Preparation method of carbon-ceramic brake material with strong oxidation resistance

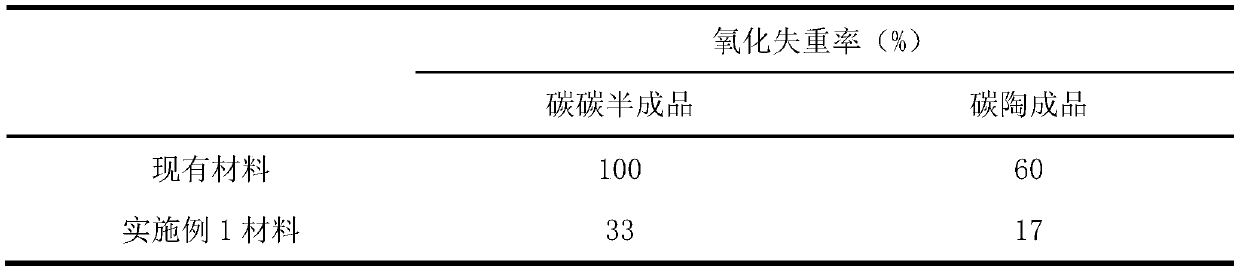

An anti-oxidation, carbon-ceramic technology, applied in mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problems of wear and friction interface stability, poor anti-oxidation performance of friction interface, etc., to reduce oxidation wear and improve anti-oxidation. The effect of oxidative power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] A method for preparing a carbon ceramic brake material with strong oxidation resistance, comprising the following steps:

[0012] 1) After high-temperature heat treatment of the three-dimensional needle-punched preform, pyrolytic carbon was deposited by chemical vapor infiltration CVI to obtain a density of 0.6g / cm 3 -1.0g / cm 3 carbon / carbon composites;

[0013] 2) Depositing boron carbide on the upper surface of the carbon / carbon composite material by chemical vapor infiltration CVI deposition to obtain a carbon / carbon-boron carbide composite material;

[0014] 3) Deposit pyrolytic carbon on the surface of carbon / carbon-boron carbide composite boron carbide by chemical vapor infiltration CVI deposition, and obtain a density of 1.3g / cm 3 -1.7g / cm 3 Multilayer structure carbon / carbon-boron carbide composite materials containing carbon-boron carbide-carbon;

[0015] 4) Carrying out high-temperature heat treatment to the multilayer structure carbon / carbon-boron carbide...

Embodiment 1

[0033] A method for preparing a carbon ceramic brake material with strong oxidation resistance, the steps are as follows:

[0034] 1) Preparation of carbon fiber preform:

[0035] First, the C fiber with the brand name T700 is made into a short fiber tire net and a non-weft fabric, and then the single layer of 0° no weft fabric, tire net, 90° no weft fabric, and tire net are laminated in sequence, and then the edge belt is used to The lower barb is used for needle punching of woven fabrics and tire nets. During the needle punching process, the barbs bring the fiber of the tire mesh layer to the vertical direction, so that the non-weft fabric and the tire mesh are integrated into one, and the density of the needle punching holes is 8 to 12 pcs / cm 2 . According to the required thickness, the three-dimensional needle-punched carbon fiber prefabricated body is obtained after repeated lamination and needle punching. The preform density is about 0.55g / cm3, the volume content of c...

Embodiment 2

[0054] A method for preparing a carbon ceramic brake material with strong oxidation resistance, the steps are as follows:

[0055] 1) Preparation of carbon fiber preform:

[0056] First, the C fiber with the brand name T700 is made into a short fiber tire net and a non-weft fabric, and then the single layer of 0° no weft fabric, tire net, 90° no weft fabric, and tire net are laminated in sequence, and then the edge belt is used to The lower barb is used for needle punching of woven fabrics and tire nets. The barbs bring the fiber of the tire mesh layer to the vertical direction during the needling process, so that the non-woven fabric and the tire mesh are integrated into one, and the density of the needle punching holes is 8-12 per cm2. According to the required thickness, the three-dimensional needle-punched carbon fiber prefabricated body is obtained after repeated lamination and needle punching. The preform density is about 0.55g / cm3, the volume content of carbon fiber i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com