A kind of three-dimensional foam type composite wave absorbing material and preparation method thereof

A composite wave-absorbing material, foam-type technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., to achieve the effect of improving electromagnetic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

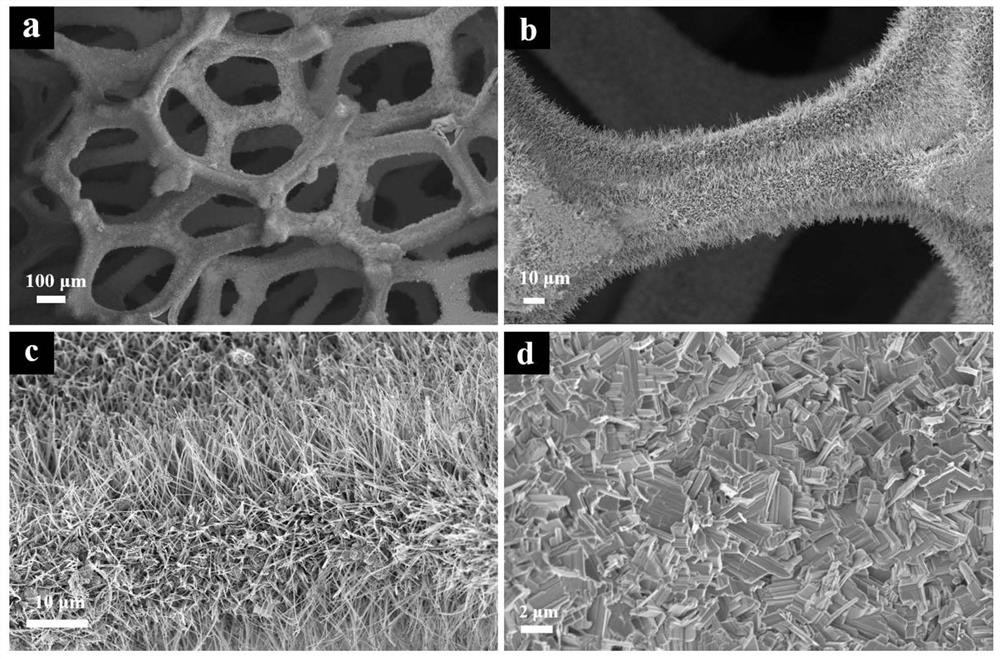

[0026] A method for preparing a composite wave-absorbing material prepared by a one-step method, characterized in that the steps are as follows:

[0027] Step 1: Alternately clean the metal foam material with 99.9% volume concentration of absolute ethanol and 99.9% volume concentration of ethyl acetate, and ultrasonically clean it in deionized water for 30 minutes to remove surface impurities.

[0028] Step 2: Dissolving the transition metal sulfide in deionized water to obtain a metal sulfide solution.

[0029] Step 3: Transfer the metal foam material removed from impurities in step 1 and the metal sulfide solution obtained in step 2 to the hydrothermal reaction kettle, seal the kettle, put the hydrothermal reaction kettle in an oven and keep it at 200-240°C, and react After 18-24 hours, cool naturally to room temperature, open the kettle, filter and wash several times until the filtrate becomes colorless and transparent, and dry to obtain a transition metal sulfide supported...

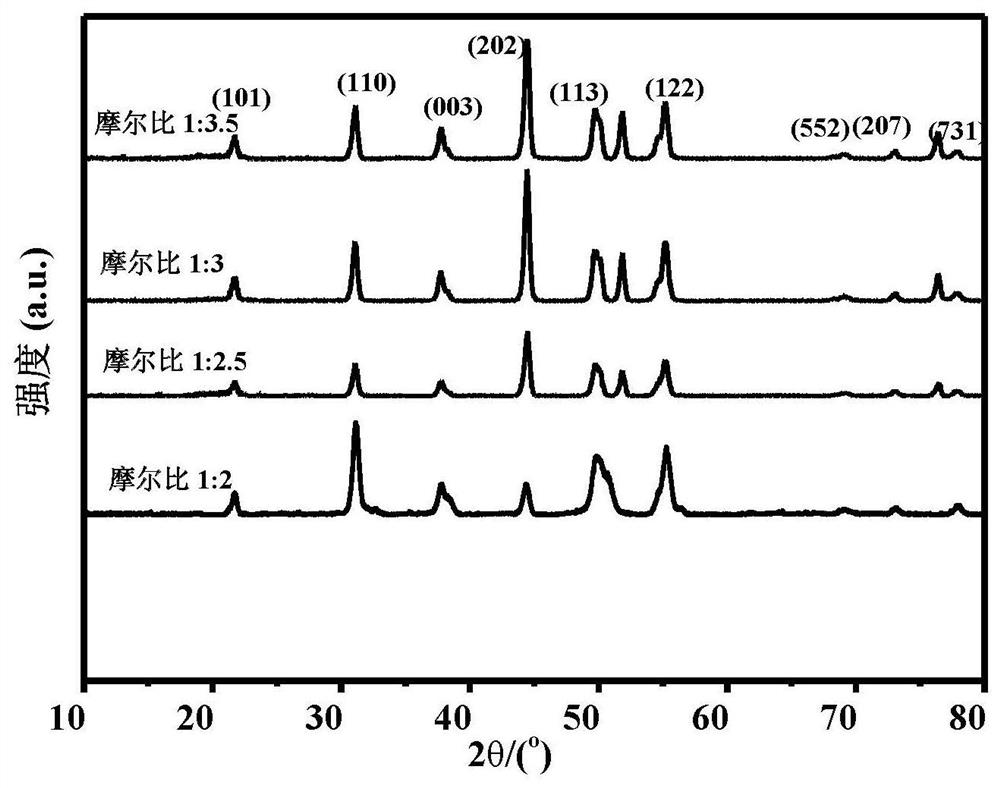

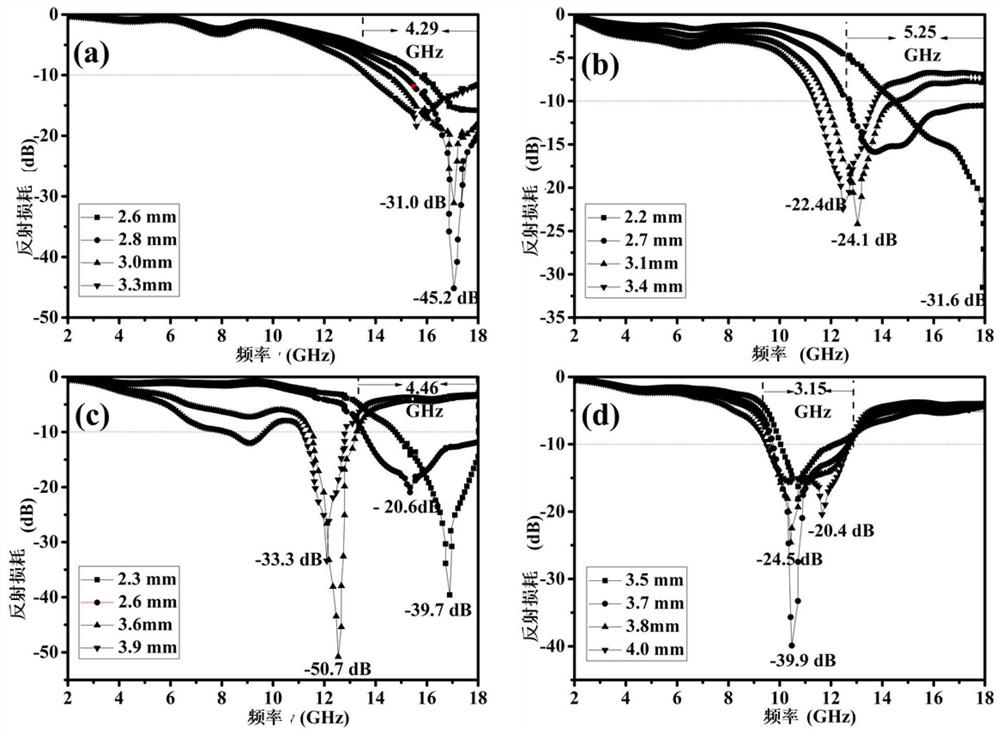

Embodiment 1

[0040] After 0.6g of nickel foam was ultrasonically cleaned with absolute ethanol and ethyl acetate, it was dried for use, 0.3g of thiourea was dissolved in 160 ml of deionized water, stirred ultrasonically for 30 min, and the above-mentioned nickel foam and solution were transferred to 200 ml of polytetrafluoroethylene In the vinyl fluoride hydrothermal reaction kettle, seal the kettle and react at 200°C for 20 hours; after the reaction is stopped, the system will automatically cool down to room temperature, open the kettle, wash the reaction product repeatedly with deionized water, dry it at room temperature, and seal it for storage until use.

Embodiment 2

[0042] After 0.6g of nickel foam was ultrasonically cleaned with absolute ethanol and ethyl acetate, it was dried for use, 0.2g of thiourea was dissolved in 160 ml of deionized water, stirred ultrasonically for 30 min, and the above nickel foam and the solution were transferred to 200 ml of polytetrafluoroethylene In the vinyl fluoride hydrothermal reaction kettle, seal the kettle and react at 200°C for 20 hours; after the reaction is stopped, the system will automatically cool down to room temperature, open the kettle, wash the reaction product repeatedly with deionized water, dry it at room temperature, and seal it for storage until use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com