Patents

Literature

45 results about "Cetyl sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SODIUM CETYL SULFATE. image source: PubChem. Health Concerns of the Ingredient: Overall Hazard . Cancer . Developmental & reproductive toxicity . Allergies & immunotoxicity . Use restrictions . Other LOW concerns: Data gaps, Ecotoxicology. About SODIUM CETYL SULFATE: Sodium Cetyl Sulfate is a sodium salt of cetyl sulfate.

Vinylon spinning oil

The invention discloses vinylon spinning oil composed of lauryl oleate, polyoxyethylene (3) cetyl sulfate, sperm oil hydrosulfate and polyethylene. The invention has reasonable formula, good use effect, and low production cost.

Owner:殷兰芳

Composite material with negative ion releasing function and preparation method thereof

InactiveCN103360657AHigh tensile strengthHigh elongation at breakPolymethyl methacrylatePolyvinyl chloride

The invention discloses a composite material with a negative ion releasing function and a preparation method thereof. The composite material comprises tourmaline powder, an auxiliary agent(s) and a macromolecule matrix(es) which are in a weight ratio of 5-20:2-10:70-93, wherein the grain size of the tourmaline powder ranges from 500 nanometers to 3 microns, the auxiliary agent is one or more than two of polyethylene glycol, polypropylene glycol, polytetramethylene glycol, cetyl sodium sulfate, cetyl sodium sulfonate, octaphenyl polyoxyethyiene and cetyl trimethyl ammonium bromide, and the macromolecule matrix is one or more than two of polyethylene, polystyrene, polymethyl methacrylate, polyurethane, polyvinyl chloride and polyacrylate. The preparation method comprises the following steps of: firstly, ball milling the tourmaline powder, the auxiliary agent and water in a ball mill or stirring and shearing in an emulsifying machine; then, drying; adding the mixture into a macromolecule reaction monomer for in-situ synthesis, or mixing the mixture with the macromolecule matrix(es) and then carrying out melt blending after mixing the mixture, so as to prepare a target product. The composite material can automatically release a large quantity of negative ions.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

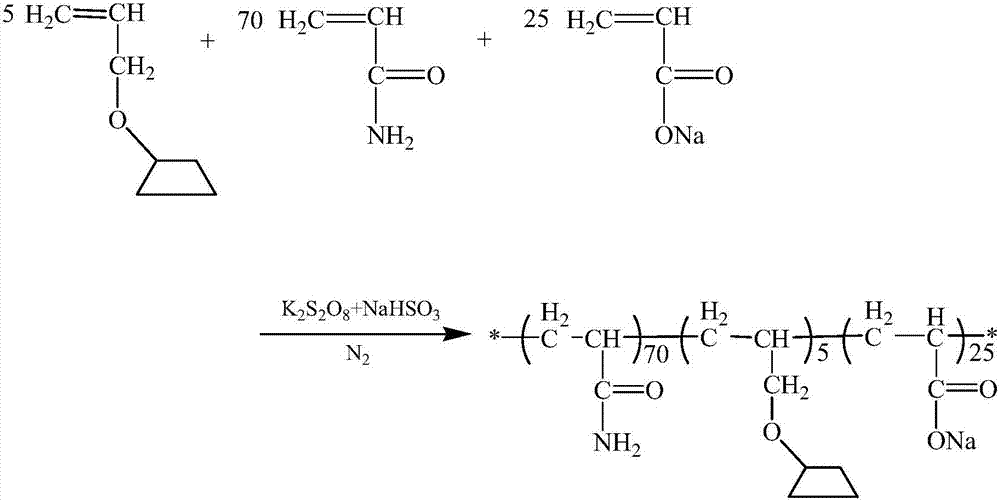

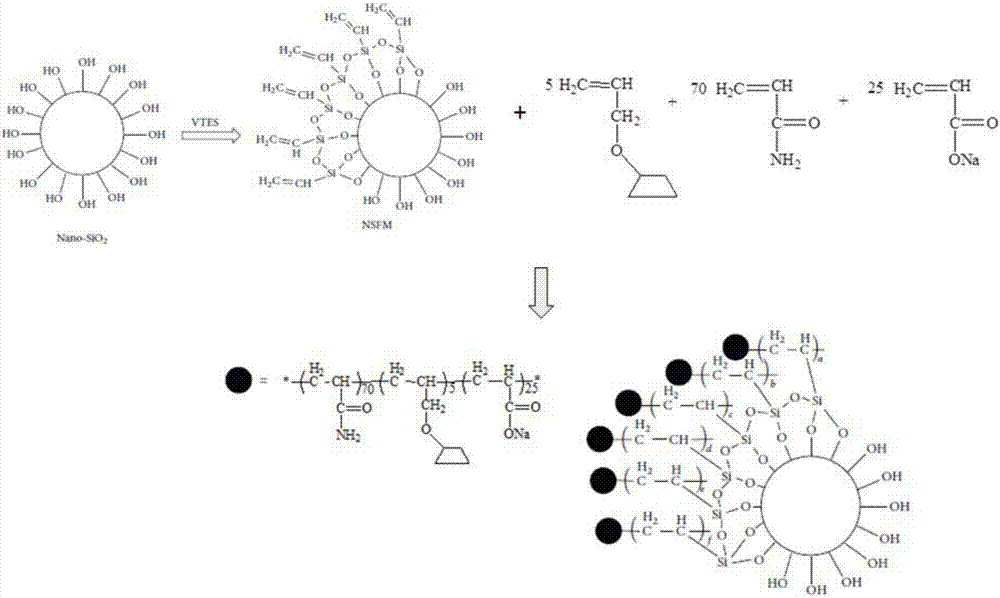

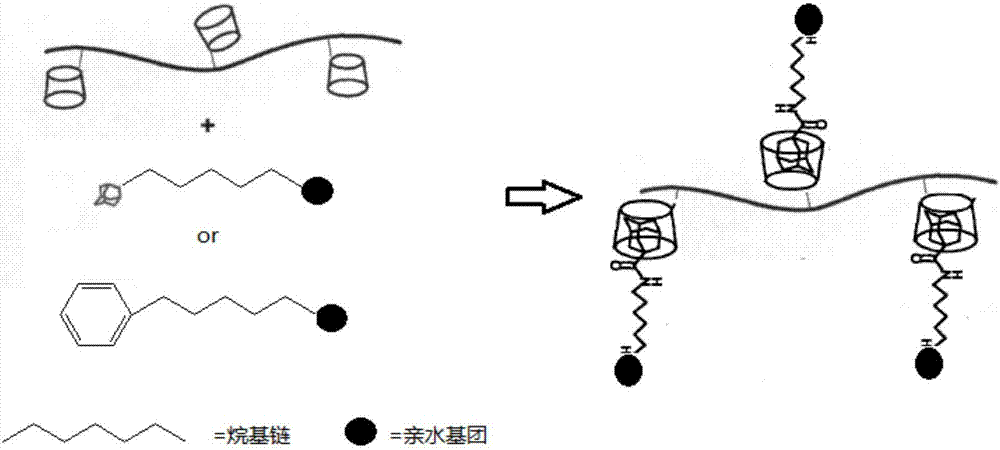

Polymer system in controllable association strength

The invention discloses a polymer system in controllable association strength. The polymer system comprises a subject cyclodextrin polymer and an object surfactant; the subject cyclodextrin polymer is selected from linear cyclodextrin polymer and modified Nano-SiO2 star-shaped macromolecule cyclodextrin polymer; the object surfactant is selected from adamantine-sodium octadecyl sulfate, adamantine-lauryl sodium sulfate, adamantine-cetyl sodium sulfate, benzyl-sodium octadecyl sulfate, benzyl-lauryl sodium sulfate and benzyl-cetyl sodium sulfate. In an application, the cyclodextrin polymer is prepared into an aqueous solution in the concentration of 0.1-0.5g / ml and then is mixed with the surfactant, the cyclodextrin advantage is utilized to wrap adamantine or benzene ring while the alkyl hydrophobic chain is exposed on the exterior of the cyclodextrin hydrophobic chamber, so that the polymer system in controllable association strength can be realized, the system viscosity is changed and the purpose of dynamically regulating the system viscosity can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-absorption-damage slick water system

The invention discloses a low-absorption-damage slick water system. The low-absorption-damage slick water system is prepared from the following components in percent by mass: 0.05-0.1% of resistance reducing agent, 0.1-0.5% of discharging aiding agent, 0.1-0.3% of desorbing agent and the balance of water, wherein the resistance reducing agent is linear polyacrylamide commonly-used in an oil field,and the weight-average molecular weight is 5-8 million; the discharging aiding agent is anion fluorocarbon surfactant; the desorbing agent is prepared from the following components in percent by mass: 8-15% of urea, 1-2% of SiO2 nanoparticle, 3-5% of cetyl sodium sulfate, 20-30% of ethylene glycol and the balance of water. The low-absorption-damage slick water system disclosed by the invention has the beneficial effects that the absorbing amount of the polyacrylamide in the slick water on the surface of shale rock can be obviously reduced, the yield-increasing effect after fracturing is improved; after the desorbing agent is added into the slick water system, the cost is increased by less than 10%, and the construction process is not changed, so that the market application prospect is wide.

Owner:SOUTHWEST PETROLEUM UNIV

Aluminum alloy die-cast surface cleaning agent and preparation method thereof

The invention discloses an aluminum alloy die-cast surface cleaning agent, comprising the following components based on 100 parts by weight in total weight: 10-15 parts of nonylphenol polyoxyethylene ether, 2-8 parts of lauryl diethanolamide, 6-18 parts of dodecyl dimethyl betaine, 8-16 parts of cetyl sodium sulfate, 1-5 parts of benzotriazole, 2-6 parts of sodium silicate, 4-6 parts of coconutt diethanol amide, 8-12 parts of sodium gluconate, 2-4 parts of span-80 and the balance of water. The invention also discloses a preparation method of the aluminum alloy die-cast surface cleaning agent. The aluminum alloy die-cast surface cleaning agent has the advantages of high cleanness, high anti-rust capability, low foam and low-temperature cleaning, is effective for nonferrous metal alloys, and in particular for die-casting alloys, and is simple in process, free of phosphate and nitrite, easy to biodegrade and environment-friendly.

Owner:SHANDONG UNIV +1

Breathable anti-abrasion anti-electrostatic and waterproof fabric and preparing method thereof

InactiveCN107740197AStable and guaranteed waterproof levelBreathable and wear-resistantConjugated cellulose/protein artificial filamentsArtificial filament heat treatmentPolyesterEthanolamine synthesis

The invention relates to the field of fabric production, in particular to a breathable anti-abrasion anti-electrostatic and waterproof fabric and a preparing method thereof. The fabric is formed by blending cotton and linen fiber, viscosity fiber and anti-electrostatic polyester fiber; the fabric is prepared from, by weight, 30-40 parts of cotton and linen fiber, 35-40 parts of viscosity fiber, 30-40 parts of anti-electrostatic polyester fiber, 33-46 parts of polylactic acid, 25-38 parts of metasilicic acid trimethyl ester, 22-28 parts of dilauryl thiodipropionate, 21-25 parts of sodium dodecyl benzene sulfonate, 13-17 parts of phosphatidyl ethanolamine, 9-14 parts of potassium metabisulfite, 8-9 parts of cetyl trimethyl ammonium bromide, 8-9 parts of hydroxypropyl starches, 5-7 parts of nano silicon dioxide, 5-7 parts of sodium cetyl sulfate, 4-6 parts of linoleic acid, 3-4 parts of silane coupling agent, 3-4 parts of binding agent and 180 parts of deionized water.

Owner:JIANGSU AOYANG SHIJIA CLOTHING CO LTD

Synthesis method of caronic anhydride

InactiveCN104151279ALow priceReduce production processOrganic chemistrySodium acetateAcetic anhydride

The invention discloses a synthesis method of caronic anhydride and belongs to the technical field of deep process of turpentine. The method includes following steps: filling a reactor with 3-carane and cetyl sodium sulfate with addition of water; performing a stirring process; adding potassium permanganate within 3 hours; carrying out a reaction with heat preservation; performing a suction filtration process; washing a filter cake with water; mixing a washed liquid and a filtrate; adjusting a pH value to 10; performing an extraction process with benzene; collecting a water layer; adjusting a pH value to 2; performing a concentrating process, a drying process, a filtering process, a washing process and a drying process; performing a mixing process with acetic anhydride and sodium acetate; carrying out a reaction; and finally adding methylbenzene and petroleum ether and performing a crystallization process to obtain the caronic anhydride. Required raw materials in the method are low in cost and the caronic anhydride is low in production cost. In addition, the method is short in reaction route and is simple in processes.

Owner:WUZHOU SONGHUA AROMATIC CHEM

Preparation method of zirconium oxide-enhanced aluminum oxide porous ceramic with closed-pore structure

The invention provides a preparation method of a zirconium oxide-enhanced aluminum oxide porous ceramic with a closed-pore structure. The preparation method comprises the following steps of mixing iridium oxide-stabilized nanometer linear square zirconium oxide powder, aluminum oxide powder containing hollow aluminum oxide spheres and aluminum oxide fiber, and a silicon dioxide sol, and performing ball milling in a ball mill, so as to obtain mixing slurry with total solid content of 7 to 45%; adding decanoic acid, cetyl sodium sulfate, octadecyl sodium sulfate or sodium lauryl sulfate powder hydrophobic modifier into the mixing slurry, using diluted hydrochloric acid to adjust the pH (potential of hydrogen) value to 3 to 9.5, mechanically stirring and foaming, injecting and molding on a gypsum board, and drying, so as to obtain a dried blank; sintering the blank at the temperature of 1300 to 1650 DEG C, so as to obtain the zirconium oxide-enhanced aluminum oxide porous ceramic with the closed-pore structure.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

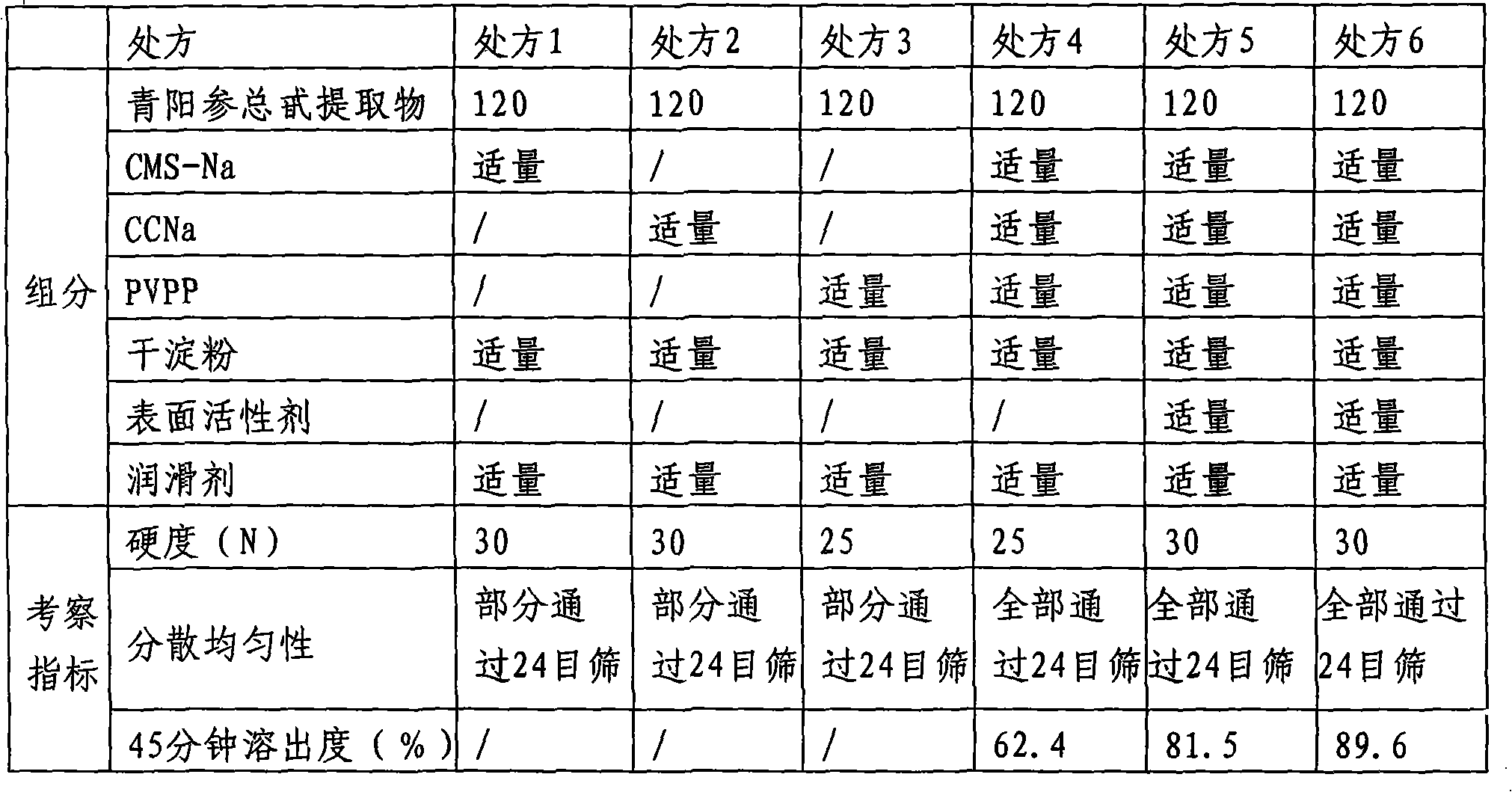

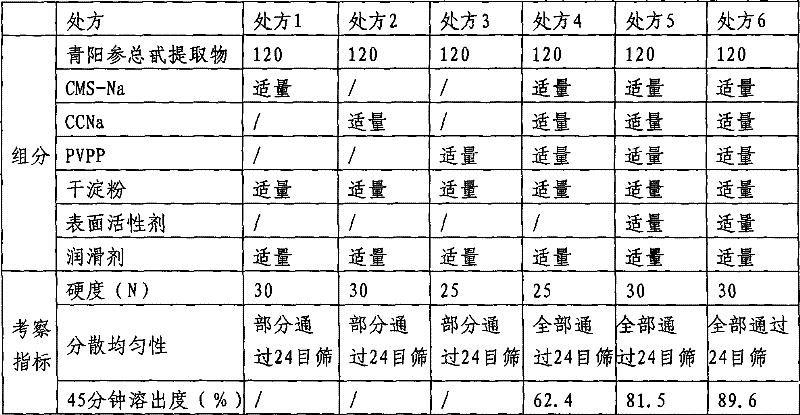

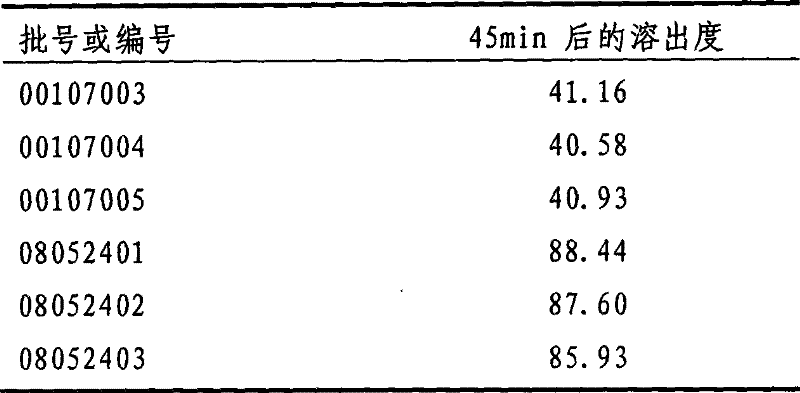

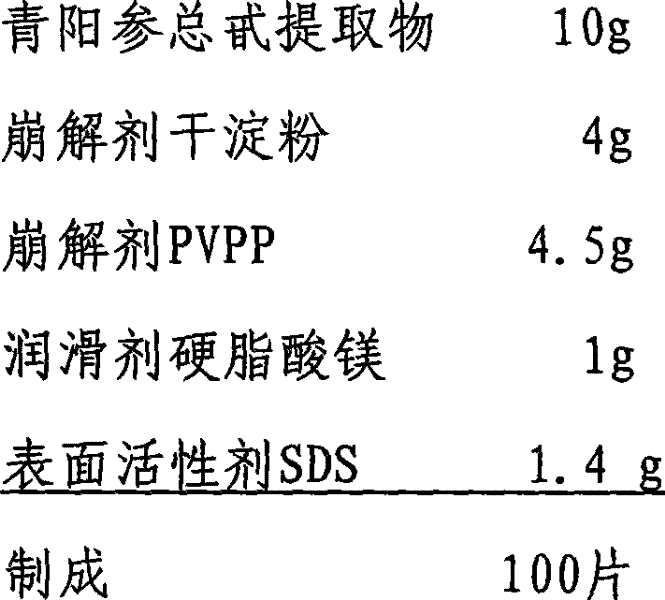

Cynanchum otophyllum schneid dispersible tablets and preparation method thereof

InactiveCN101357149AImprove bioavailabilityGive full play to the medicinal effectNervous disorderPill deliveryDissolutionMagnesium stearate

The invention discloses a cynanchum otophyllum dispersible tablet and a preparation method thereof, relating to medicines. The cynanchum otophyllum dispersible tablet is made of the following raw materials by weight portions: 50-200 portions of an extract of cynanchum otophyllum total glucoside, 20-100 portions of an disintegrating agent, 1-10 portions of a lubricant and 1-20 portions of a surfactant, wherein, the disintegrating agent is CMS-Na, CCNa, PVPP, L-HPC and dry starch, the lubricant is magnesium stearate or talcum powder or superfine silica gel powder, the surfactant is SDS, sodium hexadecyl sulfate and sodium stearyl sulfate. The preparation method consists of the following steps: 20-200 portions of total glucoside of the cynanchum otophyllum by weight is taken out and sieved with a 100-mesh sieve; 20-100 portions of the disintegrating agent by weight and 1-10 portions of the lubricant by weight are taken out and respectively sieved with the 100-mesh sieve; 1-20 portions of the surfactant by weight is taken out and sieved with a 80-mesh sieve; then the sieved extract, the sieved disintegrating agent, the sieved lubricant and the sieved surfactant are ground and evenly mixed, and then the mixture is sieved with the 80-mesh sieve, and direct compression and sieving are carried out on the sieved mixture to obtain the dispersible tablet. The dispersible tablet has high dissolution and high bioavailability, can fully exert the drug action of the cynanchum otophyllum, and the preparation method is simple and feasible while suitable for industrialized production.

Owner:GUIZHOU UNIV

Breathable wearing-resistant fabric material and preparation method thereof

The invention discloses a breathable wearing-resistant fabric material and a preparation method thereof. The preparation method comprises the following steps: by taking apocynum fiber, viscose, polylactic acid and trimethyl metasilicate as main components, adding dilauryl thiodipropionate, sodium dodecyl benzene sulfonate, phosphatidyl ethanolamine, potassium metabisulfite, cetyl trimethyl ammonium bromide, hydroxypropyl starch, nanosilicon dioxide, sodium cetyl sulfate, linoleic acid, a silane coupling agent, an adhesive and deionized water, and performing magnetic stirring, heating water bath, ball milling treatment, high-pressure homogenization, screw rod extrusion and the like, thereby obtaining the breathable wearing-resistant fabric material. The breathable wearing-resistant fabric material is good in breathability, good in fraction property, capable of meeting industrial requirements and has relatively good application prospects.

Owner:马志明

Acrylic fabric finishing agent and preparation method thereof

The invention discloses an acrylic fabric finishing agent and a preparation method thereof. The acrylic fabric finishing agent consists of the following components in parts by weight: 9-12 parts of cetyl sodium sulfate, 4-5 parts of alkyl diphenyl ether disulfonate, 6-9 parts of sodium dichloroisocyanurate, 3-4 parts of calcium chloride, 5-9 parts of tributyl phosphate, 1-2 parts of tryptophan, 22-26 parts of glycerin and 210-220 parts of water. The acrylic fabric finishing agent is prepared by stirring, mixing and heating. By using the obtained acrylic fabric finishing agent, the pilling resistance flame retardation of an acrylic fabric can be enhanced.

Owner:JIANGSU HUACHAO TEXTILE IND

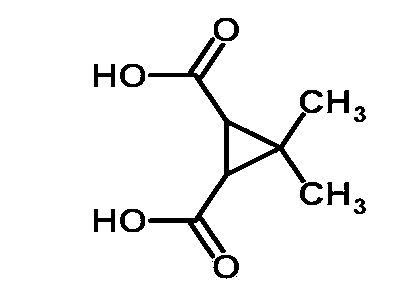

Preparation method of 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid

InactiveCN104230692AShort reaction pathReduce manufacturing costPreparation from carboxylic acid saltsCarboxylic preparation by oxidationBenzeneFiltration

The invention discloses a preparation method of 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid, which comprises the following steps: sequentially adding 3-carene, cetyl sodium sulfate and water into a reactor, gradually adding potassium permanganate into the reactor, stirring uniformly, regulating the temperature of the reactor, carrying out oxidation reaction, filtering, collecting the filtrate and filtration residue for later use, washing the filtration residue with water, collecting the washing solution, merging the filtrate and washing solution to obtain a mixed solution, regulating the pH value of the mixed solution, adding benzene for extraction, collecting the water layer solution, regulating the pH value of the water layer solution, heating for concentration, filtering, washing with water, and drying to obtain the 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid. By preparing the 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid from the 3-carene, the method shortens the reaction route and lowers the production cost.

Owner:WUZHOU CAYIN GUM

Polishing solution for stainless steel processing

The invention discloses a polishing solution for stainless steel processing, and relates to a polishing solution. The polishing solution for stainless steel processing is specifically prepared from deionized water, diamond, boron carbide, silicon carbide, zirconium oxide, lanthanum oxide, scandium oxide, hydrotalcite, diethanol amine, pentaerythritol, 1,2-diethoxyethane, urotropin, polyoxyethylene poly-oxypropylene pentaerythrilol ether, sodium dodecyl benzene sulfonate, cetyl sodium sulfate and glycerol. The finally prepared polishing solution can complete polishing of stainless steel rapidly and efficiently, the processing quality is high and stable, the defective rate is decreased, and the polishing solution has good application and promotion value.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

Method for preparing ketonic acid

InactiveCN104230693AReduce the difficulty of productionShorten the production cycleCarboxylic preparation by oxidationCarboxylic compound separation/purificationBenzeneKetonic acids

The invention discloses a method for preparing ketonic acid, belonging to the technical field of deep processing of turpentine. The method comprises the following steps: firstly, putting alpha-pinene, ammonium sulfate and cetyl sodium sulfate into a reactor, adding water, stirring, subsequently adding potassium permanganate for reaction, performing suction filtration, collecting the filtrate and the filter cakes, washing the filter cakes with water, mixing a scrubbing solution with the filtrate, adjusting the pH value by using acid, extracting by using benzene, collecting a water layer, adjusting the pH value of the water layer by using alkali, and subsequently drying, concentrating, filtering and washing, thereby obtaining ketonic acid. As the method does not need rigorous production conditions, and the production environment and the equipment are easy to achieve, the production difficulty of ketonic acid is effectively alleviated, the production period is shortened, and the production cost is lowered.

Owner:WUZHOU SONGHUA AROMATIC CHEM

Deodorization and degradation treating agent for garbage leachate and preparation method thereof

InactiveCN107867749AShorten the production cycleEliminate odorWater treatment compoundsSpecific water treatment objectivesPotassiumCarboxylic salt

The invention discloses a deodorization and degradation treating agent for garbage leachate, which is used or carrying out treatment aiming at leachate of garbage from an urban garbage landfill and agarbage power plant, The deodorization and degradation treating agent is prepared from the following components in parts by weight: 7 to 10 parts of ammonium persulfate, 4 to 7 parts of sodium persulfate, 14 to 17 parts of sodium carbonate, 3 to 5 parts of sodium silicate, 8 to 10 parts of sodium cetyl sulfate, 4 to 6 parts of lauroyl aspartic acid, 3 to 5 parts of sodium oleyl sulfate, 6 to 9 parts of sodium stearyl sulfate, 5 to 8 parts of fatty alcohol polyoxyethylene ether, 3 to 5 parts of dilauryl tartrate, 9 to 12 parts of polyglycerol, 5 to 8 parts of potassium carboxylates, 3 to 6 parts of sodium n-alkyl sulfate and 7 to 10 parts of n-butyl polyacrylate. An aqueous solution, with a mass concentration of 0.5 to 0.8 percent, of the treating agent can be used for thoroughly dissolvingsulfur-containing and nitride-containing stinking water within several seconds in a normal-temperature condition to remove a peculiar smell, and can be used for decreasing BOD5 (Biochemical Oxygen Demand 5) in black garbage leachate with a foul smell to 50 percent or below within several minutes. The invention also relates to a preparation method of the deodorization and degradation treating agent for the garbage leachate.

Owner:刘音希

Spinning oil agent

The invention discloses a spinning oil agent comprising the components: trihydroxy trimethylpropane tricaprate, lauryl polyoxyethylene ether (5) phosphate potassium salt, sodium cetyl sulfate, polyoxyethylene (10) castor oil (EL-10) and dodecyl phenol polyoxyethylene (5-6) ether 17. The spinning oil agent has reasonable formula, good use effect, low production cost and long preservation time, saves cost for enterprises, and increases economic benefits.

Owner:SUZHOU CITY WUZHONG DISTRICT TAIHU LIGHT TEXTILE

Quick detergent for roadside adlets

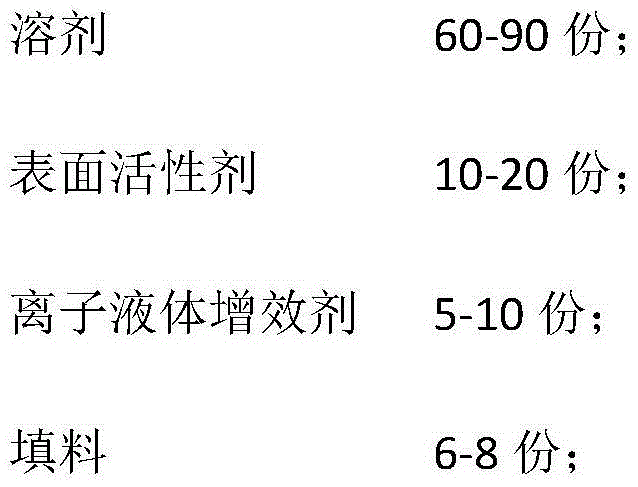

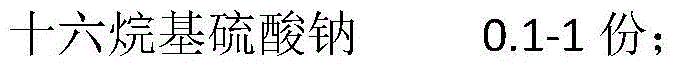

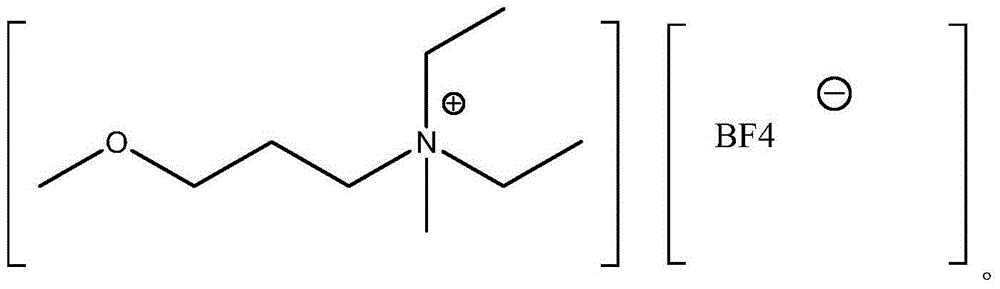

InactiveCN103614264BEfficient removalLow priceSurface-active non-soap compounds and soap mixture detergentsEthyl acetateSolvent

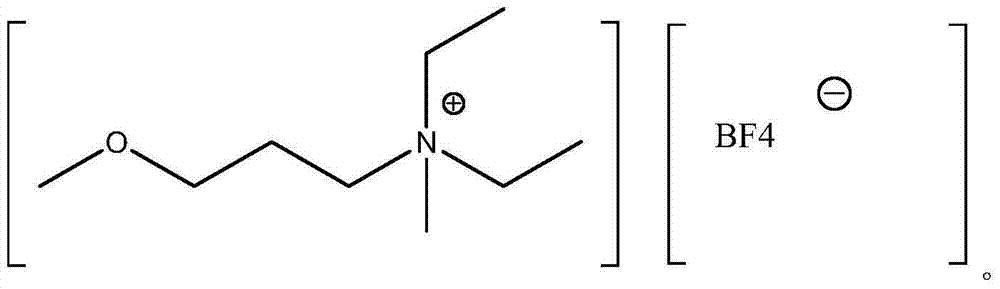

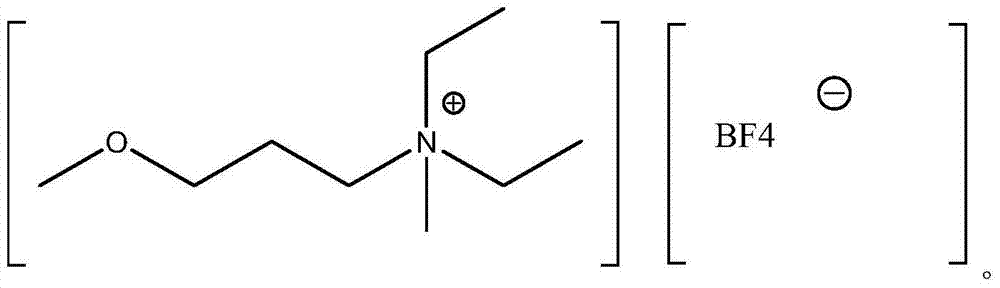

The invention relates to a quick detergent for roadside adlets, which can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards. The invention is characterized in that the detergent is prepared by mixing the following raw materials in parts by weight: 60-90 parts of solvent, 10-20 parts of surfactant, 5-10 parts of ionic liquid synergist, 6-8 parts of filler and 0.1-1 part of cetyl sodium sulfate. The solvent is a mixture of ethanol, ethyl acetate and deionized water in any ratio; and the surfactant is CH3O(CH3CH2CH2O)nCH2OCH3, wherein n=6-11. The detergent can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards, is free of chemical components which are harmful to the environment and buildings, and can not do damage to the health of cleaning personnel and building surfaces.

Owner:SUZHOU FENGRU SOFTWARE

Quick detergent for roadside adlets

InactiveCN103614264AEfficient removalLow priceSurface-active non-soap compounds and soap mixture detergentsAcetic acidChemical composition

The invention relates to a quick detergent for roadside adlets, which can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards. The invention is characterized in that the detergent is prepared by mixing the following raw materials in parts by weight: 60-90 parts of solvent, 10-20 parts of surfactant, 5-10 parts of ionic liquid synergist, 6-8 parts of filler and 0.1-1 part of cetyl sodium sulfate. The solvent is a mixture of ethanol, ethyl acetate and deionized water in any ratio; and the surfactant is CH3O(CH3CH2CH2O)nCH2OCH3, wherein n=6-11. The detergent can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards, is free of chemical components which are harmful to the environment and buildings, and can not do damage to the health of cleaning personnel and building surfaces.

Owner:SUZHOU FENGRU SOFTWARE

Adlet cleanser

InactiveCN103614265AEfficient removalLow priceSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsEthyl acetate

The invention relates to an adlet detergent, which can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards. The invention is characterized in that the detergent is prepared by mixing the following raw materials in parts by weight: 60-90 parts of solvent, 10-20 parts of surfactant, 5-10 parts of ionic liquid synergist, 6-8 parts of filler and 0.1-1 part of cetyl sodium sulfate. The solvent is a mixture of ethanol, ethyl acetate and deionized water in any ratio; and the surfactant is CH3O(CH3CH2CH2O)n(CH2CH2O)mCH3O, wherein n=2-6, and m=5-10. The detergent can quickly and efficiently remove roadside adlets on walls, bus stations and bulletin boards, is free of chemical components which are harmful to the environment and buildings, and can not do damage to the health of cleaning personnel and building surfaces.

Owner:SUZHOU FENGRU SOFTWARE

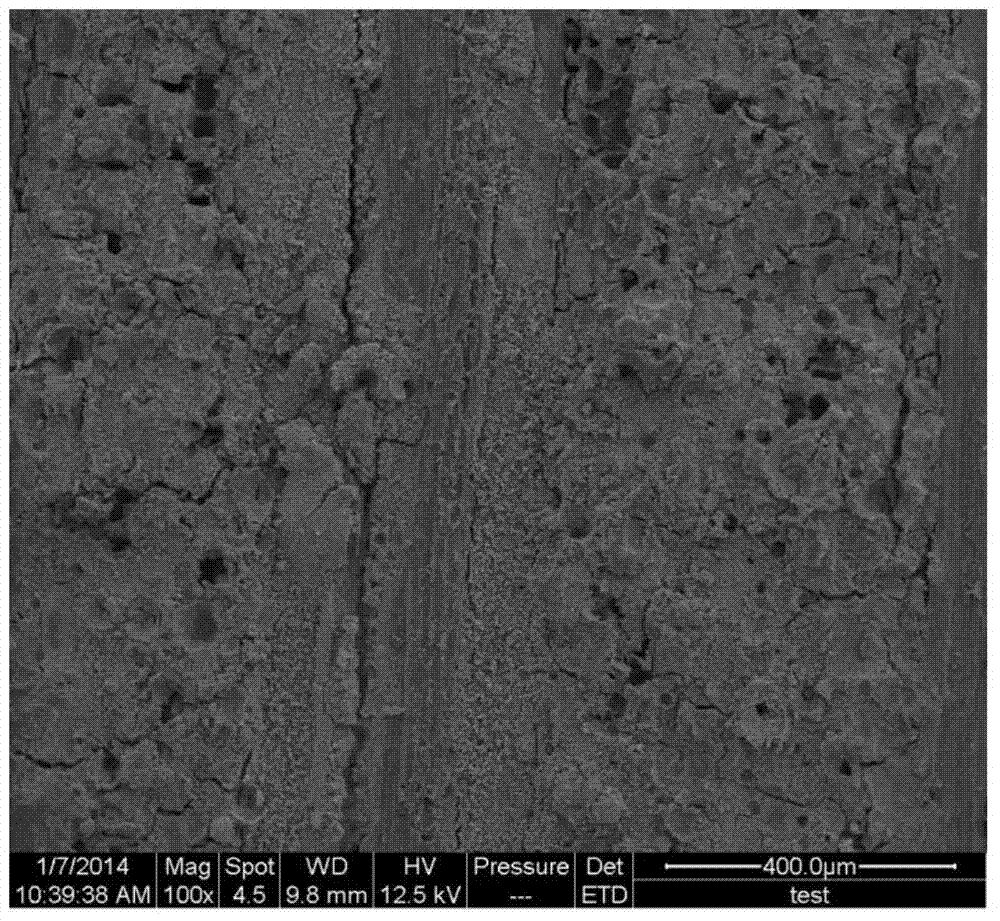

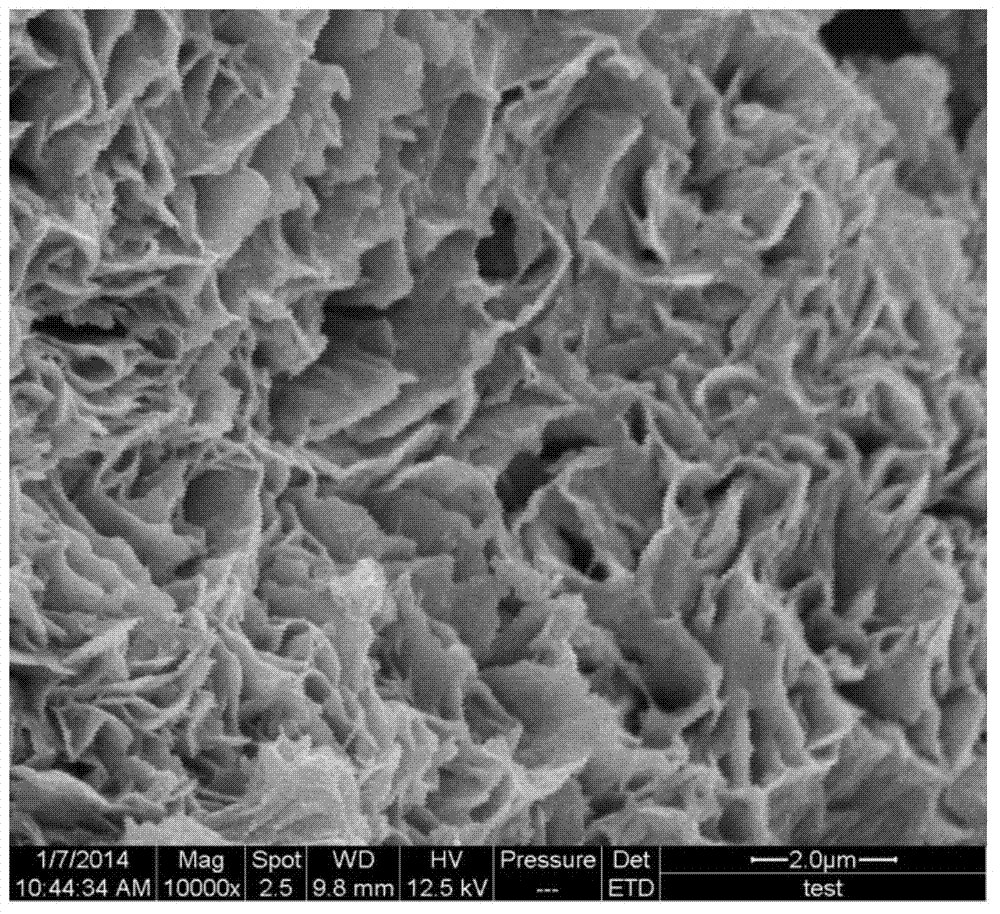

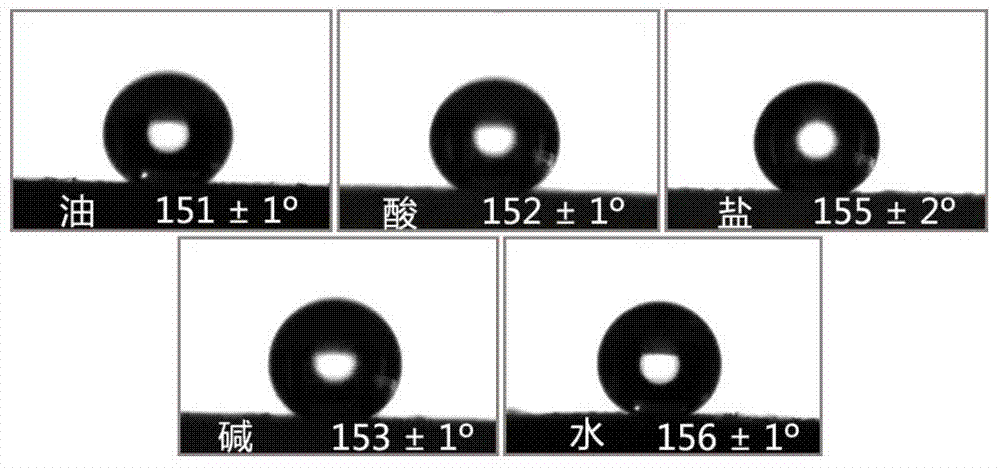

Method for preparing super-amphiphobic nano-film on bamboo surface in bionic way

InactiveCN104842421ASuperhydrophobicSuper oleophobicWood treatment detailsReed/straw treatmentPolymer scienceAlcohol

The invention discloses a method for preparing a super-amphiphobic nano-film on a bamboo surface in a bionic way. The method comprises the following steps: preparing ZnO colloid; forming a layer of ZnO gel on the bamboo surface, and forming a layer of ZnO gel film on the bamboo surface by drying; putting a prepared bamboo block loaded with the ZnO gel film into a mixed solution containing zinc nitrate, hexamethylene tetramine and cetyl sodium sulfate, moving into a reaction kettle, taking the bamboo block on which nanometer ZnO grows out, cleaning the bamboo block with deionized water for 30 minutes, drying to obtain a bamboo block loaded with the nanometer ZnO; putting the obtained bamboo block into a mixed solution of absolute ethyl alcohol, magnetically stirring for an appropriate time, taking the bamboo block out, cleaning with absolute alcohol for several times, and drying at the temperature of 80 DEG C for 12 hours. The super-amphiphobic nano-film has the advantages of self-cleaning property, oil stain resistance and the like. Meanwhile, the method is simple in preparation process, is easy to operate, and is suitable for industrial production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preparation method of high-stability dibromohydantoin disinfection solution

ActiveCN105379719AIncrease concentrationReduce stimulationBiocideOrganic chemistryBromineAqueous solution

The invention provides a preparation method of a high-stability dibromohydantoin disinfection solution. The preparation method comprises the following steps: (1) mixing soluble alkali, 5,5-dimethylhydantoin and water to obtain a water solution; dropping monomer bromine a into the water solution while stirring to obtain a reaction solution; (2) adding a dispersant into the reaction solution obtained in the step (1) and stirring to dissolve the dispersant, and dropping monomer bromine b into the solution to obtain a solution, wherein the mol ratio of the monomer bromine b to the monomer bromine a in the step (1) is 1 to 1, the mass ratio of the dispersant to the reaction solution in the step (1) is (0.01-1) to 100, and the dispersant is one of sodium dodecyl benzene sulfonate, sodium hexadecanesulfonate, sodium octadecyl benzene sulfonate, lauryl sodium sulfate, cetyl sodium sulfate or octadecyl sodium sulfate; and (3) adding a stabilizing agent and a synergist to the solution obtained in the step (2) to obtain a mixed solution, thus obtaining the high-stability dibromohydantoin disinfection solution.

Owner:山东大明消毒科技有限公司

A slippery water system with low adsorption damage

The invention discloses a low-absorption-damage slick water system. The low-absorption-damage slick water system is prepared from the following components in percent by mass: 0.05-0.1% of resistance reducing agent, 0.1-0.5% of discharging aiding agent, 0.1-0.3% of desorbing agent and the balance of water, wherein the resistance reducing agent is linear polyacrylamide commonly-used in an oil field,and the weight-average molecular weight is 5-8 million; the discharging aiding agent is anion fluorocarbon surfactant; the desorbing agent is prepared from the following components in percent by mass: 8-15% of urea, 1-2% of SiO2 nanoparticle, 3-5% of cetyl sodium sulfate, 20-30% of ethylene glycol and the balance of water. The low-absorption-damage slick water system disclosed by the invention has the beneficial effects that the absorbing amount of the polyacrylamide in the slick water on the surface of shale rock can be obviously reduced, the yield-increasing effect after fracturing is improved; after the desorbing agent is added into the slick water system, the cost is increased by less than 10%, and the construction process is not changed, so that the market application prospect is wide.

Owner:SOUTHWEST PETROLEUM UNIV

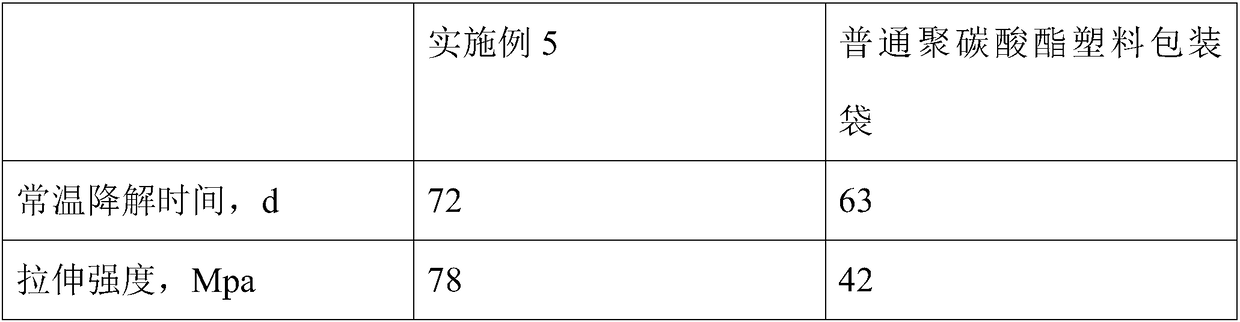

Production method of plastic packaging bag

The invention discloses a production method of a plastic packaging bag. The production method comprises the following steps: mixing magnesium hydroxide and sodium oxalate and grinding; adding polyethylene glycol acrylate, epichlorohydrin and cyclohexanone and uniformly mixing; adding tetrabutylammonium fluoride and potassium hydroxide, stirring, washing and precipitating; adding water and sodium dodecyl sulfate, stirring, filtering, washing and drying until the weight is constant; dispersing and grinding to obtain a first material; uniformly stirring polycarbonate, etherified starch, octadecytrimethyl ammonium bromide, montmorillonite, zeolite powder and an antioxidant to obtain a second material; calcining kaolin and crushing; adding hydrochloric acid, standing, filtering, washing and drying; adding the second material, the first material and cetyl sodium sulfate, continually stirring, kneading, melting, extruding and granulating; molding and cutting to obtain the plastic packaging bag.

Owner:安徽金燃塑胶科技发展有限公司

A kind of acrylic fabric finishing agent and preparation method thereof

An acrylic fabric finishing agent and a preparation method thereof. The acrylic fabric finishing agent is composed of the following components according to the weight ratio: 9-12 parts of sodium cetyl sulfate, 4-5 parts of sodium alkyl diphenyl ether disulfonate, Sodium dodecyl carboxylate is 6-9 parts, calcium chloride is 3-4 parts, tributyl phosphate is 5-9 parts, tryptophan is 1-2 parts, glycerin is 22-26 parts, water is 210-220 copies. The acrylic fiber fabric finishing agent is prepared by stirring, mixing, heating and the like, and the obtained acrylic fiber fabric finishing agent can improve the anti-pilling performance and flame retardancy of the acrylic fiber fabric.

Owner:JIANGSU HUACHAO TEXTILE IND

New method for solving wire pasting problem of silver and silver alloy bonding wires

InactiveCN105886980APromote the process of industrializationLow priceFurnace typesHeat treatment furnacesAlloySurface-active agents

The invention discloses a method for solving the wire pasting problem of bonding silver wires and silver alloy wires. According to the technical scheme, through the protective liquid formula, annealing furnace equipment modification is designed; protective liquid is prepared by following raw materials including 0.1 part to 5 parts of terpenic compounds, 0.1 part to 5 parts of alcoholic hydroxyl group organic solutions, 0.01 part to 1 part of a surface active agent and 89 parts to 99.9 parts of a thinning agent; the terpenic compounds are turpentine or lemon oil, the alcoholic hydroxyl group organic solutions are isopropyl alcohol or methyl alcohol or ethylene glycol butyl ether, the surface active agent is cetyl sodium sulfate, succinate sodium salt, and fatty alcohol polyoxyethylene ether sodium salt / fatty alcohol polyoxyethylene ether; and the thinning agent is ethyl alcohol. The method is easy to operate, the protective liquid is good in spreading wettability and stability, the service life of the bonding silver wires and the silver alloy wires is prolonged, the application bottleneck of gold wire replacement by the bonding silver wires is broken through, and the market application of silver-based bonding wires is promoted.

Owner:SINO PLATINUM METALS CO LTD

Transfer adhesive

InactiveCN108864955AImprove adhesionGood spreadabilityOrganic non-macromolecular adhesiveAdhesiveETHYLHEXYL ACETATE

The invention discloses a transfer adhesive. The transfer adhesive is prepared from the following components in parts by mass: 40 to 50 parts of methyl acrylate, 40 to 50 parts of 2-ethylhexyl acrylate, 4 to 8 parts of acrylic acid, 70 to 100 parts of water, 1 to 3 parts of sodium dodecylbenzene sulfonate, 1 to 2 parts of sodium persulfate, 1 to 3 parts of ammonia water, 2 to 5 parts of polyoxypropylene glycerol ether and 1 to 3 parts of sodium hexadecyl sulfate. The transfer adhesive disclosed by the invention has excellent bonding performance and a good coating effect, and a peeling phenomenon is not easy to occur.

Owner:常熟国和新材料有限公司

Cynanchum otophyllum schneid dispersible tablets and preparation method thereof

InactiveCN101357149BImprove bioavailabilityGive full play to the medicinal effectNervous disorderPill deliveryMedicineSodium stearyl

The invention discloses a cynanchum otophyllum dispersible tablet and a preparation method thereof, relating to medicines. The cynanchum otophyllum dispersible tablet is made of the following raw materials by weight portions: 50-200 portions of an extract of cynanchum otophyllum total glucoside, 20-100 portions of an disintegrating agent, 1-10 portions of a lubricant and 1-20 portions of a surfactant, wherein, the disintegrating agent is CMS-Na, CCNa, PVPP, L-HPC and dry starch, the lubricant is magnesium stearate or talcum powder or superfine silica gel powder, the surfactant is SDS, sodium hexadecyl sulfate and sodium stearyl sulfate. The preparation method consists of the following steps: 20-200 portions of total glucoside of the cynanchum otophyllum by weight is taken out and sieved with a 100-mesh sieve; 20-100 portions of the disintegrating agent by weight and 1-10 portions of the lubricant by weight are taken out and respectively sieved with the 100-mesh sieve; 1-20 portions ofthe surfactant by weight is taken out and sieved with a 80-mesh sieve; then the sieved extract, the sieved disintegrating agent, the sieved lubricant and the sieved surfactant are ground and evenly mixed, and then the mixture is sieved with the 80-mesh sieve, and direct compression and sieving are carried out on the sieved mixture to obtain the dispersible tablet. The dispersible tablet has high dissolution and high bioavailability, can fully exert the drug action of the cynanchum otophyllum, and the preparation method is simple and feasible while suitable for industrialized production.

Owner:GUIZHOU UNIV

A crack-resistant water-resistant coating

The invention discloses a crack-resistant and water-resistant coating, which is prepared from the following raw materials in parts by weight: 3.2-3.9 parts of glycerol carboxylate, 2.5-3.2 parts of 1-hydroxycyclohexyl phenyl ketone, and 3-8 parts of bentonite , 1.3-3.2 parts of calcium carbonate, 2.5-5 parts of 2-hydroxy-4-methoxybenzophenone, 1.2-2.5 parts of sodium diamyl succinate sulfonate, 2.5-4.5 parts of potassium pyrophosphate and spermaceti 1.8-3.6 parts of sodium alcohol sulfate. Compared with the existing waterproof paint, the present invention has the following advantages: hard paint film, good wear resistance, strong adhesion, and good water resistance, especially suitable for coating inner walls, outer walls and roofs; In addition, bentonite, sodium cetyl sulfate and potassium pyrophosphate are added to the ingredients, which have good adhesion, crack resistance and durability.

Owner:中山市粤马科技有限公司

A kind of preparation method of highly stable dibromohydantoin disinfectant

ActiveCN105379719BIncrease concentrationReduce stimulationBiocideOrganic chemistryDisinfectantSodium sulfate

The invention provides a preparation method of a high-stability dibromohydantoin disinfection solution. The preparation method comprises the following steps: (1) mixing soluble alkali, 5,5-dimethylhydantoin and water to obtain a water solution; dropping monomer bromine a into the water solution while stirring to obtain a reaction solution; (2) adding a dispersant into the reaction solution obtained in the step (1) and stirring to dissolve the dispersant, and dropping monomer bromine b into the solution to obtain a solution, wherein the mol ratio of the monomer bromine b to the monomer bromine a in the step (1) is 1 to 1, the mass ratio of the dispersant to the reaction solution in the step (1) is (0.01-1) to 100, and the dispersant is one of sodium dodecyl benzene sulfonate, sodium hexadecanesulfonate, sodium octadecyl benzene sulfonate, lauryl sodium sulfate, cetyl sodium sulfate or octadecyl sodium sulfate; and (3) adding a stabilizing agent and a synergist to the solution obtained in the step (2) to obtain a mixed solution, thus obtaining the high-stability dibromohydantoin disinfection solution.

Owner:山东大明消毒科技有限公司

Textile finishing agent added with sodium citrate and preparation method of textile finishing agent

InactiveCN106637951AImproves UV resistanceMeet industry requirementsLight resistant fibresMethacrylatePoly(ethylmethacrylate)

The invention discloses a textile finishing agent added with sodium citrate and a preparation method of the textile finishing agent. The textile finishing agent takes phthalic acid ester, ethyl methacrylate, butyl acrylate and sodium citrate as the main ingredients, N,N-diethyl-m-toluamide, tri-isopropyl phosphite, ethylene carbonate, polyvinyl chloride, diethylene glycol, sodium cetyl sulfate, sodium laureth sulfate, potassium peroxodisulfate, methyl 1,3-benzodioxol-5-ylacetate, stannous octoate, a surfactant, a thickening agent and deionized water are added, the processes of heating, stirring, ultrasonic dispersing, ball-milling and reacting under the nitrogen atmosphere are adopted, the anti-ultraviolet performance of a textile is improved after the prepared finishing agent is used on the textile, the requirements of the industry are met, and the textile finishing agent has a better application prospect.

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com