Composite gold wire and manufacture method thereof

A manufacturing method and composite gold technology, which are applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increased cost and high cost of semiconductor components, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

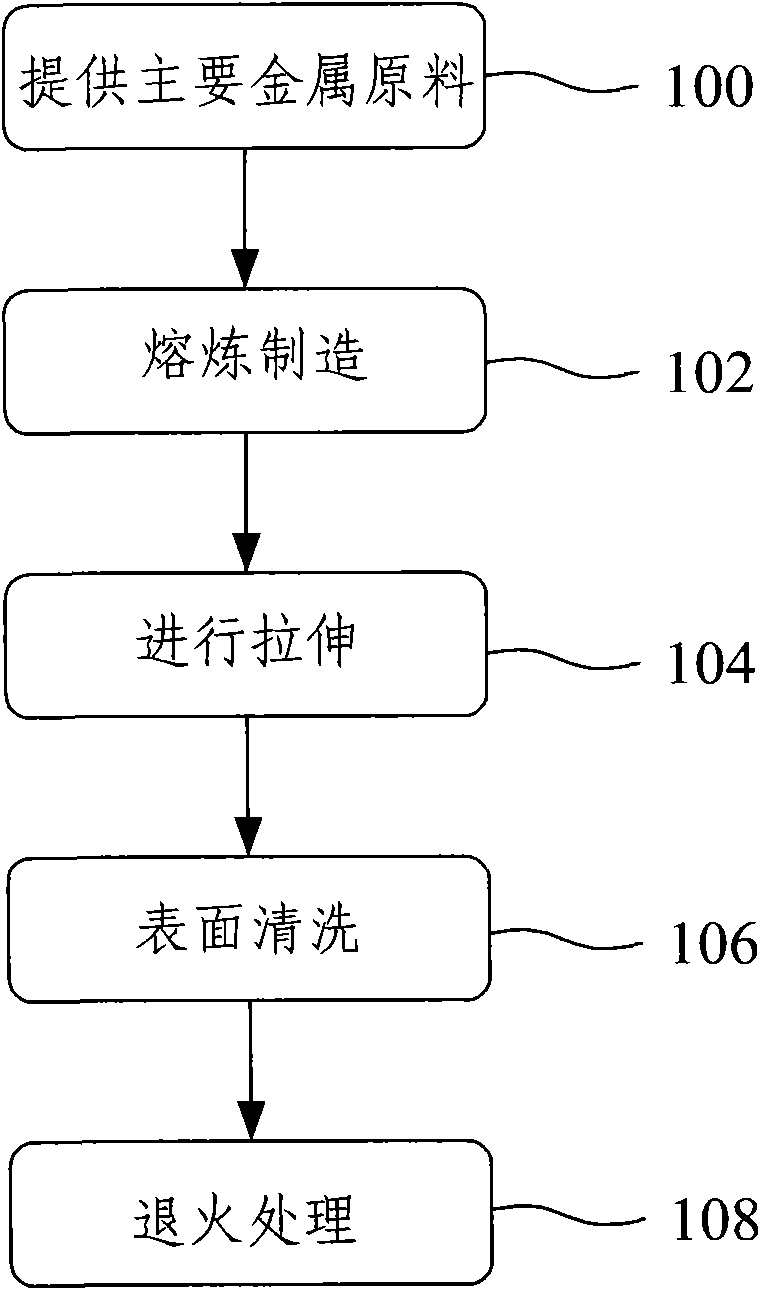

Method used

Image

Examples

Embodiment 1

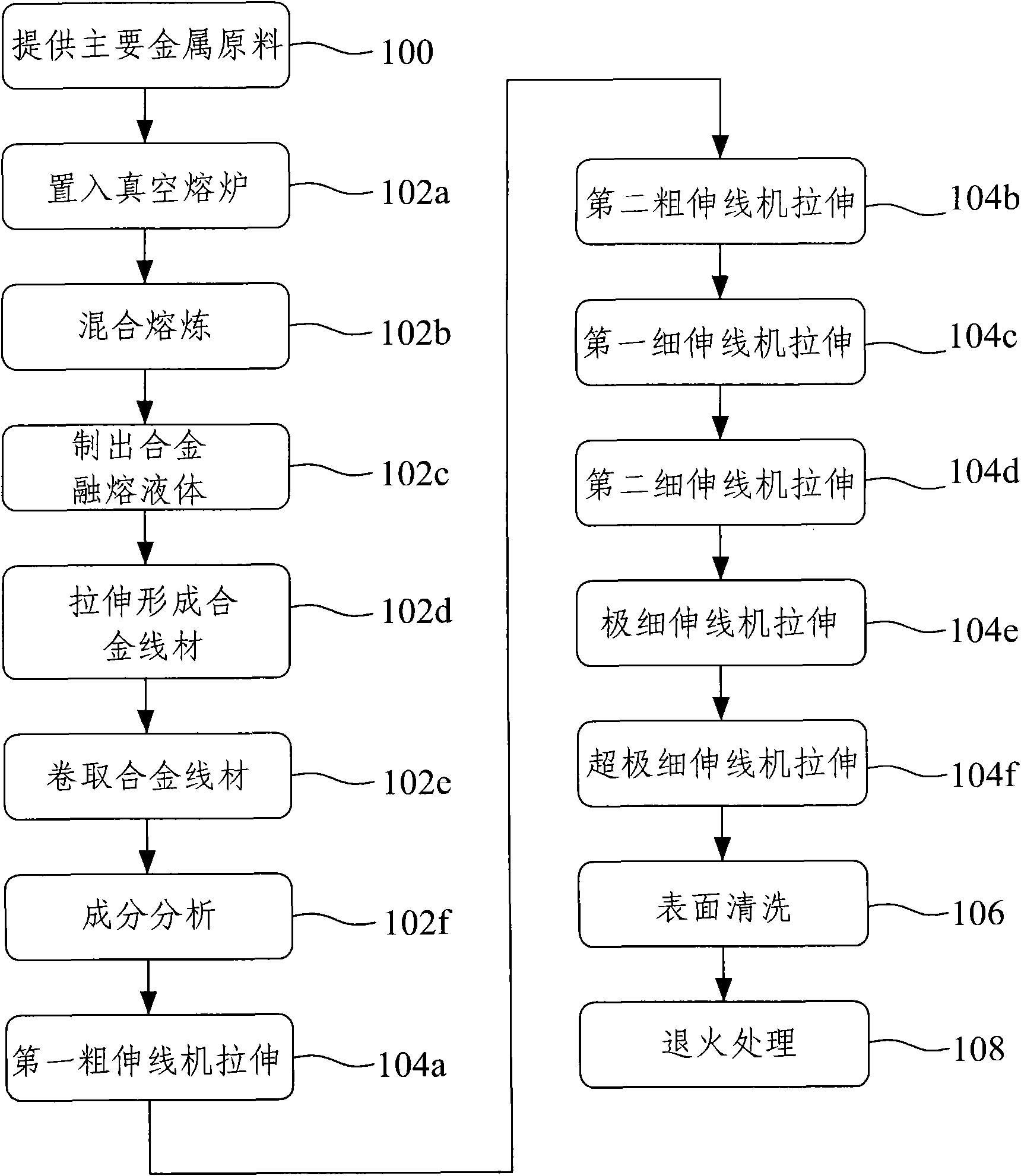

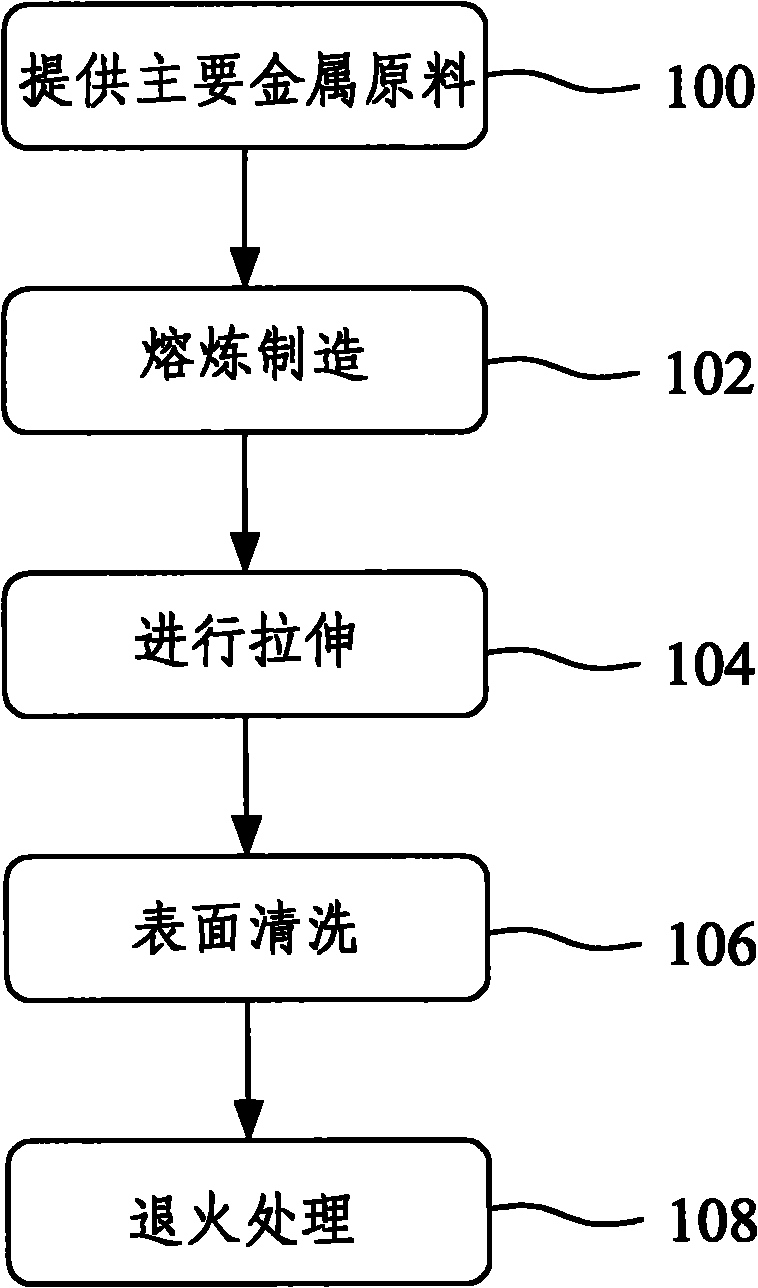

[0026] The main metal raw material including gold and silver components is placed in a vacuum furnace, and the secondary metal material with palladium component is added into the vacuum furnace, and then mixed and smelted by the vacuum furnace to produce a gold-silver-palladium alloy molten liquid. The components of the gold-silver-palladium alloy molten liquid include: 30.00% by weight of gold components, 66.00% by weight of silver components, and 4.00% by weight of palladium components.

[0027] The gold-silver-palladium alloy molten liquid is continuously cast and then drawn to draw a gold-silver-palladium alloy wire rod with a wire diameter of 4 mm. The gold-silver-palladium alloy wire is coiled by a winder, and the composition analysis of the gold-silver-palladium alloy wire is carried out.

[0028] After the gold-silver-palladium alloy wire casting is completed, the wire diameter is stretched, so that the wire diameter that was originally 4mm is stretched to 3mm by the f...

Embodiment 2

[0031] The main metal raw material including gold and silver components is placed in a vacuum furnace, and the secondary metal material with palladium component is added into the vacuum furnace, and then mixed and smelted by the vacuum furnace to produce a gold-silver-palladium alloy molten liquid. The components of the gold-silver-palladium alloy molten liquid include: 8.00% by weight of gold components, 86.00% by weight of silver components, and 6.00% by weight of palladium components.

[0032] The gold-silver-palladium alloy molten liquid is continuously casted and drawn to produce a gold-silver-palladium alloy wire rod with a wire diameter of 6 mm. The gold-silver-palladium alloy wire is coiled by a winder, and the composition analysis of the gold-silver-palladium alloy wire is carried out.

[0033] After the gold-silver-palladium alloy wire casting is completed, the wire diameter is stretched, so that the original wire diameter of 6mm is stretched to 3mm through the first...

Embodiment 3

[0036] The main metal raw material including gold and silver components is placed in a vacuum furnace, and the secondary metal material with palladium component is added into the vacuum furnace, and then mixed and smelted by the vacuum furnace to produce a gold-silver-palladium alloy molten liquid. The components of the gold-silver-palladium alloy molten liquid include: 9.99% by weight of gold components, 90.00% by weight of silver components, and 0.01% by weight of palladium components.

[0037] The gold-silver-palladium alloy molten liquid is continuously casted and drawn to produce a gold-silver-palladium alloy wire rod with a wire diameter of 8 mm. The gold-silver-palladium alloy wire is coiled by a winder, and the composition analysis of the gold-silver-palladium alloy wire is carried out.

[0038] After the gold-silver-palladium alloy wire casting is completed, the wire diameter is stretched, so that the original wire diameter of 8mm is stretched to 2mm by the first thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com