High wearing resistance normal-temperature cured bottom surface syncretic super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating, room temperature curing technology, applied in coatings and other directions, can solve the problems of complex preparation process of super-hydrophobic coating, low wear resistance of super-hydrophobic coating, etc., to achieve the feasibility of expanding application and good super-hydrophobicity , to avoid the effect of the mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

[0030] (1) Preparation of superhydrophobic silica particles:

[0031] Under the condition of heating in a water bath at 50°C, 12 g of nano-aqueous silica sol was added dropwise to 100 g of absolute ethanol. The nano-particles in the nano-aqueous silica sol were silica particles with a diameter of less than 100 nm, and the shape was spherical. Add 4g of 25vt.% ammonia water after 30 minutes, mechanically stir for 30 minutes, add 1 g of dodecyltriethoxysilane dropwise, continue stirring for 2 hours and then stand for 24 hours; the above solution is 60℃, 55 r / min rotation speed conditions Rotary steaming for 3 h to obtain a 10-fold concentrated gel-like concentrate, and then freeze-dry the concentrated gel in a freeze dryer at -85°C for 48 h to remove the solvent to obtain superhydrophobic silica powder.

[0032] (2) Preparation of super-hydrophobic coating on the bottom surface:

[0033] Add 4 g of superhydrophobic silica particles to 20 g of acetone solution, add 0....

Example Embodiment

[0035] Example 2

[0036] (1) Preparation of superhydrophobic graded particles:

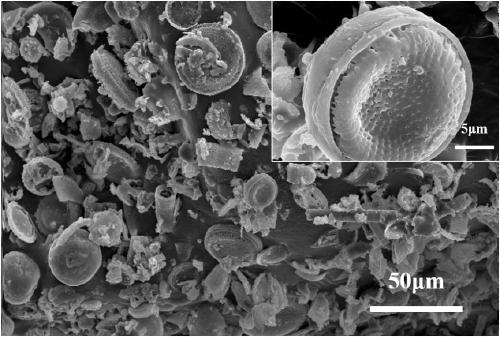

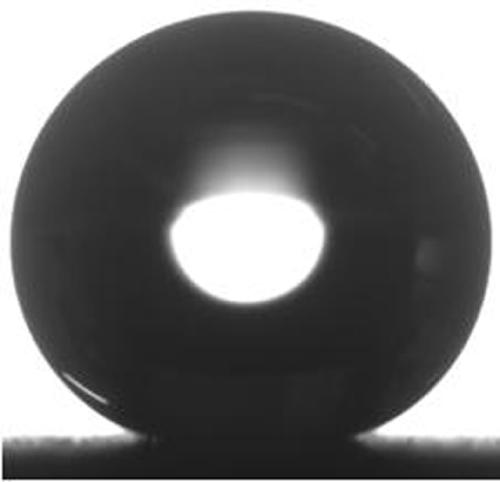

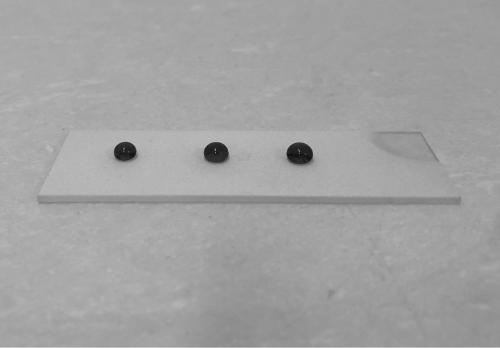

[0037] Under the condition of heating in a water bath at 55°C, 20 g of nano-aqueous silica sol was added dropwise to 100 g of absolute ethanol. The nano-particles in the nano-aqueous silica sol are silica particles with a diameter of less than 100 nm, and the shape is chain-like, mechanically stirred Add 4.5 g of 28vt.% ammonia water after 20 minutes, stir for 10 minutes and add 20 g of micron-sized diatomaceous earth particles, see figure 1 The surface of the micron-scale diatomaceous earth particles has a nano-scale pore structure with a diameter of 20-30 μm, and the shape is sheet, column, and disc. After 30 minutes of mechanical stirring, 1.5 g of dodecyltriethoxysilane was added dropwise, stirring continued for 2 hours, and then standing for 24 hours; the above solution was rotary evaporated for 3 hours under the conditions of 60℃ and 60 r / min to obtain the concentration 10 times the gel-like co...

Example Embodiment

[0041] Example 3

[0042] (1) Preparation of superhydrophobic graded particles:

[0043] Under the condition of heating in a water bath at 50°C, 12 g of nano-aqueous silica sol is added dropwise to 100 g of absolute ethanol. The nano-particles in the nano-aqueous silica sol are silica particles with a diameter of less than 100 nm, and the shape is beaded. Add 4 g of 25 vt.% ammonia water after 10 minutes, add 20 g of micron-sized diatomaceous earth particles after stirring for 20 minutes, the surface of the micron-sized diatomaceous earth particles has a nanometer-scale pore structure, and the shape is columnar. After mechanical stirring for 20 minutes Add 1 g of dodecyltriethoxysilane dropwise, continue to stir for 2 hours and then stand for 20 hours to obtain a superhydrophobic gradation solution of nano-silica and micro-diatomite composite; the above solution is 30 ℃, 80 r Rotary steaming for 5 h at a rotation speed of / min to obtain a 9-fold concentrated gel-like concentrate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com