Patents

Literature

30results about How to "No shape requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

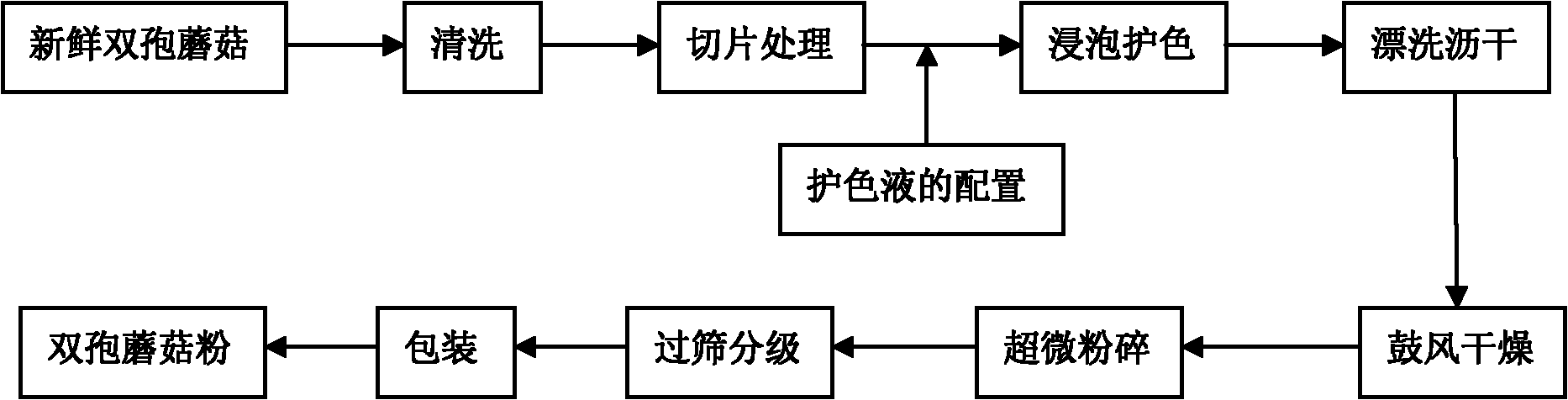

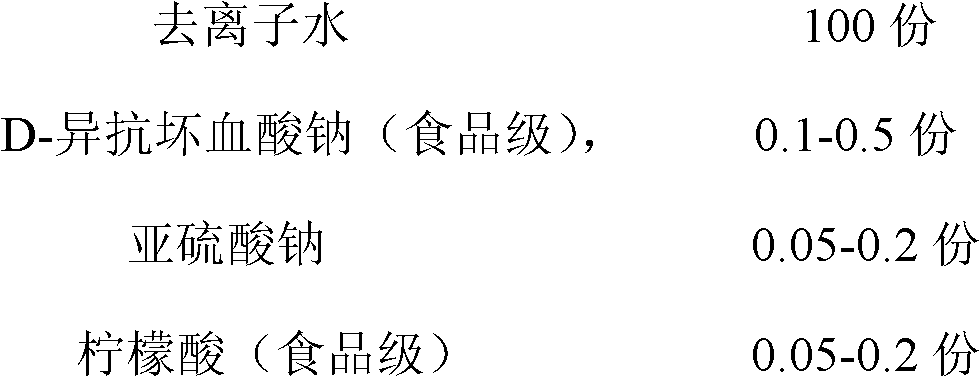

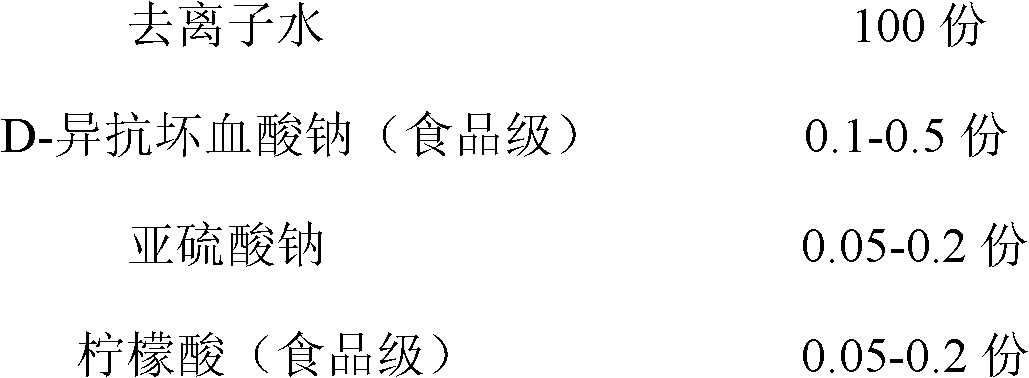

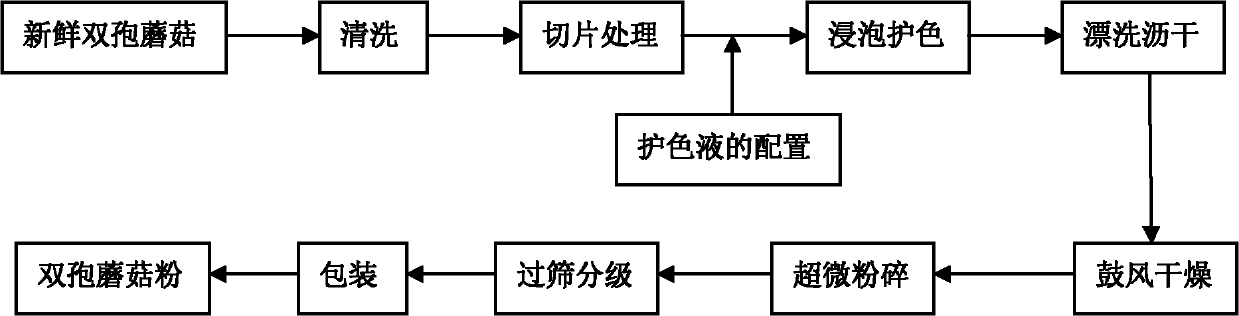

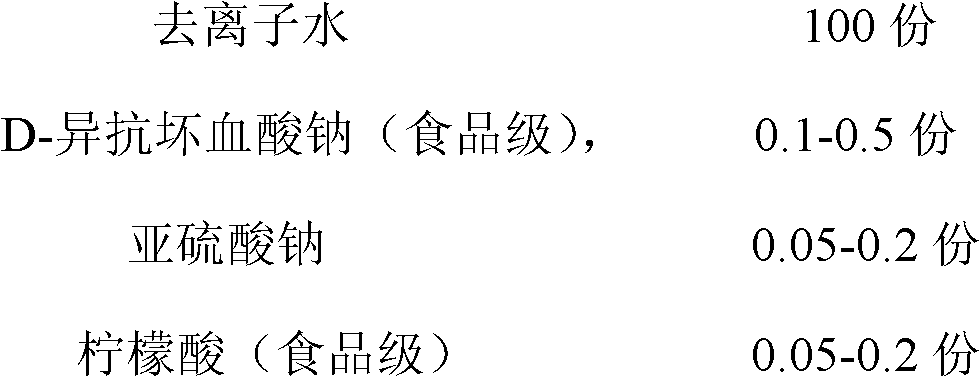

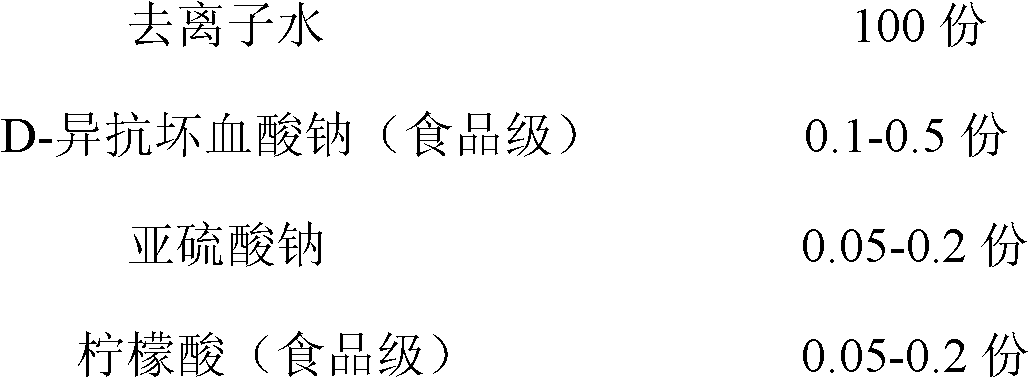

Method for preparing agaricus bisporus powder and application thereof

InactiveCN102204667ASize is not requiredNo shape requirementFood preparationSodium sulfiteSodium erythorbate

The invention provides a method for preparing agaricus bisporus powder and application thereof, and belongs to the technical field of food processing. The method comprises the following steps of: cleaning fresh agaricus bisporus, chopping the agaricus bisporus into pieces, soaking the agaricus bisporus pieces in color protecting solution of sodium D-isoascorbate, sodium sulfite and citric acid, drying and dehydrating the agaricus bisporus pieces by blowing air, and superfine grinding the dehydrated agaricus bisporus pieces to obtain the agaricus bisporus powder. The agaricus bisporus powder can be used to prepare noodles, bean strips, breads, biscuits and various puffed food.

Owner:HUAZHONG AGRI UNIV

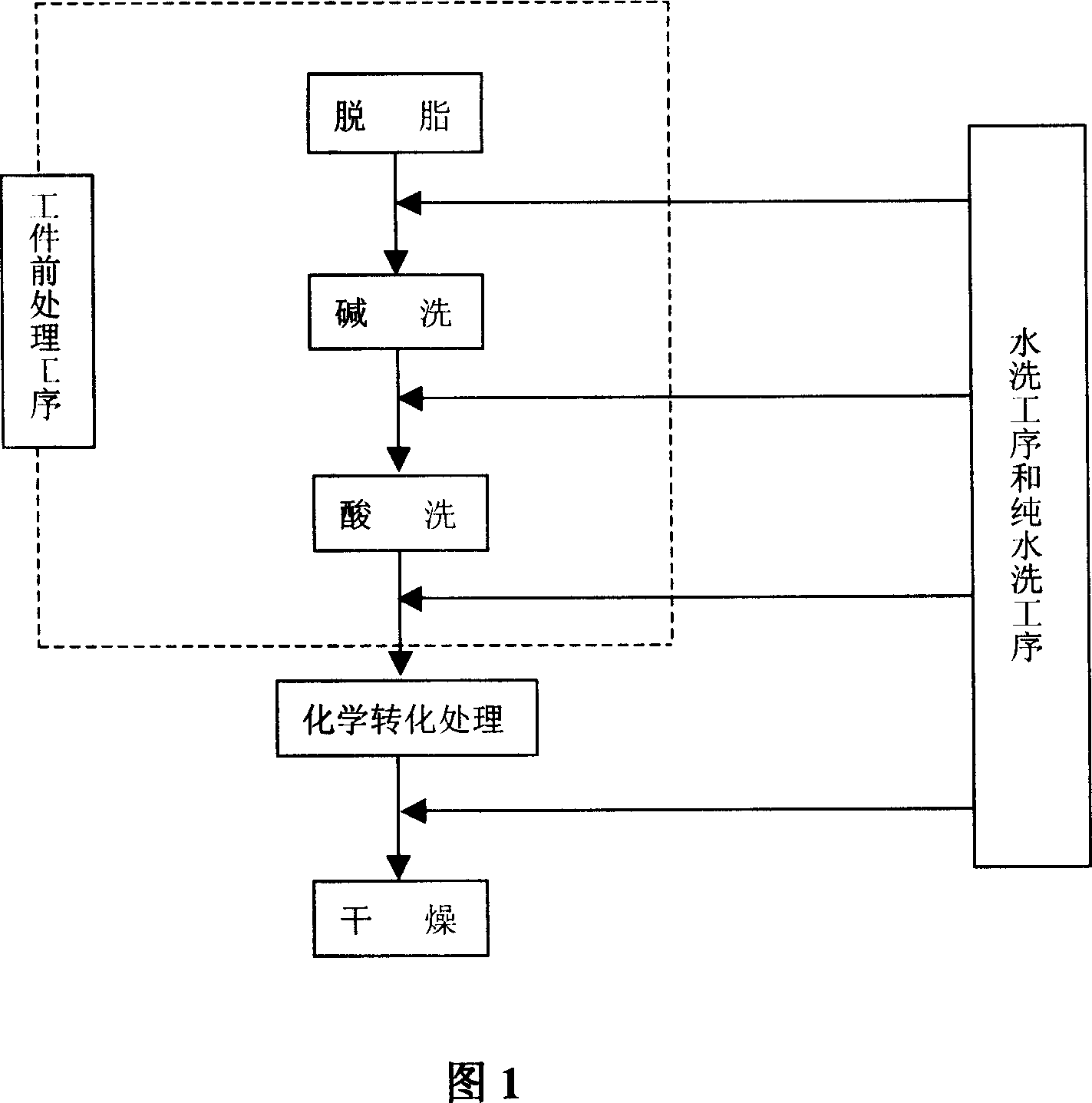

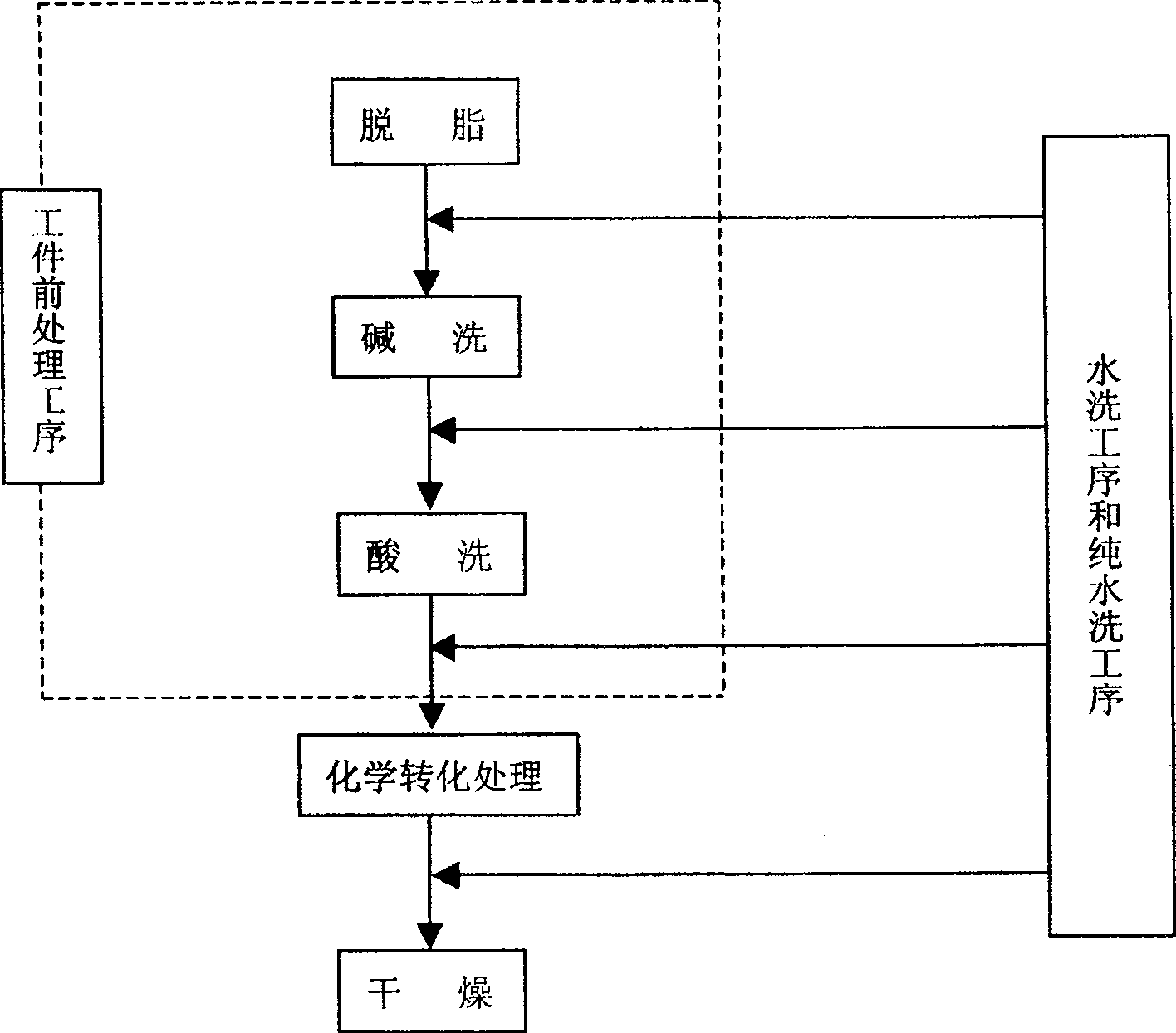

Method of treating magnesium alloy work-piece surface

InactiveCN101016627AProtectiveDecorativeMetallic material coating processesElectrolysisChemical transformation

The invention discloses a surface disposing method of electron alloys work piece, which is characterized by the following: including work piece fore treatment, chemical transformation treatment, drying treatment and washing treatment of each interprocess; dipping electron alloys work piece into inverting liquid of main filming matter and assistance filming matter as chemical transformation treatment; setting main filming matter as one or several zircon salt, manganic salt, molybdate and tungstate and so on transient metal salt; converting to Na2MoO4.2H2O content with density at 5-150g / L; setting the assistance filming matter as one or several nitrate and sulfate of lithium, sodium and potassium alkali metal; converting to LiNO3 content with density at 0.5-20g / L and pH value of inverting liquid at 2-6; controlling the disposing temperature at 10-90 deg.c and disposing time at 5-30 min. This surface film possesses properties of protection and decoration.

Owner:CHONGQING UNIV

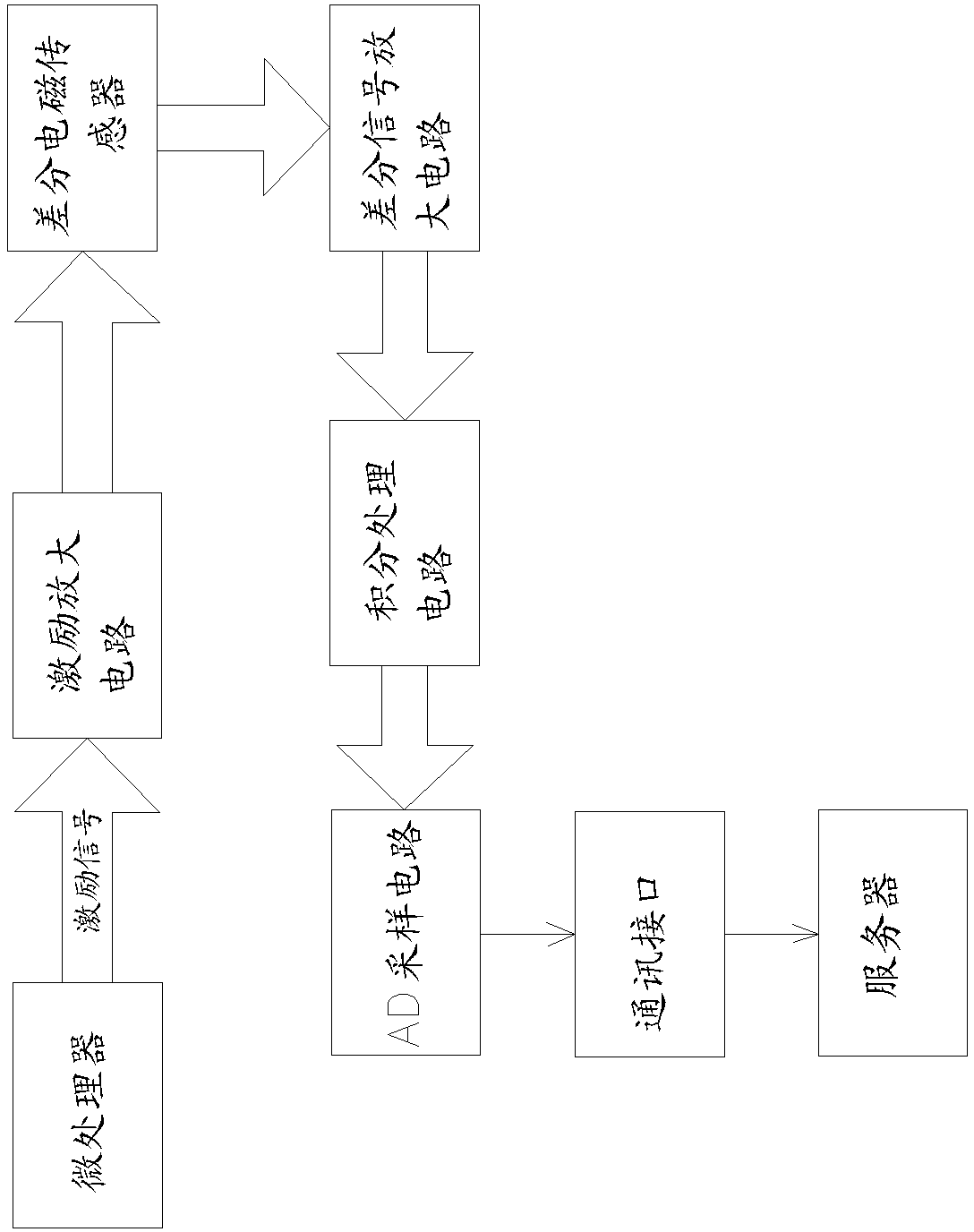

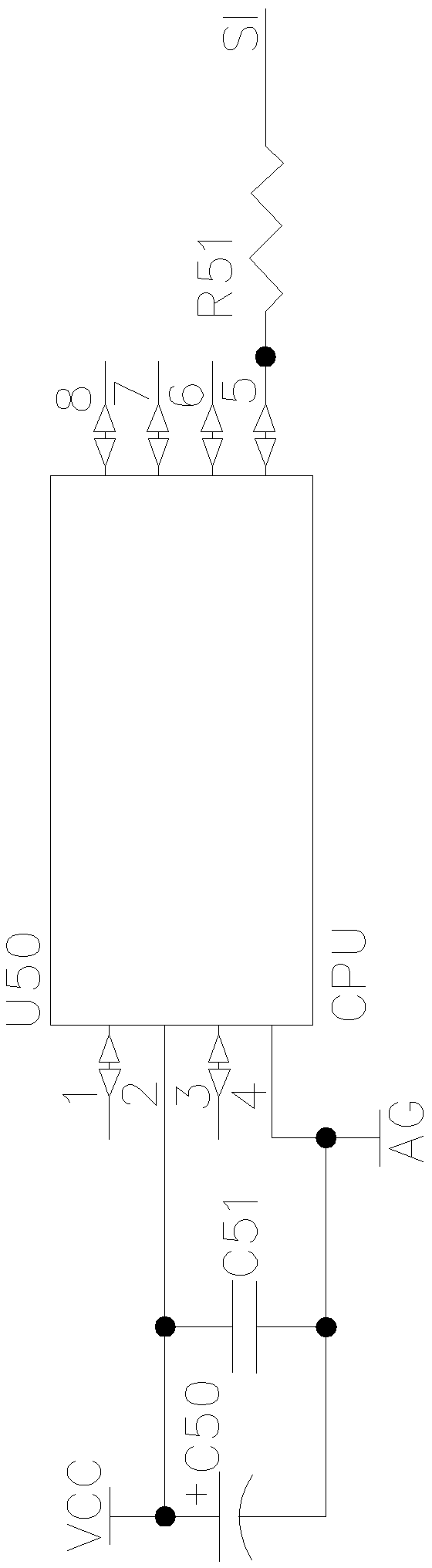

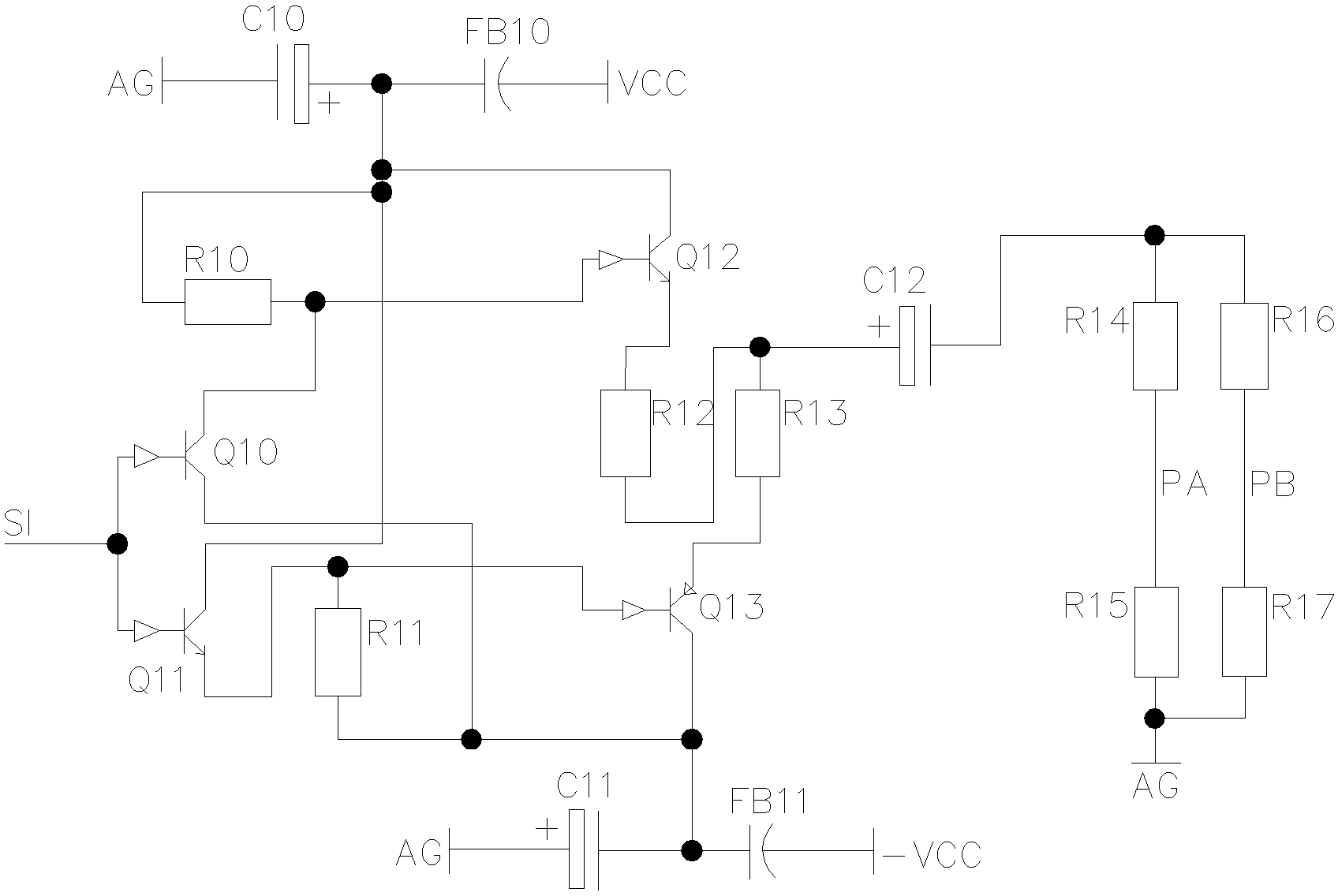

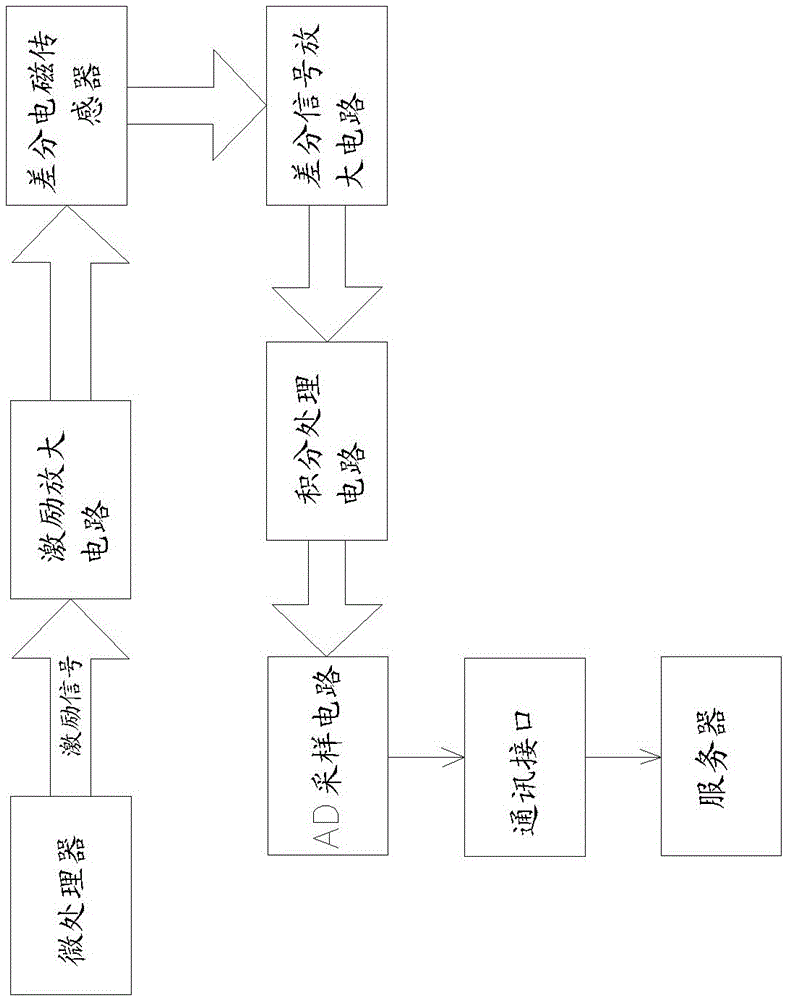

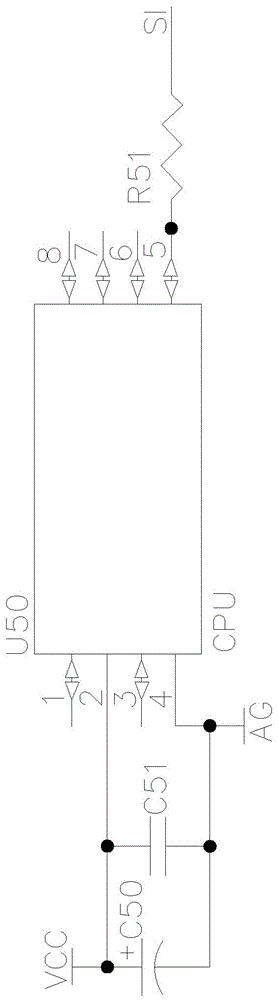

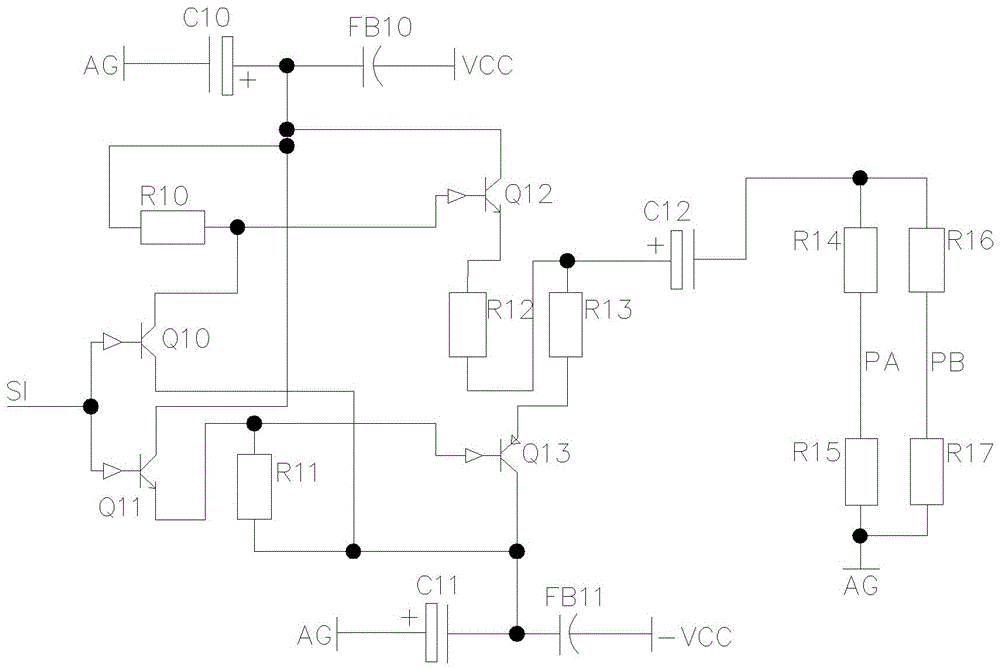

Detection apparatus and method based on electromagnetic detection signal for distinguishing inner and outer wall defects

InactiveCN103235036ASimple methodEasy to implementMaterial magnetic variablesSignal amplificationDifferential amplification

The invention discloses a detection method based on electromagnetic detection signal for distinguishing inner and outer wall defects, which comprises the following steps: the step 1: a workpiece to be detected and a detecting coil are placed in an external partial magnetic saturation environment; the step 2: a microprocessor generates a square wave excitation signal with a certain frequency, and an excitation amplification circuit carries out a power amplification of the square wave excitation signal for excitation of a first detection coil and a second detection coil; the step 3: the first detection coil and the second detection coil in a difference mode form a differential electromagnetic sensor, and the square wave excitation signal after power amplification by the excitation amplification circuit is loaded; the step 4: signals of the difference electromagnetic sensor are picked by a differential signal amplification circuit for amplification with adaptability; the step 5: the signals after differential amplification by the differential signal amplification circuit are subjected to rectification and integral processing by an integral processing circuit for determining the defects of the workpiece to be detected. The invention is applied to distinguish inner wall / outer wall defects.

Owner:厦门艾帝尔电子科技有限公司

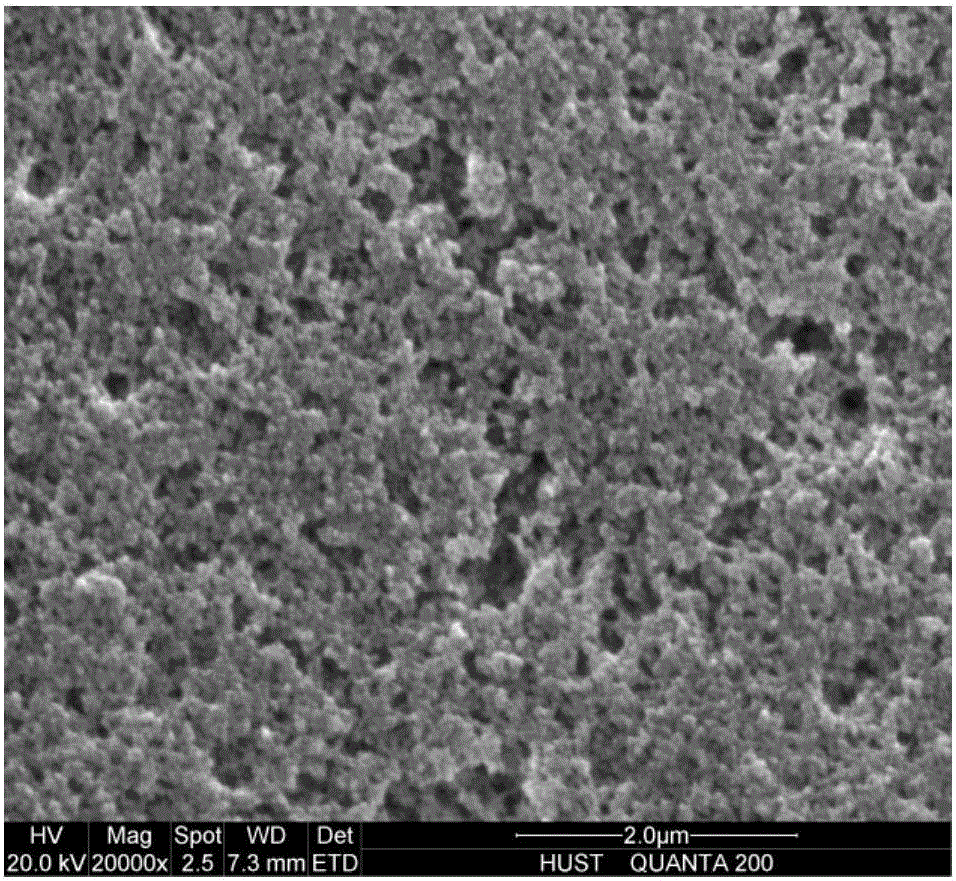

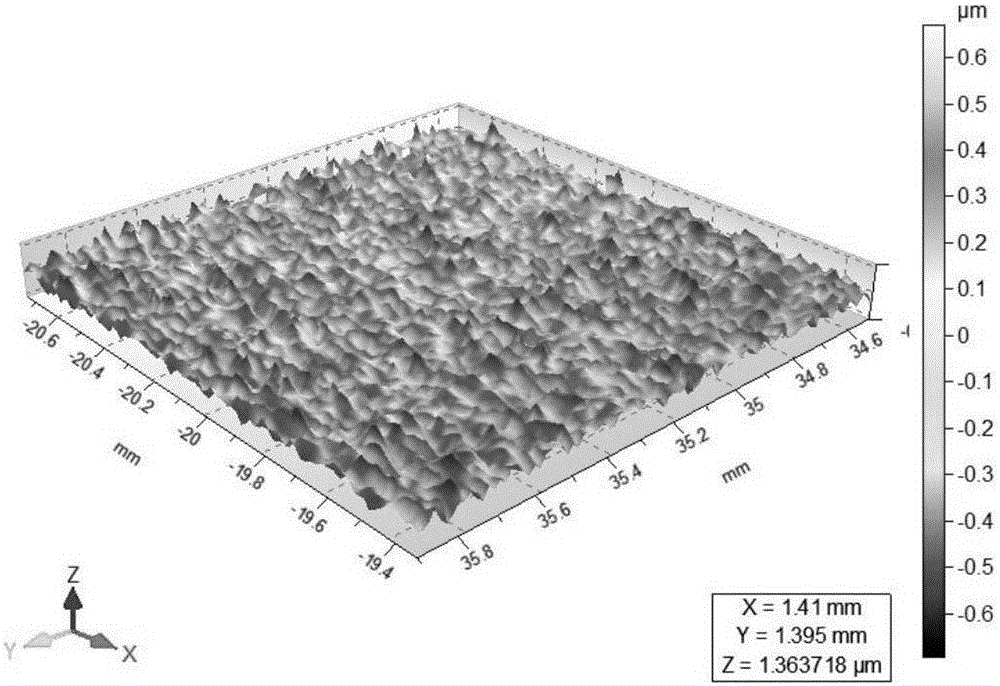

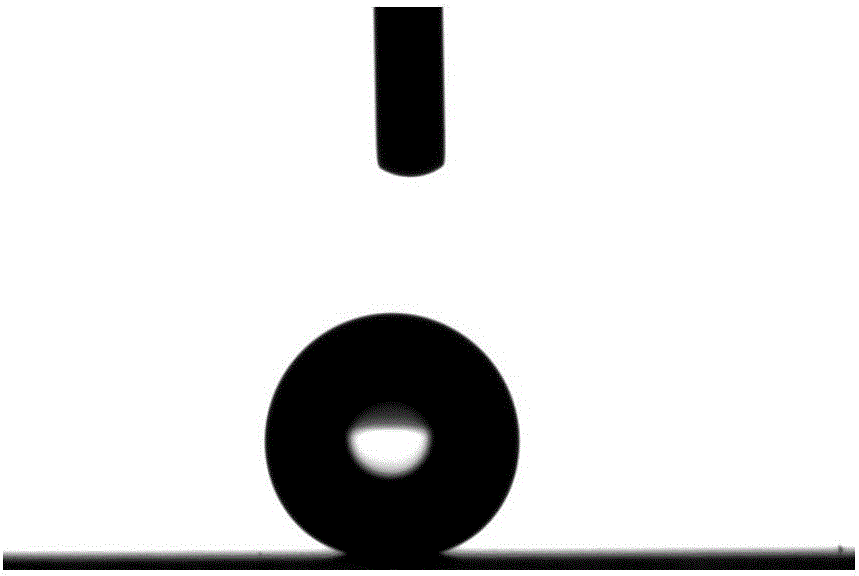

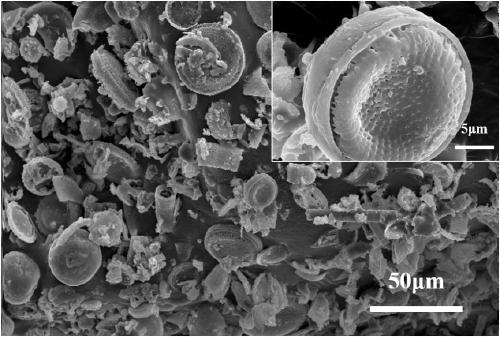

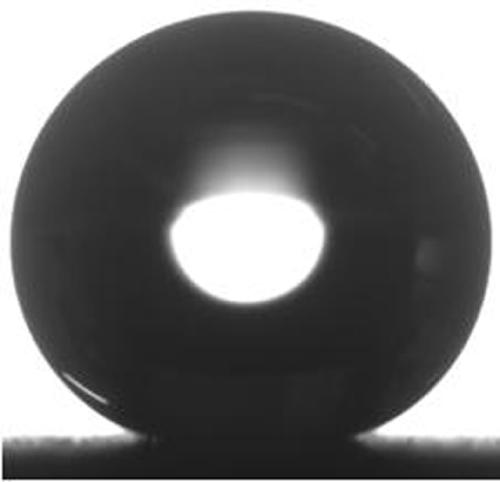

Functional gradient composite structure wear-resistant transparent super-hydrophobic coating and preparation method thereof

InactiveCN106085173ANo shape requirementSimple processLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoWear resistant

The invention discloses a functional gradient composite structure wear-resistant transparent super-hydrophobic coating and a preparation method thereof. Specifically, the method consists of: firstly coating a substrate with a polyurethane modified reinforced bonding layer, then conducting coating of a polyurethane and super-hydrophobic compound transition layer to obtain a polyurethane / polyurethane and silicon dioxide transition layer compound coating, and finally performing coating of a micro-nano super-hydrophobic layer, thus forming a polyurethane / polyurethane-silicon dioxide / silicon dioxide functional gradient composite structure wear-resistant transparent super-hydrophobic coating. The preparation method provided by the invention has the characteristics of simple process, easy operation, normal pressure and low cost, the prepared functional gradient composite structure wear-resistant transparent super-hydrophobic coating can be used for water and fouling prevention on ship surface coatings, automotive glass surfaces, mobile phone screen surfaces and other transparent materials.

Owner:WUHAN UNIV OF TECH

Microwave swelling tobacco stem processing method

InactiveCN101099598APromote productionPromote accumulationTobacco treatmentMicrowave ovenEngineering

The present invention relates to utilization of by-product tobacco stems obtained in tobacco industry, in the concrete, it relates to a technological process for puffing tobacco stems by utilizing microwave. Said technological process includes the following steps: raw material pretreatment: uniformly spraying pectin puffing agent on the dried tobacco stems; charging: making the pretreated tobacco stems be uniformly laid in a glassware; placing the glassware into a microwave oven and utilizing microwave to puff the tobacco stems, microwave frequency is 2450MH2, power is 400w and temperature is 85-95deg.C, so that the puffed tobacco stems can be obtained.

Owner:陈明功

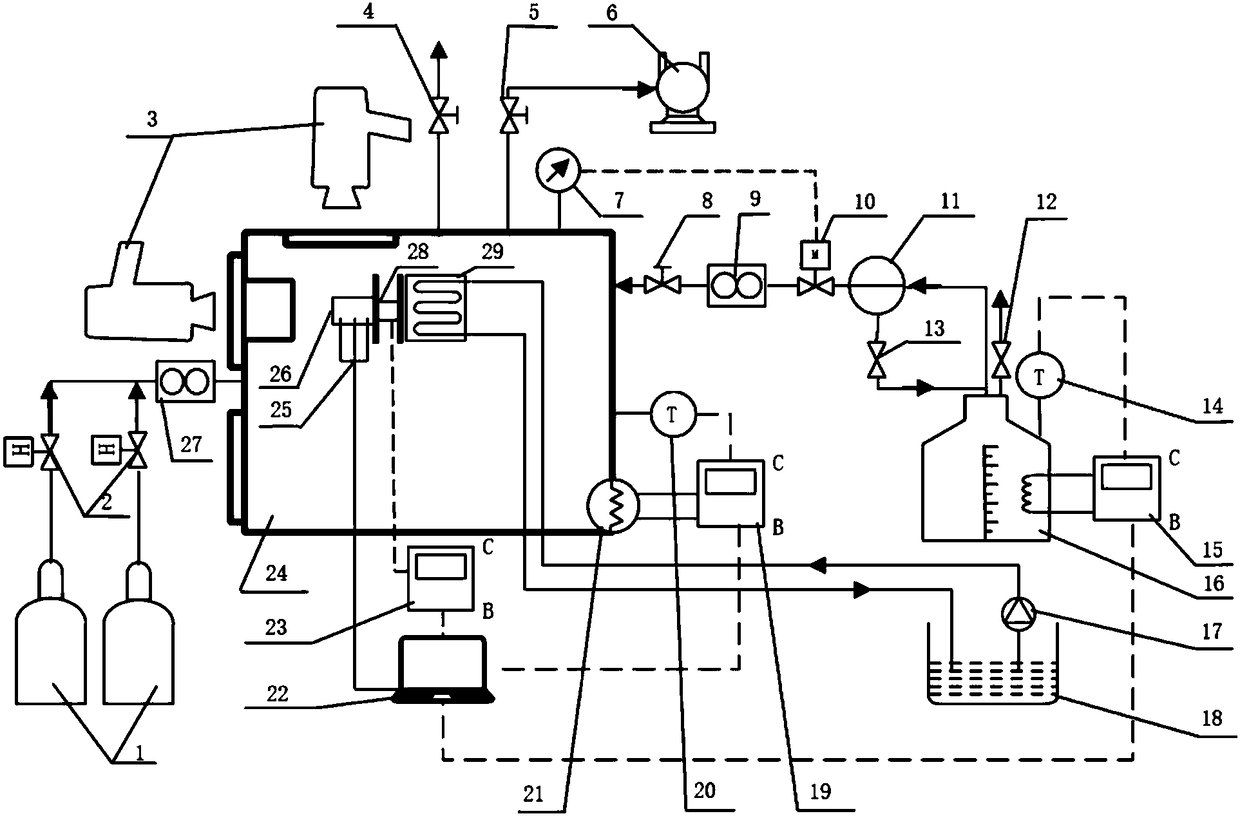

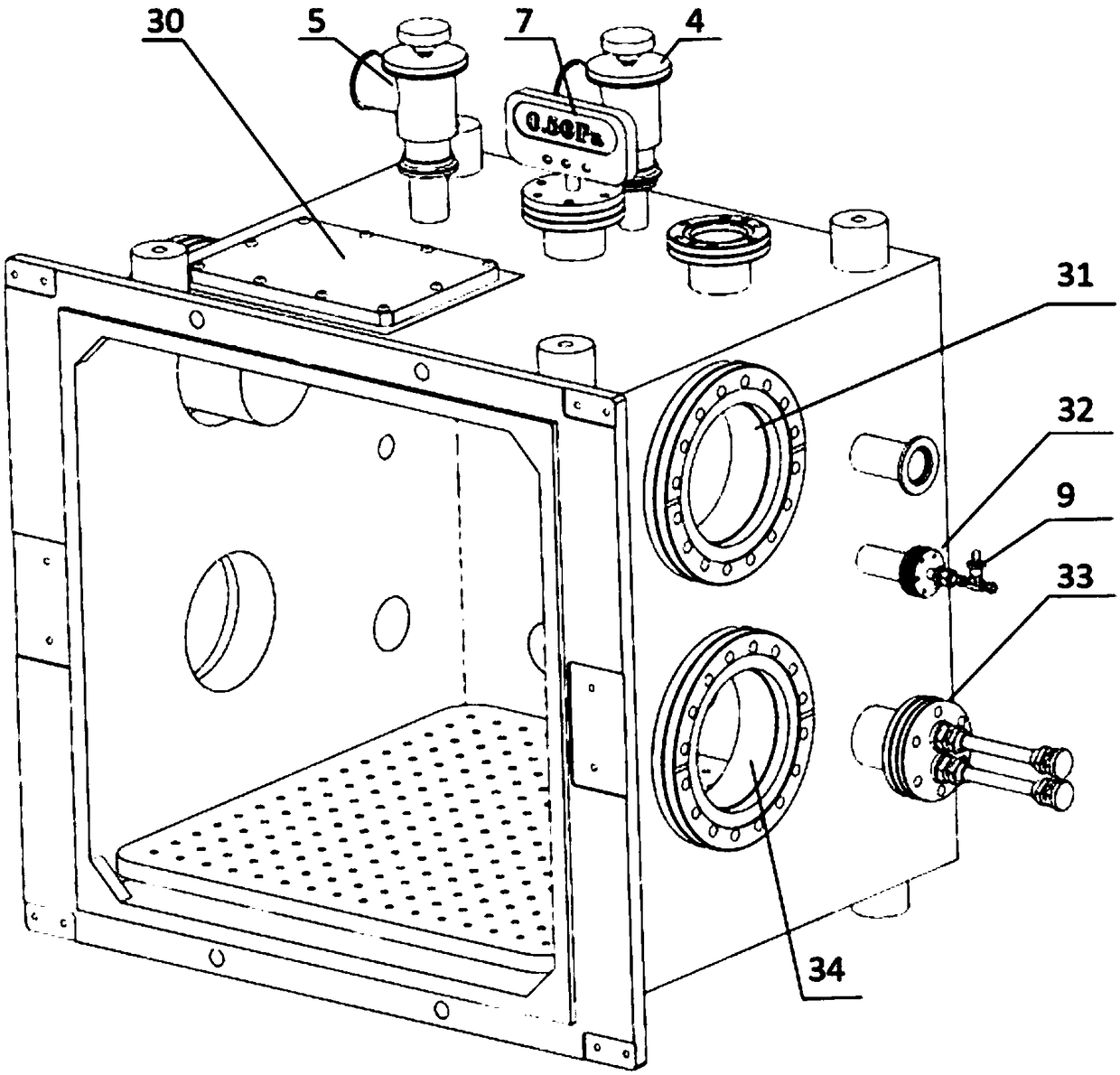

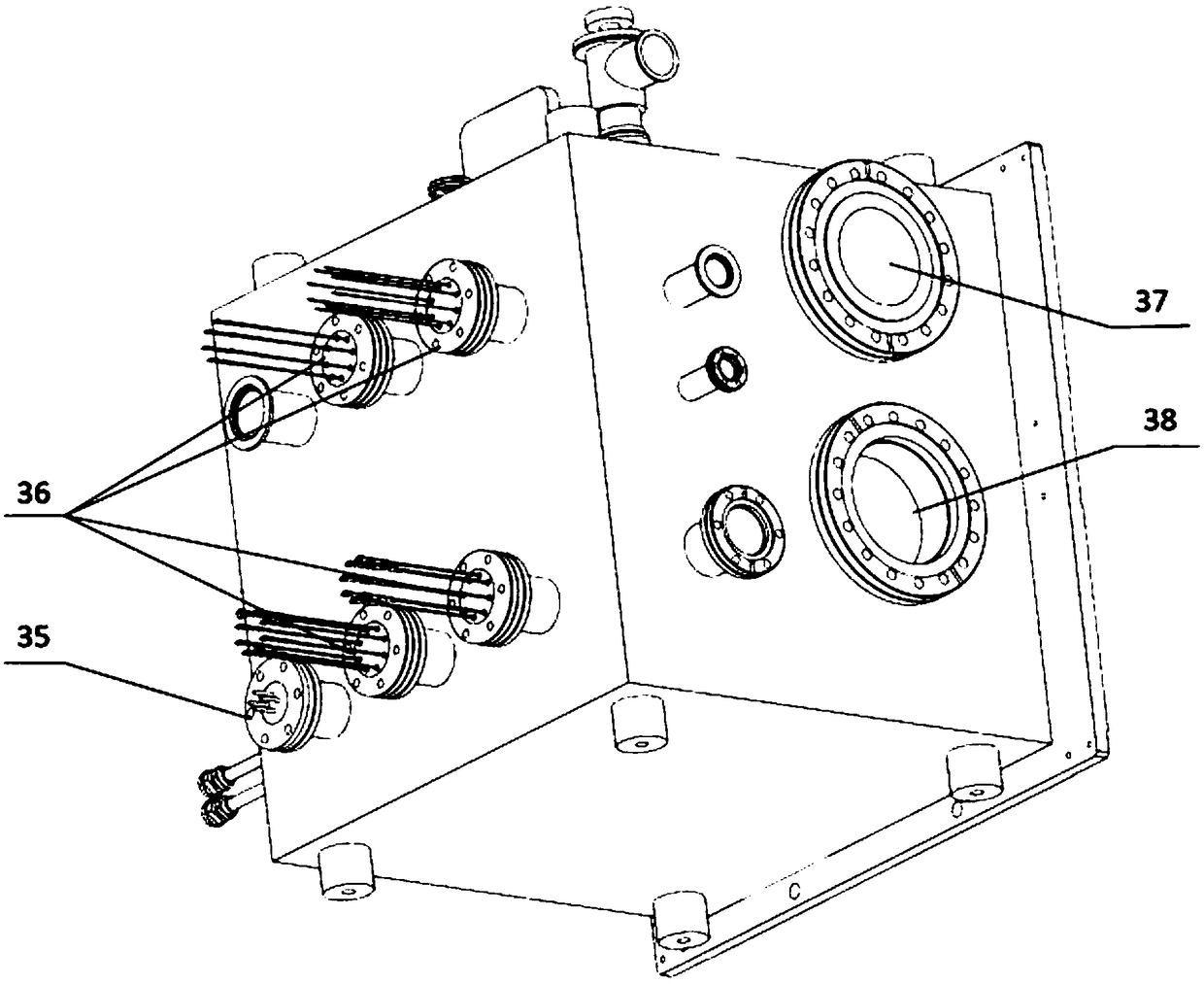

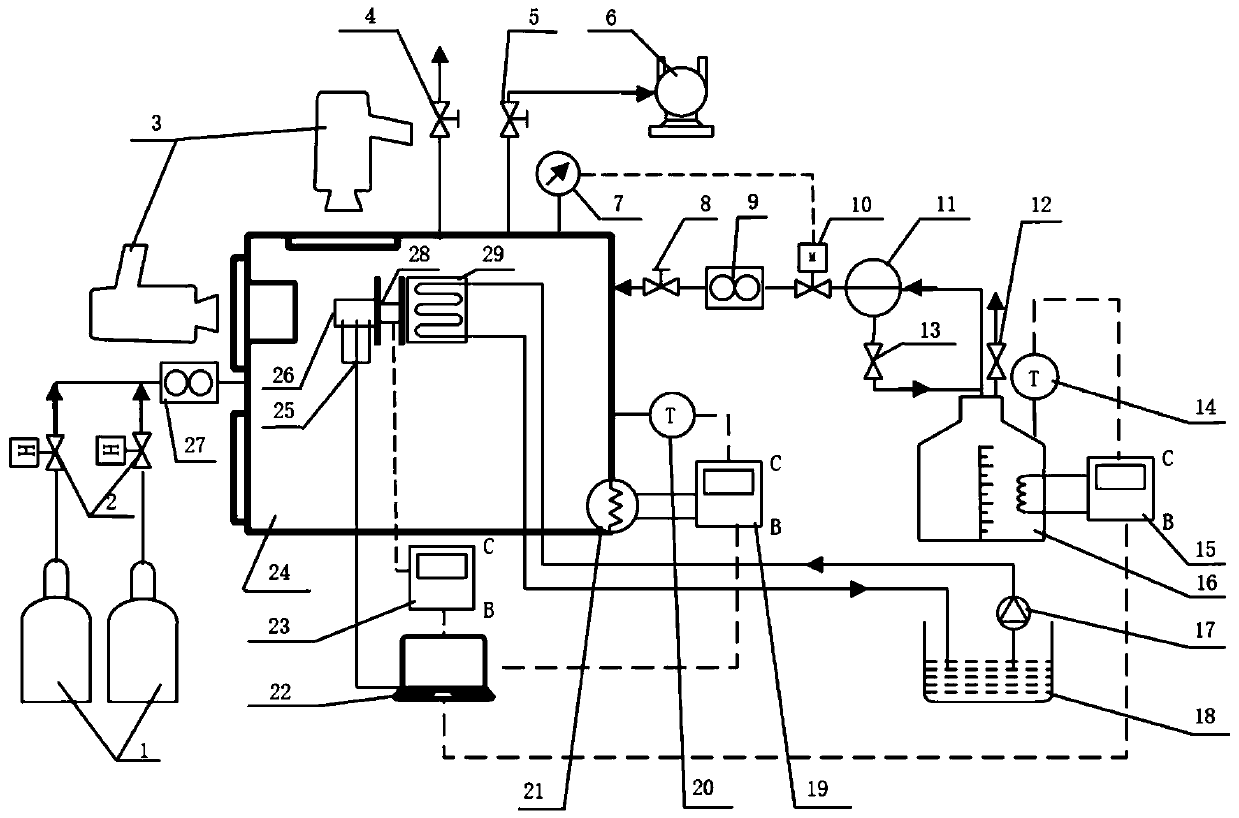

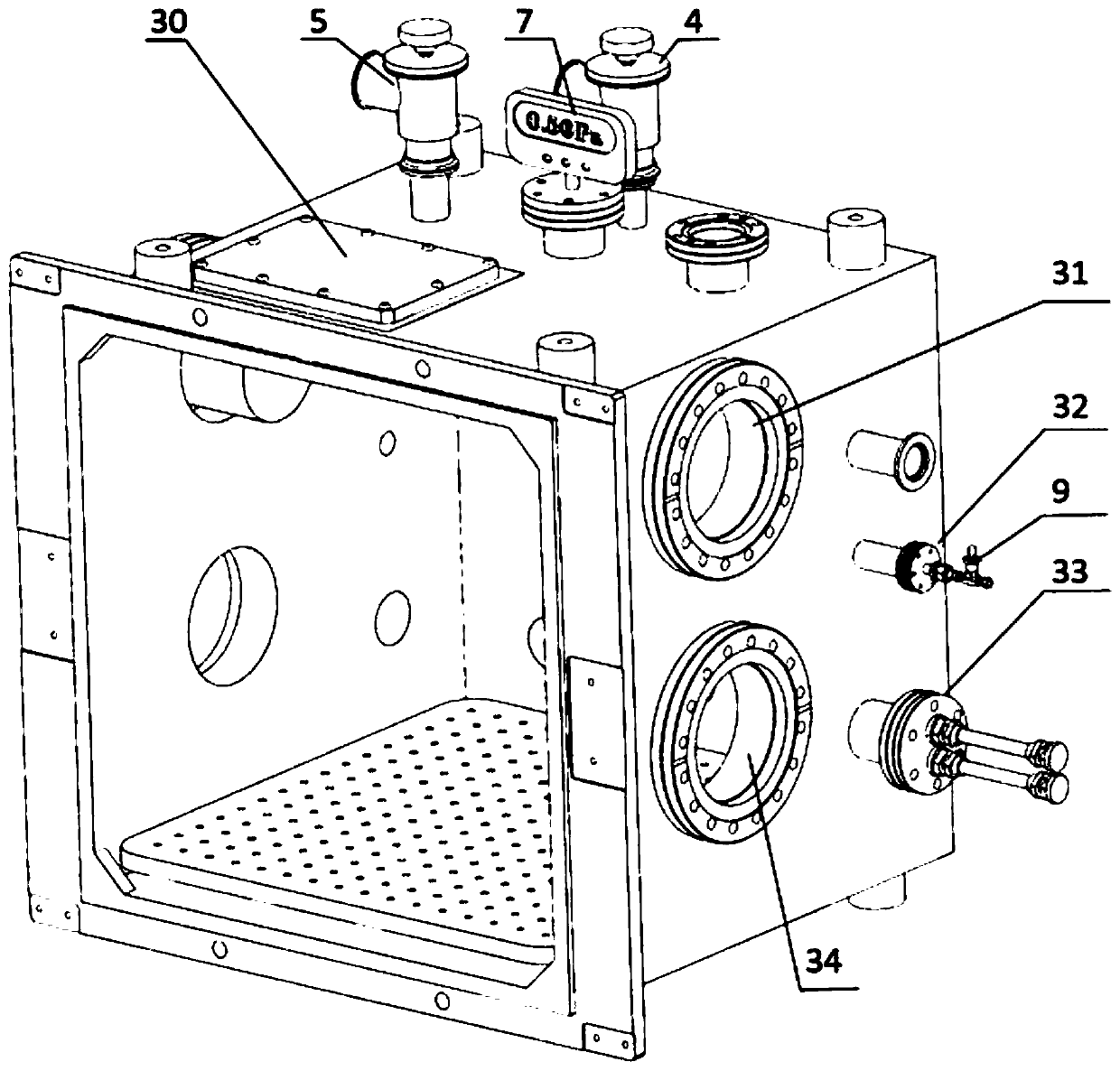

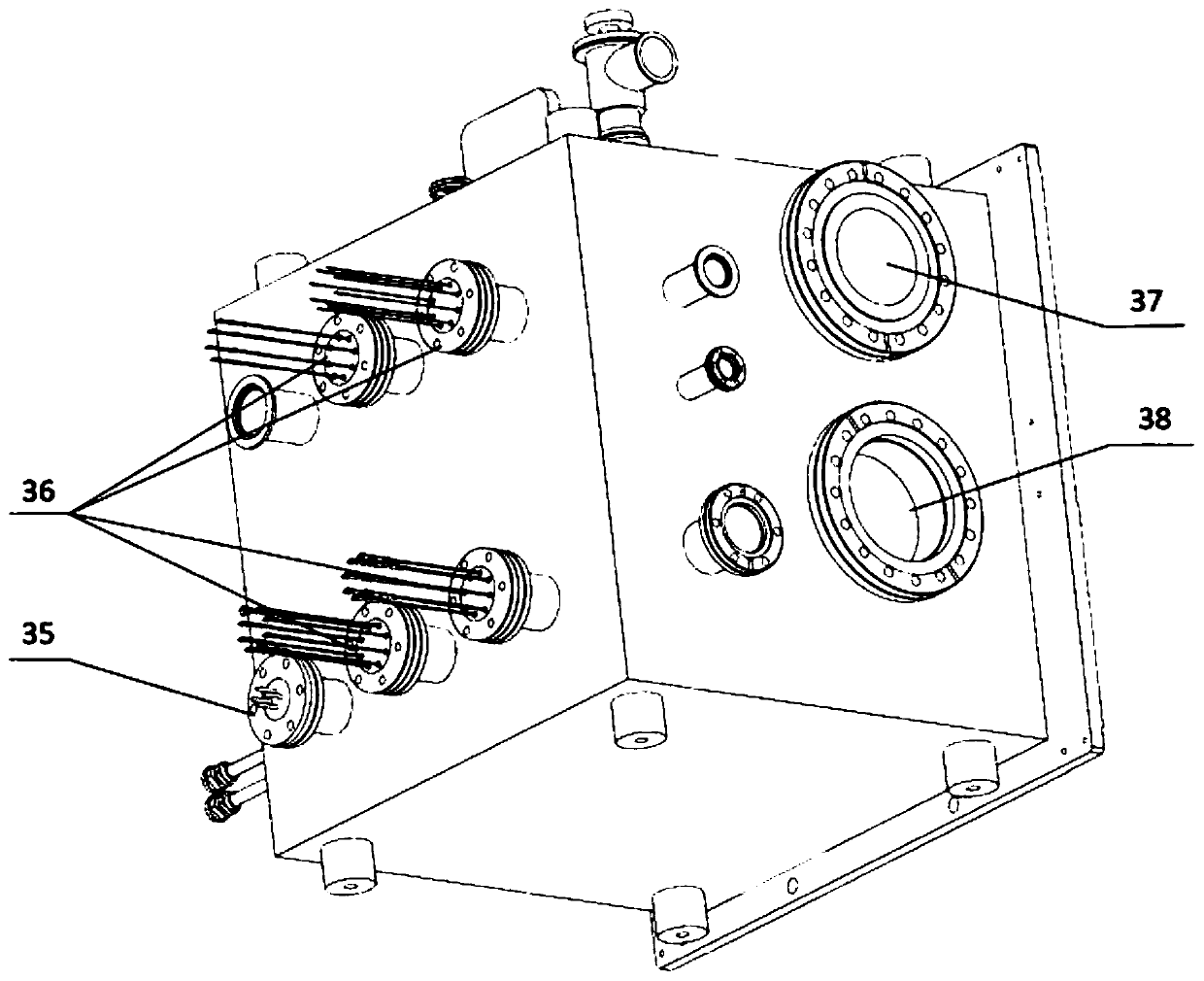

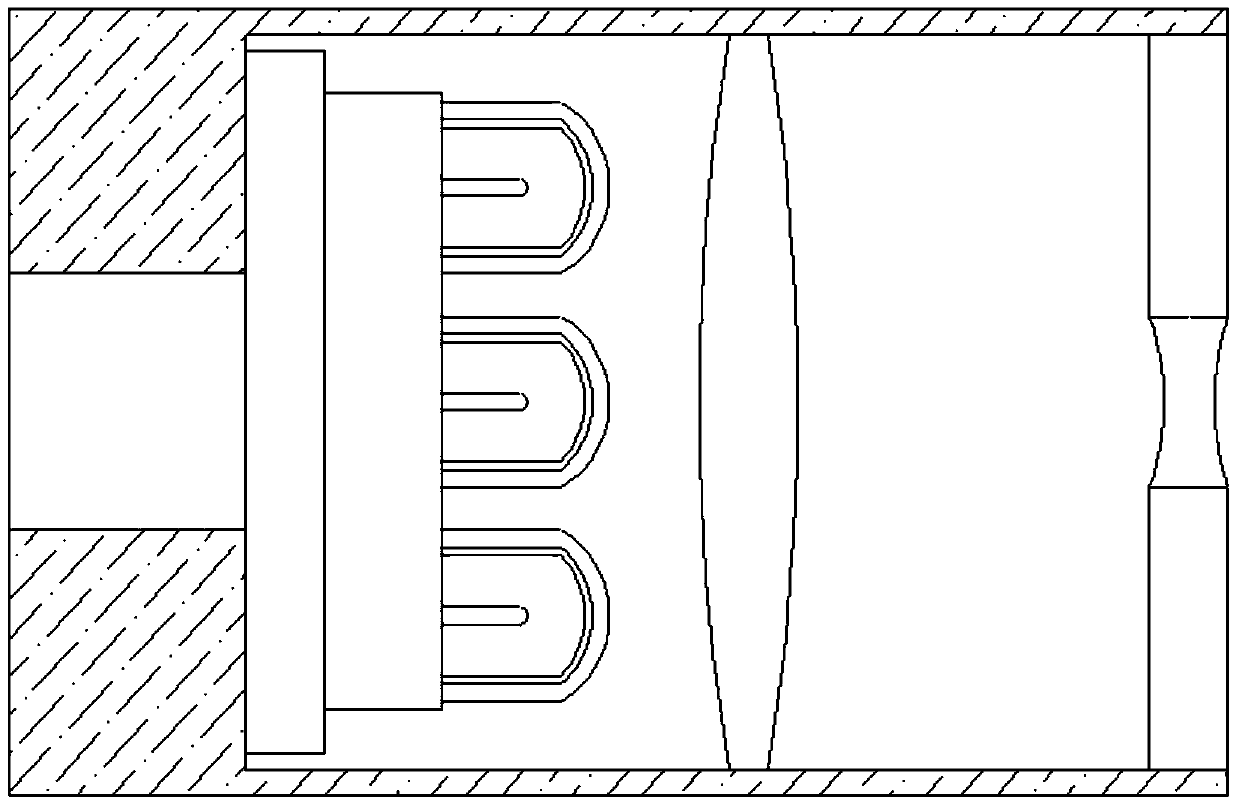

Multi-functional visualization experimental device for steam condensation heat transfer and frosting process

ActiveCN108469450ANo shape requirementImprove viewing angleMaterial heat developmentInvestigating phase/state changeSteam pressureSteam condensation

The invention belongs to the technical field of condensation heat transfer; a multi-functional visualization experimental device for steam condensation heat transfer and frosting process includes a vacuum environment system, a visualization system, a steam generation system, a gas supply system, a cooling system, a data acquisition and control system, an experimental sample and a fixture. The multi-functional visualization experimental device is a device capable of completing various steam condensation and frosting experiments; the device can be used for studying the influence of the content of multi-component non-condensable gas on condensation heat transfer, the influence of a material or surface structure on condensation heat transfer with or without non-condensable gas, condensation heat transfer with variable steam pressure and frosting phenomena and the like. At the same time, the shape of experimental samples is not needed, the observation viewing angle is large, and side shooting and high-angle shooting can be carried out at the same time.

Owner:DALIAN UNIV OF TECH

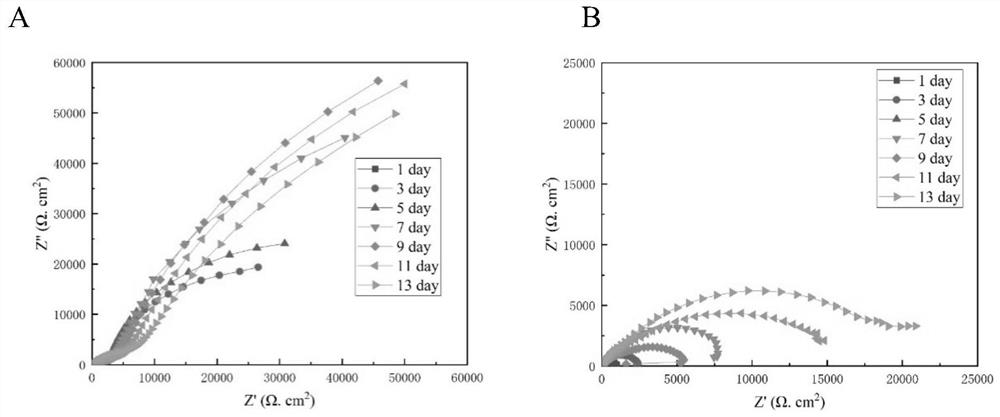

Biological corrosion inhibitor to inhibit corrosion of metal materials for seawater environment and anti-corrosion method

The invention relates to a biological corrosion inhibitor to inhibit corrosion of metal materials for the seawater environment and a protection method. The biological corrosion inhibitor contains pseudoalteromonaslipolytica which is harmless to human bodies and can form a stable organic-inorganic composite film with calcite structure on the surface of a metal material to significantly improve uniform corrosion resistance and pitting corrosion resistance of the metal material, and the film has self-reparation performance after formation. The operation is simple, dosage is little, and poison andpollution are avoided; requirements to shape and size of the processed metal material are not needed, traditional pollution-carrying surface treatment methods and corrosion inhibitors can be replaced, the metal corrosion protection cost and maintenance cost are greatly reduced, and metal structural material efficient environmentally friendly protection is achieved.

Owner:SHANGHAI MARITIME UNIVERSITY

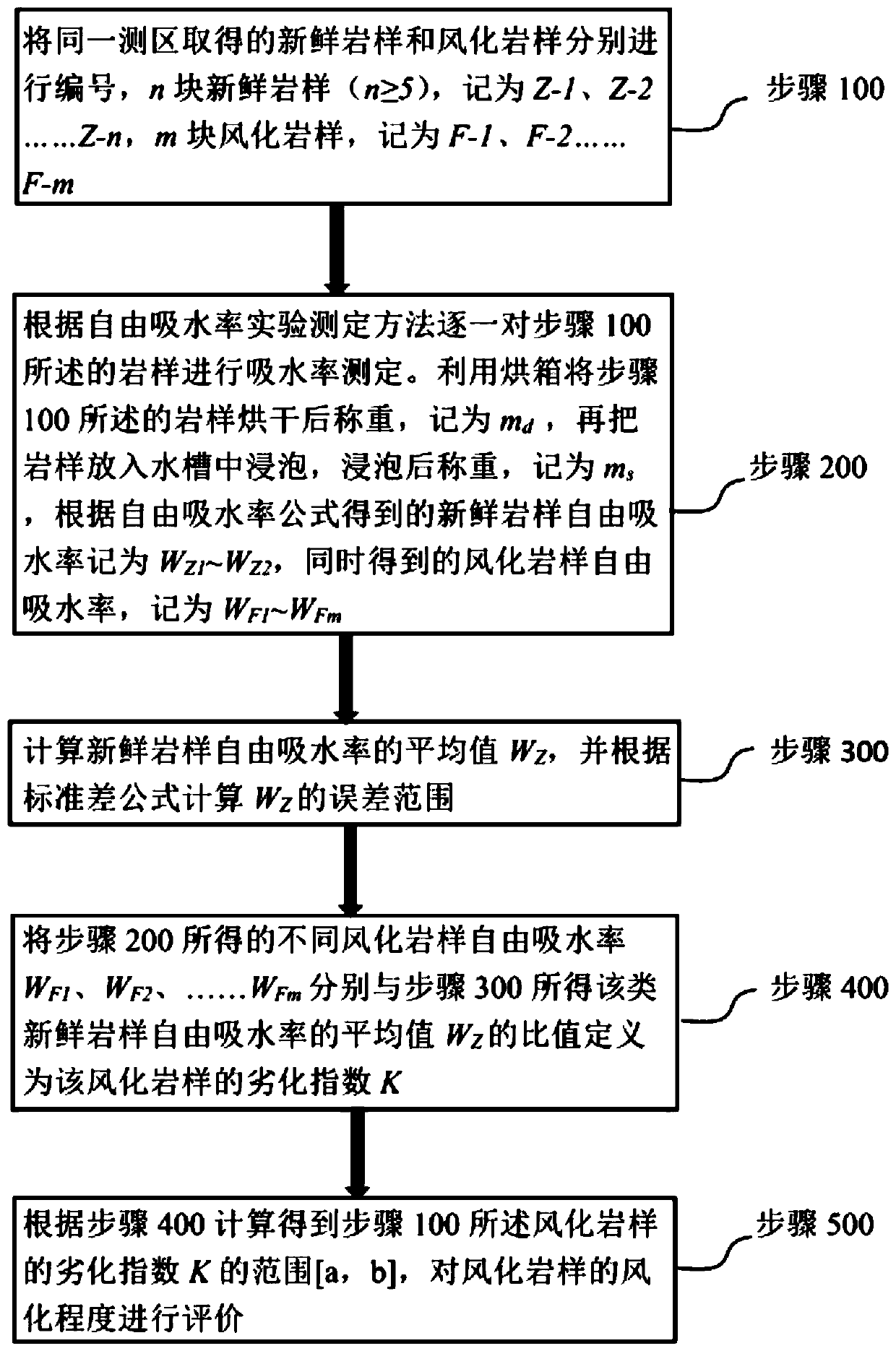

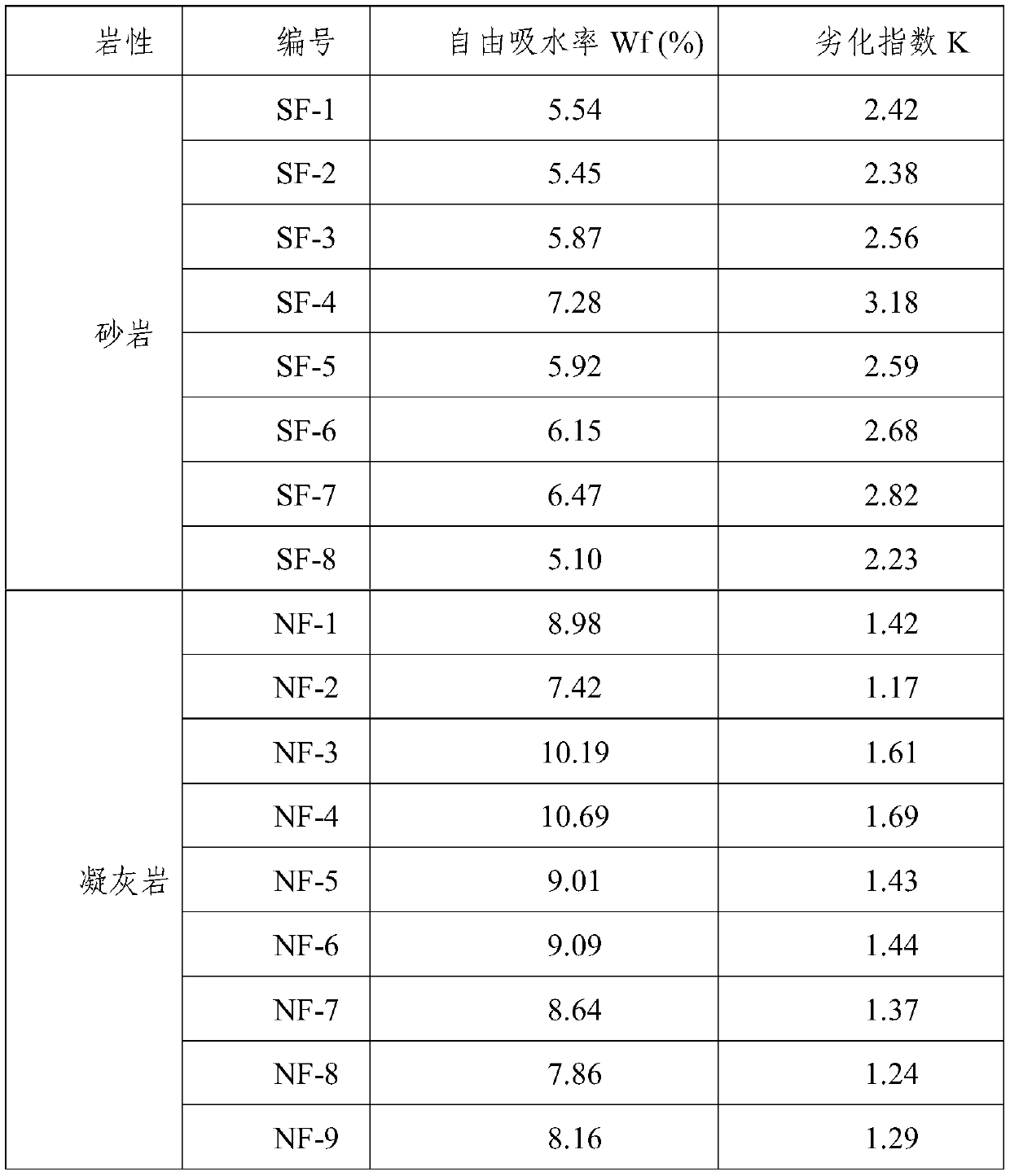

Method for quickly evaluating weathering degree of stone cultural relics

InactiveCN110927000AProtect IntegrityEasy to getWeighing by absorbing componentChemistrySoil science

The invention discloses a method for quickly evaluating the weathering degree of stone cultural relics. The method comprises the following steps: drying and weighing a weathered rock sample and a fresh rock sample in a drying oven; soaking the rock sample in water and weighing, and calculating the free water absorption rate of the rock sample; defining the ratio of the free water absorption of theweathered rock sample to the average value of the free water absorption of the fresh rock sample as the degradation index of the weathered rock sample; and determining the weathering degree grade ofthe weathered rock sample according to the degradation index range. The method is convenient to operate, and a quick, accurate and quantitative evaluation method for the weathering degree of the stonecultural relics is provided.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High wearing resistance normal-temperature cured bottom surface syncretic super-hydrophobic coating and preparation method thereof

Owner:SOUTHEAST UNIV +1

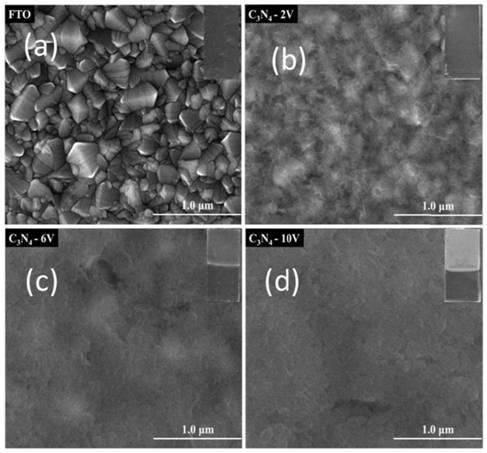

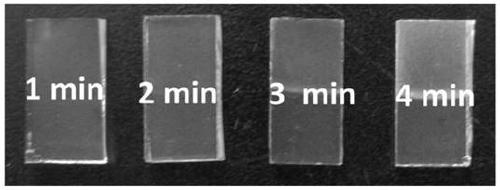

Method for preparing C3N4 film

InactiveCN109371446AControl thicknessNo shape requirementElectrophoretic coatingsElectrodesOrganic solventHigh volume manufacturing

The invention relates to a method for preparing a C3N4 film by depositing C3N4 colloidal particles onto a conductive substrate through an electrophoresis method and conducting subsequent annealing treatment with C3N4 colloid highly dispersed in an organic solvent as a precursor and a conductive material as a substrate. Different from published methods for preparing C3N4 films, raw materials are cheap and easy to obtain, the film is flat, compact, uniform and controllable in thickness and makes contact with the substrate well, the preparation process is quick, and mass production is facilitated. The C3N4 film obtained through the preparation method can be used as a C3N4 photoelectrode for reactions such as photoelectrochemical decomposition of water for hydrogen production and photocatalytic degradation of organic substances, and can also be used for purposes such as surface protection and modification of materials.

Owner:DALIAN MARITIME UNIVERSITY

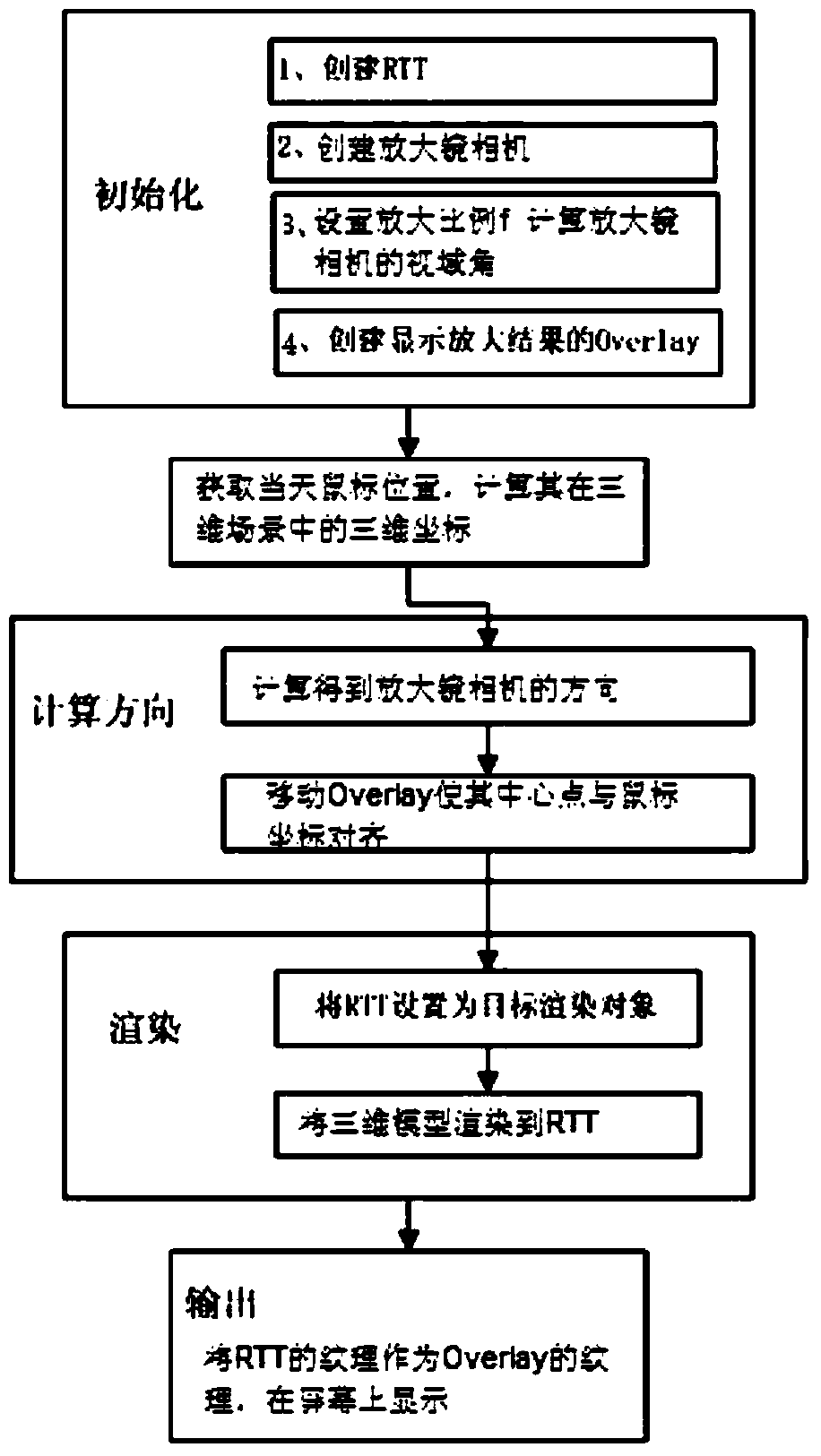

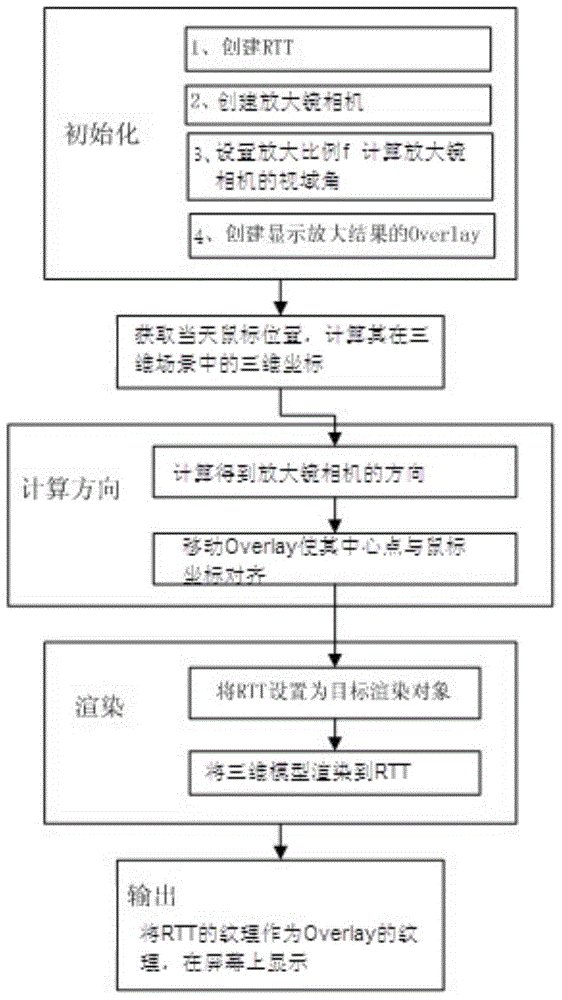

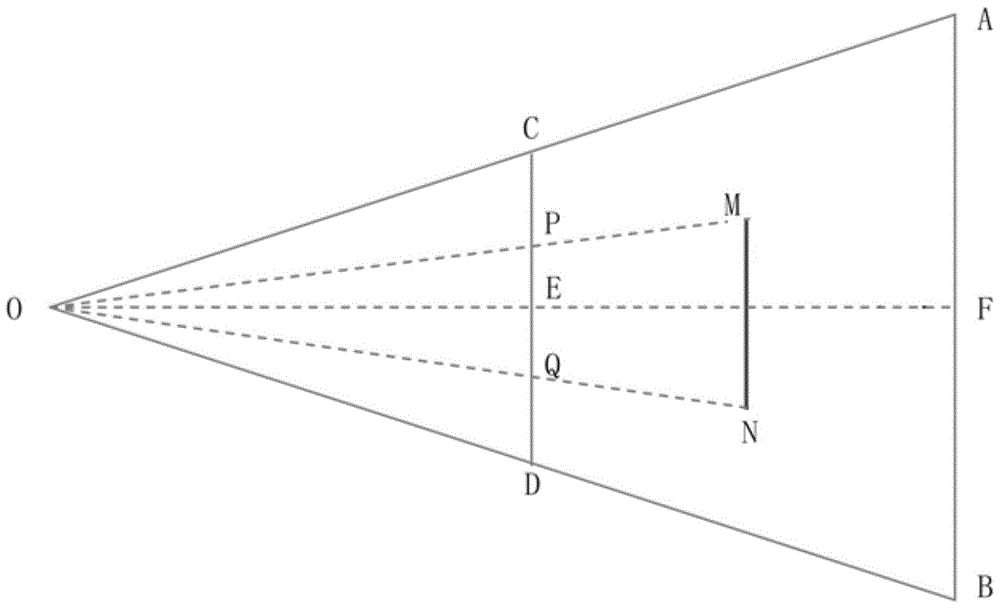

Three-dimensional scene lossless amplification method based on rendering to texture

ActiveCN104077741ANo shape requirementAdjustable magnification ratioGeometric image transformation3D-image renderingComputer graphics (images)Three dimensional model

The invention provides a three-dimensional scene lossless amplification method based on rendering to texture. The amplification ratio is set, the RTT is set to be a target rendering object, a three-dimensional model to be amplified is rendered to the RTT, the texture in the RTT serves as the texture of the Overlay and is displayed on a screen, and the lossless amplification process is completed. By means of the three-dimensional scene lossless amplification method based on rendering to texture, any local part of a three-dimensional scene can be amplified in a lossless mode, the amplification ratio can be regulated, and meanwhile the requirement for the shape of the model to be amplified in the three-dimensional scene does not exist.

Owner:武汉兆图科技有限公司

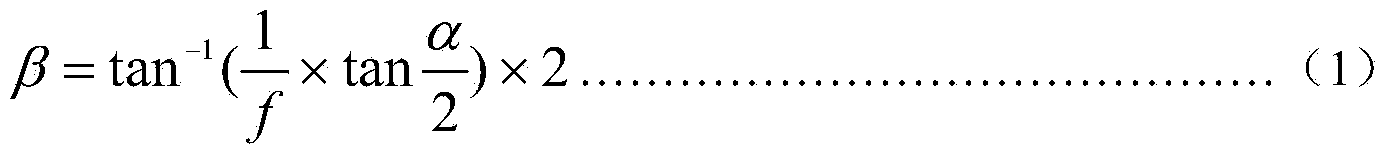

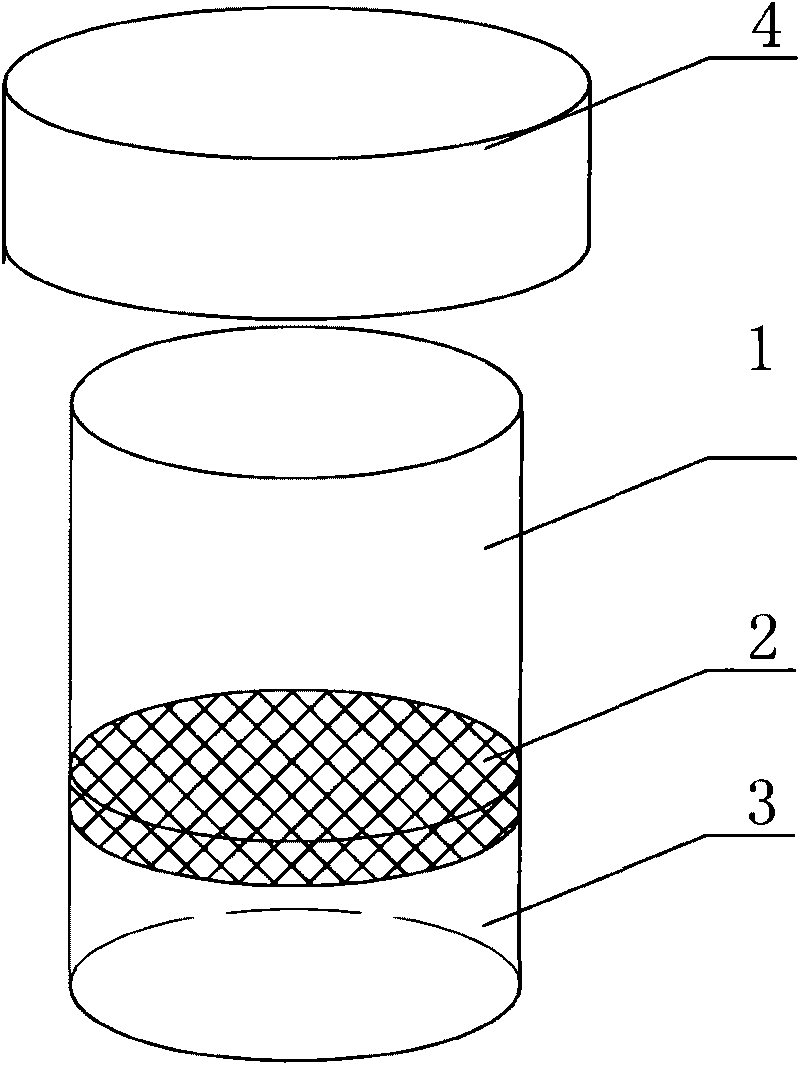

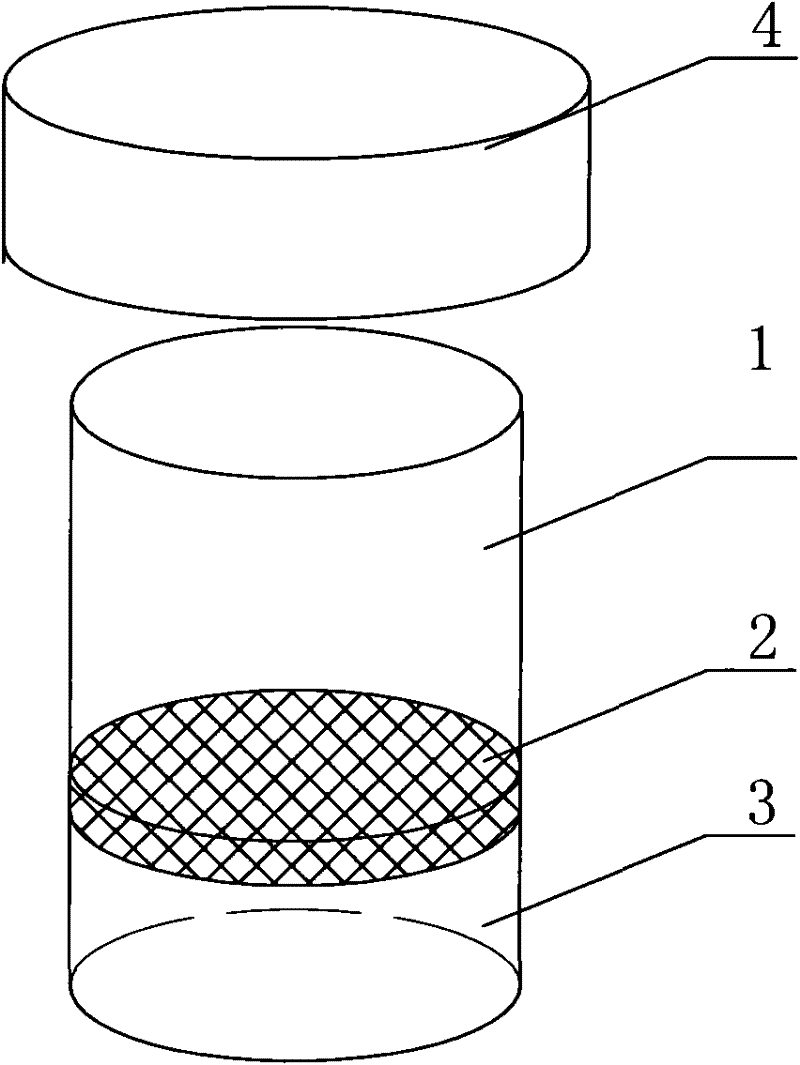

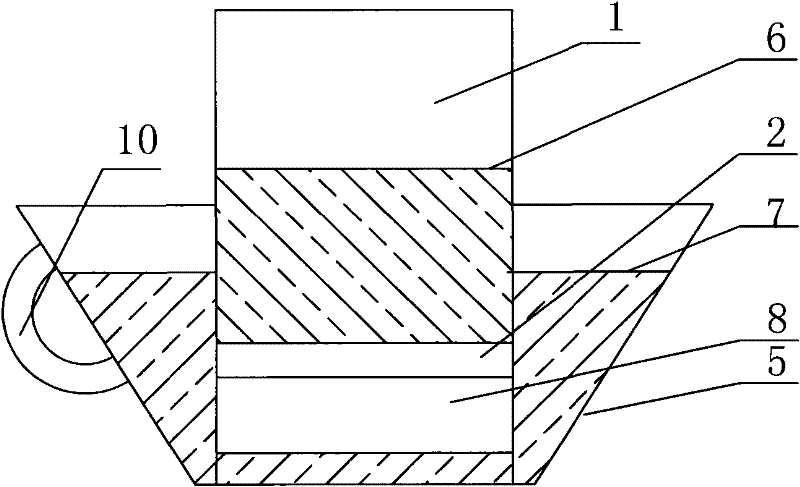

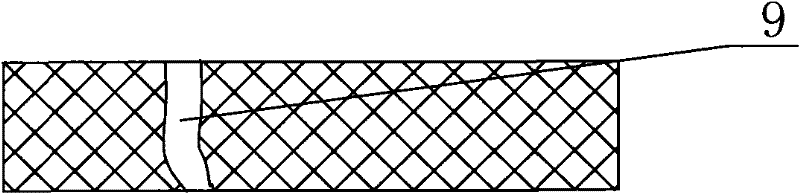

Brewer

The invention discloses a brewer which comprises an inner cup, an outer container, a filtering element and an extending part, wherein the inner cup is provided with a top opening for containing beverage to be brewed, the outer container is arranged outside the inner cup and used for containing brewing water, the filtering element is also used as the bottom of the inner cup, and the extending part is arranged below the inner cup and connected with the inner cup. When the extending part contacts with the outer container, a part of water filled in the inner cup flows into the outer container through the filtering element, a sealed air cavity is formed in a space below the bottom of the inner cup and above the bottom of the outer container by liquid flowing into the outer container, both the liquid level of outer liquid surface between the outer container and the inner cup and the liquid height of the inner liquid surface in the inner cup are not changed any more to realize static soaking of the beverage, and at the time, the inner liquid level is higher than the outer liquid level. The invention ensures that beverage to be brewed can be separated from brewing water, and has simple structure, convenient manufacture and no requirement on the shape of the outer container.

Owner:邢立勇

Method of treating magnesium alloy work-piece surface

InactiveCN100507076CRich in colorSave resourcesMetallic material coating processesTungstatePotassium

The invention provides a method for treating the surface of a magnesium alloy workpiece. The technological process includes workpiece pretreatment, chemical conversion treatment, drying treatment and water washing treatment between each process. Among them, the chemical conversion treatment is carried out by immersing the magnesium alloy workpiece in the conversion liquid composed of the main film-forming substance and the auxiliary film-forming substance; the main film-forming substance is a transition metal salt such as zirconium salt, manganese salt, molybdate, tungstate, etc. One or more of them, converted into Na2MoO4 2H2O content, the concentration is 5-150g / L; the auxiliary film-forming substance is one or more of the three alkali metal nitrates and sulfates of lithium, sodium and potassium , converted into LiNO3 content, the concentration is 0.5-20g / L; the pH value of the conversion solution is 2-6, the treatment temperature is 10-90°C, and the treatment time is 5-30 minutes. The surface film of the prepared magnesium alloy workpiece has both protective and decorative properties, and its corrosion resistance and bonding force with the paint film are not lower than the film obtained by the conversion solution containing Cr6+. Its color is diverse and the color uniformity and durability It is not inferior to the film layer obtained by electrolytic coloring or chemical dyeing.

Owner:CHONGQING UNIV

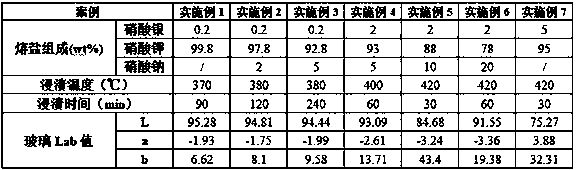

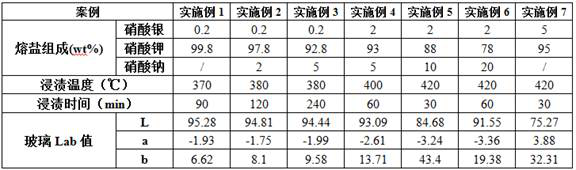

Ion diffusion coloring agent and application thereof

ActiveCN109678362AReduce the temperatureReduce manufacturing costManufacturing technologyMolten salt

The invention belongs to the technical field of manufacturing of glass products, and particularly relates to an ion diffusion coloring agent and application thereof. By adopting a molten salt dippingmethod, glass original sheets or glass products subjected to high-temperature annealing treatment are dipped into molten salt formed by mixing silver salt and other salt, the energy consumption of theion diffusion coloring process is reduced, Ag ions can be effectively diffused with the original Na and K ions in the glass, and yellow and brownish red colored glass sheets or glass products are obtained. The coloring method is simple to operate, special requirements on vessel materials are not needed, and the glass sheets and the glass products with different shapes, different sizes and different materials can be colored simultaneously. In the experiment process, the temperature is relatively low, energy consumption is reduced, the production cost is reduced and an excellent coloring effectis achieved.

Owner:KORNERSTONE MATERIALS TECH

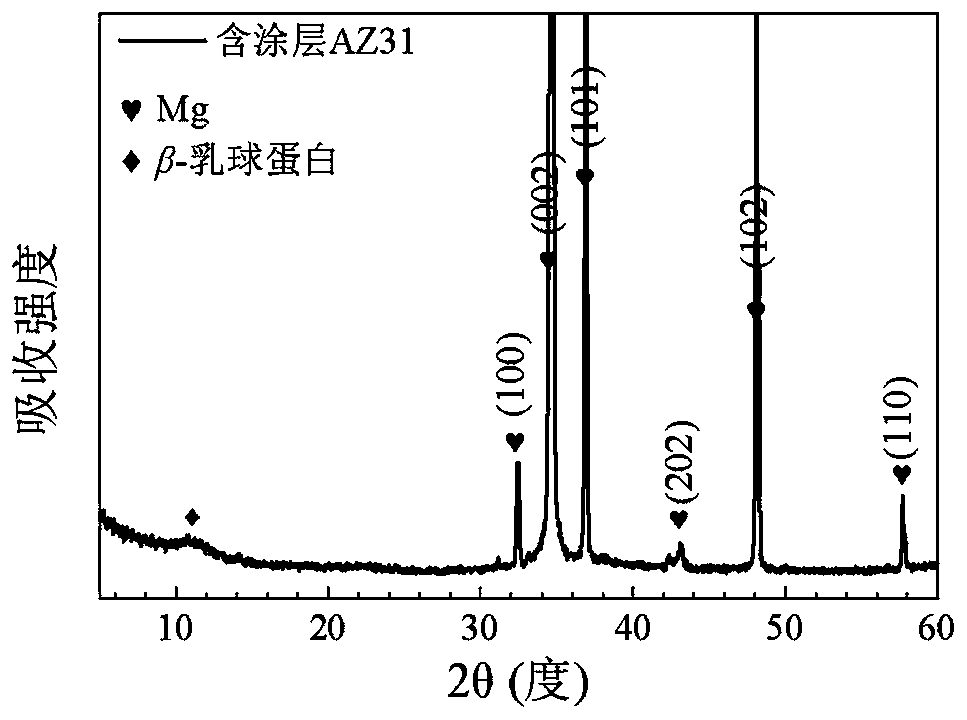

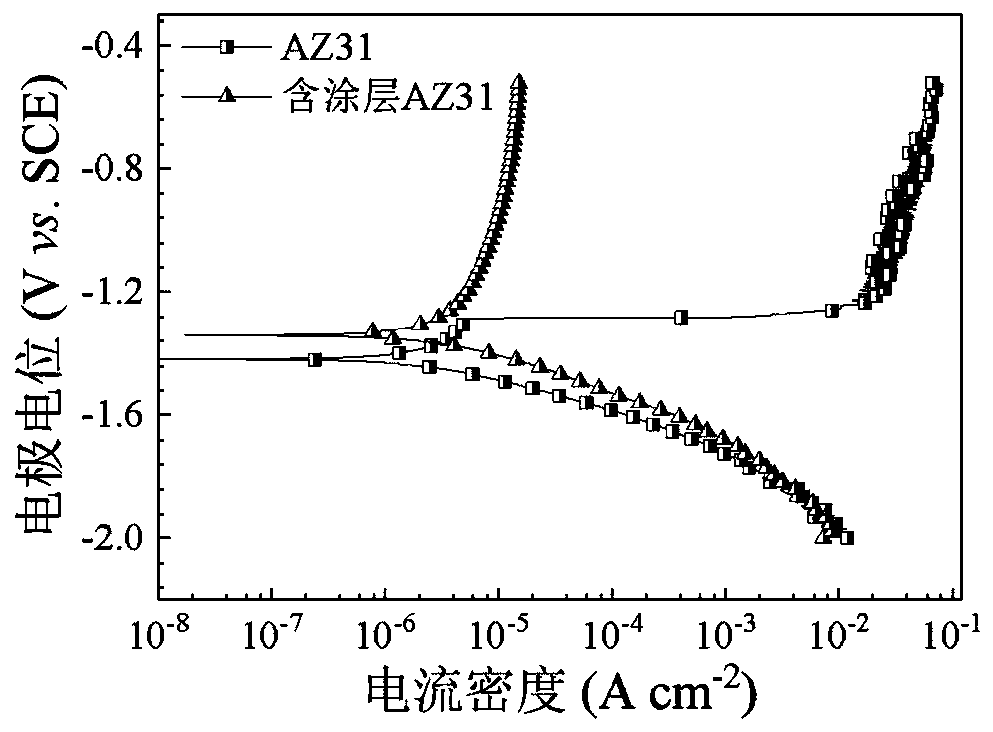

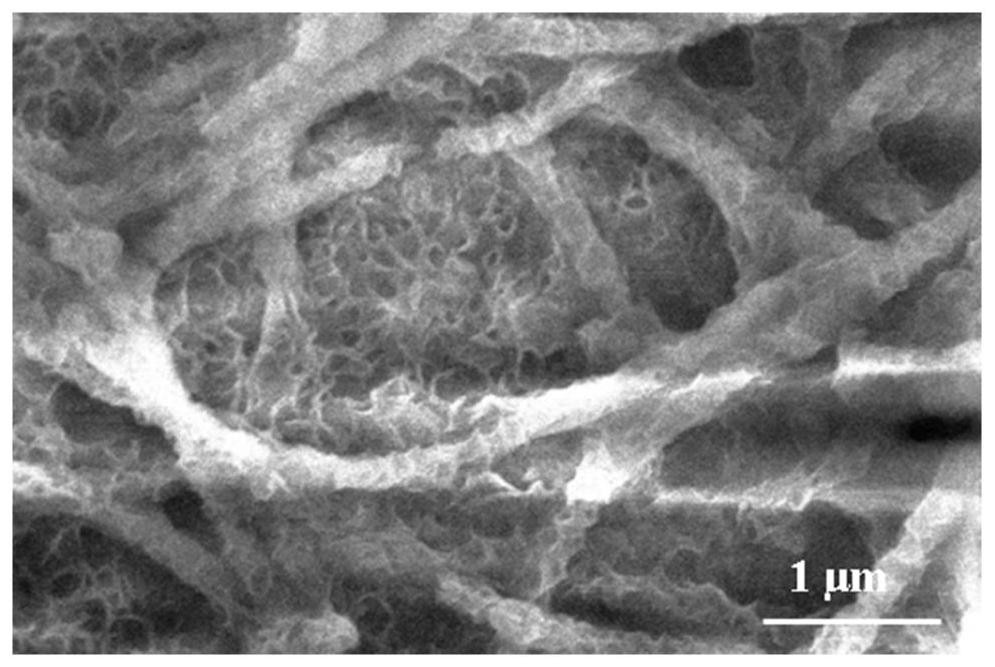

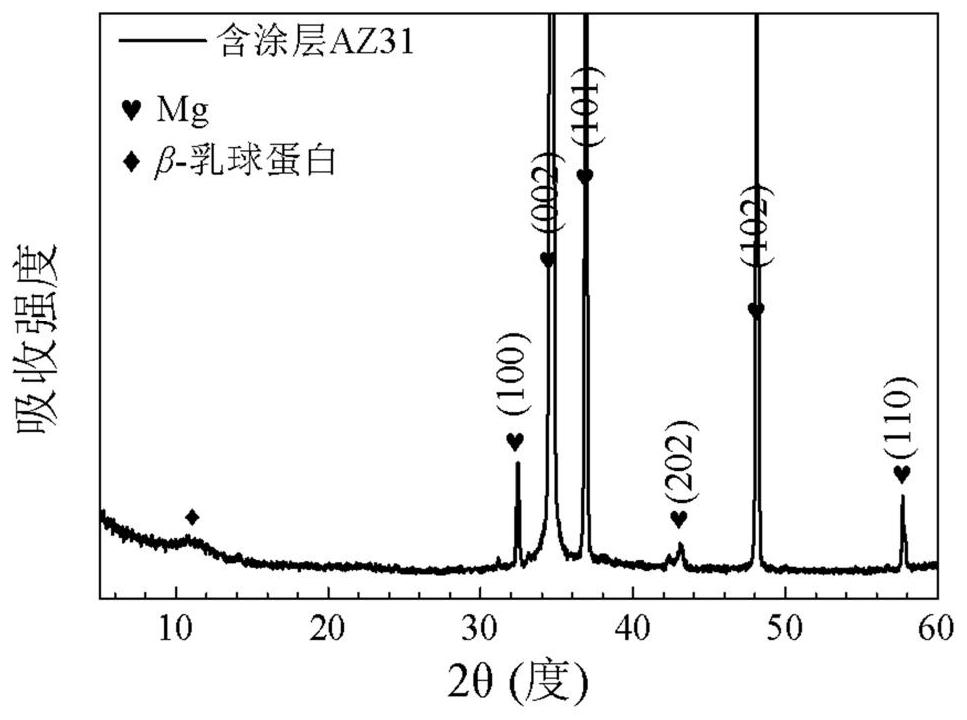

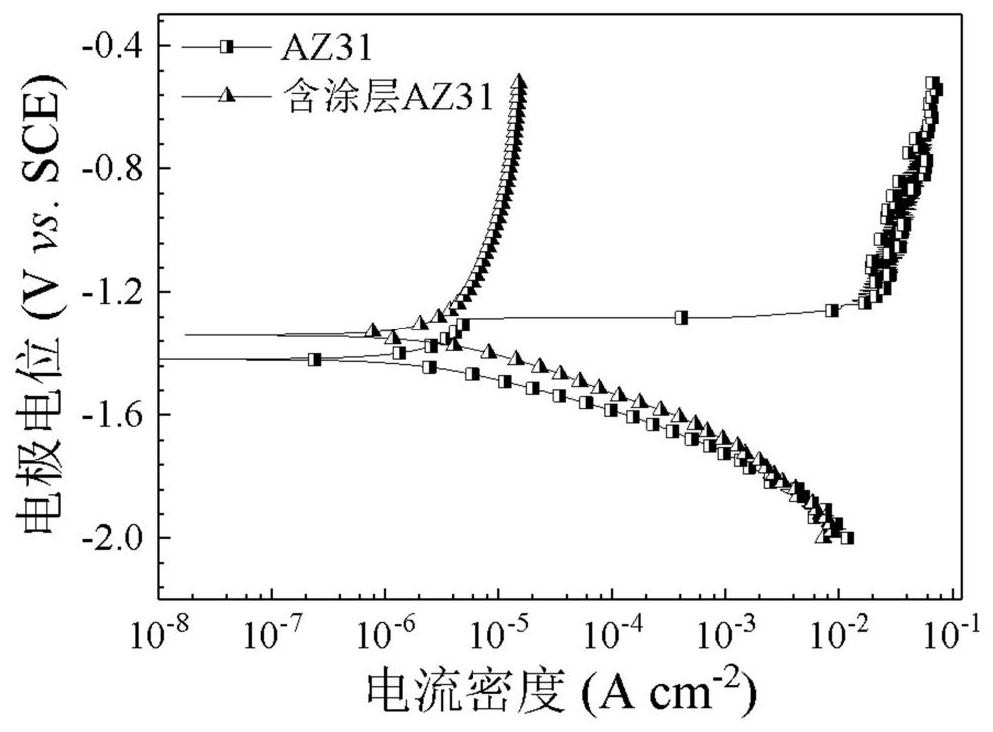

Preparation method of in-situ synthesized self-repairing magnesium alloy corrosion-resistant coating

The invention provides a preparation method of an in-situ synthesized self-repairing magnesium alloy corrosion-resistant coating. The method comprises the following specific steps: S1, using an electrospark wire cutting machine to cut magnesium alloy into a small cylindrical magnesium alloy matrix=, using different models of abrasive paper to grind and polish the small magnesium alloy cylindricalmatrix for four times, and using absolute ethyl alcohol for cleaning; S2, dissolving weighed protein powder into deionized water in a conical flask, and using a magnetic stirrer to stir a mixed solution so as to prepare a protein solution with a certain concentration; and S3, soaking the small cylindrical magnesium alloy matrix in a prepared protein solution, reacting for 1-12 hours under ultraviolet irradiation, enabling some groups in the protein to react with the surface of the small cylindrical magnesium alloy matrix, carrying out drying in a forced air drying oven after the reaction, andgenerating a layer of composite fiber membrane on the surface of the small cylindrical magnesium alloy matrix in situ. The preparation method is simple and efficient, is suitable for corrosion prevention of all general magnesium alloys, and is especially suitable for long-term corrosion prevention of magnesium alloys in a humid environment.

Owner:YANSHAN UNIV

Preparation method of self-healing magnesium alloy corrosion-resistant coating by in-situ synthesis

The invention provides a preparation method of an in-situ synthesized self-repairing magnesium alloy corrosion-resistant coating. The method comprises the following specific steps: S1, using an electrospark wire cutting machine to cut magnesium alloy into a small cylindrical magnesium alloy matrix=, using different models of abrasive paper to grind and polish the small magnesium alloy cylindricalmatrix for four times, and using absolute ethyl alcohol for cleaning; S2, dissolving weighed protein powder into deionized water in a conical flask, and using a magnetic stirrer to stir a mixed solution so as to prepare a protein solution with a certain concentration; and S3, soaking the small cylindrical magnesium alloy matrix in a prepared protein solution, reacting for 1-12 hours under ultraviolet irradiation, enabling some groups in the protein to react with the surface of the small cylindrical magnesium alloy matrix, carrying out drying in a forced air drying oven after the reaction, andgenerating a layer of composite fiber membrane on the surface of the small cylindrical magnesium alloy matrix in situ. The preparation method is simple and efficient, is suitable for corrosion prevention of all general magnesium alloys, and is especially suitable for long-term corrosion prevention of magnesium alloys in a humid environment.

Owner:YANSHAN UNIV

A Lossless Enlargement Method of 3D Scene Based on Rendering to Texture

ActiveCN104077741BNo shape requirementAdjustable magnification ratioGeometric image transformation3D-image renderingComputer graphics (images)Three dimensional model

The invention provides a three-dimensional scene lossless amplification method based on rendering to texture. The amplification ratio is set, the RTT is set to be a target rendering object, a three-dimensional model to be amplified is rendered to the RTT, the texture in the RTT serves as the texture of the Overlay and is displayed on a screen, and the lossless amplification process is completed. By means of the three-dimensional scene lossless amplification method based on rendering to texture, any local part of a three-dimensional scene can be amplified in a lossless mode, the amplification ratio can be regulated, and meanwhile the requirement for the shape of the model to be amplified in the three-dimensional scene does not exist.

Owner:武汉兆图科技有限公司

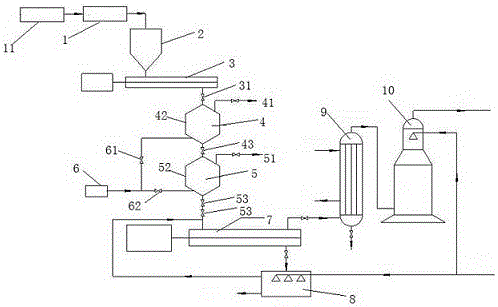

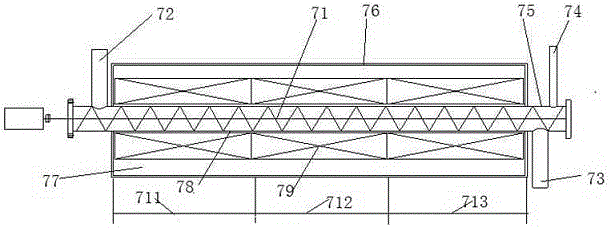

Electronic waste disposal system and method

PendingCN106540953AStabilizationContinuous processingSolid waste disposalTransportation and packagingCooling towerSlag

The invention relates to the field of pyrolysis, in particular to an electronic waste disposal system and method. The system comprises a breaking and sorting device, a feeding device, a stock bin, an intermediate storage tank, a reactor, a cooling chamber, an indirect heat exchanger and a cooling tower; the breaking and sorting device is connected with the feeding device, the intermediate storage tank is connected with the stock bin, the intermediate storage tank is connected with a feeding opening in the upper portion of the reactor, a slag outlet in the lower portion of the reactor is connected with the cooling chamber, a gas outlet of the cooling chamber is connected with the feeding opening of the reactor, the indirect heat exchanger is connected with an oil and gas outlet of the reactor, and the cooling tower is connected with the indirect heat exchanger. Therefore, electronic waste can be stably, continuously and efficiently disposed, the requirements for different treatment amounts can be met according to needs, in the pyrolysis process, the materials are stirred in the reactor along with a spiral propeller, heating is uniform, and pyrolysis is sufficient.

Owner:SHENWU TECH GRP CO LTD

A kind of biological fungicide for crude oil transportation pipeline and its application

Owner:GUANGZHOU MARITIME INST

Method for preparing agaricus bisporus powder and application thereof

InactiveCN102204667BSize is not requiredNo shape requirementFood preparationSulfite saltSodium sulfite

The invention provides a method for preparing agaricus bisporus powder and application thereof, and belongs to the technical field of food processing. The method comprises the following steps of: cleaning fresh agaricus bisporus, chopping the agaricus bisporus into pieces, soaking the agaricus bisporus pieces in color protecting solution of sodium D-isoascorbate, sodium sulfite and citric acid, drying and dehydrating the agaricus bisporus pieces by blowing air, and superfine grinding the dehydrated agaricus bisporus pieces to obtain the agaricus bisporus powder. The agaricus bisporus powder can be used to prepare noodles, bean strips, breads, biscuits and various puffed food.

Owner:HUAZHONG AGRI UNIV

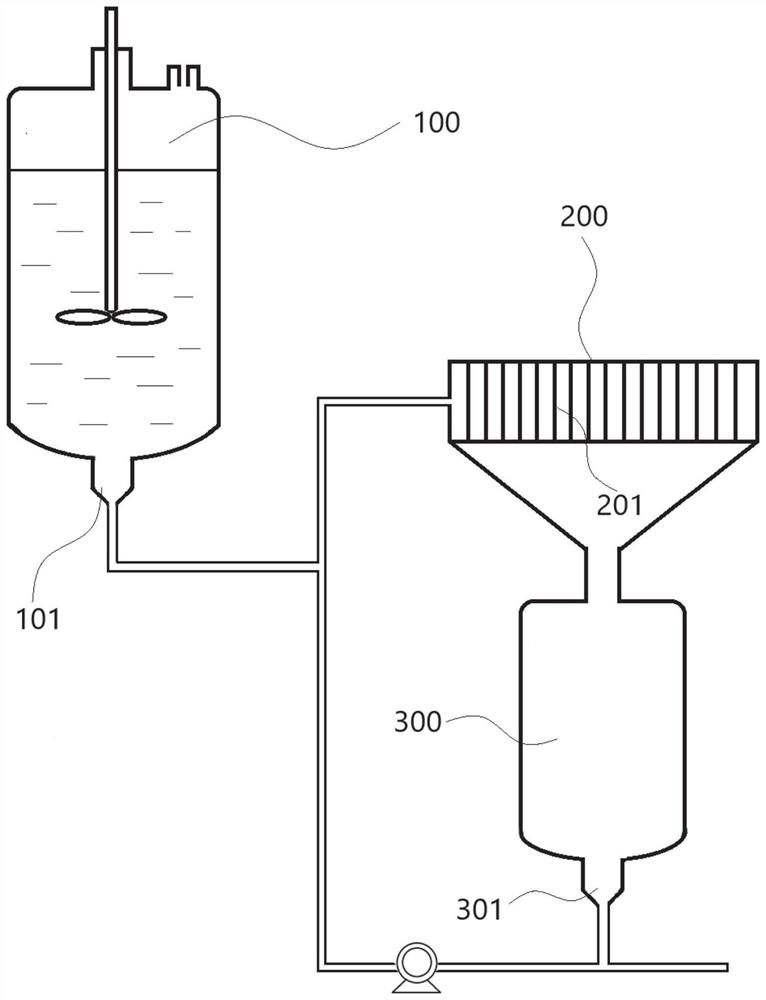

Method and device for intermittently removing heavy metals in wastewater

InactiveCN112978970AImprove toleranceNo shape requirementWater contaminantsTreatment involving filtrationIndustrial waste waterSorbent

The invention discloses a method and a device for intermittently removing heavy metals in wastewater. The method comprises the following steps: a) contacting heavy metal-containing wastewater with an adsorbent, and adsorbing to obtain a solid-liquid mixture; b) carrying out plate frame filtration on the solid-liquid mixture to realize solid-liquid separation to obtain filtrate and a filtering cake containing heavy metals; and c) monitoring the concentration of heavy metals in the filtrate, and directly discharging the filtrate if the concentration of the heavy metals in the filtrate meets a preset standard; and if the heavy metal concentration in the filtrate does not meet the preset standard, repeating the step a) until the heavy metal concentration in the filtrate meets the preset standard. According to the method, through the intermittent circulation process of adsorption, filtration, detection and discharge / readsorption, the universality of the adsorbent is perfectly solved by skillfully applying the plate-and-frame filtering, so that the method can be widely applied to the field of removal of heavy metals in industrial wastewater.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multifunctional Steam Condensation Heat Exchange and Frosting Process Visualization Experimental Device

ActiveCN108469450BNo shape requirementImprove viewing angleMaterial heat developmentInvestigating phase/state changeSteam condensationSteam pressure

The invention belongs to the technical field of condensation heat transfer; a multi-functional visualization experimental device for steam condensation heat transfer and frosting process includes a vacuum environment system, a visualization system, a steam generation system, a gas supply system, a cooling system, a data acquisition and control system, an experimental sample and a fixture. The multi-functional visualization experimental device is a device capable of completing various steam condensation and frosting experiments; the device can be used for studying the influence of the content of multi-component non-condensable gas on condensation heat transfer, the influence of a material or surface structure on condensation heat transfer with or without non-condensable gas, condensation heat transfer with variable steam pressure and frosting phenomena and the like. At the same time, the shape of experimental samples is not needed, the observation viewing angle is large, and side shooting and high-angle shooting can be carried out at the same time.

Owner:DALIAN UNIV OF TECH

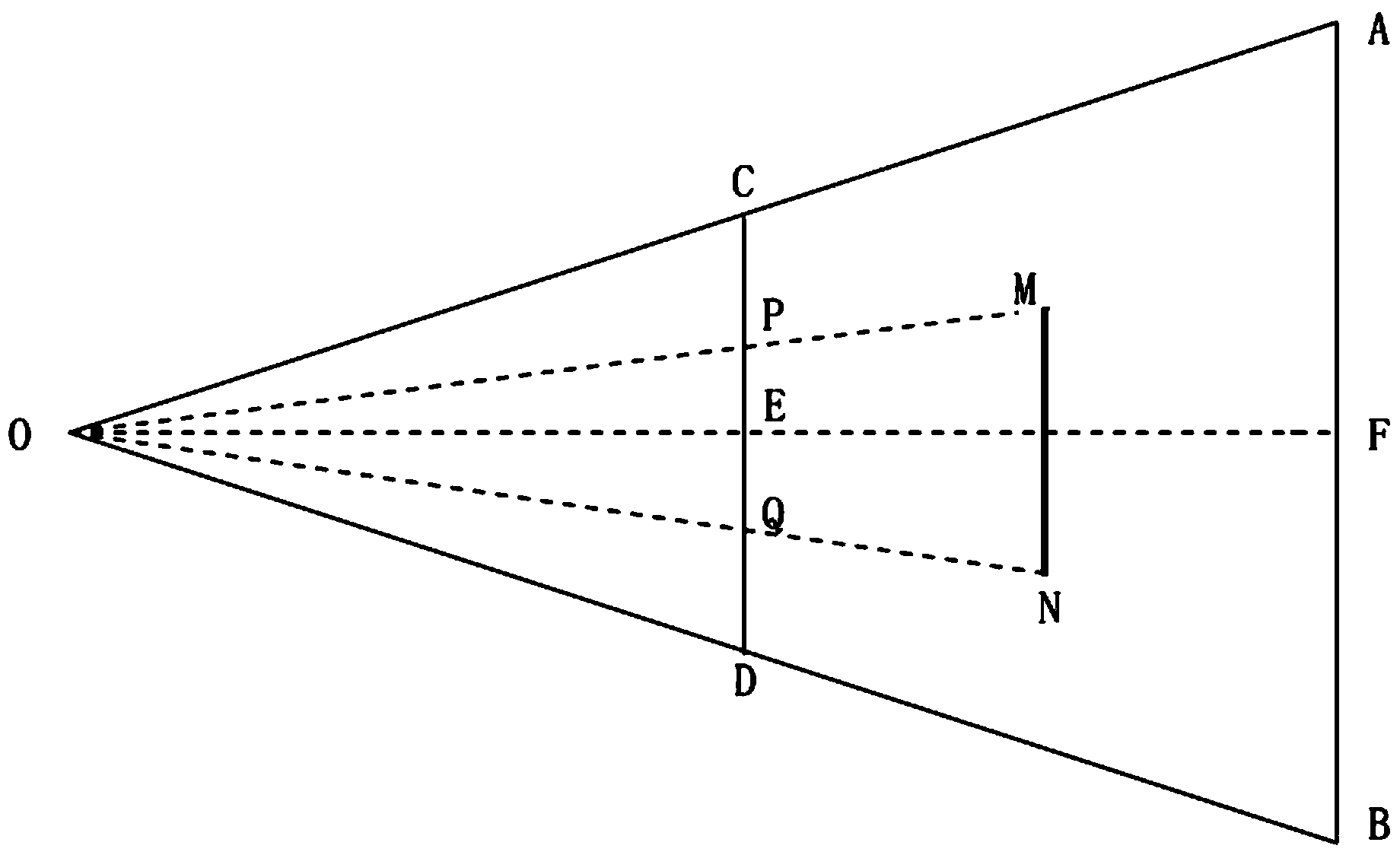

Handheld volume measuring device based on linear laser

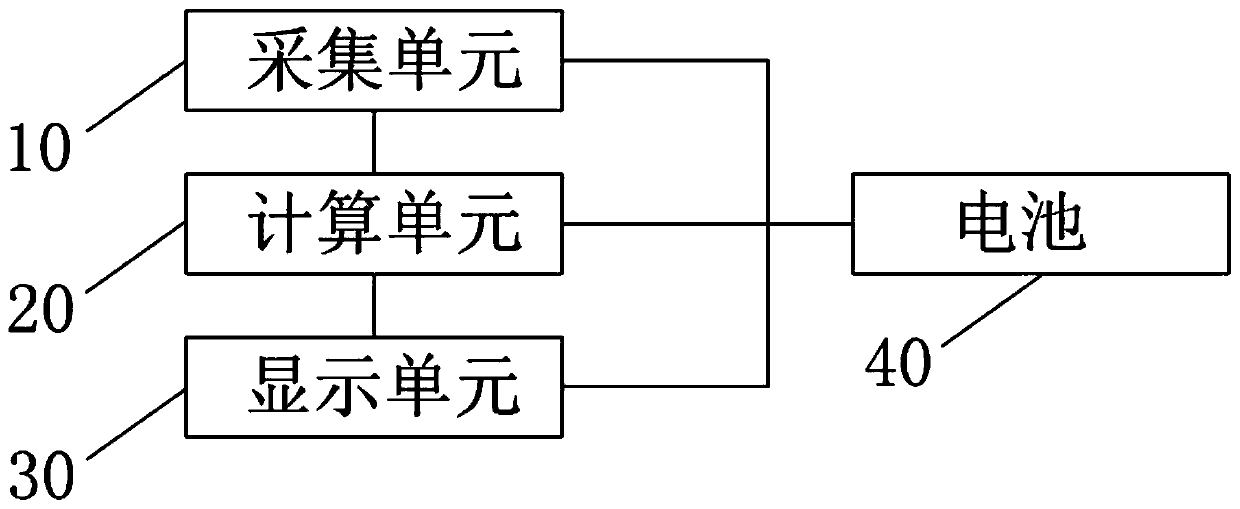

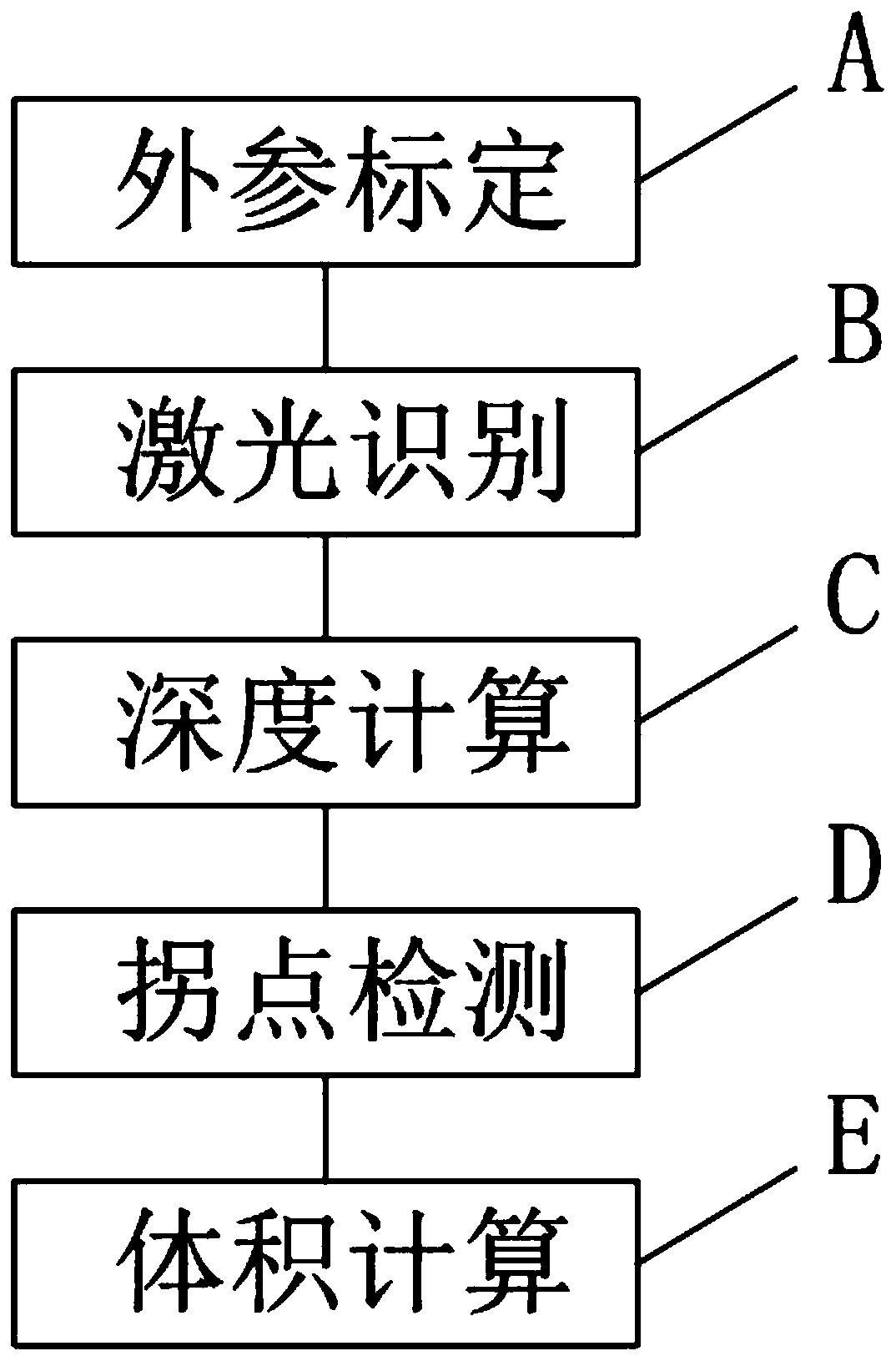

PendingCN111598957AImprove measurement accuracyNo shape requirementImage analysisContainer/cavity capacity measurementComputer hardwareColor image

The invention relates to the field of computer vision, in particular to a handheld volume measuring device based on linear laser, which comprises an acquisition unit for emitting linear laser, scanning a measured object through the linear laser and acquiring a color image of the measured object; a calculation unit which is electrically connected with the acquisition unit, and is used for calculating the volume of the object through the color image transmitted by the acquisition unit; a display unit which is electrically connected with the calculation unit, and is used for displaying the colorimage acquired by the acquisition unit and displaying a calculation result; and a battery which is electrically connected with the acquisition unit, the calculation unit and the display unit and supplies power to the acquisition unit, the calculation unit and the display unit. The handheld volume measuring device can realize full-automatic measurement, does not depend on manpower, is high in measurement accuracy, has no requirement on the shape of the material of an object, is flexible and convenient to hold by hand, can complete volume measurement without a depth camera, and greatly reduces the cost.

Owner:武汉市异方体科技有限公司

A crop nutrition safety detection device

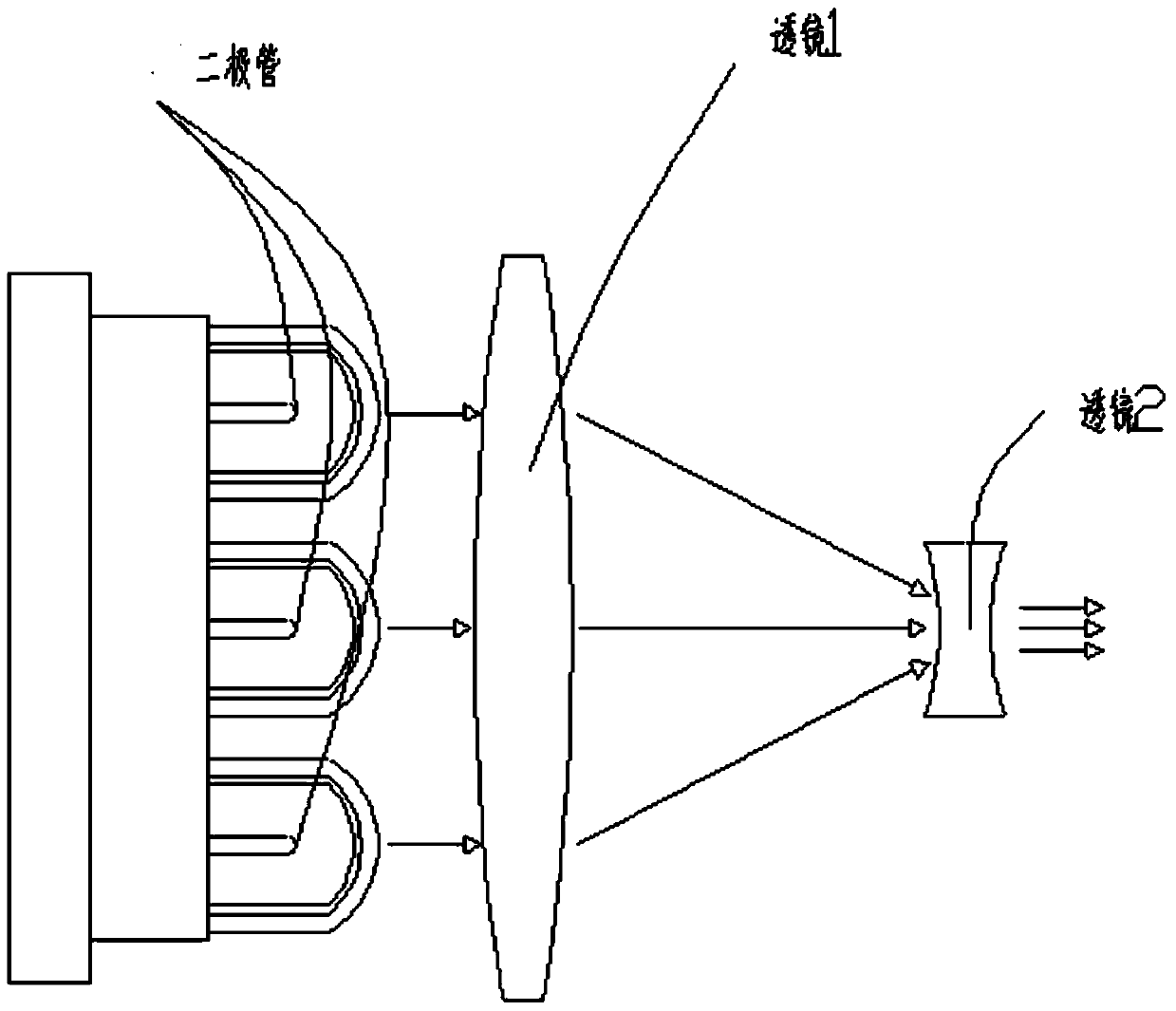

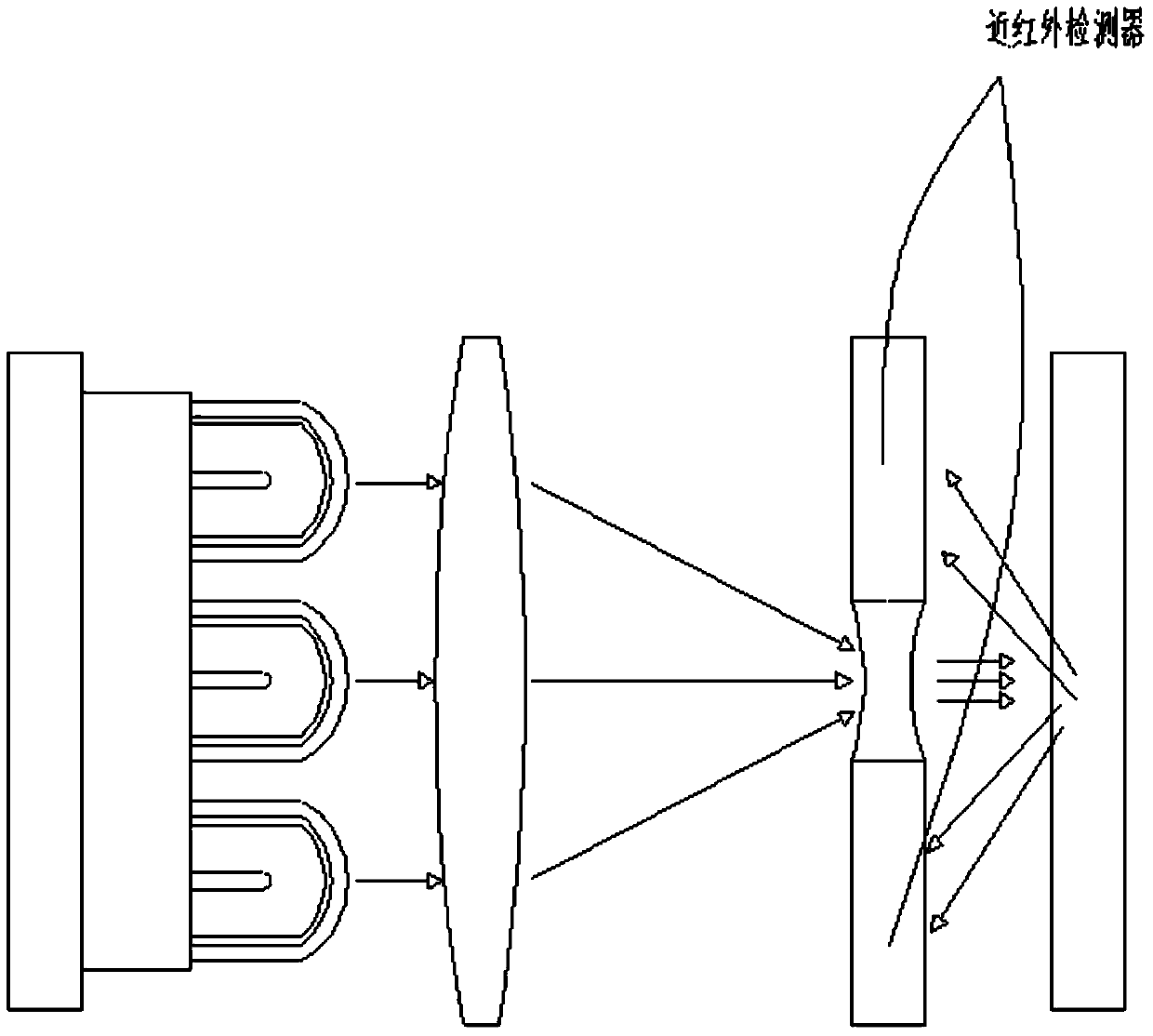

InactiveCN105866066BEvenly arrangedQuantity is easy to controlMaterial analysis by optical meansEngineeringLight-emitting diode

The invention discloses a crop-nutrition security detection device. A light emitting diode serves as a light source, as near-infrared light emitted by the light emitting diode is near-infrared light with the single-frequency-band wave length, if the content of some ingredient is detected, only one or two or three light emitting diodes are matched to be capable of completing detection, and if the device is adopted, near-infrared full spectrum collection is not required; meanwhile, the more pertinence is achieved, if the multiple ingredients are detected, the multiple near-infrared light emitting diodes can be preset; according to the preset procedure, some one or several light emitting diodes are projected when detection is determined, and the multiple near-infrared light emitting diodes can be arranged in an array mode and can also be arranged in a single arrangement mode.

Owner:SHENZHEN KUNLUN BUSINESS INVESTMENT CO LTD

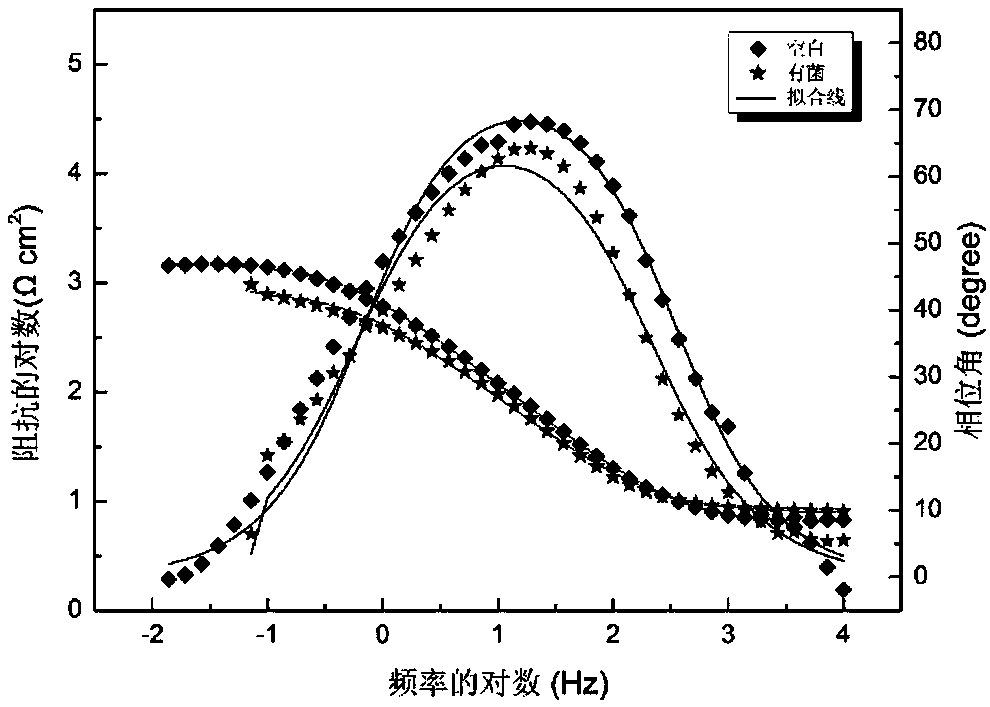

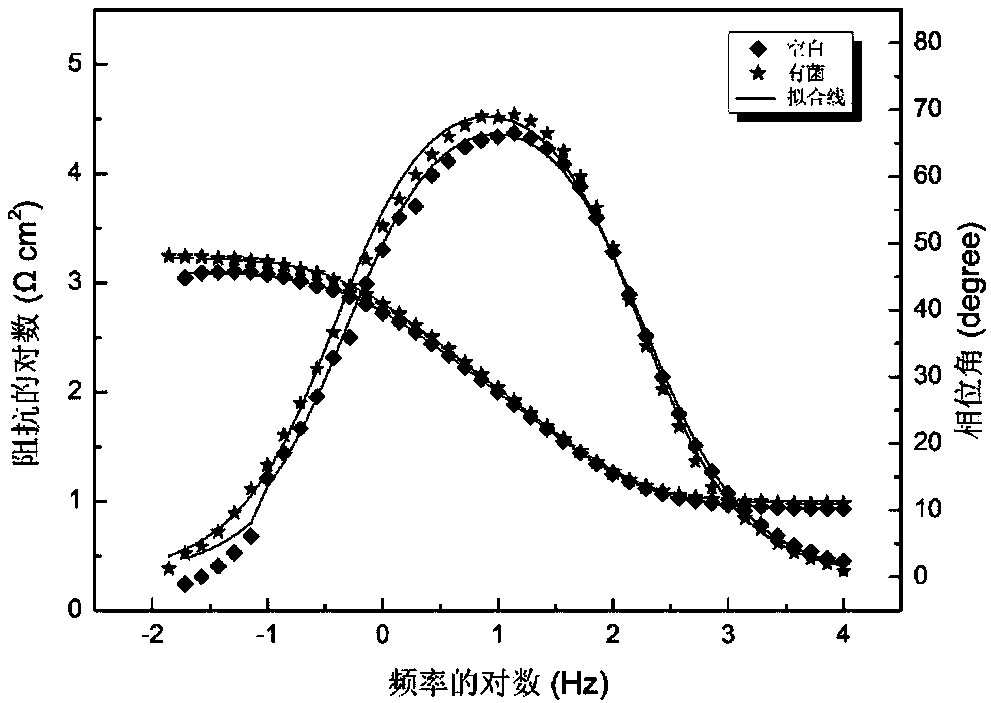

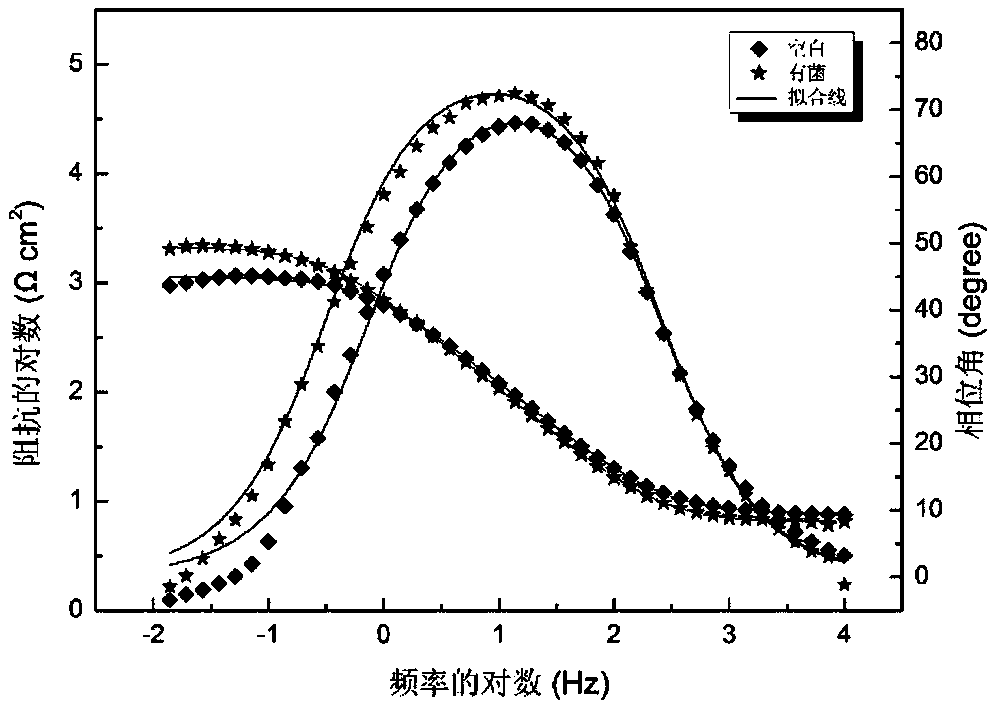

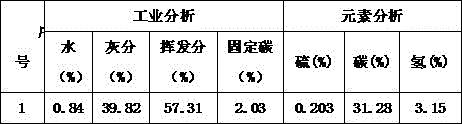

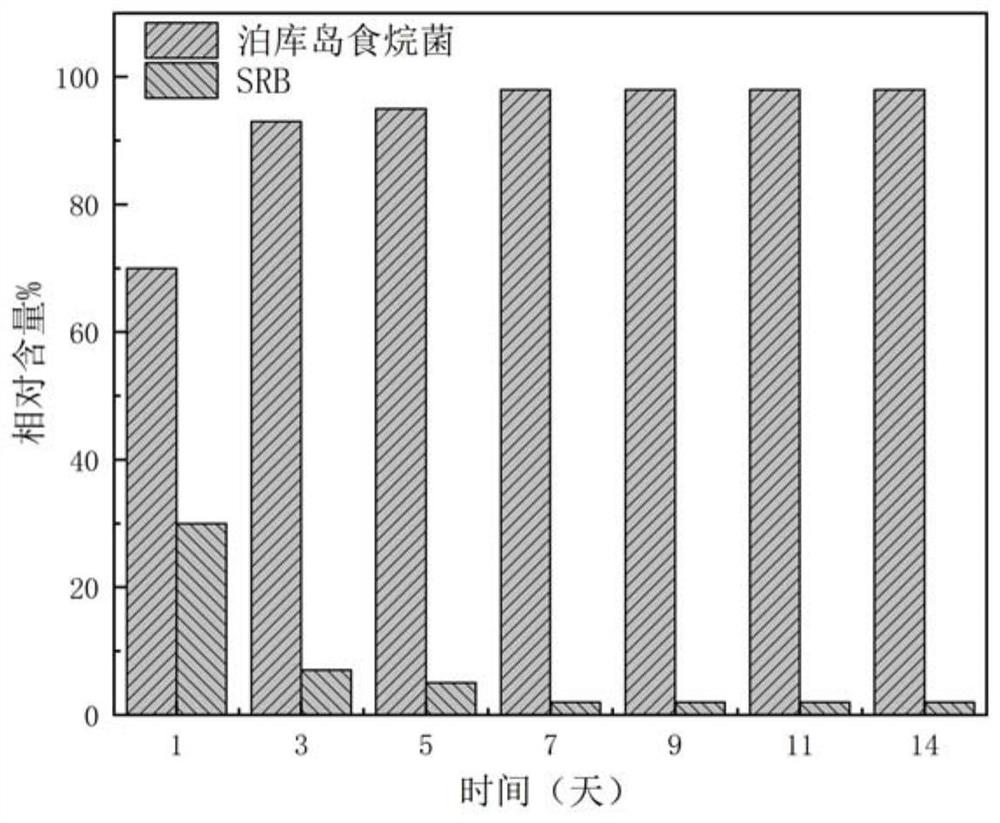

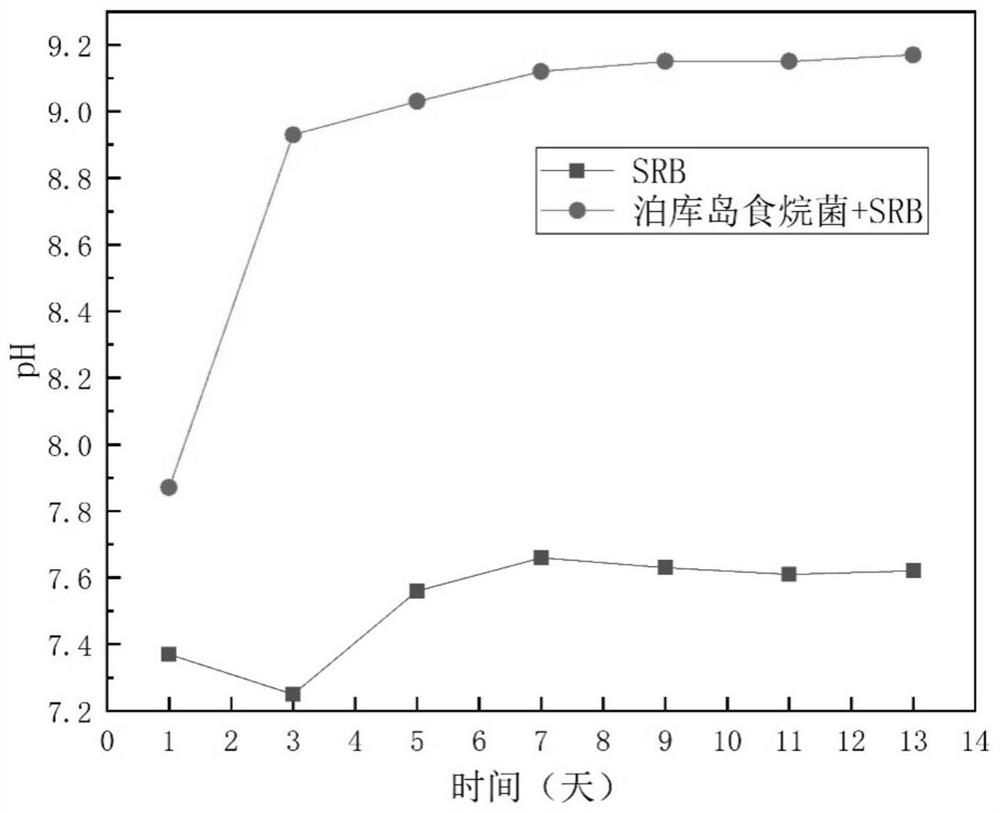

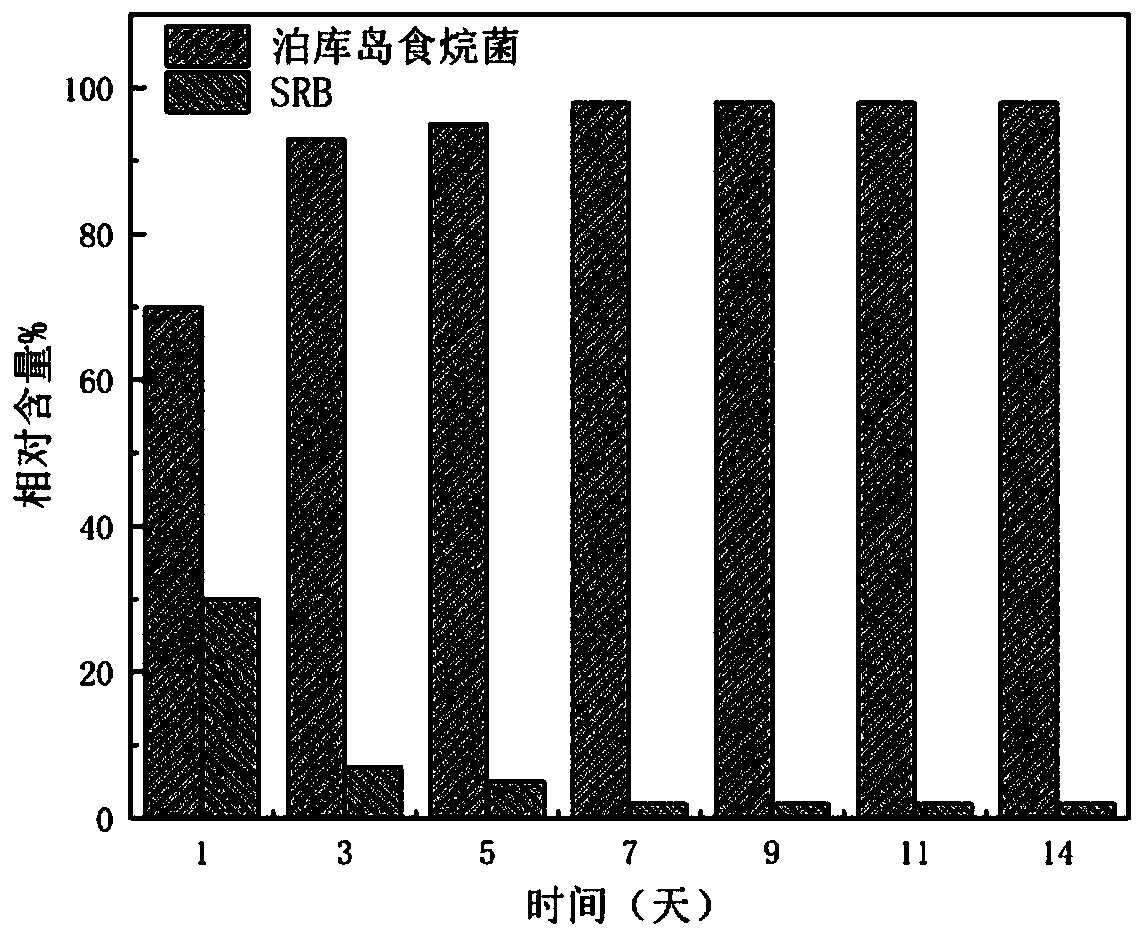

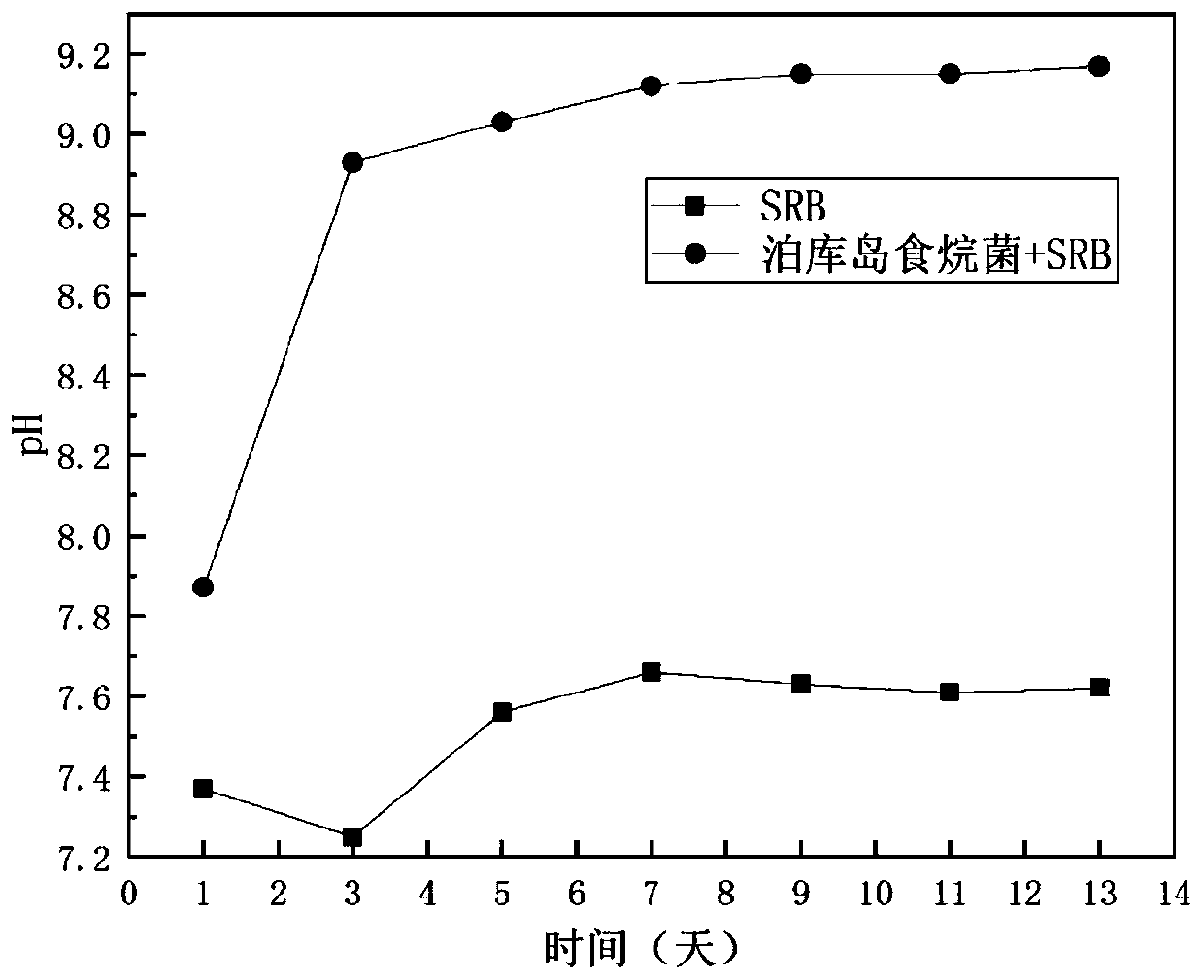

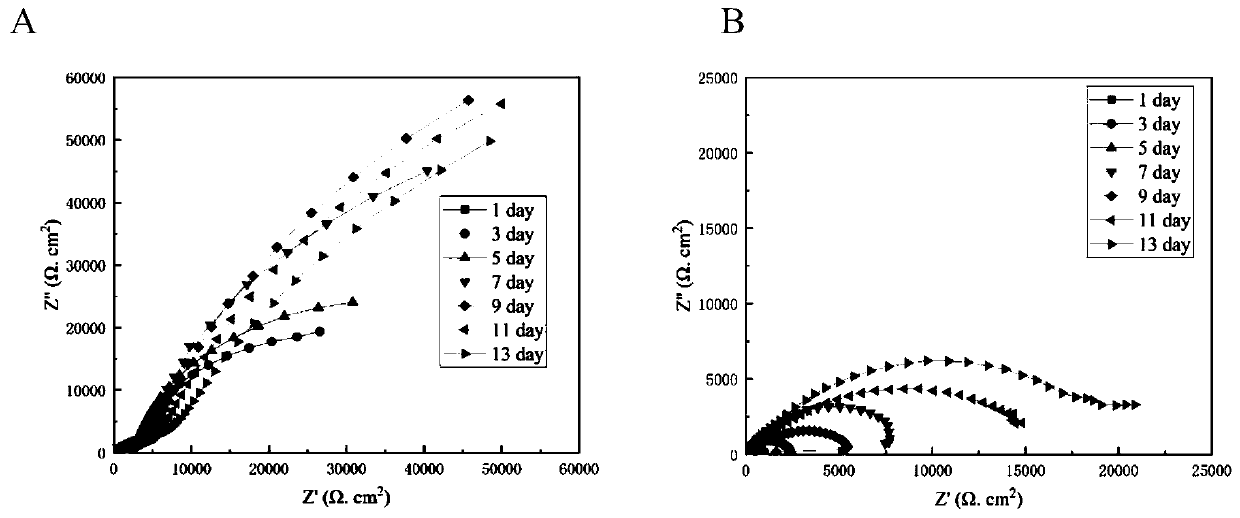

Biological bactericide for crude oil transportation pipelines, and applications thereof

The invention provides a biological bactericide for a crude oil transportation pipeline, wherein the biological bactericide comprises the following main components: Alcanivorax borkumensis, has no pathogenicity, is less in dosage, simple and convenient to use and environment-friendly compared with conventional inorganic and organic bactericides, and belongs to an environment-friendly bactericide.According to the invention, the biological bactericide can improve the pH value in the environment and effectively inhibit the microbial corrosion of metals, wherein the corrosion rate of an X70 pipeline steel can be reduced by 200 times; the biological bactericide is non-corrosive, wherein the corrosion resistance is improved along with the prolonging of the soaking time of a metal sample; according to the principle of the biological bactericide, the pH value is changed, so that the biological bactericide is not suitable for the survival of other microorganisms, and the defect that the traditional bactericide is easy to generate drug resistance is avoided; the biological bactericide disclosed by the invention is used for metal protection of crude oil transportation pipelines, is simple tooperate, has no requirements on the size and the shape of the pipeline, and can greatly reduce the cost of inhibiting microbial corrosion of the pipeline in petroleum enterprises as long as fluid flows through.

Owner:GUANGZHOU MARITIME INST

A kind of ion diffusion colorant and its application

The invention belongs to the technical field of glass product manufacturing, and in particular relates to an ion diffusion colorant and its application. The present invention adopts the molten salt dipping method, and the original glass sheet or glass product which has been annealed at high temperature is immersed in the molten salt mixed with silver salt and other various salts, so as to reduce the energy consumption of the ion diffusion coloring process, and make Ag The ions can effectively diffuse with the original Na and K ions in the glass to obtain yellow and brown-red colored glass flakes or glass products. The coloring method is simple to operate, has no special requirements on the material of the utensils, and can color glass sheets and glass products of different shapes, sizes and materials at the same time. During the experiment, the temperature is lower, which is beneficial to reduce energy consumption and production cost, and has excellent coloring effect.

Owner:KORNERSTONE MATERIALS TECH

Microwave swelling tobacco stem processing method

InactiveCN101099598BReduce energy consumptionHigh energy utilization efficiencyTobacco treatmentMicrowave ovenEngineering

The present invention relates to utilization of by-product tobacco stems obtained in tobacco industry, in the concrete, it relates to a technological process for puffing tobacco stems by utilizing microwave. Said technological process includes the following steps: raw material pretreatment: uniformly spraying pectin puffing agent on the dried tobacco stems; charging: making the pretreated tobaccostems be uniformly laid in a glassware; placing the glassware into a microwave oven and utilizing microwave to puff the tobacco stems, microwave frequency is 2450MH2, power is 400w and temperature is85-95deg.C, so that the puffed tobacco stems can be obtained.

Owner:陈明功

Brewer

The invention discloses a brewer which comprises an inner cup, an outer container, a filtering element and an extending part, wherein the inner cup is provided with a top opening for containing beverage to be brewed, the outer container is arranged outside the inner cup and used for containing brewing water, the filtering element is also used as the bottom of the inner cup, and the extending partis arranged below the inner cup and connected with the inner cup. When the extending part contacts with the outer container, a part of water filled in the inner cup flows into the outer container through the filtering element, a sealed air cavity is formed in a space below the bottom of the inner cup and above the bottom of the outer container by liquid flowing into the outer container, both the liquid level of outer liquid surface between the outer container and the inner cup and the liquid height of the inner liquid surface in the inner cup are not changed any more to realize static soakingof the beverage, and at the time, the inner liquid level is higher than the outer liquid level. The invention ensures that beverage to be brewed can be separated from brewing water, and has simple structure, convenient manufacture and no requirement on the shape of the outer container.

Owner:邢立勇

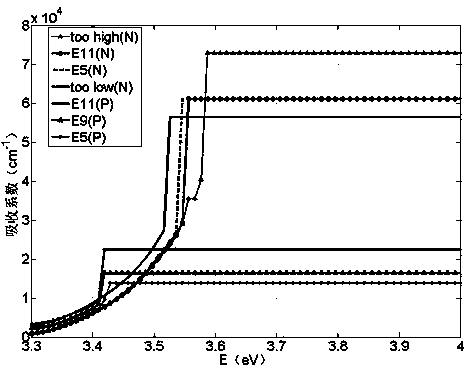

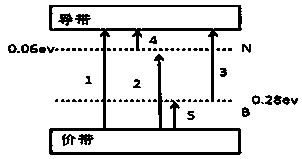

A non-destructive determination method for the conductivity type of silicon carbide crystal

ActiveCN108037439BNo damageNo shape requirementIndividual semiconductor device testingUltraviolet absorptionVisible near infrared

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Detection device and method for distinguishing inner and outer wall defects based on electromagnetic detection signals

InactiveCN103235036BSimple methodEasy to collectMaterial magnetic variablesSignal amplifierExcitation signal

The invention discloses a detection method for distinguishing inner and outer wall defects based on electromagnetic detection signals, comprising: step 1: placing the workpiece to be tested and the detection coil in an external local magnetic saturation environment; step 2: generating a certain frequency by a microprocessor square wave excitation signal, and amplify the power of the square wave excitation signal through the excitation amplifier circuit to excite the first detection coil and the second detection coil; step 3: form the first detection coil and the second detection coil in differential mode Constitute a differential electromagnetic sensor, load the square wave excitation signal after power amplification by the excitation amplifier circuit; step 4: pick up the signal of the differential electromagnetic sensor through the differential signal amplifier circuit, and perform adaptive amplification; step 5: use the integral processing circuit to The differentially amplified signal of the differential signal amplification circuit is rectified and integrated to determine the defect of the workpiece under test. The present invention is applied to differentiate inner wall / outer wall defects.

Owner:厦门艾帝尔电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com