Method for preparing C3N4 film

A C3N4, thin film technology, applied in the direction of electrodes, electrolytic coatings, electrophoretic plating, etc., can solve the problems of poor contact between the film and the conductive substrate, complex film preparation process, difficult to effectively control the film thickness, etc., to solve the problem of uncontrollable thickness, thin film The effect of controllable electrode thickness and simple and cheap preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example illustrates an example of an electrophoretic deposition setup:

[0029] figure 1 For electrophoretic deposition of C 3 N 4 Schematic diagram of the apparatus used to prepare the films. Electrophoretic deposition is carried out in a two-electrode system, that is, both the working electrode and the counter electrode are conductive substrates, and the C 3 N 4 The precursor colloidal solution was ultrasonically homogeneous, and then the two electrodes were placed in C 3 N 4 Electrophoretic deposition is carried out by applying a DC voltage between the electrodes in the precursor colloidal solution.

Embodiment 2

[0031] This example illustrates C 3 N 4 Examples of precursor colloid preparation:

[0032] 2g C 3 N 4 Add 40mL of 98% concentrated sulfuric acid to the powder material and stir for 8 hours, then slowly add 200mL of aqueous solution and sonicate for 8 hours, centrifuge the precipitate on a 10,000-rpm centrifuge and wash it with water, then centrifuge, repeat 5-6 times until the centrifugation does not stop, and then centrifuge at 18,000 rpm get C 3 N 4 colloid, which was added to 120mL organic solvent, and ultrasonicated for 1 hour to obtain C 3 N 4 colloidal solution. Figure 2 shows the C 3 N 4 TEM images of colloidal particles and C 3 N 4 Photo of the colloidal solution, showing that the C prepared by this method 3 N 4 The size of the colloidal particles is about 20nm, and the particle size is uniform. In addition, the particles can be stably dispersed in organic solvents for a long time, which is suitable for the subsequent electrophoretic deposition process. ...

Embodiment 3

[0034] This example shows that by changing the electrophoretic deposition voltage to change C 3 N 4 Examples of control of thin film electrode thickness:

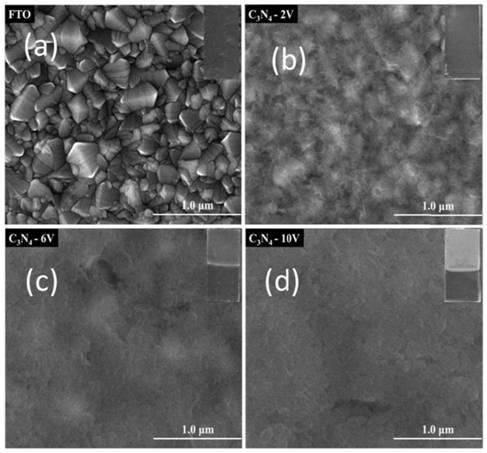

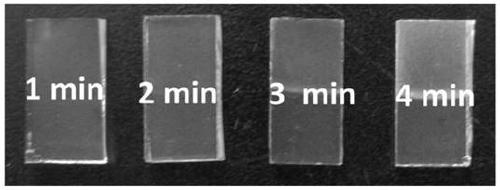

[0035] Put the precursor electrode prepared in Example 2 into the electrophoretic deposition reactor, use FTO conductive glass as the working motor and counter electrode of electrophoretic deposition, control the electrophoretic deposition time to 1min, and control the deposition voltage to 2V, 6V, and 10V for deposition, followed by natural drying at room temperature. image 3 The electron microscope image (SEM) shows the change of the surface morphology of the FTO substrate with the increase of the deposition voltage. It can be seen that the surface of the FTO conductive glass composed of rough particles is gradually covered by C 3 N 4 Covered with a thin film, the FTO substrate can be clearly seen at 2V, and the FTO substrate is basically covered by C at 6V. 3 N 4 Film coverage, the FTO substrate is completely cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com