In-situ suspension polymerization preparation method of nanocomposite material consisting of polyvinyl chloride and silicon dioxide and product thereof

A nano-composite material and silica technology, which is applied in the field of nano-silica modification, can solve problems such as difficulty in controlling sticking kettles, and achieve stable monomer suspension droplets, improved controllability, and increased compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

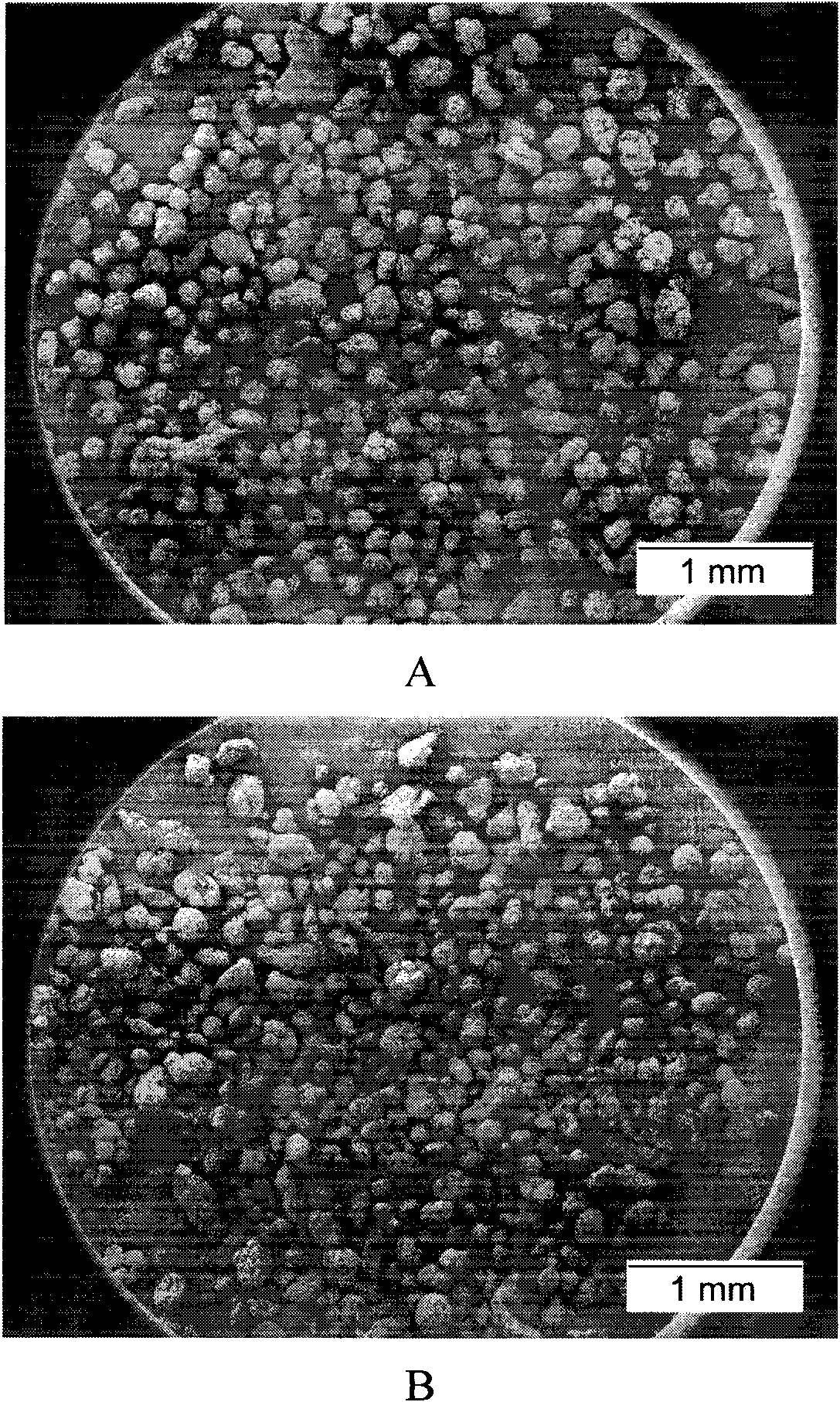

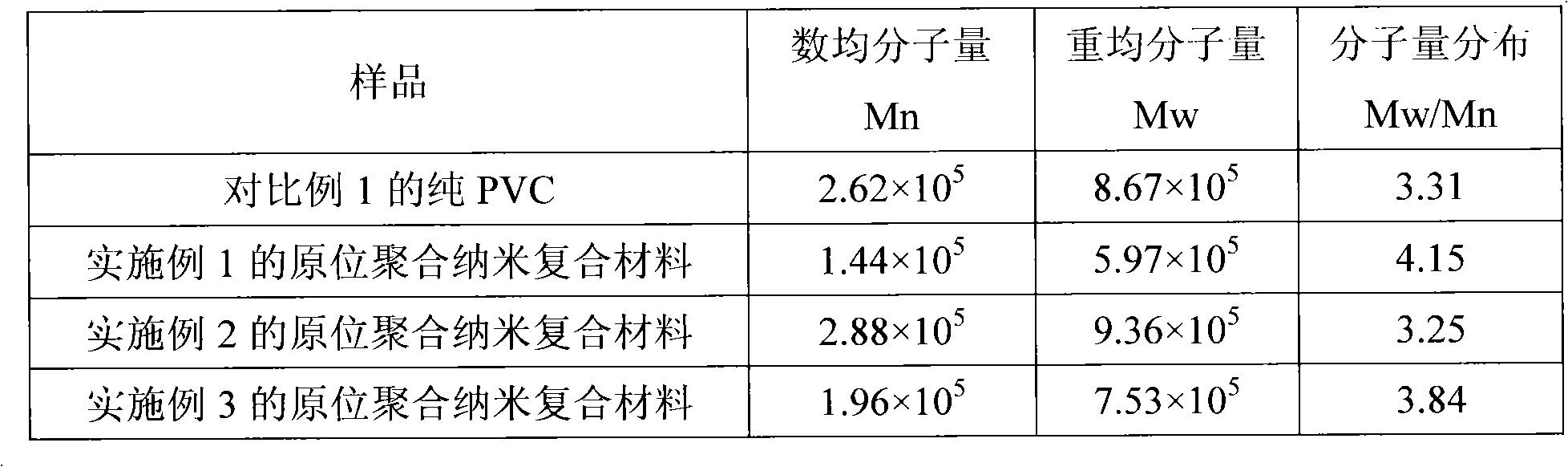

[0052] 1. Preparation of modified nano-silica: disperse 10g of nano-silica with an average particle size of 12 nm in 400ml of toluene, heat to 120°C under stirring, add 10g of dimethylchlorosilane, and Keep stirring and reacting for 12 hours, then filter, wash the filtrate several times with a mixed solvent of ethanol and water 1:1 (volume ratio), dry the washed silicon dioxide in a vacuum oven at 110°C, grind and pass A 200-mesh sub-sieve was used to obtain the modified nano-silica.

[0053] 2. Prepare the nanocomposite material that polyvinyl chloride and silicon dioxide form: under the protection of nitrogen, with modified nano silicon dioxide 1.10g (modified nano silicon dioxide and vinyl chloride monomer mass percent are 0.1%), remove Add 1800ml of ionized water, 0.5g of dibenzoyl peroxide initiator, and 0.5g of hydroxypropyl methylcellulose as dispersant into the suspension polymerization reactor, and then inject 1100g of vinyl chloride monomer. Stir at a slow speed of ...

Embodiment 2

[0055] 1. Preparation of modified nano-silica: Disperse 10g of nano-silica with an average particle size of 25 nm in 200ml of dimethyl sulfoxide, heat to 120°C under stirring, add 25g of octadecyl trimethyl Oxysilane, keep stirring and reacting at the above temperature for 12 hours and then filter, wash the filtrate several times with a mixed solvent of ethanol and water 1:1 (volume ratio), and put the washed silicon dioxide in a vacuum oven at 110 ℃ drying, grinding and passing through a 200-mesh sieve to obtain modified nano silicon dioxide.

[0056] 2. Prepare the nanocomposite material that polyvinyl chloride and silicon dioxide form: under nitrogen protection, with modified nano silicon dioxide 11.0g (modified nano silicon dioxide and vinyl chloride monomer mass percentage are 1%), remove Add 2000ml of ionized water, 0.6g of initiator azobisisoheptanonitrile, and 0.5g of dispersant methylcellulose into the suspension polymerization reactor, and then inject 1100g of vinyl ...

Embodiment 3

[0058] 1. Preparation of modified nano-silica: Disperse 10g of nano-silica with an average particle size of 50 nm in 300ml of acetone, heat to 130°C under stirring, add 30g of hexamethyldisilazane, and Keep stirring and reacting at the above temperature for 6 hours and then filter, wash the filtrate with a mixed solvent of ethanol and water 1:1 (volume ratio) several times, dry the washed silica in a vacuum oven at 110°C, and grind Pass through a 200-mesh sieve to obtain modified nano silicon dioxide.

[0059] 2. prepare the nanocomposite material that polyvinyl chloride and silicon dioxide form: under nitrogen protection, with modified nano silicon dioxide 50.0g (modified nano silicon dioxide and vinyl chloride monomer mass percent are 5%), remove 2500ml of ionized water, 0.8g of bis(2-ethylhexyl) peroxydicarbonate as initiator, 0.3g of gelatin as dispersant and 0.5g of methyl cellulose were added into the suspension polymerization reactor, and then 1000g of vinyl chloride mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com