FeCo alloy/CuO double-plating magnetic carbon fiber and preparation method and application

A carbon fiber and coating technology, applied in the field of FeCo alloy/CuO double-coated magnetic carbon fiber and preparation, can solve the problems of less research, and achieve the effects of simple process, optimized impedance matching and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

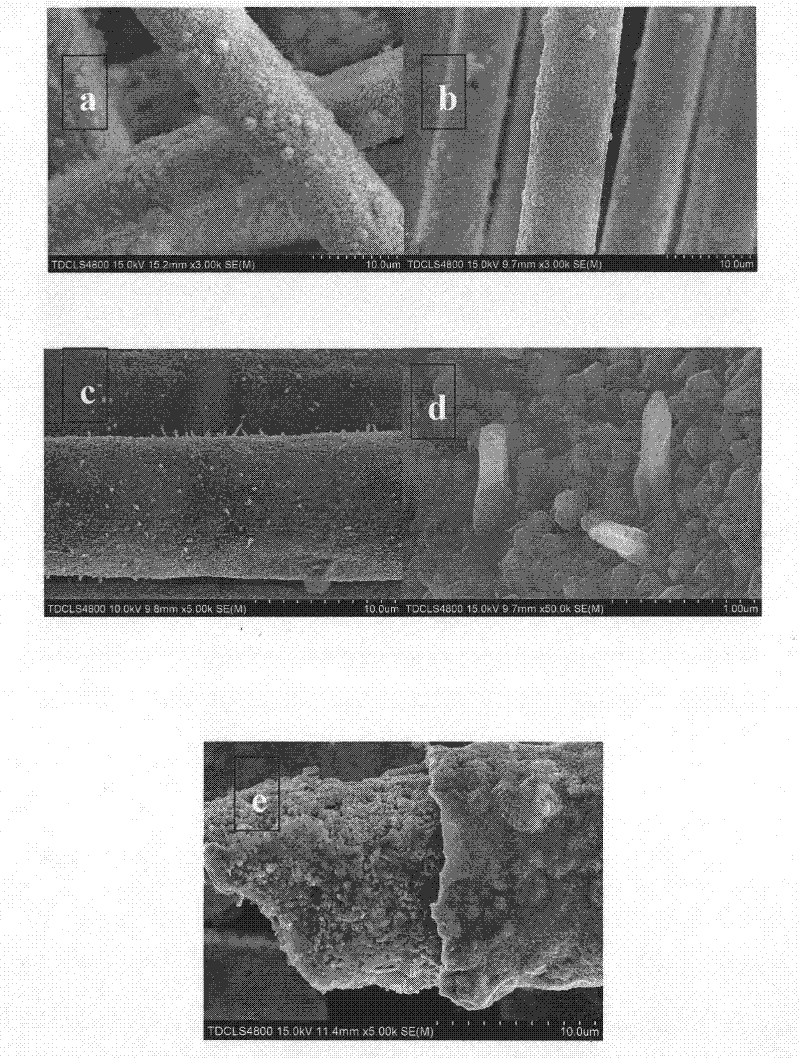

[0018] Pretreatment of carbon fiber: firstly, continuous carbon fiber (polyacrylonitrile-based continuous carbon fiber, Dalian Xingke Carbon Fiber Co., Ltd., number DLXK2003, each bundle contains 12000 carbon fiber monofilaments, and the diameter of the monofilament is about 7 μm) is placed in a muffle furnace at 500 ° C Keep it warm for 15 minutes, and then immerse it in 40ml of nitric acid solution with a volume fraction of 50% for 1 hour for oxidation treatment.

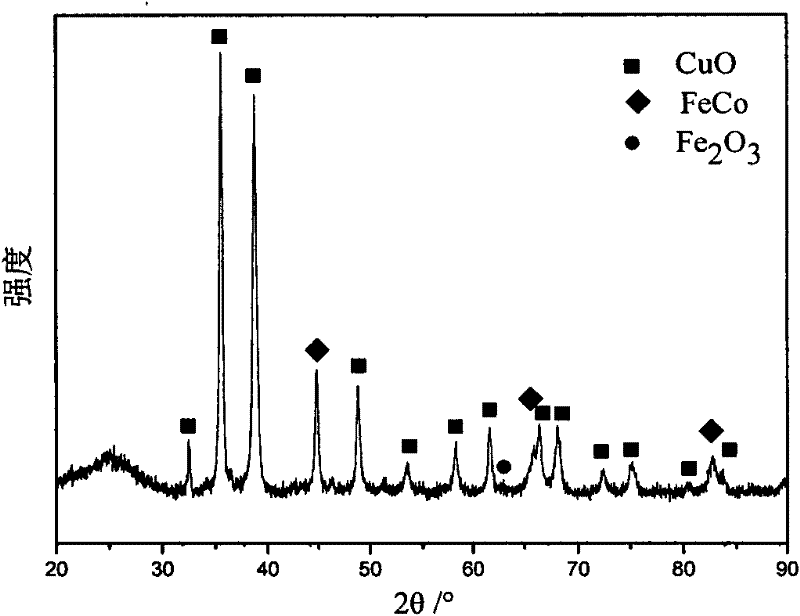

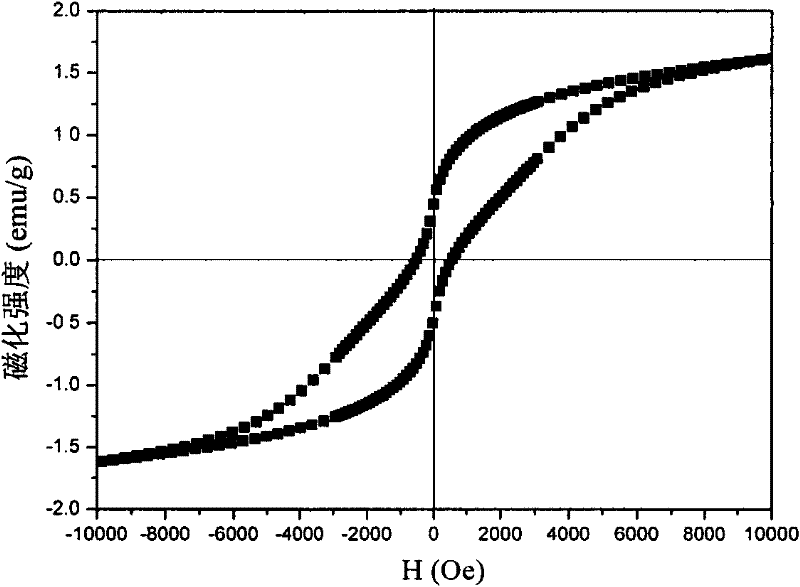

[0019] The composition of the FeCo alloy plating solution is as follows: the concentration of ferrous sulfate and divalent cobalt sulfate is 90g / L, the concentration of boric acid is 30g / L, the concentration of cetyl sodium sulfate is 0.1g / L, and the mass fraction of pH value is 10 % dilute sulfuric acid solution to adjust to 3-4. The electroplating of FeCo alloy uses a high-purity iron plate with a purity of 99.99% as the anode, and the oxidized carbon fiber as the cathode, with a current of 0.5A, electromagnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com