Alloy plating liquid for modular printed circuit board surface treatment

A printed circuit board and surface treatment technology, applied in the secondary processing of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of low economic efficiency and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

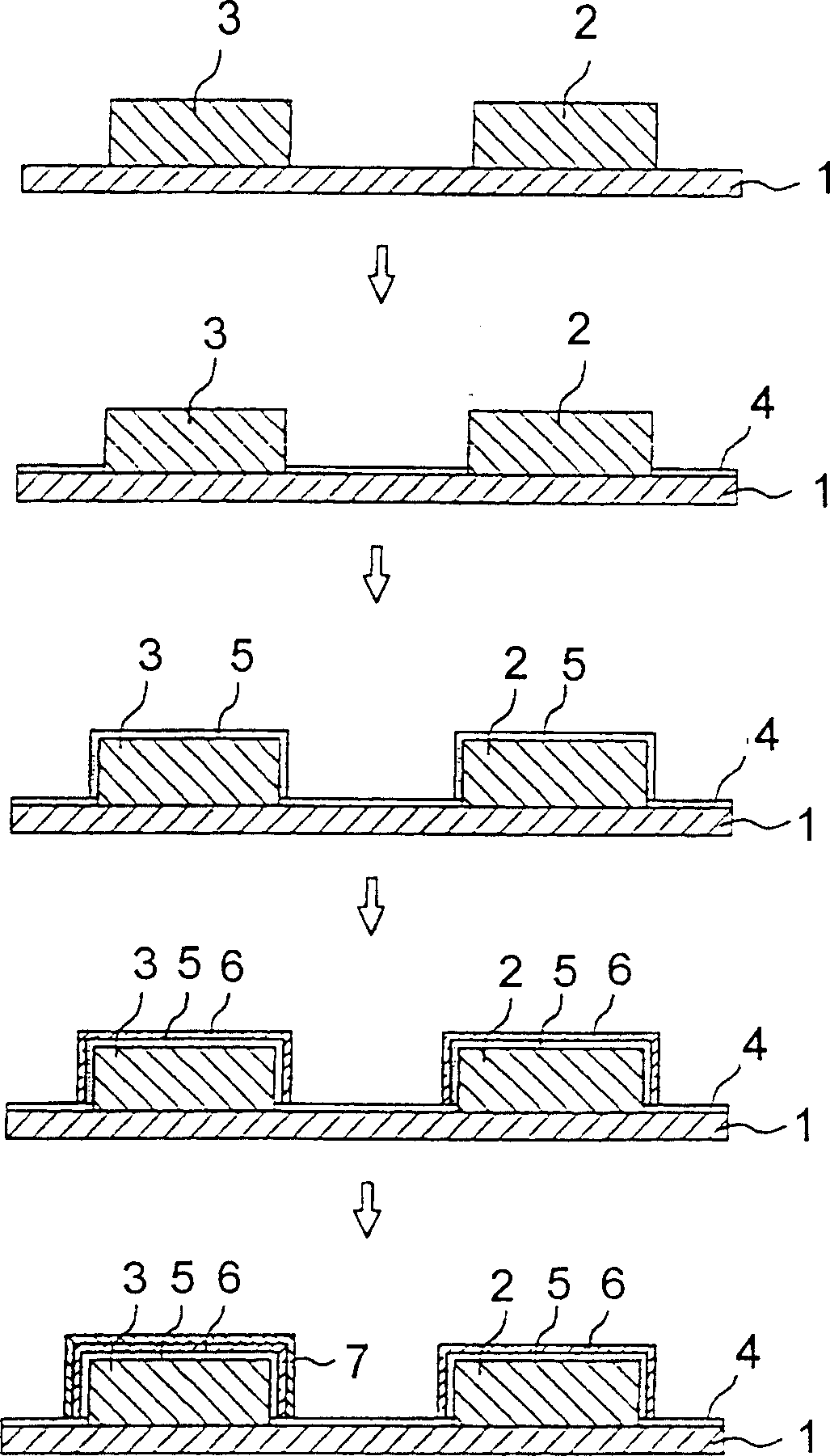

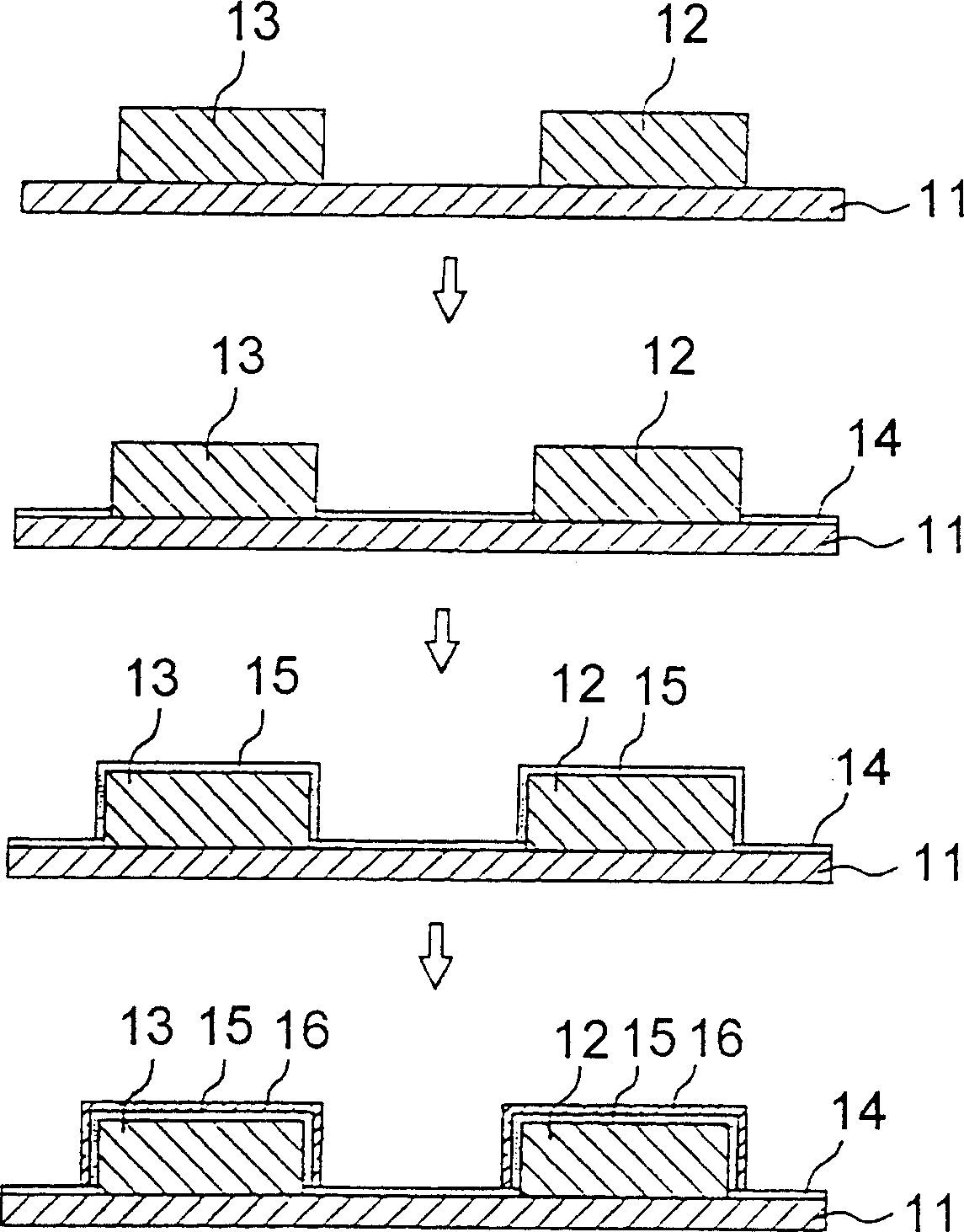

Method used

Image

Examples

Embodiment 1

[0043] Prepare an aqueous alloy plating solution having the composition shown in Table 1 below, and then activate the electroless nickel-plated modular PCB with 3% hydrochloric acid solution at 25° C. for 1 minute. While adjusting the temperatures of the three plating solution baths to 60°C, 70°C and 80°C, the PCB was immersed in the plating solution for 10 minutes for plating. As such, the plating solution was not stirred and the pH of the plating solution was 4.5.

[0044] Table 1

[0045] Element

content

30g / l

10g / l

10g / l

0.25g / l

5g / l

Nitriloacetic acid

3g / l

[0046] After the plating process, the board was washed with water, dried at 80° C. for 15 minutes, and then solderability and wear resistance were measured by the following conditions and methods.

[0047] - Solderability

[0048] The p...

Embodiment 2

[0059] Prepare an aqueous alloy plating solution having the composition shown in Table 3 below, and then use 3% hydrochloric acid solution at 25° C. to activate the electroless nickel plating layer of the electroless nickel-plated modular PCB for 1 minute. The plating process was performed using a plating solution at 80° C. at plating time periods of 5 minutes, 10 minutes, and 15 minutes. At this time, the plating solution was not stirred, and the pH of the plating solution was 4.5.

[0060] table 3

[0061] Element

content

50g / l

10g / l

10g / l

0.25g / l

Potassium gold cyanide

5g / l

3g / l

[0062] Then, post-processing was performed in the same manner as in Example 1, and solderability and wear resistance were measured. The results are shown in Table 4 below.

[0063] period

Embodiment 3

[0065] Prepare an aqueous alloy plating solution having the composition shown in Table 5 below, and then use 3% hydrochloric acid solution at 25° C. to activate the electroless nickel-plated modular PCB for 1 minute. Then, the plating process was performed for 10 minutes using a plating solution at 80° C., and the stirring conditions were 0.1 m / s, 0.2 m / s, and 0.3 m / s, respectively.

[0066] table 5

[0067] Element

content

40g / l

potassium cyanide

6g / l

Methylthiourea

1.5g / l

0.1g / l

Potassium gold cyanide

2.5g / l

DTPA-5Na

3g / l

[0068] Then, post-processing was performed in the same manner as in Example 1, and solderability and wear resistance were measured. The results are shown in Table 6 below.

[0069] to stir

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com