Method for preparing super-amphiphobic nano-film on bamboo surface in bionic way

A nano-film, super-amphiphobic technology, which is applied in wood treatment, wood heating, wood impregnation, etc., can solve the problems such as the super-amphiphobic function on the surface of bamboo that has not yet been found, and achieve the effect of easy operation and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for biomimetic preparation of super-amphiphobic nano-films on the surface of bamboo, comprising the following steps:

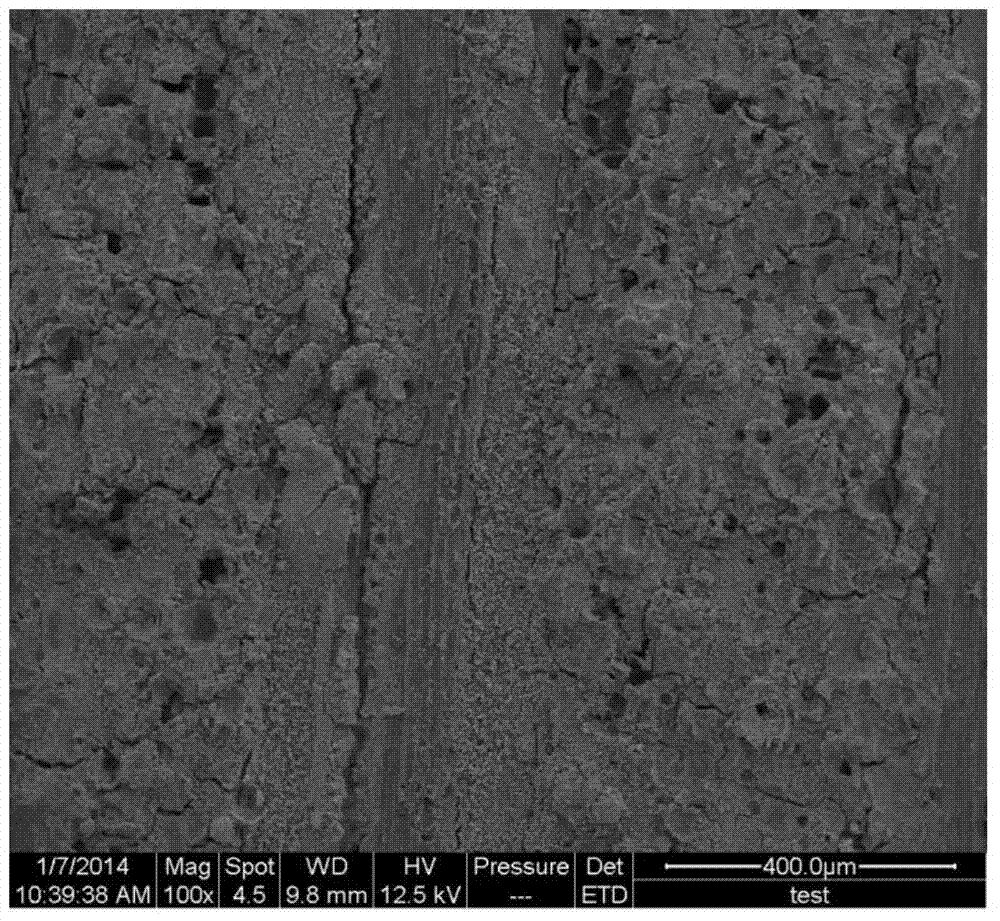

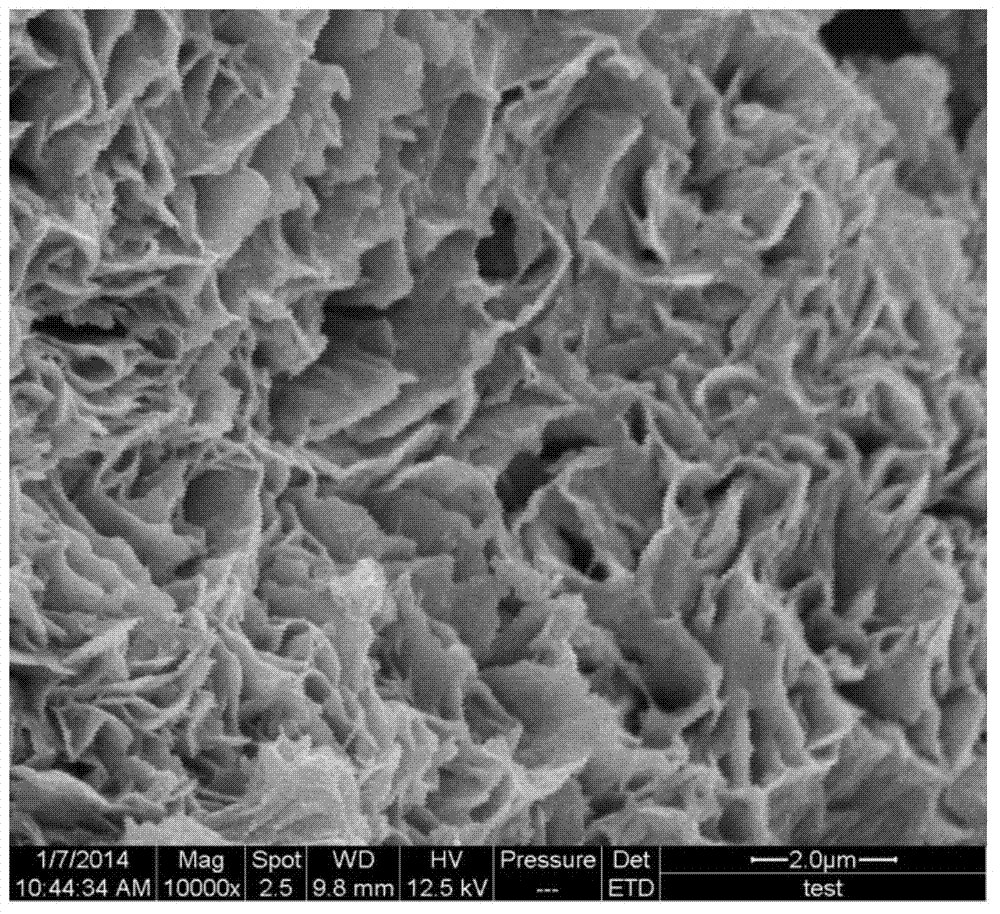

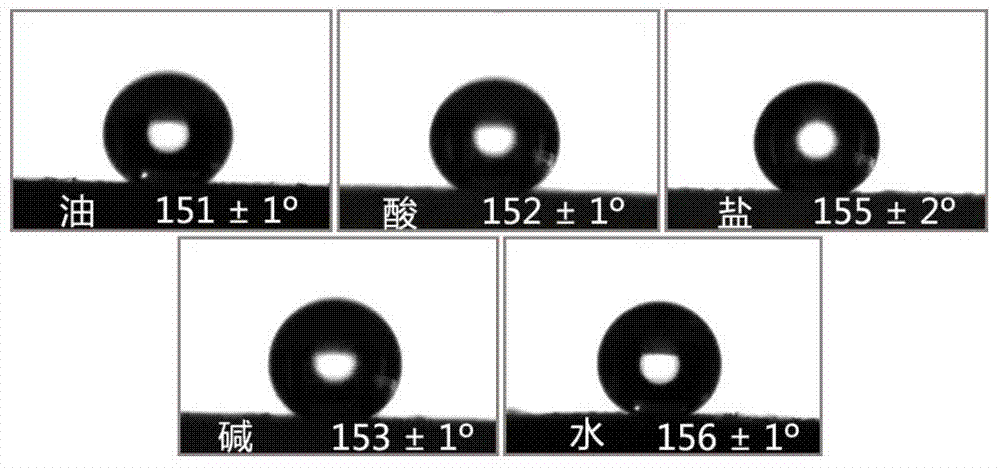

[0023] 1. Dissolve 0.75M zinc acetate in methanol to prepare a solution, mix it with 1 volume of ethanolamine solution, and stir at 60°C for 30 minutes to prepare ZnO colloid; 2. Form a layer of ZnO colloid on the surface of bamboo by pulling and dipping After drying at 80°C, a layer of ZnO gel film can be formed on the surface of bamboo, and the process from dipping to drying is repeated 5 times; 3. Put the prepared bamboo block loaded with ZnO gel film into a layer containing 0.1 M zinc nitrate, 0.1M hexamethylenetetramine and 0.04M sodium hexadecyl sulfate mixed solution, moved into the reaction kettle, reacted at 95°C for 1h, then took out the bamboo pieces with nano-ZnO growth, and washed them with deionized water Wash for 30 minutes and dry at 50°C for 24 hours to obtain bamboo pieces loaded with nano-ZnO; 4. Put the bamboo pieces loaded ...

Embodiment 2

[0025] A method for biomimetic preparation of super-amphiphobic nano-films on the surface of bamboo, comprising the following steps:

[0026] 1. Dissolve 0.75M zinc acetate in methanol to prepare a solution, mix it with 1 volume of ethanolamine solution, and stir at 60°C for 30 minutes to prepare ZnO colloid; 2. Form a layer of ZnO colloid on the surface of bamboo by pulling and dipping After drying at 80°C, a layer of ZnO gel film can be formed on the surface of bamboo, and the process from dipping to drying is repeated 8 times; 3. Put the prepared bamboo block loaded with ZnO gel film into a layer containing 0.2 M zinc nitrate, 0.2M hexamethylenetetramine and 0.05M hexadecyl sodium sulphate mixed solution, moved into the reaction kettle, reacted at 90°C for 2h, then took out the bamboo pieces with nano-ZnO, and washed them with deionized water Wash for 30 minutes and dry at 50°C for 24 hours to obtain bamboo pieces loaded with nano-ZnO; 4. Put the bamboo pieces loaded with n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com