resistance of the bipolar plate and a gas diffusion layer, but also improves corrosion resistant. Electrical conductivity and the corrosion resistance can basically reach the level of those of the stainless steel bipolar plate plated with precious metal. The improvement is simple in modification, low in cost and superior in performance after modification.

Owner:江苏新源动力有限公司

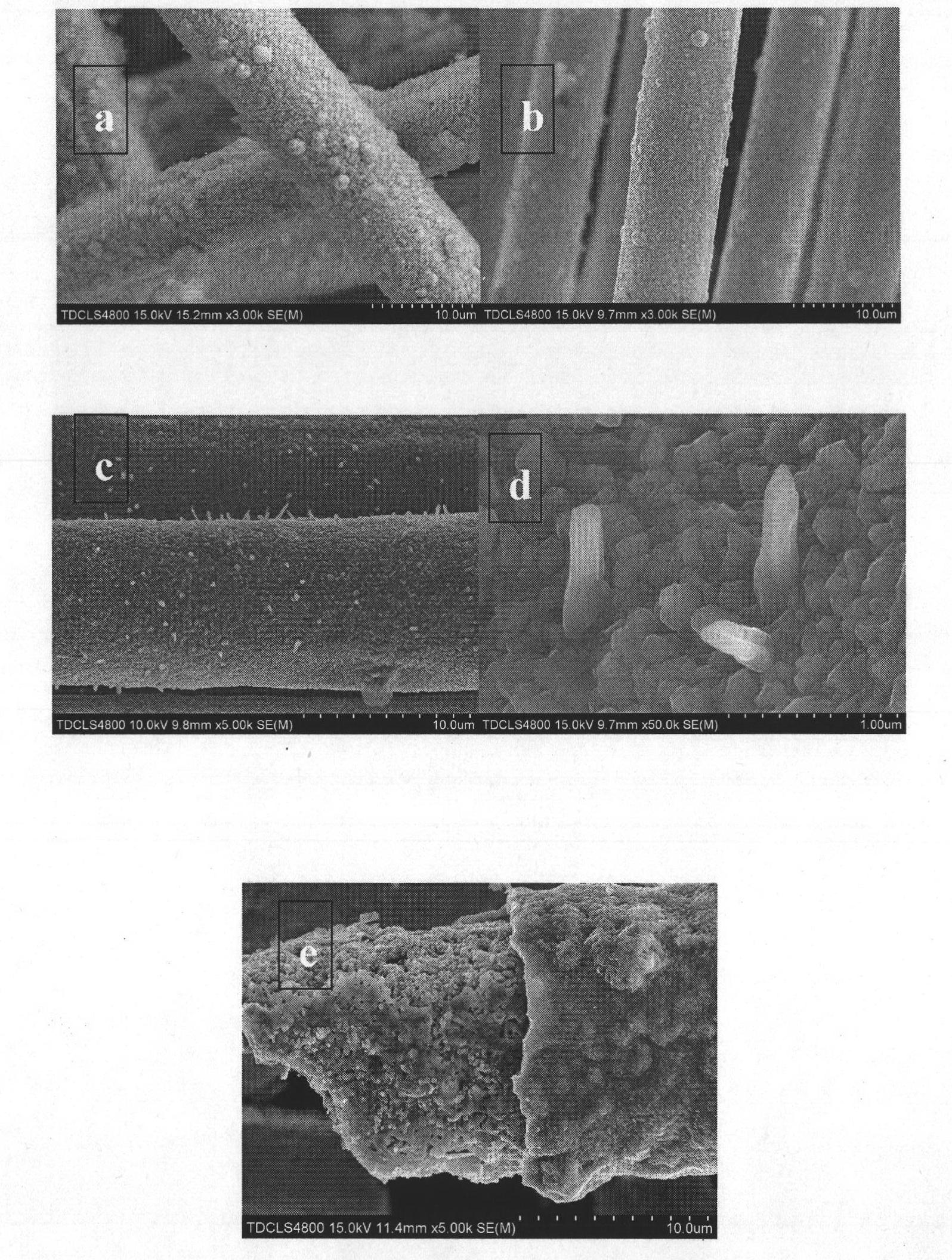

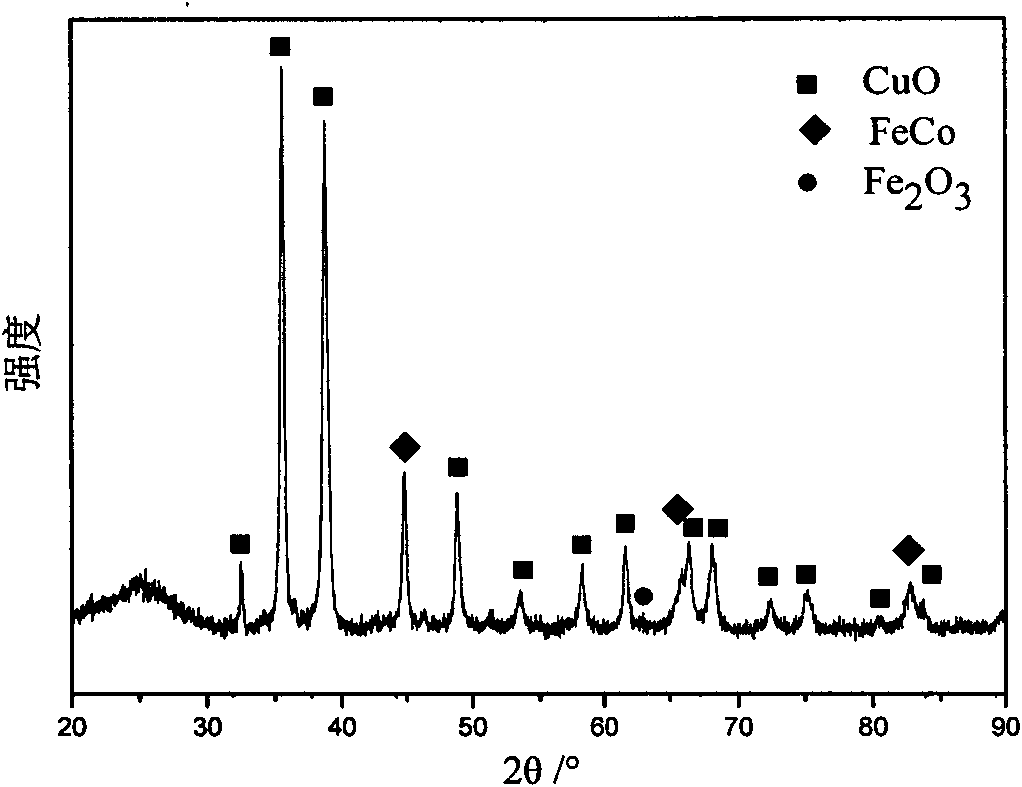

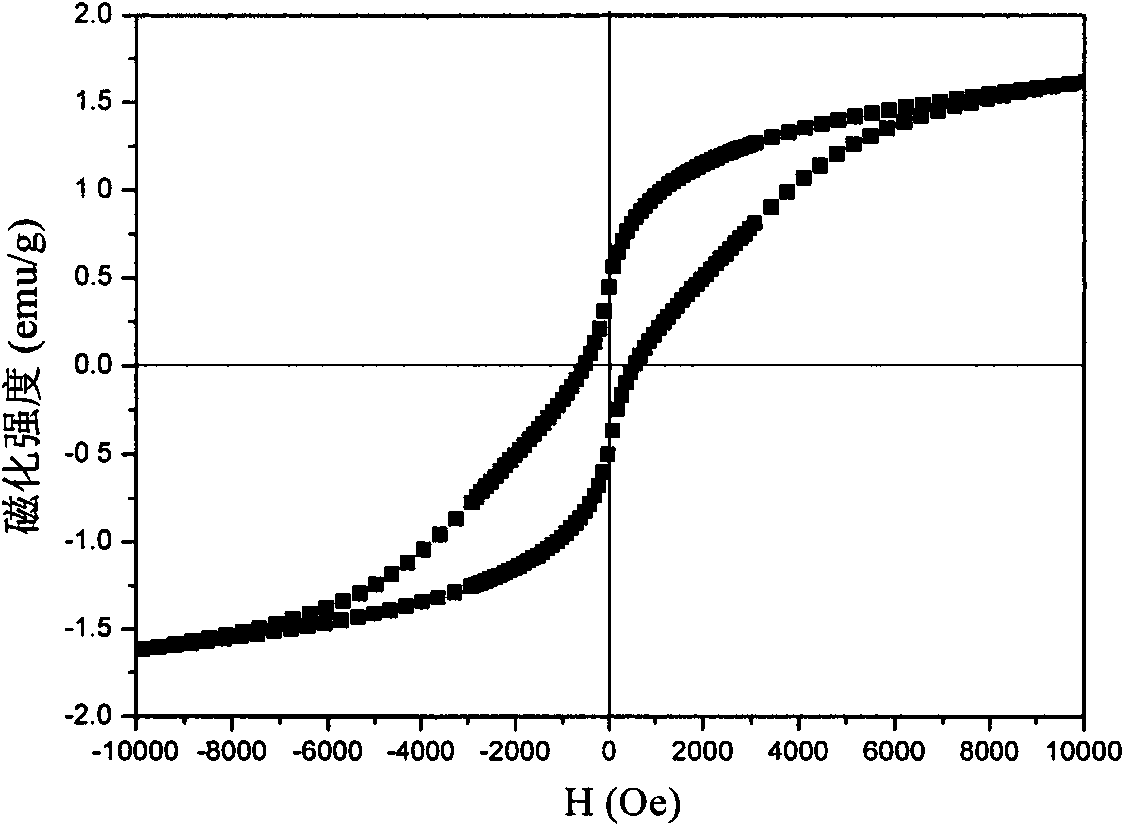

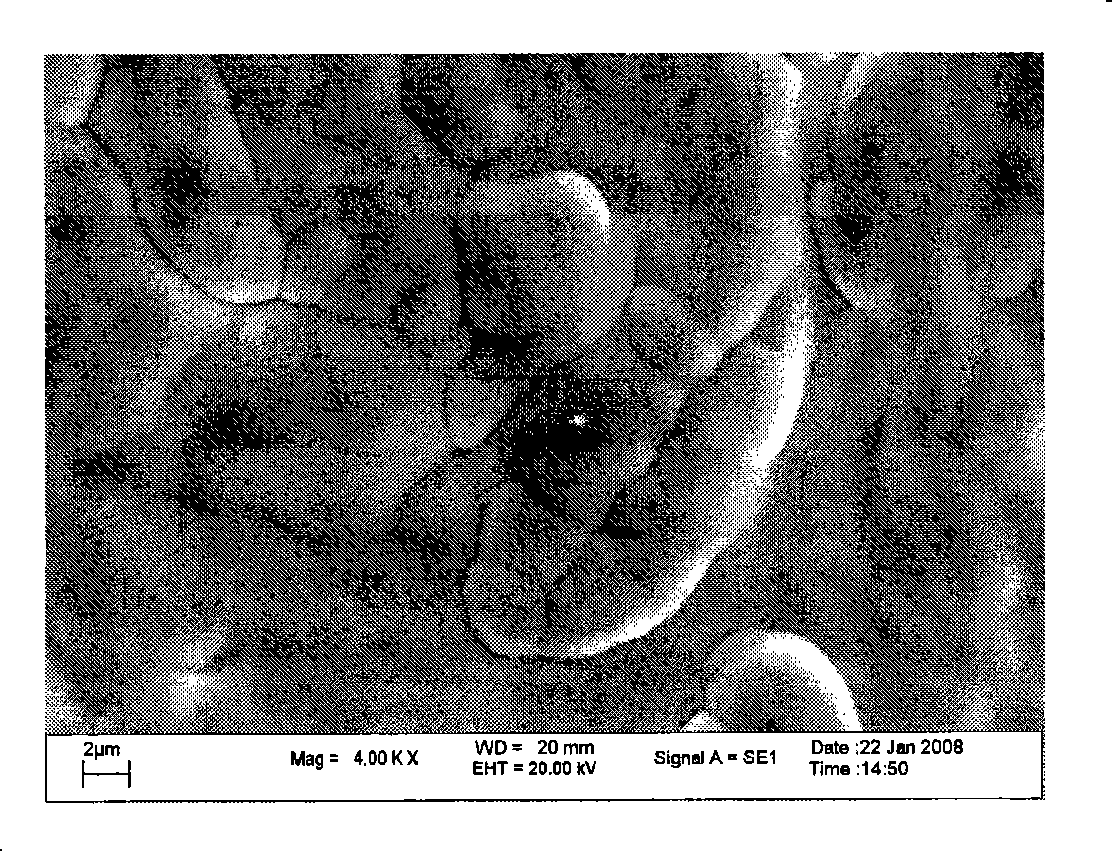

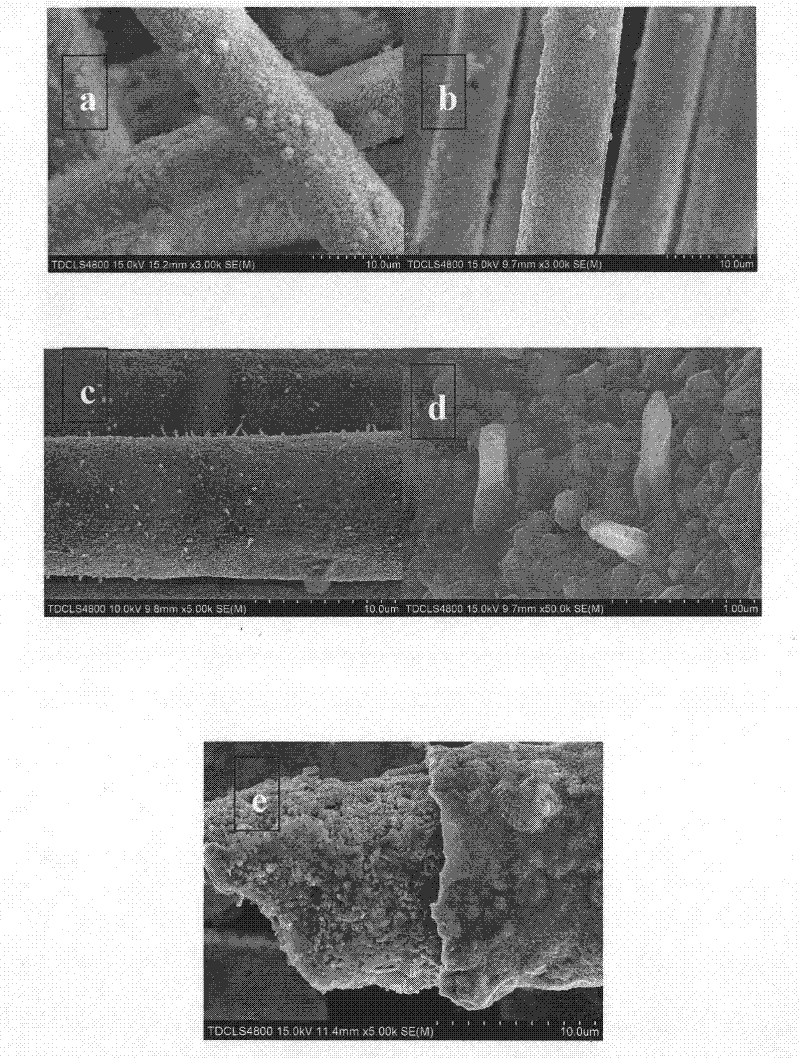

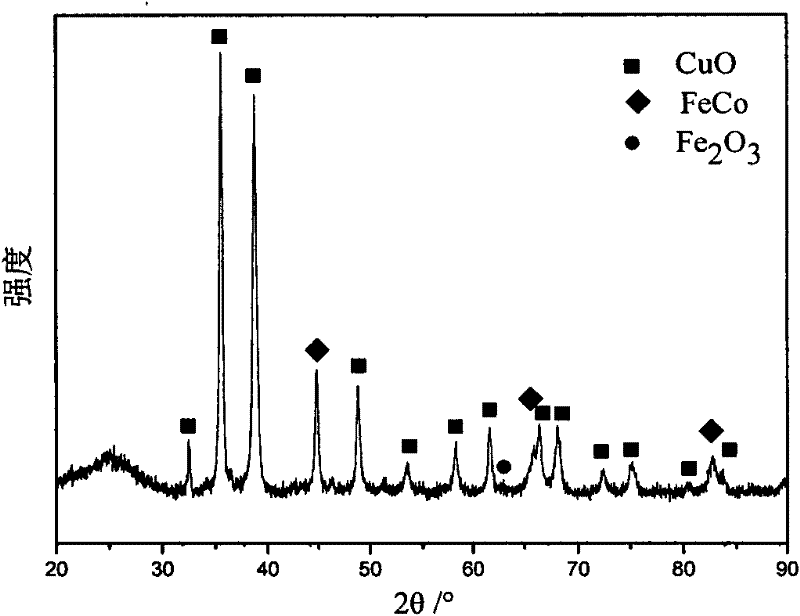

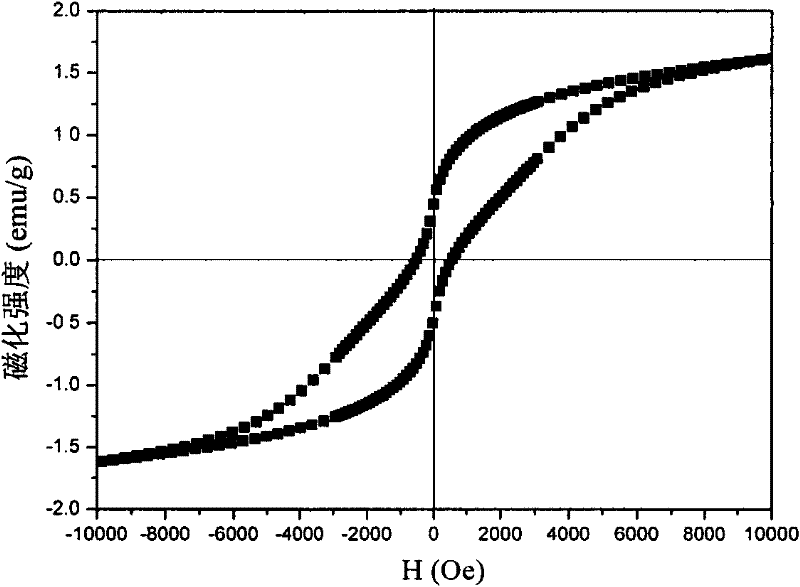

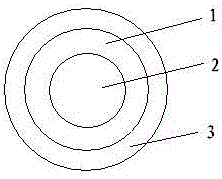

FeCo alloy/CuO double-plating magnetic carbon fiber and preparation method and application

InactiveCN102154816AImprove electromagnetic parametersReduce reflectionOther chemical processesCarbon fibresFiberCarbon fibers

The invention relates to FeCo alloy / CuO double-plating magnetic carbon fiber and a preparation method and application. FeCo alloy and Cu plating are successively electroplated on the surface of the pretreated continuous carbon fiber by use of the traditional electroplating means, CuO plating is formed after thermal oxidation, and columnar CuO with diameter of about 100 nm is formed on the surface. The electromagnetic parameters of the carbon fiber are improved through the alloy / oxide double-plating; the modified magnetic carbon fiber has high-frequency and high-strength microwave absorption performance, and has microwave loss of less than -10 dB at the frequency band from 2-18 GHz; and when the frequency is 9.6 GHz, the composite material with thickness of only 1.6 mm shows the maximum microwave absorption valve of -47.56 dB. The magnetic carbon fiber provided by the invention has uniform and dense magnetic double-plating, is simple in preparation process, high in production efficiency and excellent in microwave absorption performance, and can be used as a novel low-density microwave absorption material.

Owner:江苏飞荣达新材料科技有限公司

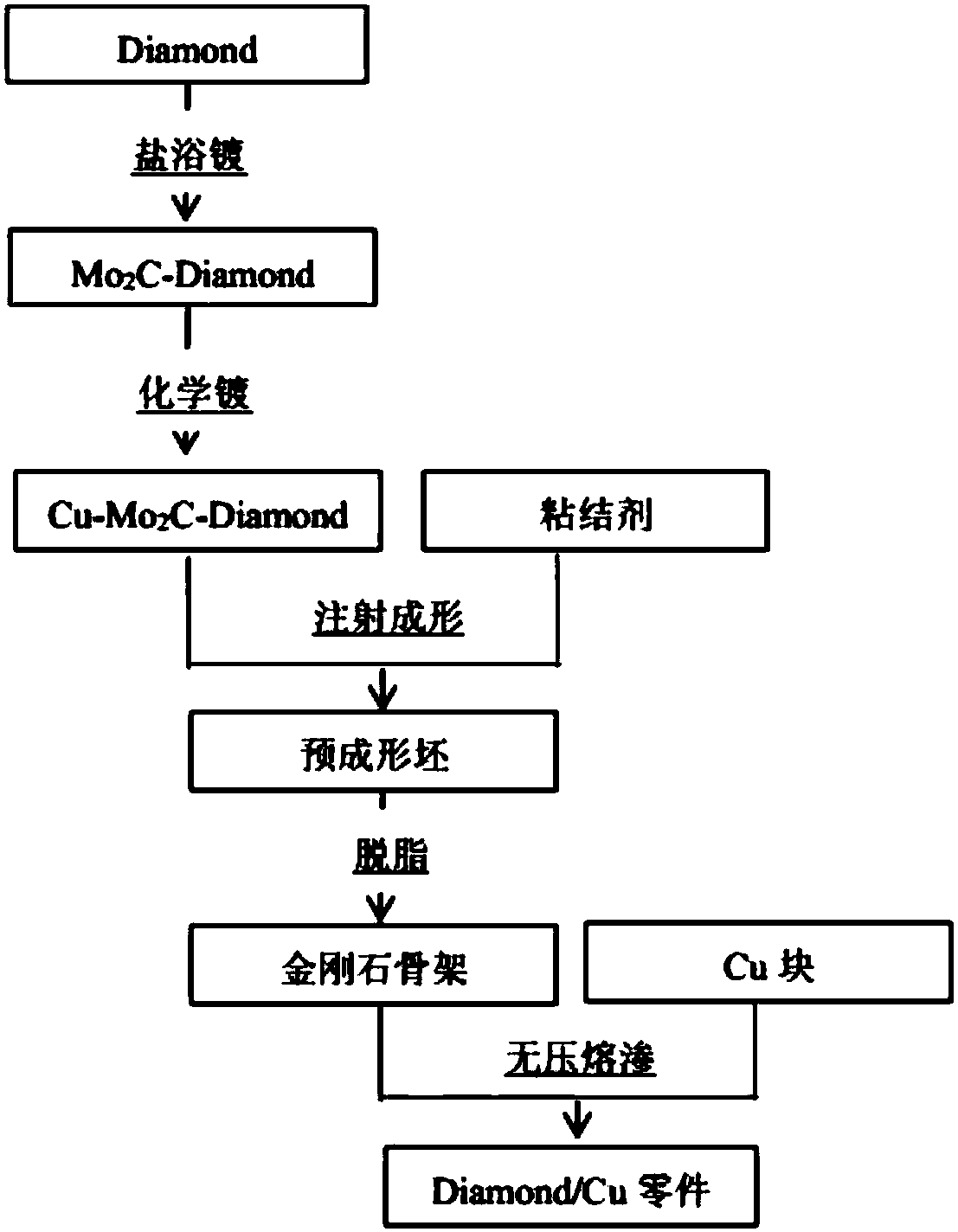

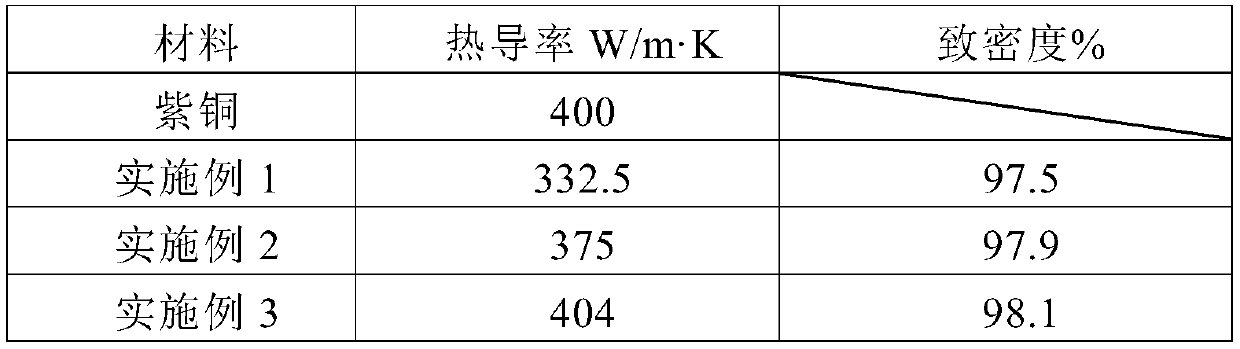

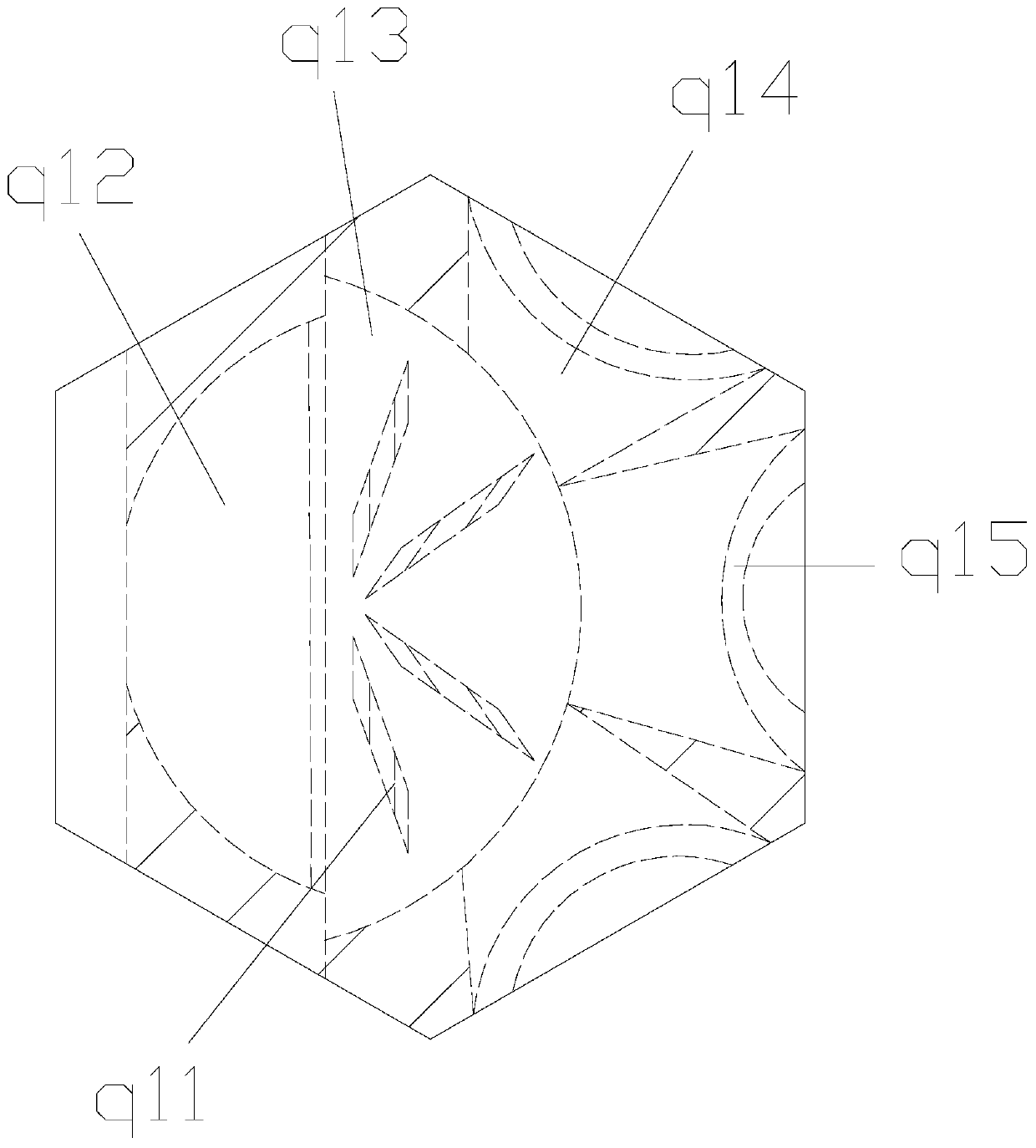

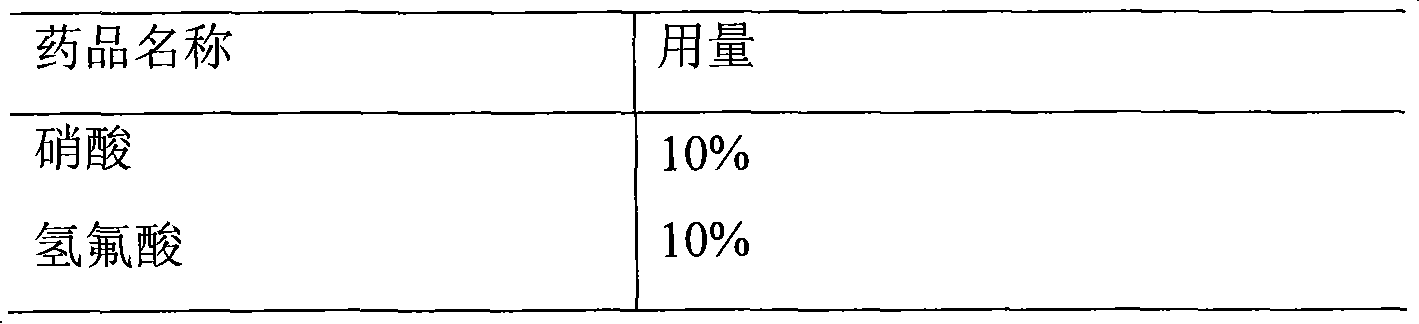

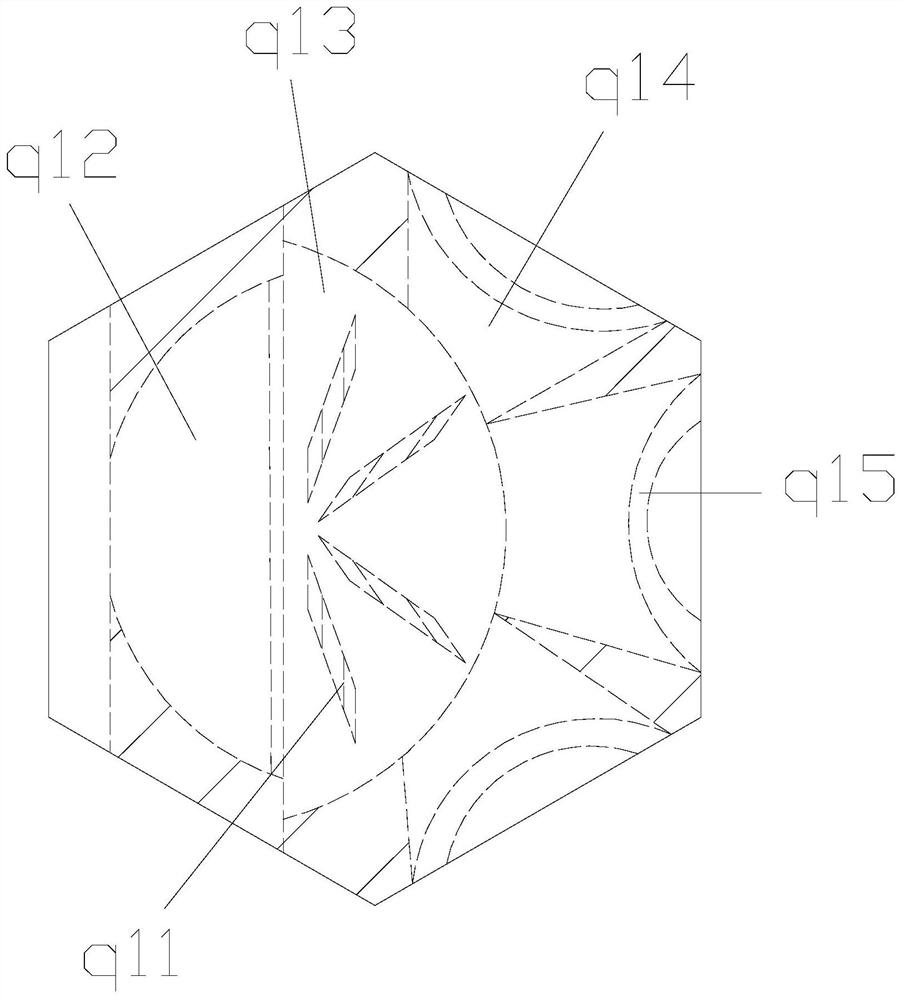

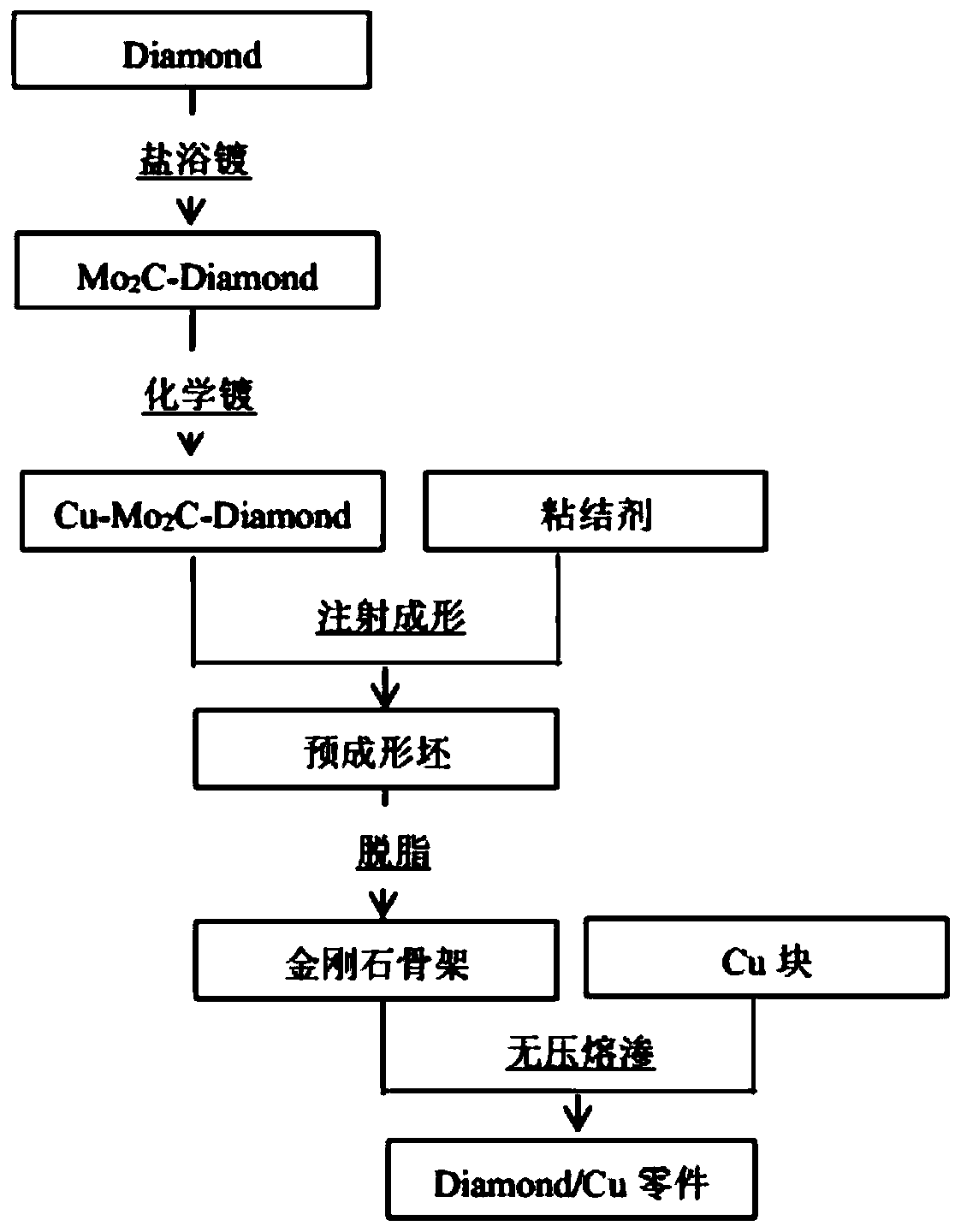

Method for preparing diamond/copper composite material by combining injection molding technology

ActiveCN107855533AHigh densityVolume fraction adjustmentTransportation and packagingMetal-working apparatusChemical platingCopper plating

The invention relates to a method for preparing a diamond / copper composite material by combining an injection molding technology. The method comprises the steps of adopting a salt-bath plating technology for plating a layer of uniform Mo2C on a diamond surface so as to improve the wettability of diamond and copper, then adopting a chemical plating method for continuously plating the copper on a surface of the Mo2C layer, and controlling the thickness of a copper plating layer by controlling the Cu2+ content in a plating solution, so that double-plating Cu-Mo2C-Diamond powder with the copper-bearing volume fraction being 1 percent to 10 percents is prepared; then mixing the quantitative Cu-Mo2C-Diamond powder and a multi-polymer component paraffin base binder to form uniform feeding; afterpelletizing, achieving injection molding on an injection molding machine; and after enabling a preformed blank to pass through a solvent and to be subjected to thermal degreasing, pre-sintering at high temperature, carrying out a vacuum pressureless infiltration technology on the obtained blank, and permeating a copper liquid into a diamond framework through a capillary action of pores, so that adiamond / copper composite material part with high volume fraction is obtained. The method provided by the invention can be used for directly preparing the Diamond / Cu composite material part in a complicated shape, the diamond is high in volume fraction and uniform and compact in texture, and the diamond / copper composite material can be produced in batch and can be low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

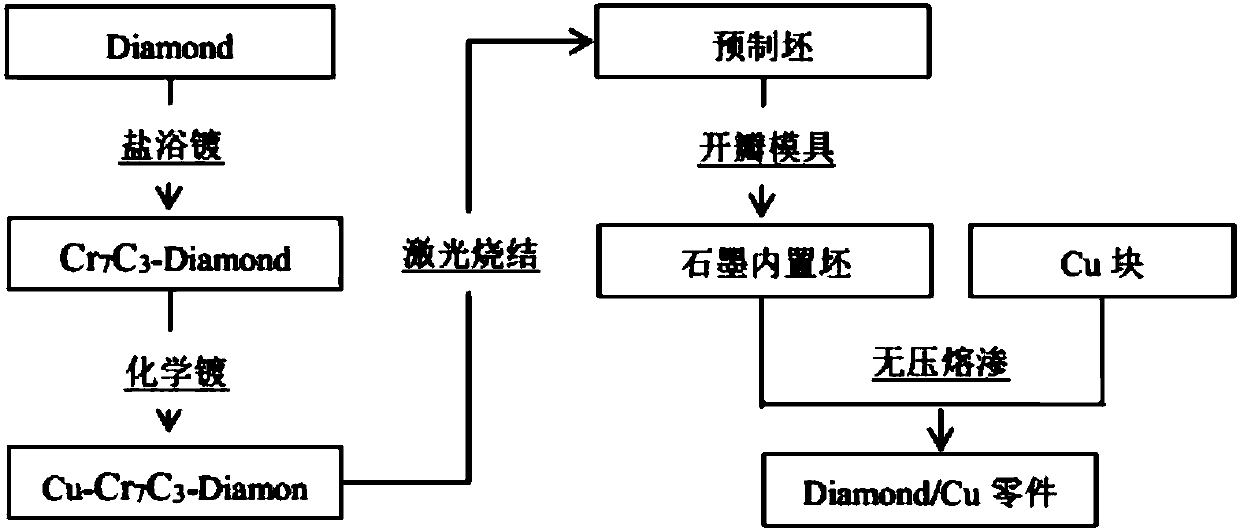

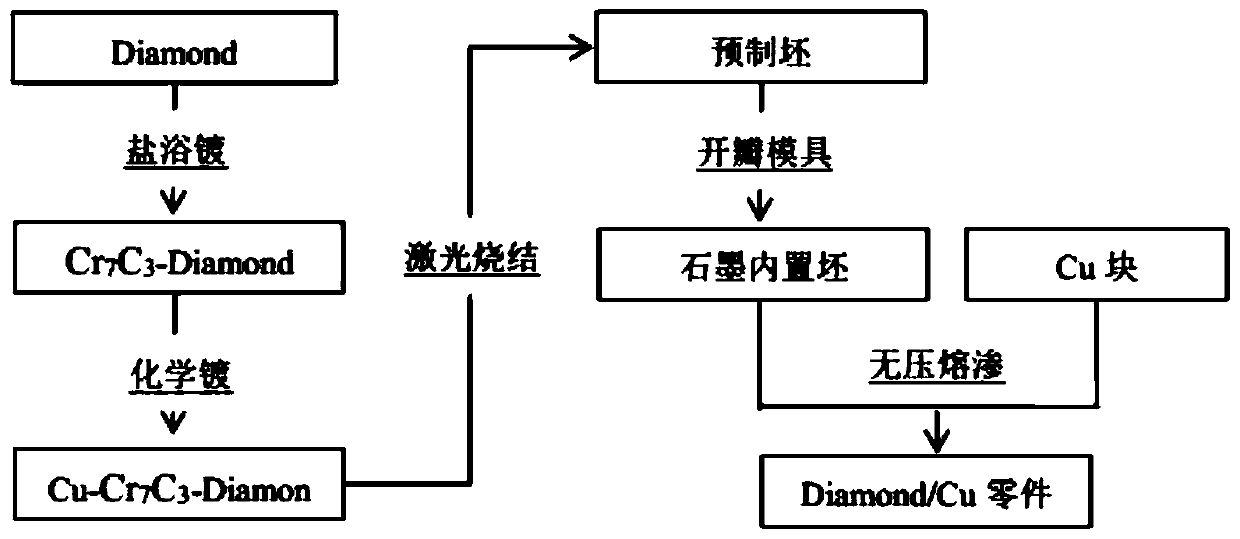

Method for preparing diamond/copper composite material by combining 3D printing technology

ActiveCN107900327AImprove wettabilityNot easy to overcomeAdditive manufacturing apparatusTransportation and packagingChemical platingCopper plating

The invention provides a method for preparing a diamond / copper composite material by combining a 3D printing technology and belongs to the field of diamond composite materials. Through a salt bath plating technology, a layer of even Cr7C3 is plated on the surface of diamond so as to improve the wettability of diamond and copper, then copper plating continues to be conducted on the surface of the Cr7C3 layer through a chemical plating mode, the thickness of a copper plating layer is controlled by controlling the content of Cu<2+> in a plating solution, and thus double-plating-layer Cu-Cr7C3-Diamond powder is prepared. Through the 3D printing technology, the double-plating-layer diamond powder is subjected to laser cladding, the copper-plated layer on the surfaces of diamond particles is melted to be mutually stuck to form a porous prefabricated blank skeleton with a specific shape, and then the porous prefabricated blank skeleton is placed into a split graphite mold to be prepared intoa diamond / copper composite material part with a complex shape through pressureless infiltration of a copper solution. According to the method for preparing the diamond / copper composite material by combining the 3D printing technology, the composite material with the even structure and high compactness can be prepared, the diamond / copper composite material part with the complex shape can further bedirectly prepared, the difficulty that a diamond / copper composite material is hard to machine is overcome, and customized production can be conducted according to the requirement.

Owner:UNIV OF SCI & TECH BEIJING

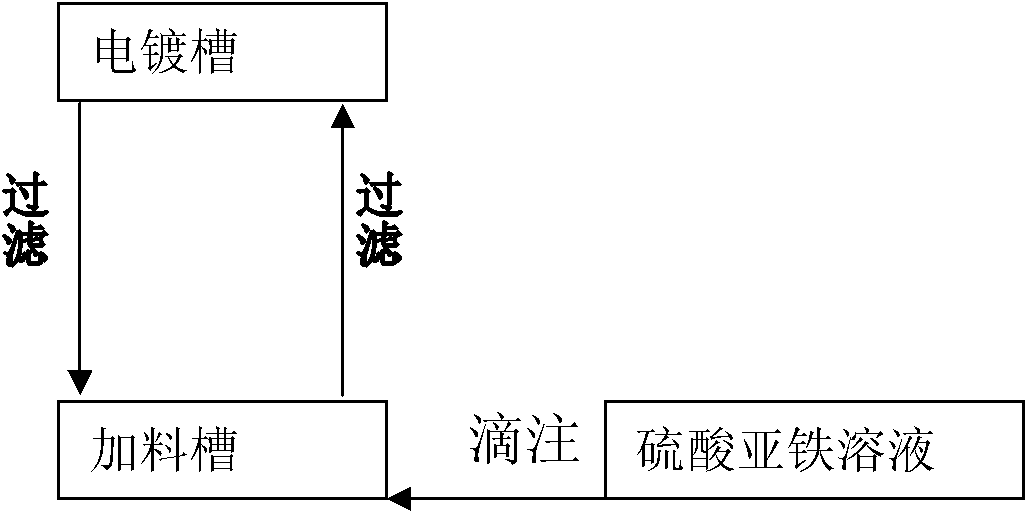

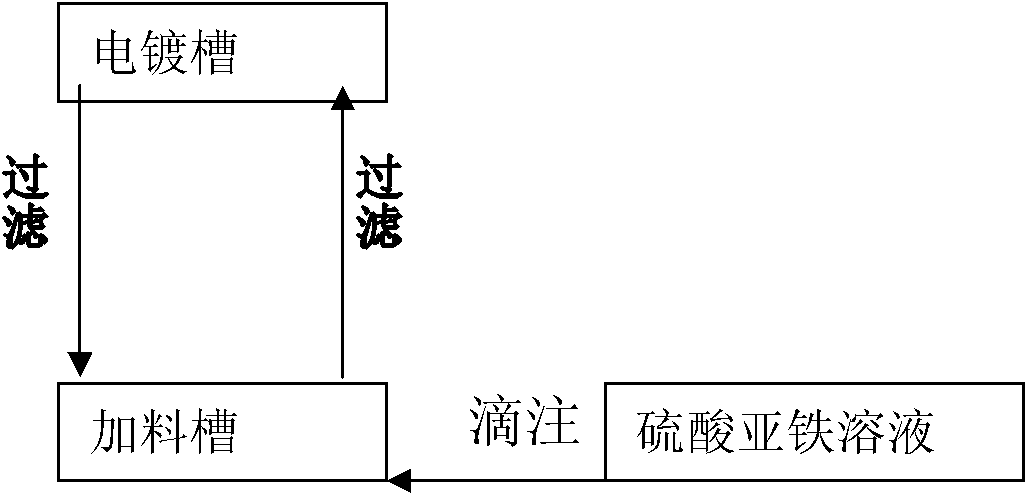

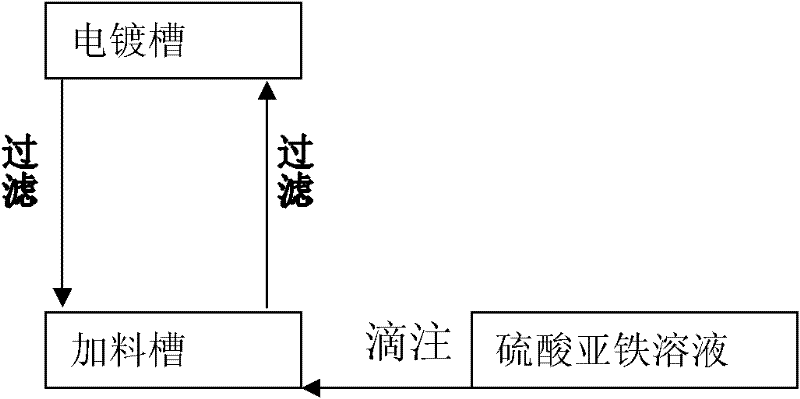

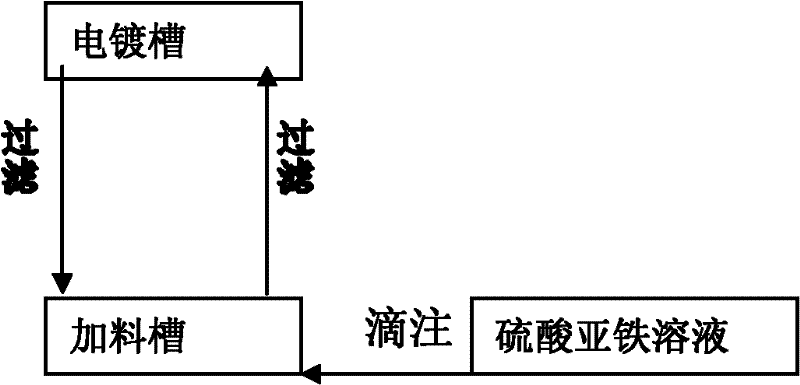

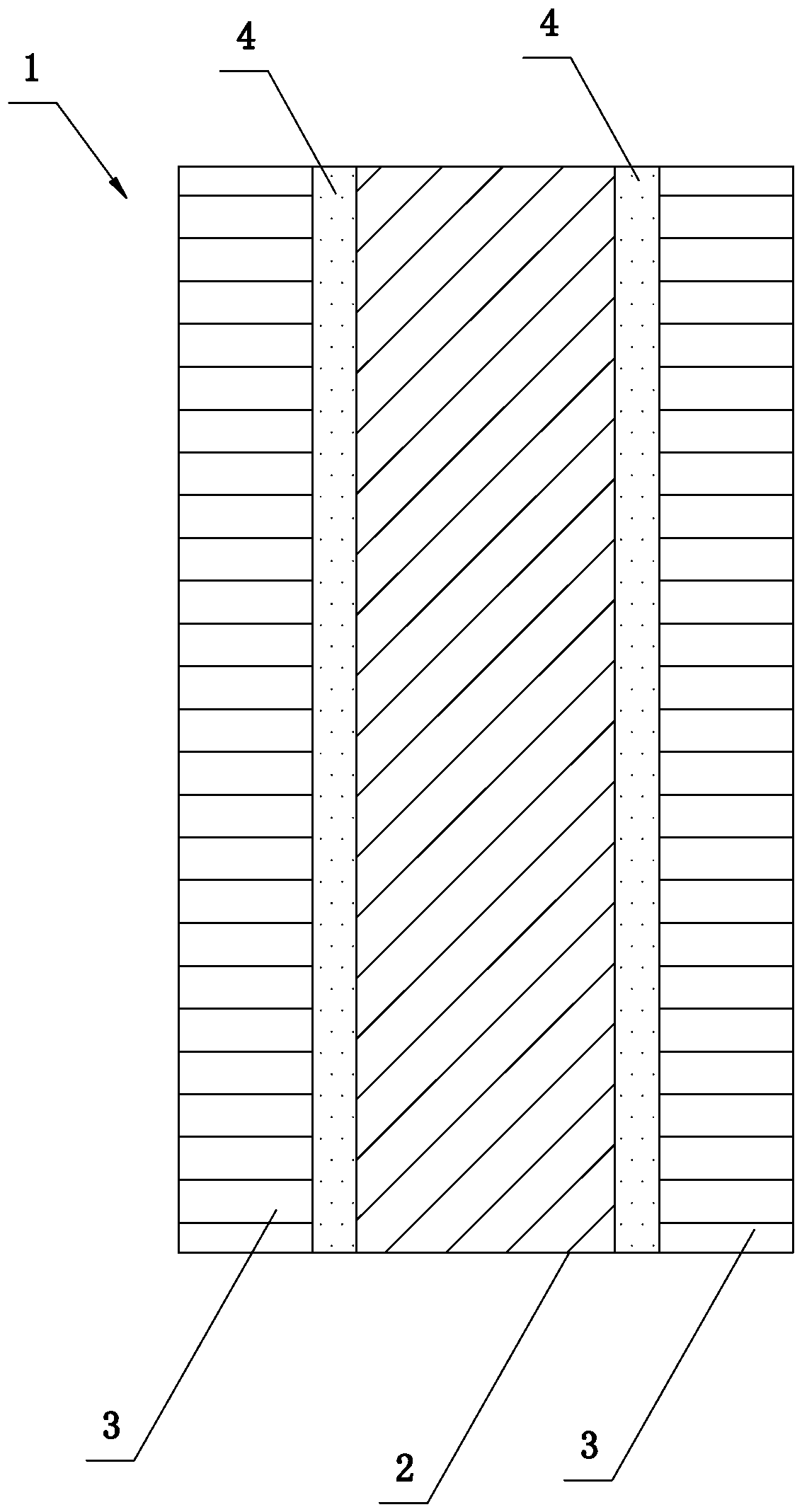

Double-plating steel belt and plating process

The invention relates to a double-plating steel belt and a plating process, which is especially suitable for plating perforated steel belts and punched steel belts for manufacturing electrodes. The invention aims to solve the technical problems of high cost and low corrosion resistance of a steel belt on which a pure nickel layer is plated. The double-plating steel belt of the invention is characterized in that a nickel iron alloy plating of 2-4mu m is plated on a substrate steel belt, and a nickel layer of 0.5-2mu m is plated on the nickel iron alloy plating. In the invention, the nickel iron alloy plating part is used for replacing the pure nickel layer, thus the cost is lower; and simultaneously, in the plating method of the invention, a mode of dropping ferrous sulfate into a plating solution is used for replenishing the Fe2<+> ions consumed in the plating process, and the area ratio of an iron plate to a nickel plate of an anode does not need to be controlled, thus the process maintenance is simple.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Method of laser cladding copper-based diamond particle reinforced composite coating on copper alloy surface

InactiveCN111424270AInhibit the degree of graphitizationQuality improvementLiquid/solution decomposition chemical coatingAlloy substrateMetallic materials

The invention belongs to the field of metal material surface modification, and discloses a method of preparing a copper-based diamond particle reinforced composite coating using a laser cladding technology on copper and copper alloy surfaces. The method comprises the following steps of sequentially plating metal chromium and silver on the surface of a diamond particle to form a chromium / silver double-coated diamond particle; mixing the chromium / silver double-coated diamond particle and red copper powder to prepare diamond / red copper mixed powder; laying the diamond / red copper mixed powder on acopper alloy substrate, then laying the red copper powder, and carrying out sintering and curing molding; and then using a laser cladding method to melt the pre-placed diamond / red copper mixed powder, and forming the copper-based diamond particle reinforced composite coating after solidification. According to the method of preparing the copper-based diamond particle reinforced composite coating using the laser cladding technology on the copper and copper alloy surfaces provided by the invention, the diamond particles are pretreated by the double plating layer, the structural damage of the diamond particles in machining is effectively avoided, and meanwhile, the bonding problem of the diamond and a copper matrix is solved.

Owner:SHANGHAI JIAO TONG UNIV

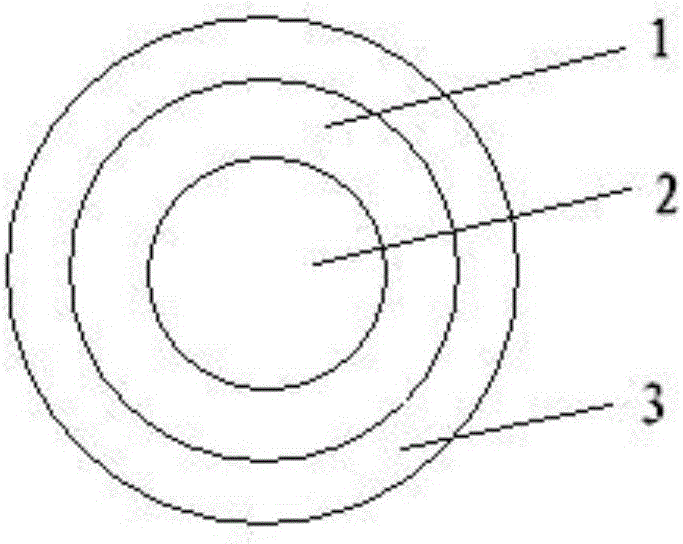

Manufacturing method of palladium-plated gold-plated double-plating bonding copper wire

InactiveCN103219249ASemiconductor/solid-state device detailsSolid-state devicesMinor metalsCopper wire

The invention discloses a double-plating bonding copper wire of a three-layer structure. The innermost layer of the copper wire is a copper core formed due to the fact that trace metal elements are added to high-purity copper, the surface of the copper core is plated with a pure-palladium conductive layer, and the surface of the pure-palladium conductive layer is plated with a pure-gold conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

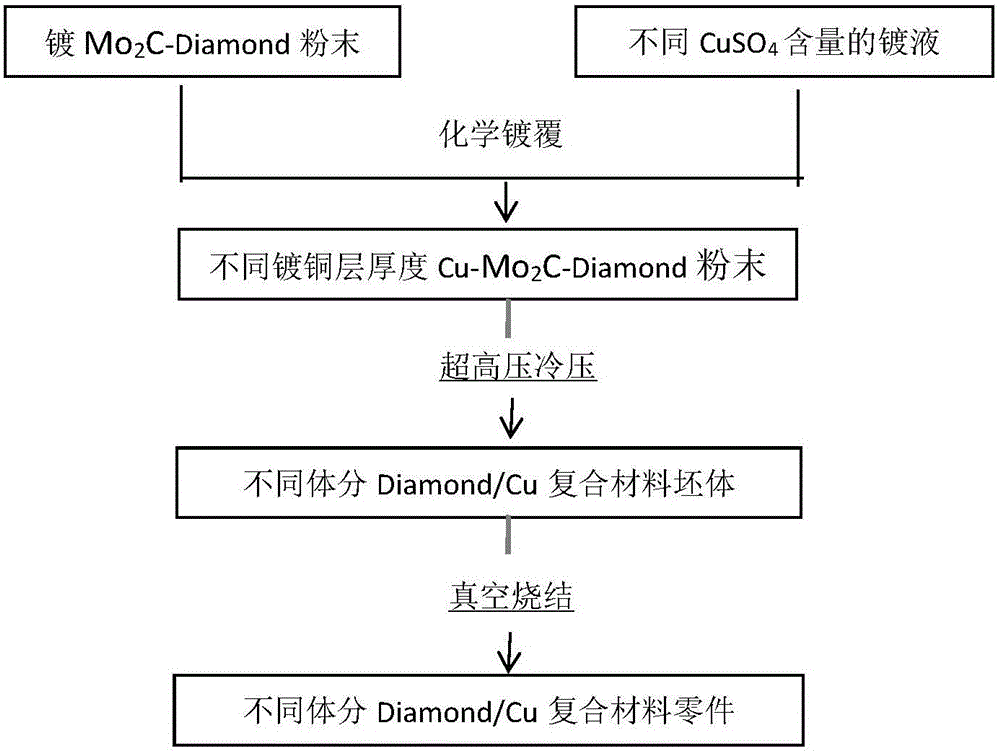

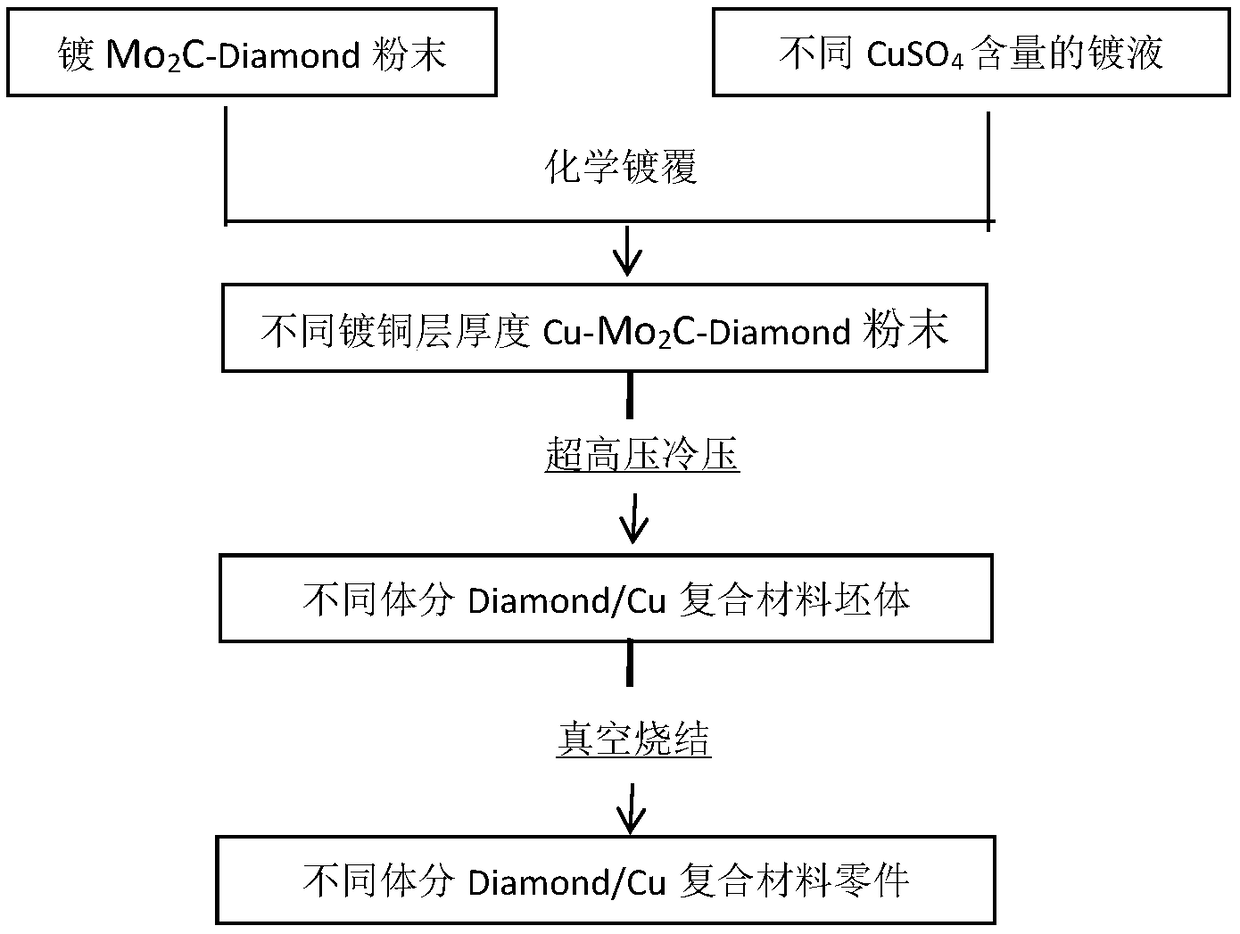

Method for preparing diamond/copper composite material parts with high volume fraction

ActiveCN106583735AVolume fraction adjustmentHigh densityLiquid/solution decomposition chemical coatingUltra high pressureChemical plating

The invention provides a method for preparing diamond / copper composite material parts with high volume fraction. The method comprises the following steps: plating the surface of diamond with a uniform Mo2C layer by using a salt-bath plating technology to improve wettability of the diamond and copper; and then continuing copperizing the surface of the Mo2C layer by using a chemical plating method, and controlling the thickness of a copperizing layer by controlling the content of Cu2+ in a plating solution so as to prepare copper-containing double-plating-layer Cu-Mo2C-Diamond powder with the volume fraction of 30-50 vol.%. The Cu-Mo2C-Diamond powder is formed by an ultra-high-pressure cold pressing method, and Diamond / Cu composite material parts are prepared by a vacuum pressureless sintering method. The method has the advantages that the Diamond / Cu composite material parts with complicated shapes and high volume fractions of (50-70 vol. %) can be directly prepared, meanwhile, composite materials are uniform in structure and high in compactness, the Diamond / Cu composite material parts can be produced in batches, and the production cost is low.

Owner:UNIV OF SCI & TECH BEIJING

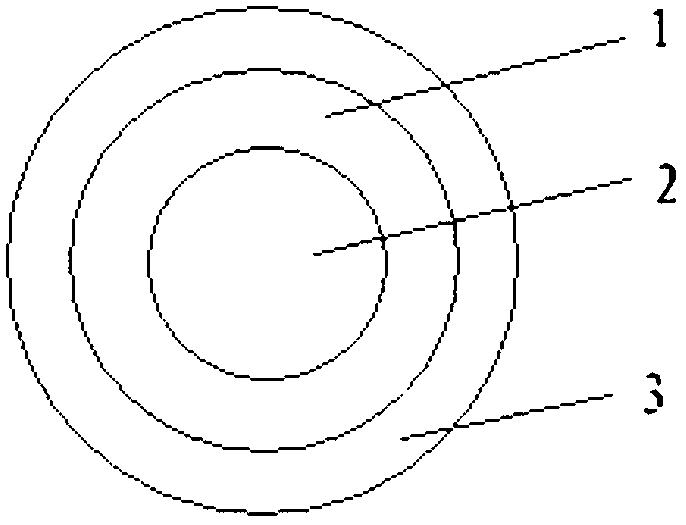

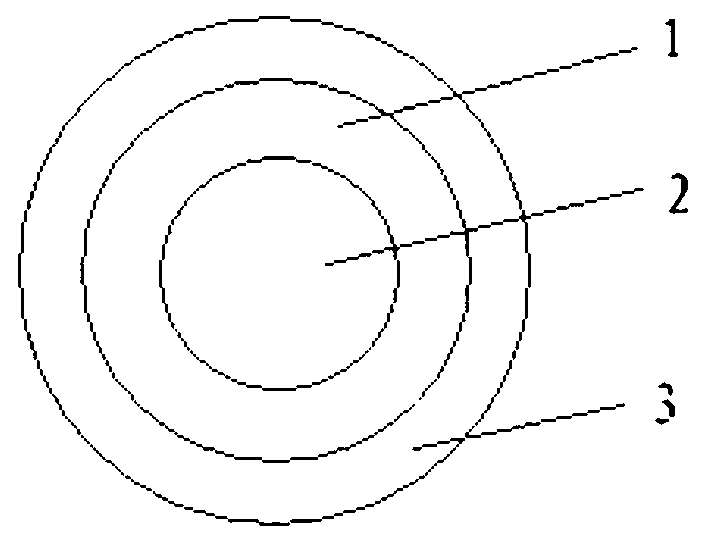

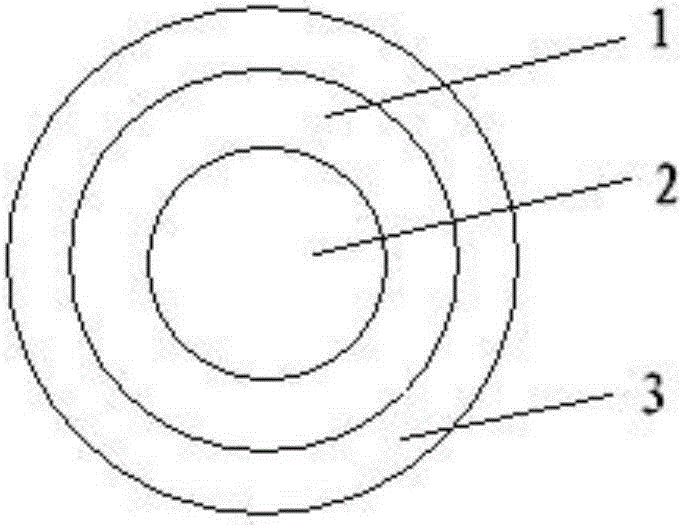

Palladium-plated gold-plated double-plating bonding copper wire

The invention discloses a palladium-plated gold-plated double-plating bonding copper wire of a three-layer structure. The innermost layer is a copper core formed due to the fact that trace metal elements are added to high-purity copper, a pure-palladium conductive layer plates the surface of the copper core, and a pure-gold conductive layer plates the surface of the pure-palladium conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

Double-plating steel belt and plating process

The invention relates to a double-plating steel belt and a plating process, which is especially suitable for plating perforated steel belts and punched steel belts for manufacturing electrodes. The invention aims to solve the technical problems of high cost and low corrosion resistance of a steel belt on which a pure nickel layer is plated. The double-plating steel belt of the invention is characterized in that a nickel iron alloy plating of 2-4mu m is plated on a substrate steel belt, and a nickel layer of 0.5-2mu m is plated on the nickel iron alloy plating. In the invention, the nickel iron alloy plating part is used for replacing the pure nickel layer, thus the cost is lower; and simultaneously, in the plating method of the invention, a mode of dropping ferrous sulfate into a plating solution is used for replenishing the Fe2<+> ions consumed in the plating process, and the area ratio of an iron plate to a nickel plate of an anode does not need to be controlled, thus the process maintenance is simple.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Alloy plating liquid for modular printed circuit board surface treatment

InactiveCN1477922ASimple processImprove productivityLiquid/solution decomposition chemical coatingConductive pattern reinforcementOrganic acidThio-

Disclosed is an aqueous alloy plating solution for surface treatment of a modular PCB. The plating solution comprises 1-30 wt % of an organic acid having at least one sulfonic acid group (-SO3H), 0.1-20 wt % of a complexing agent, 0.1-15 wt % of a thio-compound having at least one -S-, 0.05-5 wt % of a water soluble gold compound, 0.001-1 wt % of a water soluble silver compound and 0.1-10 wt % of a sequestering agent, based upon the weight of the plating solution. According to this invention, all plating properties required for the modular PCB are obtained through a single plating process, instead of the conventional double plating process.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

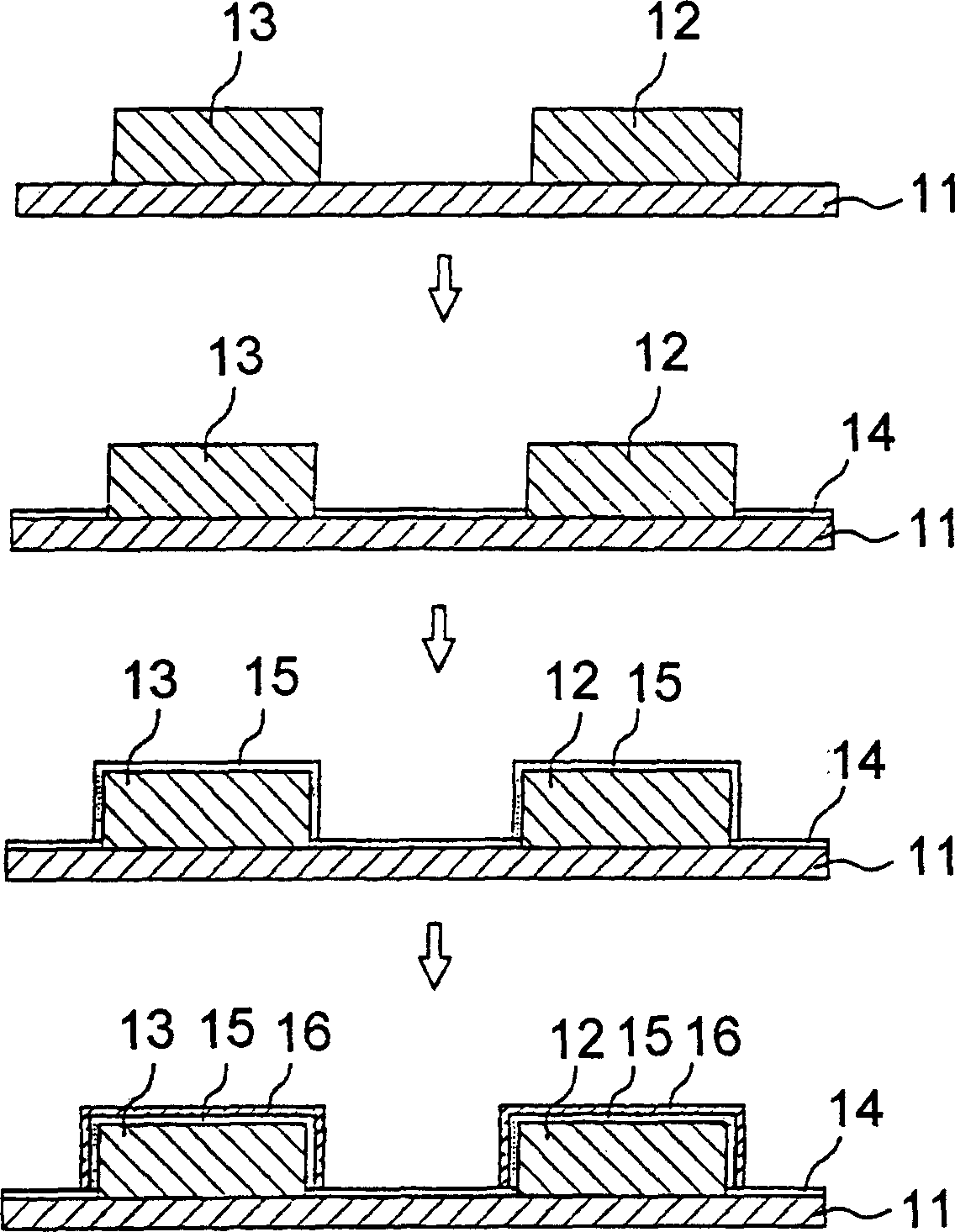

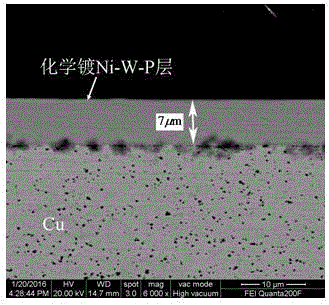

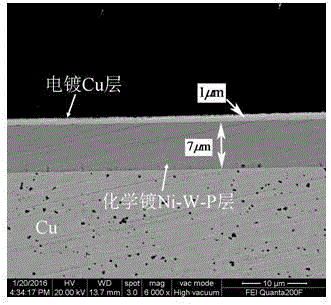

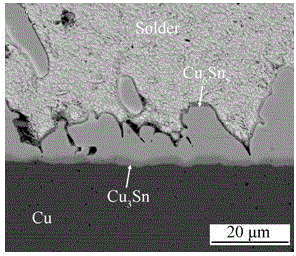

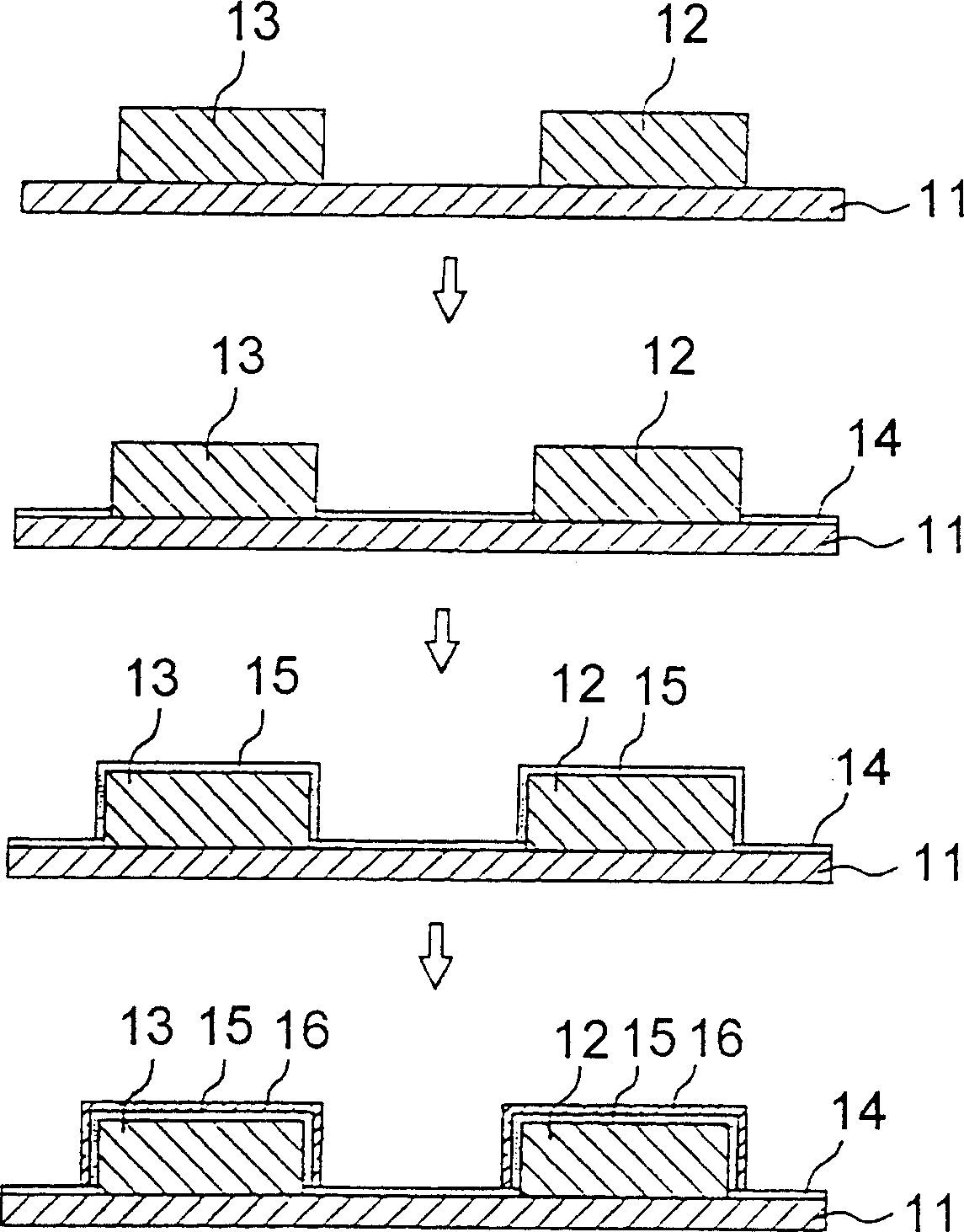

Preparation process for double plating layers capable of inhibiting growth of lead-free solder joint interface compound, of substrate

ActiveCN106480454AEasy to operateStable electroless plating processLiquid/solution decomposition chemical coatingSuperimposed coating processChemical platingChemical compound

The invention discloses a preparation process for double plating layers capable of inhibiting the growth of a lead-free solder joint interface compound, of a substrate. The double plating layers comprise a chemical plating Ni-W-P layer and an electroplating Cu layer. The chemical plating Ni-W-P layer comprises the following components in percentage by mass: 77-80% of Ni, 14-16% W and 6-7% of P, and the thickness of the plating layer is 3-10[mu]m; and the thickness of the electroplating Cu layer is 0.5-3[mu]m. The components of the Ni-W-P / Cu double plating layers prepared by the preparation process disclosed by the invention meet the use requirements of a barrier layer of a tin-based solder joint interface reaction in electronic packaging, and moreover, the plating layers are in close bonding with the substrate, smooth, uniform in thickness, and compact in structure. The preparation process disclosed by the invention has the advantages of being simple in process flow, easy to control process parameters, and the like; and the prepared Ni-W-P / Cu double plating layers have a quite effective inhibition effect on the growth of the tin-based solder joint interface compound.

Owner:NANCHANG UNIV

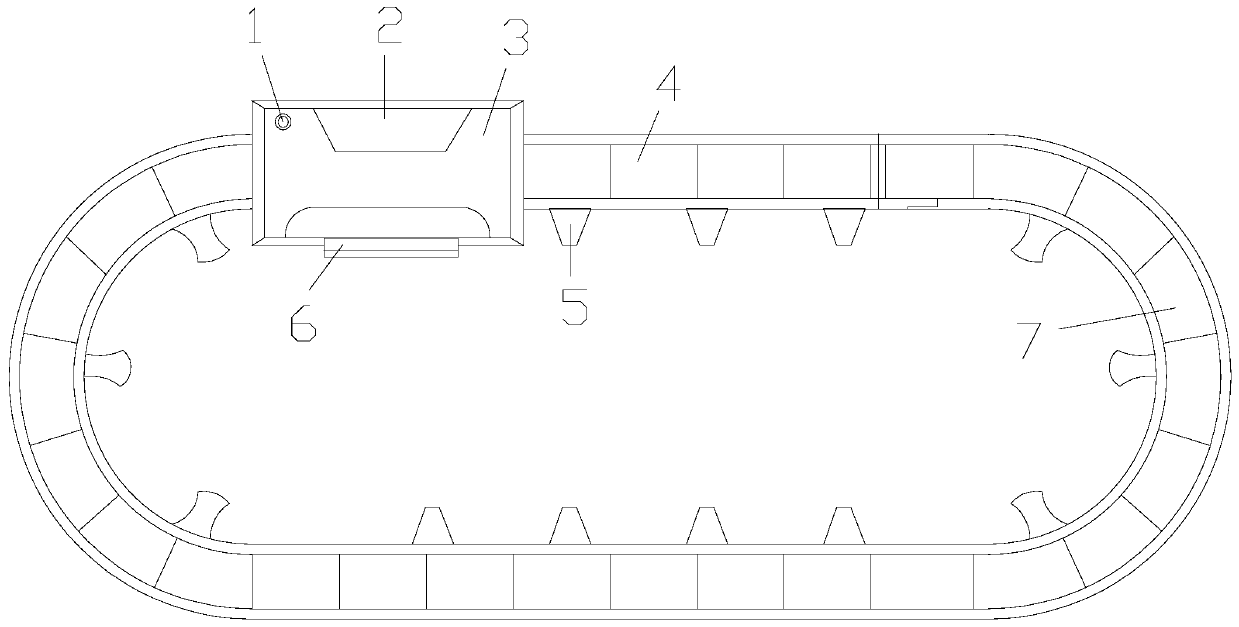

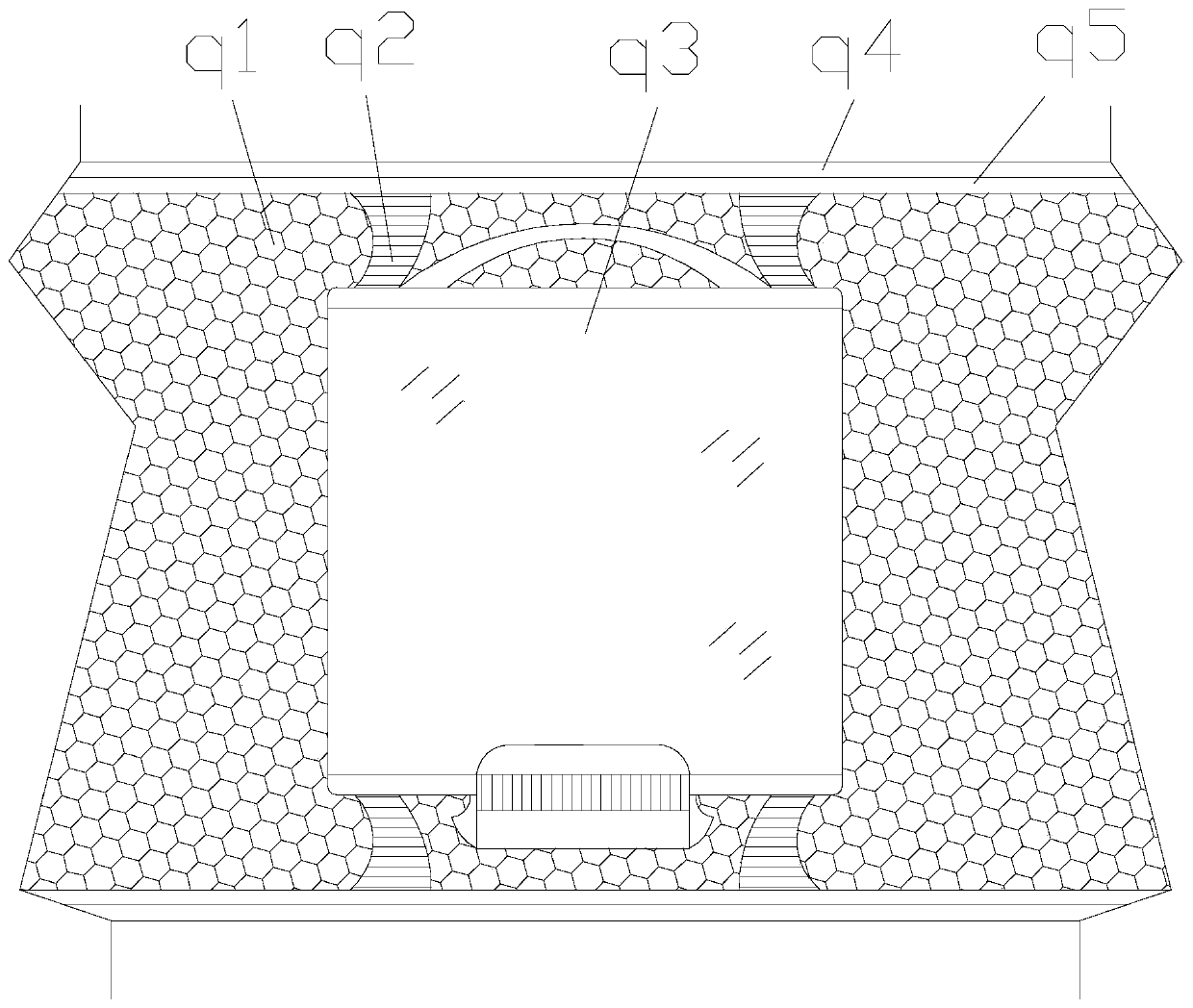

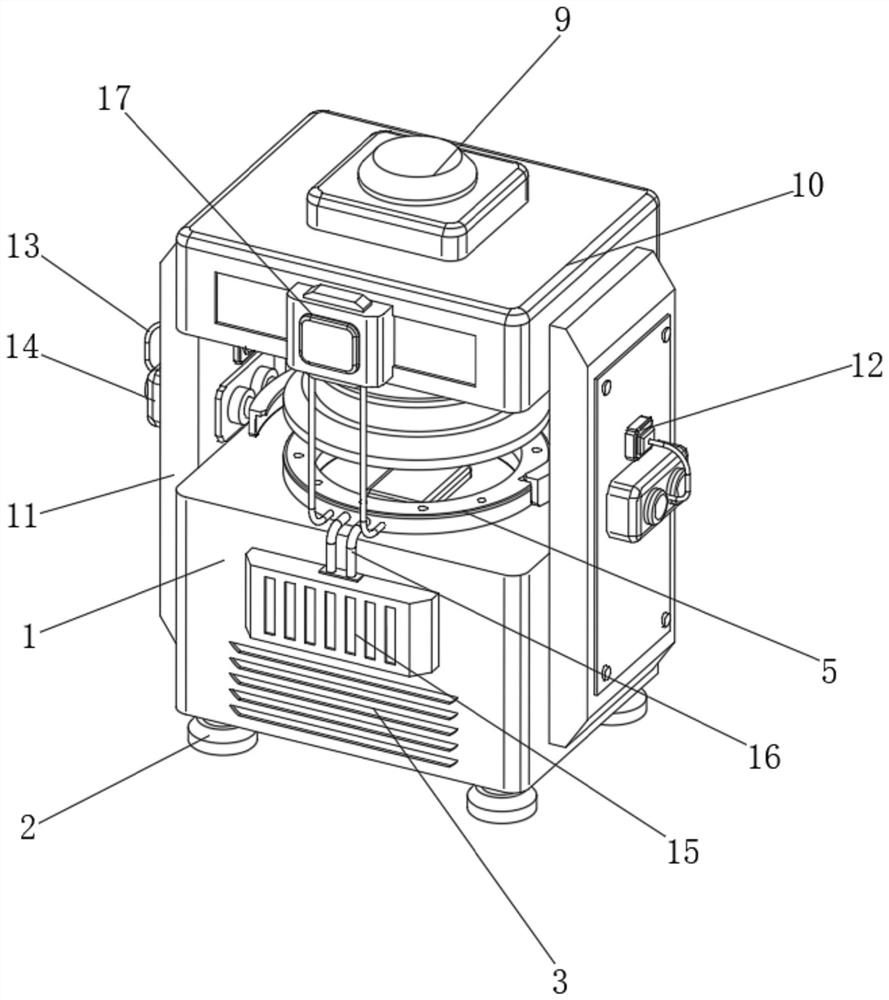

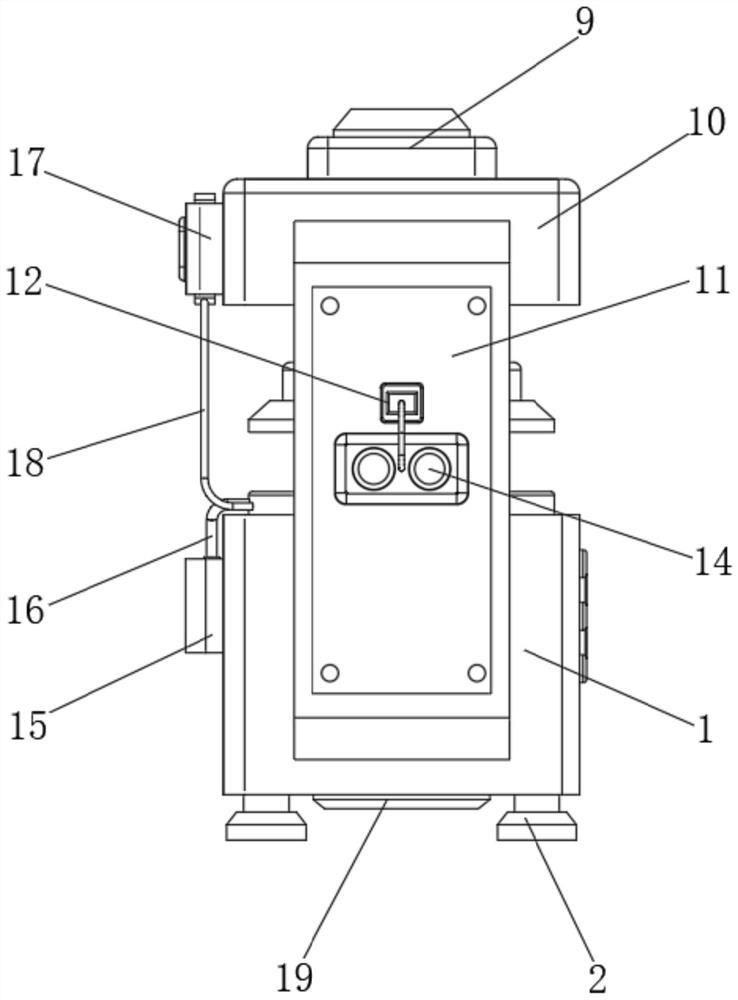

Novel short-range zinc liquid electroplating assembly line

The invention provides a novel short-range zinc liquid electroplating assembly line. The novel short-range zinc liquid electroplating assembly line structurally comprises a fault warning lamp, a turning and side trimming plate, a zinc-plated cover buckle, a short-range zinc liquid electroplating device, support frames, an external power strip and a rowed conveying frame, wherein the fault warninglamp is mounted at the upper left end of the top end surface of the zinc-plated cover buckle in an embedded mode; and the back of the short-range zinc liquid electroplating device is welded to the support frames. The assembly line is capable of directly carrying out the electroplating process of a steel plate, loading the steel plate by using a steel plate short-range double-plating mechanism, pressing a plating liquid guiding and conveying mechanism by using the self weight of the steel plate under the assistance of the steel plate short-range double-plating mechanism, enabling the plating liquid guiding and conveying mechanism which is in a sealed state originally to open an external conveying opening, and forming a zinc protection layer on the surface of the steel plate; a transferringoperation of a mechanical arm can be directly replaced; the original weight of the steel plate is used as a power element in the process of the electroplating process; and the time needed by the electroplating process can be shortened.

Owner:嘉兴市金鹰新材料股份有限公司

A palladium-plated gold-plated double-coated bonding copper wire

InactiveCN103219312BSemiconductor/solid-state device detailsSolid-state devicesCopper wireDouble bond

The invention discloses a palladium-plated gold-plated double-plating bonding copper wire of a three-layer structure. The innermost layer is a copper core formed due to the fact that trace metal elements are added to high-purity copper, a pure-palladium conductive layer plates the surface of the copper core, and a pure-gold conductive layer plates the surface of the pure-palladium conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

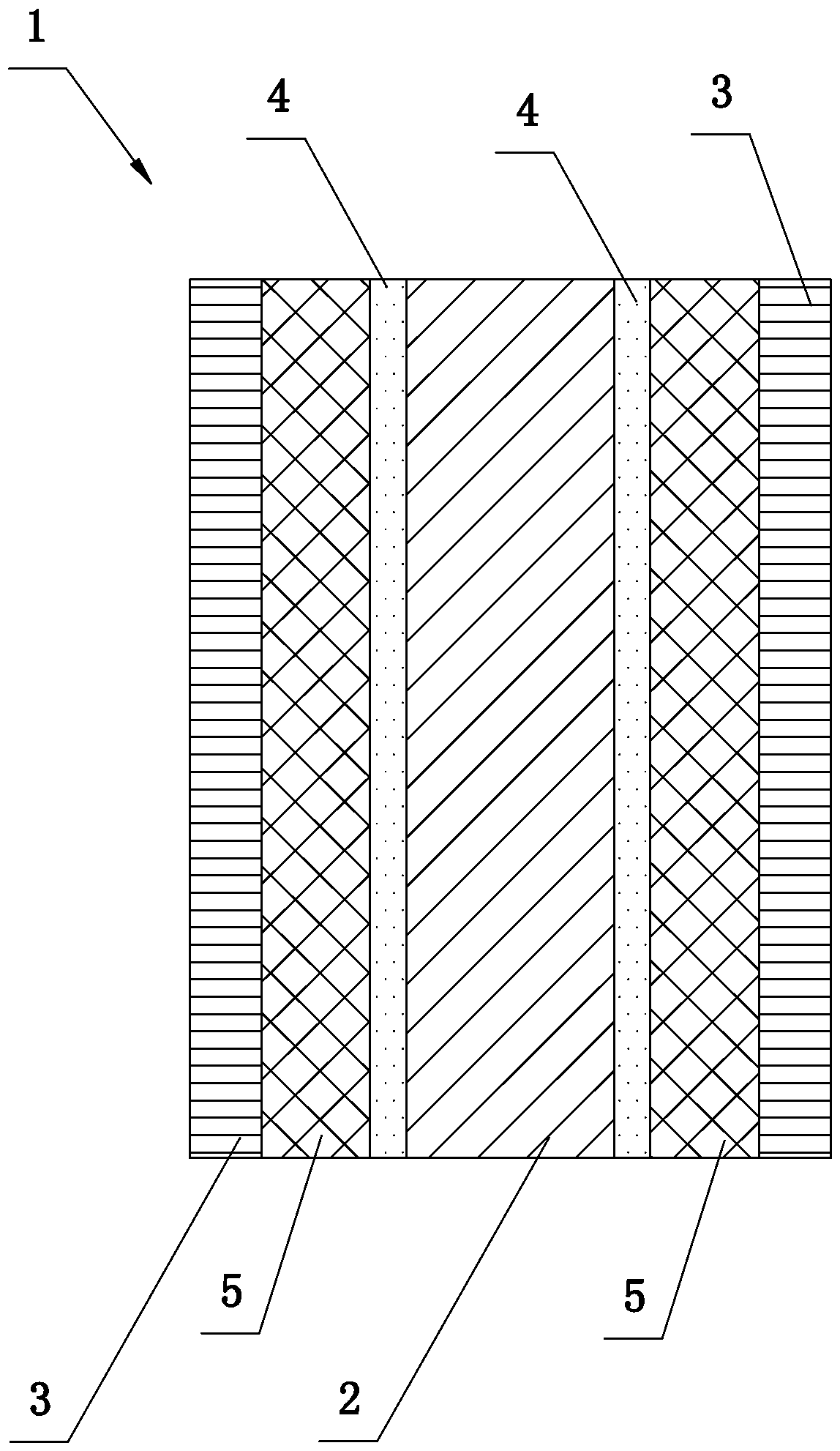

Sealing-in method for packaging outer shell with aluminum silicon carbide

InactiveCN101293294BSimple and economical crafting systemSoldering apparatusSemiconductor/solid-state device manufacturingMetallic materialsMetal

The invention pertains to the field of metallic material and provides a method for sealing a sealed cover when SiCp / Al composite material is used as an encapsulation encloser and a cover plate. The method is applicable to the encapsulation enclosers of micro-electronics appliances such as a hybrid integrated circuit, a millimeter wave / micron wave integrated circuit and a multichip module in micro-electronics encapsulation. Double-layer plating is carried out on the surface of the SiCp / Al composite material; the SiCp / Al composite material encloser with a surface coating and the cover plate arewelded together by Sn based solder. The method not only reduces production cost greatly, but also solves the problem of difficulty in sealing and connection of the SiCp / Al composite material, thus paving the way for widely using the SiCp / Al composite material as the material of enclosers and cover plates by related metal encloser factories.

Owner:UNIV OF SCI & TECH BEIJING

Iron-plated and platinum-plated double-plating-layer bonding copper wire

InactiveCN111653541AUniform surfaceReduce noiseSemiconductor/solid-state device detailsVacuum evaporation coatingPlatinumCopper wire

The invention discloses an iron-plated and platinum-plated double-plating-layer bonding copper wire, and relates to the technical field of bonding wires. The iron-plated and platinum-plated double-plating-layer bonding copper wire comprises a copper core material, and the iron plating layer is plated on the surface of the copper core material; and the platinum plating layer is plated on the surface of the iron plating layer. The surface of the copper core material is plated with an iron plating layer after being smelted and roughly stretched; a platinum plating layer is plated on the surface of the iron plating layer after medium stretching; and superfine stretching is performed to obtain the iron-plated and platinum-plated double-plating-layer bonding copper wire. Layer-by-layer stretching and layer-by-layer plating are adopted, the good final plastic deformation capacity is achieved, the iron-platinum double plating is consistent in deformation, uniform in surface, compact and complete in the pressure machining process, particularly, sufficient deformation during welding bonding is facilitated, and the breaking force and reliability are improved. Moreover, the ferromagnetic iron-platinum alloy layer at the joint of the double plating layers can play a role in shielding, so that the noise in the bonding wire is reduced. And meanwhile, the iron-plated platinum alloy layer protects the single crystal copper bonding wire and prevents the single crystal copper bonding wire from oxidation.

Owner:南京微米电子产业研究院有限公司 +1

A method for preparing diamond/copper composite materials combined with 3D printing technology

ActiveCN107900327BHigh dimensional accuracyImprove performanceAdditive manufacturing apparatusTransportation and packagingCopper platingHigh density

A method for preparing a diamond / copper composite material combined with 3D printing technology belongs to the field of diamond composite materials. The present invention adopts the salt bath coating technology to coat a layer of uniform Cr on the diamond surface. 7 C 3 Used to improve the wettability of diamond and copper, and then use the electroless plating method to continue on the Cr 7 C 3 Copper plating on the surface of the layer, by controlling the Cu in the plating solution 2+ content to control the thickness of the copper plating layer, thereby preparing a double-coated Cu-Cr 7 C 3 ‑Diamond powder. 3D printing technology is used to laser clad the double-coated diamond powder, and the copper-coated layer on the surface of the diamond particles is melted and bonded to each other to form a porous preform skeleton with a specific shape, and then put into the open-flap graphite mold to infiltrate copper through pressureless Liquid preparation of diamond / copper composite parts with complex shapes. This process can prepare composite materials with uniform structure and high density, and can also directly prepare diamond / copper composite parts with complex shapes, which solves the difficulty that diamond / copper composite materials are difficult to machine, and can be customized according to demand. .

Owner:UNIV OF SCI & TECH BEIJING

A kind of manufacturing method of palladium-plated gold-plated double-coated bonding copper wire

InactiveCN103219249BSemiconductor/solid-state device detailsSolid-state devicesCopper platingCopper wire

The invention discloses a double-plating bonding copper wire of a three-layer structure. The innermost layer of the copper wire is a copper core formed due to the fact that trace metal elements are added to high-purity copper, the surface of the copper core is plated with a pure-palladium conductive layer, and the surface of the pure-palladium conductive layer is plated with a pure-gold conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

FeCo alloy/CuO double-plating magnetic carbon fiber and preparation method and application

InactiveCN102154816BImprove electromagnetic parametersReduce reflectionCarbon fibresFibre chemical featuresFiberCarbon fibers

The invention relates to FeCo alloy / CuO double-plating magnetic carbon fiber and a preparation method and application. FeCo alloy and Cu plating are successively electroplated on the surface of the pretreated continuous carbon fiber by use of the traditional electroplating means, CuO plating is formed after thermal oxidation, and columnar CuO with diameter of about 100 nm is formed on the surface. The electromagnetic parameters of the carbon fiber are improved through the alloy / oxide double-plating; the modified magnetic carbon fiber has high-frequency and high-strength microwave absorption performance, and has microwave loss of less than -10 dB at the frequency band from 2-18 GHz; and when the frequency is 9.6 GHz, the composite material with thickness of only 1.6 mm shows the maximum microwave absorption valve of -47.56 dB. The magnetic carbon fiber provided by the invention has uniform and dense magnetic double-plating, is simple in preparation process, high in production efficiency and excellent in microwave absorption performance, and can be used as a novel low-density microwave absorption material.

Owner:江苏飞荣达新材料科技有限公司

Palladium-plated silver-plated double-coated copper wire

InactiveCN103219311BOvercome the defect of poor ductilityLow production costSemiconductor/solid-state device detailsSolid-state devicesCopper wireDouble bond

The invention discloses a double-plating bonding copper wire of a three-layer structure. The innermost layer of the copper wire is a copper core formed due to the fact that trace metal elements are added to high-purity copper, a pure-palladium conductive layer plates the surface of the copper core, and a pure-silver conductive layer plates the surface of the pure-palladium conductive layer. The trace metal elements include tin, magnesium and aluminum.

Owner:溧阳市虹翔机械制造有限公司

Protection method of magnesium alloy workpiece for marine environment

PendingCN114525509AImprove pass rateImprove quality consistencyAnodisationPretreated surfacesMetal coatingMicro arc oxidation

The invention discloses a protection method of a magnesium alloy workpiece for a marine environment, which adopts double-layer protection of an inner layer and an outer layer, and comprises the steps of micro-arc oxidation, conductive paint coating, baking and curing, alkaline chemical nickel plating, acidic chemical nickel plating, sealing and drying, the inner layer adopts a micro-arc oxidation film which is firmly combined with a matrix, and the outer layer adopts a micro-arc oxidation film which is firmly combined with the matrix; the outer layer adopts double-layer nickel plating of a bottom plating layer and a surface plating layer, the bottom plating layer adopts alkaline chemical nickel plating and is plated on the inner layer, the combination is firm, the surface plating layer adopts acid chemical nickel plating and is plated on the bottom plating layer, sealing treatment is performed, the porosity is reduced, the surface is compact, and the finished product is silver gray in appearance, slightly yellow, high in percent of pass, good in quality consistency and free of bubbling or layering phenomenon; through a 200 DEG C thermal shock test, the magnesium alloy micro-arc oxidation film is continuous, uniform, complete and free of pulverization, looseness and scratches, through a 672 h neutral salt spray test, the protection grade Rp is not lower than 9 grade, and the technical bottleneck that the magnesium alloy micro-arc oxidation film is difficult to be plated with a metal coating is broken through.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Drawing die for double-layer aluminum-plated plate

PendingCN114669663AGuaranteed stabilityPrecise positioningShaping toolsMetal working apparatusBi layerAlclad

Owner:滁州市康乾嘉业模具设备制造有限公司

A short-range zinc liquid electroplating line

Owner:嘉兴市金鹰新材料股份有限公司

Alloy plating liquid for modular printed circuit board surface treatment

InactiveCN1245856CSimple processImprove productivityLiquid/solution decomposition chemical coatingConductive pattern reinforcementOrganic acidThio-

Disclosed is an aqueous alloy plating solution for surface treatment of a modular PCB. The plating solution comprises 1-30 wt % of an organic acid having at least one sulfonic acid group (-SO3H), 0.1-20 wt % of a complexing agent, 0.1-15 wt % of a thio-compound having at least one -S-, 0.05-5 wt % of a water soluble gold compound, 0.001-1 wt % of a water soluble silver compound and 0.1-10 wt % of a sequestering agent, based upon the weight of the plating solution. According to this invention, all plating properties required for the modular PCB are obtained through a single plating process, instead of the conventional double plating process.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

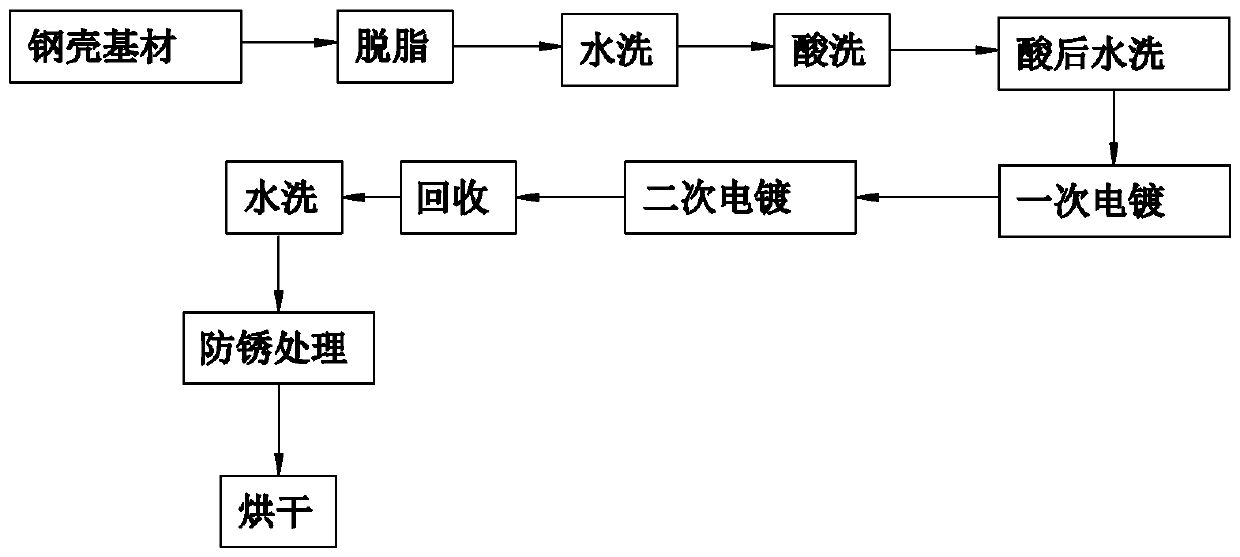

A double-layer nickel plating process for a battery steel shell and a battery steel shell obtained by the process

ActiveCN105506689BImprove corrosion resistanceSpeed up corrosionJackets/cases materialsMetallurgyElectrical battery

Owner:FUJIAN JINYANG TECH CO LTD

A method of preparing diamond/copper composite parts with high volume fraction

ActiveCN106583735BVolume fraction adjustmentHigh densityLiquid/solution decomposition chemical coatingUltra high pressureChemical plating

The invention provides a method for preparing diamond / copper composite material parts with high volume fraction. The method comprises the following steps: plating the surface of diamond with a uniform Mo2C layer by using a salt-bath plating technology to improve wettability of the diamond and copper; and then continuing copperizing the surface of the Mo2C layer by using a chemical plating method, and controlling the thickness of a copperizing layer by controlling the content of Cu2+ in a plating solution so as to prepare copper-containing double-plating-layer Cu-Mo2C-Diamond powder with the volume fraction of 30-50 vol.%. The Cu-Mo2C-Diamond powder is formed by an ultra-high-pressure cold pressing method, and Diamond / Cu composite material parts are prepared by a vacuum pressureless sintering method. The method has the advantages that the Diamond / Cu composite material parts with complicated shapes and high volume fractions of (50-70 vol. %) can be directly prepared, meanwhile, composite materials are uniform in structure and high in compactness, the Diamond / Cu composite material parts can be produced in batches, and the production cost is low.

Owner:UNIV OF SCI & TECH BEIJING

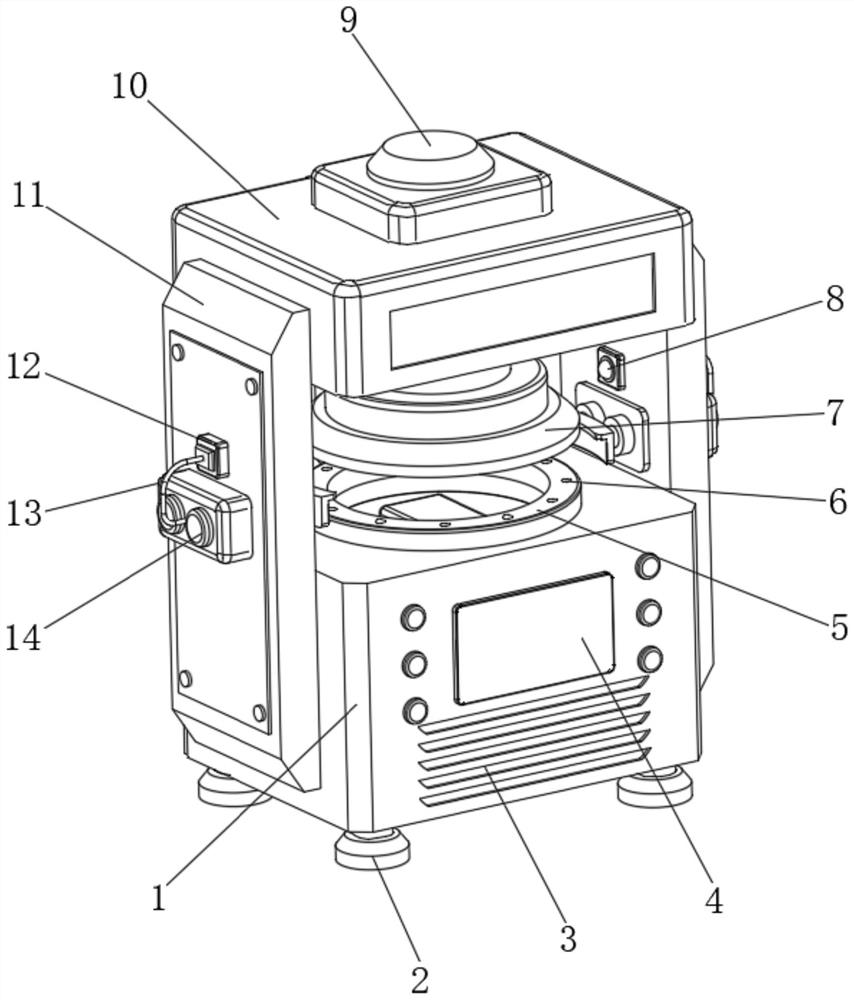

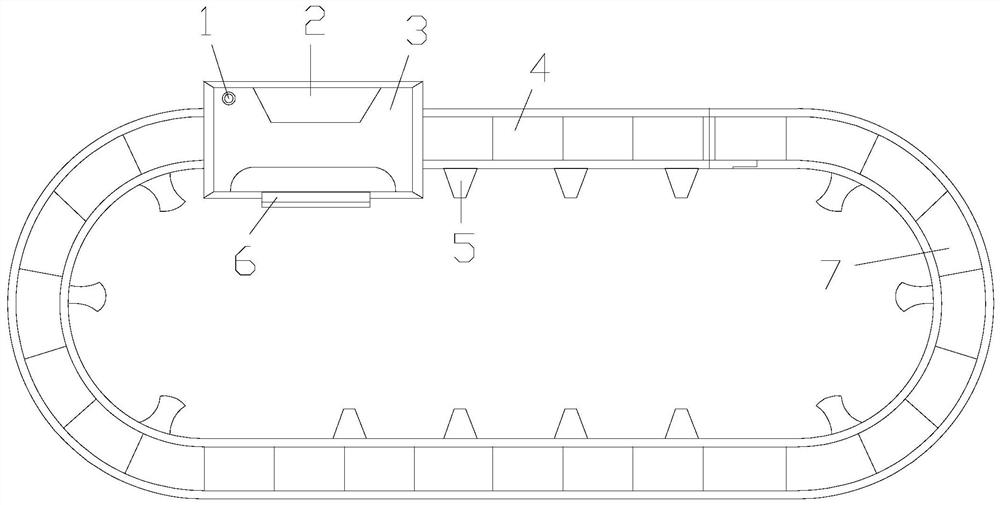

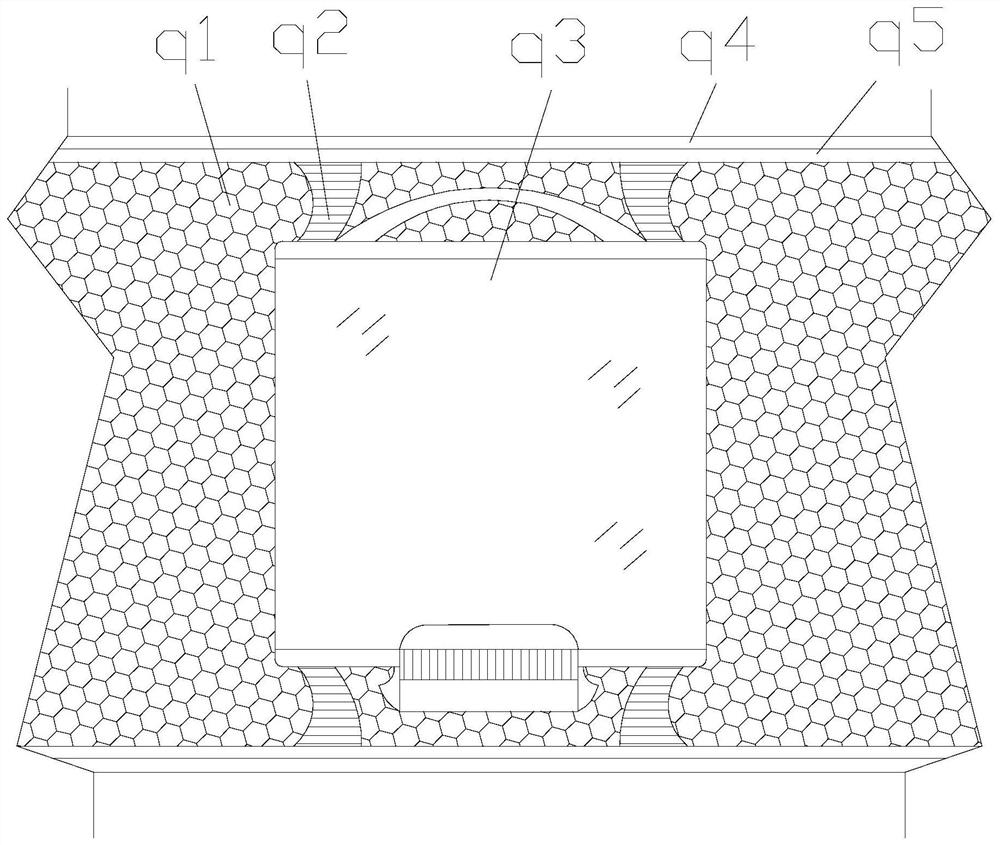

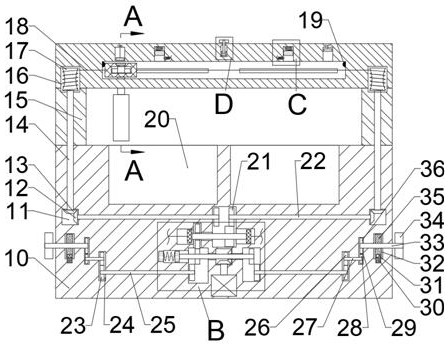

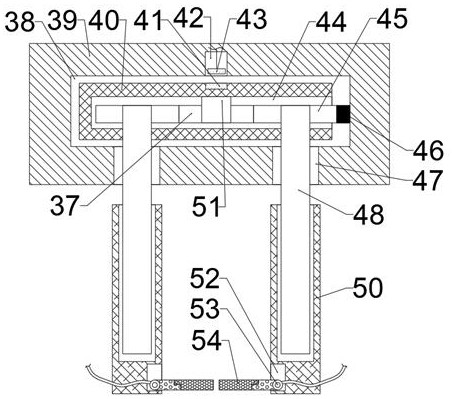

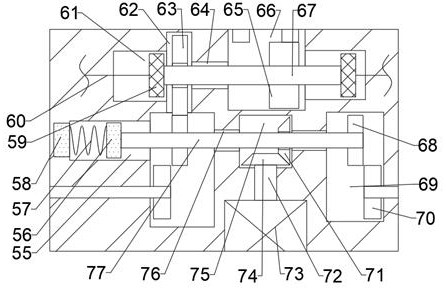

Automatic electroplating device with adjustable single and double plating layers

The invention relates to the related field of industrial electroplating, and discloses an automatic electroplating device with adjustable single and double plating layers. The automatic electroplating device comprises a main box body, a transposition cavity is arranged in the main box body, the left side of the transposition cavity communicates with a transposition transmission cavity, and the left side of the transposition transmission cavity communicates with a transposition gear cavity; plate cavities in left-right symmetry are formed in the left side of the transposition gear cavity and the right side of the transposition cavity in a communicating mode, a motor transmission cavity is formed in the lower side of the transposition cavity, the position of a main contact block is changed through a timing knob to adjust the time needed by electroplating coating metal, a workpiece can be accurately taken out within the specified time, the situation that the coating of the workpiece is too little or too much is avoided, meanwhile, the electroplated workpiece is automatically placed and taken through a hanging rod on a telescopic rod, the electric shock risk caused by manual operation is avoided, on the other hand, the device can be directly switched between single-layer electroplating and double-layer electroplating by twisting a double-layer knob, and the tedious process of manual operation is avoided.

Owner:成都九叶草科技有限公司

A method for preparing diamond/copper composite material combined with injection molding technology

ActiveCN107855533BHigh densityVolume fraction adjustmentTransportation and packagingMetal-working apparatusCopper platingChemical plating

A method for preparing diamond / copper composite materials combined with injection molding technology, using salt bath plating technology to coat a layer of uniform Mo on the diamond surface 2 C is used to improve the wettability of diamond and copper, and then the electroless plating method is used to continue on the Mo 2 Copper plating on the surface of layer C, by controlling Cu in the plating solution 2+ content to control the thickness of the copper plating layer, thereby preparing a double-coated Cu-Mo with a copper volume fraction of 1% to 10%. 2 C‑Diamond Powder. Quantitative Cu‑Mo 2 C‑Diamond powder is mixed with a multi-polymer component paraffin-based binder to form a uniform feed. After granulation, it is injection-molded on an injection molding machine. The resulting preform is pre-sintered at a high temperature after solvent and thermal degreasing to obtain The blank is infiltrated into the diamond skeleton through the capillary action of the copper liquid through the vacuum pressureless infiltration technology, so as to obtain a diamond / copper composite material part with a high volume fraction. The invention can directly prepare Diamond / Cu composite parts with complex shapes, has high diamond volume fraction, uniform and compact structure, can be produced in batches, and has low production cost.

Owner:UNIV OF SCI & TECH BEIJING

A kind of method for preparing high-performance diamond/copper composite material

ActiveCN111992708BReduce thermal resistanceImprove wettabilityAdditive manufacturing apparatusTransportation and packagingHigh energyHigh energy laser beam

The invention discloses a method for preparing a high-performance diamond / copper-based composite material. Aiming at the problems of poor wettability of copper and diamond, weak interface bonding, and easy occurrence of graphitization of diamond at high temperature, the invention adopts magnetron sputtering technology to prepare diamond The surface is uniformly plated with a layer of B or strong carbide elements Ti, Zr, Nb, Cr to improve its interface bonding strength, and then a layer of metal copper is sputtered with a thickness of 1-3 μm; Heat treatment at 500-700°C for 5-30min to make the coatings diffuse and react with each other to achieve metallurgical bonding; using selective laser melting (SLM) technology to sinter the copper alloy powder and the surface-modified diamond particles, extremely fast The cooling rate significantly refines the matrix alloy structure and improves the strength of the composite material. The surface modification of the double coating effectively avoids the graphitization of diamond under the high-energy laser beam; Spark plasma sintering (SPS) is used to further improve the density of the workpiece. ; Combined with aging heat treatment, the solid solution atoms are uniformly precipitated in the copper matrix, and the thermal conductivity and mechanical properties of the composite material are comprehensively improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com