A double-layer nickel plating process for a battery steel shell and a battery steel shell obtained by the process

A battery steel shell and process technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc., can solve problems such as insufficient corrosion resistance, achieve no change in bonding force, delay corrosion rate, improve The effect of anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

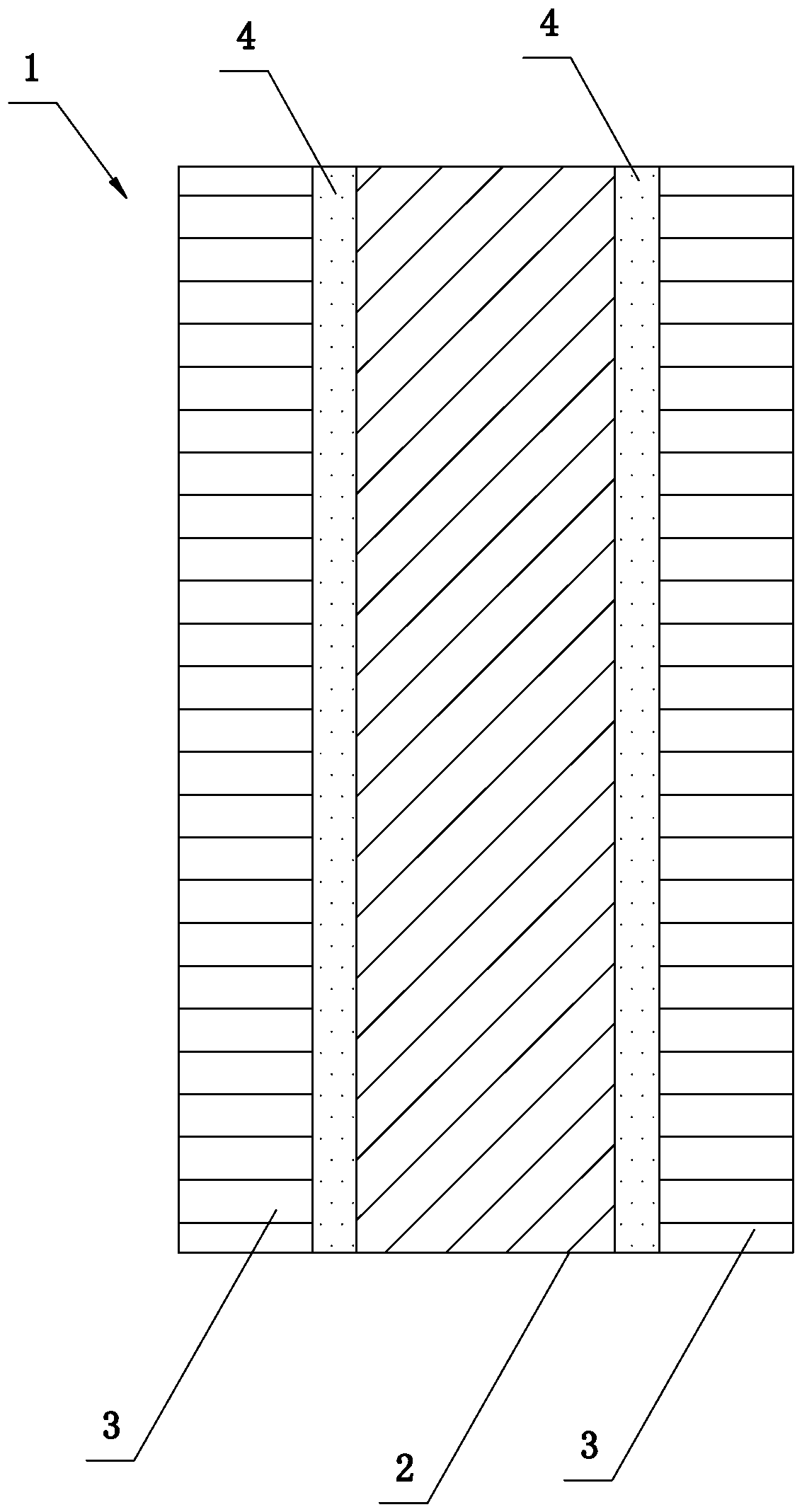

[0031] refer to figure 1 and figure 2 . A battery steel case 1 with improved corrosion performance, comprising a steel case base material 2 and a bright nickel-plated layer 3, the surface of the steel case base material 2 is covered with a semi-bright surface with an oxidation potential greater than that of the bright nickel-plated layer 3 Nickel plating layer 4 , the upper surface of the semi-bright nickel plating layer 4 is covered with the above bright nickel plating layer 3 .

[0032] refer to figure 1 and figure 2 . As a preferred solution of this embodiment, the sum of the thicknesses of the semi-bright nickel plating layer 4 and the bright nickel plating layer 3 is 1.8 μm-2.3 μm. As a more preferred solution of this embodiment, the thickness of the semi-bright nickel plating layer 4 is 0.5 μm˜1.5 μm.

[0033] refer to figure 1 and figure 2 . The thickness of the semi-bright nickel plating layer 4 may be 1.2 μm, while the thickness of the bright nickel platin...

Embodiment 2

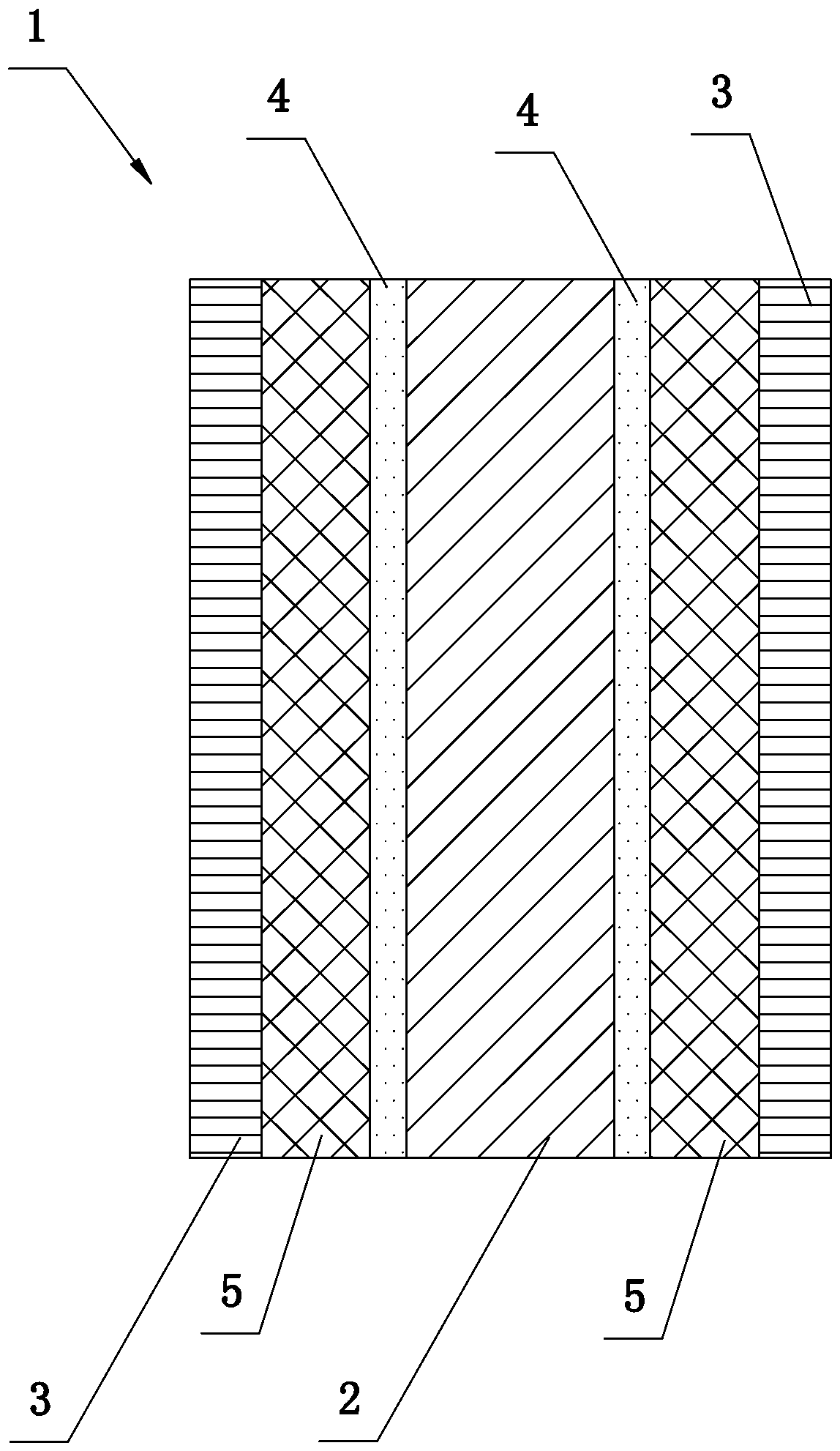

[0042] refer to image 3 and Figure 4 . A battery steel case 1 with improved corrosion resistance, comprising a steel case base material 2, a bright nickel-plated layer 3, a semi-bright nickel-plated layer 4 with an oxidation potential greater than that of the bright nickel-plated layer 3, and a semi-bright nickel-plated layer 4 with an oxidation potential lower than The high-sulfur nickel plating layer 5 of the bright nickel plating layer 3, the semi-bright nickel plating layer 4 covers the surface of the steel shell base material 2, and the upper surface of the semi-bright nickel plating layer 4 is covered with the High sulfur nickel plating layer 5, the upper surface of the high sulfur nickel plating layer 5 is covered with the bright nickel plating layer 3.

[0043] refer to image 3 and Figure 4. As a preferred solution of this embodiment, the sum of the thicknesses of the semi-bright nickel plating layer 4 , the high-sulfur nickel plating layer 5 and the bright ni...

Embodiment 3

[0054] Select three groups of samples to analyze the anti-corrosion performance of the experimental products

[0055] Coating thickness of each sample (thickness of the outer middle part of the steel shell μm)

[0056]

1

2

3

4

5

Sample A

2.03

1.98

1.94

2.13

1.89

Sample B

1.98

2.00

1.88

1.99

2.09

Sample C

2.12

1.95

2.22

1.97

1.90

[0057] Among them, sample A is the battery steel case 1 prepared by the existing electroplating technology, sample B is the battery steel case 1 described in the first embodiment, and sample C is the battery steel case 1 described in the second embodiment.

[0058] Figure 5 An example diagram showing the antirust effect of the battery steel case 1 in the prior art in the salt spray test. Figure 6 An example diagram showing the antirust effect of the battery steel case 1 in Example 1 of the present invention subjected to a salt spray test. Figure 7 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com