Method of laser cladding copper-based diamond particle reinforced composite coating on copper alloy surface

A technology of diamond particles and laser cladding, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problem that it is difficult to form an effective interface bond between copper substrate and diamond particles, which is not conducive to the melting and melting of coating and substrate. Problems such as the effective combination of the interface and the loss of the physical properties of diamond in the atomic structure can achieve the effects of inhibiting the degree of graphitization, high thermal conductivity, and protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

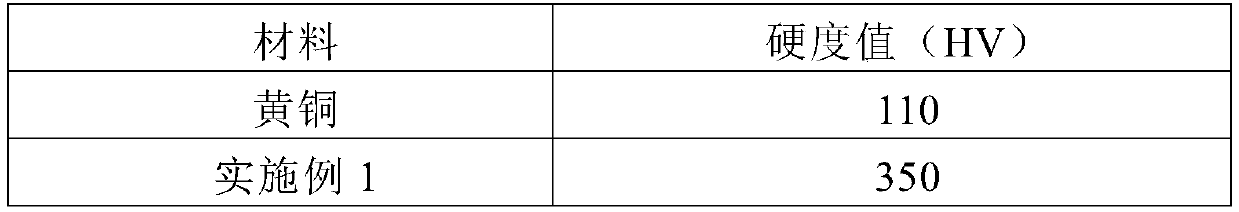

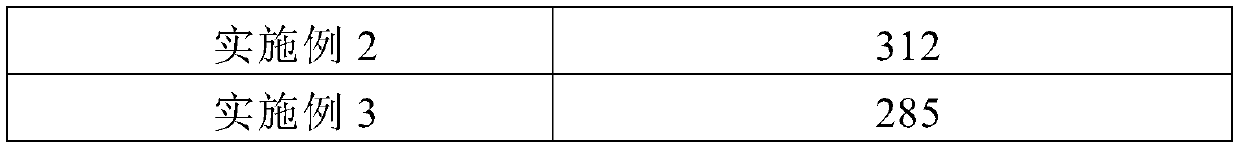

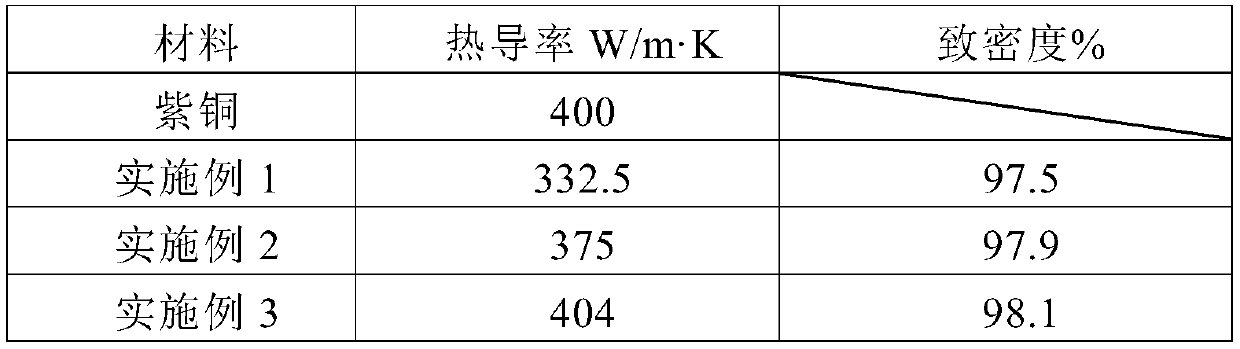

Embodiment 1

[0032] (1) Select diamond particles with an average particle size of 300 mesh, and perform ultrasonic cleaning on the diamond particles in acetone and absolute ethanol environments in sequence. After the end, take them out and wash them with deionized water until neutral. The working pressure is normal pressure, and ultrasonic cleaning The time is 15min, and the cleaning temperature is 20°C;

[0033] (2) Diamond particles, Cr powder and mixed salt NaCl-KCl (mass ratio NaCl:KCl=1:1) are configured as mixed raw materials, the mass ratio of diamond particles: Cr powder: mixed salt is 1:3:5~10, Then heat it to 950°C at a heating rate of 5°C / min in a tube-type resistance furnace with argon gas and keep it for 1h for reaction sintering. At high temperature, the Cr powder in the molten salt reacts with the surface of the diamond to form Cr 7 C 3 / Cr layer. After cooling with the furnace, the product is repeatedly ultrasonically cleaned and sieved to obtain diamond particles coated ...

Embodiment 2

[0041] (1) The diamond particles with an average particle size of 200 mesh are subjected to ultrasonic cleaning in acetone and absolute ethanol environments in turn, and after the end, they are taken out and washed with deionized water until neutral, wherein the working pressure is normal pressure, ultrasonic cleaning The time is 15min, and the cleaning temperature is 20°C;

[0042] (2) Select diamond particles, Cr powder and mixed salt NaCl-KCl (mass ratio NaCl:KCl=1:1) to configure mixed raw materials, the mass ratio of diamond micropowder: Cr powder: mixed salt is 1:4:5~10, Then heat it to 700°C at a heating rate of 10°C / min in a tube-type resistance furnace with argon gas and keep it for 1.5h for reaction sintering. At high temperature, the Cr powder in the molten salt reacts with the surface of the diamond to form Cr 7 C 3 / Cr layer. After cooling with the furnace, the product is repeatedly ultrasonically cleaned and sieved to obtain diamond particles coated with Cr on ...

Embodiment 3

[0050] (1) The diamond micropowder with an average particle size of 100 mesh is subjected to ultrasonic cleaning in acetone and absolute ethanol environments in sequence, and after the end, it is taken out and washed with deionized water to neutrality, wherein the working pressure is normal pressure, and the ultrasonic cleaning time is 15min, the cleaning temperature is 20°C;

[0051] (2) Select diamond particles, Cr powder and mixed salt NaCl-KCl (mass ratio NaCl:KCl=1:1) to configure mixed raw materials, the mass ratio of diamond particles: Cr powder: mixed salt is 1:5:5~10, Then heat it to 800°C at a heating rate of 10°C / min in a tube-type resistance furnace with argon gas and keep it for 1h for reaction sintering. At high temperature, the Cr powder in the molten salt reacts with the surface of the diamond to form Cr 7 C 3 / Cr layer, after cooling with the furnace, the product is repeatedly ultrasonically cleaned and sieved to obtain diamond particles coated with Cr on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com