Acrylic resin composition

A technology of acrylic resin and composition, applied in the field of acrylic resin composition, can solve problems such as poor hardness and strength, etc., and achieve the effects of improving performance, reducing energy consumption and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

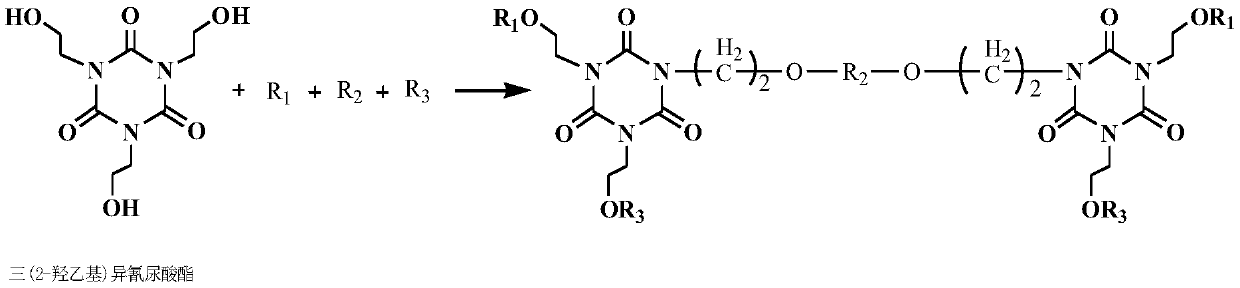

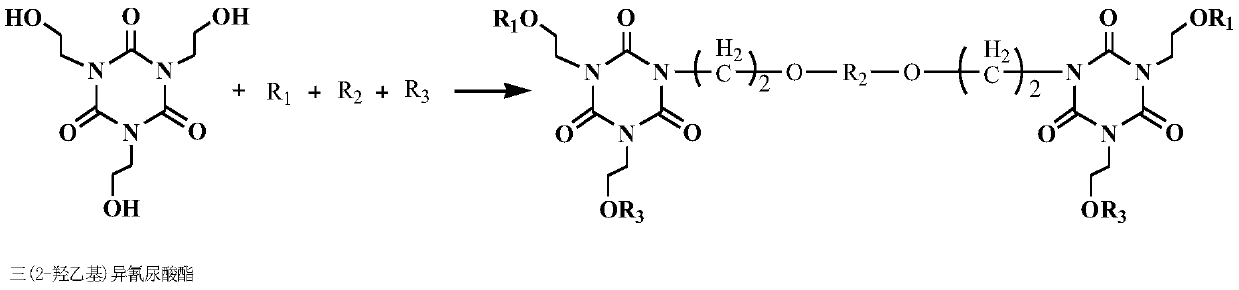

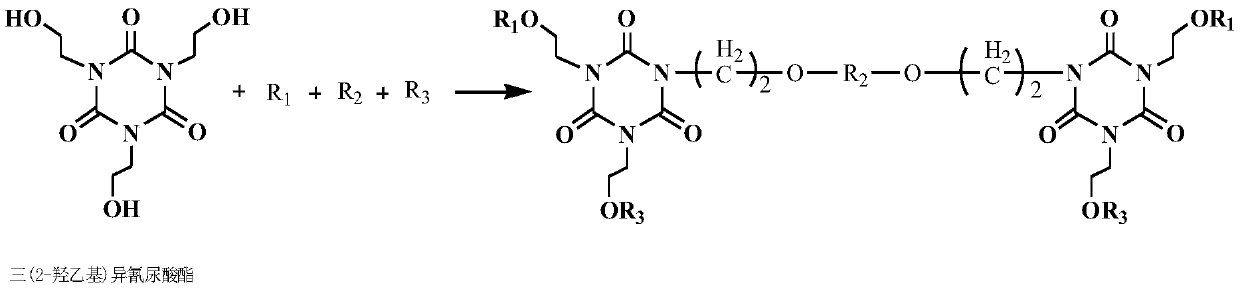

[0045] Preparation of modified acrylic resin:

[0046] The reactor is placed on the stirrer, and 20 grams of tris (2-hydroxyethyl) isocyanurate, 11 grams of acrylic acid, 5 grams of acetic acid, 25 grams of toluene, 6 grams of n-heptane, 1.5 gram p-toluenesulfonic acid, 0.1 gram hydroquinone. The temperature of the reactor was raised to 80° C. and stirred for 1 hour, and then the temperature of the reactor was raised to 115° C. and stirred for 4 to 6 hours to obtain the product. The product was cooled to room temperature, washed three times with deionized water, distilled under reduced pressure to remove the solvent in the product, and filtered to obtain the modified acrylic resin.

[0047] Preparation of acrylic resin composition:

[0048] Get 10 grams of the above-mentioned modified acrylic resin, add 3 grams of isobornyl acrylate, add 0.25 grams of (2-ethylhexanoic acid) tert-butyl peroxide, 0.3 grams of silicon dioxide, stir for degassing, and then put Put it into an ov...

Embodiment 2

[0050] Preparation of modified acrylic resin:

[0051] The reactor is placed on the stirrer, and 20 grams of tris (2-hydroxyethyl) isocyanurate, 18.6 grams of bisphenol F type epoxy resin, 0.025 grams of vitriol oil, 30 grams of toluene are added successively in the reactor to 130°C, stirred for 4-6 hours, cooled the reactor to 80°C, and added 0.08 g of p-tert-butylphenol, 0.04 g of hydroquinone, 1 g of p-toluenesulfonic acid, and 8 g of cyclohexane into the reactor , stirred for 10 min, then added 6.56 g of methacrylic acid and 11.3 g of n-octanoic acid, raised the temperature to 125° C., and stirred for 4 to 6 hours to obtain the product. The product was cooled to room temperature, washed three times with deionized water, distilled under reduced pressure to remove the solvent in the product, and filtered to obtain the modified acrylic resin.

[0052] Preparation of acrylic resin composition:

[0053] Get 10 grams of the above-mentioned modified acrylic resin, add 3 grams of ...

Embodiment 3

[0055] Preparation of modified acrylic resin:

[0056] The reaction vessel is placed on the stirrer, and 20 grams of tris (2-hydroxyethyl) isocyanurate, 8.53 grams of methacrylic acid, 8.24 grams of n-octanoic acid, 25 grams of toluene, 6 grams of n-heptyl are added successively in the reactor Alkanes, 0.36 grams of p-toluenesulfonic acid, 0.1 grams of hydroquinone. The reactor was heated to 80° C., stirred for 1 hour, then heated to 100° C., stirred for 2 to 3 hours, then cooled to room temperature and subjected to water removal treatment. Then add 30 grams of isocyanate-terminated polyurethane prepolymer and 0.02 grams of environment-friendly catalyst into the reactor, and stir for 3-4 hours to obtain the product. Wash the product three times with deionized water, distill under reduced pressure, remove the solvent in the product, and filter to obtain the modified acrylic resin.

[0057] Preparation of acrylic resin composition:

[0058] Get 10 grams of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com