Patents

Literature

46results about How to "Improve mechanical wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

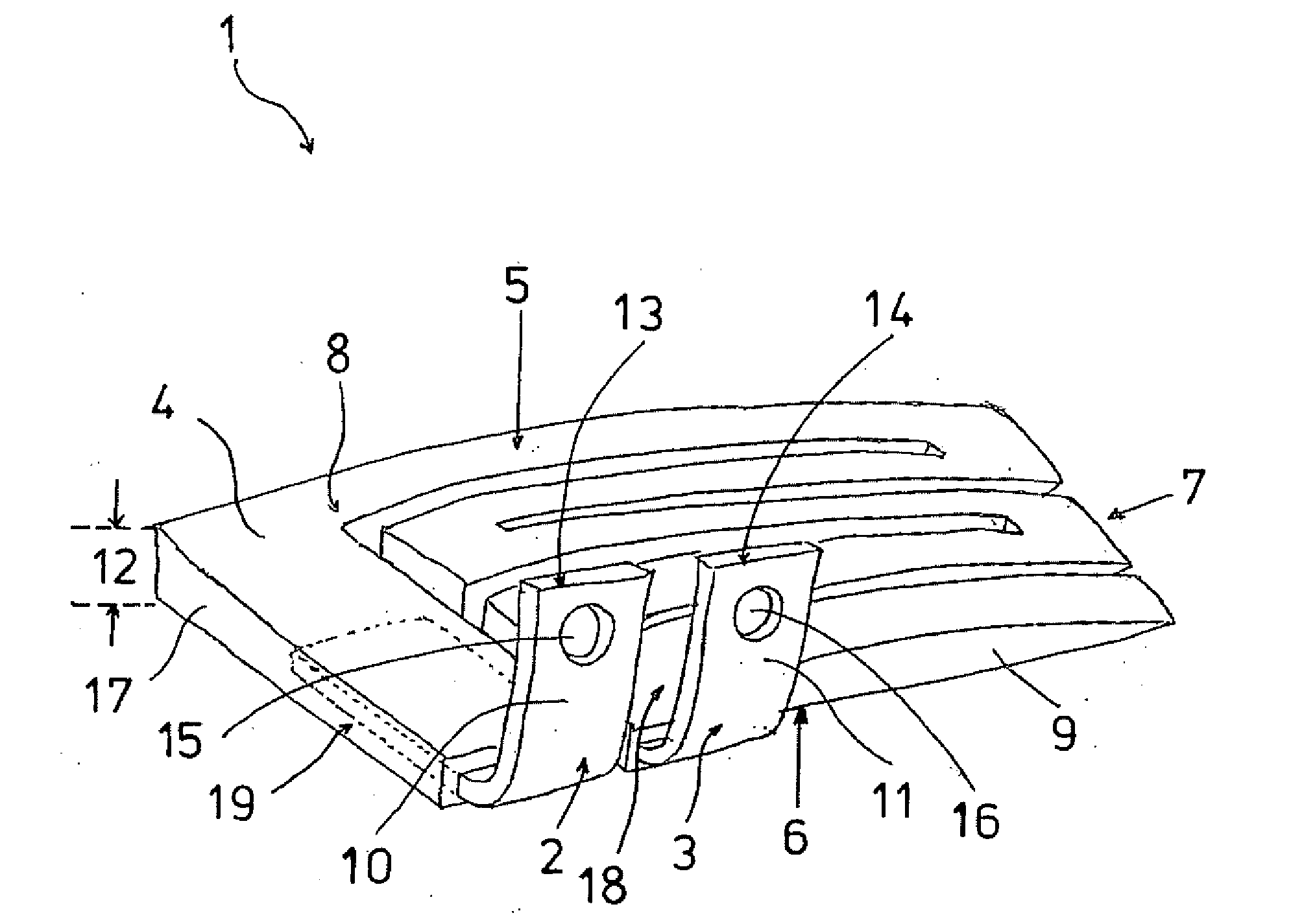

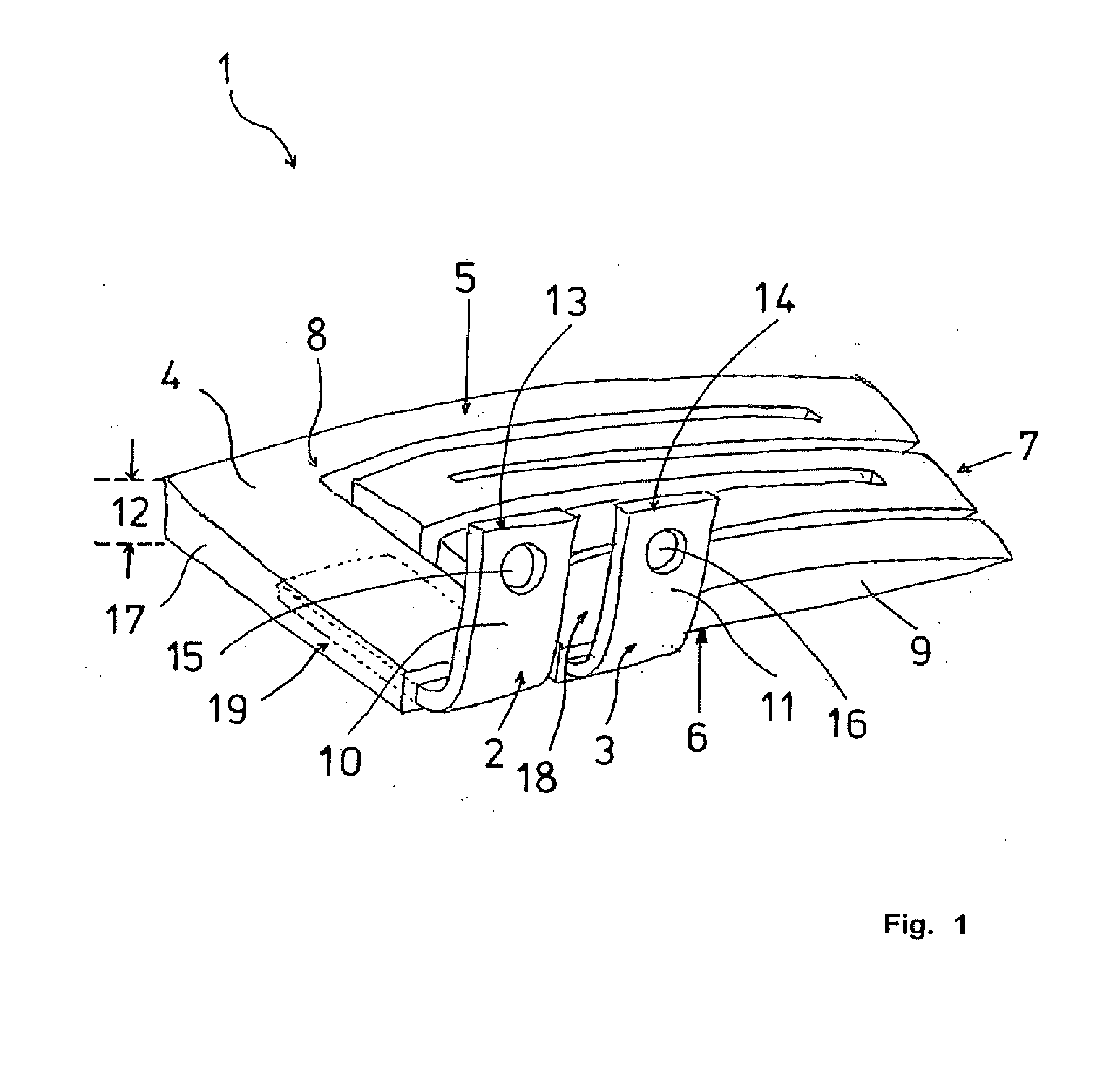

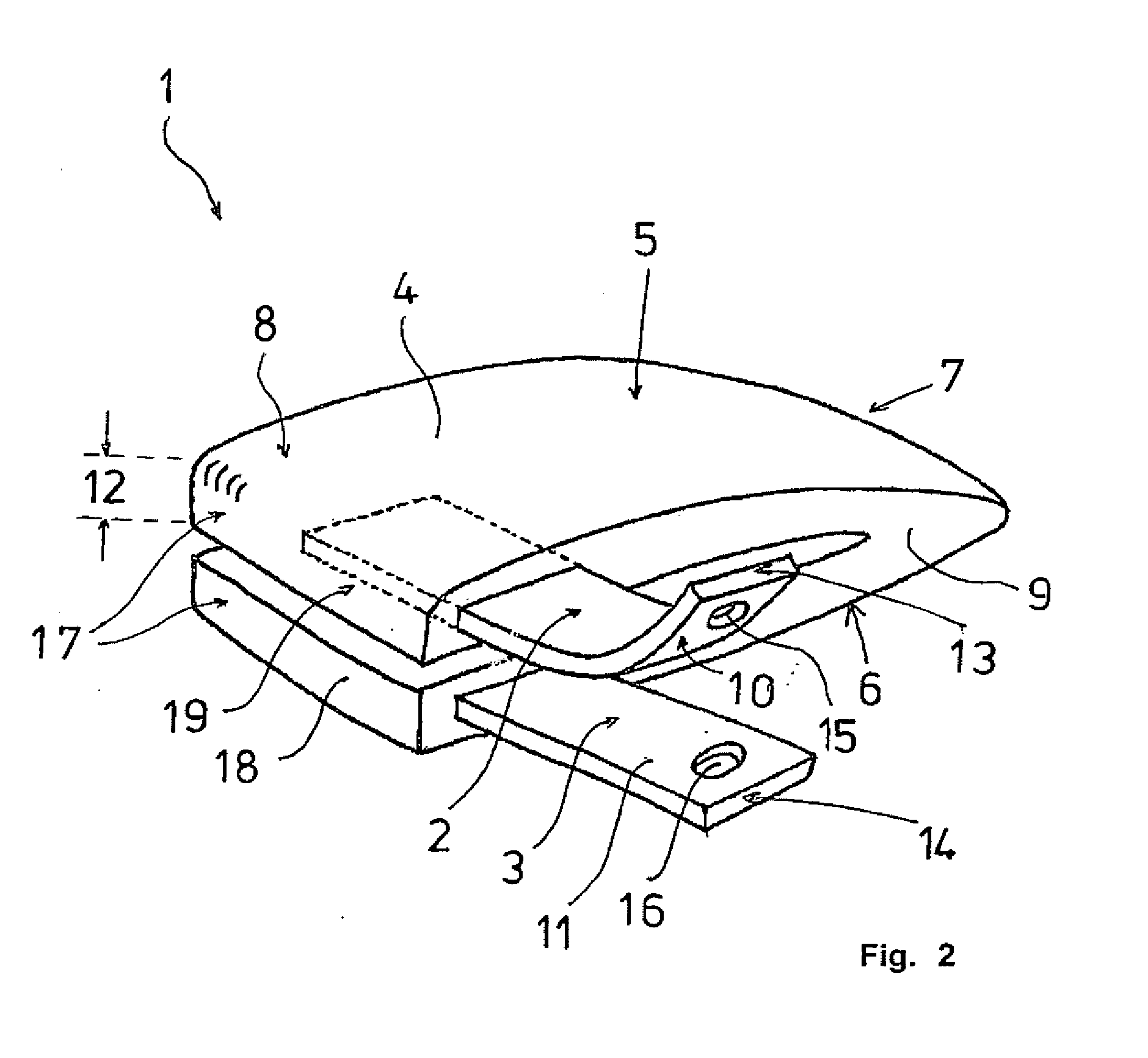

Electrical heating element

InactiveUS20090314767A1Improve mechanical wear resistanceImprove corrosion resistanceHeating element materialsEngineeringResistor

An electrical heating element, in particular for a hot-wedge film welding device, having two electrodes and a heating resistor arranged between the electrodes such that an application of an electrical voltage to the electrodes results in heat being produced along the length of the heating resistor. The heating resistor is designed to correspond to the shape of a heating wedge of a film welding machine, such that it can replace the heating cartridge and the hot wedge of a conventional film welding device. It is preferably produced from a conductive ceramic material and is distinguished by uniform heat distribution, good thermal conductivity and resistance to wear, as well as by excellent corrosion resistance.

Owner:LEISTER TECHNOLOGIES

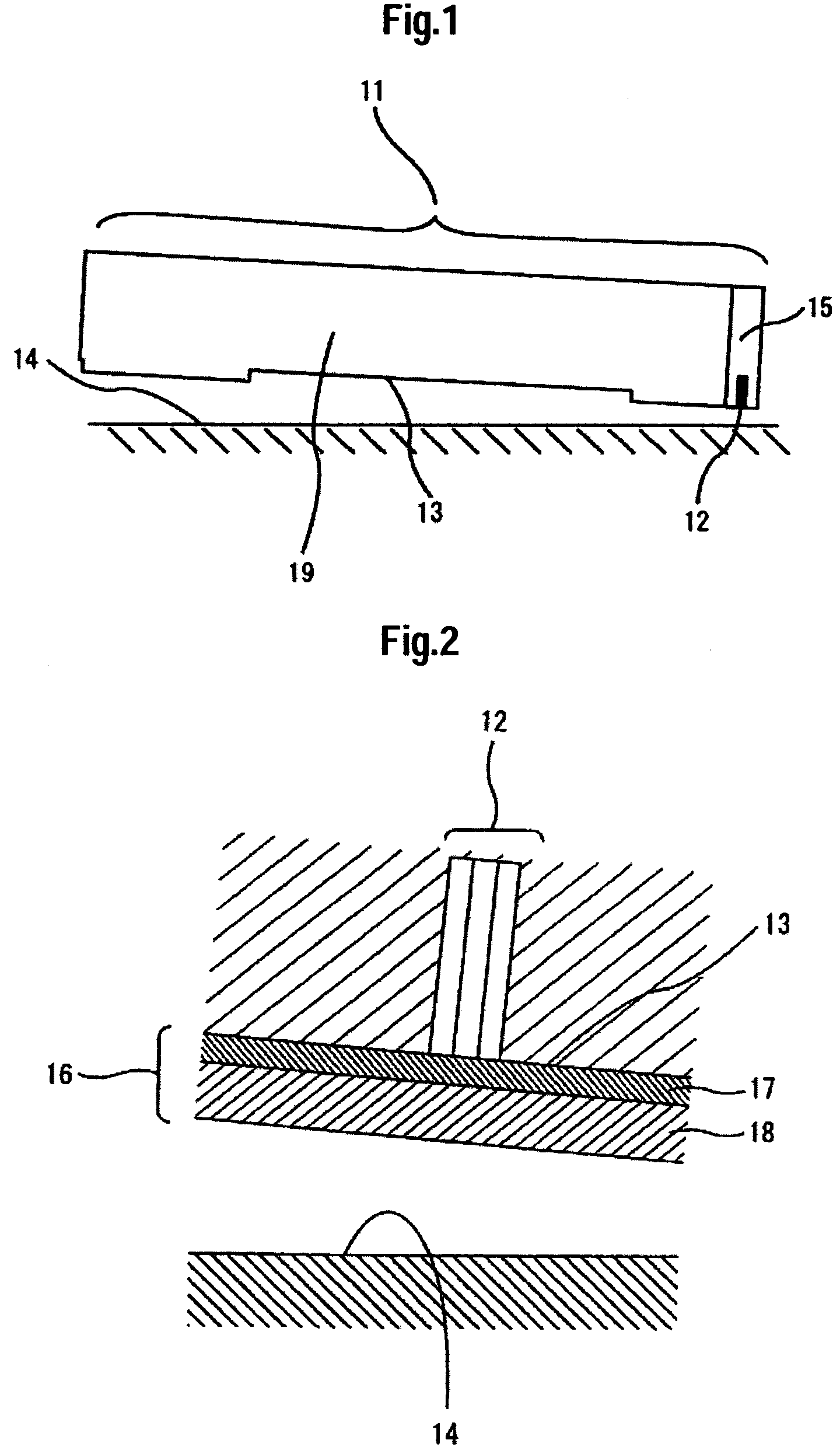

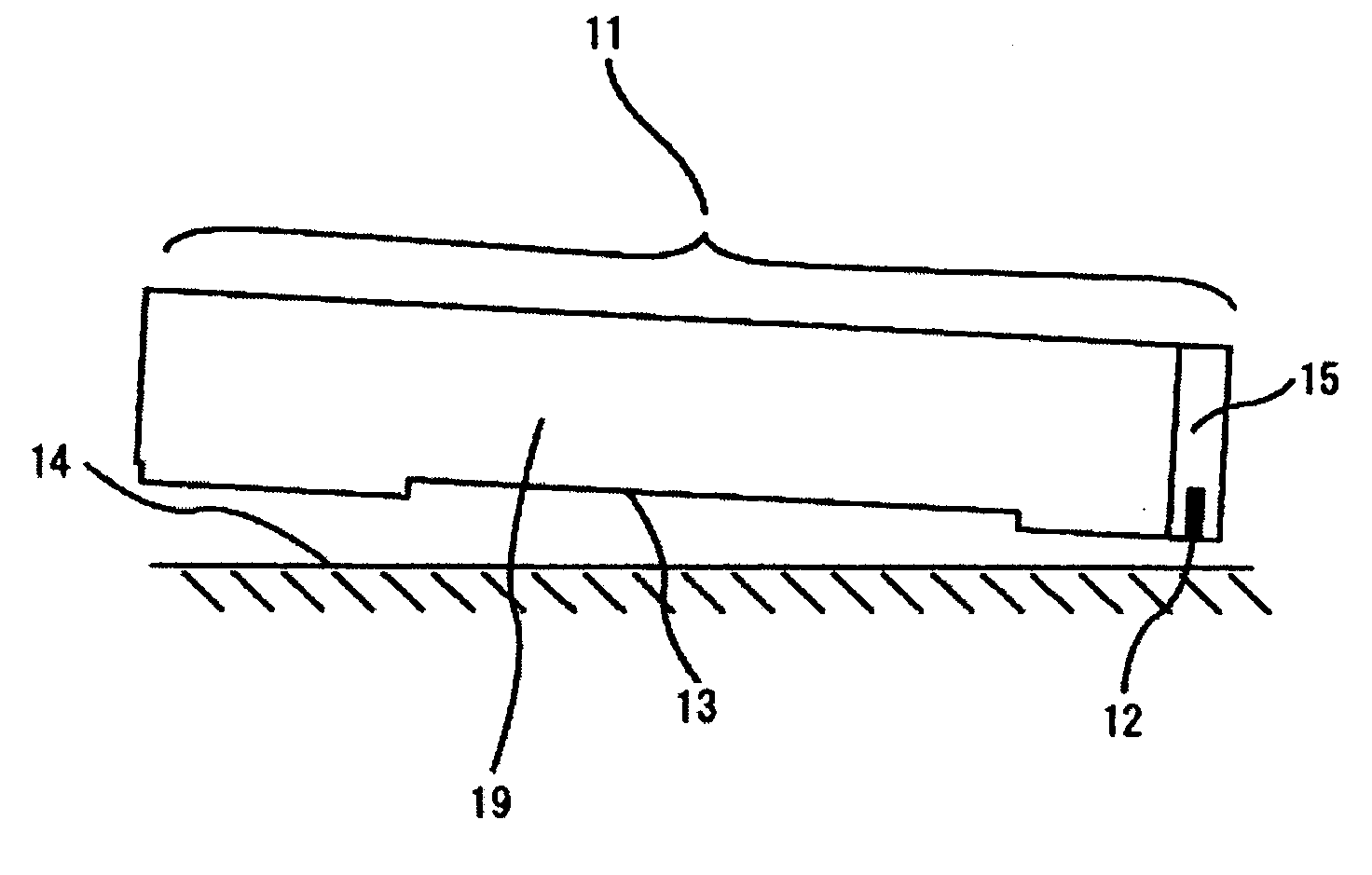

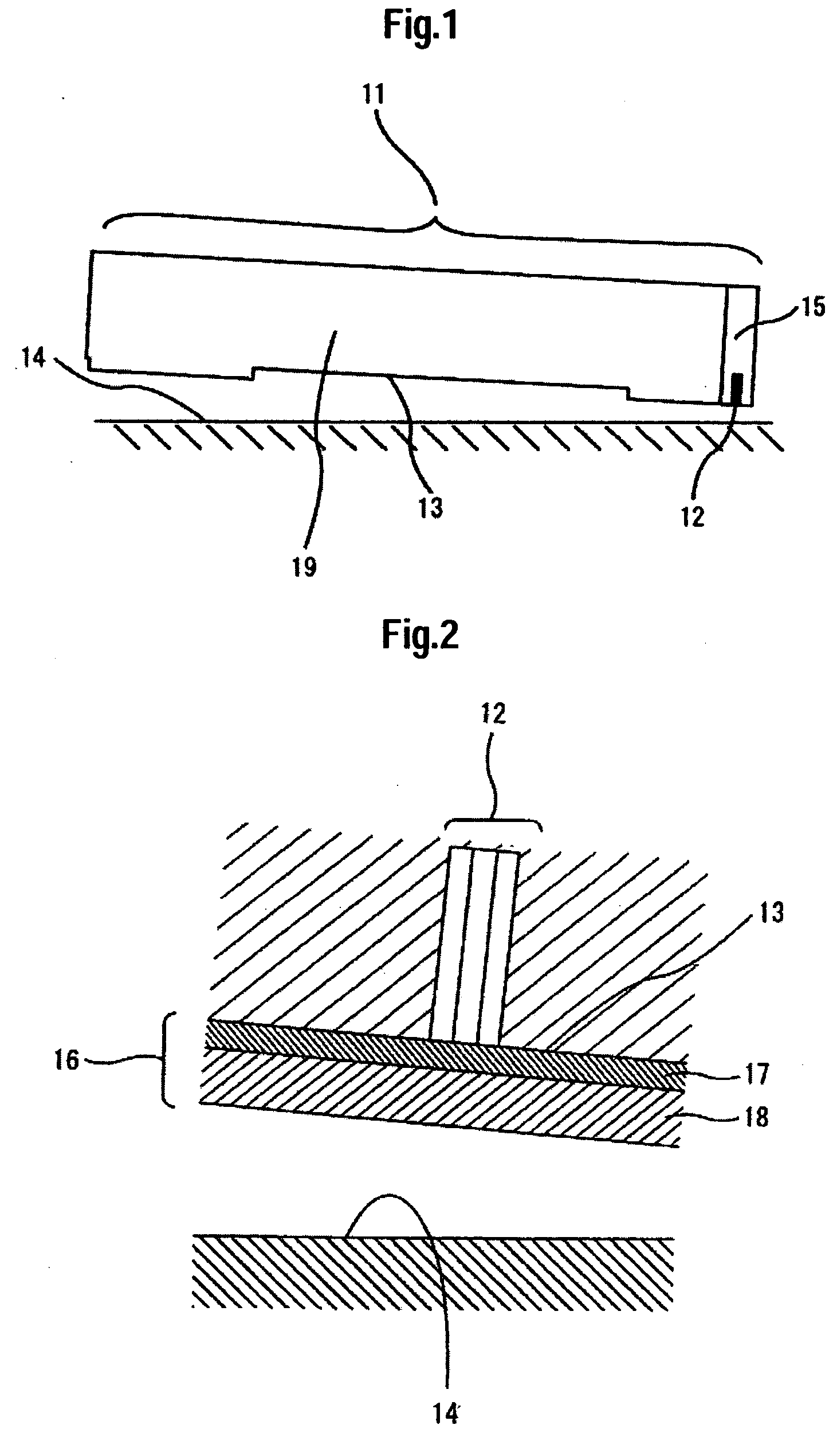

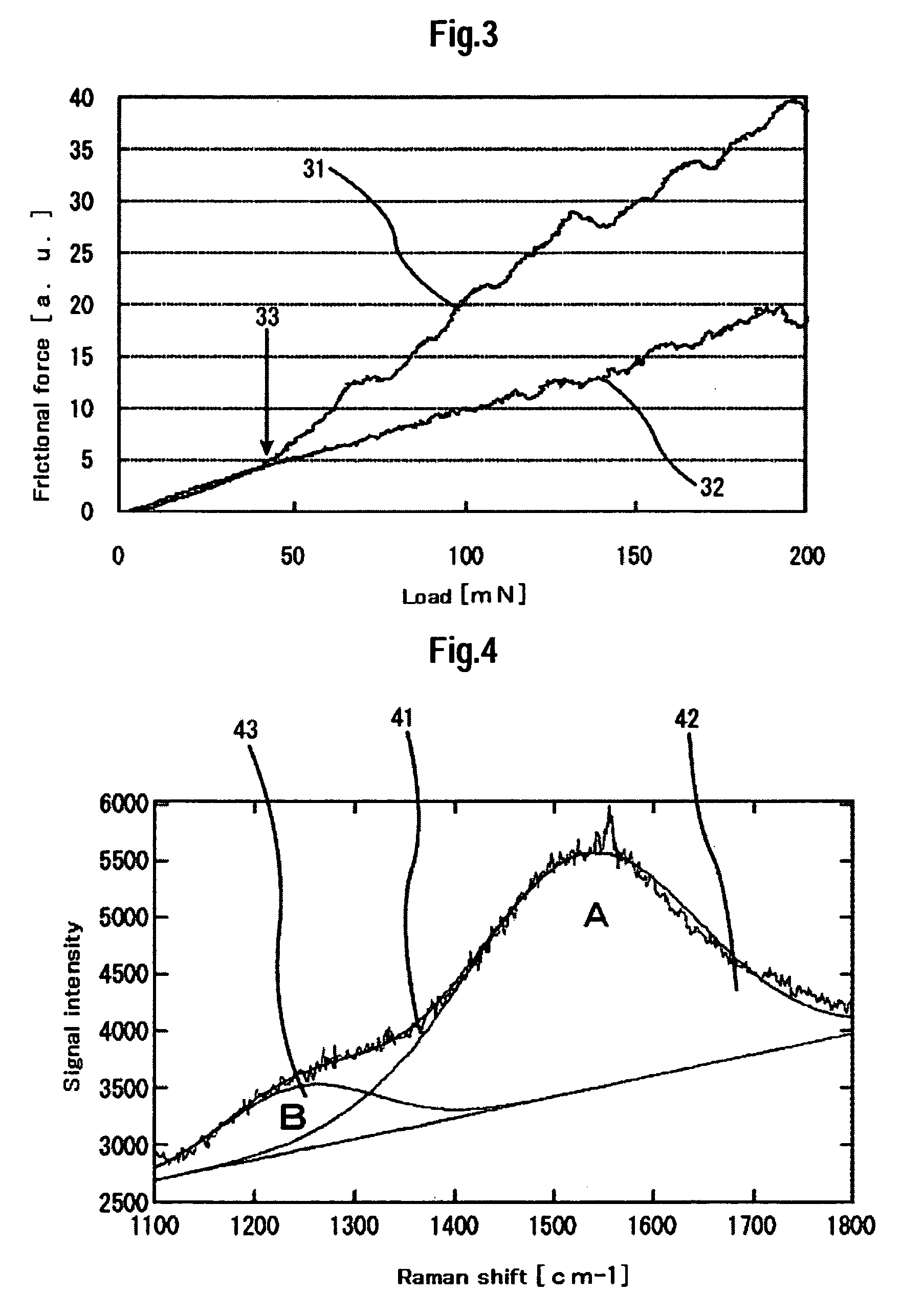

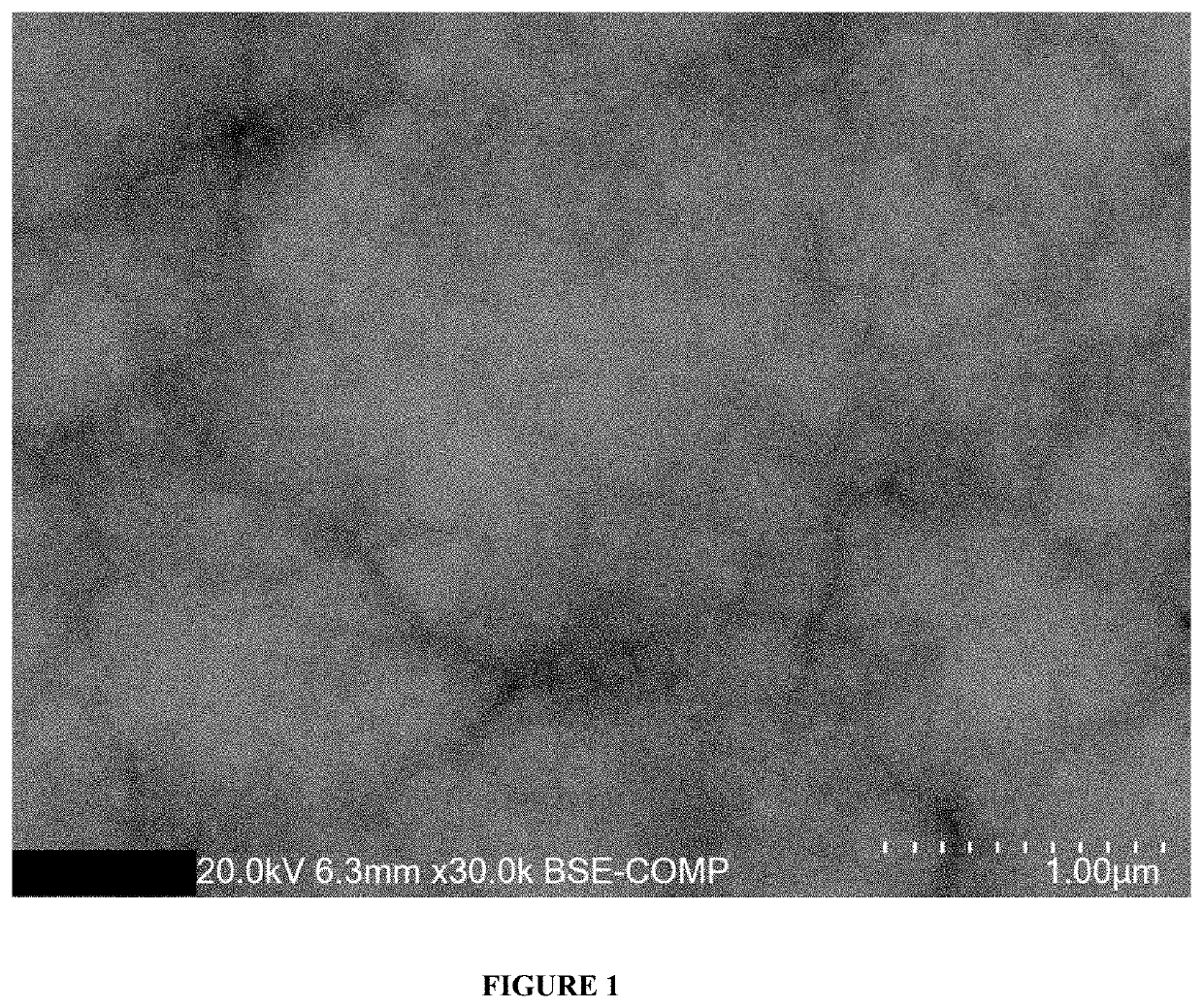

Magnetic head with air bearing surface protection film

InactiveUS7286326B2Maintain good propertiesIncrease resistanceManufacture head surfaceFluid-dynamic spacing of headsHigh densityMechanical wear

Embodiments of the invention provide an air bearing surface protection film having good corrosive resistance, electrical insulative property and mechanical wear resistance in the state of an extremely thin film. In one embodiment, an air bearing surface protection film having good corrosive resistance, electrical insulative property and mechanical wear resistance in a state of an extremely thin film is obtained by disposing a thin silicon nitride film having high density, high electric resistance, chemical stability and high adhesion with a substrate as a lowermost air bearing surface protection film and disposing a film comprising tetrahedral amorphous carbon and nitrogen as an uppermost air bearing surface protection film.

Owner:WESTERN DIGITAL TECH INC

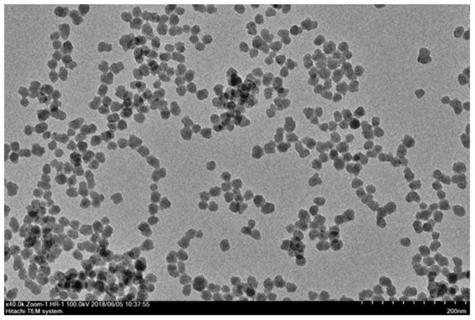

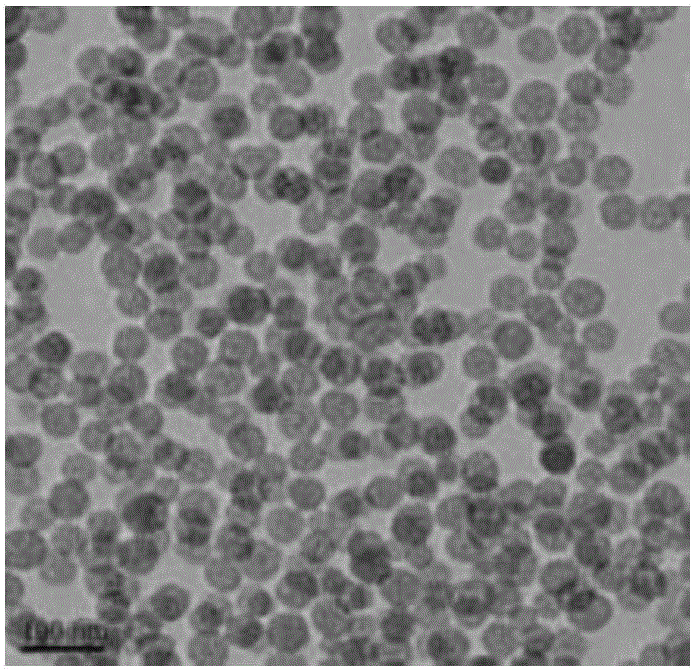

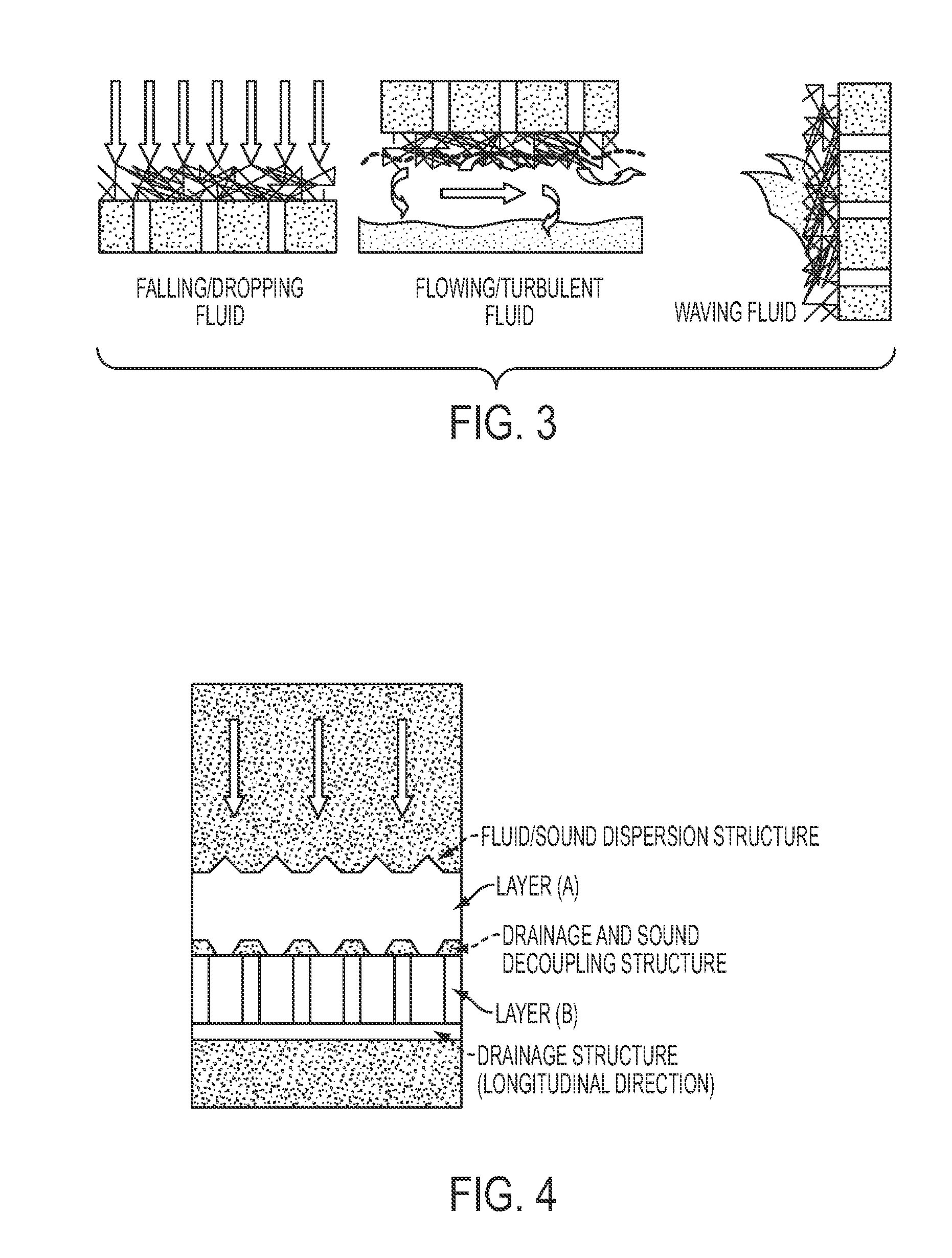

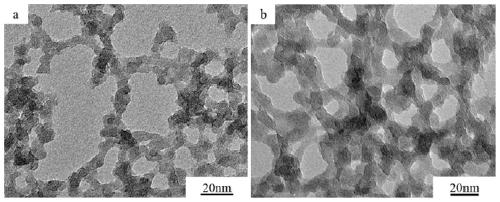

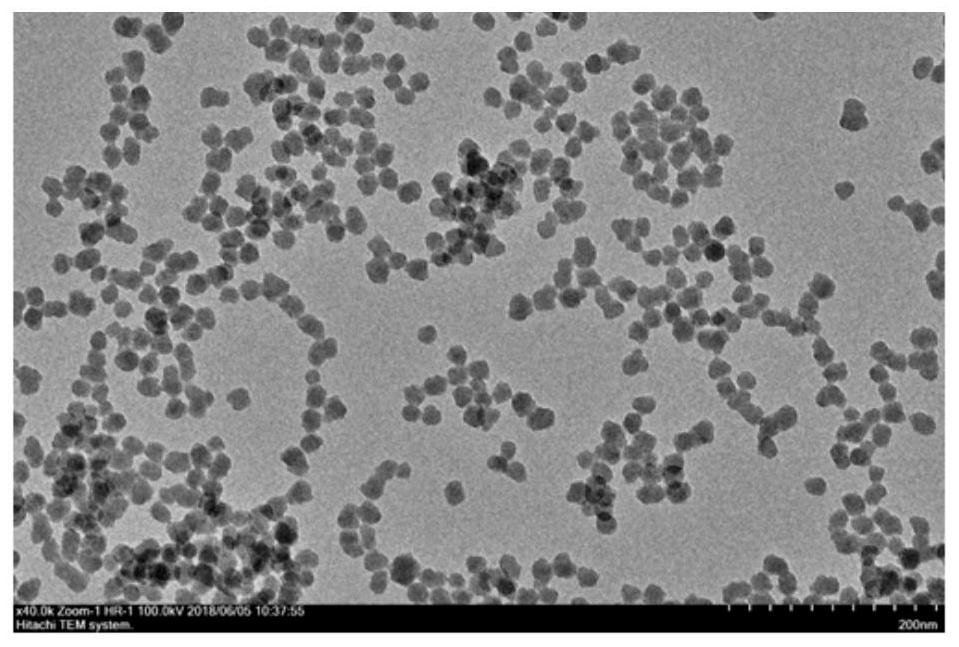

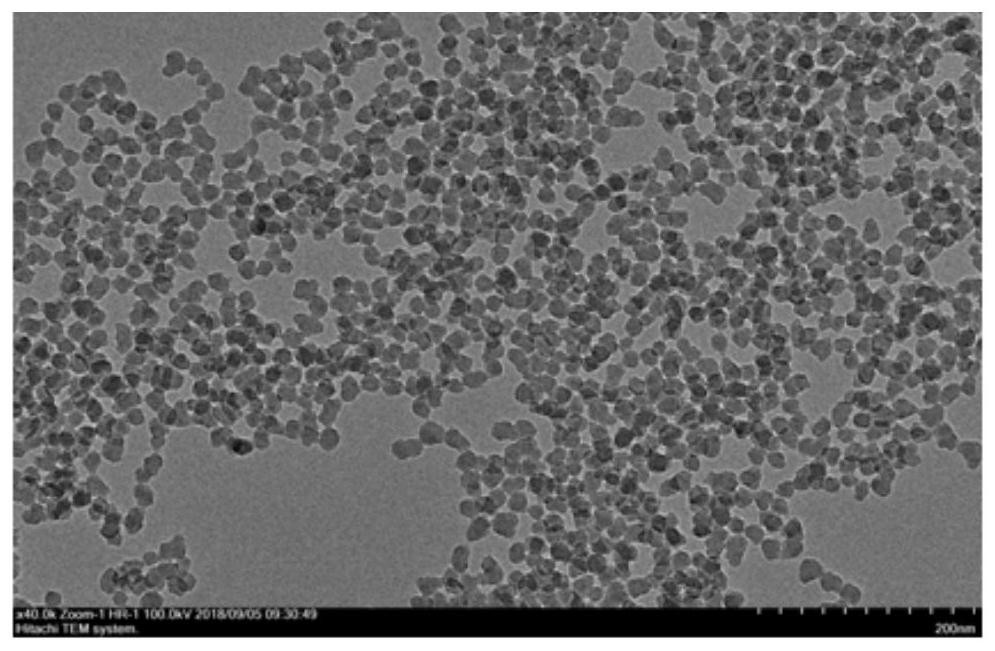

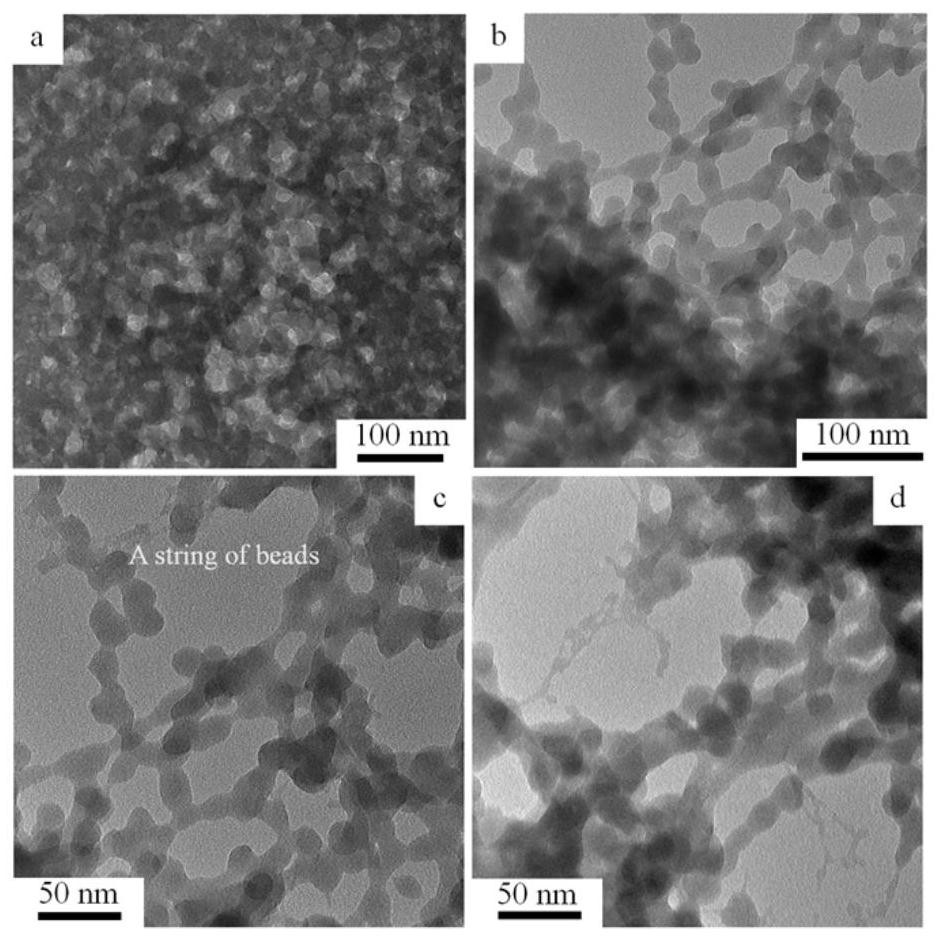

Silicon dioxide nanometer composite material and preparation method and application thereof

ActiveCN109627814AReduced stabilityReduce weather resistanceCoatingsComposite filmWeather resistance

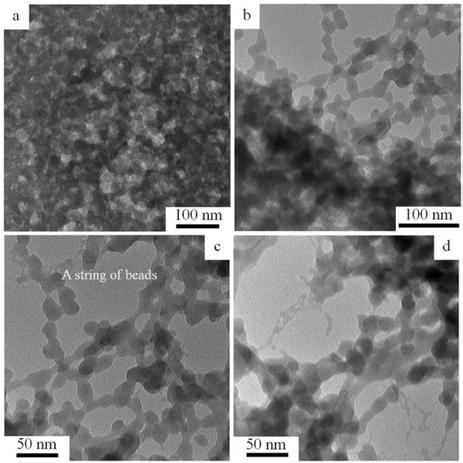

The invention provides a silicon dioxide nanometer composite material and a preparation method and application thereof. The silicon dioxide nanometer composite material is mainly formed by compoundingsilicon dioxide nanoparticle suspension and nanometer silicon dioxide acidic sol, wherein the particle size of silicon dioxide nanometer particles in the silicon dioxide nanometer particle suspensionis 5-30 nm; the nanometer silicon dioxide acidic sol is provided with chain nanosilicon dioxide, and the veneer content of the nanometer silicon dioxide acidic sol is 70-90%. A silicon dioxide nanometer composite thin film prepared from the silicon dioxide nanometer composite material has good effects of antireflection, self cleaning and mist prevention, meanwhile has good mechanical abrasion resistance and weather resistance, is good in firmness with a matrix, is not limited during usage, can exert effects for a long term in the field, and is wide in application range.

Owner:STATE POWER INVESTMENT CORP RES INST +1

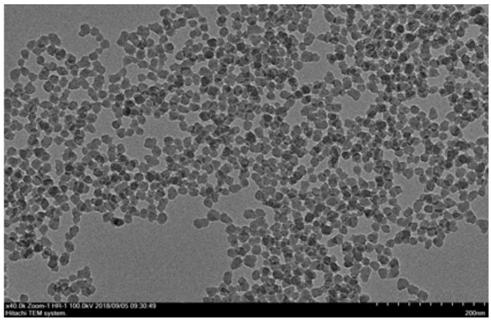

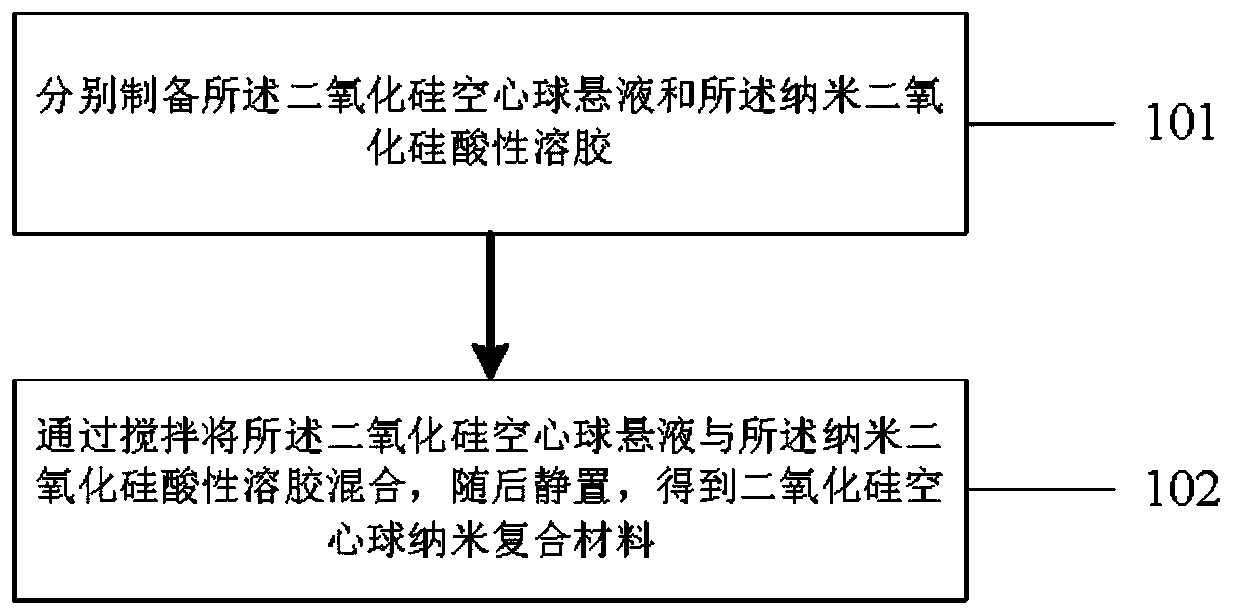

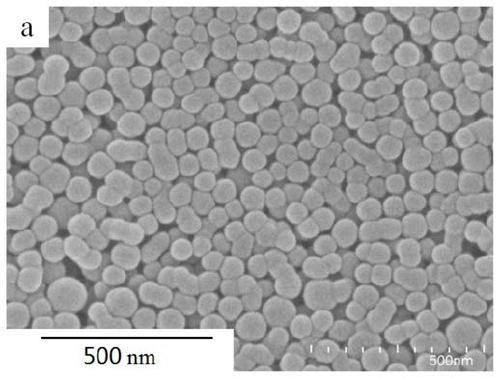

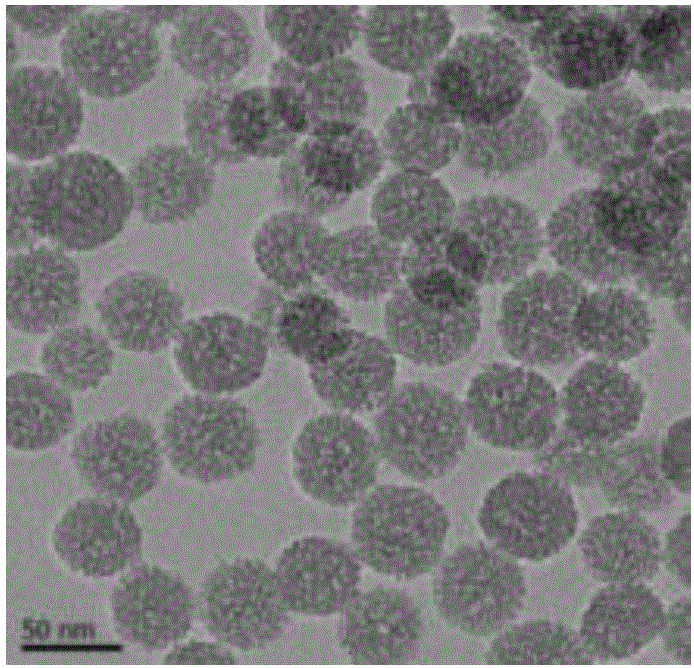

Silicon dioxide hollow sphere nano composite material, and preparation and application thereof

ActiveCN109704347AImprove performanceEasy to operateMaterial nanotechnologySilicaWeather resistanceAnti-fog

The invention relates to a silicon dioxide hollow sphere nano composite material, and a preparation and application thereof, and relates to the field of nano materials. The preparation method of the silicon dioxide hollow sphere nano composite material comprises the following steps: separately preparing a silicon dioxide hollow sphere suspension and a nano silicon dioxide acidic sol, mixing the silicon dioxide hollow sphere suspension with the nano silicon dioxide acidic sol by stirring, and then carrying out standing to obtain the silicon dioxide hollow sphere nano composite material. A silicon dioxide nano composite coating prepared from the silicon dioxide nano composite material disclosed by the invention has good anti-reflection, permeability-increasing, self-cleaning and anti-fog effects, and meanwhile, the coating also has good mechanical wear resistance and weather resistance, and has good firmness with a substrate. High-temperature calcination or other post-treatment modes arenot needed for preparing the coating, the coating can exert an effect outdoors for a long time, and the application range is wide.

Owner:UNIV OF SCI & TECH BEIJING

Magnetic head with air bearing surface protection film

InactiveUS20050264938A1Maintain good propertiesIncrease resistanceManufacture head surfaceFluid-dynamic spacing of headsTectorial membraneHigh density

Embodiments of the invention provide an air bearing surface protection film having good corrosive resistance, electrical insulative property and mechanical wear resistance in the state of an extremely thin film. In one embodiment, an air bearing surface protection film having good corrosive resistance, electrical insulative property and mechanical wear resistance in a state of an extremely thin film is obtained by disposing a thin silicon nitride film having high density, high electric resistance, chemical stability and high adhesion with a substrate as a lowermost air bearing surface protection film and disposing a film comprising tetrahedral amorphous carbon and nitrogen as an uppermost air bearing surface protection film.

Owner:WESTERN DIGITAL TECH INC

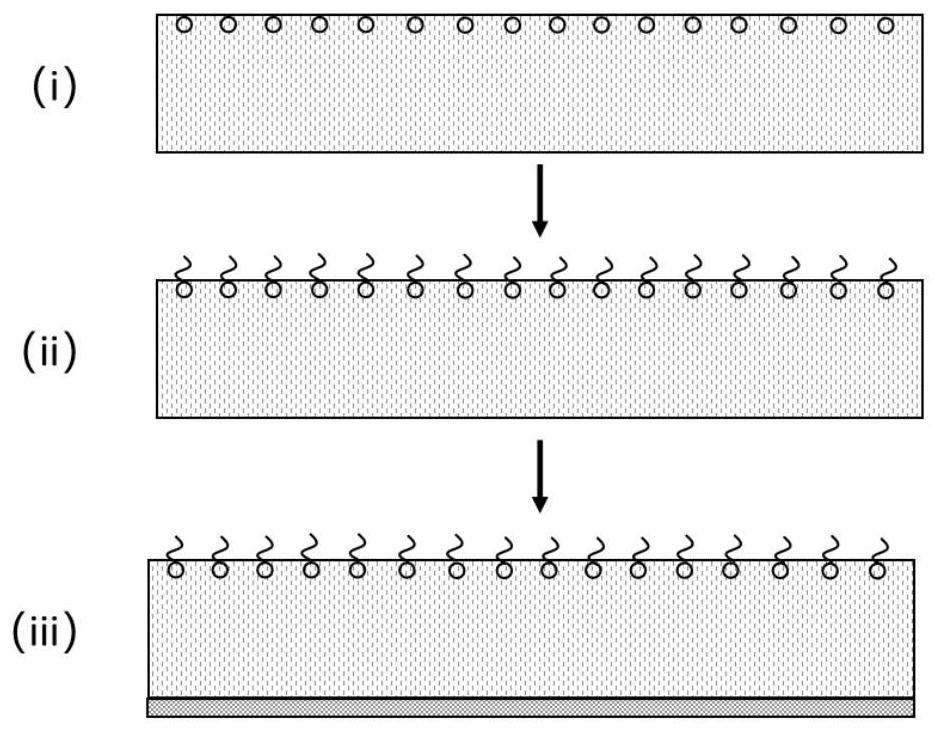

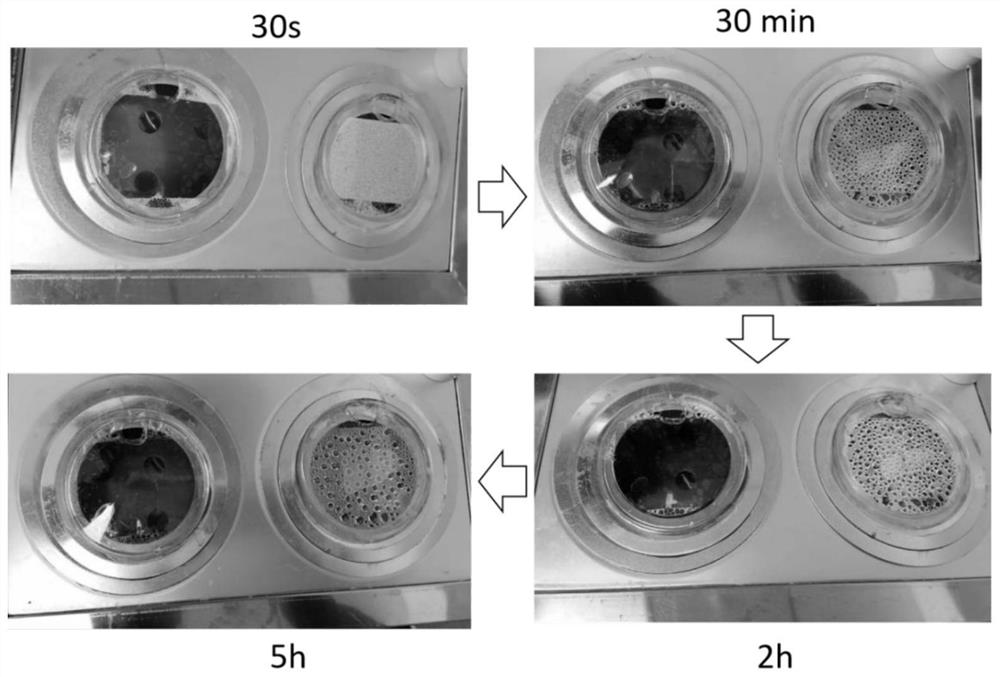

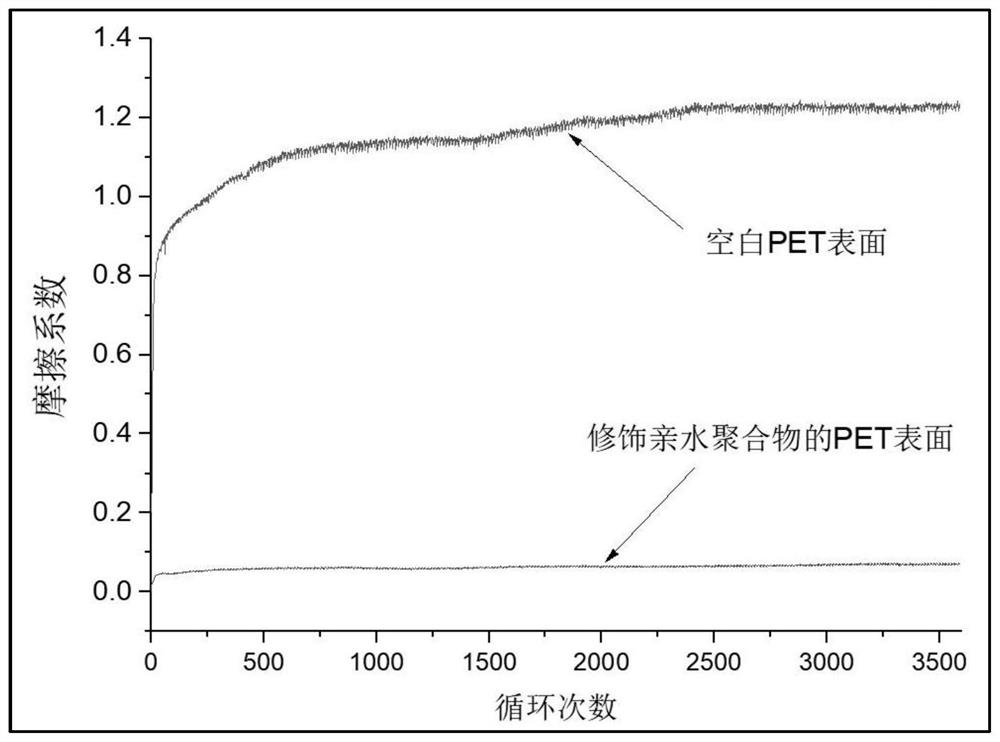

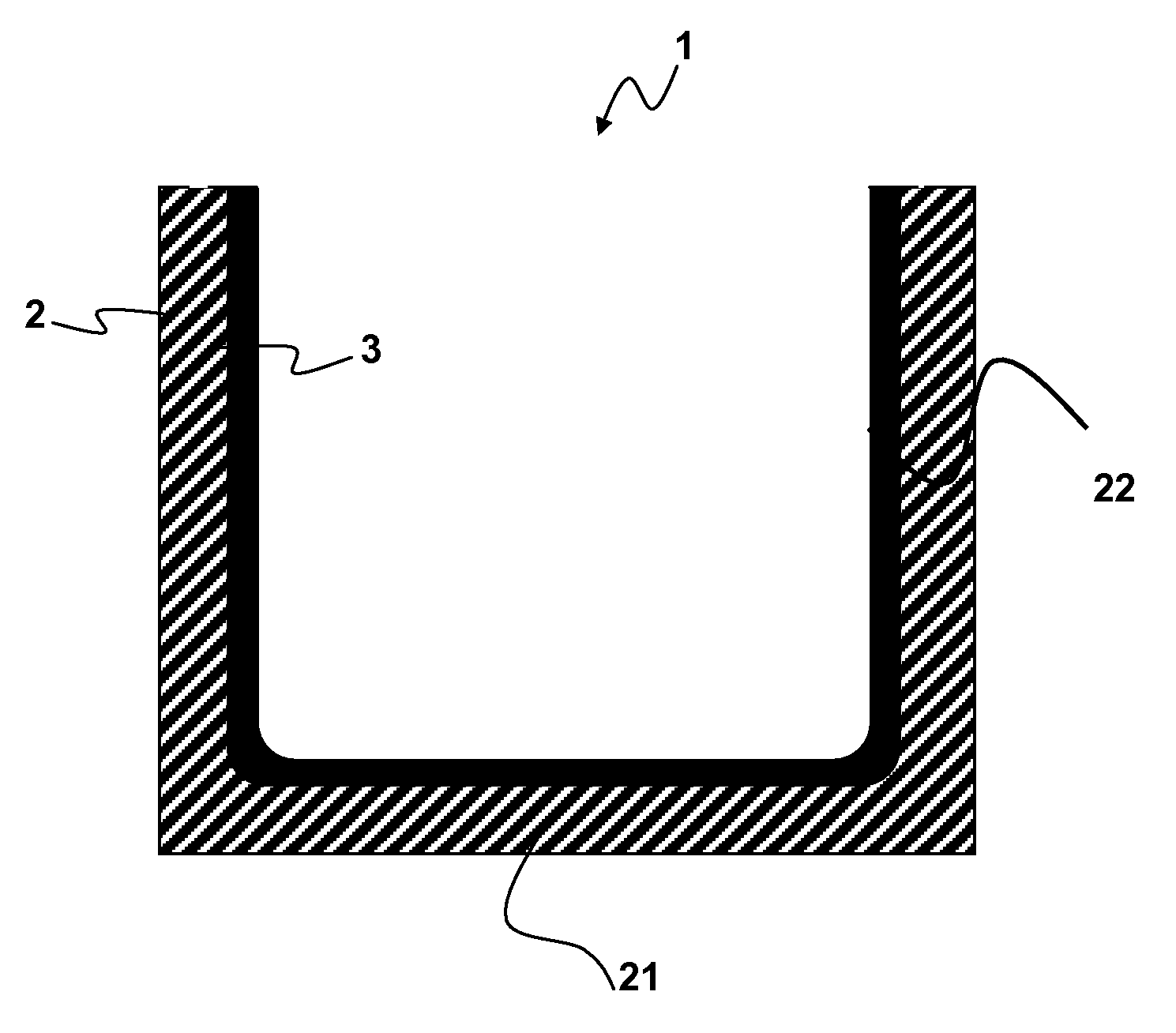

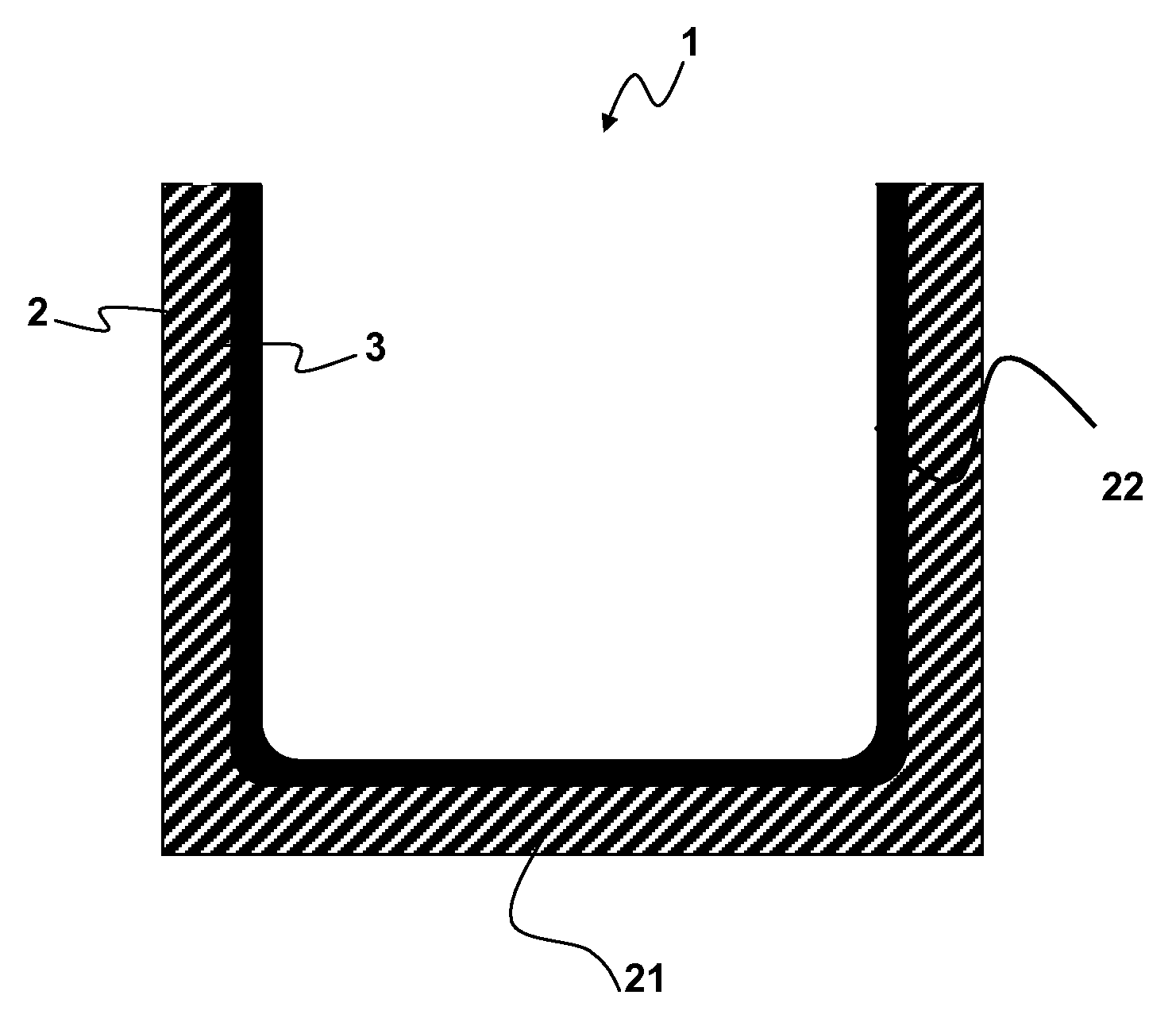

Polymer brush modified transparent anti-fog patch and preparation method thereof

ActiveCN111621240AImprove mechanical wear resistanceAvoid the loss of anti-fogFilm/foil adhesivesPolymer scienceHydrophilic polymers

The invention provides a polymer brush modified transparent anti-fog patch and a preparation method thereof, and belongs to the technical field of anti-fog materials. The polymer brush modified transparent anti-fog patch comprises a transparent polymer base film, a hydrophilic polymer brush layer located on one side of the transparent polymer base film and an organic binder layer located on the other side of the transparent polymer base film. And the hydrophilic polymer brush layer grows on the surface of the transparent polymer base film in a grafting manner in a photo-initiation manner. According to the invention, the hydrophilic polymer brush layer is generated through photo-initiated surface free radical polymerization, and the hydrophilic polymer brush layer is connected with the transparent polymer base film through covalent bonds, so that the bonding strength is high, and the problem that the anti-fog performance is reduced due to loss of a hydrophilic polymer under the hydration effect can be avoided; the grafted hydrophilic polymer brush chain segment can quickly absorb water mist and hydrate and form a transparent water film to generate an anti-fog effect, and the hydrophilic polymer brush layer has excellent mechanical wear resistance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

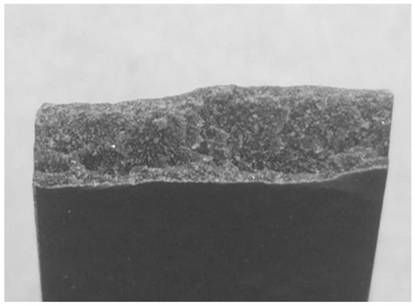

Crucible for the crystallization of silicon and process for making the same

InactiveUS8298333B2Fast and cheap to producePrevent peelingPolycrystalline material growthBy pulling from meltCrucibleIngot

A protective coating is prepared for, and applied to, crucibles used in the handling of molten materials that are solidified in the crucible and then removed as ingots. Crucibles containing this protective coating may be used for the solidification of silicon. The coating has a specified oxygen content and contains a mineral binder and silicon nitride or silicon oxynitride.

Owner:VESUVIUS USA CORP

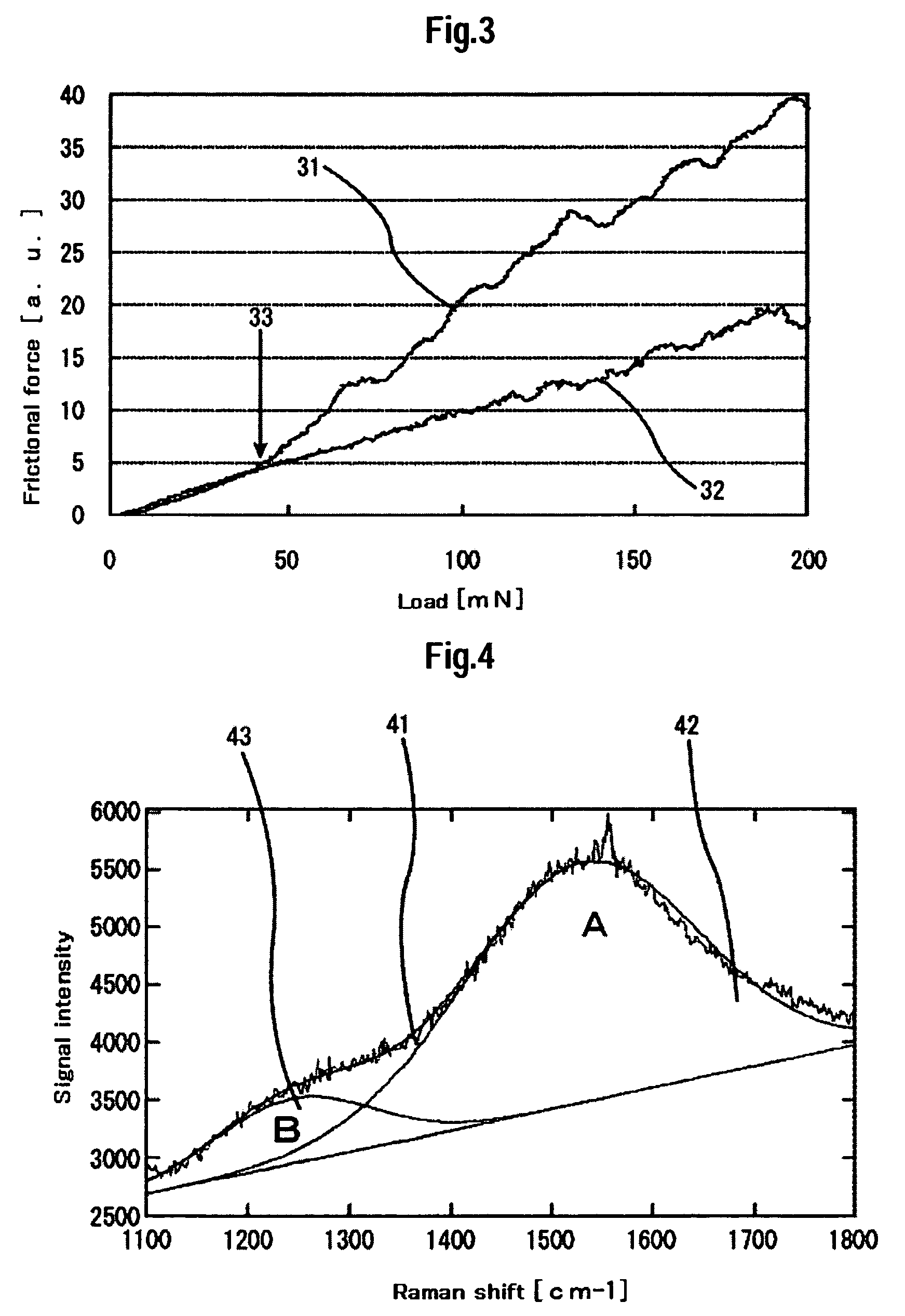

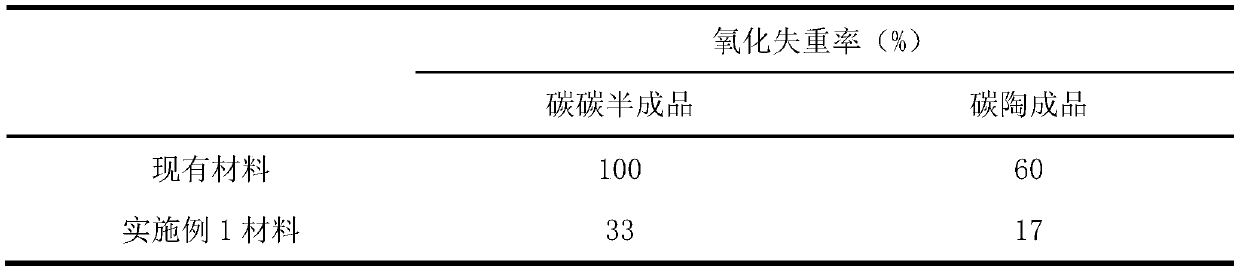

Preparation method of carbon-ceramic brake material with strong oxidation resistance

InactiveCN111056855AImprove antioxidant capacityReduce oxidation wearFriction liningActuatorsMolten siliconOxidation resistant

The invention relates to a preparation method of a carbon-ceramic brake material with strong oxidation resistance. The method is based on a three-dimensional needled carbon / ceramic brake material. A carbon / carbon-boron carbide composite material is obtained by introducing a CVI deposition B4C process technology between pyrolytic carbon and pyrolytic carbon; a siliconizing treatment is carried outafter a high-temperature treatment; the antioxidant carbon / carbon-boron carbide-silicon carbide composite material with a density of 1.9 g / cm<3> to 3.0 g / cm<3> is obtained; according to the method, the pyrolytic carbon matrix and the carbon fibers in the boron carbide layer can be effectively protected from being eroded by oxygen, meanwhile, the pyrolytic carbon layer outside the boron carbide layer is not influenced and reacts with molten silicon to generate silicon carbide, the integrity of the boron carbide layer is protected; the distribution uniformity of ceramic phases in each area is improved, the mechanical wear resistance of a carbon / carbon area is improved by utilizing the high hardness of boron carbide, the expansion path of cracks in the material failure process is prolonged through the multi-layer structure design, stress release is facilitated, the bearing capacity of the matrix is improved, and the strength and toughness of the brake material become better.

Owner:山东道普安制动材料有限公司

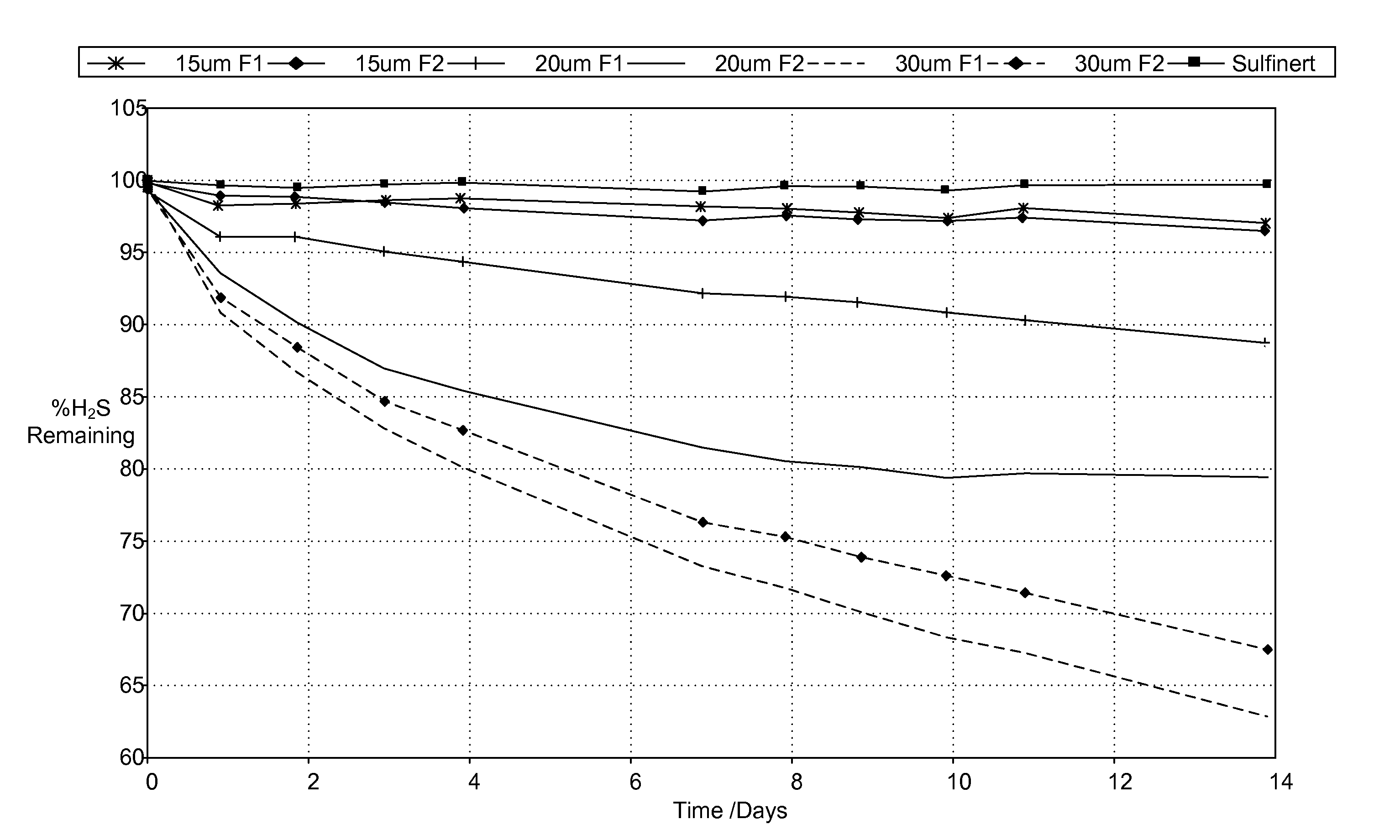

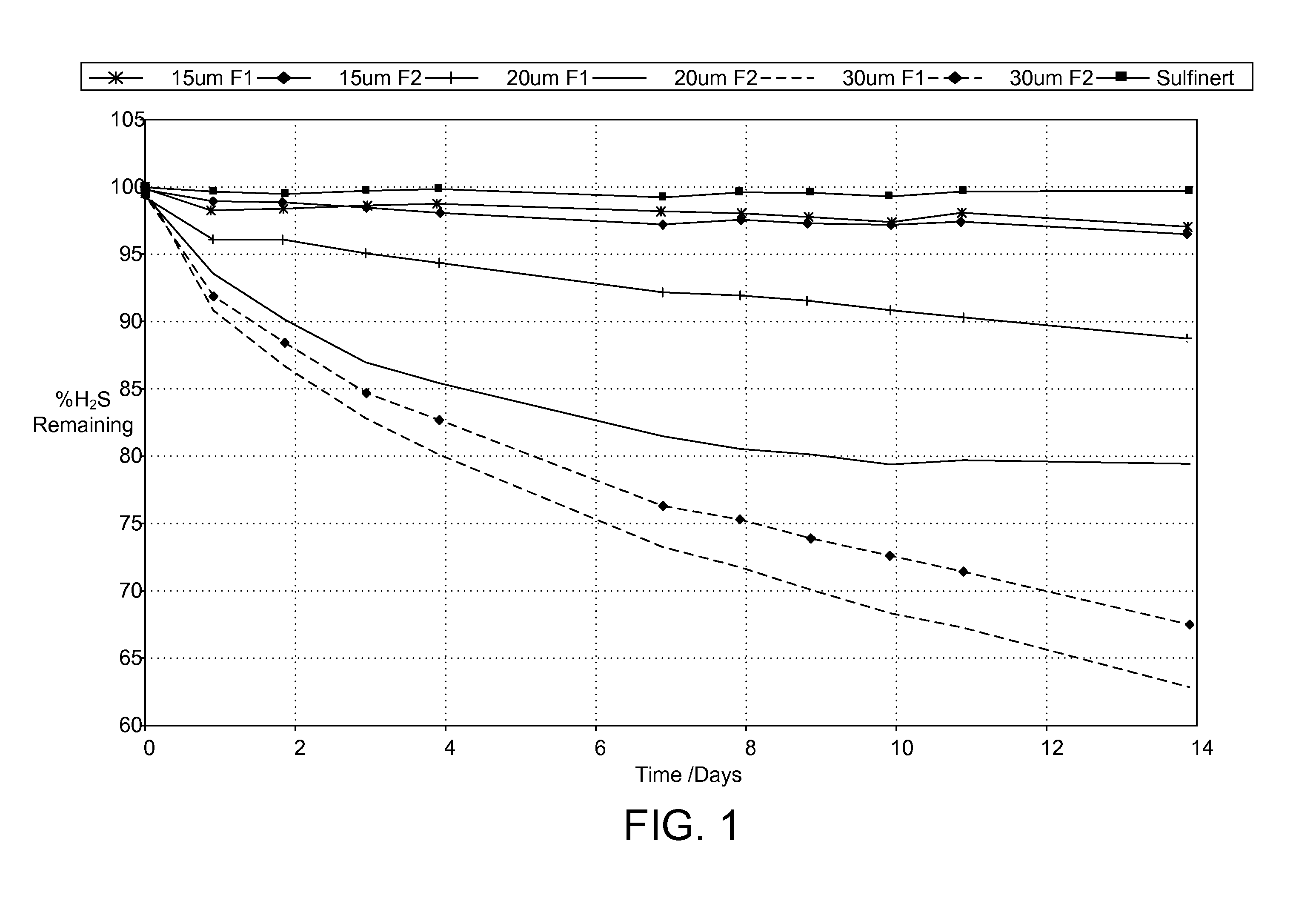

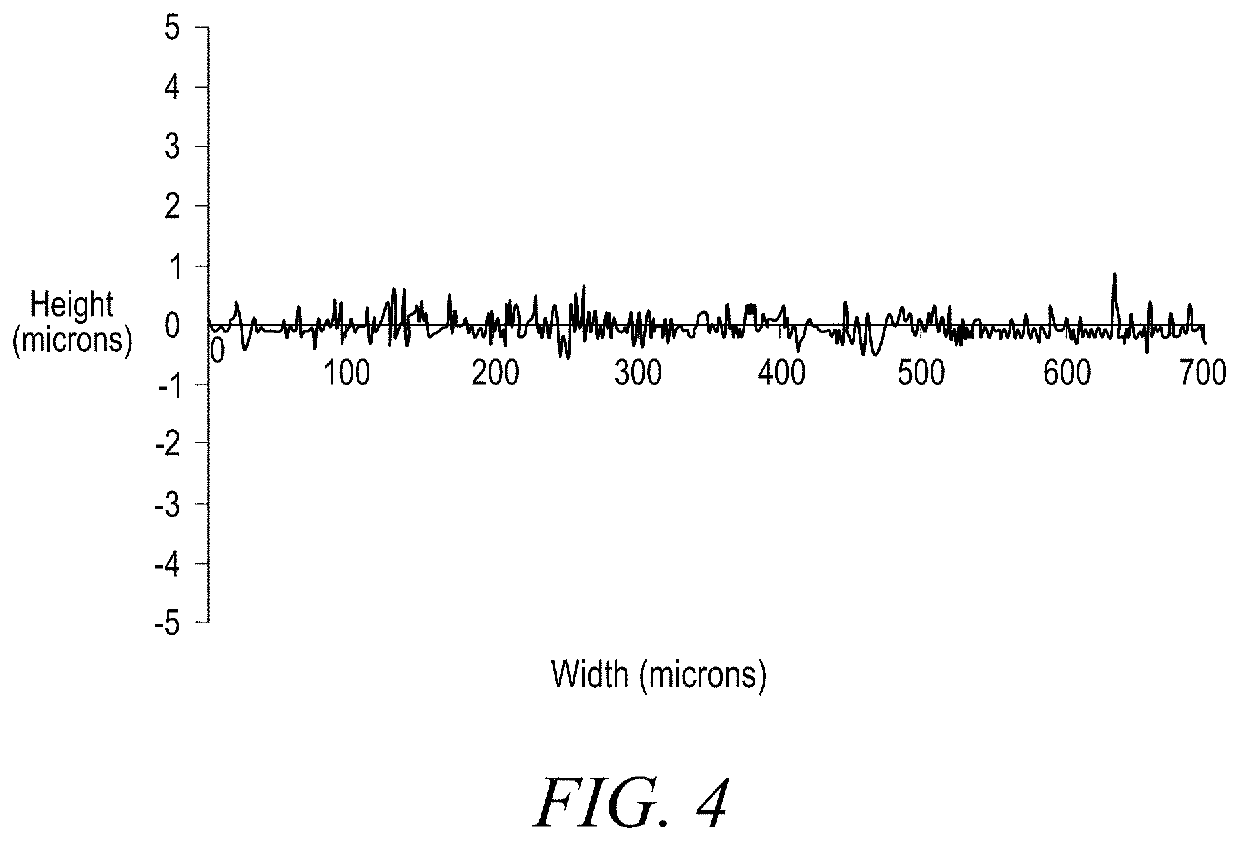

Sampling device with diamond-like carbon coating

InactiveUS20100116046A1Improve mechanical wear resistanceAvoid absorptionBorehole/well accessoriesCarbon coatingMetal

A diamond-like carbon coating is provided on a metal interior surface of a sample chamber of a well fluid sampling apparatus to render the sample chamber substantially impervious to the absorption of at least H2S, mercury, and / or mercaptans. The coating is a dense, amorphous, diamond-like carbon with an sp3 content greater than about 65% and is composed of about 70 percent (%) carbon, 30 percent (%) hydrogen. The coating may be applied over the surface in one or more layers by a suitable method, e.g., plasma assisted chemical vapor deposition or a PAVCD process, and is between about 10 and about 20 microns thick. One or more of the layers of the coating includes a small percentage of silicon to increase both the adherence to the metal interior surface of the sample chamber and the absorption resistance of the coating. The resulting sample chamber provides H2S, mercaptan, and mercury retention of greater than about 95% of the original concentration in samples stored up to 14 days.

Owner:SCHLUMBERGER TECH CORP

Rubber composition containing silane coupling agent and carbon nanotubes and preparation method of rubber composition

The invention relates to the field of rubber preparation, in particular to rubber composition containing a silane coupling agent and carbon nanotubes and a preparation method of the rubber composition. The rubber composition is prepared from substances as follows: rubber, the silane coupling agent, 0.1-5 parts by weight of the carbon nanotubes, white carbon black and an aid, wherein the aid is prepared from a softener, an anti-ageing agent, sulfur and a vulcanization accelerator. The preparation method comprises steps as follows: the rubber, the silane coupling agent, the carbon nanotubes and the white carbon black are added to water to be mixed, and a suspending liquid is prepared; a flocculant is added to the suspending agent, and the mixture is dried; a product is added to an internal mixer, the softener and the anti-ageing agent are added, and the mixture is mixed; secondary mixing is performed, and super glue is cooled; the super glue is added to sulfur and the vulcanization accelerator, and the rubber composition is obtained after being turned and batched out. Due to the special structure of the carbon nanotubes and the function of a group of the silane coupling agent, additives in the rubber are more uniformly mixed, the property of finished products of the rubber is more stable, and besides, the performance of the rubber in the aspects of mechanical abrasion resistance, corrosion resistance, rebound resilience, low-compression permanent deformation and the like is remarkably improved.

Owner:SHANDONG RUICHUAN SILICON IND

Self-cleaning coating with transmittance-increasing and wear-resisting functions and preparation method of self-cleaning coating

ActiveCN105713425AWith wear resistanceImprove mechanical wear resistanceSilicaAntifouling/underwater paintsSio2 nanoparticleTransmittance

The invention provides a self-cleaning coating with transmittance-increasing and wear-resisting functions and a preparation method of the self-cleaning coating, belongs to the technical field of building coatings and solves the problems of poor wear resistance and hydrophilicity of a conventional self-cleaning coating. According to the method, ammonia water and tetraethoxysilane are added to a reaction container containing absolute ethyl alcohol and stirred at the temperature of 60 DEG C for 8-12 h, and solid SiO2 nanoparticles are obtained; then, the solid SiO2 nanoparticles, hexadecyl trimethyl ammonium bromide and diethylamine are mixed and stirred in a water bath at the temperature of 60 DEG C for 1-2 h, tetraethoxysilane is added, the mixture reacts for 3 h, and a reaction solution is obtained; finally, hydrogen peroxide is added to the reaction solution and stirred, the obtained product is centrifuged and washed, and the self-cleaning coating with the transmittance-increasing and wear-resisting functions is obtained. The invention further provides the self-cleaning coating with transmittance-increasing and wear-resisting functions, which is prepared with the preparation method. The coating has high light transmittance, good mechanical wear resistance and excellent wettability.

Owner:JINLIN HAICHUAN TECH CO LTD

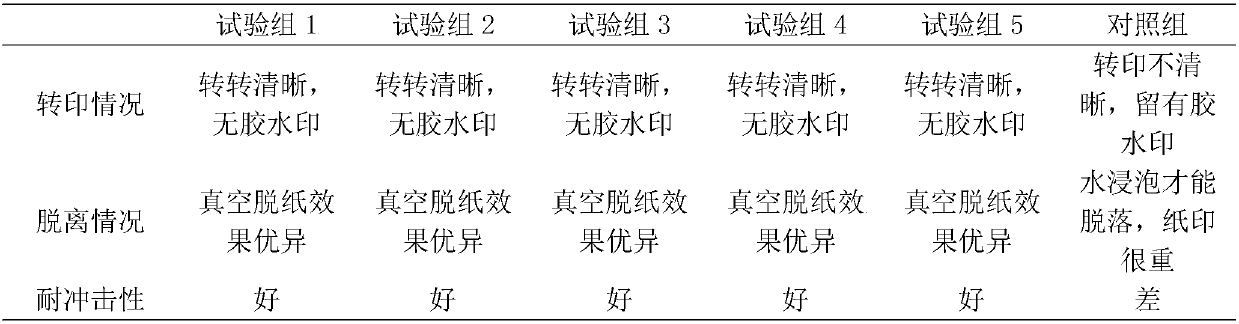

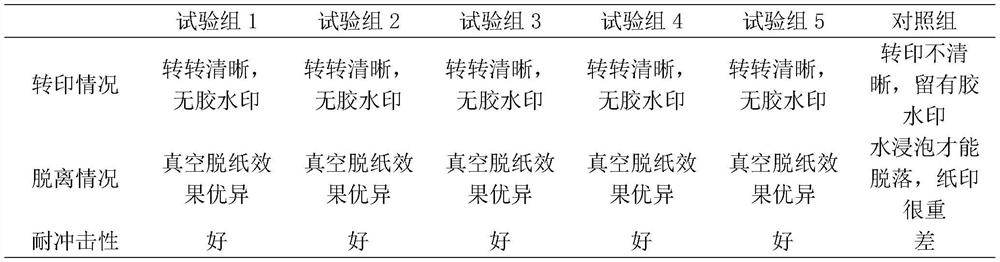

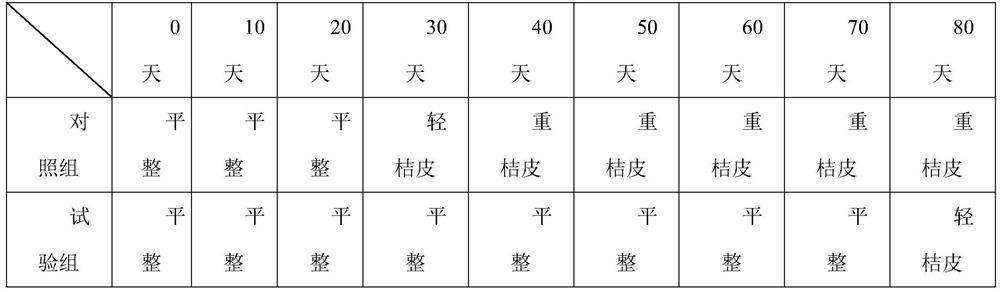

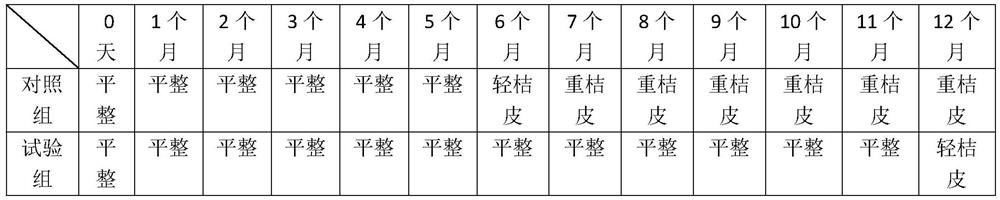

Heat transfer printing paper detaching agent preparation method, prepared heat transfer printing paper detaching agent and application thereof

The invention discloses a heat transfer printing paper detaching agent preparation method which includes the steps: material preparation: grinding carboxyl acrylic resin and epoxy acrylic resin into fine powder and sieving the fine powder by a 160-mesh screen; proportioning: in weight percent, preparing 10-40% of carboxyl acrylic resin, 10-40% of epoxy acrylic resin, 5-30% of white carbon black, 5-30% of amide wax, 5-20% of dodecanedioic acid, 3-15% of organic zinc salt and 10-20% of canola oil into a backing material; mixing: transferring the prepared backing material into a vertical mixing cylinder and mixing the prepared backing material for 10-30 minutes to prepare a heat transfer printing paper detaching agent. The invention further discloses the heat transfer printing paper detachingagent and an application of the heat transfer printing paper detaching agent to the technical field of heat transfer printing. The stability of a heat transfer printing powder coating can be effectively improved by the heat transfer printing paper detaching agent.

Owner:梧州市泽和高分子材料有限公司

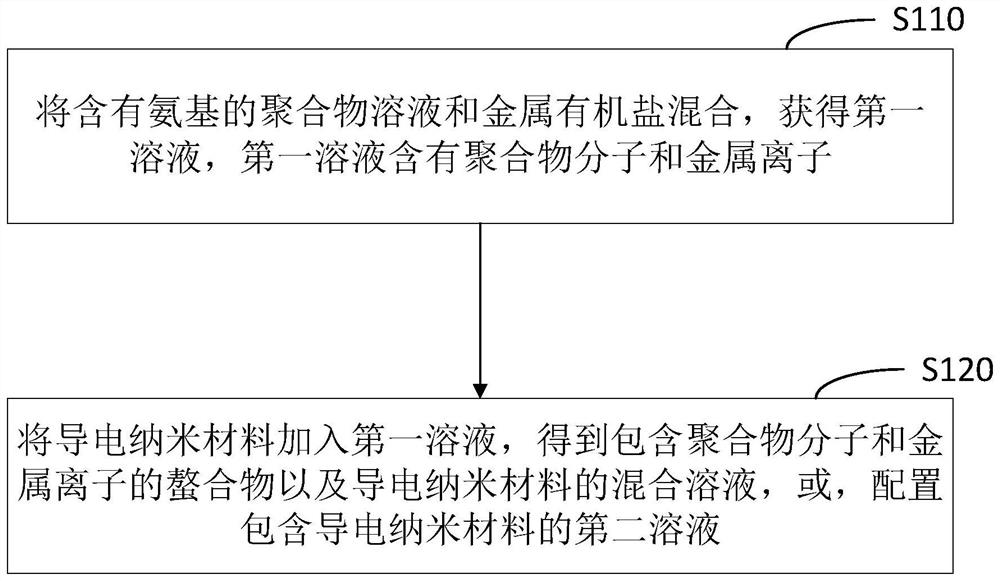

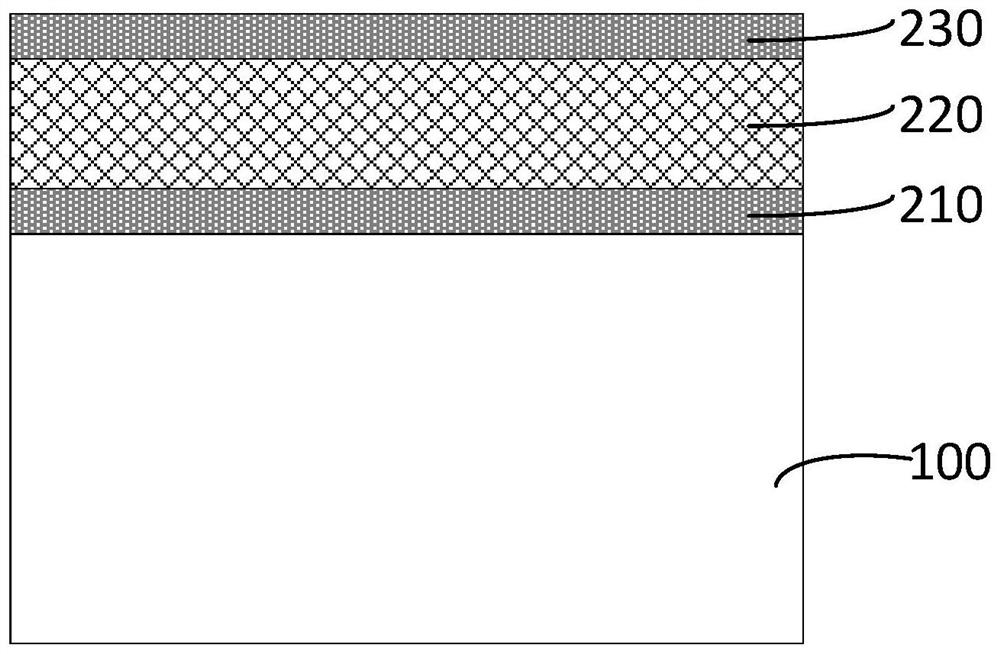

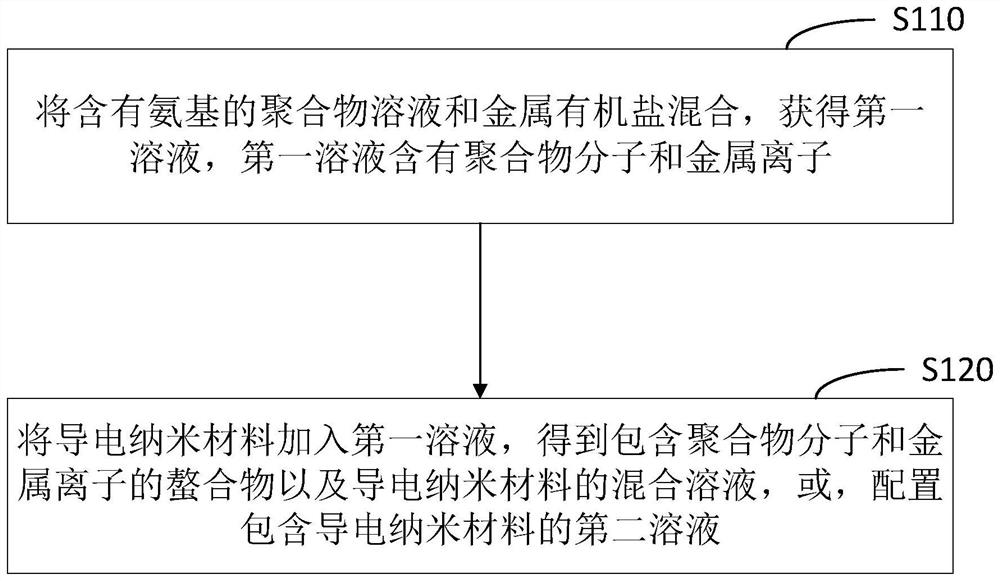

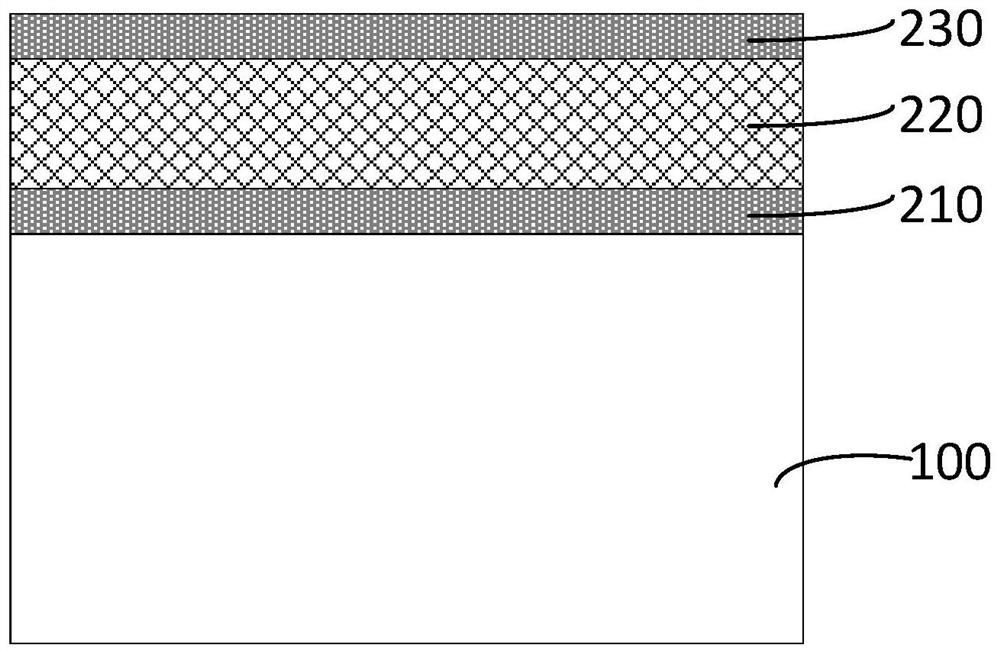

Anti-static coating material, preparation method thereof, anti-static coating and forming method thereof

ActiveCN114106688AImprove mechanical wear resistanceMechanical wear resistance adjustmentSpecial surfacesElectrically-conductive paintsPolymer scienceConductive materials

The invention discloses an anti-static coating material and a preparation method thereof, and an anti-static coating and a forming method thereof, the anti-static coating material is characterized by comprising a chelate of polymer molecules and metal ions and a conductive nano-material, the polymer molecules contain amino groups, and when the anti-static coating material is prepared, the polymer molecules contain amino groups, and when the anti-static coating material is prepared, the polymer molecules contain amino groups. A conductive nano material is used as a main conductive material, the conductive requirement of the coating can be met, a polymer containing amino and a chelate of metal ions are added, amino in polymer molecules interacts with the metal ions, a compound with conductive performance is obtained, the conductive performance of the anti-static coating is further improved, and meanwhile the anti-static performance of the anti-static coating is improved. And the mechanical wear resistance of the coating can also be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

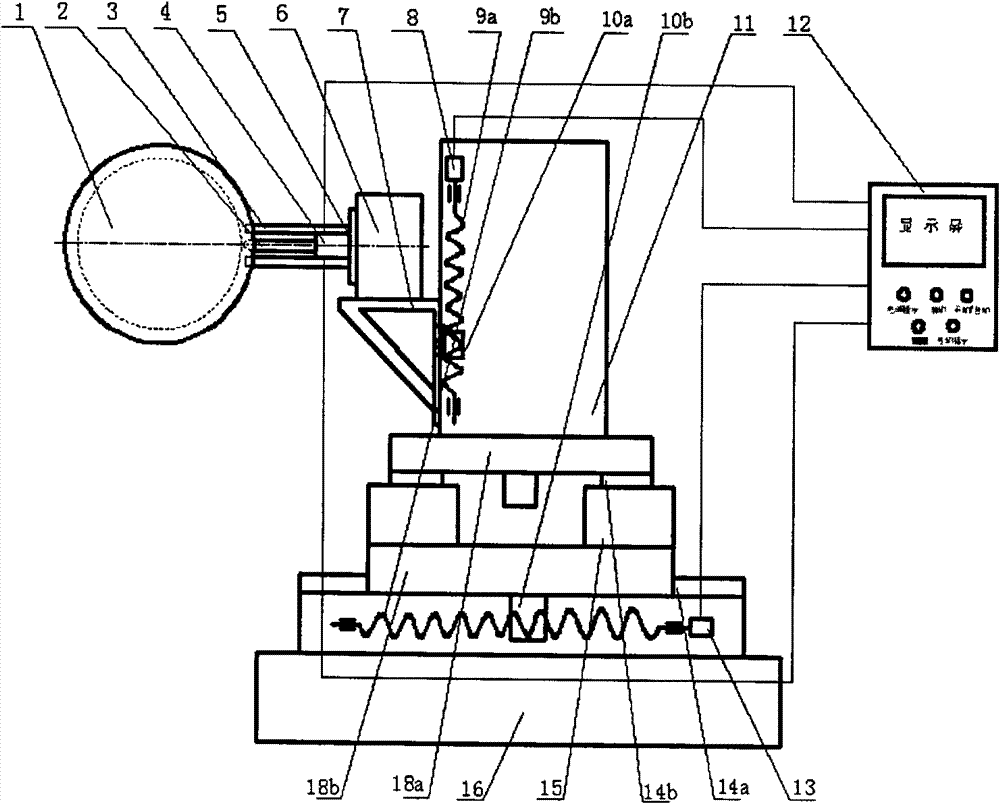

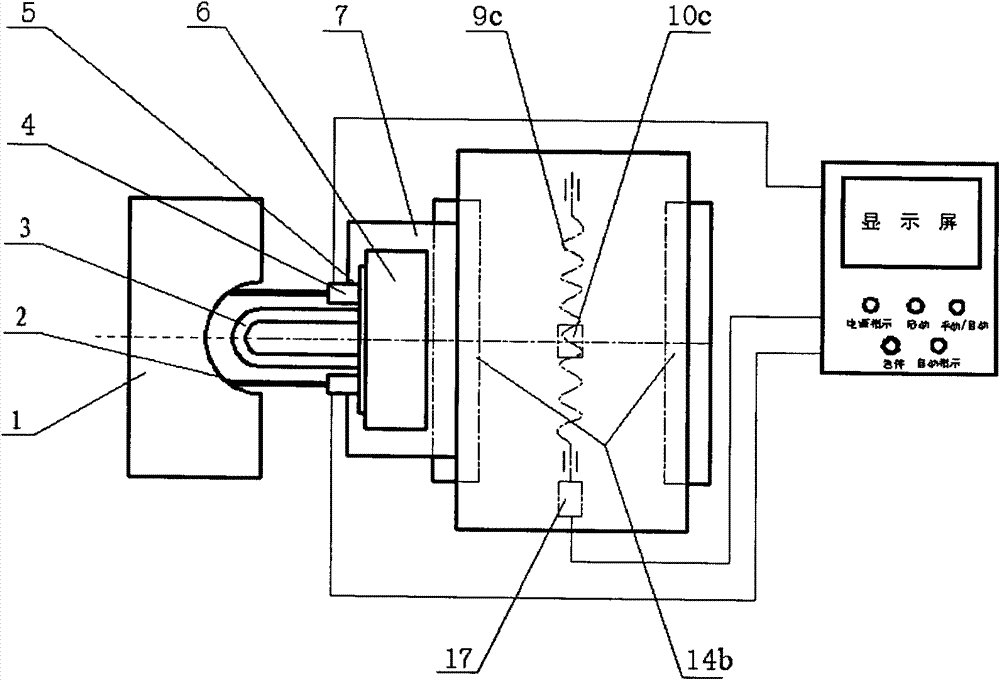

Device for automatically detecting relative position of quenching sensor and rotary supporting raceway

InactiveCN101974669BHigh compressive strengthImprove mechanical wear resistanceIncreasing energy efficiencyQuenching devicesControl systemBall screw

The invention provides a device for detecting a relative position of a quenching sensor and a rotary supporting raceway, belonging to the technical field of industrial measurement. The device mainly comprises a ruby probe, a pressure sensor, a flange, a transformer bracket, a servo motor, a ball screw, a screw nut, an upright post, a control system, a guide rail, a supporting seat, a base, a sliding plate, and the like. In the device, the ruby probe is used for inducing, the pressure sensor is used for feedback, and the control system is used for displaying and adjusting the relative positionof the quenching sensor and the rotary supporting raceway. The detection device provided by the invention has simple structure and convenient use, is used for automatically detecting the relative position of the quenching sensor and the raceway, can effectively lighten the labor intensity of workers, acutely ensure the depth and the evenness of a quenching layer, improve the quality of the quenching layer on the raceway surface and the use performance of a rotary support.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

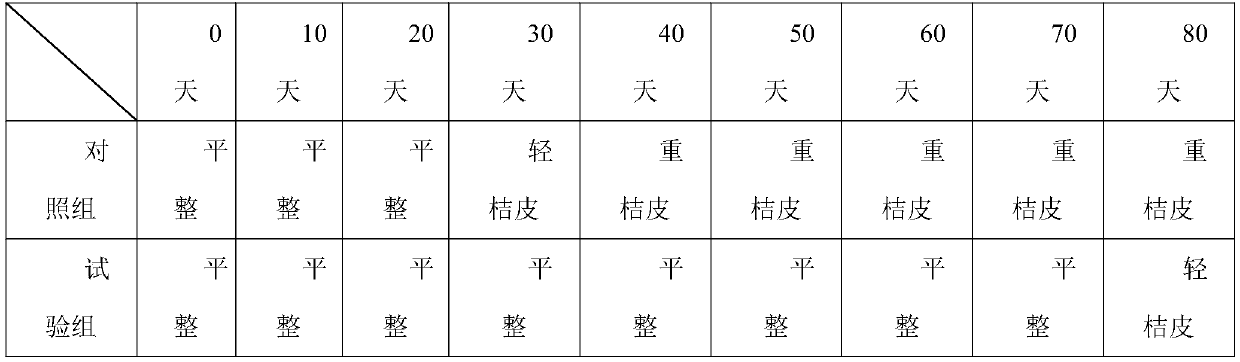

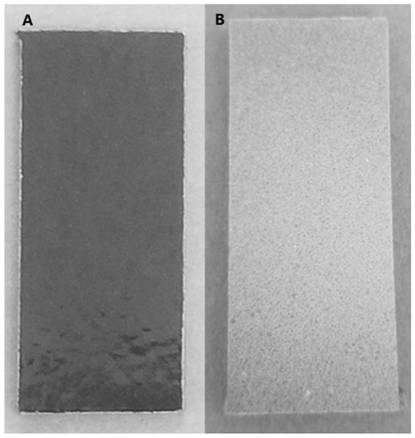

Super-hydrophobic phenolic sheet and preparation method thereof

ActiveCN110983861AEasy to prepareSimple preparation processLamination ancillary operationsSpecial paperPolymer sciencePolyvinyl chloride

The invention provides a super-hydrophobic phenolic sheet and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a phenolic resin / organic solvent mixed solution with a preset concentration, infiltrating a paper-based material with the prepared mixed solution, and carrying out drying to obtain a prepreg; carrying out stacking hot press molding treatment and pretreatment on the prepreg to obtain a phenolic sheet; then, preparing a polyvinyl chloride / tetrahydrofuran mixed solution, and adding an organic solvent to obtain a super-hydrophobic coating; and finally, subjecting the surface of the phenolic sheet to spraying-drying treatment with the super-hydrophobic coating so as to obtain the super-hydrophobic phenolic sheet. The super-hydrophobic phenolic sheet provided by the invention has impact strength of 11.978 kJ / m<2>, a density of 1.41 g / cm<3>, elastic modulus of 23.8 GPa and bending strength of 642.7 Mpa and a contact angle of 160 degrees or above; and the contact angle of the super-hydrophobic phenolic sheet with kraft paper attached to the substrate of the phenolic sheet can be kept at 155 degrees or above, so the super-hydrophobic phenolic sheet has an excellent hydrophobic property.

Owner:HUBEI POLYTECHNIC UNIV

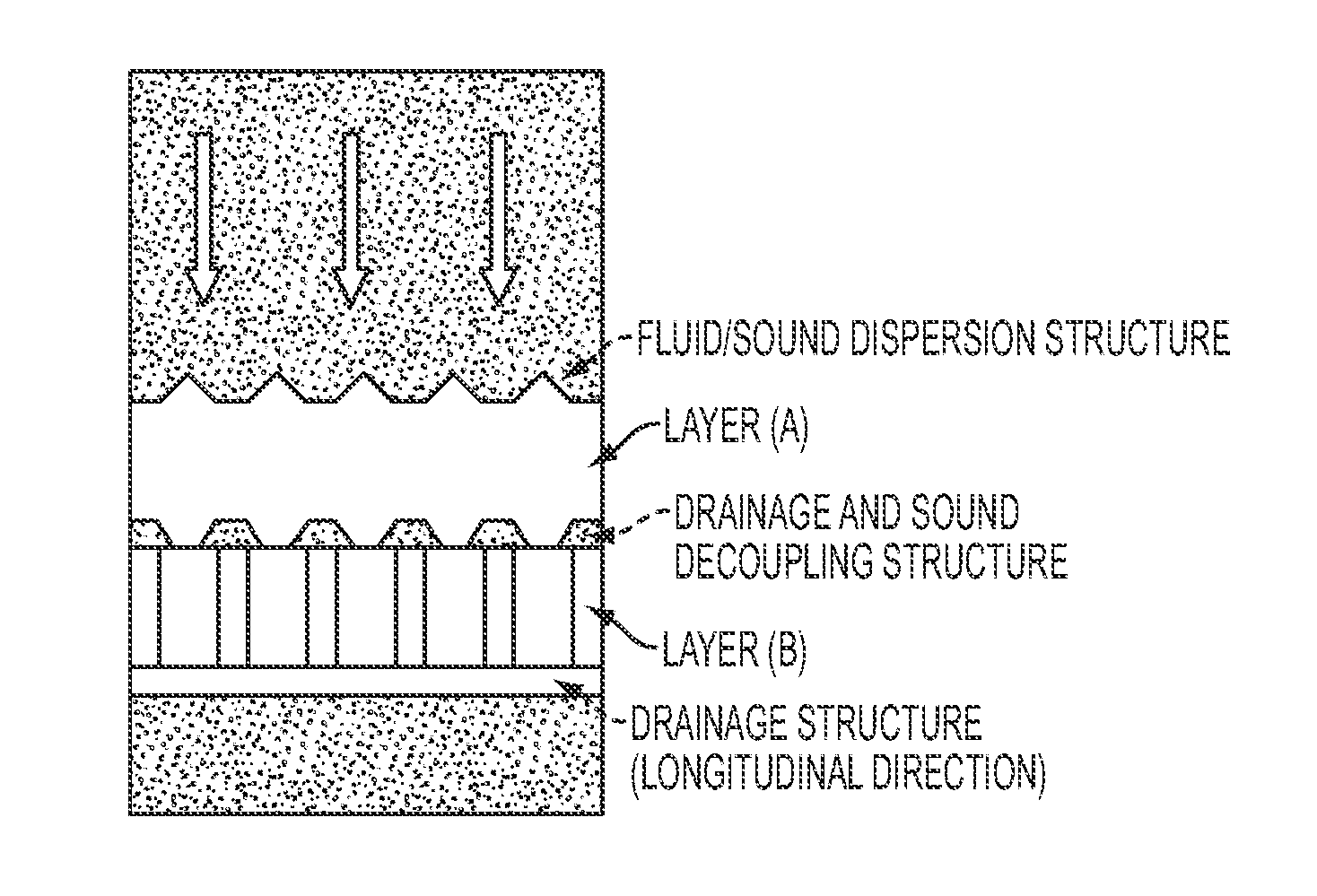

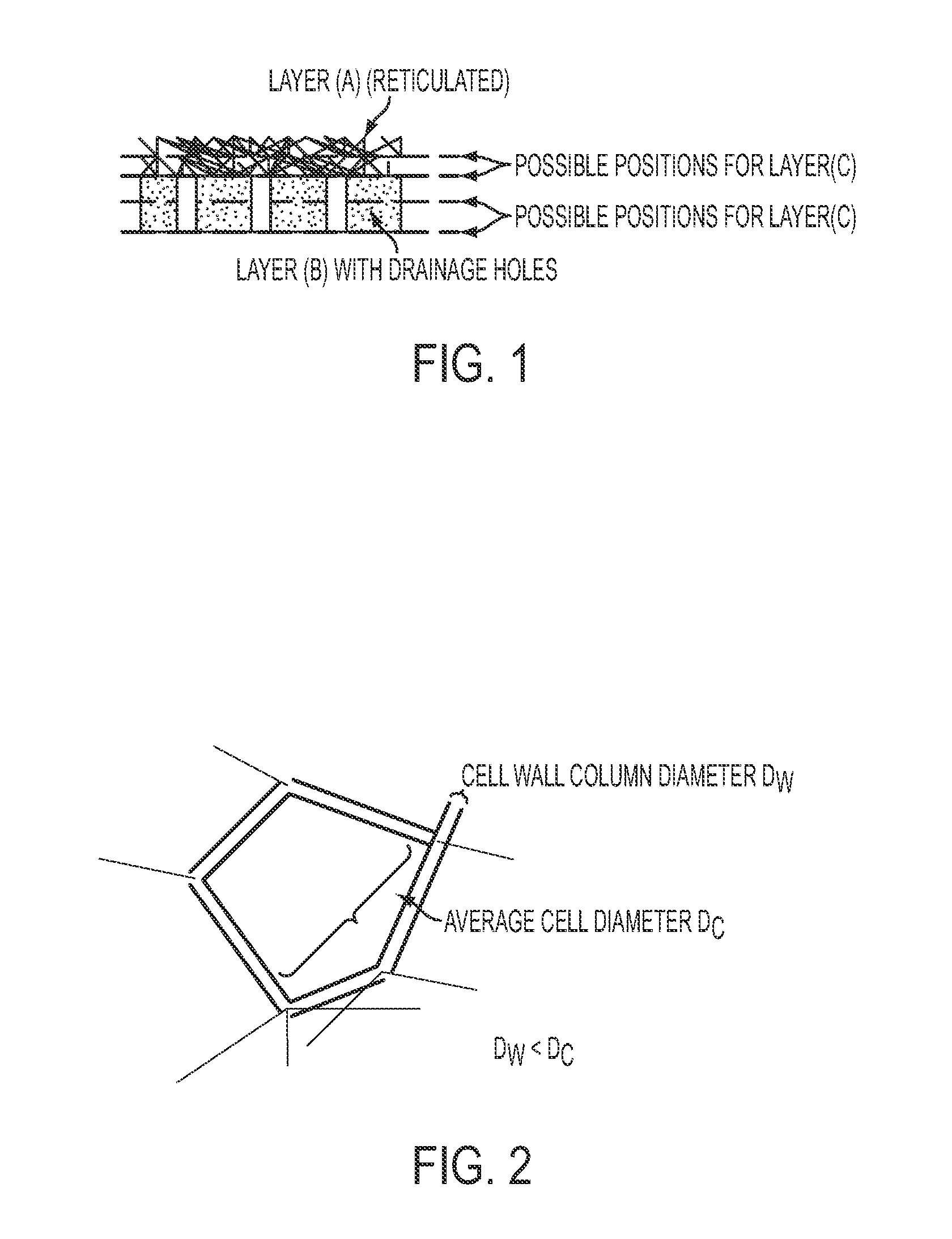

Floating device providing noise reduction properties

InactiveUS20110303483A1Significant and sustainable level of noise reductionImprove mechanical wear resistanceEfficient regulation technologiesSound proofingEngineeringNoise reduction

Owner:ARMACELL ENTERPRISE GMBH & CO KG

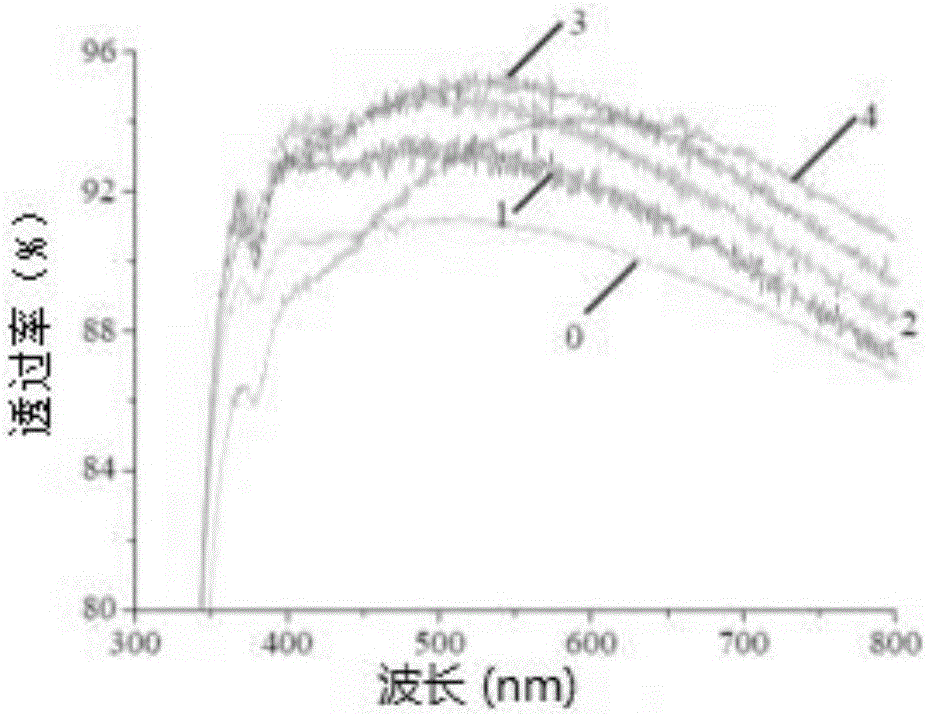

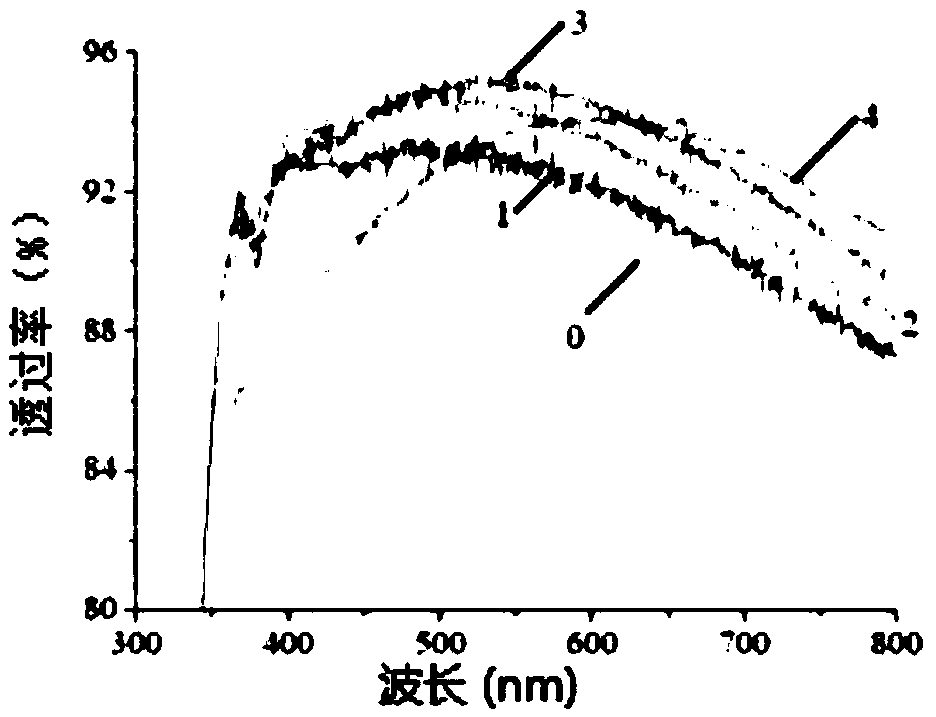

Hydrophobic SiO2 nano mixed liquor, functional coating and preparation

The invention relates to a hydrophobic SiO2 nano mixed liquor, a functional coating and preparation. The hydrophobic SiO2 nano mixed liquor is formed by compounding a hydrophobic SiO2 nano particle suspension modified by an organic fluorine functional group and a nano-SiO2 acid sol; the average particle size of the hydrophobic SiO2 nano particles in the hydrophobic SiO2 nano particle suspension is10nm, and the particle surfaces are modified by the organic fluorine functional group; the nano-SiO2 acid sol has chain-shapednano-SiO2, and the condensation degree of the nano-SiO2 acid sol is 70-90%. The functional coating prepared on the glass surface by using SiO2 nano mixed liquor has the good anti-reflection performance (the light transmittance is greater than 96%) and the superhydrophobicperformance (the contact angle is greater than 150 degrees), and the properties of superhydrophobic self-cleaning, antifogging, oil stain prevention and the like can be achieved; the coating has goodmechanical wear resistance, and is firmly combined with the substrate, using is not limited, the coating can be used for playing a role for a long time outdoor, and the range of application is wide.

Owner:UNIV OF SCI & TECH BEIJING

Anti-wrinkling bacteriostatic finishing agent for real silk and preparation method of anti-wrinkling bacteriostatic finishing agent

InactiveCN110284332AImprove performanceAnti-agingWrinkle resistant fibresBiochemical treatment with enzymes/microorganismsPolymer scienceDioxyethylene Ether

The invention provides an anti-wrinkling bacteriostatic finishing agent for real silk and a preparation method of the anti-wrinkling bacteriostatic finishing agent. The anti-wrinkling bacteriostatic finishing agent is prepared from, by weight, 60-80 parts of polysiloxane-modified polyurethane / nanometer SiO2 composite raw materials, 5-10 parts of nonylphenol polyoxyethylene ether, 2-5 parts of polyglycerol-3 diisostearate, 8-15 parts of isopropanol, 2-6 parts of polyacrylic acid, 4-8 parts of chitosan, 3-6 parts of natural rubber, 3-8 parts of a dispersing agent, 6-12 parts of a softening agent and 10-20 parts of water; polysiloxane is quaternary ammonium salt-grafted polysiloxane, and nanometer SiO2 is amino-modified nanometer SiO2. A real silk fabric finished by the finishing agent has good antibacterial performance and anti-wrinkling performance, the mechanical strength of the real silk fabric is improved, and therefore the finishing agent has an important application prospect in the textile field.

Owner:SUZHOU INST OF TRADE & COMMERCE

A kind of preparation method of thermal transfer paper release agent, prepared thermal transfer paper release agent and application thereof

Owner:梧州市泽和高分子材料有限公司

A self-cleaning coating with antireflection and abrasion resistance and preparation method thereof

ActiveCN105713425BWith wear resistanceImprove mechanical wear resistanceSilicaAntifouling/underwater paintsWater bathsMechanical wear

The invention provides a self-cleaning coating with transmittance-increasing and wear-resisting functions and a preparation method of the self-cleaning coating, belongs to the technical field of building coatings and solves the problems of poor wear resistance and hydrophilicity of a conventional self-cleaning coating. According to the method, ammonia water and tetraethoxysilane are added to a reaction container containing absolute ethyl alcohol and stirred at the temperature of 60 DEG C for 8-12 h, and solid SiO2 nanoparticles are obtained; then, the solid SiO2 nanoparticles, hexadecyl trimethyl ammonium bromide and diethylamine are mixed and stirred in a water bath at the temperature of 60 DEG C for 1-2 h, tetraethoxysilane is added, the mixture reacts for 3 h, and a reaction solution is obtained; finally, hydrogen peroxide is added to the reaction solution and stirred, the obtained product is centrifuged and washed, and the self-cleaning coating with the transmittance-increasing and wear-resisting functions is obtained. The invention further provides the self-cleaning coating with transmittance-increasing and wear-resisting functions, which is prepared with the preparation method. The coating has high light transmittance, good mechanical wear resistance and excellent wettability.

Owner:JINLIN HAICHUAN TECH CO LTD

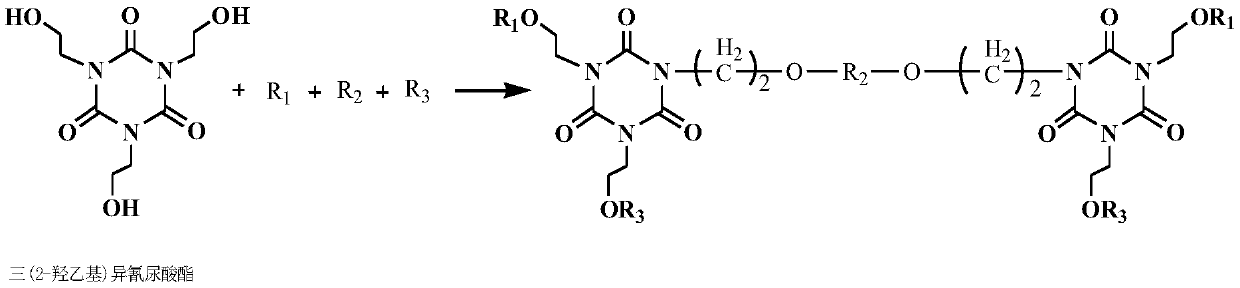

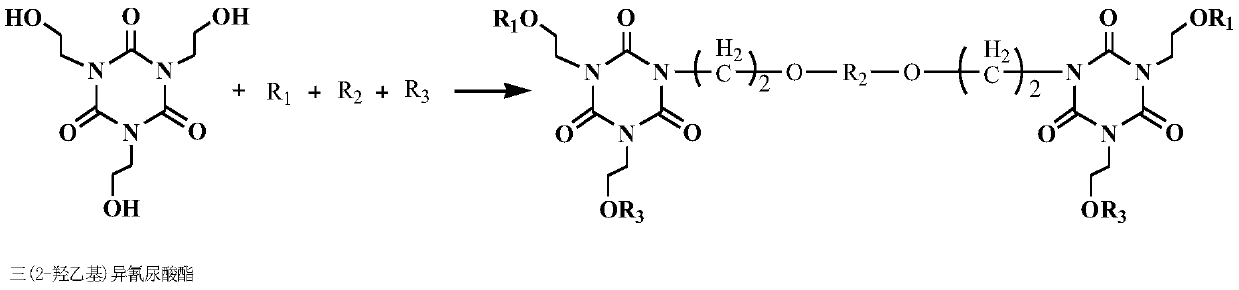

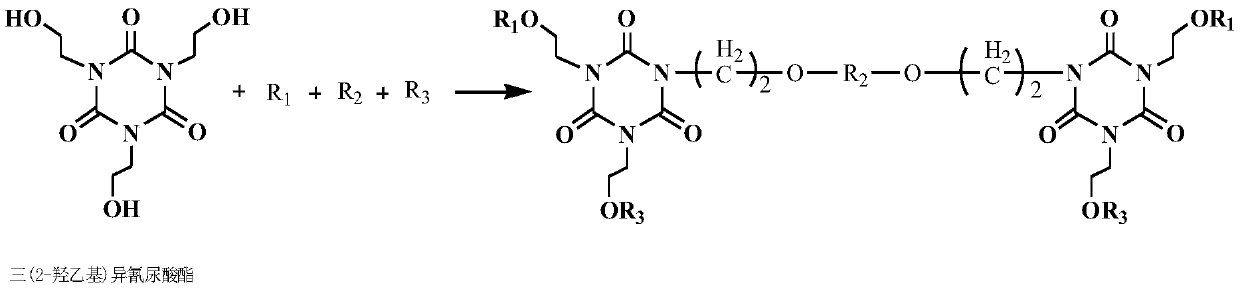

Acrylic resin composition

The invention belongs to the technical field of high polymer materials, and particularly relates to an acrylic resin composition. The acrylic resin composition is prepared from the following raw materials in parts by mass: 50-90 parts of modified acrylic resin, 10-40 parts of an active diluent, 1-30 parts of filler and 1-6 parts of a thermal initiator. The modified acrylic resin is formed by polymerizing tri(2-hydroxyethyl)isocyanurate, organic acid or organic alcohol containing carbon-carbon double bonds, and organic acid, organic alcohol, organic amine, polyurethane or epoxy resin. The modified acrylic resin composition prepared from the modified acrylic resin prepared in the invention can be rapidly cured at a low temperature, so the curing rate of the acrylic resin composition at a lowtemperature is improved, and the application range of the acrylic resin composition is broadened.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

Configuration method of antistatic coating material, antistatic coating and forming method thereof

ActiveCN114106688BImprove mechanical wear resistanceMechanical wear resistance adjustmentSpecial surfacesElectrically-conductive paintsPolymer scienceConductive materials

The present application discloses an antistatic coating material and a configuration method thereof, an antistatic coating and a method for forming the same, wherein the antistatic coating material is characterized in that it includes: a chelate compound of polymer molecules and metal ions and Conductive nanomaterials, wherein the polymer molecules contain amino groups. When configuring antistatic coating materials, conductive nanomaterials are used as the main conductive material, which can meet the conductive requirements of the coating, and the addition of amino group-containing polymers and metal ions Chelate compound, the amino group in the polymer molecule interacts with the metal ion to obtain a complex with electrical conductivity, which can not only further improve the electrical conductivity of the antistatic coating, but also improve the mechanical wear resistance of the coating.

Owner:HUAZHONG UNIV OF SCI & TECH

Acid aqueous binary silver-bismuth alloy electroplating compositions and methods

ActiveUS11434577B2Improve conductivityReduce electrical contact resistanceCellsThiolPhysical chemistry

Aqueous acid binary silver-bismuth alloy electroplating compositions and methods enable electroplating silver rich binary silver-bismuth deposits. The aqueous acid binary silver-bismuth alloy electroplating compositions include thiol terminal aliphatic compounds having carboxyl or sulfonic groups which enable deposition of silver rich binary silver-bismuth alloys having deposits which are matte to semi-bright, uniform and have a low coefficient of friction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Acidic aqueous binary silver-bismuth alloy electroplating compositions and methods

PendingUS20210172082A1Improve electrical performanceReduce electrical contact resistancePhysical chemistryAlloy

Aqueous acid binary silver-bismuth alloy electroplating compositions and methods enable electroplating silver rich binary silver-bismuth deposits. The aqueous acid binary silver-bismuth alloy electroplating compositions include 5-membered heterocyclic nitrogen compounds with a thiol functionality which enable deposition of the silver rich binary silver-bismuth alloys. The silver rich silver-bismuth deposits are matte to semi-bright, uniform and have a low coefficient of friction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

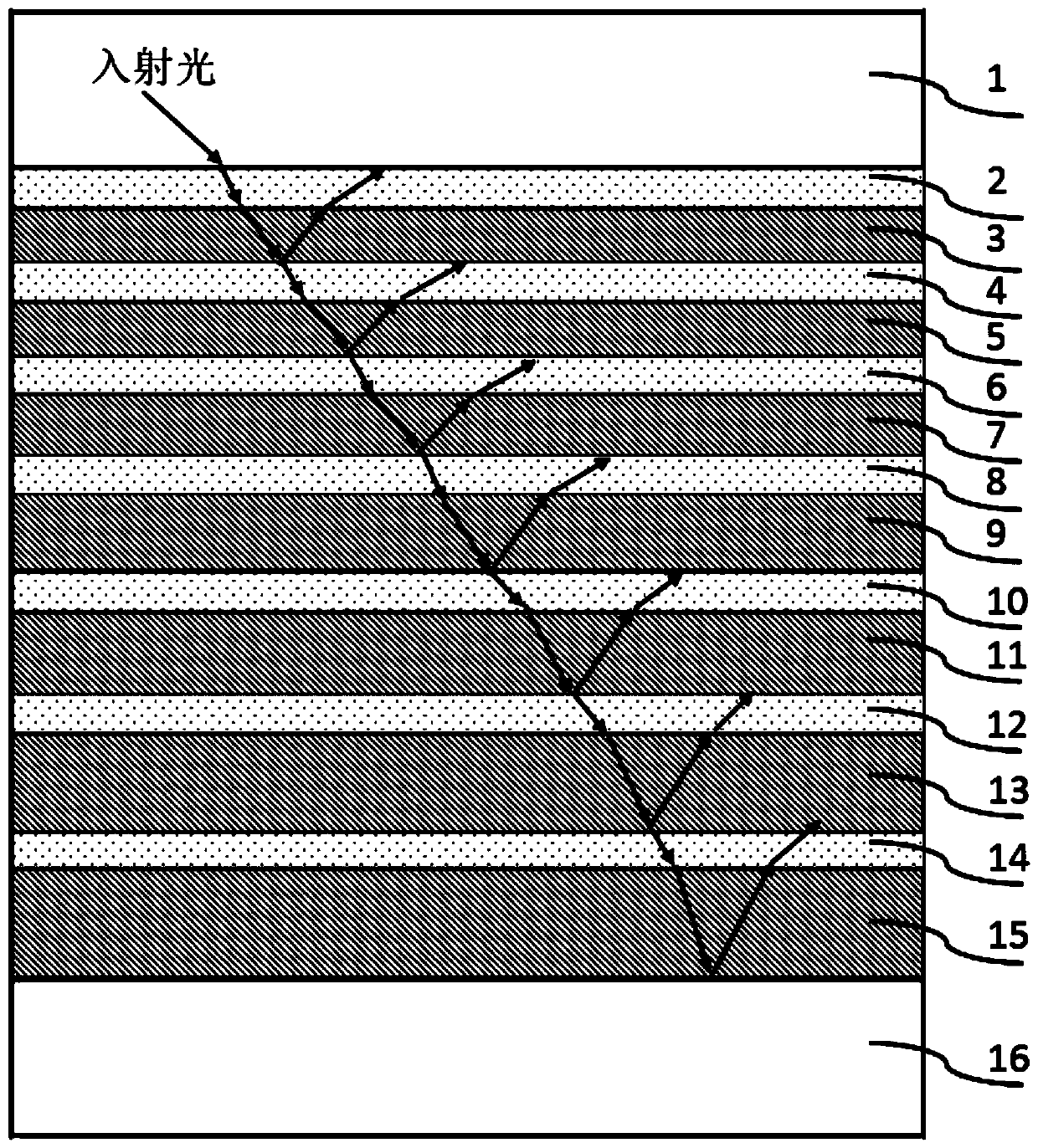

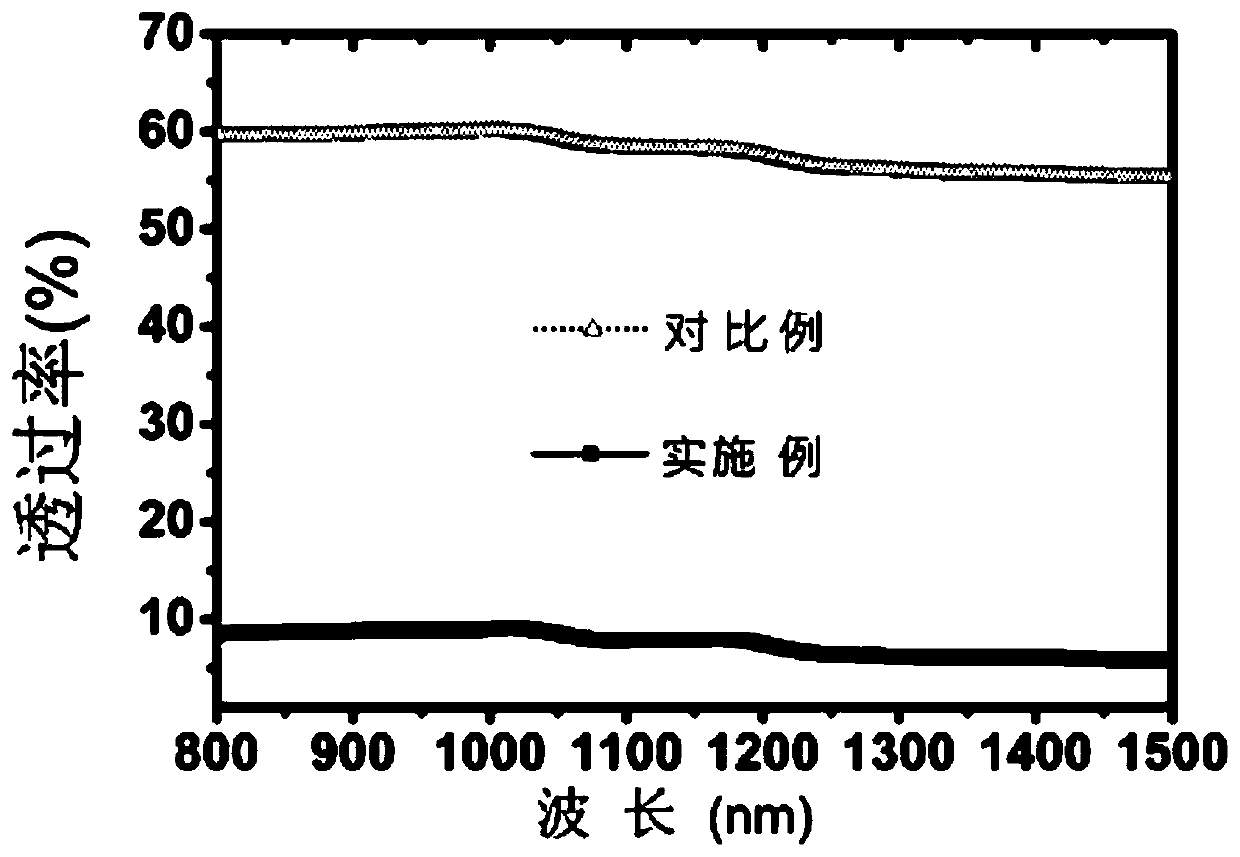

High reflectivity multilayer heat insulation window film, and preparation method thereof

ActiveCN110103549AImprove ductilityImprove thermal conductivitySynthetic resin layered productsVacuum evaporation coatingTransmittancePet substrate

The invention belongs to the field of optical film, and more specifically relates to a high reflectivity multilayer heat insulation window film which his high in reflectivity on infrared light, and apreparation method thereof. The high reflectivity multilayer heat insulation window film comprises a PET sealing layer, a first reflecting layer, a second reflecting layer, a third reflecting layer, afourth reflecting layer, a fifth reflecting layer, a sixth reflecting layer, a seventh reflecting layer, an eighth reflecting layer, a ninth reflecting layer, a tenth reflecting layer, an eleventh reflecting layer, a twelfth reflecting layer, a thirteenth reflecting layer, a fourteenth reflecting layer, and a PET substrate layer, which are laminated successively, and is prepared through magnetronsputtering. The high reflectivity multilayer heat insulation window film is invented based on optical interference enhancing principles, reflective constructive interference of light of different wavelengths in infrared light is realized, so that transmission effect is reduced, high reflective effect on infrared light (800 to 1500nm) is achieved, and the transmittance is only 8%.

Owner:精一门(常州)光学薄膜有限公司

A kind of silicon dioxide nanocomposite material and its preparation method and application

The invention provides a silicon dioxide nanometer composite material and a preparation method and application thereof. The silicon dioxide nanometer composite material is mainly formed by compoundingsilicon dioxide nanoparticle suspension and nanometer silicon dioxide acidic sol, wherein the particle size of silicon dioxide nanometer particles in the silicon dioxide nanometer particle suspensionis 5-30 nm; the nanometer silicon dioxide acidic sol is provided with chain nanosilicon dioxide, and the veneer content of the nanometer silicon dioxide acidic sol is 70-90%. A silicon dioxide nanometer composite thin film prepared from the silicon dioxide nanometer composite material has good effects of antireflection, self cleaning and mist prevention, meanwhile has good mechanical abrasion resistance and weather resistance, is good in firmness with a matrix, is not limited during usage, can exert effects for a long term in the field, and is wide in application range.

Owner:STATE POWER INVESTMENT CORP RES INST +1

Superhydrophobic phenolic resin laminate and preparation method thereof

ActiveCN110983861BEasy to prepareSimple preparation processLamination ancillary operationsSpecial paperSuperhydrophobePolymer science

The invention provides a superhydrophobic phenolic resin laminate and a preparation method thereof. First, prepare a predetermined concentration of phenolic resin / organic solvent mixed solution to infiltrate the paper-based material, and then dry it to obtain a prepreg; then perform stacking thermocompression molding and pretreatment on the prepreg to obtain a phenolic resin laminate; then , prepare a polyvinyl chloride / tetrahydrofuran mixed solution and then add an organic solvent to obtain a superhydrophobic coating; finally, use a superhydrophobic coating to spray-dry the surface of the phenolic resin laminate to obtain a superhydrophobic phenolic resin laminate. The impact strength of the superhydrophobic phenolic resin laminate provided by the invention reaches 11.978kJ / m 2 , with a density of 1.41g / cm 3 , the elastic modulus and bending strength reached 23.8GPa and 642.7Mpa respectively, and its contact angle reached more than 160°, while the contact angle of the laminate with kraft paper attached to the substrate can be maintained above 155°, which has excellent hydrophobic properties.

Owner:HUBEI POLYTECHNIC UNIV

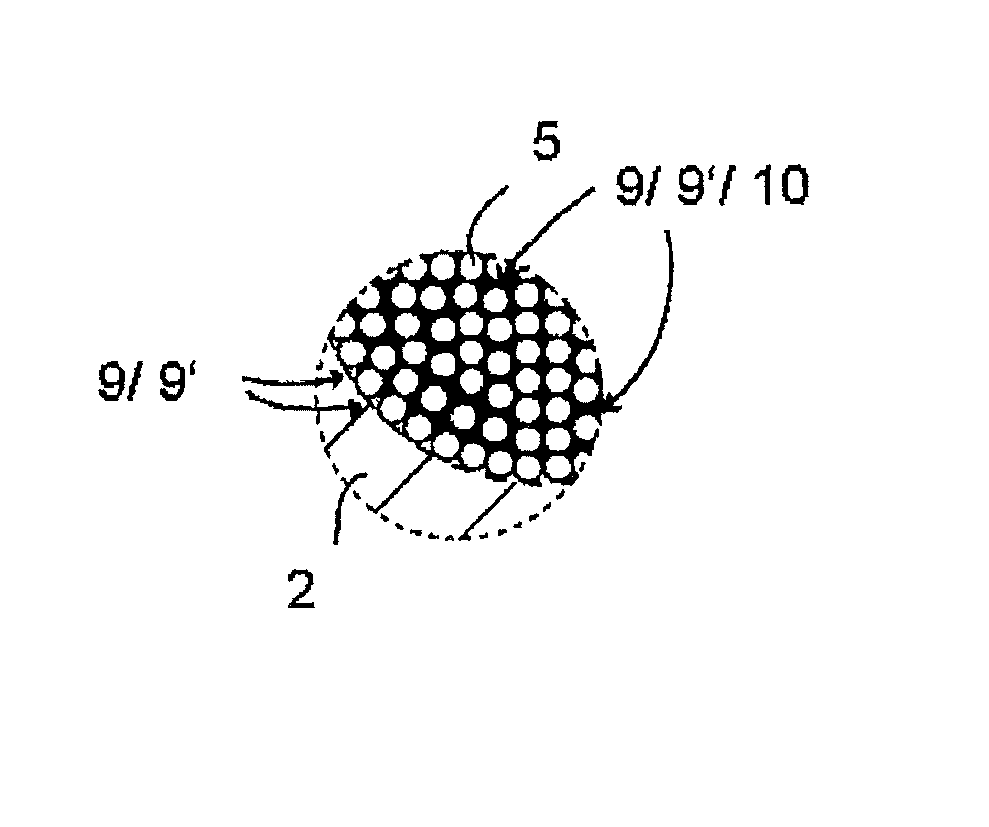

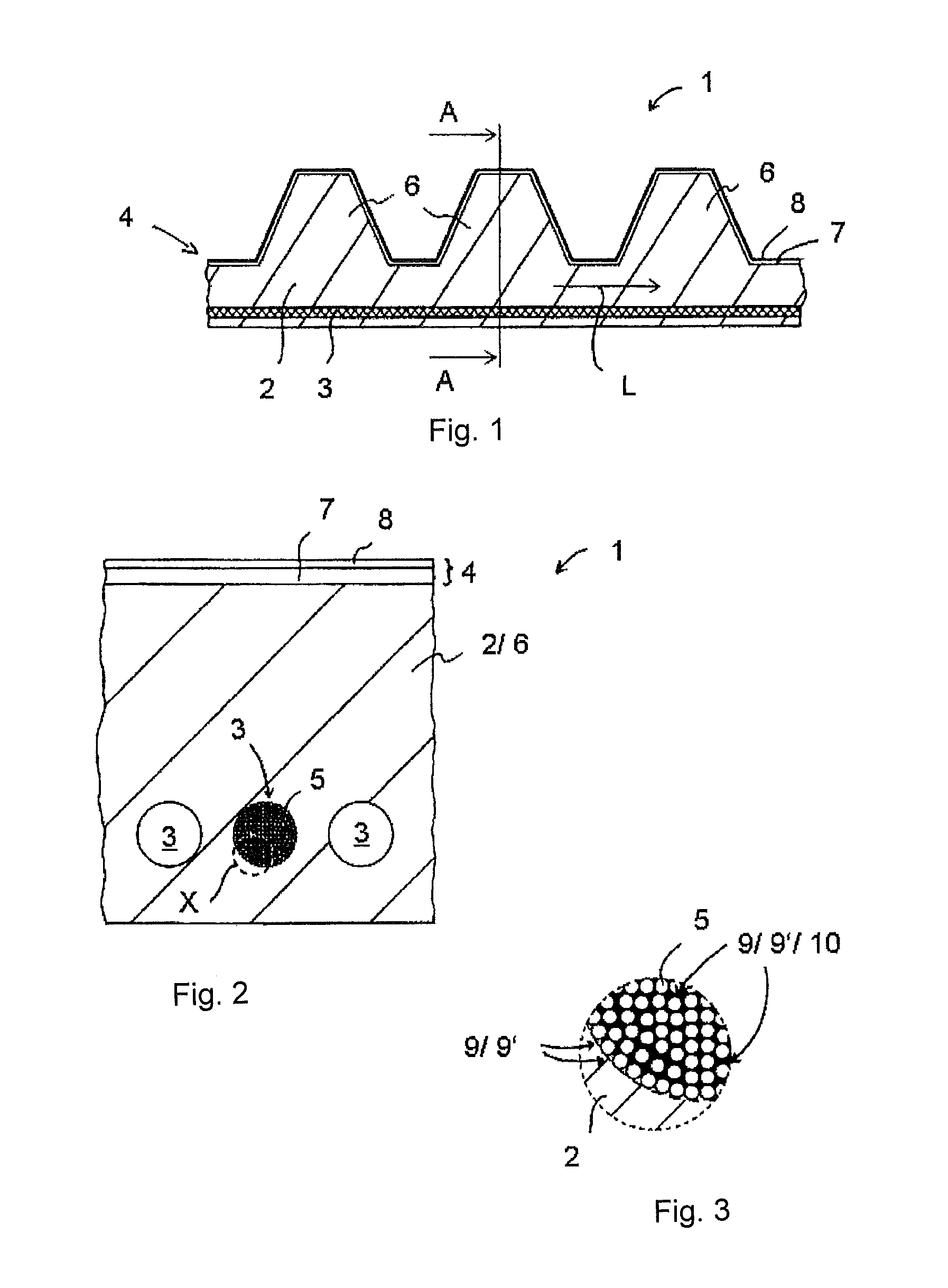

Drive belt for transmitting a drive movement, and method for producing a drive belt

ActiveUS9441706B2High strengthImprove mechanical wear resistanceV-beltsRopes and cables for vehicles/pulleyFiberCarbon fibers

A drive belt having a belt body which is made of a flexible material and a tensile reinforcement that extends in belt axial direction and which is surrounded by said belt body in sections at least to improve the tensile strength of the body in belt longitudinal direction wherein the tensile reinforcement is a carbon cord made of a plurality of twisted carbon fibers with a plurality of cavities between the fibers which are charged with a filler material in part at least. A first portion of the carbon fiber cavities is charged with a rupture risk reducing filler of a type different from the belt body flexible material and a second portion of said cavities of the carbon fibers is filled with belt body flexible material. The carbon cord has less than 0.2 mg of belt body flexible material per one millimeter3 cord volume.

Owner:ARNTZ BET GMBH & CO

Acid aqueous binary silver-bismuth alloy electroplating compositions and methods

ActiveUS20210115582A1Improve conductivityReduce electrical contact resistanceCellsThiolPhysical chemistry

Aqueous acid binary silver-bismuth alloy electroplating compositions and methods enable electroplating silver rich binary silver-bismuth deposits. The aqueous acid binary silver-bismuth alloy electroplating compositions include thiol terminal aliphatic compounds having carboxyl or sulfonic groups which enable deposition of silver rich binary silver-bismuth alloys having deposits which are matte to semi-bright, uniform and have a low coefficient of friction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Auxiliary anode assembly for cathode protection of ice breaker

PendingCN111705320AAvoid problems with direct exposure to sea waterEffective protectionChemical vapor deposition coatingElectrical connectionEngineering

The invention provides an auxiliary anode assembly for cathode protection of an ice breaker, and belongs to the technical field of electrochemistry. The auxiliary anode assembly comprises an anode body, a conductive rod, an anode bracket and a perforated protective cover. The anode bracket is made from insulating materials, and the anode body is arranged in the anode bracket. The conductive rod isconnected to the back of the anode body and used for electric connection of a cable and the anode body. The perforated protective cover is made from insulating materials, is fixed on the top of the anode bracket, and is sealed and fixed to the anode bracket. A boron-doped diamond intermediate layer is deposited on a titanium substrate in advance, so that the stability and the mechanical abrasionresistance of the anode body are remarkably improved. The anode bracket is matched with the rigid insulation perforated protective cover to physically isolate the anode body from floating ice, so thatmechanical damage is not likely to occur, effective discharge of cathode protection current is guaranteed, and the auxiliary anode assembly can reliably work for a long time in an ice navigation process, is suitable for an impressed current cathode protection system of a polar navigation ship, and is used for preventing seawater corrosion of a ship shell, a rudder plate and a propeller.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com