Silicon dioxide nanometer composite material and preparation method and application thereof

A nanocomposite material, silica technology, applied in the field of nanomaterials, can solve the problems of poor film and glass substrate firmness, poor mechanical wear resistance and weather resistance, anti-reflection and anti-reflection durability, etc., to avoid stability problems, Improved wear resistance, stability and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0080] Example 1-1 Preparation of silica nanoparticle suspension

[0081] Under the condition of condensation and reflux, 2L of ethanol and 100mL of concentrated ammonia water were stirred and mixed in a water bath at about 60°C; after the temperature was constant, 60mL of tetraethoxysilane was added to the above mixed solution, and after stirring for 12h, the The reaction product is placed in a fume hood to remove ammonia water until the pH of the product reaches 7.0-7.5 to obtain a silica nanoparticle suspension, wherein the content of silica nanoparticles is about 7.5 mg / mL, which can be sealed and stored at room temperature.

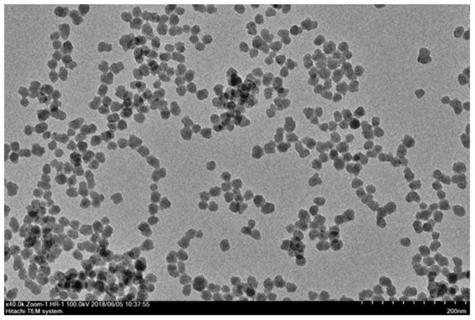

[0082] figure 1 is the transmission diagram of the silica nanoparticle suspension prepared above; figure 1 It can be seen that the average particle size of the silica nanoparticles in the suspension prepared in this example is about 20 nm.

Embodiment 1-2

[0083] Example 1-2 Preparation of silica nanoparticle suspension

[0084] Under the condition of condensation reflux, 20L of ethanol and 1000mL of concentrated ammonia water were stirred and mixed in a water bath at about 60°C; after the temperature was constant, 600mL of tetraethoxysilane was added to the above mixed solution, and after stirring for 12 hours, the The reaction product is placed in a fume hood to remove ammonia water until the pH of the product reaches 7.0-7.5 to obtain a silica nanoparticle suspension, wherein the content of the silica nanoparticle is about 7.5 mg / mL.

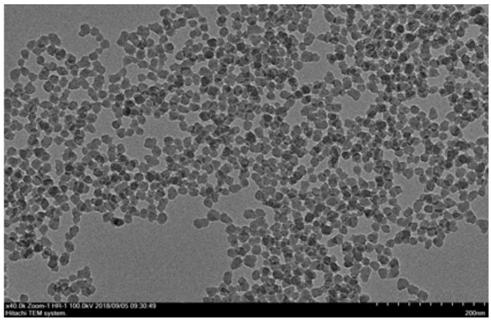

[0085] figure 2 is the transmission diagram of the silica nanoparticle suspension prepared above; figure 2 It can be seen that the average particle size of the silica nanoparticles in the suspension prepared in this example is about 20 nm; -30nm accounts for about 10%. It can be seen that the preparation method of the silica nanoparticle suspension of the present invention has good repeata...

Embodiment 1-3

[0086] Example 1-3 Preparation of Silica Nanoparticle Suspension

[0087] Under the condition of condensation and reflux, 20L of ethanol and 800mL of concentrated ammonia water were stirred and mixed in a water bath at about 30°C; after the temperature was constant, 300mL of tetraethoxysilane was added to the above mixed solution, and after stirring for 20h, the The reaction product is placed in a fume hood to remove ammonia water until the pH of the product reaches 7.0-7.5 to obtain a silica nanoparticle suspension, wherein the content of the silica nanoparticles is about 4 mg / mL, and the average particle size is about 10 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com