FeCo alloy/CuO double-plating magnetic carbon fiber and preparation method and application

A technology of carbon fiber and coating, applied in the direction of carbon fiber, fiber treatment, chemical instruments and methods, etc., can solve problems such as less research, and achieve the effect of simple process, increased absorption, and weakened reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

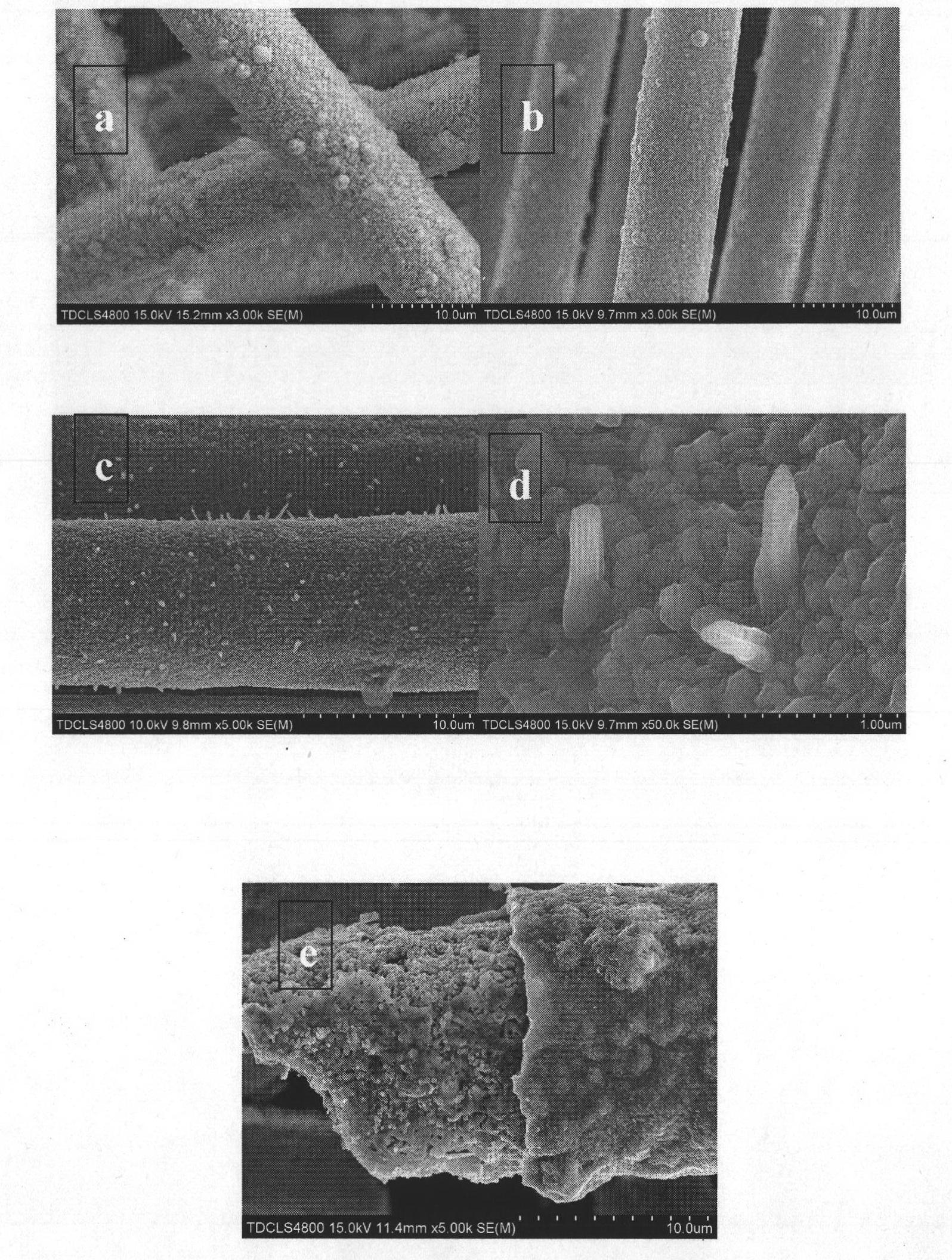

[0018] Pretreatment of carbon fiber: First, the continuous carbon fiber (polyacrylonitrile-based continuous carbon fiber, Dalian Xingke Carbon Fiber Co., Ltd., number DLXK2003, each bundle contains 12,000 carbon fiber monofilaments, with a diameter of about 7μm) in a muffle furnace at 500°C Incubate for 15 minutes, and then soak in 40ml of 50% nitric acid solution for 1 hour oxidation treatment.

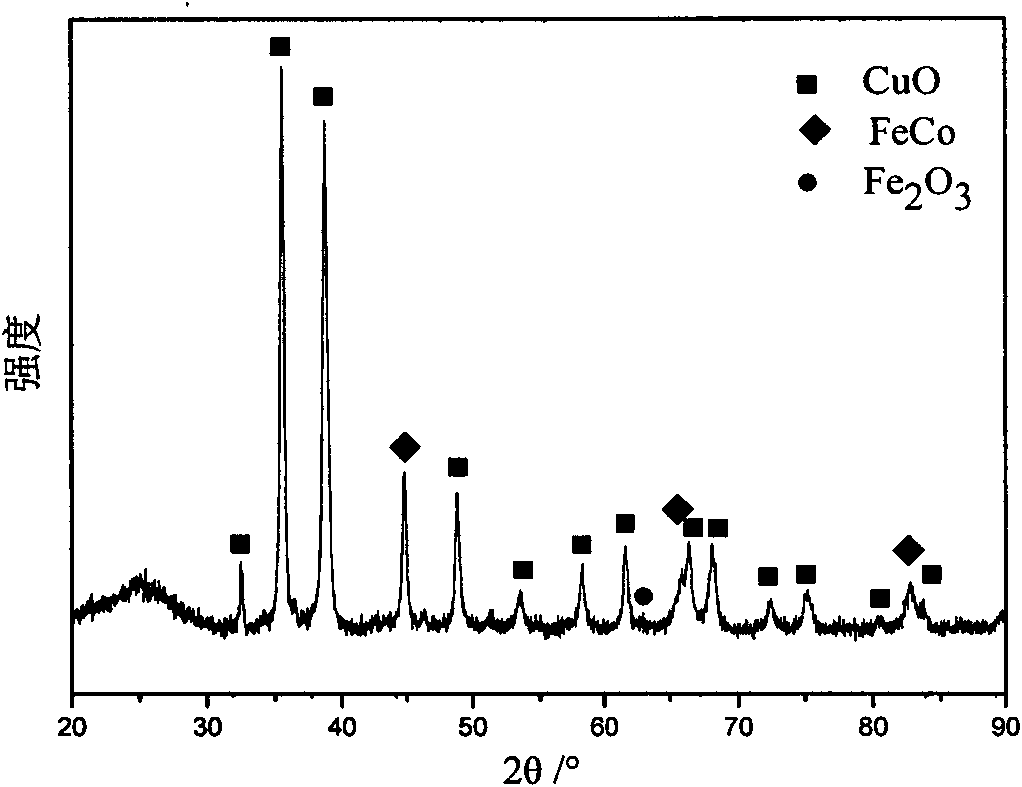

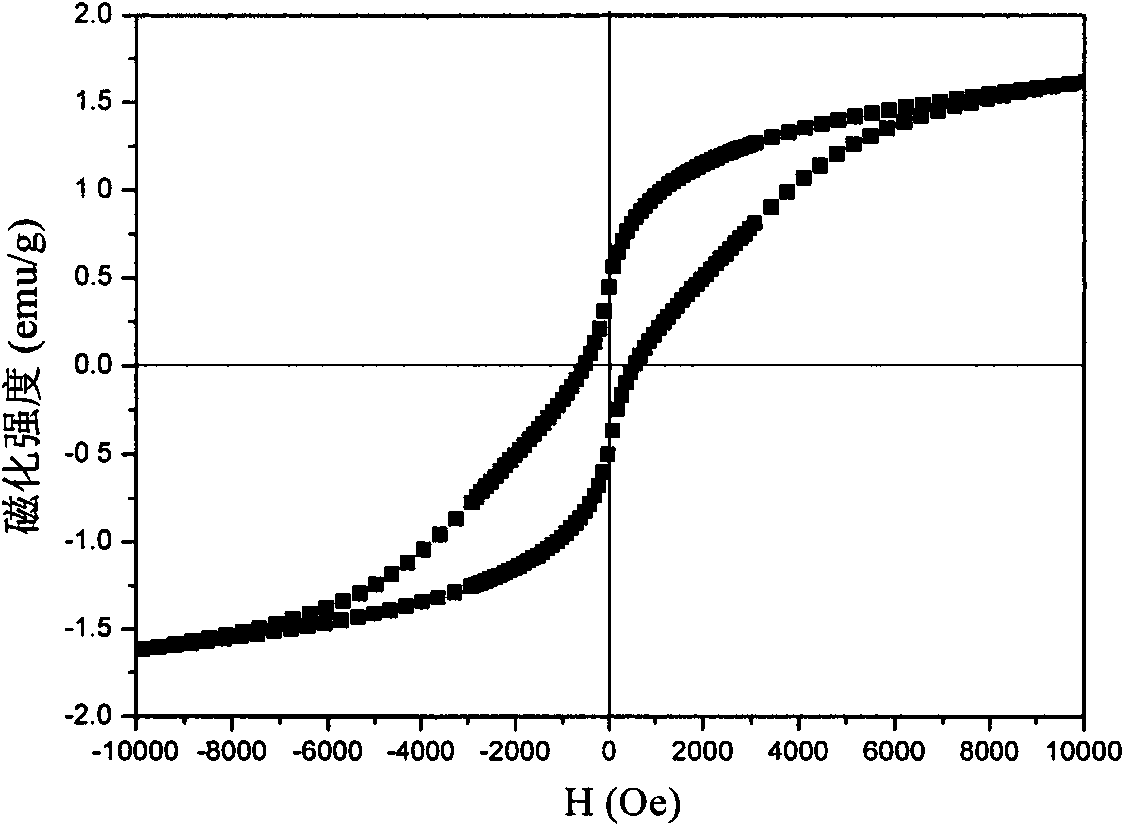

[0019] The composition of the FeCo alloy plating solution is: the concentration of ferrous sulfate and cobalt dibasic sulfate are both 90g / L, the concentration of boric acid is 30g / L, the concentration of sodium cetyl sulfate is 0.1g / L, and the mass fraction of pH is 10 % Dilute sulfuric acid solution is adjusted to 3-4. For FeCo alloy electroplating, a high-purity iron plate with a purity of 99.99% is used as the anode, and the carbon fiber after oxidation treatment is used as the cathode. The current is 0.5A, electromagnetic stirring is performed at 35°C, and the electroplating time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com