Multifunctional Steam Condensation Heat Exchange and Frosting Process Visualization Experimental Device

A technology of steam condensation and experimental device, applied in the field of condensation heat transfer, can solve problems such as poor versatility, and achieve the effect of large viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

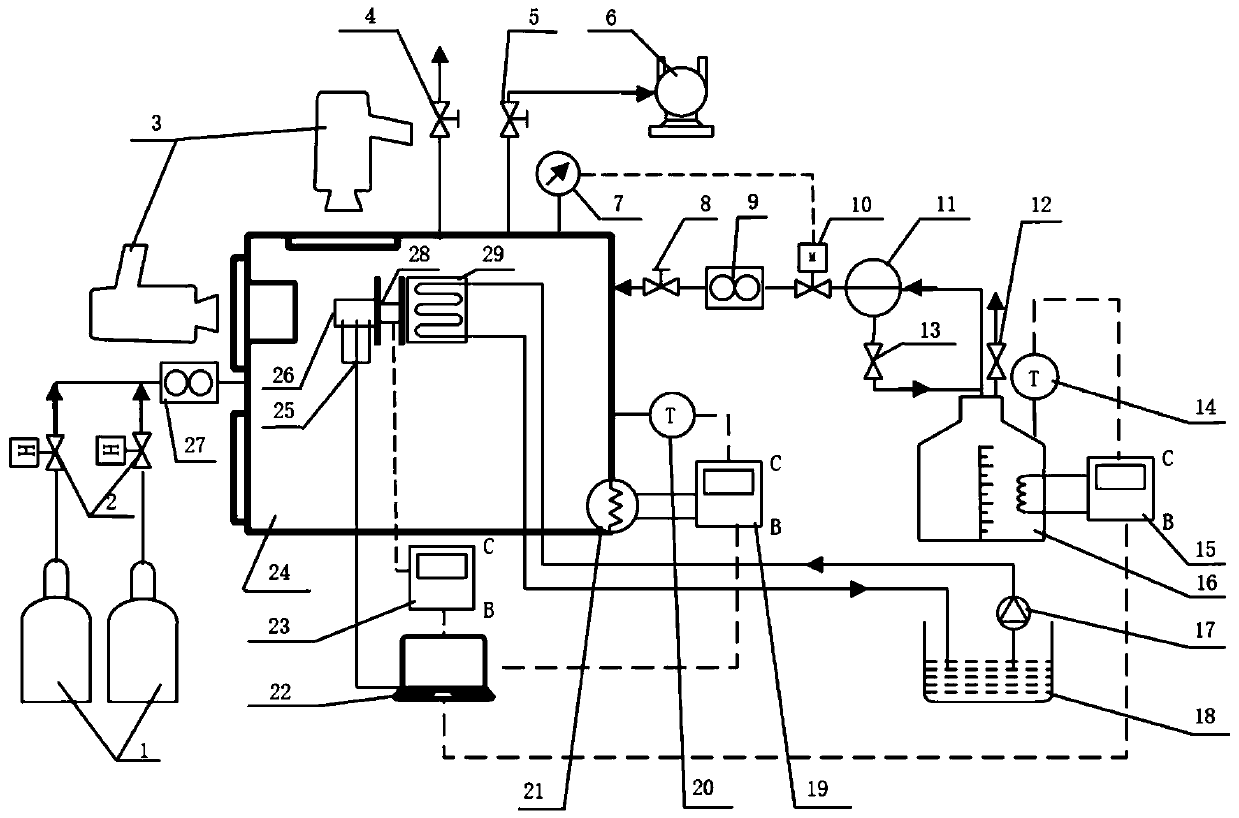

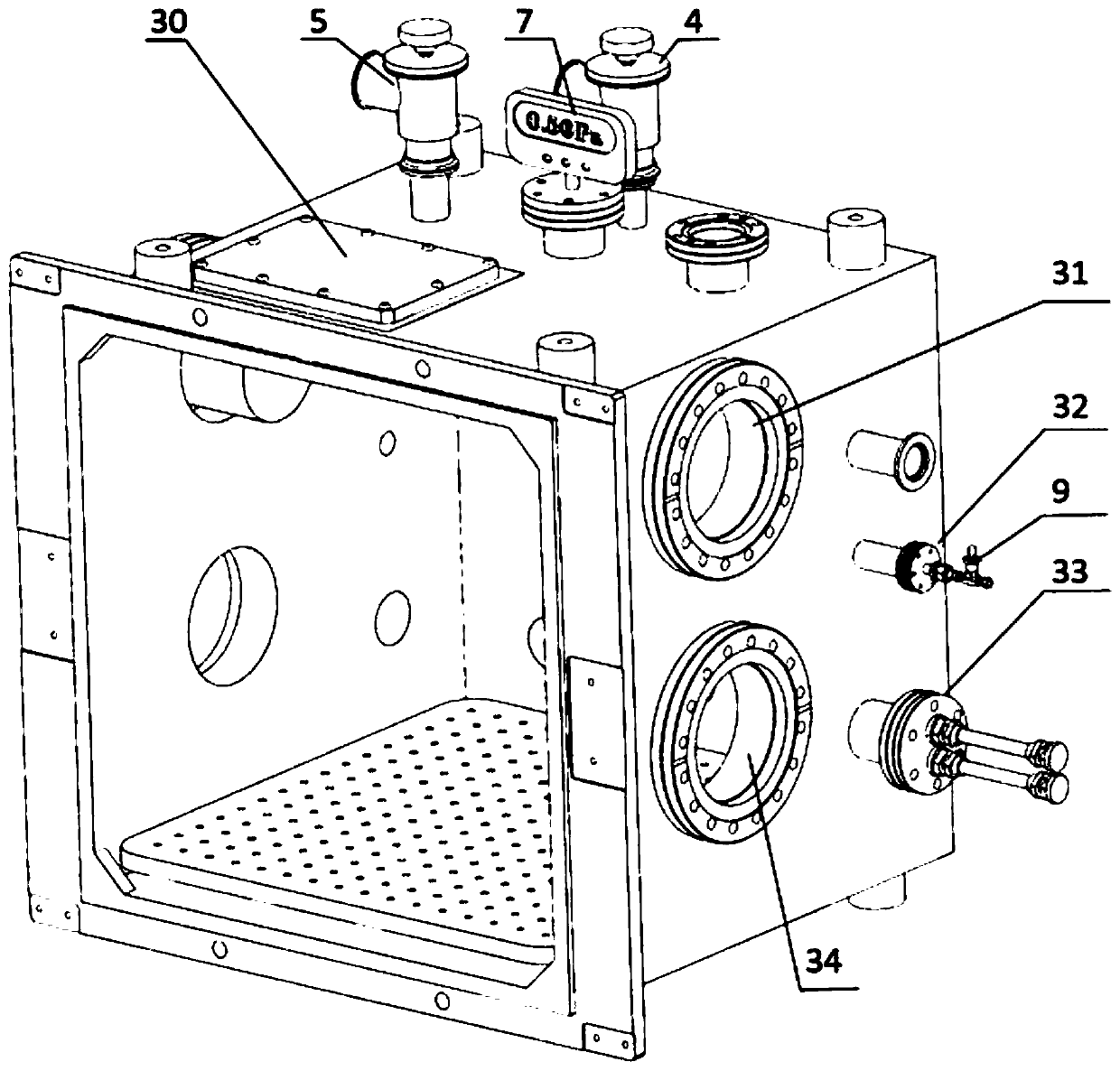

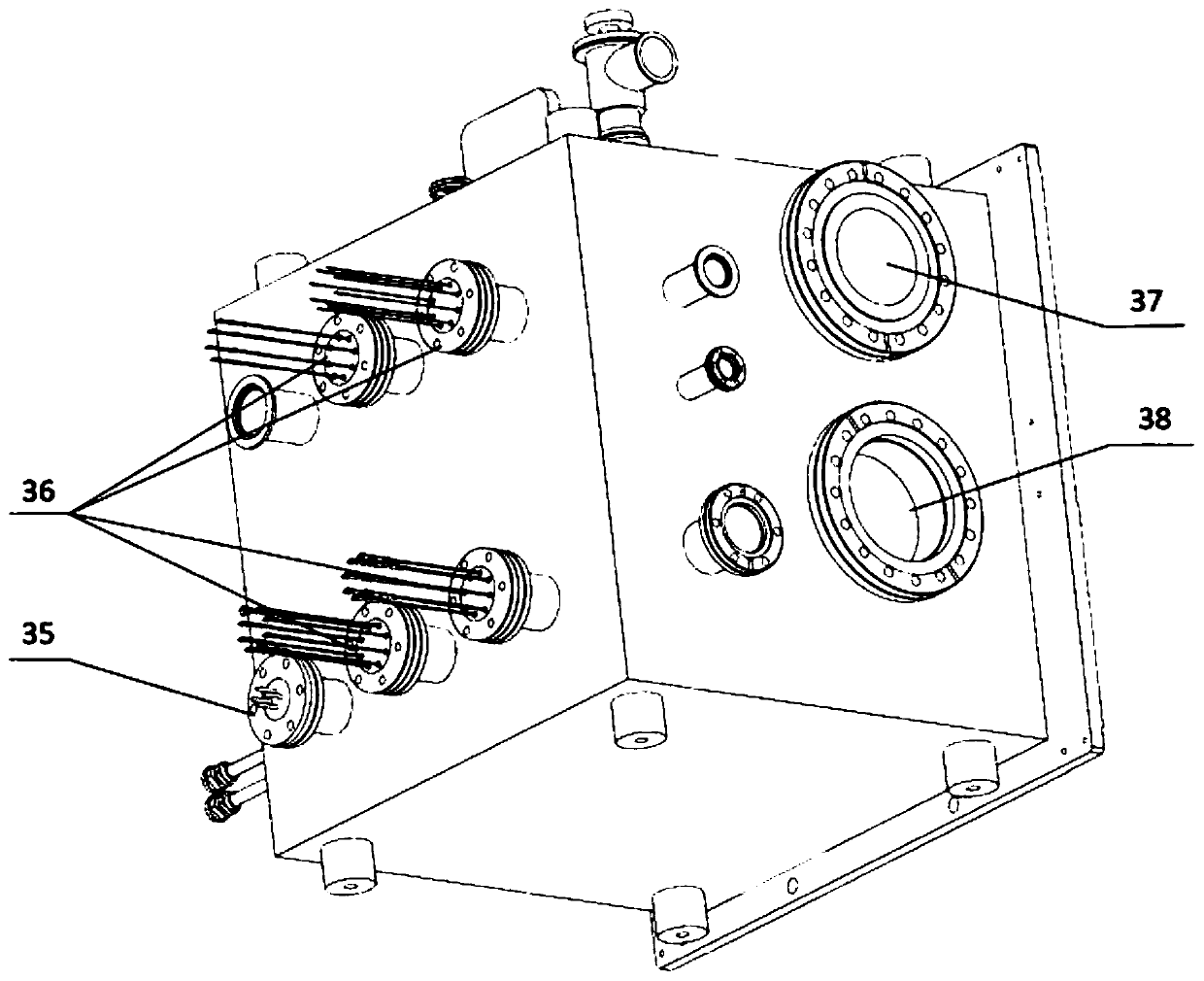

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

[0027] Depend on figure 1 It can be seen that the present invention adopts the method of placing the entire experimental sample in the sealed chamber 24 to meet the environmental conditions required for the experiment. Therefore, the experimental device of the present invention has no requirements on the shape and placement direction of the experimental sample 26, and can simultaneously satisfy Horizontal and vertical pipes as well as flake test samples. The environmental condition parameters that can be provided by the sealed chamber 24 include temperature, air pressure, gas composition, and sample temperature. The steam temperature in the boiler 16 adopts closed-loop control, and the power regulator of the boiler 16 can adjust the heating power of the boiler 16 according to the water temperature in the furnace measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com