Automatic spraying camouflage coating for manipulators and method for preparing automatic spraying camouflage coating

An automatic spraying and manipulator technology, applied in the field of coatings, can solve problems such as inability to spray camouflage patterns, inconsistent width, film thickness, and inability to solve paints, achieve excellent protection and decoration performance, reduce hazards to operators, and avoid paint. The effect of membrane sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

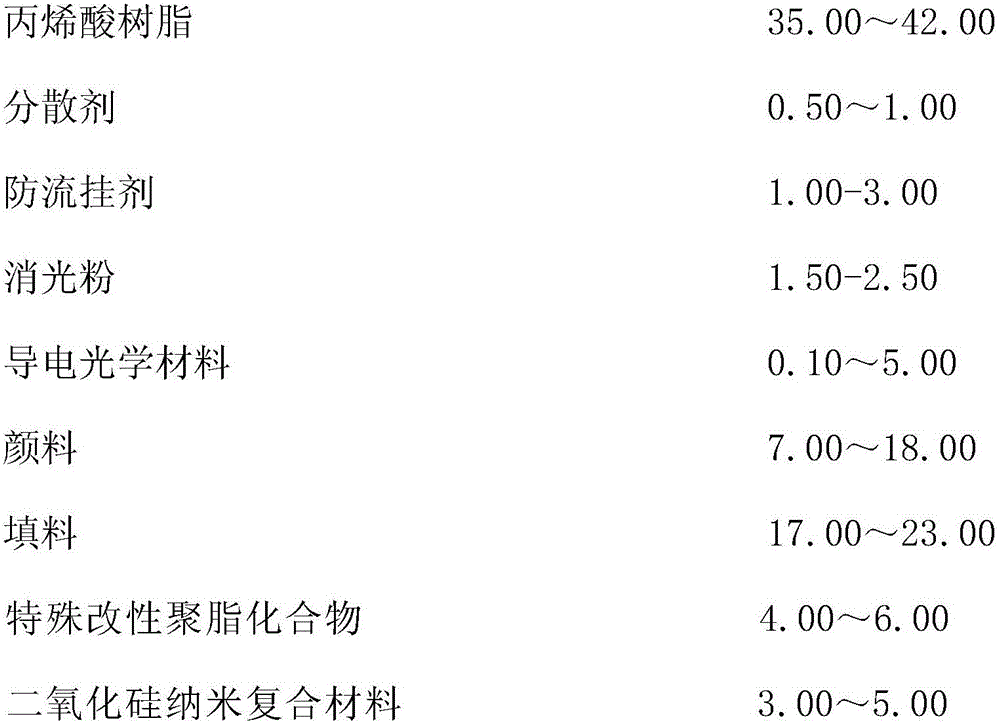

[0043] A kind of manipulator automatic spraying camouflage dark green camouflage paint, comprises the raw material of following mass parts:

[0044]

[0045] Wherein the mixed solvent is:

[0046] Ethanol 3.0

[0047] Xylene 5.0

[0048] Butyl acetate 7.6.

Embodiment 2

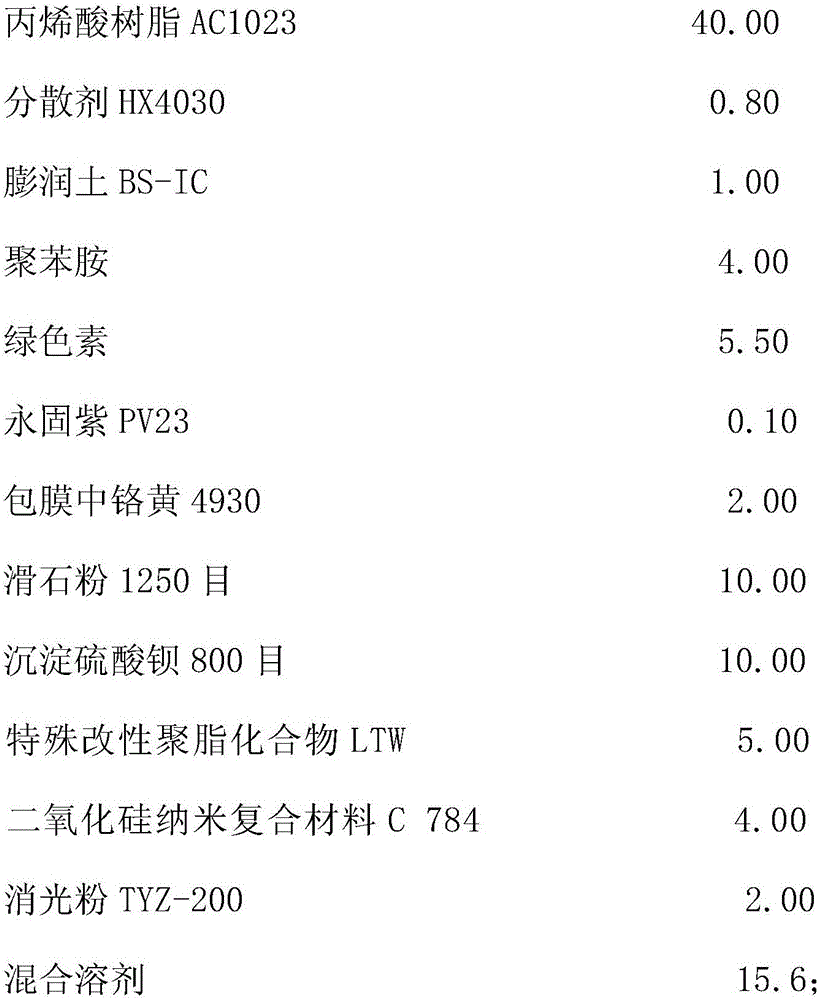

[0050]A kind of green camouflage paint in camouflage automatic spraying by manipulator, comprises the raw material of following mass parts:

[0051]

[0052] Wherein the mixed solvent is:

[0053] Ethanol 2.50

[0054] Xylene 4.20

[0055] Butyl acetate 6.00.

Embodiment 3

[0057] A kind of manipulator automatic spraying camouflage sand color camouflage paint, comprises the raw material of following mass parts:

[0058]

[0059]

[0060] Wherein the mixed solvent is:

[0061] Ethanol 2.40

[0062] Xylene 4.10

[0063] Butyl acetate 6.00.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com