Preparation process for double plating layers capable of inhibiting growth of lead-free solder joint interface compound, of substrate

A preparation process and a technology of lead-free solder joints, which are applied in metal material coating process, liquid chemical plating, plating of superimposed layers, etc., can solve problems that have not been reported, and achieve simple and easy operation, good effect, Even and fine plating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

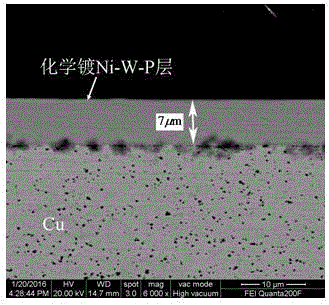

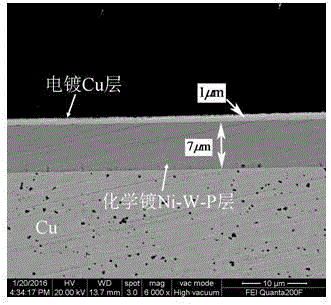

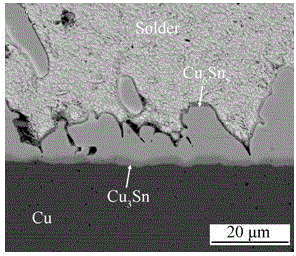

[0032] The invention discloses a double coating preparation process of electroless plating Ni-W-P / electroplating Cu on a metal substrate that inhibits the growth of lead-free solder joint interface compounds. Pure copper is selected as the metal substrate, and a layer of Ni-W-P is chemically plated on the metal substrate first, the thickness of the coating is about 3~10µm, and then a thinner layer of copper is electroplated on it, and the thickness of the electroplating layer is about 0.5~3µm.

[0033] The preparation of the electroless plating solution is to mix nickel sulfate, sodium citrate, sodium hypophosphite, lactic acid, ammonium chloride and sodium tungstate, add water and stir evenly, and then use ammonia solution to adjust the pH to 7; the nickel sulfate in the electroless plating solution is 30g / L, sodium citrate is 35g / L, sodium hypophosphite is 30g / L, lactic acid is 16ml / L, ammonium chloride is 1mol / L, and sodium tungstate is 30g / L. Drugs such as nickel sulfate,...

Embodiment 2

[0037] The method of the present embodiment is the same as Example 1, except that sodium citrate is 30g / L, and potassium pyrophosphate is 300g / L. The resulting electroless plating rate is about 2.75 µm / h and the electroplating rate is 0.19 µm / min.

Embodiment 3

[0039] The method of the present embodiment is with embodiment 1, and difference is that nickel sulfate is 35g / L, and potassium pyrophosphate is 200g / L. The resulting electroless plating rate was about 2.88 µm / h and the electroplating rate was 0.18 µm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com