Detection device and method for distinguishing inner and outer wall defects based on electromagnetic detection signals

A technology of electromagnetic detection and detection method, applied in the direction of material magnetic variables, etc., can solve problems such as difficult to use, and achieve the effect of easy implementation, simple design and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

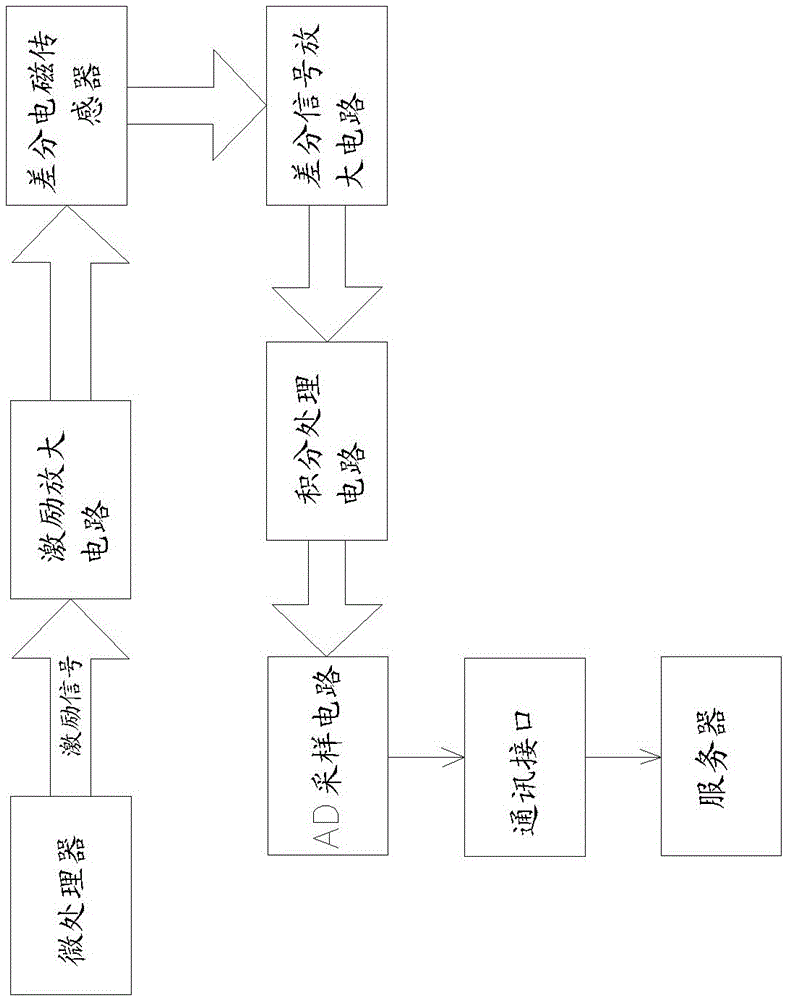

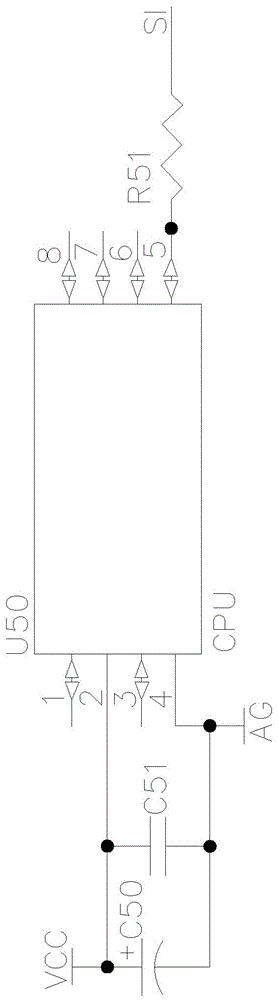

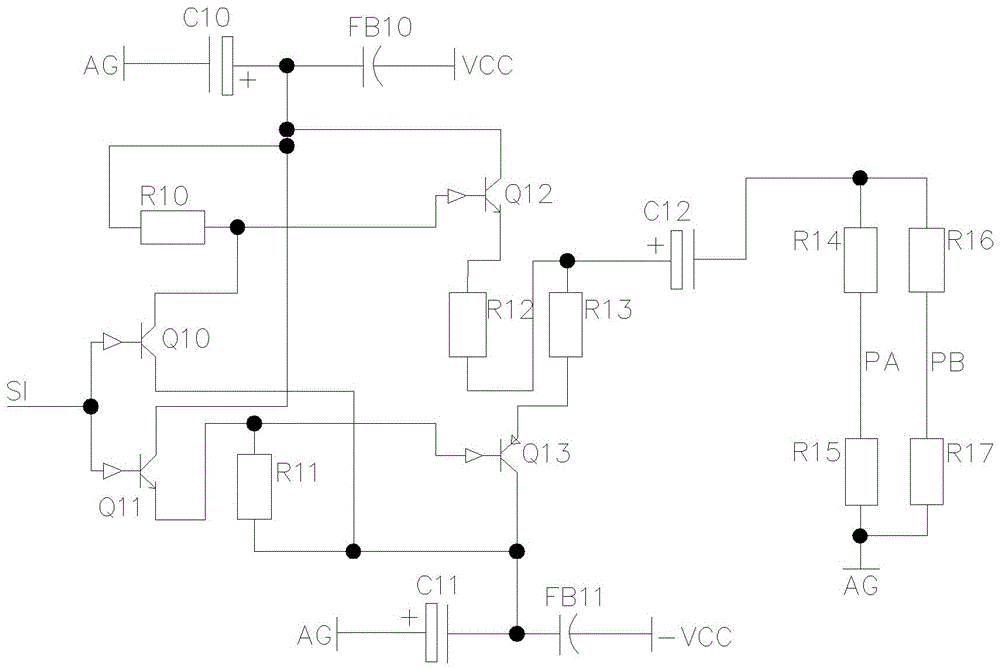

[0034] The effect of eddy current testing on the identification of near-surface defects is obvious: if an alternating current is applied to a coil, the current passing through it will not change under certain conditions. If the coil is brought close to the workpiece to be tested, an eddy current will be induced in the workpiece. will change; since the size of the eddy current varies with whether there is a defect in the workpiece, the magnitude of the coil current change can reflect whether there is a defect; in addition, with the skin effect, the detected information can only reflect the surface of the workpiece or the near surface of the workpiece. situation at the surface. Aiming at the fact that general electromagnetic eddy current detection cannot distinguish the front and back distribution of material defects, the present invention provides a detection device and method for distinguishing inner and outer wall defects based on electromagnetic detection signals, and utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com