A kind of preparation method of bn/carbide coating composite carbon fiber electromagnetic shielding material

An electromagnetic shielding material and composite carbon fiber technology, which is applied in the fields of magnetic field/electric field shielding, coating, metal material coating technology, etc., can solve problems such as difficulty in meeting the use requirements, low electromagnetic parameters, and inability to meet the requirements of electromagnetic shielding materials at high temperatures. , to achieve good electromagnetic shielding performance, good compactness, compactness and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

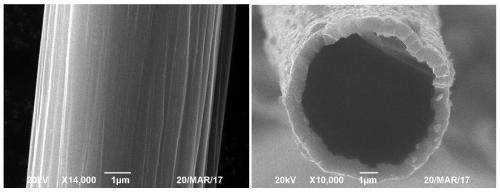

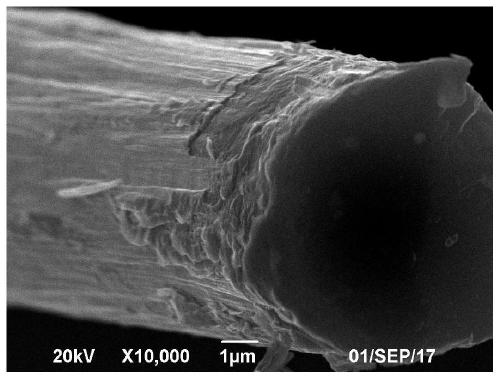

Image

Examples

Embodiment 1

[0037] A method for preparing a BN / carbide double-coated composite carbon fiber material with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at 720°C for 10 minutes; Put the carbon fiber treated in step 1 into acetone and ultrasonically clean it for 15 minutes; 3. Prepare the BN coating on the surface of the carbon fiber treated in step 2 by radio frequency magnetron sputtering, which is the lower BN layer; 4. Treat the carbon fiber in step 3 The carbon fiber is prepared on the surface of the TiC coating by radio frequency magnetron sputtering, that is, the upper carbide layer, which completes the preparation of the BN / TiC coating on the surface of the carbon fiber; the purity of the BN target in step 3 is 99.999%, vacuum before sputtering The degree is 8.0×10 -4 Pa, RF sputtering power is 1500W, deposition time is 120min, distance between target and fiber is 60mm, argon gas flow ...

Embodiment 2

[0041] A method for preparing a BN / carbide coated composite carbon fiber material with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 750° C. for 10 minutes; 2. Put step 1 The treated carbon fiber is put into acetone and ultrasonically cleaned for 15min; 3. The carbon fiber after step 2 is treated on the surface by radio frequency magnetron sputtering to prepare a BN coating, which is the lower BN layer; 4. The carbon fiber after step 3 is treated in the The surface adopts DC magnetron sputtering method to prepare VC coating, that is, the upper carbide layer, which completes the preparation of BN / VC coating on the carbon fiber surface; wherein the purity of the BN target in step 3 is 99.999%, and the vacuum degree before sputtering is 8.0×10 -4 Pa, the RF sputtering power is 2000W, the deposition time is 90min, the distance between the target and the fiber is 6...

Embodiment 3

[0045] A method for preparing a BN / carbide coated composite carbon fiber material with electromagnetic shielding function in this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 700 ° C for 10 minutes; 2. Step 1 The treated carbon fiber is put into acetone and ultrasonically cleaned for 15min; 3. The carbon fiber treated in step 2 is prepared on the surface by DC magnetron sputtering method to prepare a BN coating, that is, the lower BN layer; 4. The carbon fiber treated in step 3 is placed on the The surface adopts radio frequency magnetron sputtering method to prepare ZrC coating, i.e. the upper carbide layer, which completes the preparation of the carbon fiber surface BN / ZrC coating; wherein the purity of the BN target in step 3 is 99.999%, and the vacuum degree before sputtering is 8.0×10 -4 Pa, the DC sputtering current is 60mA, the deposition time is 40min, the distance between the target and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com