A short-range zinc liquid electroplating line

An assembly line and zinc liquid technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of assembly line or electroplating tank impact, strict transmission interval and position requirements, limited positioning ability of mechanical arm, etc., and achieve the goal of shortening the time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

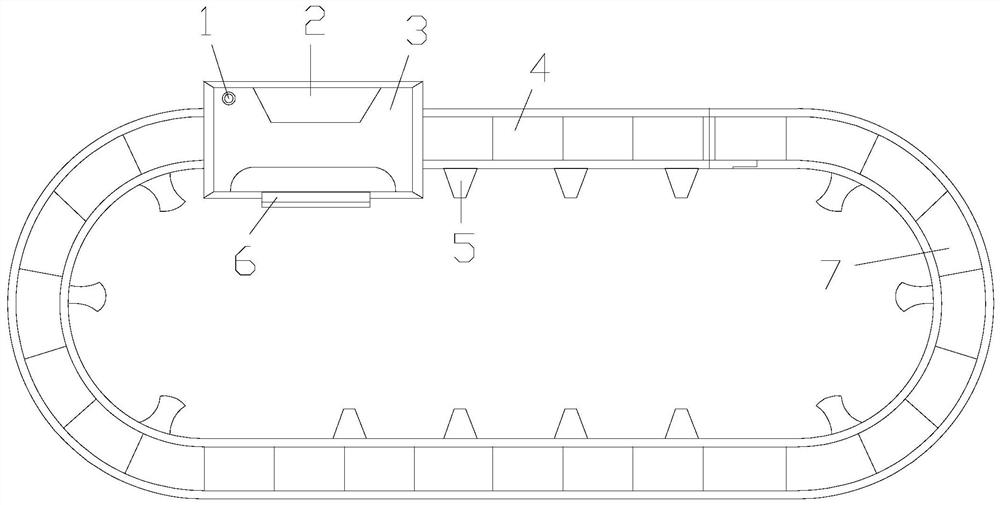

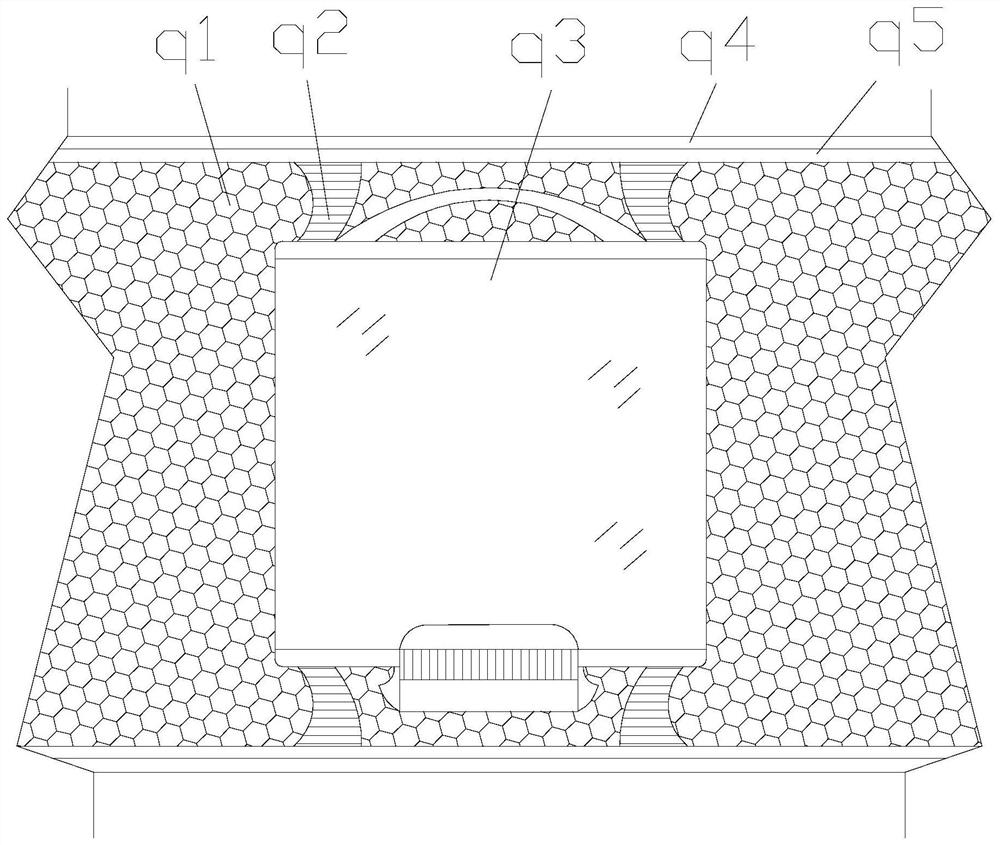

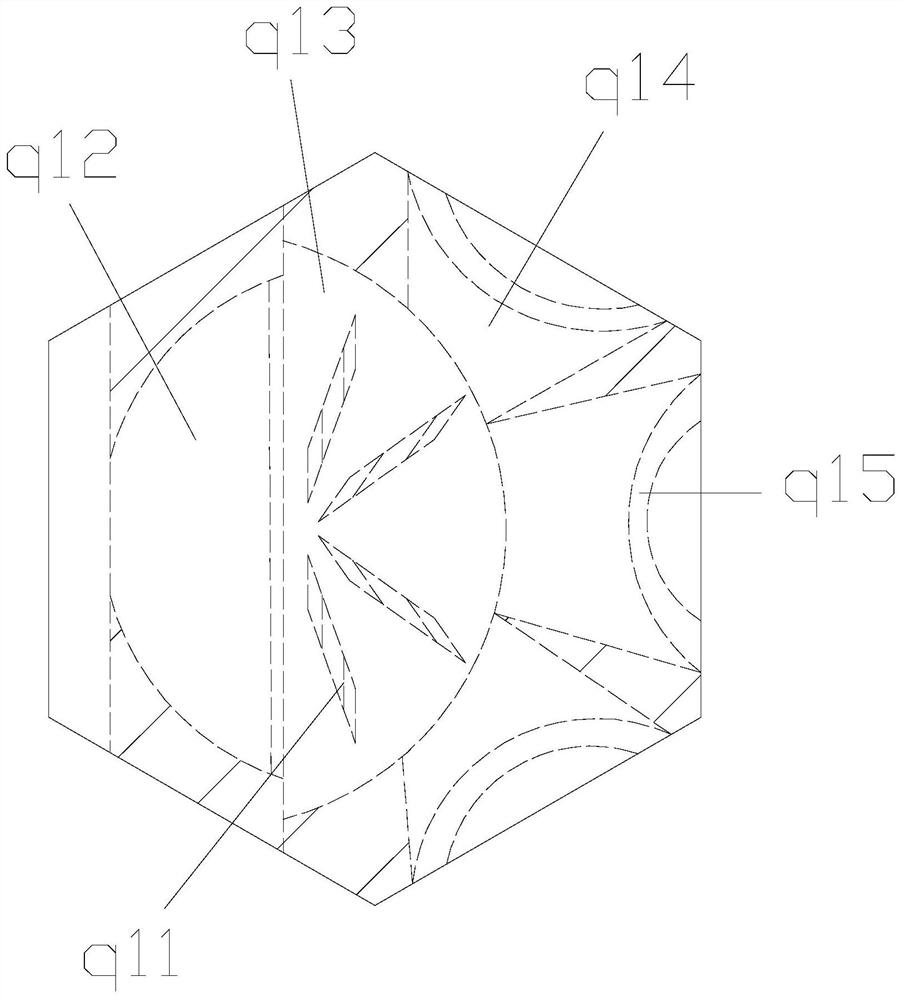

[0027] as attached figure 1 To attach Figure 7 Shown:

[0028] The invention provides a short-range zinc liquid electroplating line, the structure of which includes a fault alarm light 1, a flip side repair plate 2, a galvanized cover buckle 3, a short-range zinc liquid electroplating device 4, a support frame 5, an external power supply bar 6, and a row transmission Frame 7, the fault alarm lamp 1 is installed on the upper left end of the top surface of the galvanized cover buckle 3 by embedding, the back of the short-range zinc bath electroplating device 4 is welded with the support frame 5, and the galvanized cover buckle 3 is provided with There is an overturned side repair panel 2, the external power supply bar 6 is installed inside the bottom of the galvanized cover buckle 3 by embedding, the back of the sub-row transmission frame 7 is welded to the support frame 5, and the short-range zinc bath electroplating device 4 Including plating solution guiding mechanism q1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com