Low-dielectric-constant hollow aluminum oxide/silicon dioxide nano composite material and application thereof

A technology of nano-composite materials and low dielectric constant, applied in the field of material chemistry, can solve the problems of differences in dielectric properties and wide application of unfavorable materials, and achieve the effects of high stability, high hardness and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

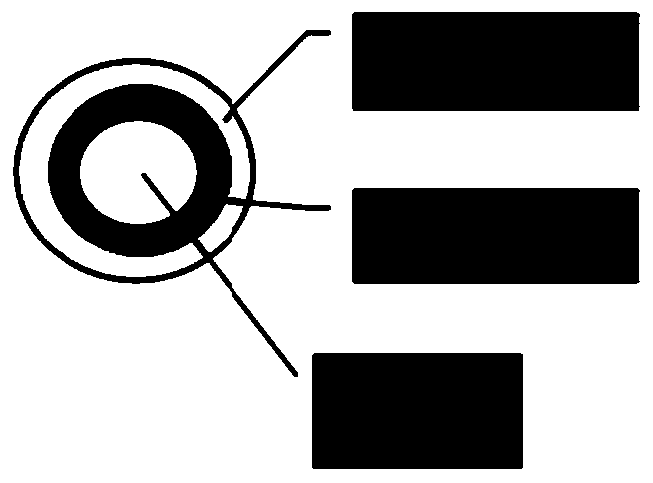

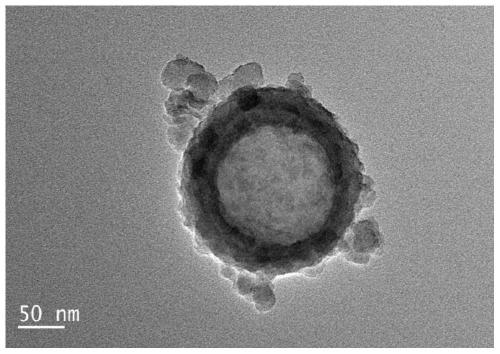

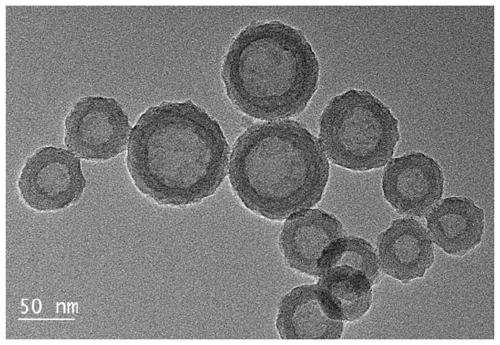

Image

Examples

Embodiment 1

[0060] The preparation method of the low dielectric constant hollow alumina / silicon dioxide nanocomposite described in this embodiment comprises the following steps:

[0061] (1) Take calcium chloride and surfactant (hexadecyltrimethylammonium bromide) according to the mass ratio of 8:1, add water to prepare the solution as a template solution, and add 1% mass fraction of EDTA as a structure-directing agent , the calcium chloride mass concentration is controlled to be 0.9g / ml, and the template solution is added to 800r / min high-speed magnetic stirring by an ultrasonic nebulizer (the diameter of the ultrasonic atomizing sheet is 18mm, and the vibration frequency is 1.7MHz), and The ammonia solution with a mass fraction of 16% adjusts the pH of the system to 10; then continuously feeds small bubbles with a content of 40% CO 2 Gas to form nano-calcium carbonate template, and the atomized droplets can form nano-calcium carbonate template particles with a size of 5-500nm in the alk...

Embodiment 2

[0069] The preparation method of the low dielectric constant hollow alumina / silicon dioxide nanocomposite described in this embodiment comprises the following steps:

[0070] (1) Take calcium chloride and surfactant (sodium lauryl sulfate) according to the mass ratio of 5:1, add water preparation solution as template solution, and add 1% mass fraction EDTA as structure directing agent, control calcium chloride The mass concentration is 0.05g / ml, and the template solution is added to 800r / min high-speed magnetic stirring through an ultrasonic nebulizer (the diameter of the ultrasonic atomizing sheet is 18mm, and the vibration frequency is 1.7MHz), and a mass fraction of 16% is added. Ammonia solution adjusts the pH of the system to 8; then continuously feeds CO 2 Gas to form nano-calcium carbonate template, and the atomized droplets can form nano-calcium carbonate template particles with a size of 5-500nm in the alkaline reaction system;

[0071] (2) After the template particl...

Embodiment 3

[0078] The preparation method of the low dielectric constant hollow alumina / silicon dioxide nanocomposite described in this embodiment comprises the following steps:

[0079] (1) Get calcium chloride and surfactant (hexadecyltrimethylammonium chloride) according to the mass ratio of 40:1, add water preparation solution as template solution, control calcium chloride mass concentration to be 5g / ml, pass Ultrasonic atomizer (ultrasonic atomization plate diameter is 18mm, vibration frequency is 1.7MHz) to add the template solution to 800r / min high-speed magnetic stirring, and add ammonia solution with a mass fraction of 16% to adjust the pH of the system to 12; then Continuously inject small bubbles with 40% CO content 2 Gas to form nano-calcium carbonate template, and the atomized droplets can form nano-calcium carbonate template particles with a size of 5-500nm in the alkaline reaction system;

[0080] (2) After the template particles formed in step (1) are separated by high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com