Patents

Literature

81 results about "Silica nanocomposite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the preparation of metal-containing nanostructured films

InactiveUS7001669B2Sufficient structural integrityHigh mechanical strengthNanotechLayered productsNanowireMesoporous silica

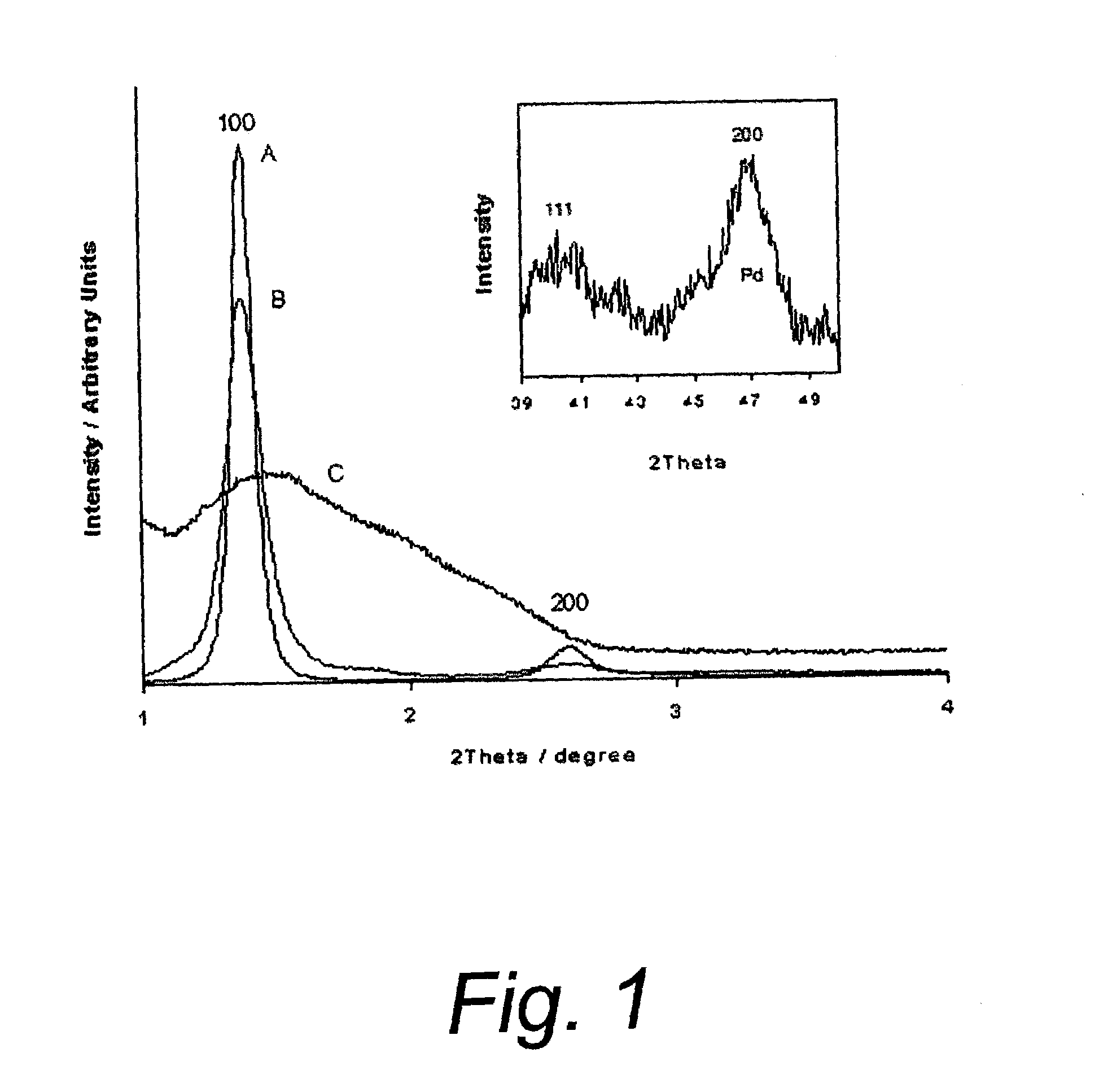

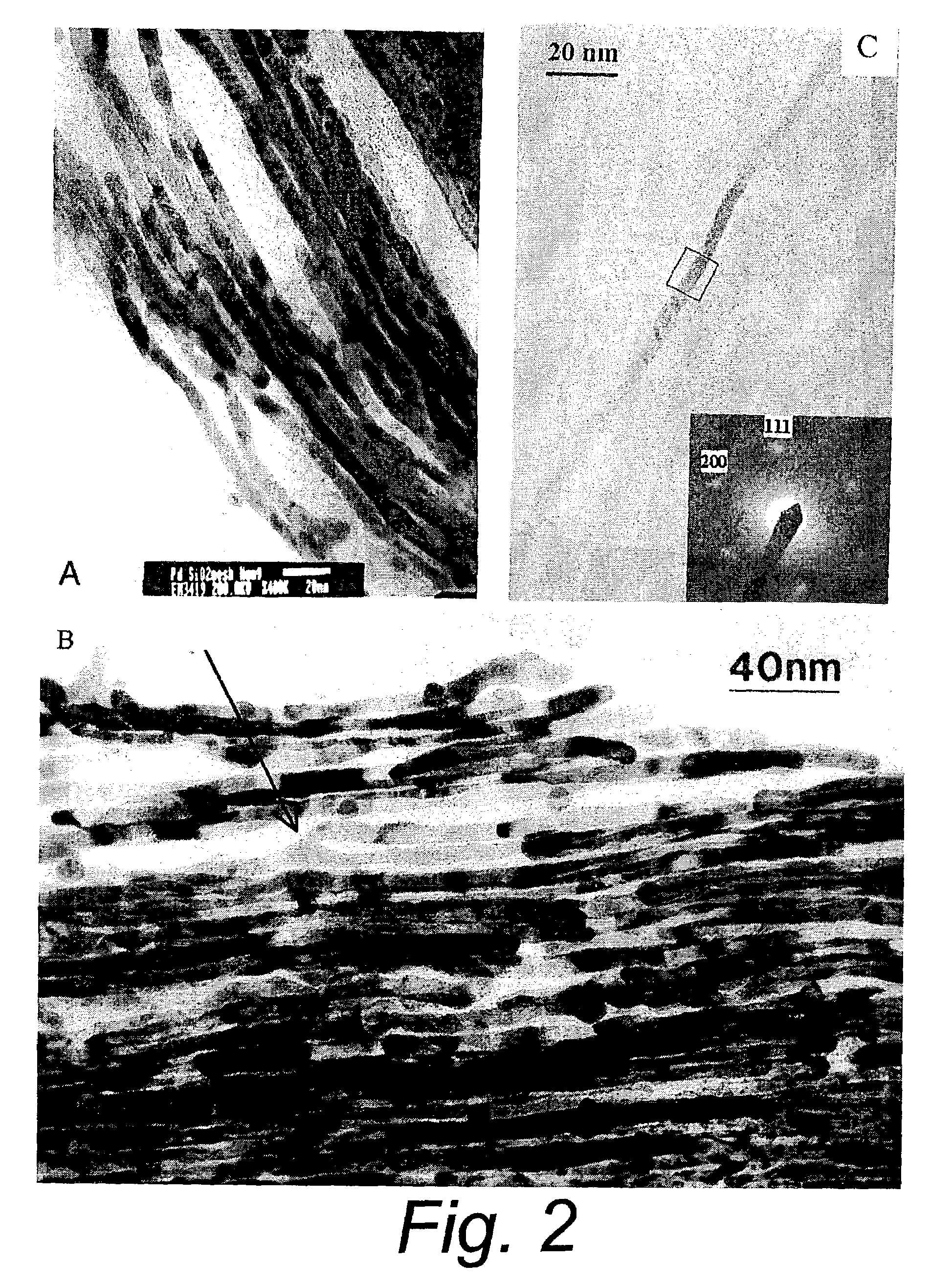

Metal-containing nanostructured films are prepared by electrodepositing a metal-containing composition within the pores of a mesoporous silica template to form a metal-containing silica nanocomposite. The nanocomposite is annealed to strengthen the deposited metal-containing composition. The silica is then removed from the nanocomposite, e.g., by dissolving the silica in an etching solution to provide a self-supporting metal-containing nanostructured film. The nanostructured films have a nanowire or nanomesh architecture depending on the pore structure of the mesoporous silica template used to prepare the films.

Owner:TULANE EDUCATIONAL FUND

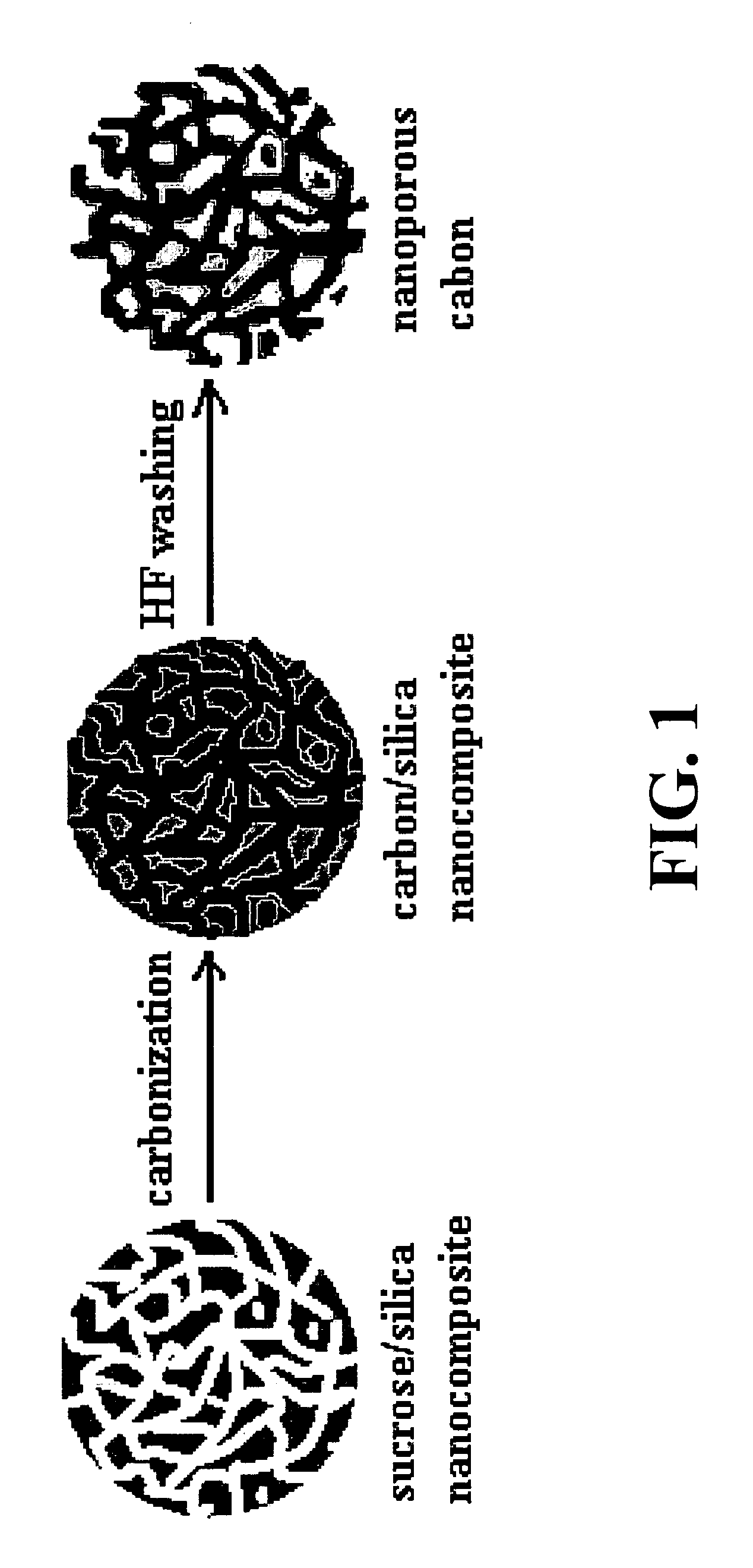

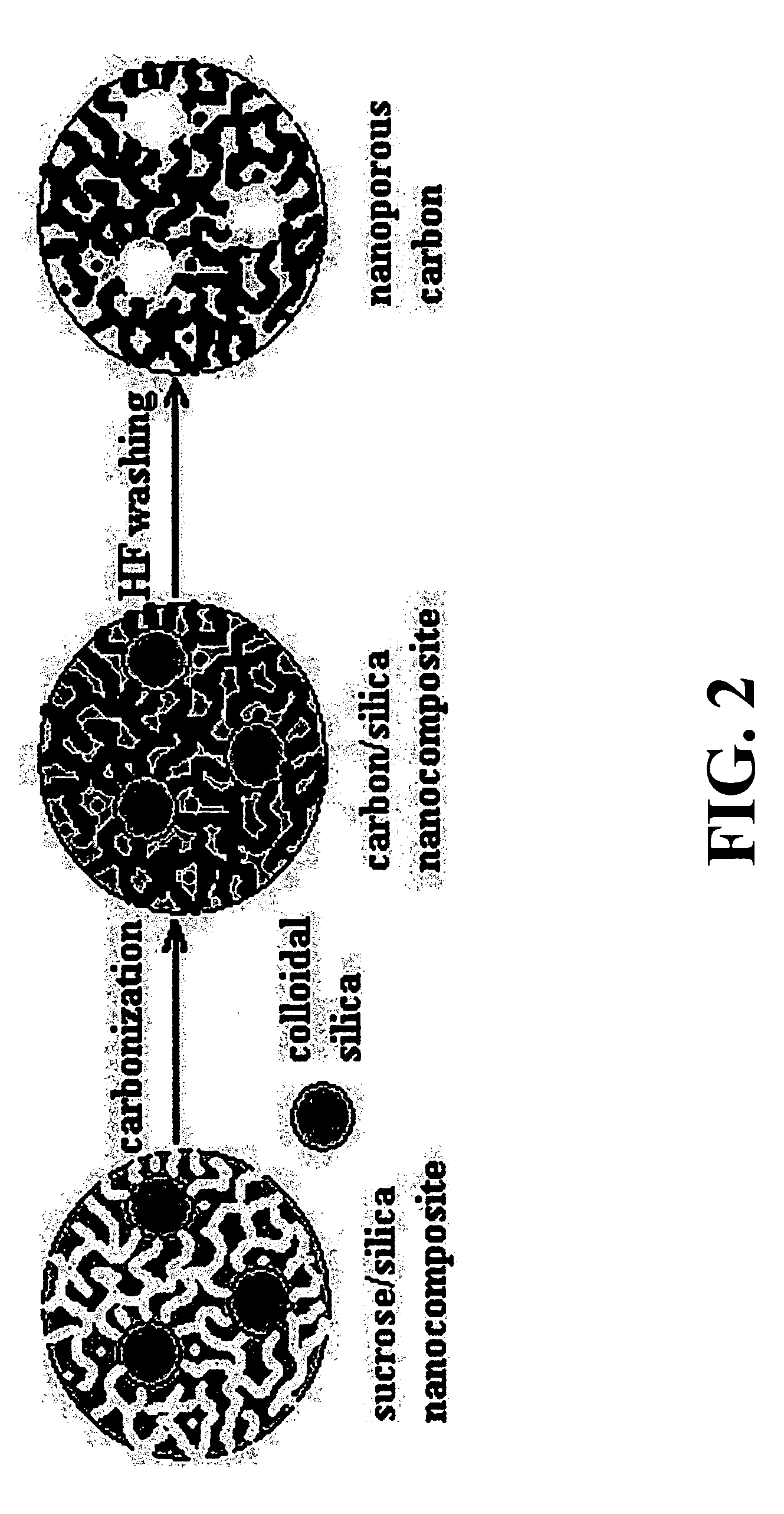

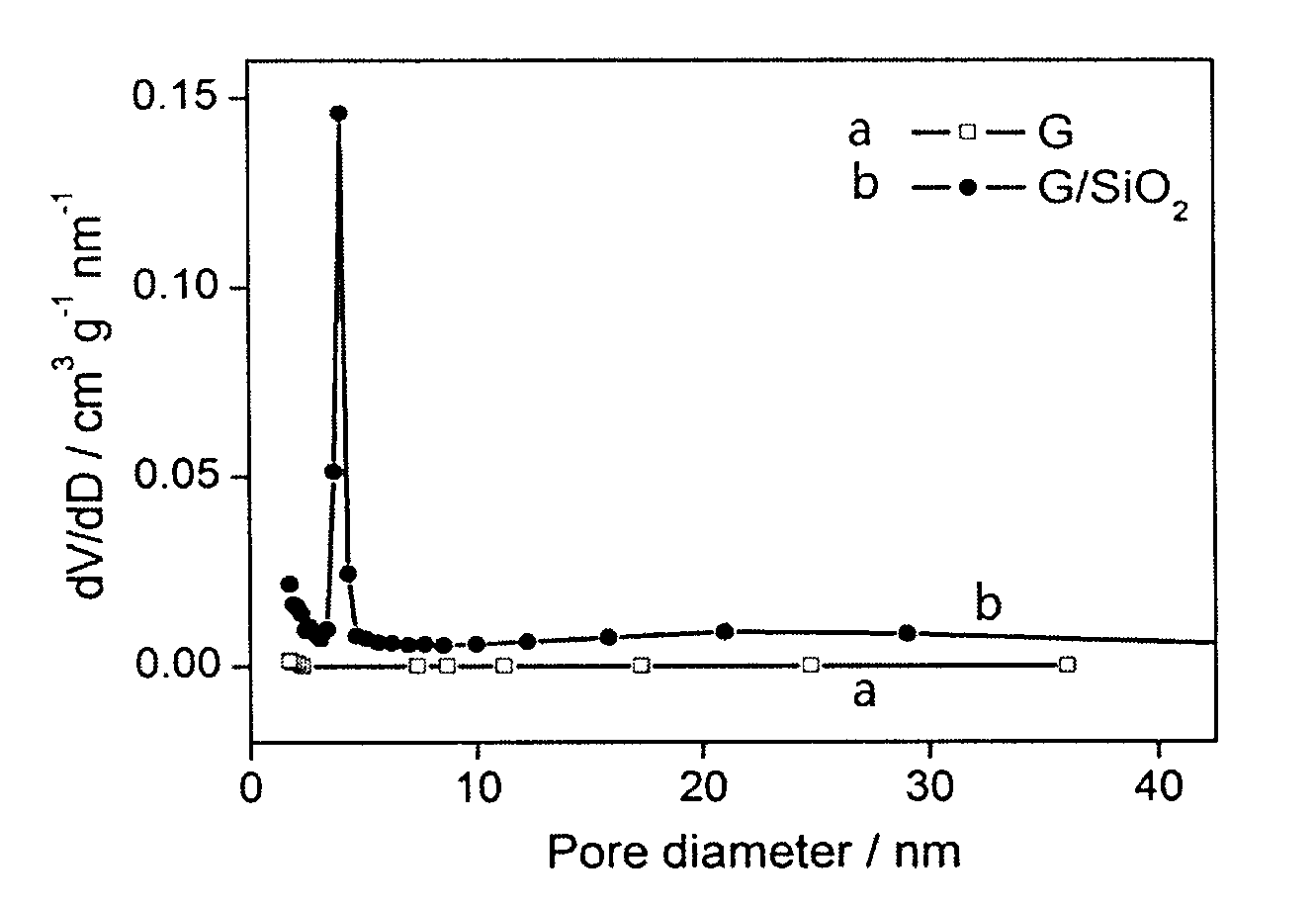

Mesoporous carbon films and methods of preparation thereof

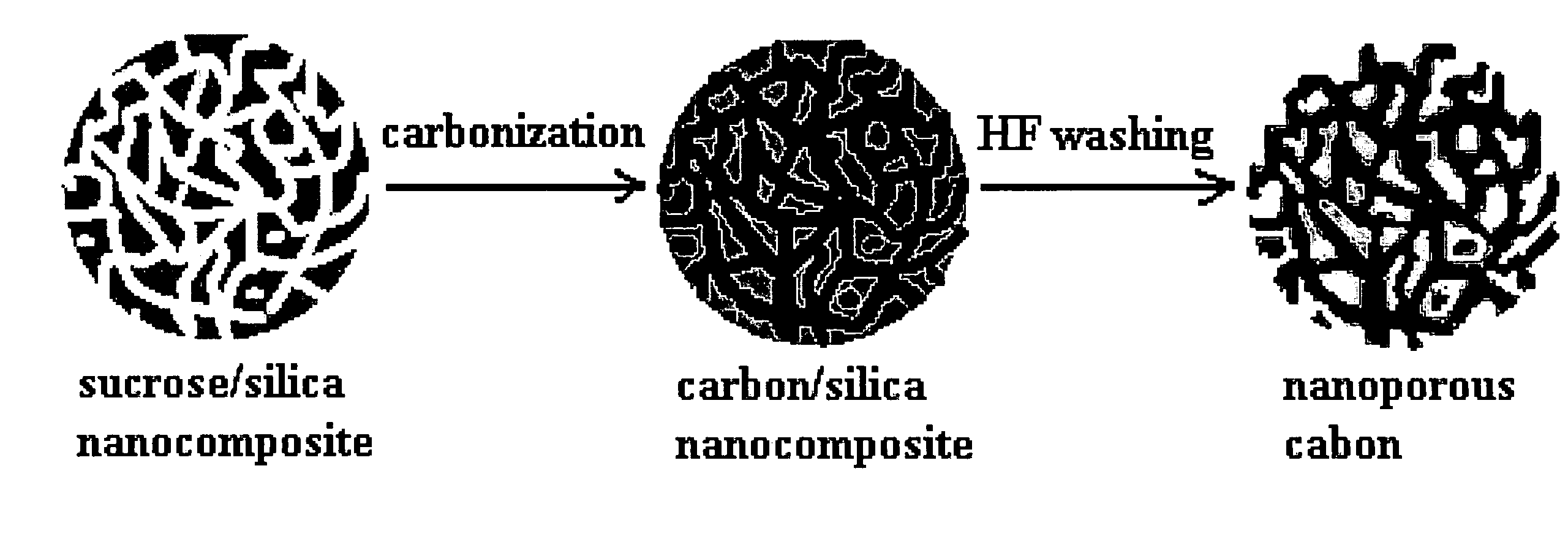

A mesoporous carbon film having a unimodal pore structure comprises a film of carbon defining an open network of interconnected primary pores arrayed in a uniform, random manner throughout the film. The pores in the film have an average pore diameter in the range of about 2 to about 3 nm, and the diameters of the pores have a substantially unimodal pore diameter distribution. Not more than about 20% of the pores in the film have a diameter of less than about 1 nm. The mesoporous carbon films can be prepared by depositing a thin film of an aqueous sol-gel composition comprising a polysiloxane gel precursor, and a water soluble carbohydrate onto a substrate, heating the thin film to carbonize the carbohydrate and form a carbon / silica nanocomposite film, and removing the silica from the carbon / silica nanocomposite film to provide a continuous mesoporous carbon film. Suspending colloidal silica in the aqueous sol-gel composition prior to depositing the thin film on the substrate affords a mesoporous carbon film having a hierarchical, bimodal pore structure, which includes spherical secondary pores randomly distributed throughout the film and interconnecting with the network of primary pores.

Owner:TULANE EDUCATIONAL FUND

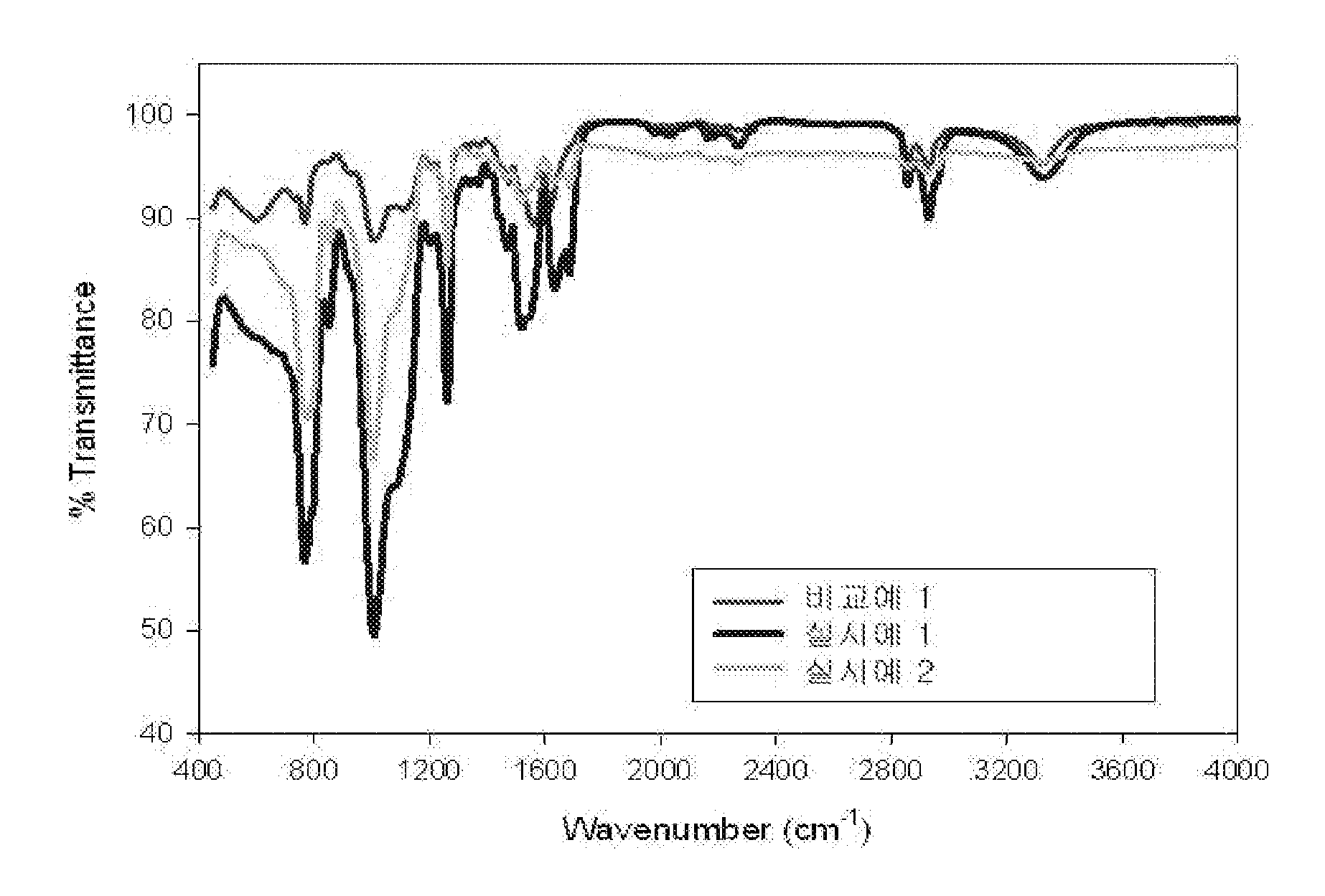

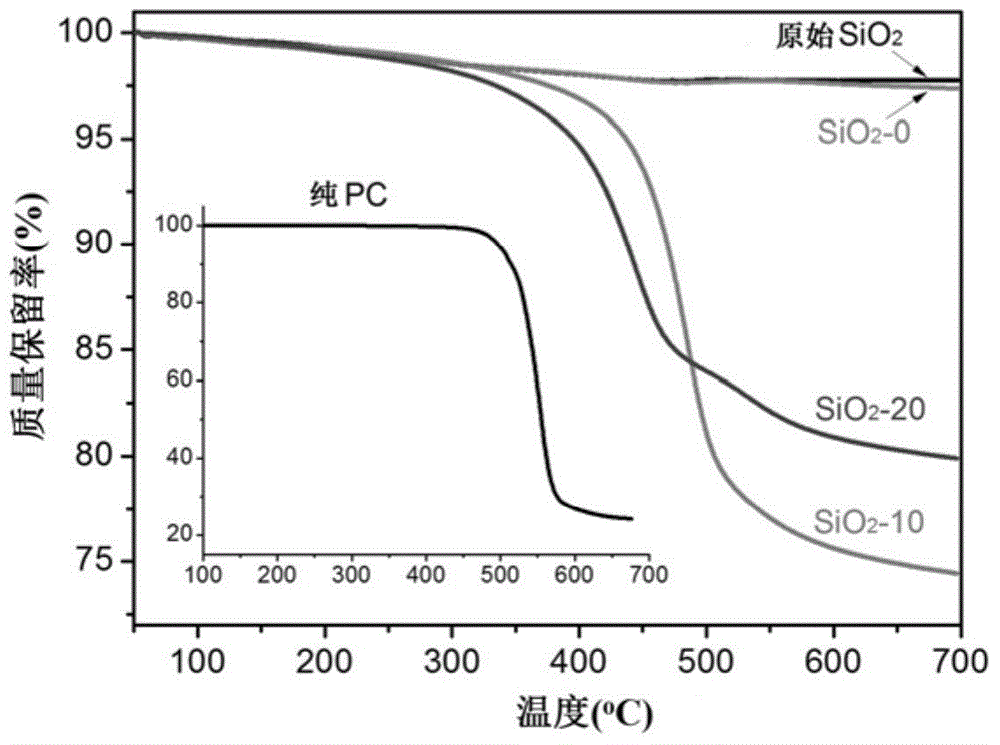

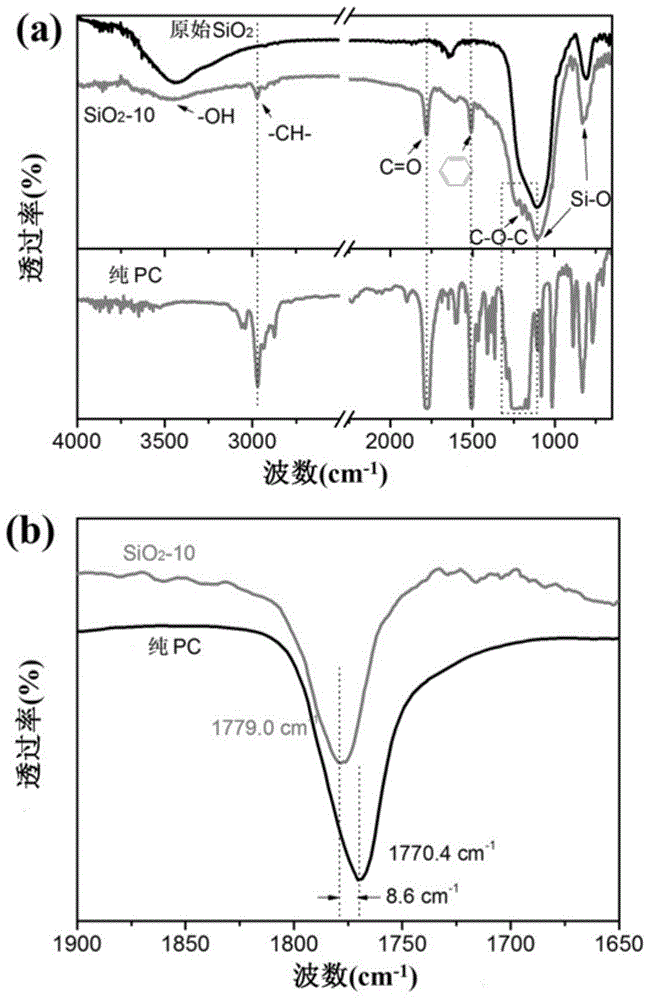

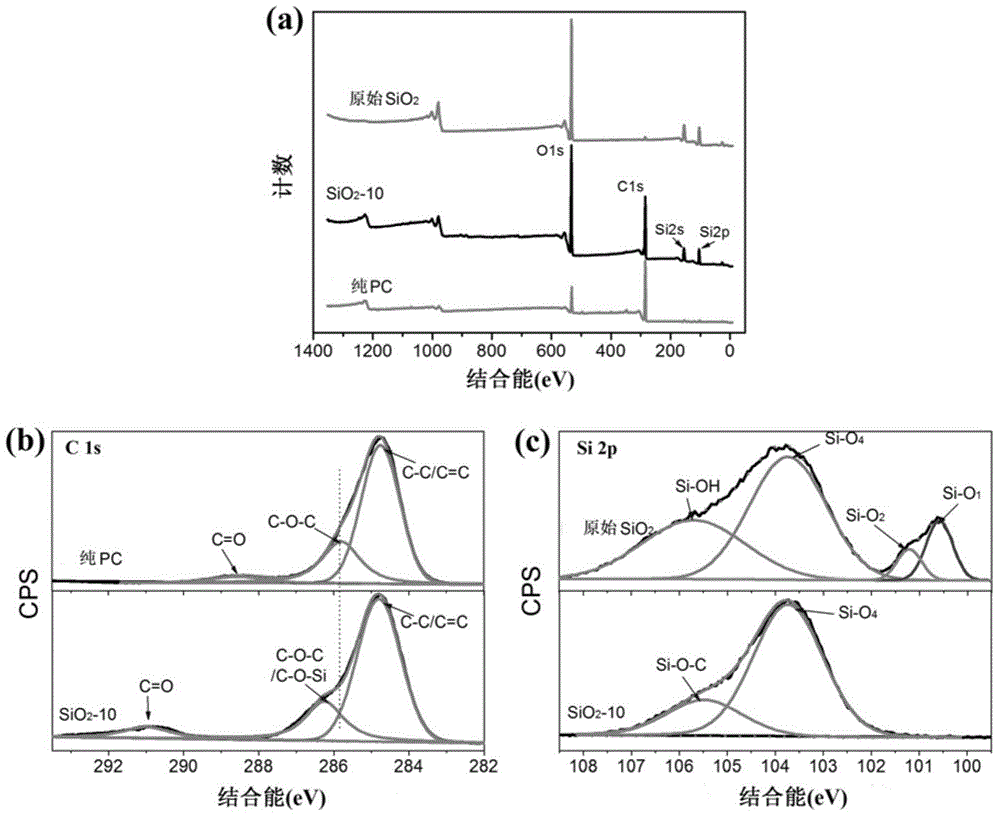

Silica nanocomposite, method of preparing the silica nanocomposite, composite foam and method of preparing the composite foam

Provided is a silica nanocomposite including silica and a siloxane-based polymer covalently bonded to the silica.

Owner:SAMSUNG ELECTRONICS CO LTD

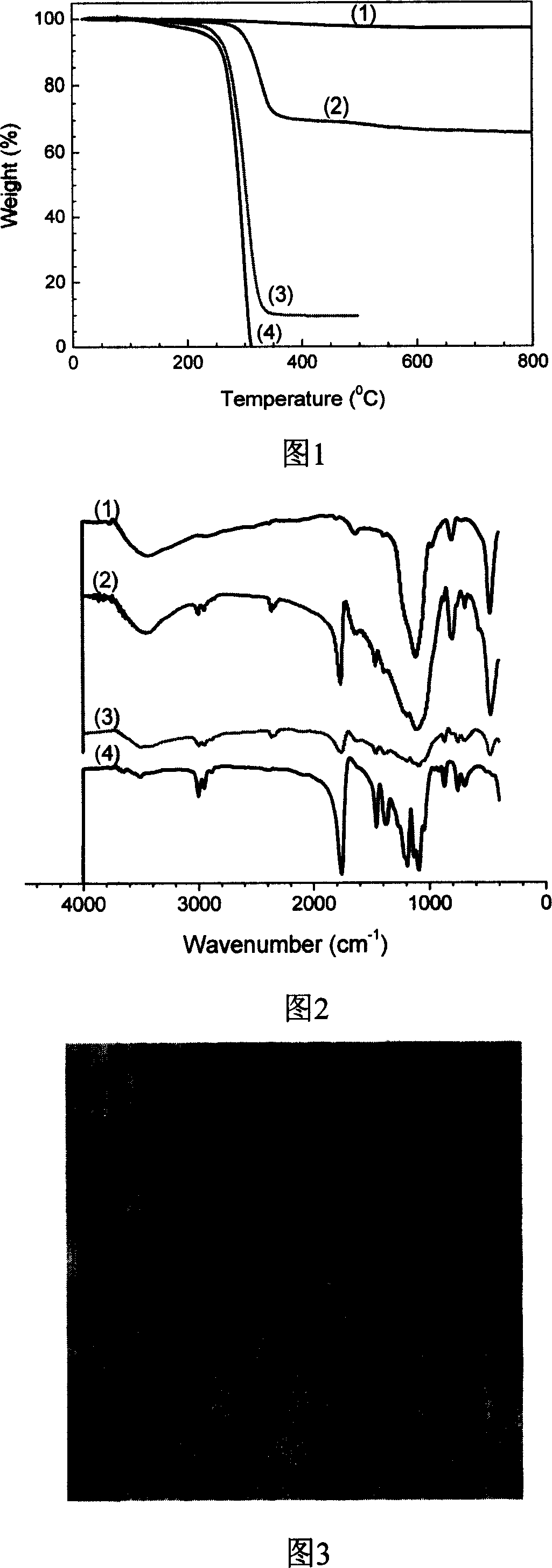

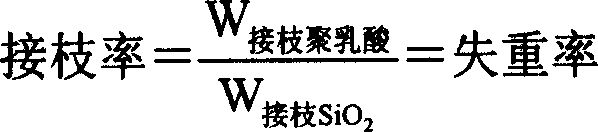

Method for preparing polylactic acid/nanometer silicon dioxide composite material

The invention discloses a method for preparing a polylactic acid / nanometer silicon dioxide composite material. A silane coupling agent is adopted to perform chemical surface modification on silicon dioxide; the modified silicon dioxide and lactide are taken as raw materials, and a system is kept in a high vacuum state in the presence of a catalyst; the temperature is higher than 140 DEG C, and the in-situ ring-opening polymerization is performed with stirring of a magnetic force; and the polylactic acid / nanometer silicon dioxide composite material is obtained. In the method, during the in-situ polymerization, lactide ring-opening polymerization is performed to form polylactic acid, and the polylactic acid is grafted to the surface of SiO2 in the form of a covalent bond so as to obtain the polylactic acid / nanometer silicon dioxide composite material with high dispersivity.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

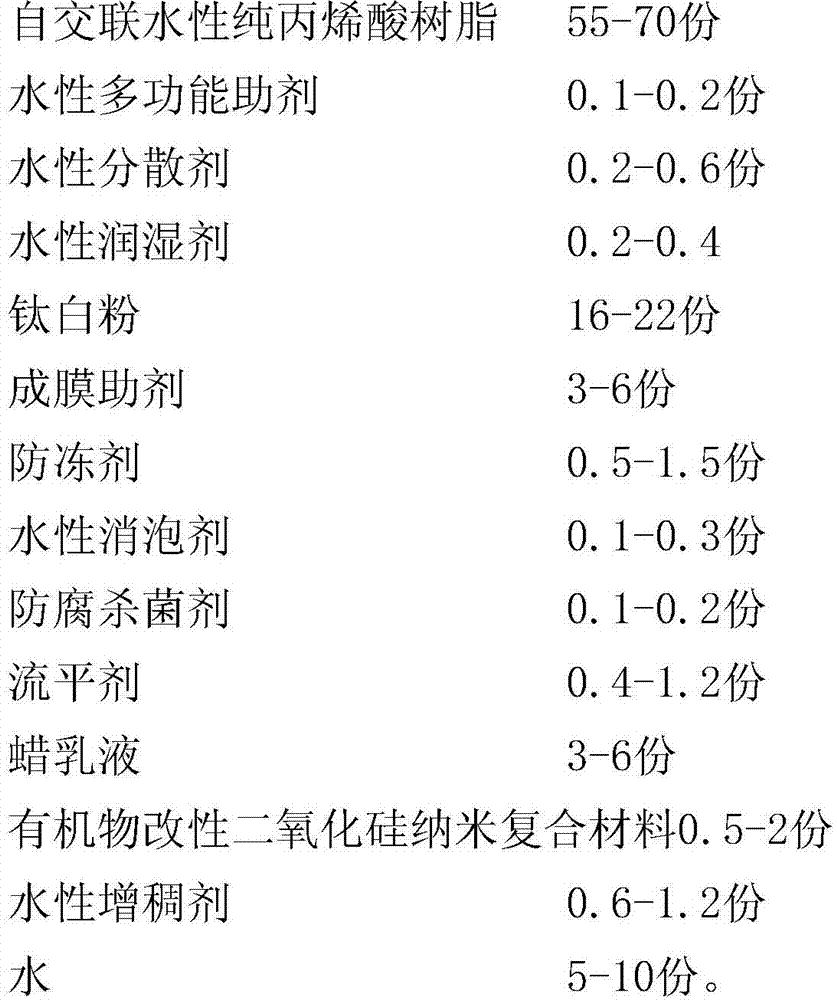

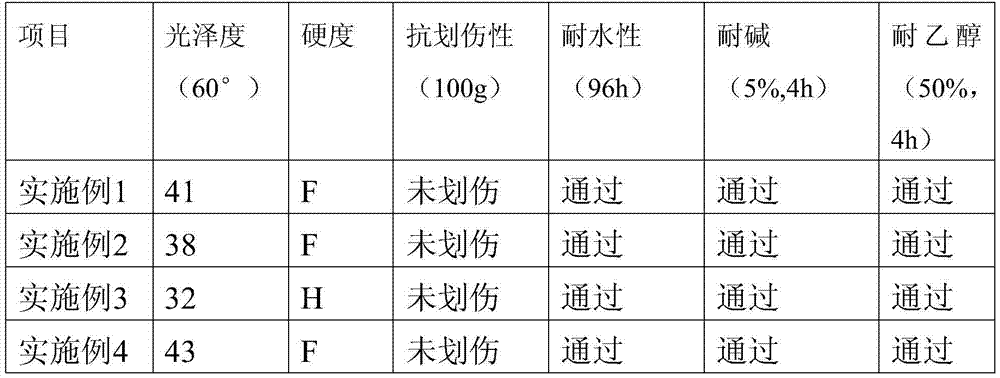

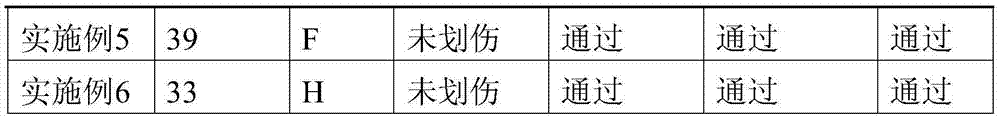

Waterborne woodware matte white finish with high scratch resistance and high performance

The invention relates to waterborne woodware matte white finish with high scratch resistance and high performance. The finish is mainly prepared from the following raw materials (by weight): 55-70 parts of self-crosslinking waterborne pure acrylic resin, 0.1-0.2 part of a waterborne multifunction additive, 0.2-0.6 part of an aqueous dispersant, 0.2-0.4 part of a waterborne wetting agent, 16-22 parts of titanium dioxide, 3-6 parts of a coalescing agent, 0.5-1.5 parts of an antifreezing agent, 0.1-0.3 part of a water-based defoamer, 0.1-0.2 part of an anticorrosion and bactericidal agent, 0.4-1.2 parts of a leveling agent, 3-6 parts of a wax emulsion, 0.5-2 parts of an organic modified silica nanocomposite material, 0.6-1.2 parts of a waterborne thickening agent and 5-10 parts of water. The prepared waterborne woodware matte white finish has prominent scratch resistance, high hardness and good water resistance and chemical resistance.

Owner:SKSHU PAINT

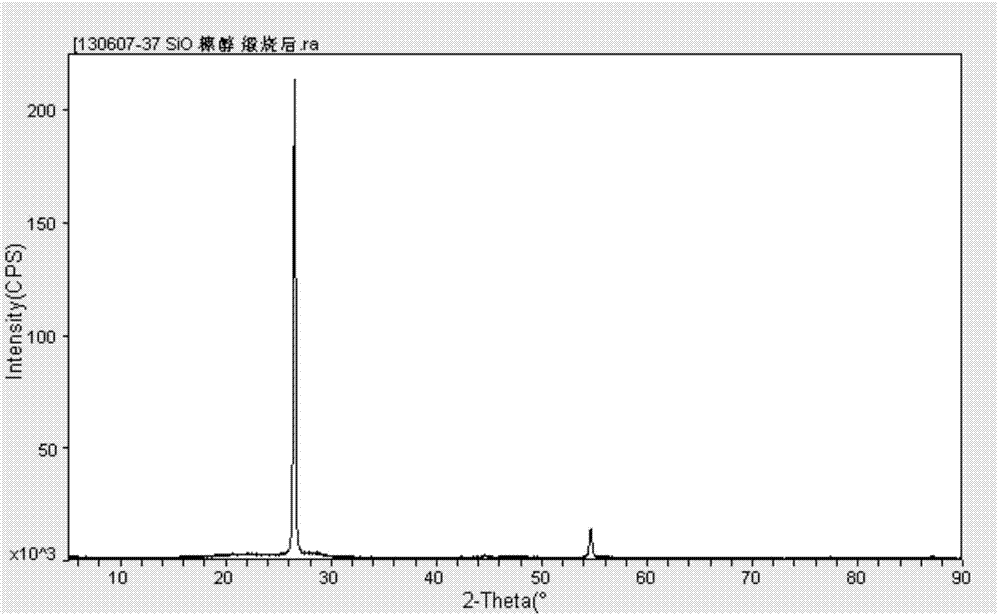

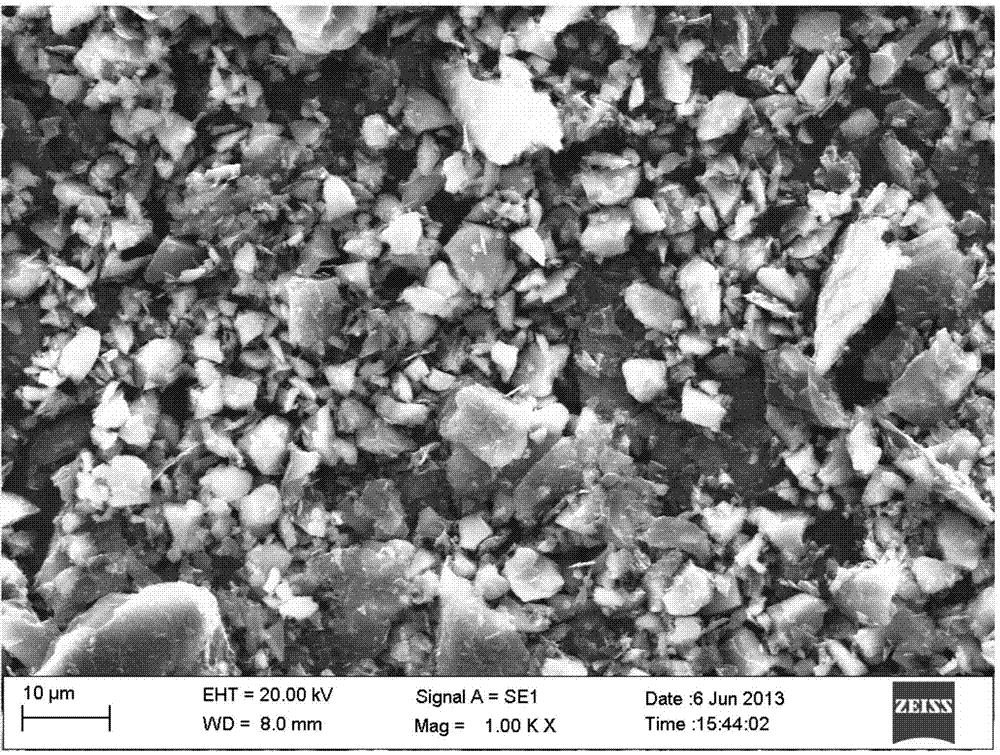

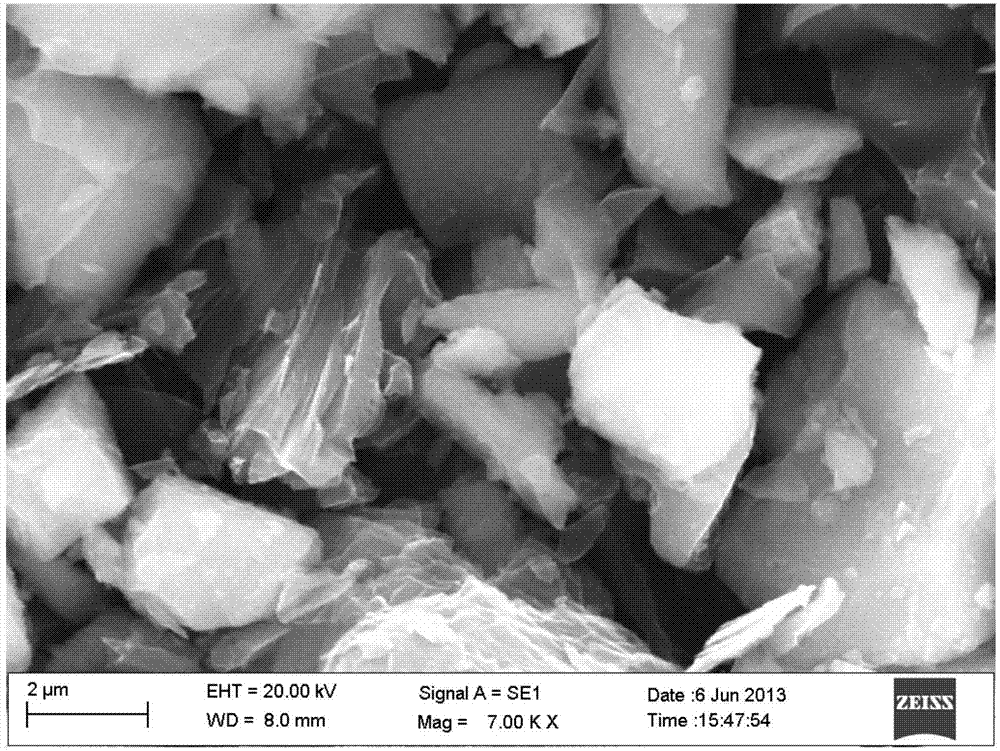

Preparation method and application of carbon coated carbon nitride/silicon-silicon nitride/silicon dioxide composite material

ActiveCN104241618ALow equipment requirementsSimple reaction conditionsMaterial nanotechnologyCell electrodesSilica particleCarbon nitride

The invention discloses a preparation method and application of a carbon coated carbon nitride / silicon-silicon nitride / silicon dioxide composite material. The preparation method comprises the steps of firstly preparing a carbon coated silicon / silicon dioxide nano-composite material, and then preparing the carbon coated carbon nitride / silicon-silicon nitride / silicon dioxide composite material. The nano-composite material is of a carbon coated structure containing pyrolytic carbon and carbon nitride. Silicon and silicon nitride particles are compounded on the surfaces of silicon dioxide particles. A carbon coated layer is located on the silicon-silicon nitride / silicon dioxide nano-composite material. The carbon coated carbon nitride / silicon-silicon nitride / silicon dioxide composite material prepared by means of the method has the advantages of being high in specific capacity and cycle performance and is suitable for lithium-ion secondary cell application and industrial production.

Owner:李宏斌

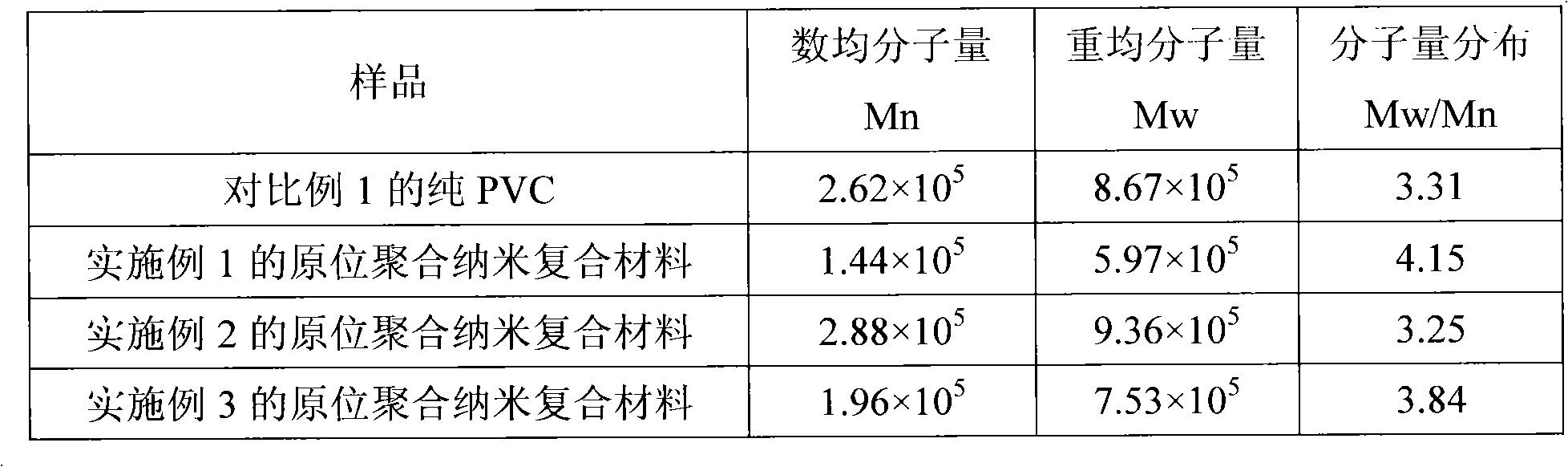

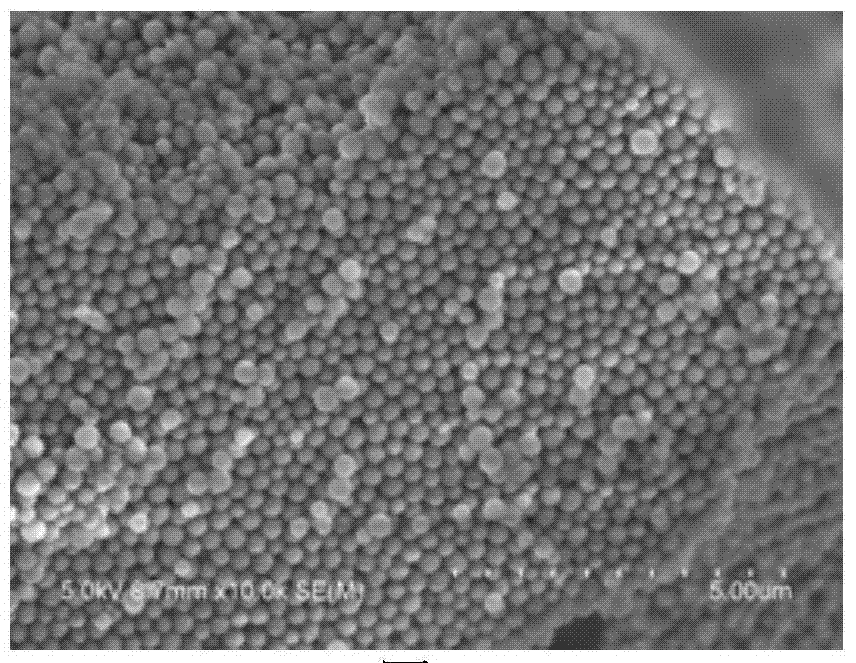

In-situ suspension polymerization preparation method of nanocomposite material consisting of polyvinyl chloride and silicon dioxide and product thereof

ActiveCN101851308AImprove performanceEnhanced interfacial interaction forcePolyvinyl chlorideSilicon dioxide

The invention belongs to the field of a nanocomposite material of polyvinyl chloride and silicon dioxide, in particular to an in-situ suspension polymerization preparation method of the nanocomposite material consisting of the polyvinyl chloride and the silicon dioxide and a product thereof, as well as a modification technology of nano-silicon dioxide used for the nanocomposite material. The preparation method prepares the nanocomposite material consisting of the polyvinyl chloride and the silicon dioxide through the in-situ suspension polymerization method, which comprises the steps of uniformly dispersing the modified nano-silicon dioxide in vinyl chloride monomers and carrying out in-situ suspension polymerization by regulating the parameters of the polymerization process, thereby realizing the control of particle size of polyvinyl chloride particles and effectively preventing sticking a kettle. Various properties of polymerized resin are greatly improved in comparison with the pure polyvinyl chloride resin, and the method is simple and easy to operate, thereby conveniently controlling the composition, the structure and the properties of the composite material and being characterized by stable structure and uniform dispersion of inorganic nano-particles.

Owner:INST OF CHEM CHINESE ACAD OF SCI

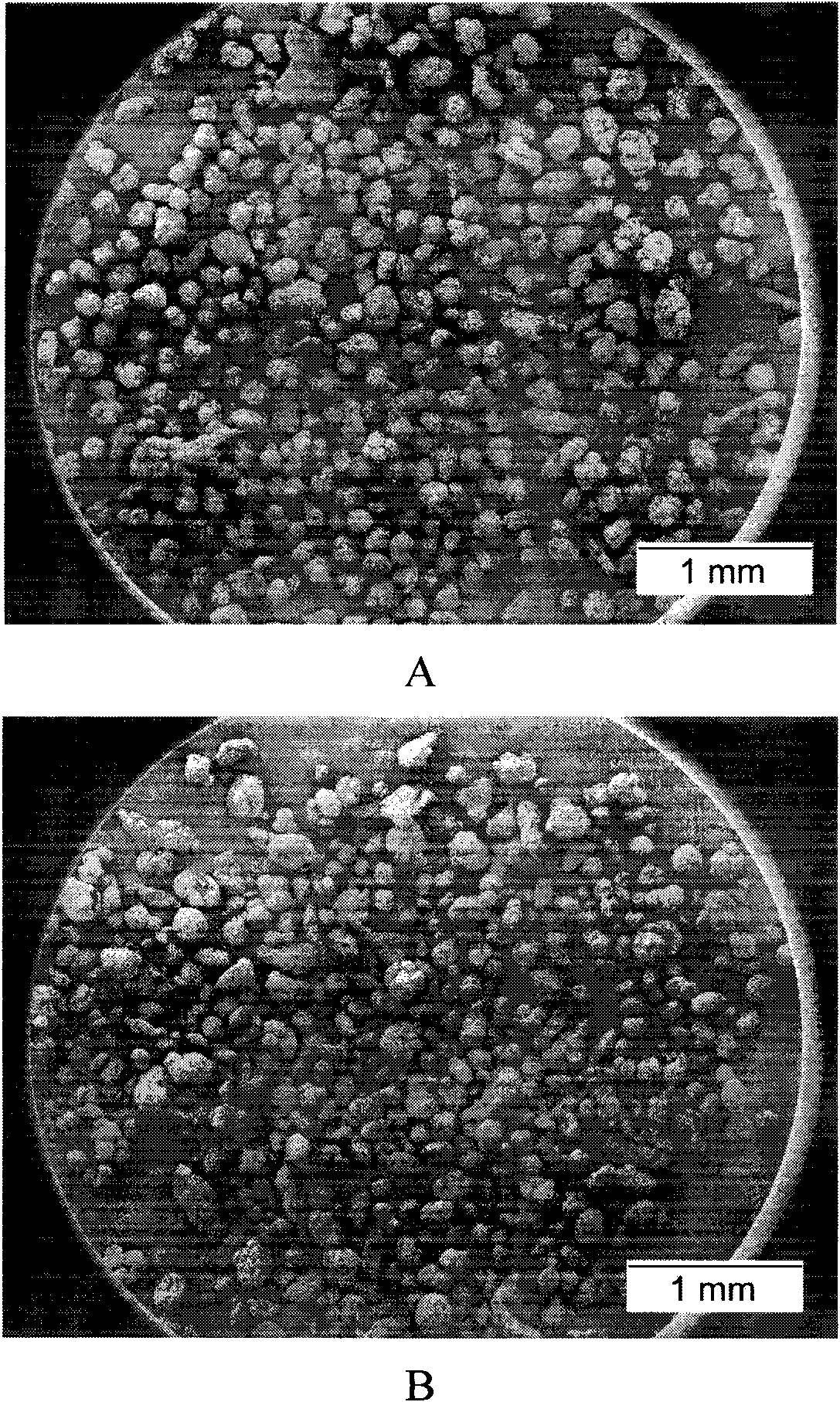

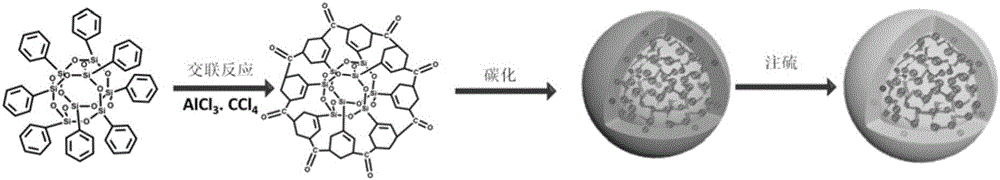

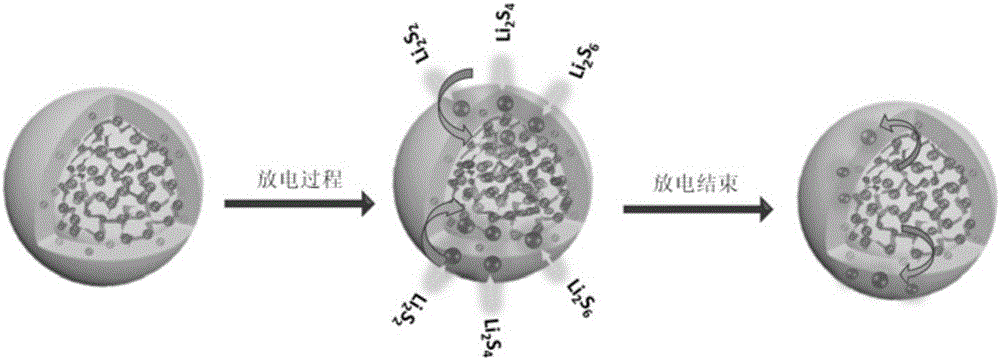

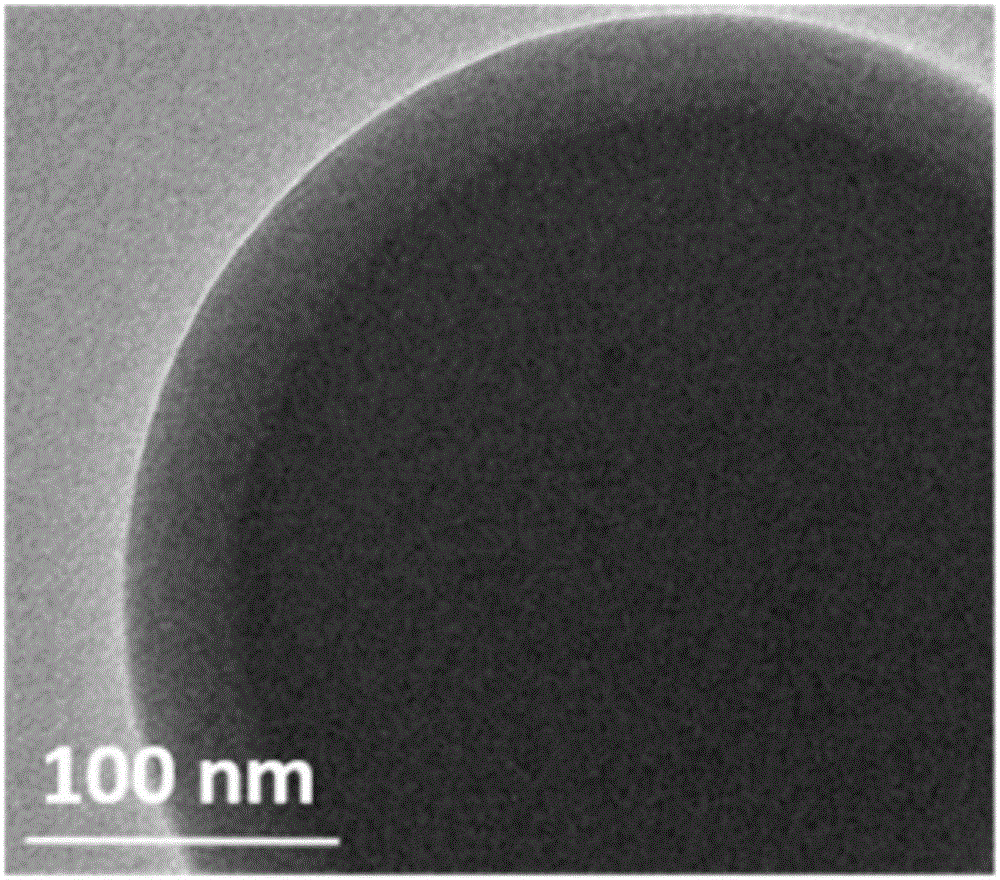

Porous carbon spheres-coated silicon/silicon dioxide nano-composite material and preparation method and application thereof

ActiveCN105789571AImproved pore size distributionLarge specific surface areaMaterial nanotechnologyCell electrodesPorous carbonElectric capacity

The invention provides a porous carbon spheres-coated silicon / silicon dioxide nano-composite material and a preparation method and an application thereof. The porous carbon spheres-coated silicon / silicon dioxide nano-composite material comprises a silicon / silicon dioxide nano-composite material and porous carbon spheres, wherein the porous carbon spheres coat the silicon / silicon dioxide nano-composite material and comprise micropores and mesopores. The porous carbon spheres-coated silicon / silicon dioxide nano-composite material can form physical and chemical adsorption on polysulfide when used as an anode material for a lithium-sulfur battery, is high in sulfur loading capacity and demonstrates excellent electric capacity and cycling stability; and active materials are not easy to lose.

Owner:PEKING UNIV

Method of preparing polylactic acid/silicon dioxide nano composite material from acidic silicasol

The invention discloses a preparing method of polylactic acid / silica dioxide nanometer composite material with acidic silicasol, which comprises the following steps: (1) mixing acidic silicasol lactic acid raw material under the condition of agitation and hypersonic or agitation and hypersonic; getting nanometer grade dispersing mixture; (2) dewatering and prepolying the mixture from step (1); getting lactic acid prepolymer with silica dioxide nanometer particle; (3) adding into activator; proceeding original position melting polycondensation or original position melting solid phase polycondensation; getting the product. The raw material of this invention is cheap and available, which can used to plastic, packing material, agricultural film, fiber and biological material domain.

Owner:ZHEJIANG UNIV

Method for preparing natural rubber-silicon dioxide nano composite material by in-situ grafting polymerization

InactiveCN101418063ASmall particle sizeImprove mechanical propertiesHydrophilic monomerPolymer science

The invention provides a method for utilizing in-situ graft polymerization to prepare a natural rubber-silica nano-composite material. The method comprises the following steps of adopting a coupling agent to modify the surface of nano-silica, leading double bond into the surface of the nano-silica, directly blending the nano-silica with lacteous natural rubber, adding hydrophilic monomer for in-situ graft polymerization and closely combining the silica with the natural rubber in a chemical bond mode through the bridge function of hydrophilic monomer polymers, so as to prepare the natural rubber-silica nano-composite material. The preparation method realizes that the uniform distribution and small particle size of the nano-silica in the natural rubber, improves the mechanical properties of the natural rubber, and provides technical guarantee for preparing the nano-composite material rubber products with excellent comprehensive properties.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Preparation of high solid polyester polyol/silica nanocomposite resin with low viscosity and related nanocomposite coatings

InactiveUS20060122314A1Excellent abrasion resistanceHigh hardnessSpecial tyresPolyurea/polyurethane coatingsPolyesterColloidal silica

A high solid polyester polyol / silica nanocomposite resin with low viscosity is synthesized by an in situ polymerization method, namely conducting condensation polymerization of polyol / diacid monomer with a molar ratio of 1.1˜1.5 in the presence of colloidal silica nanoparticles with a diameter of 10˜150 nm. The resulted nanocomposite resins has a solid content of >95%, molecular weight of 1000˜5000 g / mol and hydroxyl value of 80-200 mg KOH / g, and a viscosity in the range of 800-2000 mPa.s. The viscosities are especially lower than those obtained by a blending method. The nanosilica content in the nanocomposite resin is 1˜15% (based on the total solid content of nanocomposite resin). The high solid polyester polyol / silica nanocomposite resin was curable with isocyanate or melamine to prepare high solid transparent nanocomposite coatings with obviously improved abrasion and scratch resistance, hardness, weatherability etc.

Owner:FUDAN UNIV

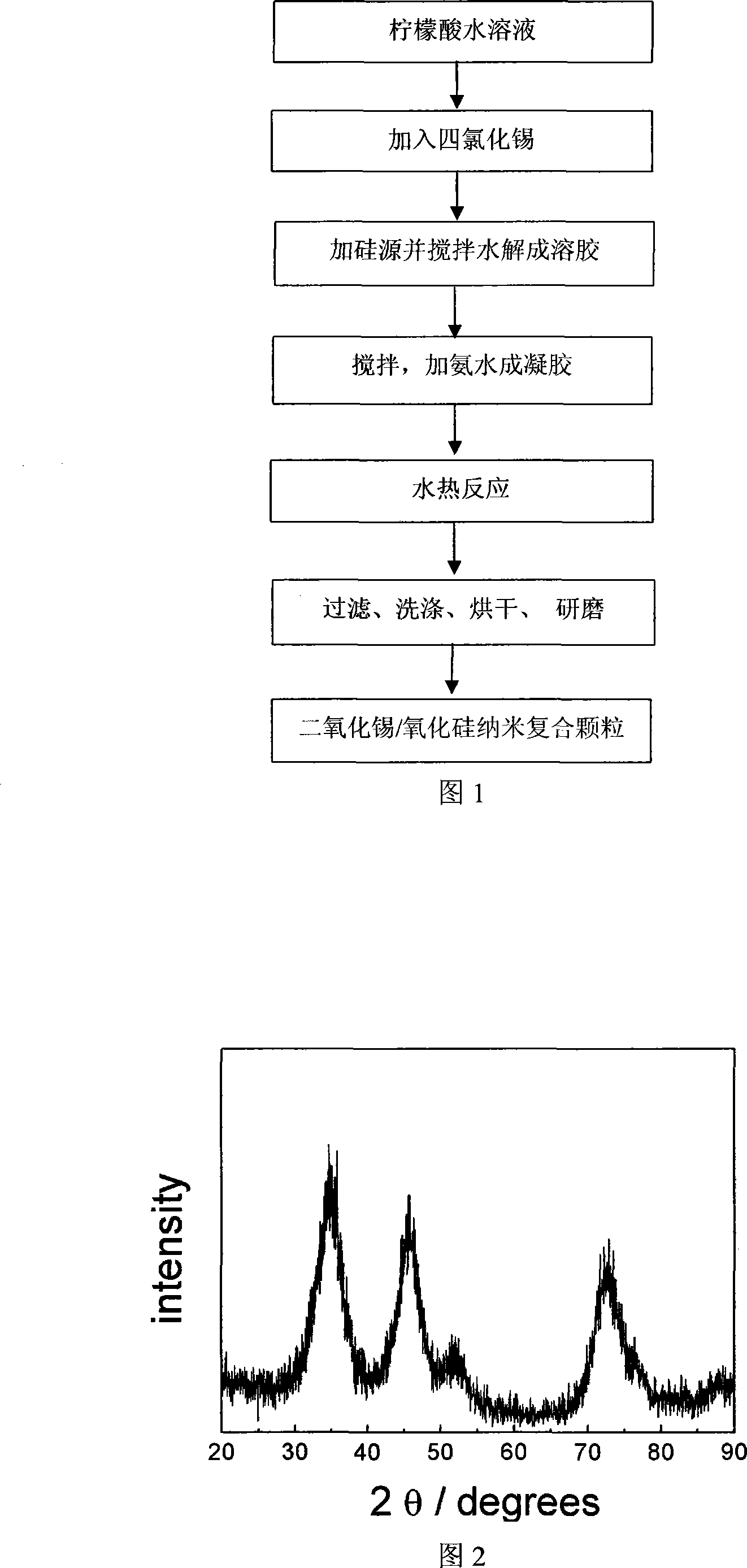

Method for preparing stannic oxide/silica nano composite material

The invention discloses a preparation method of a tin dioxide / silicon oxide nanocomposite material, which belongs to the technical field of inorganic chemical materials, and specifically relates to a preparation method of a tin dioxide nanometer material. The invention uses tin tetrachloride as a tin source, sodium silicate or tetraethyl orthosilicate as a silicon source, and adopts a sol-gel-hydrothermal reaction crystallization process to prepare the tin dioxide / silicon oxide nanocomposite material. In the prepared tin dioxide / silicon oxide nanocomposite material, the silicon oxide is mainly coated on the surface of the tin dioxide. The preparation method of the invention is simple, easy to operate and suitable for large-scale production. The prepared tin dioxide / silicon oxide nanocomposite material prepared by sol-gel-hydrothermal method has uniform particles, large specific surface area, good stability and monodispersity, and can be used in gas sensors, photocatalysts, photoelectric materials and catalyst supports.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Low-dielectric-constant hollow aluminum oxide/silicon dioxide nano composite material and application thereof

ActiveCN111547729ALow dielectric constantLow refractive indexSilicaAluminium hydroxide preparationThermal dilatationRefractive index

The invention belongs to the technical field of material chemistry and relates to a low-dielectric-constant hollow aluminum oxide / silicon dioxide nano composite material, and further discloses a preparation method and application thereof. The low-dielectric-constant hollow aluminum oxide / silicon dioxide nano composite material is of a laminated shell structure with a closed cavity structure; aluminum oxide is directionally deposited on the outer surface of a hollow silicon dioxide shell layer; an inner shell is a silicon dioxide layer; an aluminum oxide shell body is deposited and grown on thesurface of the silicon dioxide layer; since the advantages of the aluminum oxide and silicon dioxide are effectively combined, and the advantages of low dielectric constant, low refractive index andhigh-frequency dielectric stability of the hollow silicon dioxide can be exerted at the same time; and the advantages of high strength, chemical erosion resistance, low thermal conductivity, low thermal expansion coefficient and the like of the aluminum oxide material are utilized, so that the material can meet the performance requirements in the antireflection field and the 5G millimeter wave frequency band field.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Process for in-situ polymerization preparation of nylon 6/epoxy resin/silicon dioxide nano composite materials

The invention discloses an in-situ polymerization method for preparation of nylon 6 / epoxide resin / silica dioxide nanocomposite, which consists of the following steps:a)preparing epoxide resin siloxane solution by graft reaction and hydrolytic reaction; b) before or in the aminocaprolactam cycle-open reaction, introducing the epoxide resin siloxane solution into the mediator of the said aminocaprolactam cycle-open reaction, simultaneously adding the water and the anti-oxidant; c) making the aminocaprolactam open ring and polymerize to prepare high-strength and super ductility nylon-6 / epoxide resin / silica dioxide nanocomposite. The invention makes the silicate react with the hydroxy group of the epoxide resin under the accelerating effect, then dissolvent, water and acid (or alkali) are added to hydrolyze. Because the silicasol surface graft and adsorb epoxide resin, the agglomeration of the earth silicon nanoparticles can be effectively avoided. On the other hand, because the epoxy radicals can react with the amidol and the carboxyl of the nylon-6 molecular chain to form partial interpenetration network architecture, accordingly the diphasic boundary action can be effectively improved. It has a good cooperating knife-bar with the nano earth silicon, so it can largely improve the bruise resistance of the materials as well as the hot strength of the composite, in which the hot strength has increased by 30 % compared with nylon-6 and the bruise resistance is 3-5 times of the nylon-6.

Owner:XIANGTAN UNIV

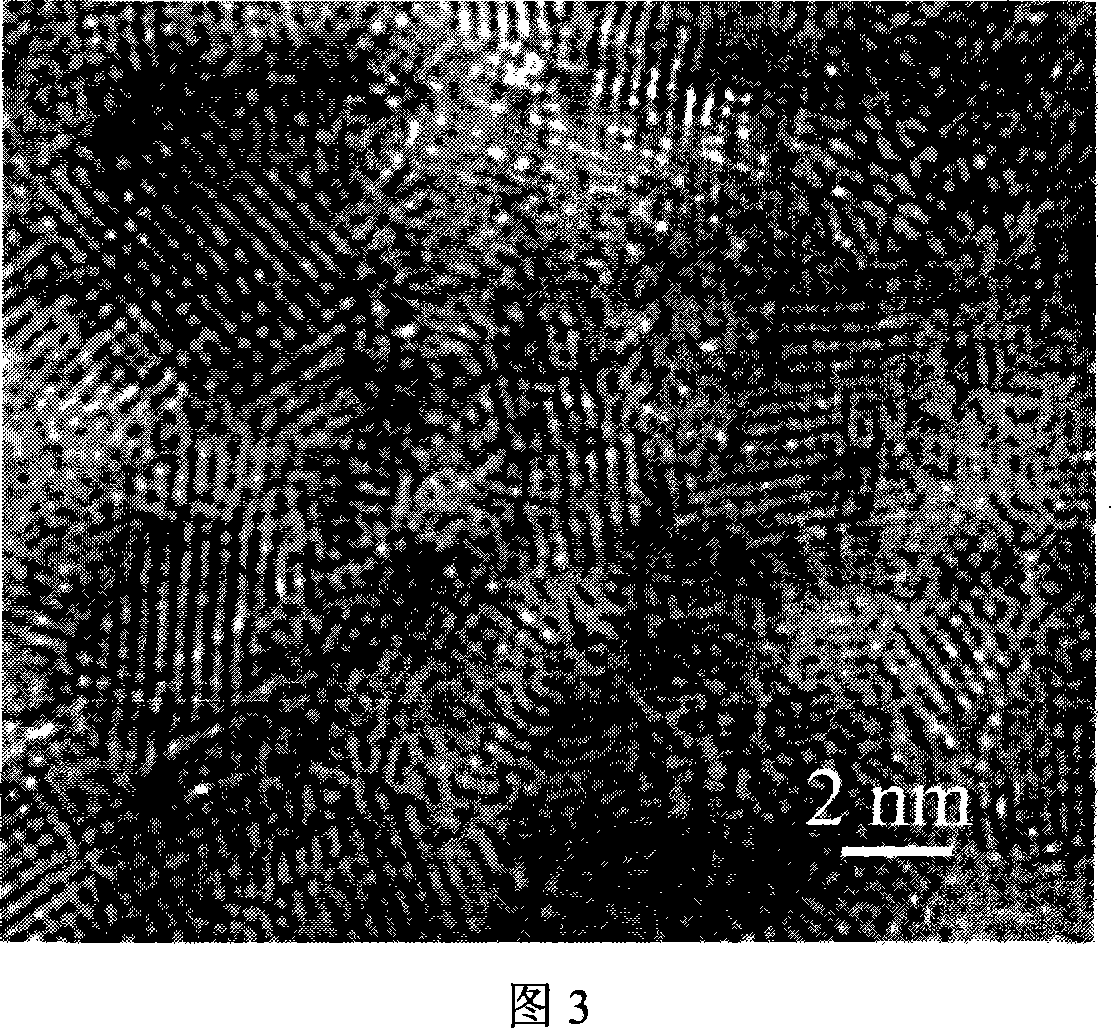

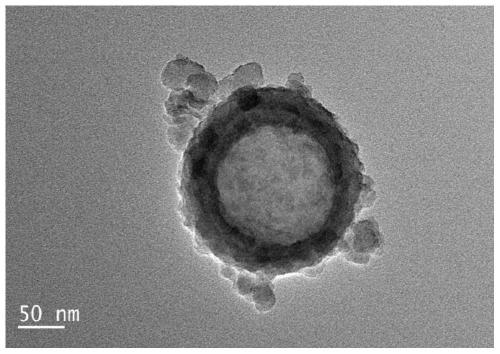

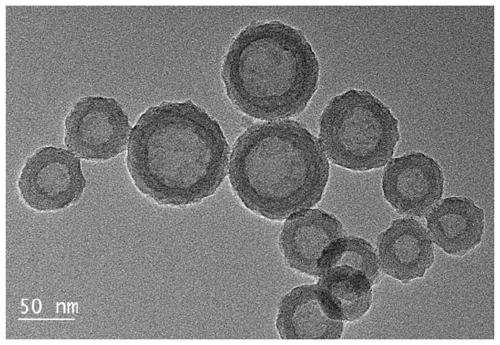

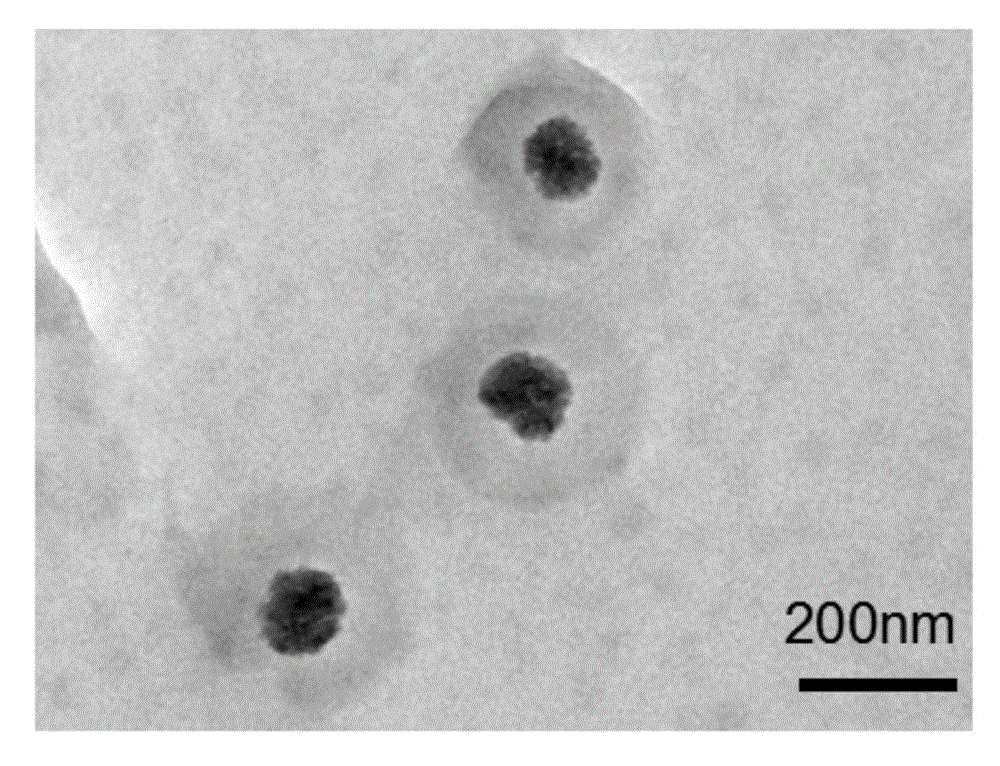

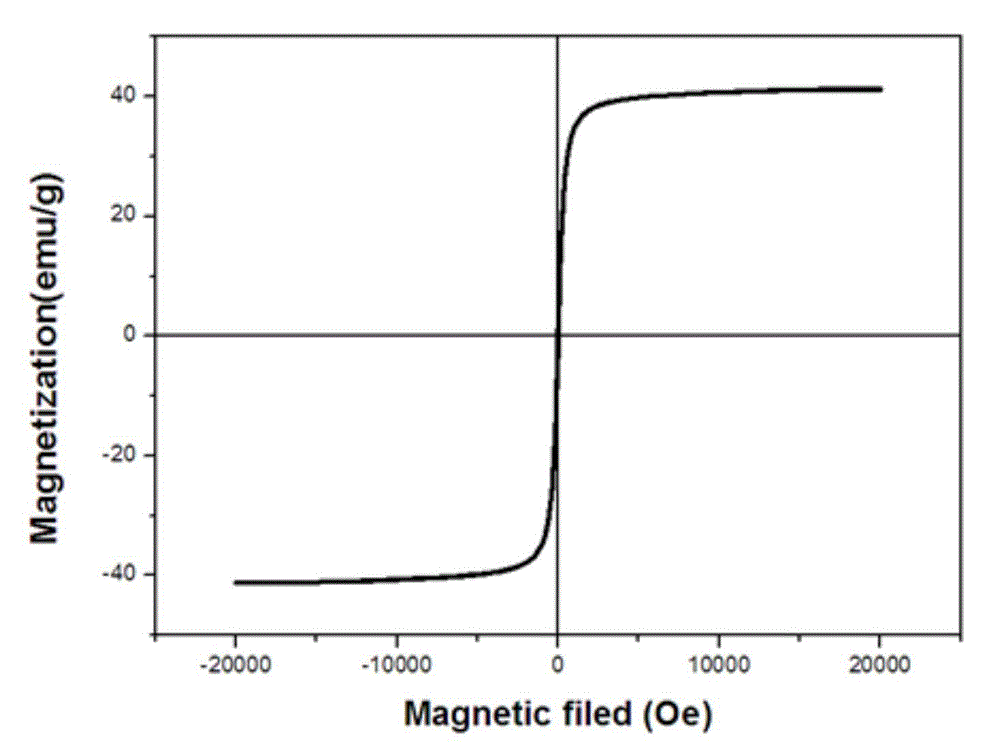

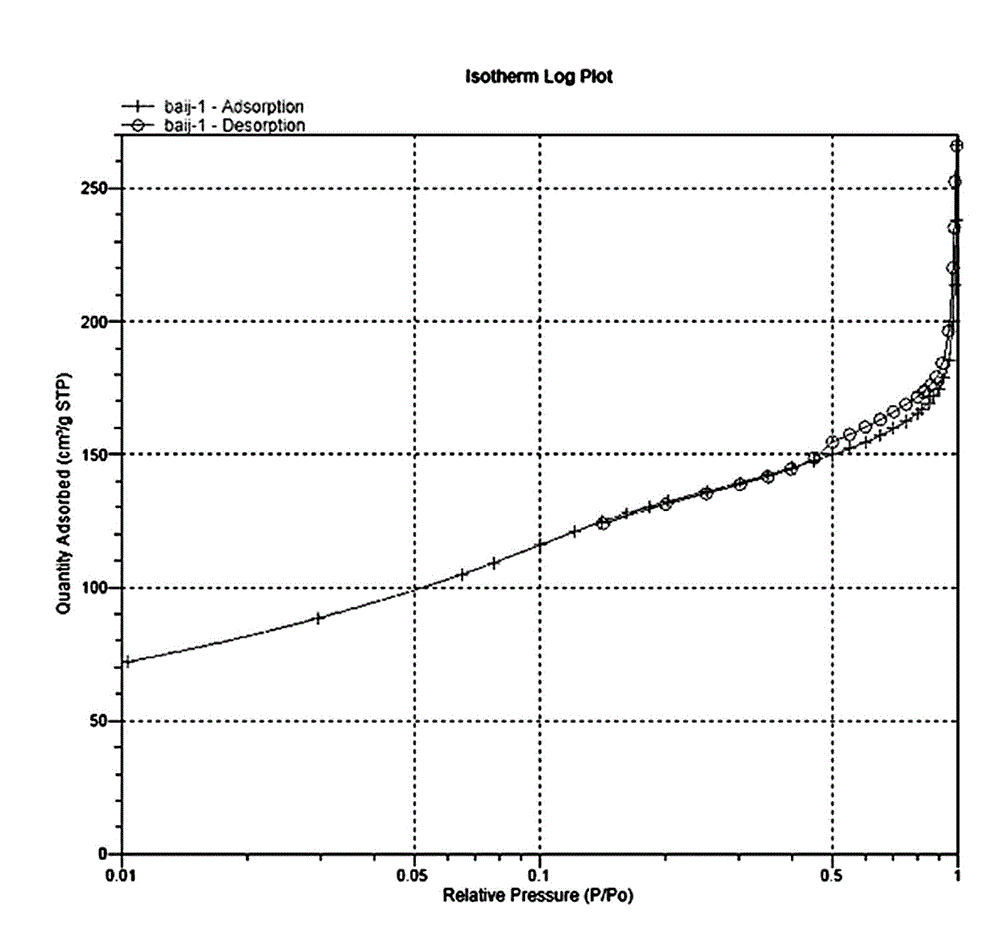

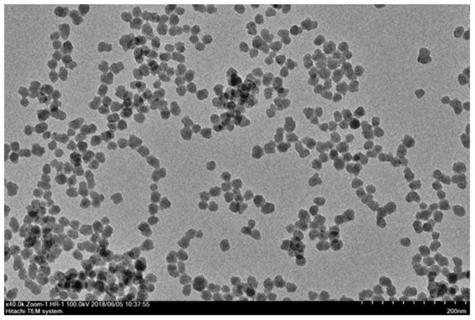

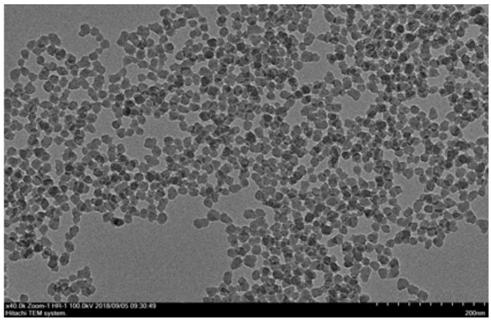

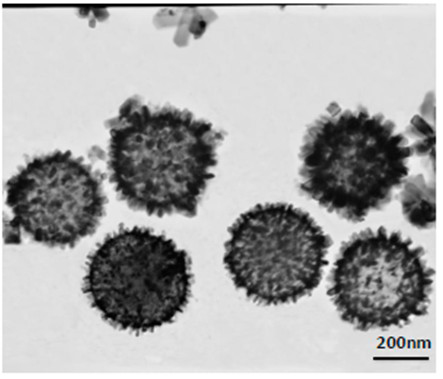

Rapid preparation method and application of core-shell spherical magnetic mesoporous silica nanocomposites

InactiveCN105084424AUniform shapeQuality is easy to controlMaterial nanotechnologySilicaFerrite nanoparticlesMesoporous silica

The invention provides a rapid preparation method of core-shell spherical magnetic mesoporous silica nanocomposites. The invention also provides an application of the core-shell spherical magnetic mesoporous silica nanocomposites in diagnosis and treatment of tumors. According to the preparation method, spherical magnetic ferrite nanoparticles are prepared by an alkali hydrolysis method; and by using the spherical magnetic ferrite nanoparticles as seed particles and by the utilization of self-assembly behavior of a surfactant in an aqueous solution and an inorganic silicon source, the surface of the magnetic ferrite nanoparticles is rapidly coated with a layer of mesostructured silica nanocomposites so as to obtain the core-shell spherical magnetic mesoporous silica nanocomposites. The method is time-saving and reaction condition is pure water phase. By the method, a lot of the core-shell spherical magnetic mesoporous silica nanocomposites can be prepared within a short time.

Owner:JILIN UNIV

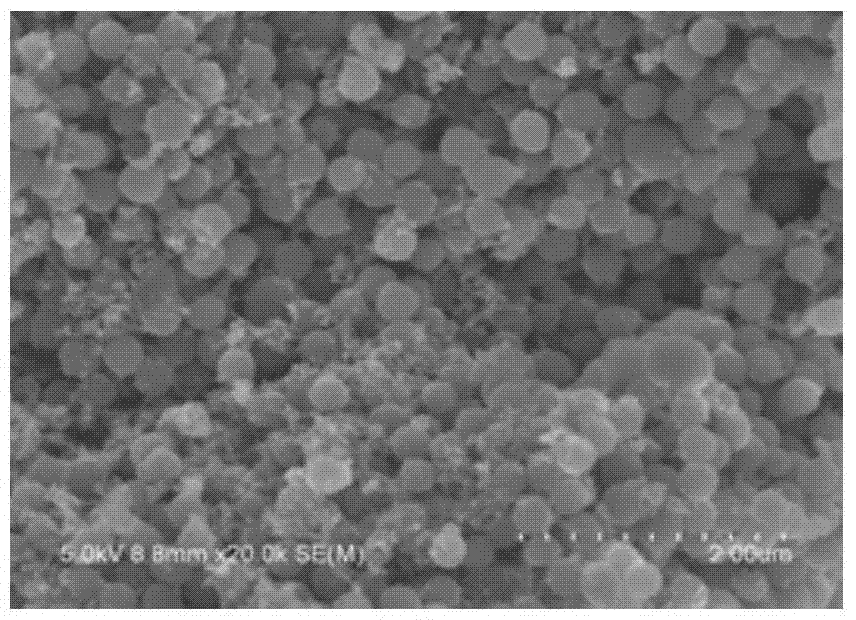

Silicon dioxide nanometer composite material and preparation method and application thereof

ActiveCN109627814AReduced stabilityReduce weather resistanceCoatingsComposite filmWeather resistance

The invention provides a silicon dioxide nanometer composite material and a preparation method and application thereof. The silicon dioxide nanometer composite material is mainly formed by compoundingsilicon dioxide nanoparticle suspension and nanometer silicon dioxide acidic sol, wherein the particle size of silicon dioxide nanometer particles in the silicon dioxide nanometer particle suspensionis 5-30 nm; the nanometer silicon dioxide acidic sol is provided with chain nanosilicon dioxide, and the veneer content of the nanometer silicon dioxide acidic sol is 70-90%. A silicon dioxide nanometer composite thin film prepared from the silicon dioxide nanometer composite material has good effects of antireflection, self cleaning and mist prevention, meanwhile has good mechanical abrasion resistance and weather resistance, is good in firmness with a matrix, is not limited during usage, can exert effects for a long term in the field, and is wide in application range.

Owner:STATE POWER INVESTMENT CORP RES INST +1

Method for preparing silica/lignin type polyurethane foam material

The invention discloses a method for preparing a silica / lignin type polyurethane foam material. The method comprises: utilizing lignin in rice husks and silica to prepare a uniform lignin / silica nanocomposite material with good dispersibility by employing a sol-gel method, then employing a one-step foaming method to ultrasonically disperse and dissolve the lignin / silica nanocomposite material in polyether polyol, and finally compounding with raw materials such as isocyanate and the like to obtain the silica / lignin type polyurethane foam material. The employed uniform lignin / silica nanocomposite material is cheap and easily available; the whole preparation process is simple in technology, green and environment-friendly; and the method not only helps to reduce the cost of polyurethane foam products, but also helps to change waste into values, reduce environment pollution and the like, and has important meaning.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing Nano composite material of amorphous carbon / silicon dioxide

InactiveCN101003373ASimple preparation processHigh reactivityNanostructure manufactureSilicaSucrosePresent method

This invention relates to method for preparing amorphous carbon / silica nanocomposite. The method solves the problems of complex process, low yield, high impurity content and ununiform particle size distribution faced by the present methods in preparing carbon / silica nanocomposite. The method comprises: (1) mixing silica sol, sucrose and deionized water; (2) stirring; (3) gelatinizing the sol; (4) heat-treating the gel; (5) cooling to obtain amorphous carbon / silica nanocomposite. The method has simple process, and does not need any catalyst. The ratio of carbon to silica in the product can be easily controlled. Carbon and silica both exist in the amorphous states, and combine to form uniform particles on nanometer scale. The product has high reactivity, and can be used as the raw material for SiC nanomaterial, SiC-containing composite and Si-O-C-containing composite.

Owner:HARBIN INST OF TECH

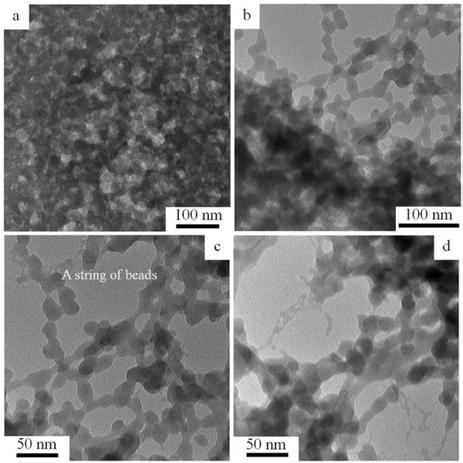

Mesoporous graphite/silicon dioxide composite counter electrode for dye sensitized solar cells and method for preparing mesoporous graphite/silicon dioxide composite counter electrode

InactiveCN102709070ALarge specific surface areaHigh catalytic activityLight-sensitive devicesFinal product manufactureSolar cellUltrasonic dispersion

The invention discloses a mesoporous graphite / silicon dioxide composite counter electrode for dye sensitized solar cells and a method for preparing the mesoporous graphite / silicon dioxide compound counter electrode, the composite counter electrode consists of an electric conduction substrate and a mesoporous graphite / silicon dioxide composite membrane, and is prepared in the following steps that: firstly, adding silicon dioxide nano-particles into graphite oxide suspension, and putting in the hydrazine hydrate solution after ultrasonic dispersion for reduction, and heating the mixture at 60-110 DEG C for reaction for 1-12 hours, thus forming the mesoporous graphite / silicon dioxide nanocomposite suspension; and dripping the suspension onto the clean electric conduction substrate for forming the mesoporous graphite / silicon dioxide membrane, regulating the thickness of the membrane to 1-20mum through repeating the operation, namely forming the composite counter electrode. The mesoporous graphite / silicon dioxide composite counter electrode has a simple technology and moderate conditions, the produced counter electrode has high catalytic activity and is low in cost, so the cost of the counter is greatly decreased, and the mesoporous graphite / silicon dioxide composite counter electrode is expected to be applied in the mass industrial production of the dye sensitized solar cells.

Owner:江苏有则创投集团有限公司 +1

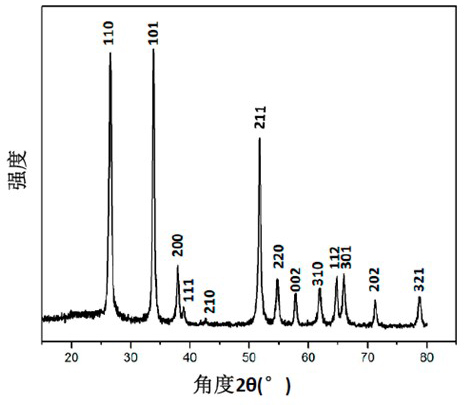

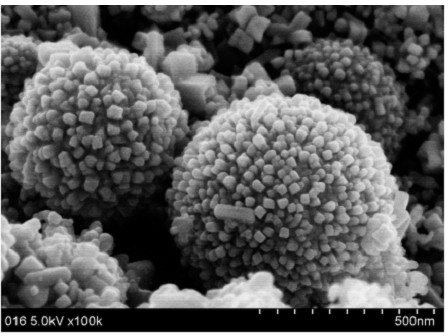

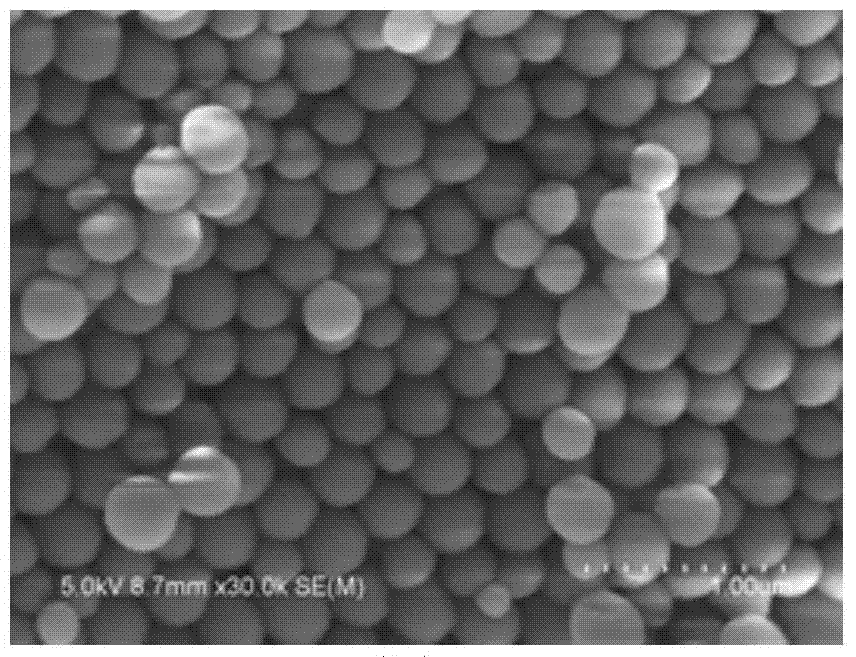

Preparation method of stannic oxide/silica composite nano-particle

ActiveCN102515177ASimple processEasy to operateMaterial nanotechnologySilicaNano compositesReaction temperature

The invention discloses a preparation method of a stannic oxide / silica composite nano-particle. The stannic oxide / silica composite nano-particle has a sea urchin-shaped structure. The preparation method provided by the invention comprises the following steps that one or more silicon sources and one or more tin sources are dissolved into a mixed solvent of water and ethanol so that a precursor solution is obtained; and the precursor solution is fed into a burning reactor by an injection pump and then undergoes a hydrolysis reaction at a reaction temperature of 1500 to 2000 DEG C, wherein spherical silica particles are produced in a fire and then heterogeneous nucleation and oriented growth of stannic oxide on the surfaces of the spherical silica particles are carried out so that the stannic oxide / silica composite nano-particles having sea urchin-shaped structures are obtained finally. The preparation method provided by the invention adopts simple equipment, can be realized easily and is conducive to realization of industrial continuous preparation.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of cross-linked sodium carboxymethyl cellulose

ActiveCN102604131AHigh light transmittanceHigh viscosityPigment treatment with non-polymer organic compoundsCross-linkNano composites

The invention relates to a preparation method of cross-linked sodium carboxymethyl cellulose. The preparation method of the cross-linked sodium carboxymethyl cellulose comprises the following steps of: adding an inorganic acid catalyst into sodium carboxymethyl cellulose solution to change a reaction system to be acidic; after reaction, adding a cross-linking agent; removing oxygen and charging nitrogen; prepolymerizing and polymerizing to obtain cross-linked carboxymethyl cellulose solution; dropwise adding alkalized ethanol-water solution to obtain cross-linked sodium carboxymethyl cellulose solution; and drying to obtain the cross-linked sodium carboxymethyl cellulose powder. According to the preparation method, a silicon dioxide composite nanomaterial, silicon dioxide-hydroxyl propyl acrylate, is used as the cross-linking agent, sodium carboxymethyl cellulose is used as a raw material, and cross-linking is performed under an alkaline condition to prepare the cross-linked sodium carboxymethyl cellulose. The cross-linked sodium carboxymethyl cellulose prepare by the invention has the characteristics of high transparence, high viscosity, high swelling degree and the like, and hasextremely high industrial application value.

Owner:美信佳中维药业股份有限公司

Preparation of high solid polyester polyol/silica nanocomposite resin with low viscosity and related nanocomposite coatings

A high solid polyester polyol / silica nanocomposite resin with low viscosity is synthesized by an in situ polymerization method, namely conducting condensation polymerization of polyol / diacid monomer with a molar ratio of 1.1˜1.5 in the presence of colloidal silica nanoparticles with a diameter of 10˜150 nm. The resulted nanocomposite resins has a solid content of >95%, molecular weight of 1000˜5000 g / mol and hydroxyl value of 80-200 mg KOH / g, and a viscosity in the range of 800-2000 mPa.s. The viscosities are especially lower than those obtained by a blending method. The nanosilica content in the nanocomposite resin is 1˜15% (based on the total solid content of nanocomposite resin). The high solid polyester polyol / silica nanocomposite resin was curable with isocyanate or melamine to prepare high solid transparent nanocomposite coatings with obviously improved abrasion and scratch resistance, hardness, weatherability etc.

Owner:FUDAN UNIV

Method for preparing nanometer silicon dioxide composite material with super concentrated emulsion

The invention discloses a method for preparing a nanometer silicon dioxide composite material with super concentrated emulsion. The method comprises the following steps: firstly, macerating silicon dioxide in butyl oleate for surface modification, leaching out excess butyl oleate with ethyl alcohol for multiple times, dripping modified silicon dioxide, styrene and triene propyl cyanuric acid ester which are used as an oil phase, and azodiisobutyronitrile as an initiating agent into an aqueous phase of deionized water and sodium dodecyl sulfate at a room temperature, and under the protection of nitrogen, obtaining jelly glue-shaped super concentrated emulsion; and transferring the super concentrated emulsion into a centrifugal test tube for centrifugation, removing upper-layer air bubbles, then introducing in the nitrogen, sealing the centrifugal test tube with a rubber plug, placing the centrifugal test tube in a water bath for polyreaction, and successfully preparing a nanometer composite material containing different parts by weight of silicon dioxide through the super concentrated emulsion. The nanometer composite material is added to transparent resin of PC / PMMS / PS and the like, so that the effect of light diffusion is achieved. The nanometer composite material has good ultraviolet resistance and good weather resistance when being applied to packaging materials, optical materials, plastic and the like.

Owner:SHANGHAI UNIV

Method for preparing polymer/SiO2 nano composite material

ActiveCN104788933ASuitable for mass productionSimple methodPigment treatment with macromolecular organic compoundsPolymeric surfaceNano composites

The invention relates to a method for preparing an inorganic nanoparticle composite material, and in particular to a method for preparing a polymer / SiO2 nano composite material. The method for preparing the polymer / SiO2 nano composite material comprises the following step: commixing or melt-blending a polymer with functionalized SiO2 nanoparticles, thereby obtaining the polymer / SiO2 nano composite material, wherein the mass ratio of the polymer to the functionalized SiO2 nanoparticles is 100:(1-6), the functionalized SiO2 nanoparticles are polymer surface modified SiO2 nanoparticles, and the polymer molecule chain is chemically grafted to the surface of nano SiO2 through degradation of the polymer in the physical melt commixing process. The method for preparing the polymer-based nano composite material is relatively applicable to quantization production and is simple in process and low in cost.

Owner:ZHENGZHOU UNIV

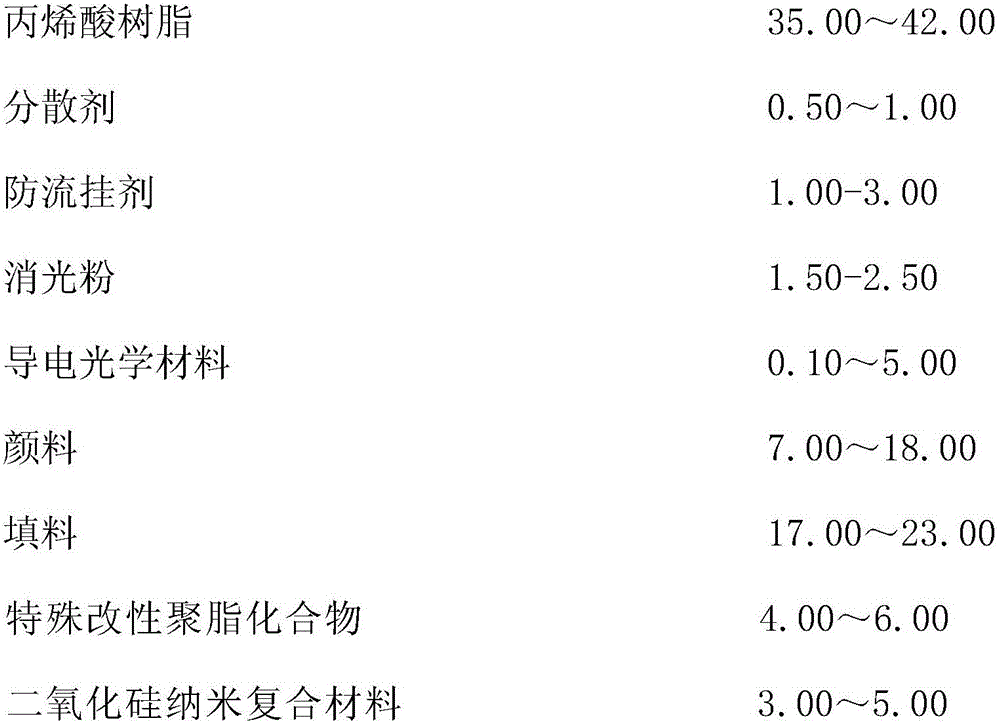

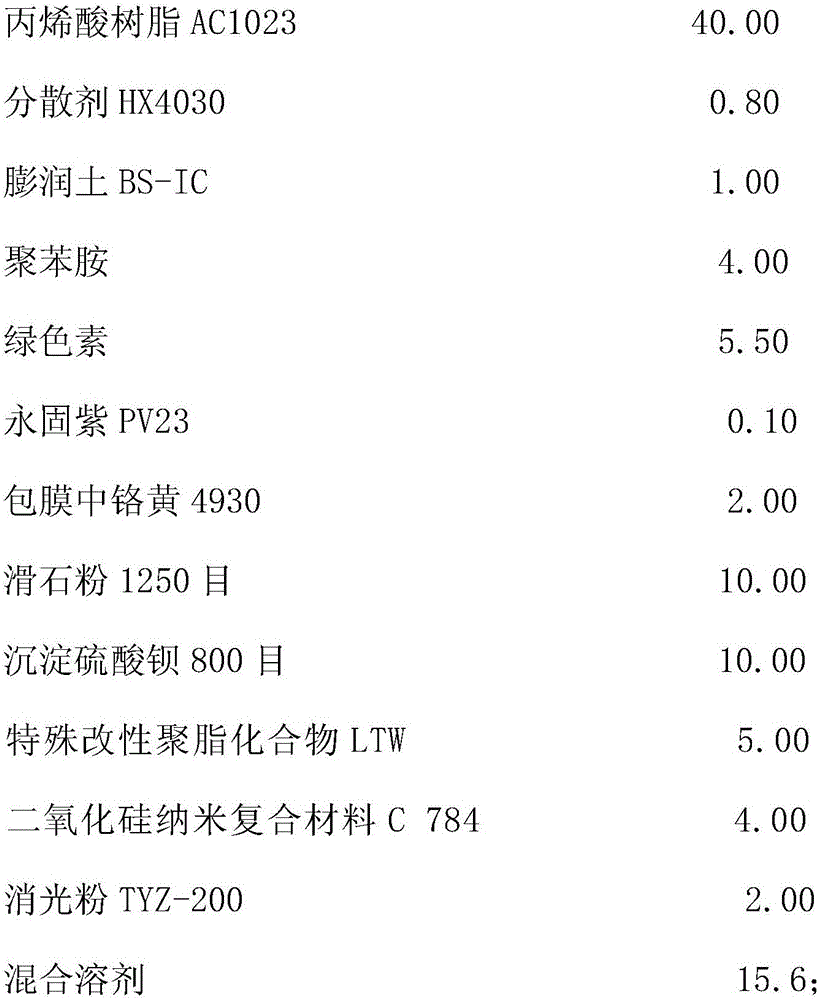

Automatic spraying camouflage coating for manipulators and method for preparing automatic spraying camouflage coating

The invention discloses automatic spraying camouflage coating for manipulators and a method for preparing the automatic spraying camouflage coating. The method includes (1), adding 35.00-42.00 parts of acrylic resin, 0.50-1.00 part of dispersing agents, 1.00-3.00 parts of anti-sagging agents, 1.50-2.50 parts of extinction powder, 0.10-5.00 parts of electrically conductive optical materials, 7.00-18.00 parts of pigment, 17.00-23.00 parts of fillers and 6.00-8.50 parts of mixed solvents into an accessory tank and uniformly stirring the acrylic resin, the dispersing agents, the anti-sagging agents, the extinction powder, the electrically conductive optical materials, the pigment, the fillers and the mixed solvents to obtain first mixtures; (2), grinding the first mixtures by the aid of a sand mill until the fineness of the first mixtures reaches 18-22 micrometers; (3), adding 4.00-6.00 parts of special modified polyester compounds, 3.00-5.00 parts of silicon dioxide nanometer composite materials and 6.00-8.50 parts of mixed solvents into paste and uniformly stirring the special modified polyester compounds, the silicon dioxide nanometer composite materials, the mixed solvents and the paste to obtain second mixtures; (4), regulating the viscosity of the second mixtures until the viscosity of the second mixtures reaches coating-4 cup 65-80 S; (5), filtering and packaging the automatic spraying camouflage coating. The automatic spraying camouflage coating and the method have the advantages that the automatic spraying camouflage coating is reasonable in design and has tone which is consistent with natural backgrounds, anti-infrared camouflage effects of spectral reflection curves can be realized by the automatic spraying camouflage coating, and problems in the aspects of sagging, drying speeds, surface smoothness and the like in automatic paint spraying procedures can be solved.

Owner:CHANGZHOU JIAERKE SIMULATION EQUIP CO LTD

Titanium dioxide/silicon dioxide nanometer composite material and preparation method and application thereof

InactiveCN104258836AExcellent performance in catalytic organic dyesLow pricePhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeSolvent

The invention discloses a titanium dioxide / silicon dioxide nanometer composite material and a preparation method and application thereof. The preparation method comprises the following steps: a, preparing nanometer silica sol by adopting a sol method; b, mixing the nanometer silica sol, hexadecyl trimethyl ammonium bromide and tetrabutyl titanate in the presence of solvents, carrying out contact reaction, so as to prepare a faint yellow precipitate; c, mixing and refluxing the faint yellow precipitate, hydrochloric acid and acetone, so as to prepare white powder; and d, heating the white powder to the temperature of 350-650 DEG C at a temperature rise rate of 1-10 DEG C per minute, carrying out heat treatment for 0.5-24 hours, so as to prepare the titanium dioxide / silicon dioxide nanometer composite material. The nanometer composite material has the functions of nanometer titania, the production cost can be reduced, and the utilization rate is increased, so that the nanometer composite material can be widely applied to photocatalytic degradation organic dyestuffs. Meanwhile, the preparation method is simple in process, and raw materials are readily available.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Method for preparing natural rubber-silicon dioxide nano composite material by in-situ grafting polymerization

InactiveCN101418063BSmall particle sizeImprove mechanical propertiesHydrophilic monomerPolymer science

The invention provides a method for utilizing in-situ graft polymerization to prepare a natural rubber-silica nano-composite material. The method comprises the following steps of adopting a coupling agent to modify the surface of nano-silica, leading double bond into the surface of the nano-silica, directly blending the nano-silica with lacteous natural rubber, adding hydrophilic monomer for in-situ graft polymerization and closely combining the silica with the natural rubber in a chemical bond mode through the bridge function of hydrophilic monomer polymers, so as to prepare the natural rubber-silica nano-composite material. The preparation method realizes that the uniform distribution and small particle size of the nano-silica in the natural rubber, improves the mechanical properties ofthe natural rubber, and provides technical guarantee for preparing the nano-composite material rubber products with excellent comprehensive properties.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

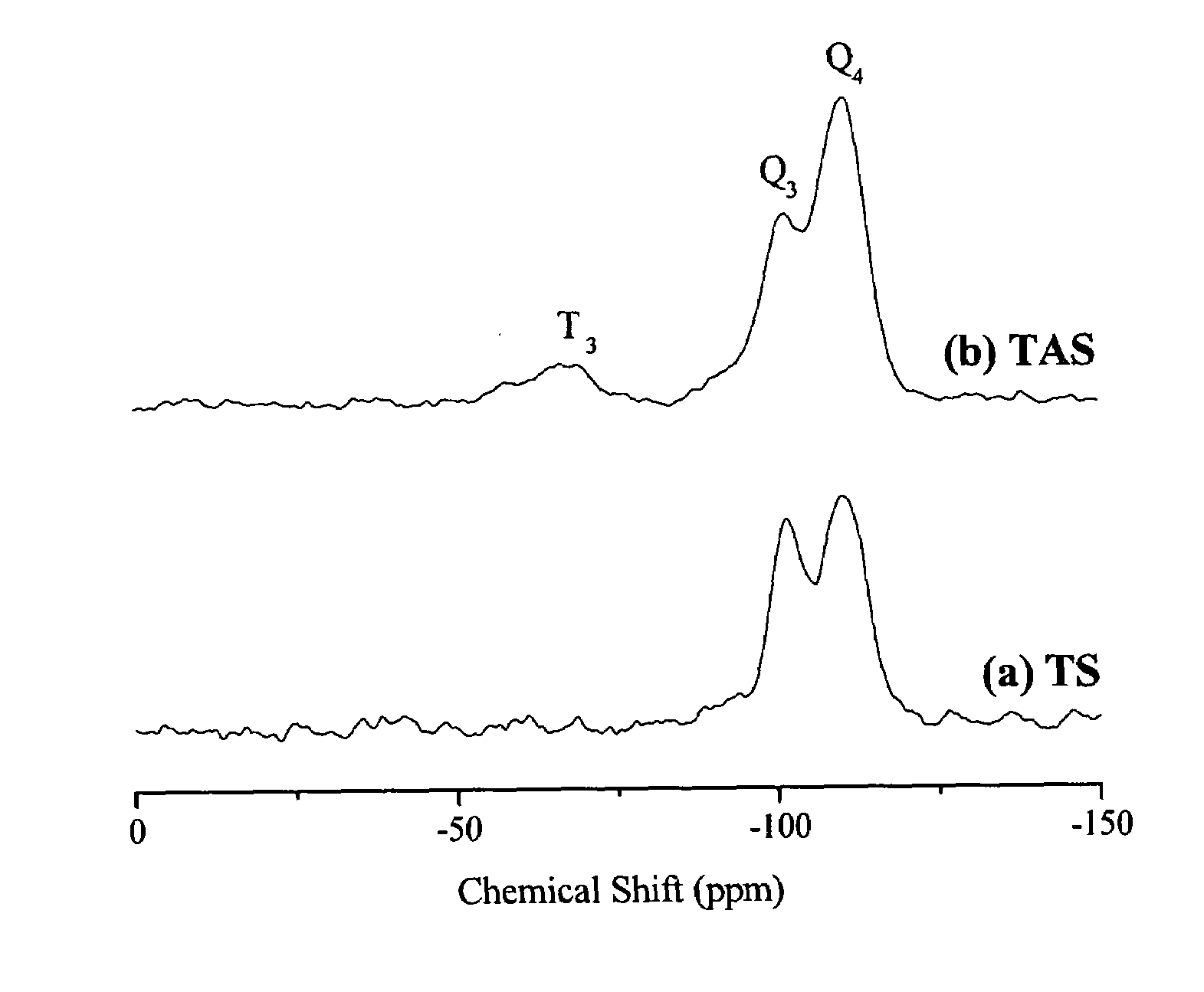

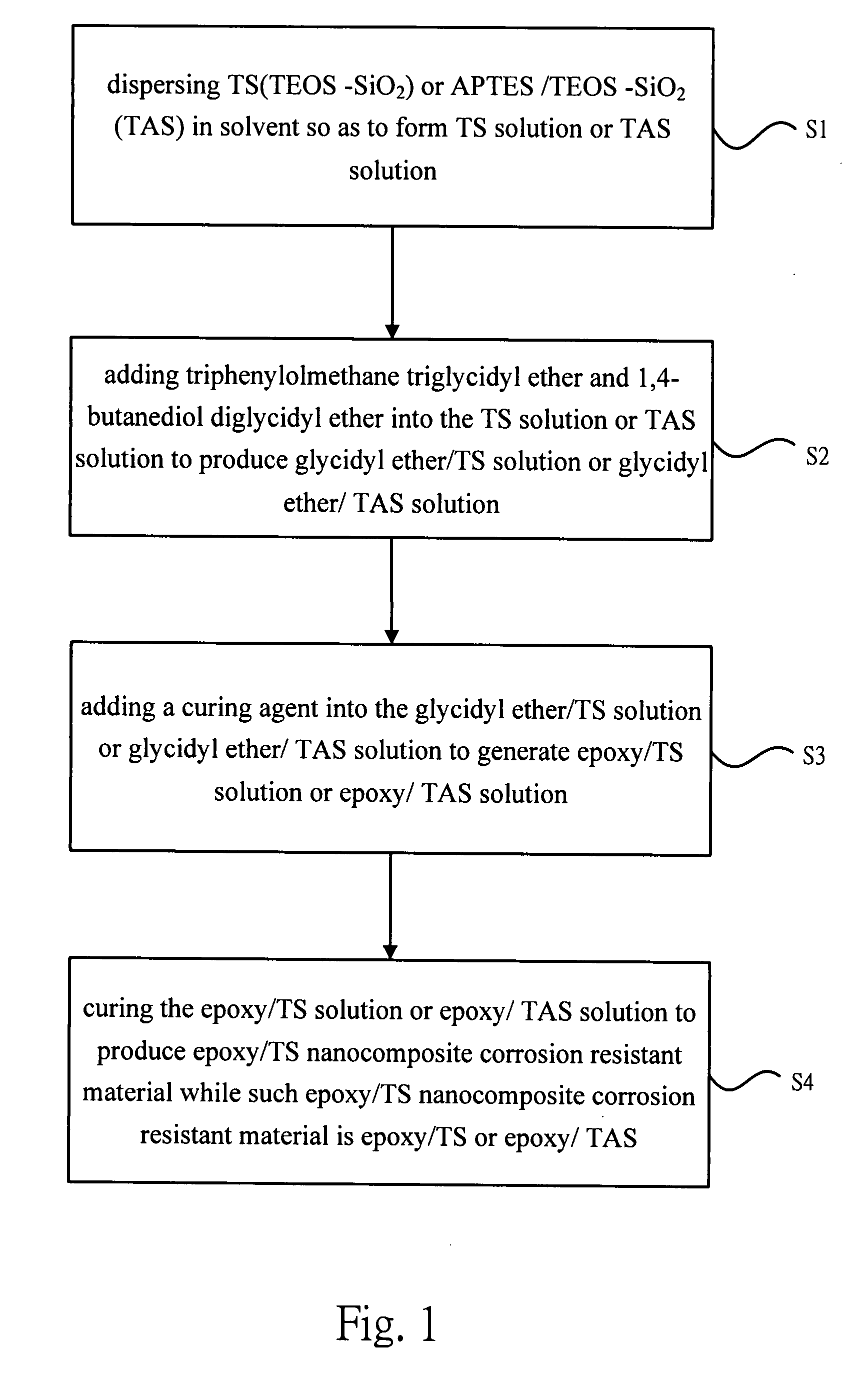

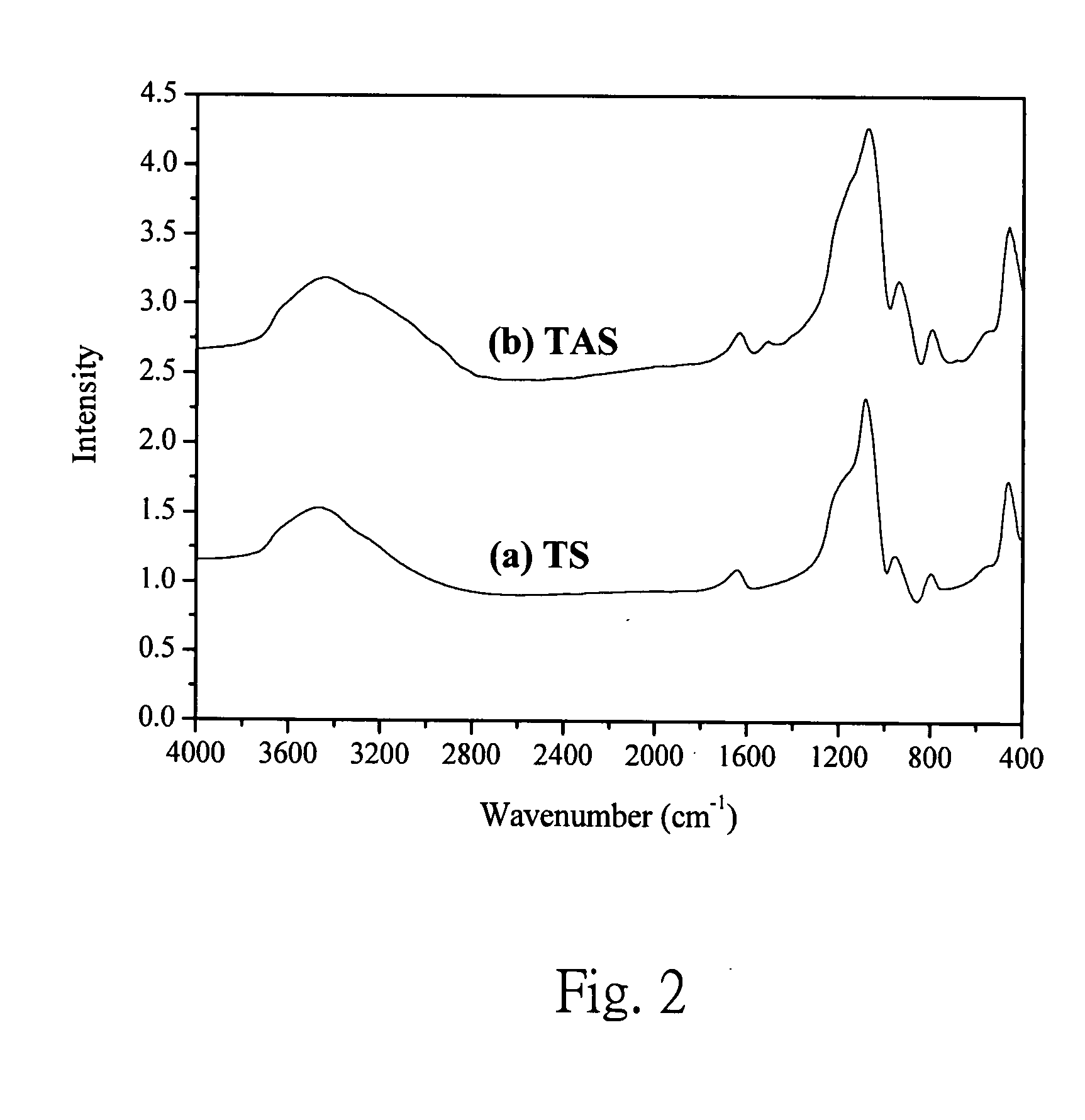

Epoxy/modified silicon dioxide corrosion resistant nanocomposite material and preparation method thereof

An epoxy / modified silicon dioxide corrosion resistant nanocomposite material and a preparation method thereof are disclosed. The method includes the steps of: dispersing TS(TEOS-SiO2) or APTES / TEOS-SiO2 (TAS) in solvent so as to form TS solution or TAS solution; adding triphenylolmethane triglycidyl ether and 1,4-butanediol diglycidyl ether into the TS solution or TAS solution to produce glycidyl ether / TS solution or glycidyl ether / TAS solution. Add a curing agent into the glycidyl ether / TS solution or glycidyl ether / TAS solution to generate epoxy / TS solution or epoxy / TAS solution. After curing, obtain epoxy / modified silicon dioxide nanocomposite corrosion resistant material. The material is applied to optoelectronics or other fields for corrosion prevention.

Owner:NAT CHUNG SHAN INST SCI & TECH

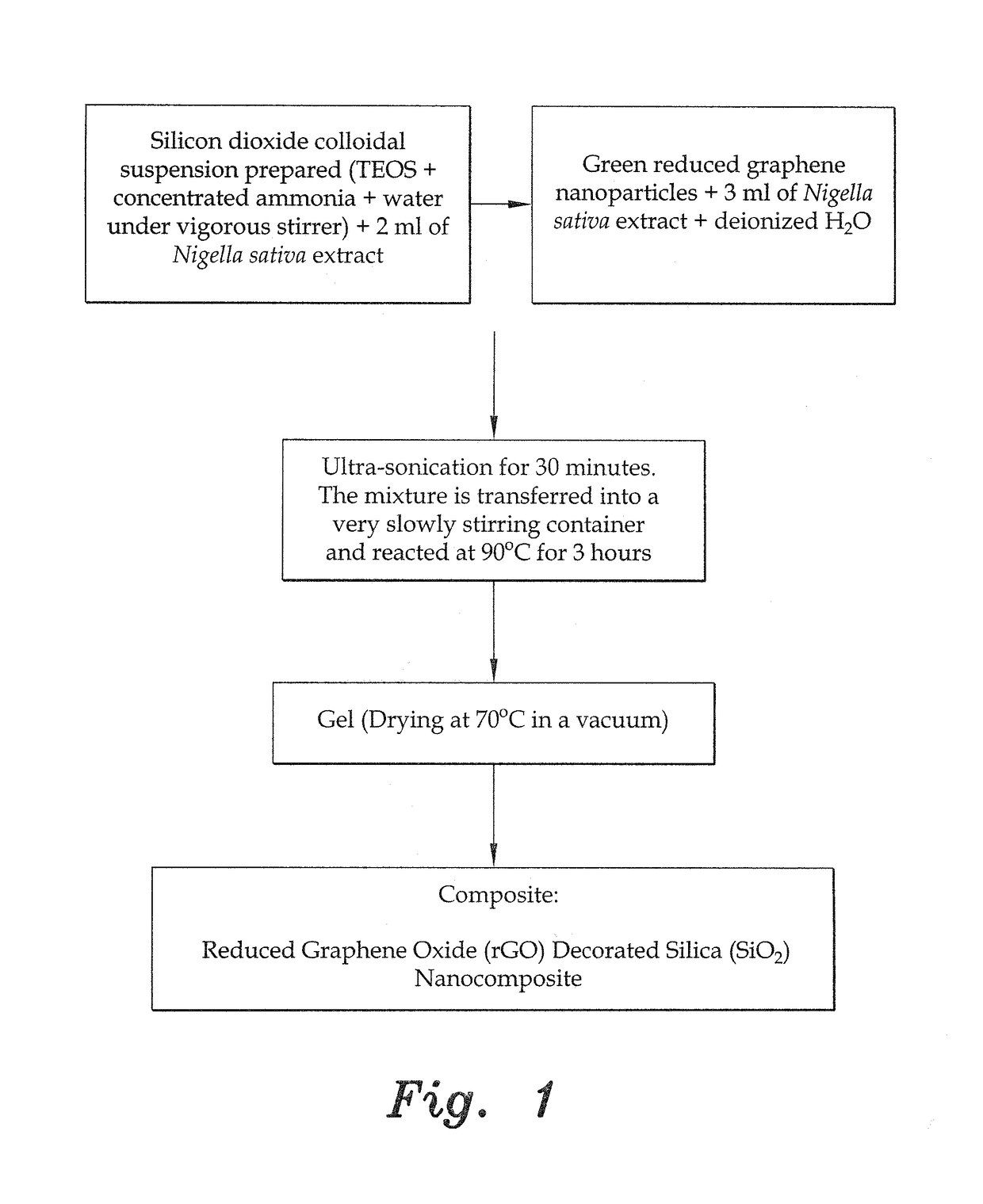

Green synthesis of reduced graphene oxide silica nanocomposite using nigella sativa seeds extract

InactiveUS10052302B2Organic active ingredientsInorganic active ingredientsAdemetionineSilicon dioxide

Owner:KING SAUD UNIVERSITY

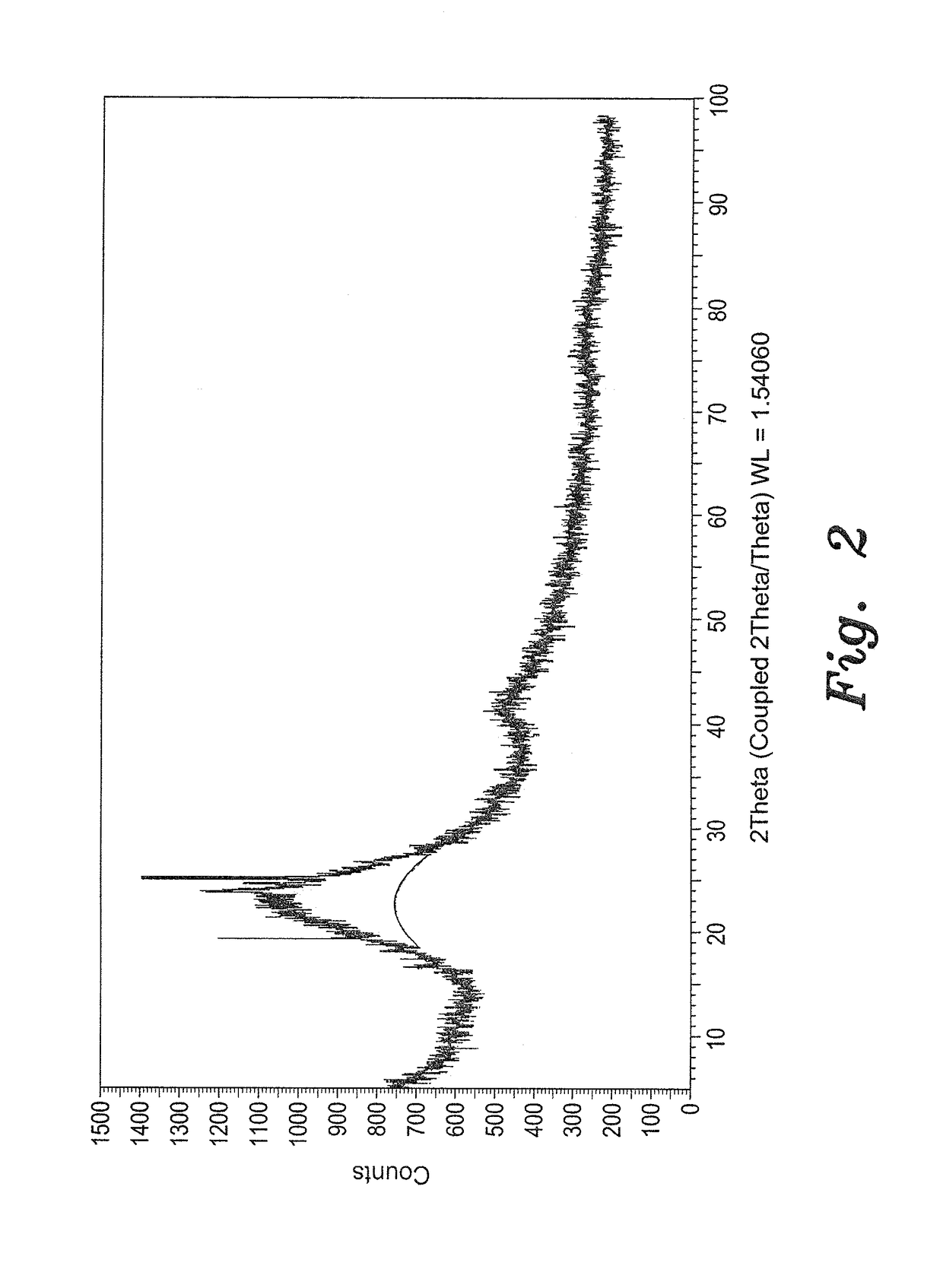

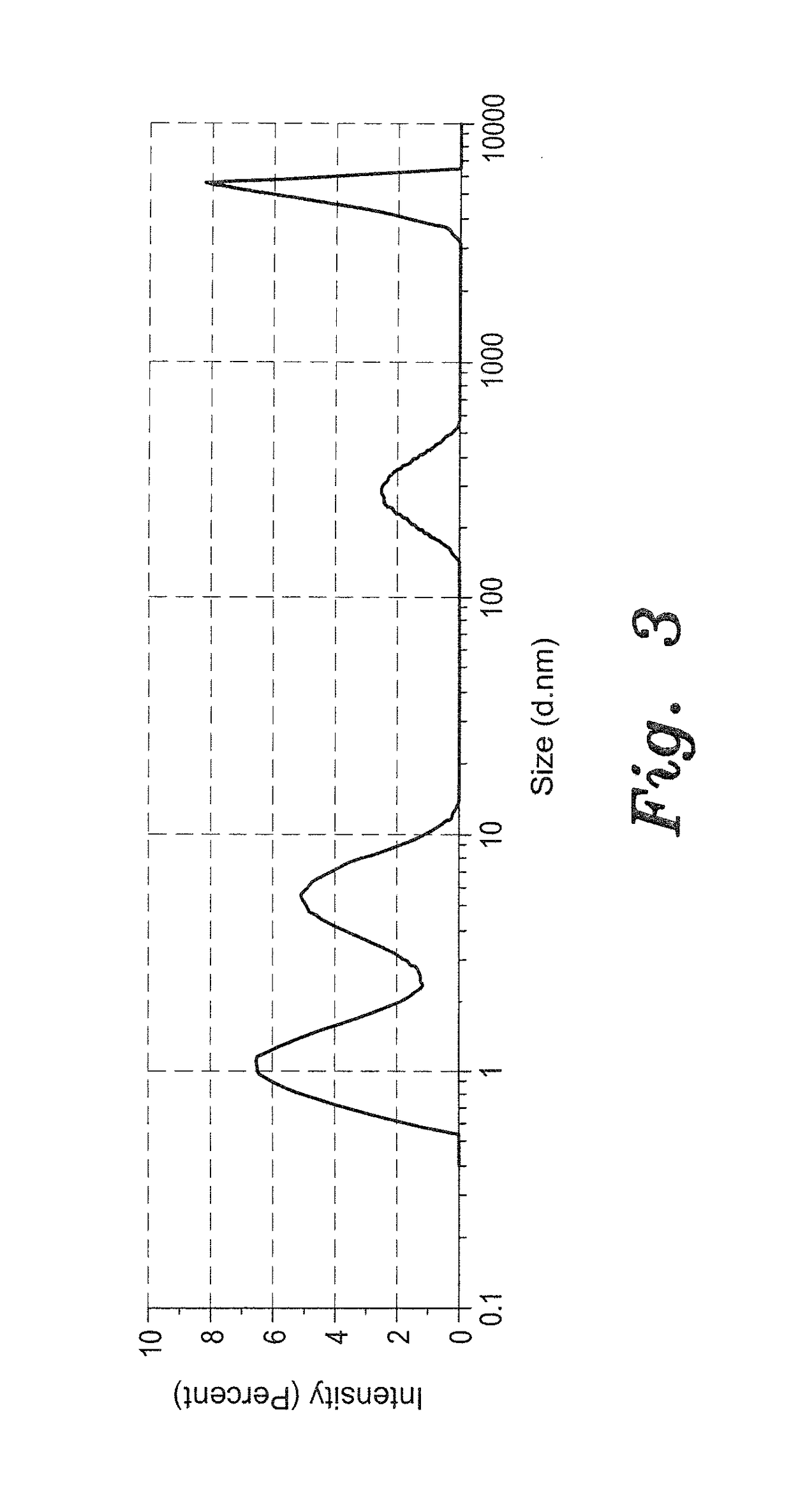

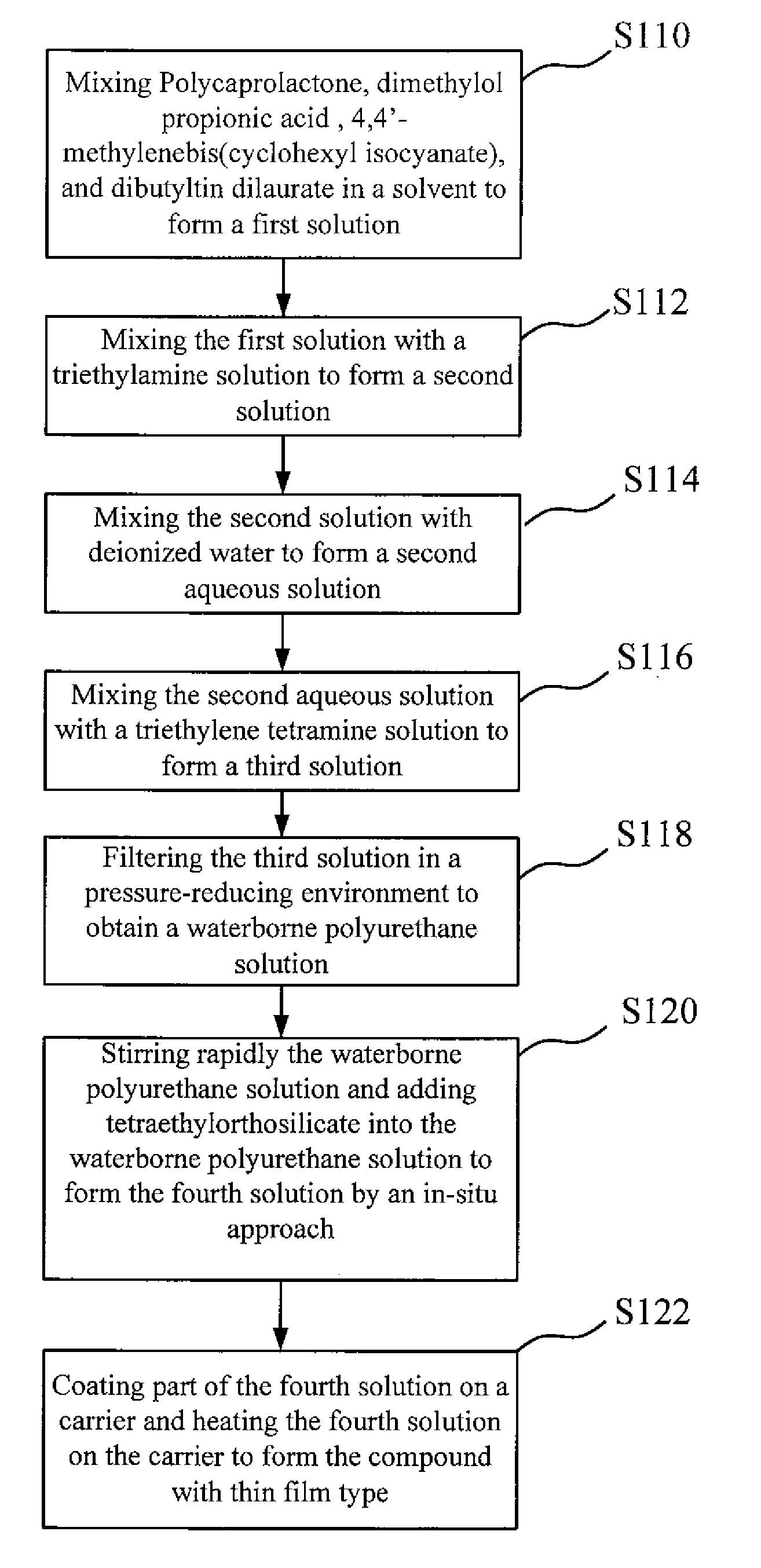

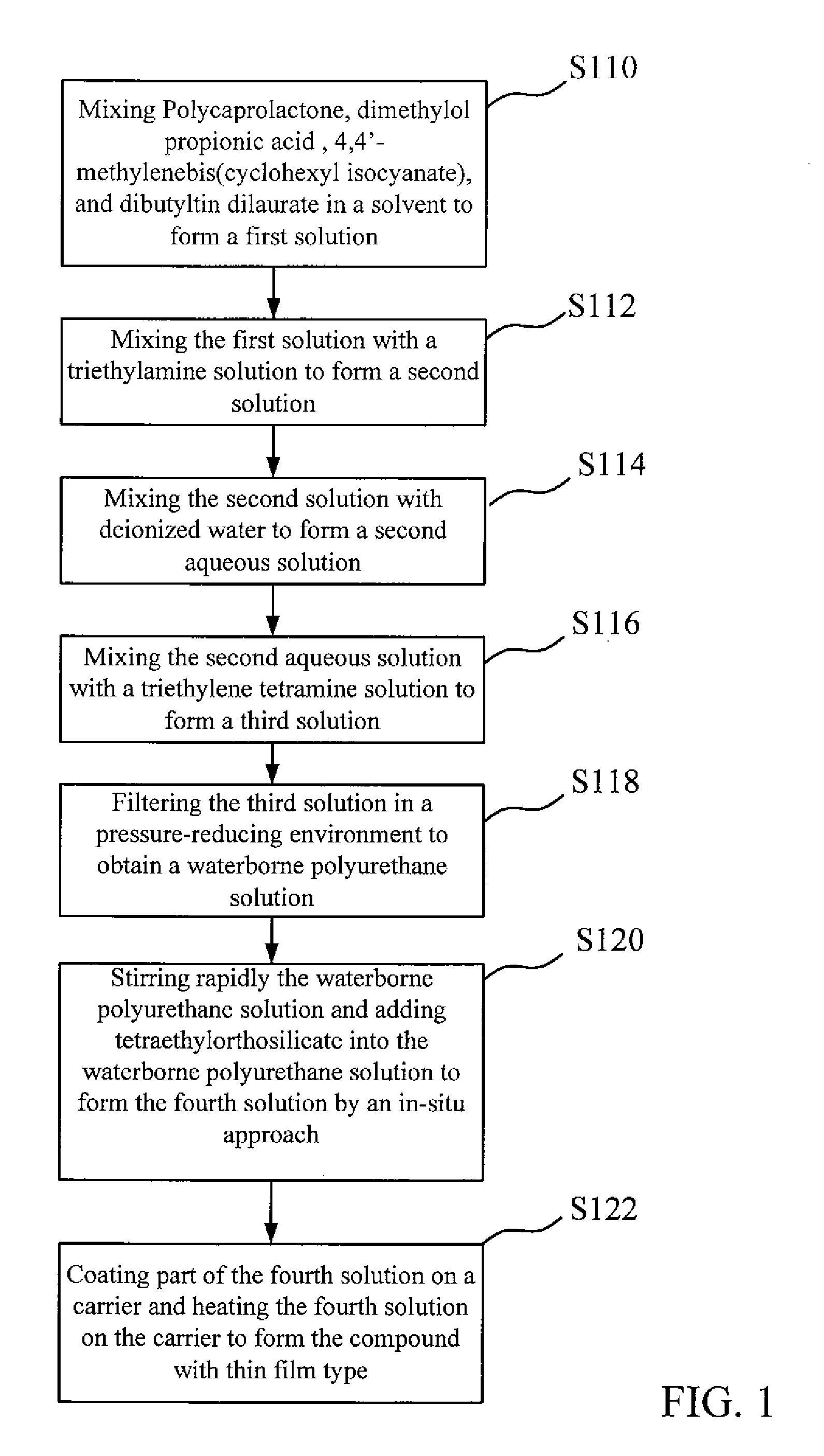

Compound and method for producing the same

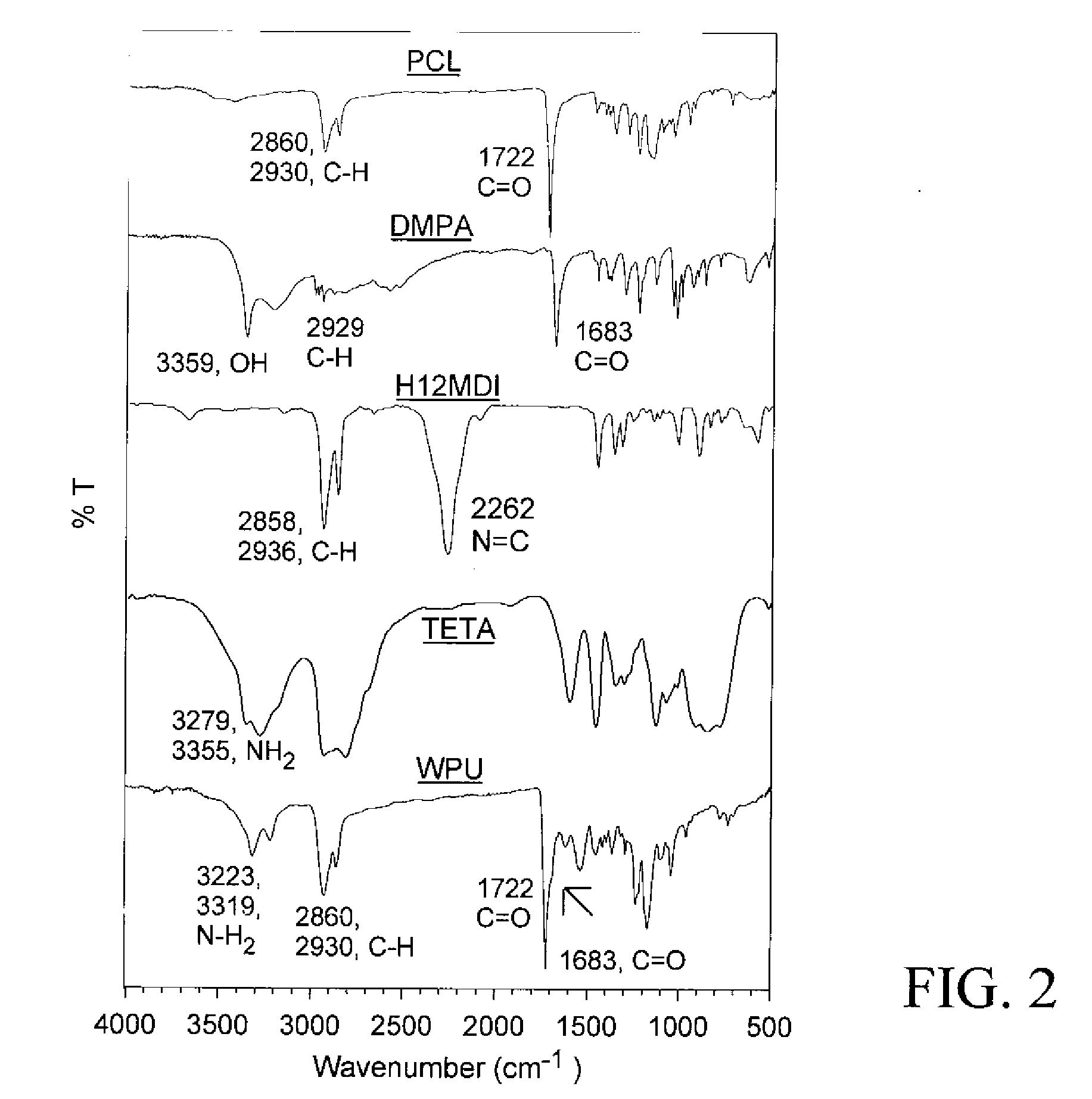

ActiveUS20100143597A1Pretreated surfacesPolyurea/polyurethane coatingsPropanoic acidCyclohexylisocyanate

The invention provides a compound and method of producing the same. The method of the invention includes the following steps. First of all, Polycaprolactone (PCL), dimethylol propionic acid (DMPA), 4,4′-methylenebis (cyclohexyl isocyanate) (H12MDI), and dibutyltin dilaurate (DBT) are mixed in a solvent in the first place and a solution is formed. This solution is then mixed with triethylamine (TEA) and triethylene tetramine (TETA). After that, amino-terminated anionic waterborne polyurethane (WPU) is produced. A sol-gel process is proceeded with a mixture of amino-terminated anionic waterborne polyurethane, tetraethylorthosilicate (TEOS) without any extra catalyst, and a compound, waterborne polyurethane-silica nanocomposite materials, is eventually produced.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com