Composite coated fiber with electromagnetic shielding function and preparation method thereof

A composite coating, electromagnetic shielding technology, applied in the direction of coating, carbon fiber, fiber processing, etc., can solve the problems of low electromagnetic parameters, can not meet the requirements of electromagnetic shielding materials, etc., to achieve good compactness, coating thickness and particle size can be accurate Control, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

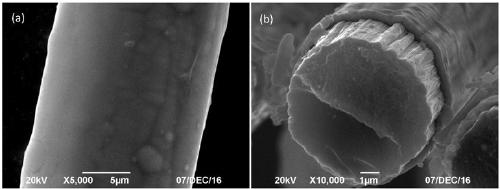

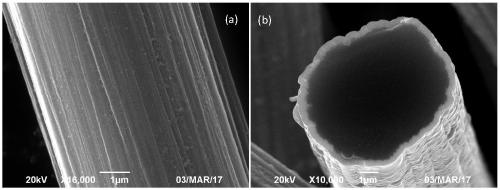

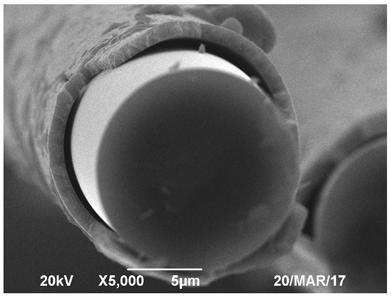

[0035] A method for preparing a composite coated fiber with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 700° C. for 10 minutes; 2. Put the carbon fiber treated in step 1 into Ultrasonic cleaning in acetone for 15min; 3. The carbon fibers processed in step 2 are prepared on the surface by radio frequency magnetron sputtering method to prepare FeCo alloy coating, that is, the lower magnetic layer; Controlled sputtering method to prepare aluminum oxide coating; 5. The carbon fiber after step 4 is processed on the surface by radio frequency magnetron sputtering method to prepare FeCo alloy coating, that is, the upper magnetic layer, that is, to complete the carbon fiber surface FeCo-Al 2 o 3 -Preparation of FeCo composite coating; wherein the composition ratio of the FeCo target in steps 3 and 5 is Fe:Co=50:50, the purity is 99.999%, and the vacuum degree before...

Embodiment 2

[0038] A method for preparing a composite coated fiber with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 700° C. for 10 minutes; 2. Put the carbon fiber treated in step 1 into Ultrasonic cleaning in acetone for 15min; 3. The carbon fiber after step 2 is processed on the surface by radio frequency magnetron sputtering method to prepare FeNi alloy coating, i.e. the lower magnetic layer; 4. The fiber after step 3 is processed on the surface by DC magnetic Controlled sputtering method to prepare aluminum oxide coating; 5. The carbon fiber after step 4 is processed on the surface using radio frequency magnetron sputtering method to prepare FeNi alloy coating, that is, the upper magnetic layer, that is, to complete the carbon fiber surface FeNi-Al 2 o 3 -Preparation of FeNi composite coating; wherein the composition ratio of the FeNi target in steps 3 and 5 is Fe:N...

Embodiment 3

[0041] A method for preparing a composite coated fiber with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 700° C. for 10 minutes; 2. Put the carbon fiber treated in step 1 into Ultrasonic cleaning in acetone for 15min; 3. The carbon fiber treated in step 2 is prepared on the surface by radio frequency magnetron sputtering method to prepare NiCo alloy coating, that is, the lower magnetic layer; Prepare alumina coating by controlled sputtering method; 5. Prepare NiCo alloy coating by radio frequency magnetron sputtering method on the surface of the carbon fiber after step 4 treatment, that is, the upper magnetic layer, that is, complete the carbon fiber surface NiCo-Al 2 o 3 -Preparation of NiCo composite coating; wherein the composition ratio of the NiCo target in steps 3 and 5 is Ni:Co=75:25, the purity is 99.999%, and the vacuum degree before sputtering is 8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com