Manufacturing method of palladium-plated gold-plated double-plating bonding copper wire

A technology for bonding copper wires and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., and can solve problems such as poor electrical conductivity and poor ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

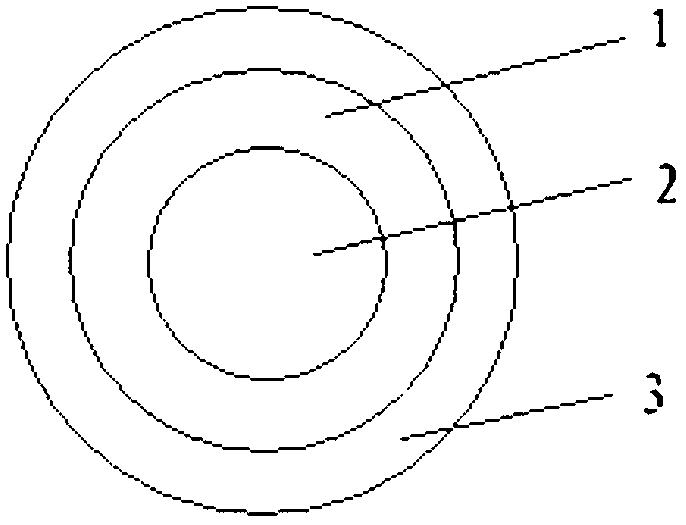

[0012] like figure 1 As shown, the double-coated bonding copper wire proposed by the present invention includes a copper core 1 , a palladium-plated layer 2 and a gold-plated layer 3 . Among them, the copper core 1 is made of high-purity copper with a purity greater than 99.9995% as a raw material, and is formed by adding tin, magnesium and aluminum for single crystal melting; Plated on the surface of the copper core; the gold-plated layer 3 is metal gold with a purity greater than 99.99%, which is electroplated on the surface of the palladium-plated layer 2 through an electroplating process. Wherein, based on 100 parts by weight of the final double-coated bonding copper wire containing palladium-plated layer and gold-plated layer, that is, 100wt%, the content of pure copper in the copper core is 92.6-93.8wt%, and the pure palladium conductive layer The content of the pure gold conductive layer is 2.7-5.4wt%, the content of the pure gold conductive layer is 1-2.5wt%, the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com