Mesoporous graphite/silicon dioxide composite counter electrode for dye sensitized solar cells and method for preparing mesoporous graphite/silicon dioxide composite counter electrode

A mesoporous graphene and solar cell technology, applied in the field of dye-sensitized solar cells, can solve the problems of high cost and high energy consumption of platinum counter electrodes, and achieve the effects of good energy conversion efficiency, high catalytic activity and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

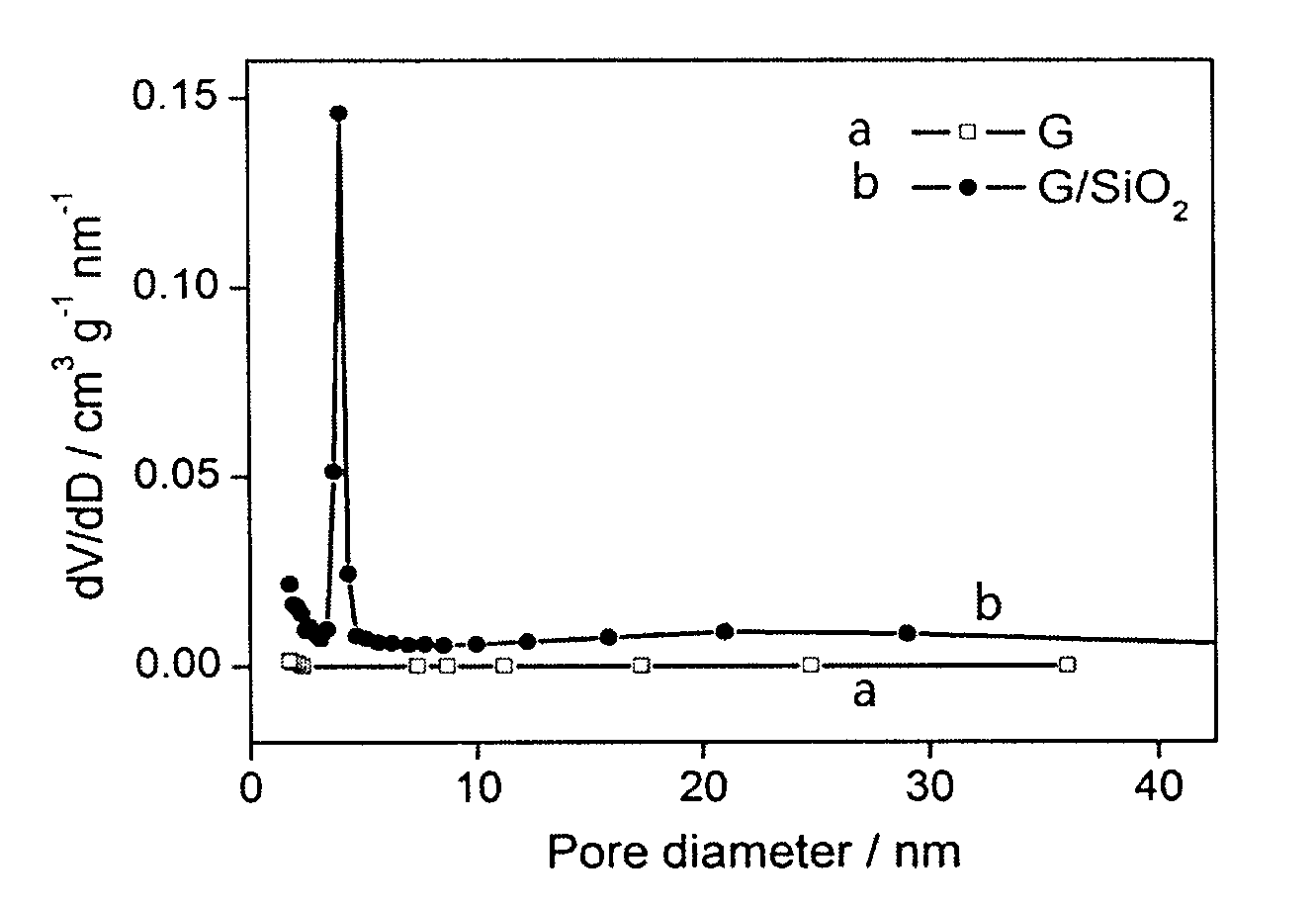

[0019] Add 5 mg of silica nanoparticles with a particle size of 10 nm to 10 mL of 0.25 mg / mL graphene oxide aqueous suspension, and form graphene oxide / silica with a mass ratio of 1:2 after ultrasonic dispersion Then add 25 μL of hydrazine hydrate solution with a mass fraction of 10% to the suspension, heat the reaction at 100°C for 2 hours, and then reduce the graphene oxide to graphene to form mesoporous graphene / Suspensions of silica nanocomposites with a mesoporous structure and a specific surface area of 229.0 m 2 / g, the pore size is 4 nm and has a narrow distribution (as shown in the accompanying drawings figure 2 shown). Finally, drop the suspension on the cleaned conductive glass. After the water evaporates completely, a layer of apparently uniform mesoporous graphene / silicon dioxide film is formed on the conductive glass. Repeat the above operation to regulate the thickness of the film to 2.5 μm, that is, the mesoporous graphene / silicon dioxide composite counte...

Embodiment 2

[0022] Add 0.5 mg of silica nanoparticles with a particle size of 50 nm to 10 mL of 0.1 mg / mL graphene oxide aqueous suspension, and form graphene oxide / silica with a mass ratio of 1:0.5 after ultrasonic dispersion Then add 10 μL of hydrazine hydrate solution with a mass fraction of 10% to the suspension, heat the reaction at 110°C for 1 h, and then reduce the graphene oxide to graphene to form mesoporous graphene / Suspension of silica nanocomposite material; finally drop the suspension on the cleaned conductive glass, and form a layer of apparently uniform mesoporous graphene / silicon dioxide film on the conductive glass after the water evaporates completely , repeating the above operations to adjust the thickness of the membrane to 1 μm, that is, the mesoporous graphene / silicon dioxide composite counter electrode is obtained. This electrode was then used as a counter electrode in dye-sensitized solar cells.

[0023] The counter electrode was assembled into DSSCs according to...

Embodiment 3

[0025] Add 50 mg of silica nanoparticles with a particle size of 100 nm to 10 mL of 1 mg / mL graphene oxide aqueous suspension, and form a graphene oxide / silica composite with a mass ratio of 1:5 after ultrasonic dispersion. suspension; then add 100 μL of hydrazine hydrate solution with a mass fraction of 10% to the suspension, heat and react at 60°C for 12 hours, and then reduce the graphene oxide in it to graphene to form mesoporous graphene / silica nano Suspension of composite material; finally drop the suspension on the cleaned conductive glass, and form a layer of apparently uniform mesoporous graphene / silicon dioxide film on the conductive glass after the water evaporates completely, repeat the above operations Regulating the thickness of the membrane to be 20 μm, the mesoporous graphene / silicon dioxide composite counter electrode is obtained. This electrode was then used as a counter electrode in dye-sensitized solar cells.

[0026] The counter electrode was assembled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com