Patents

Literature

500results about "Aluminium hydroxide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

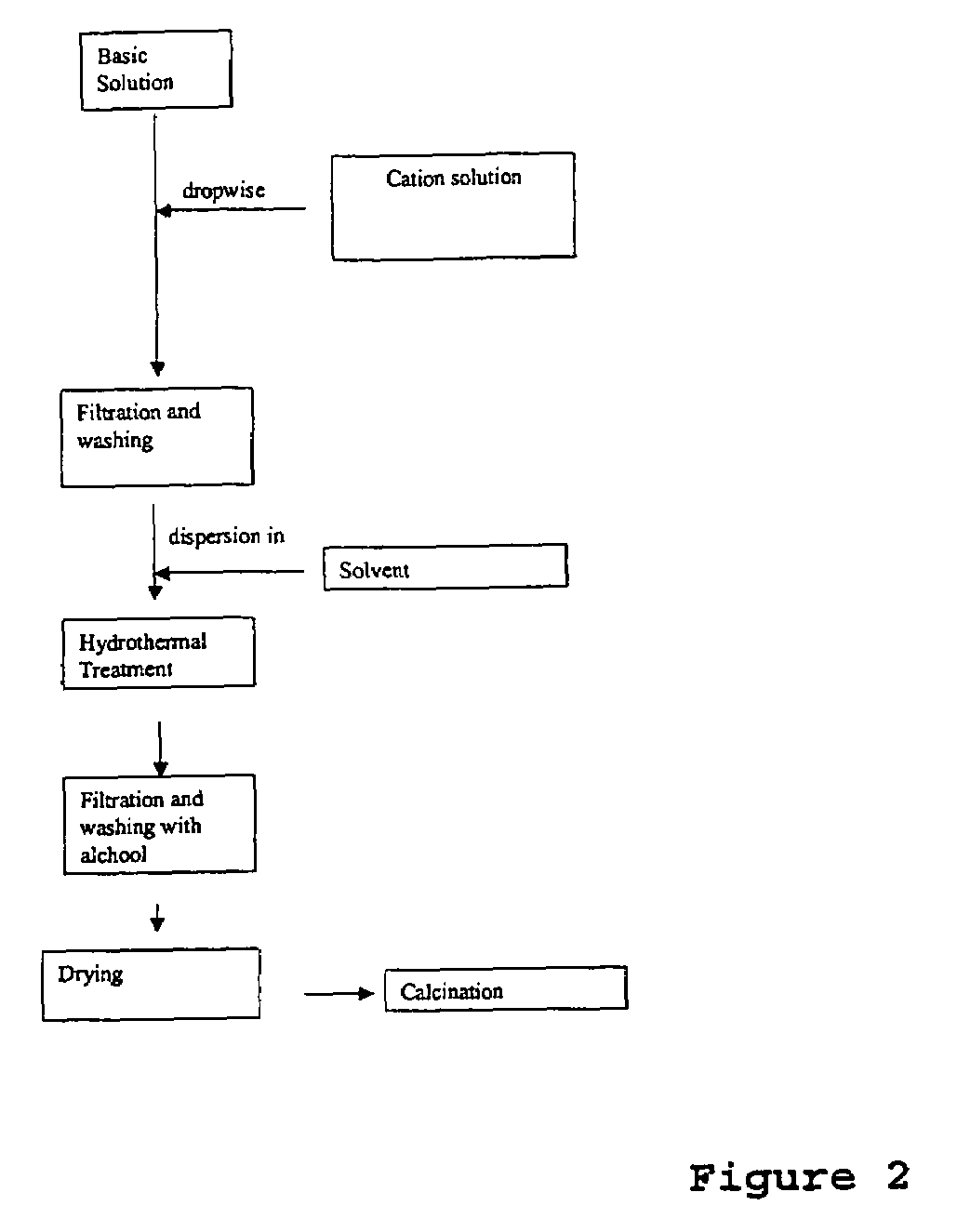

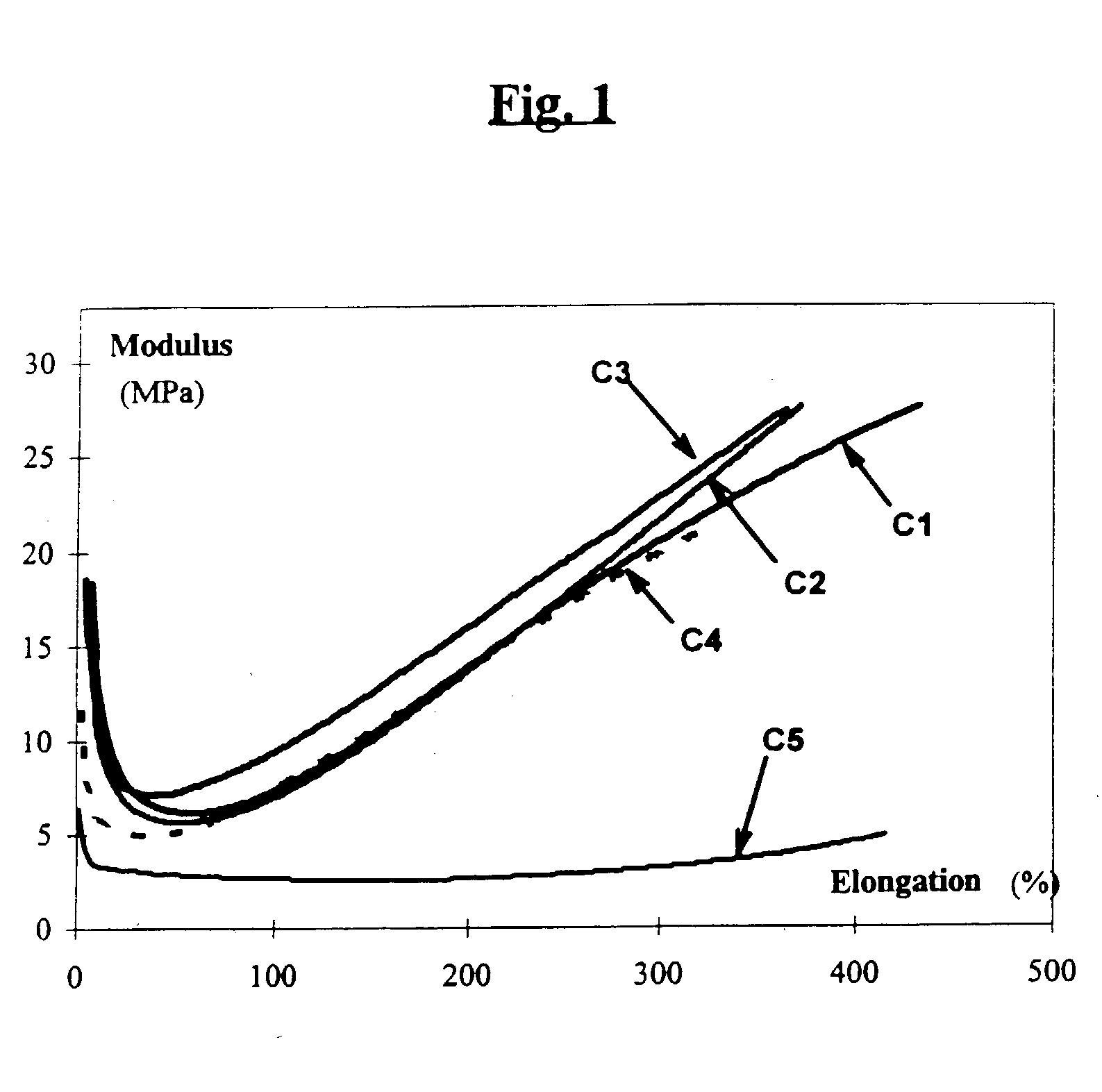

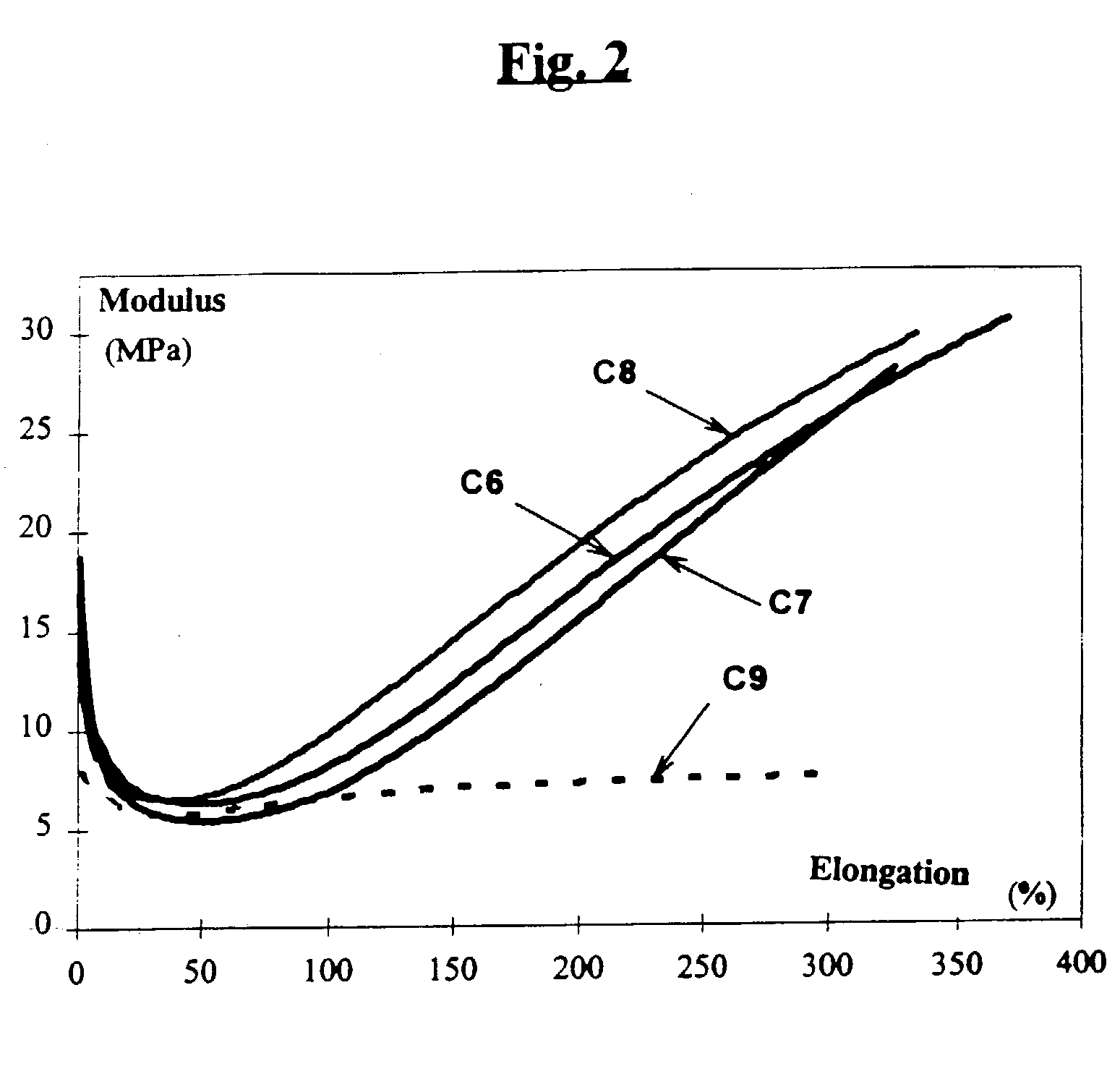

Reinforcing aluminum-based filler and rubber composition comprising such a filter

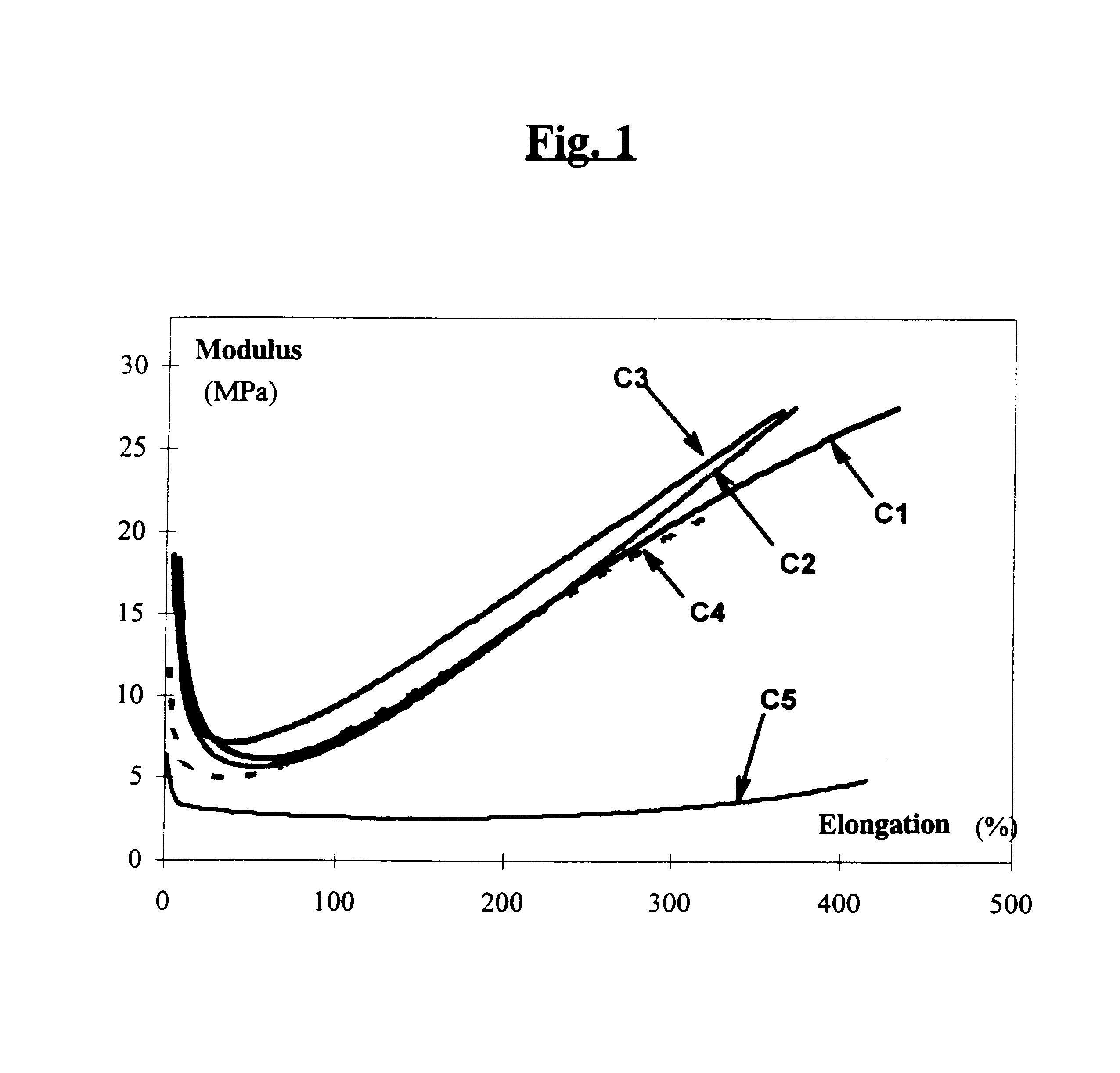

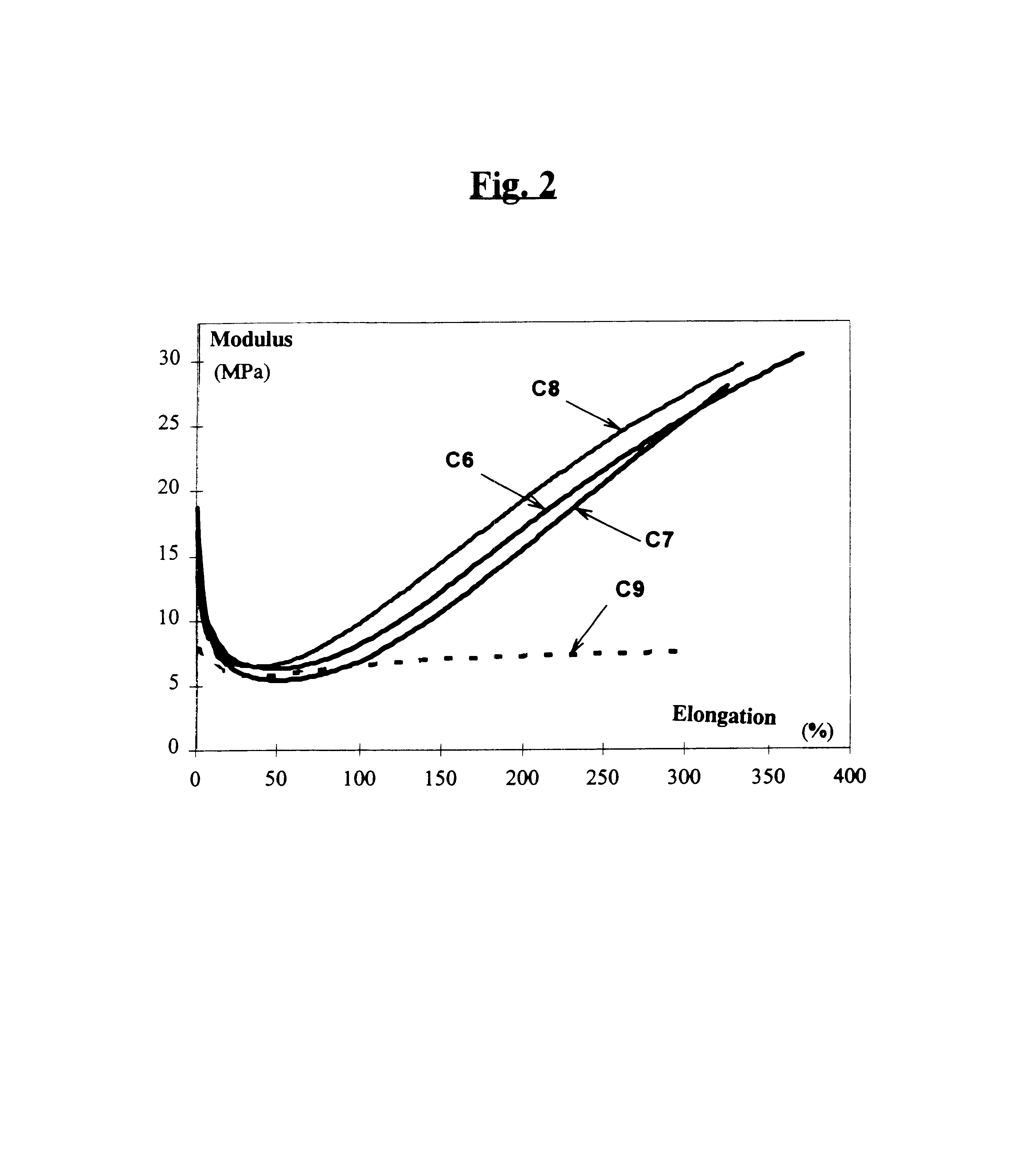

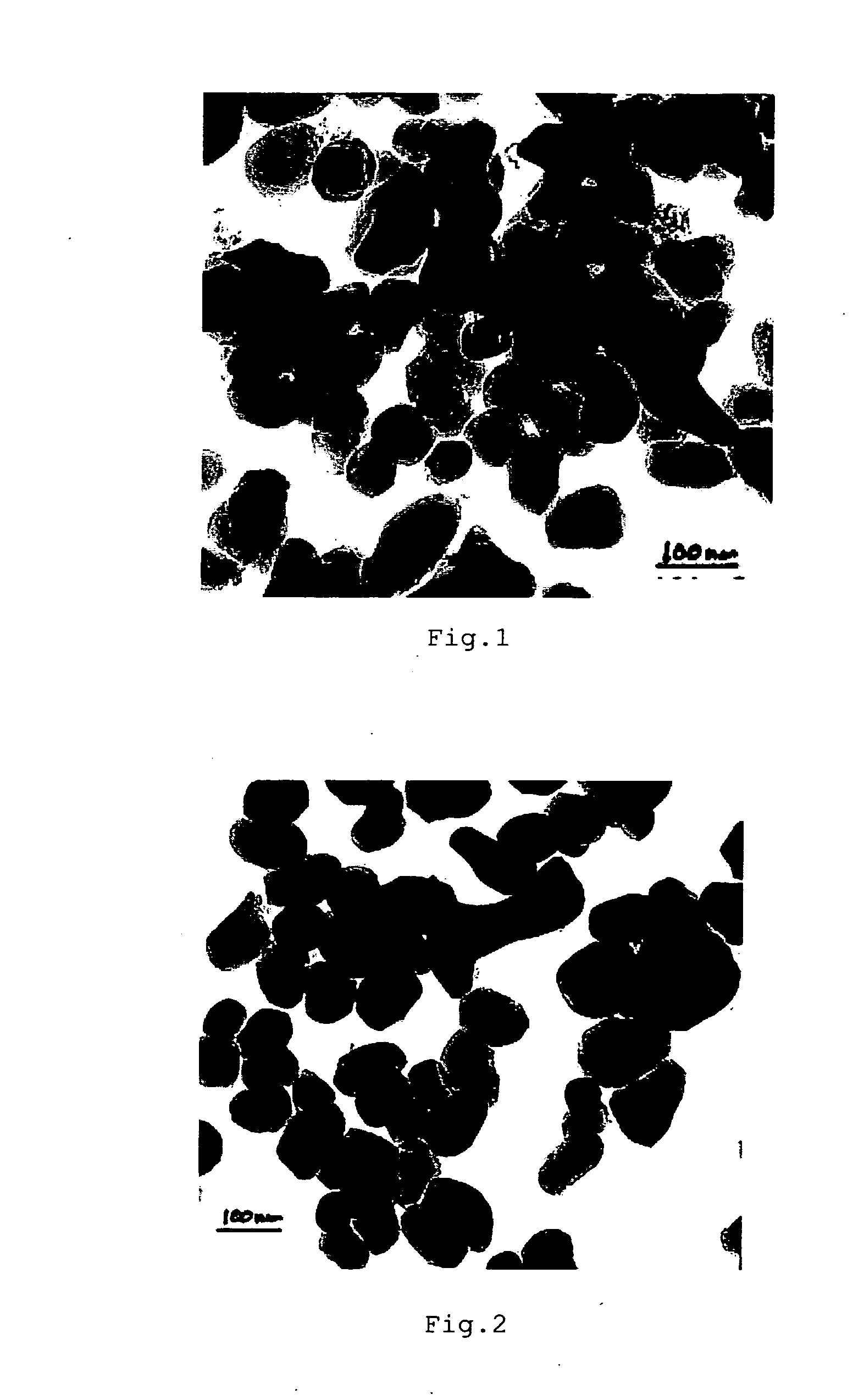

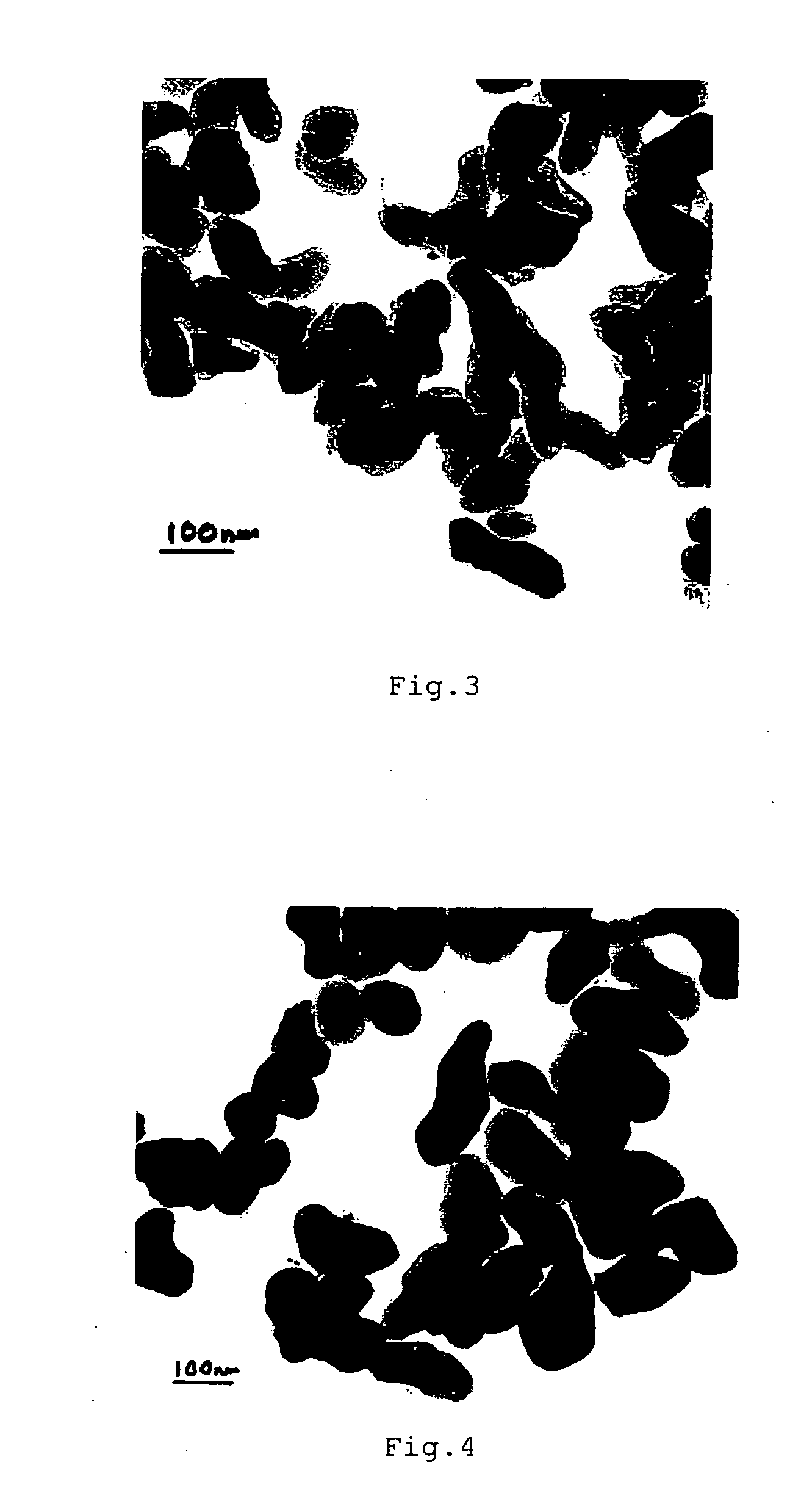

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers):the specific BET surface area of which is between 30 and 400 m2 / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10-3 mum-1 / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

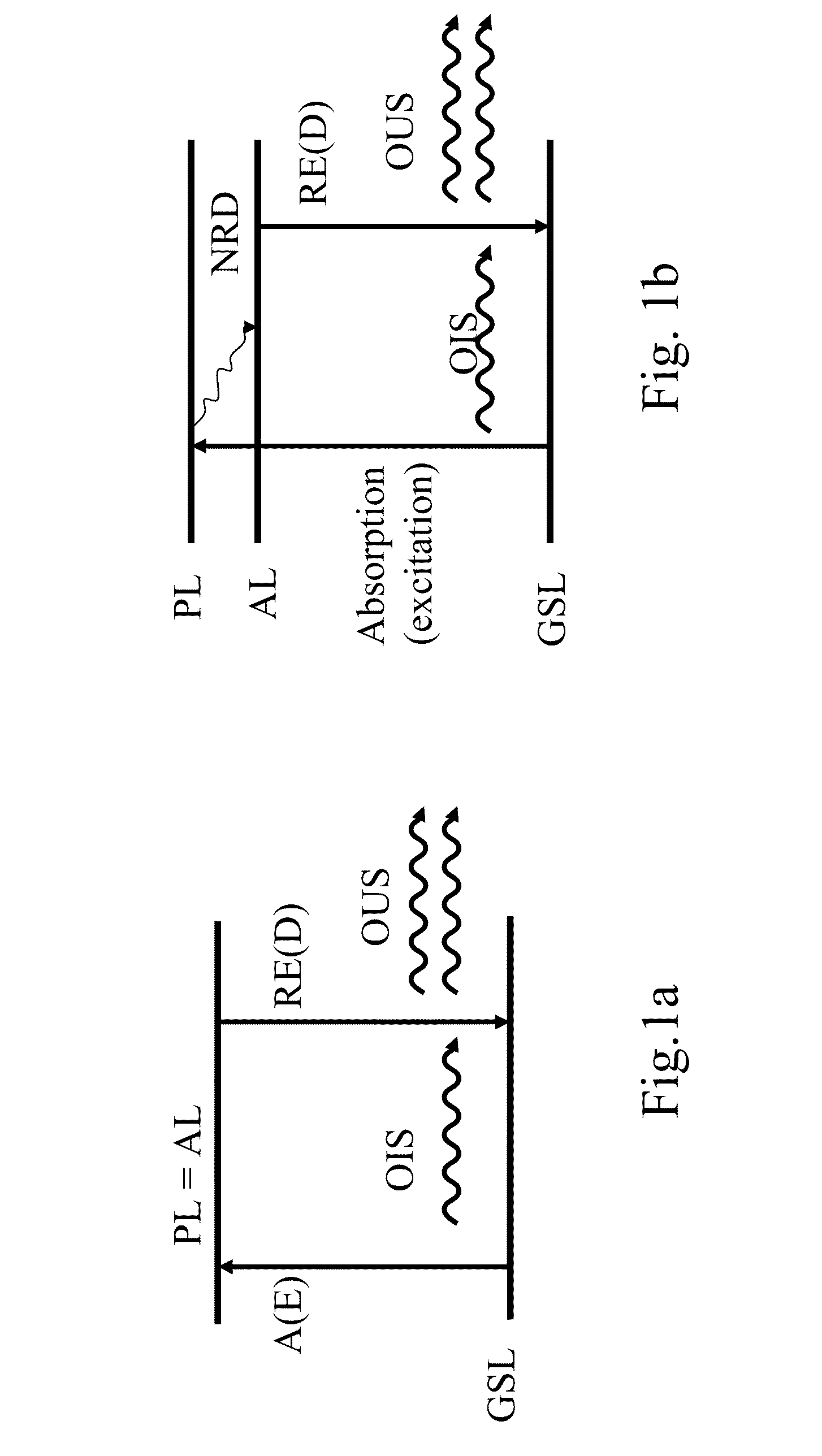

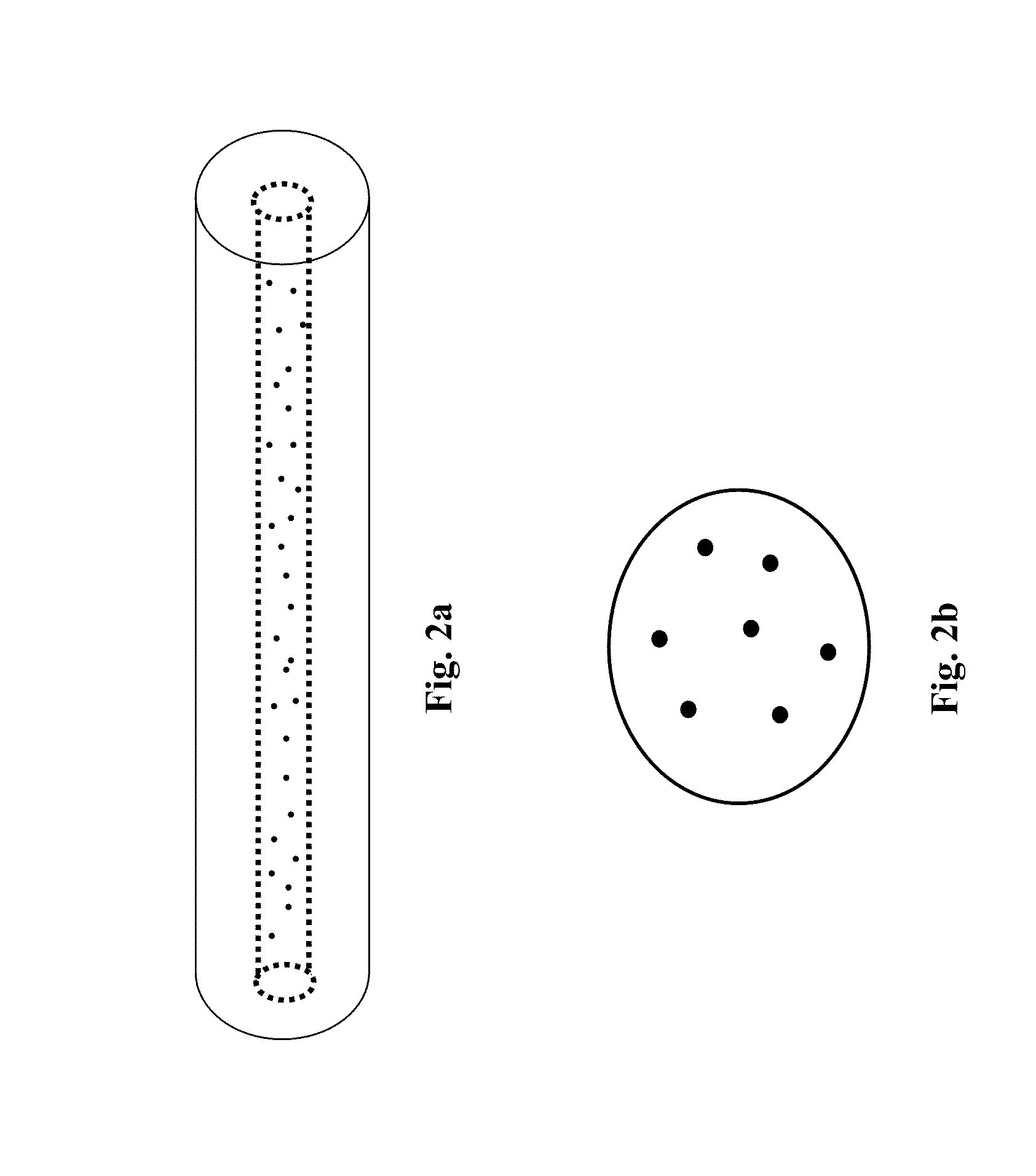

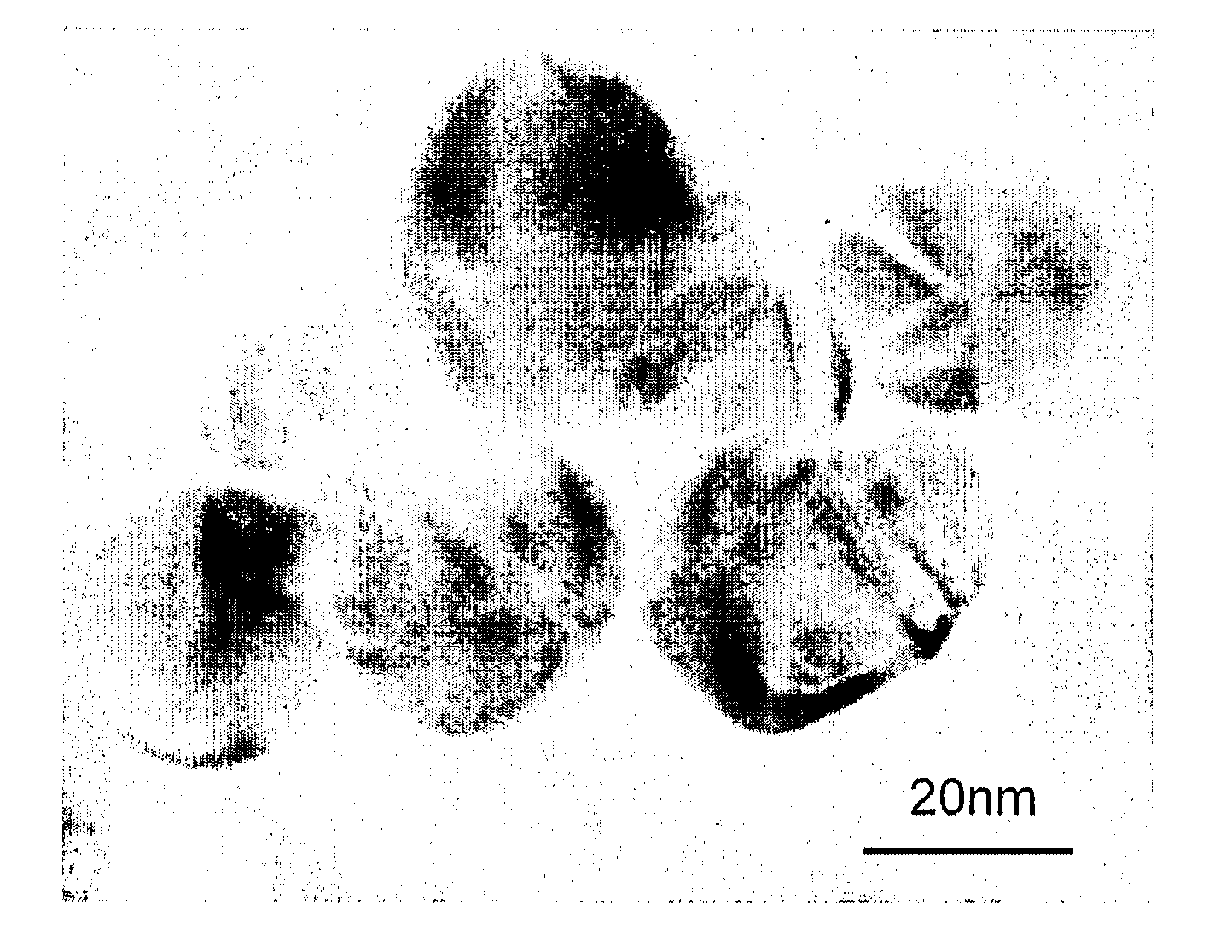

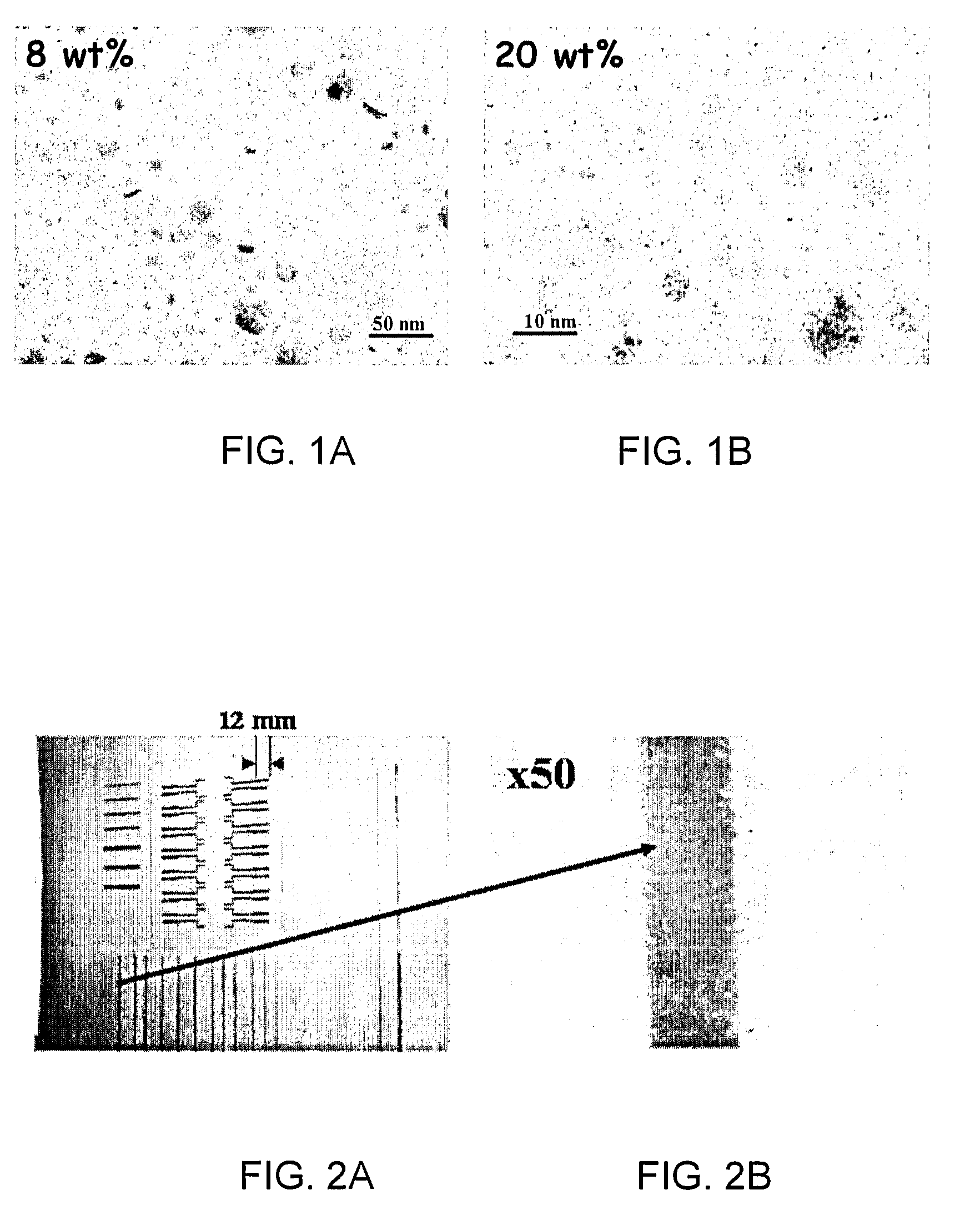

Amplifying Optical Fiber and Method of Manufacturing

InactiveUS20100118388A1Improve efficiencyIncrease output powerGlass optical fibreMaterial nanotechnologyRare-earth elementNanoparticle

Disclosed is an amplifying optical fiber having a central core and an optical cladding surrounding the central core. The central core is based on a silica matrix that includes nanoparticles, which are composed of a matrix material that includes doping ions of at least one rare earth element. The amplifying optical fiber can be employed, for example, in an optical amplifier and an optical laser.

Owner:DRAKA COMTEQ BV

Preparation method for aluminum oxide by direct forming method

InactiveCN102923744AReduce drynessReduce stepsAluminium oxide/hydroxide preparationAluminium hydroxide preparationHydrated aluminaAluminium hydroxide

The invention discloses a preparation method for aluminum oxide by a direct forming method. The method is characterized in that the aluminum oxide is directly formed by a wet filter cake, wherein pore volume is 0.3-0.8ml / g; a specific surface area is 150-300 m<2> / g; and crushing strength is 30-120 N / particle; the preparation process comprises the steps: a) meta-aluminate containing aluminum or a strong acid salt compound is neutralized with a precipitator solution at a temperature of 30-80 DEG C and pH of 6-9; accessory ingredient is added in a neutralizing process; mixture is aged for at least 10min after neutralizing; b) prepared aluminium hydroxide gel is washed by de-ionized water for 4-10 times; dosage of the de-ionized water for each time is 10-40 times of mass of a dried substrate of prepared aluminium hydroxide; a hydrated alumina filter cake is obtained after washing and filtering; content of the aluminium hydroxide in the filter cake is controlled to be 5-50%; and c) the accessory ingredient is added into one or various liquid in the step a) and step b); the filter cake after washing is formed by a normal forming method; and the formed filter cake is dried at a temperature of 80-120 DEG C and calcined at a temperature of 450-1000 DEG C to obtain a finished product of the aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

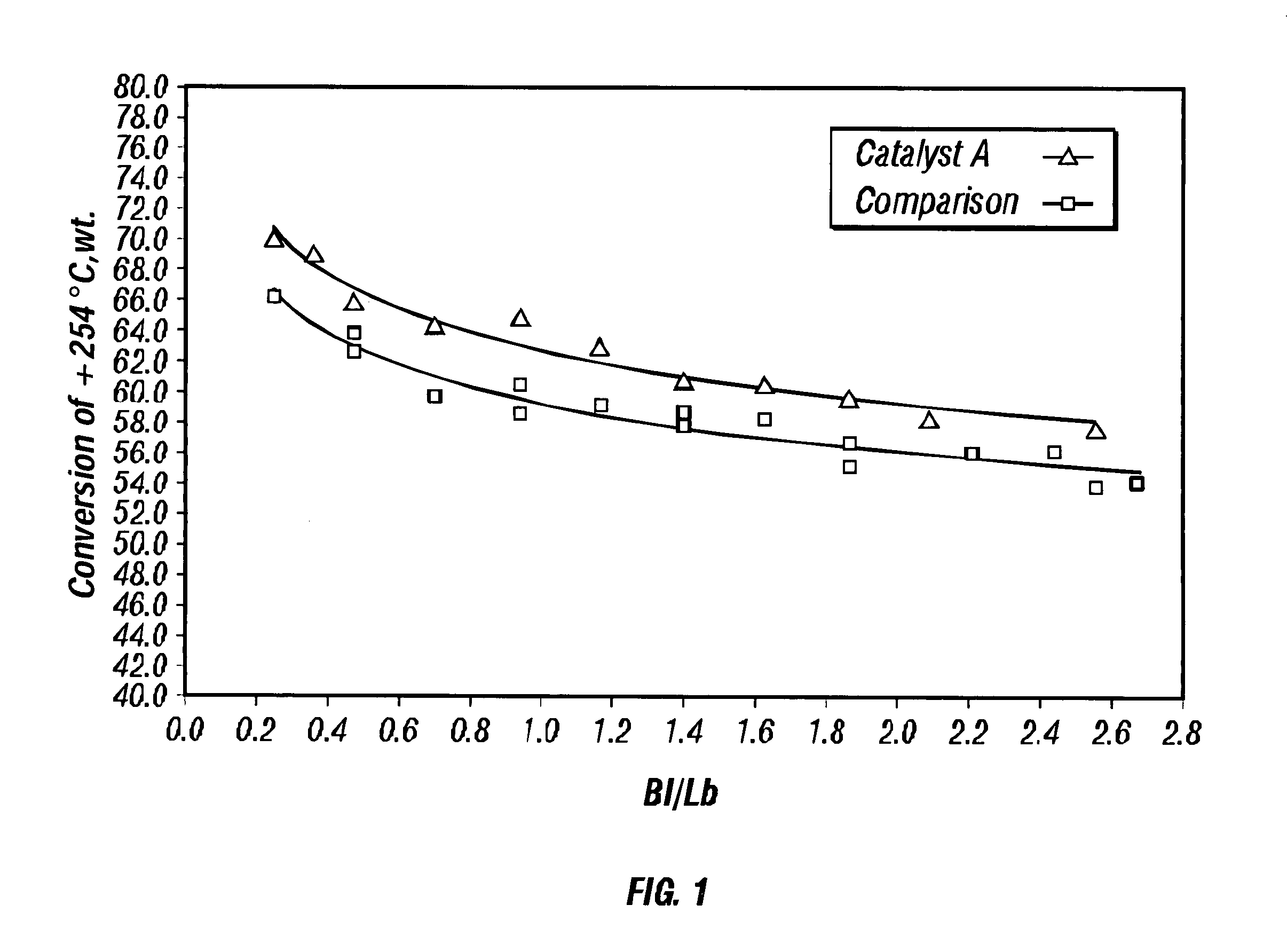

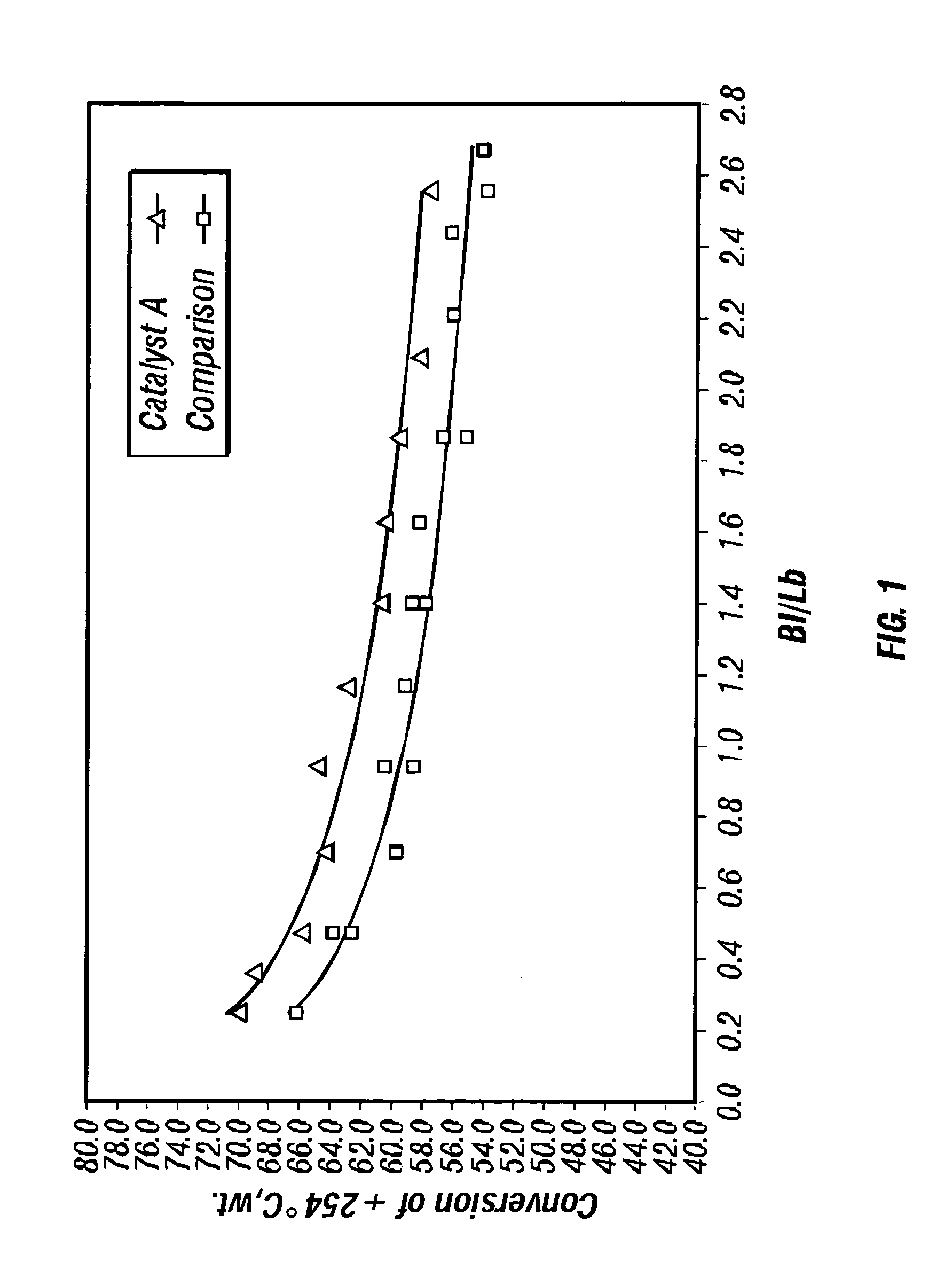

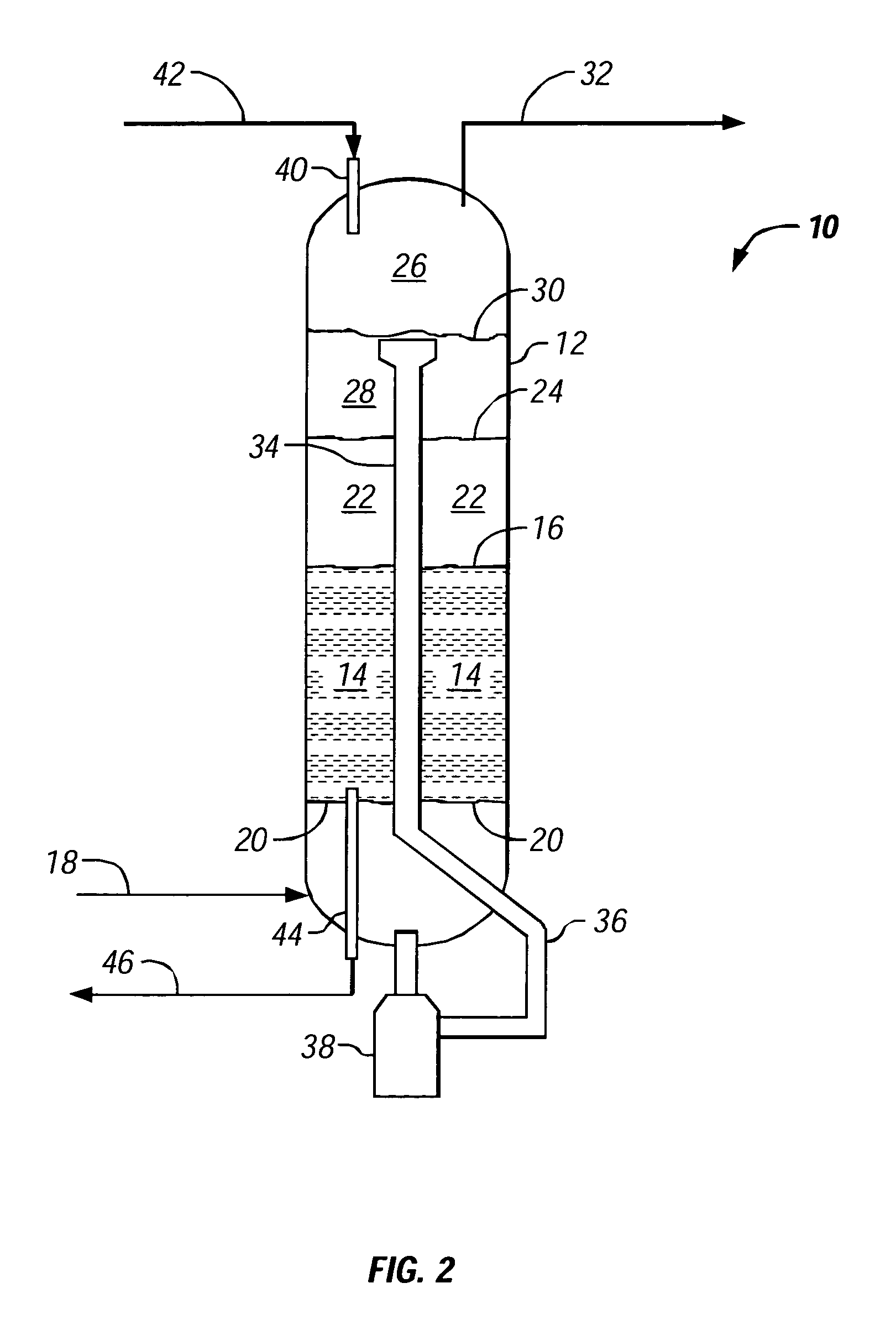

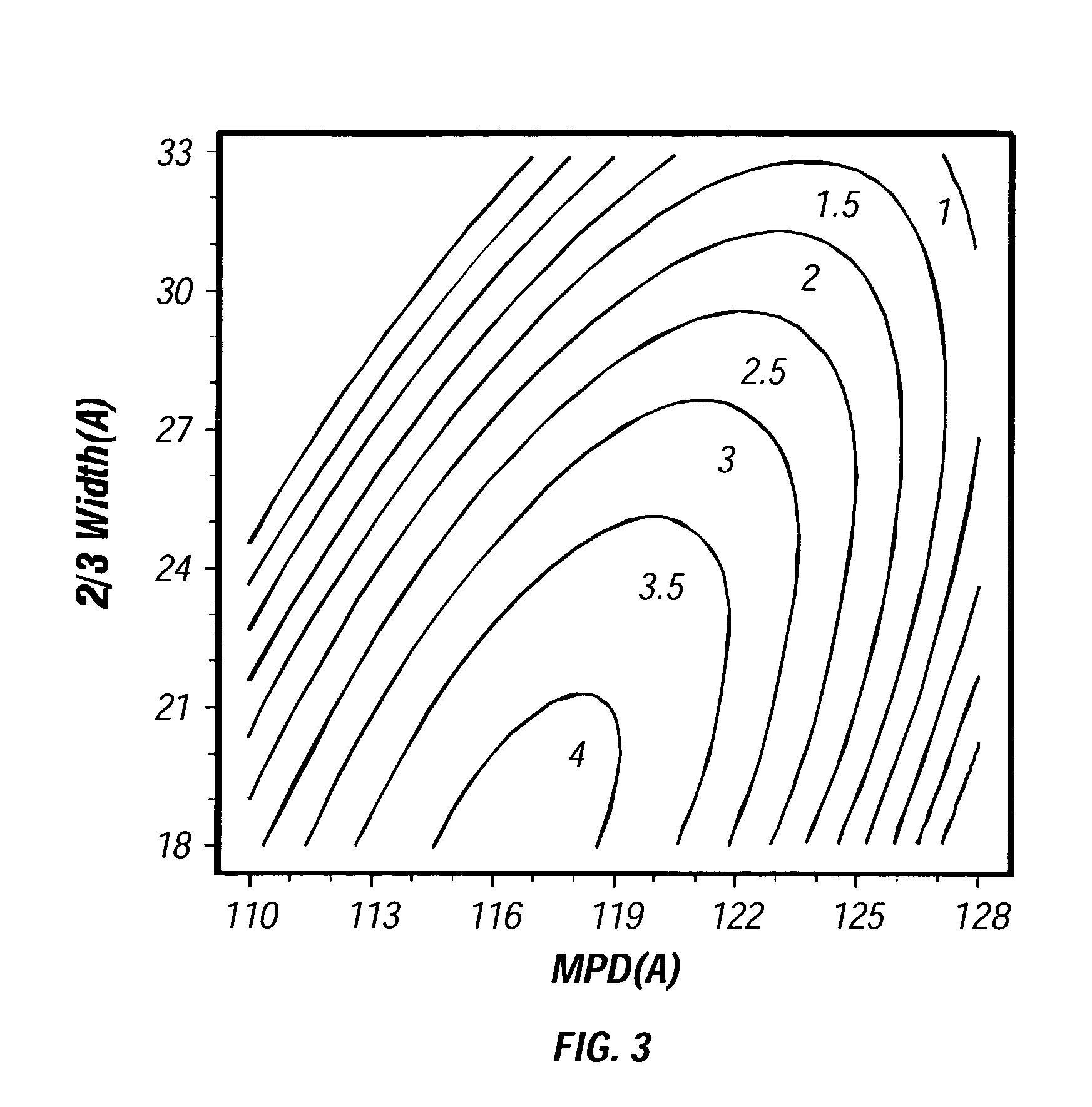

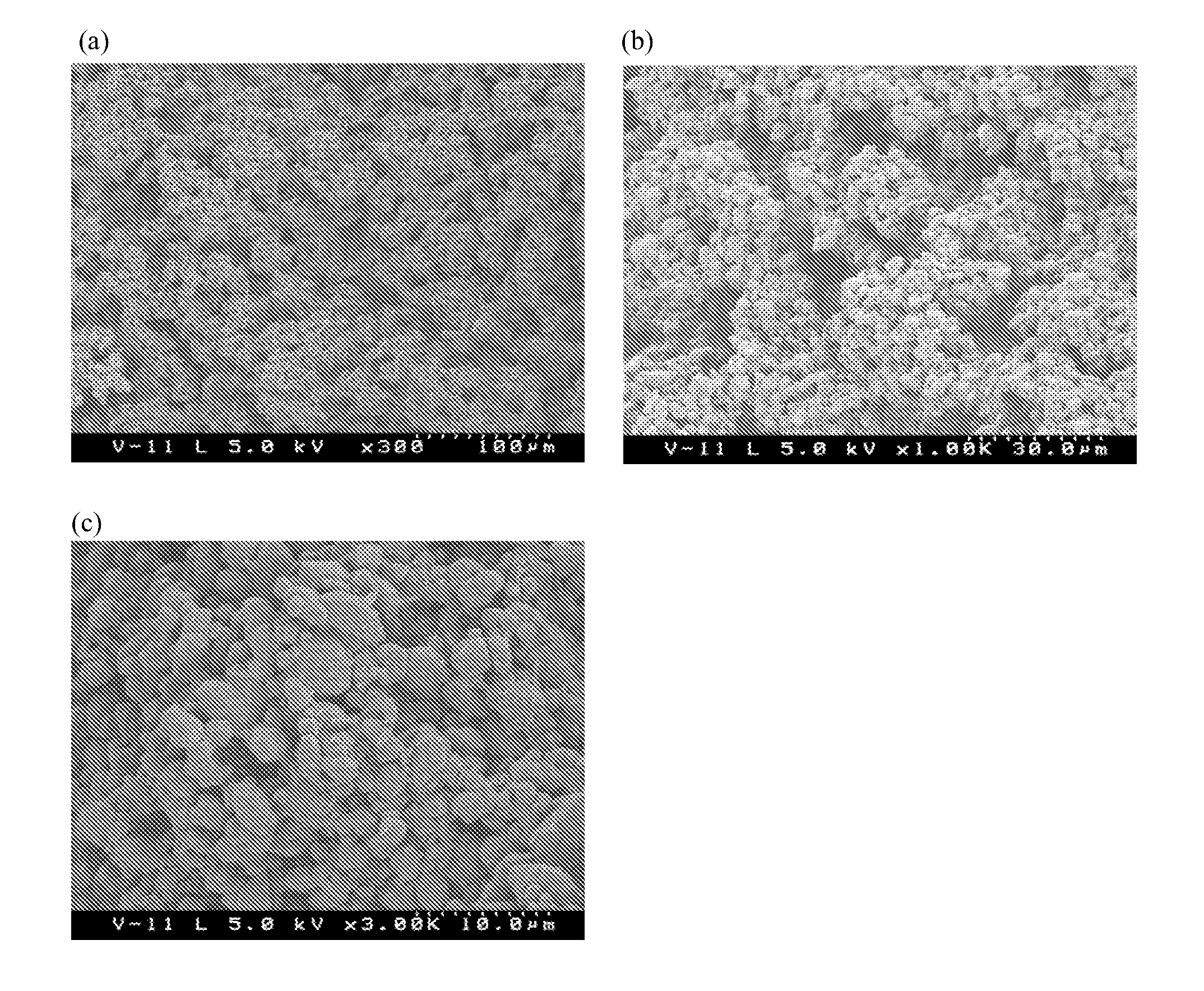

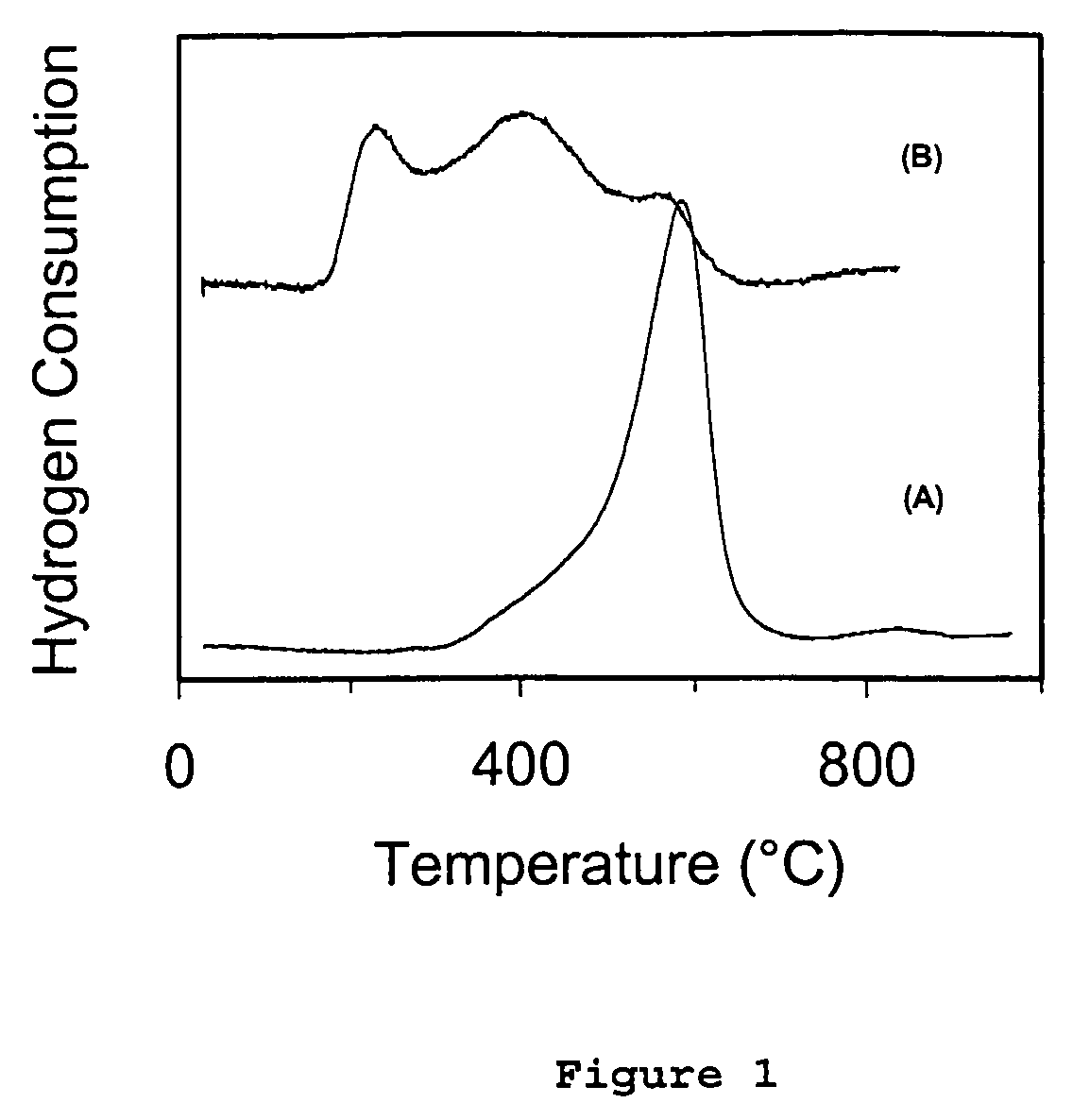

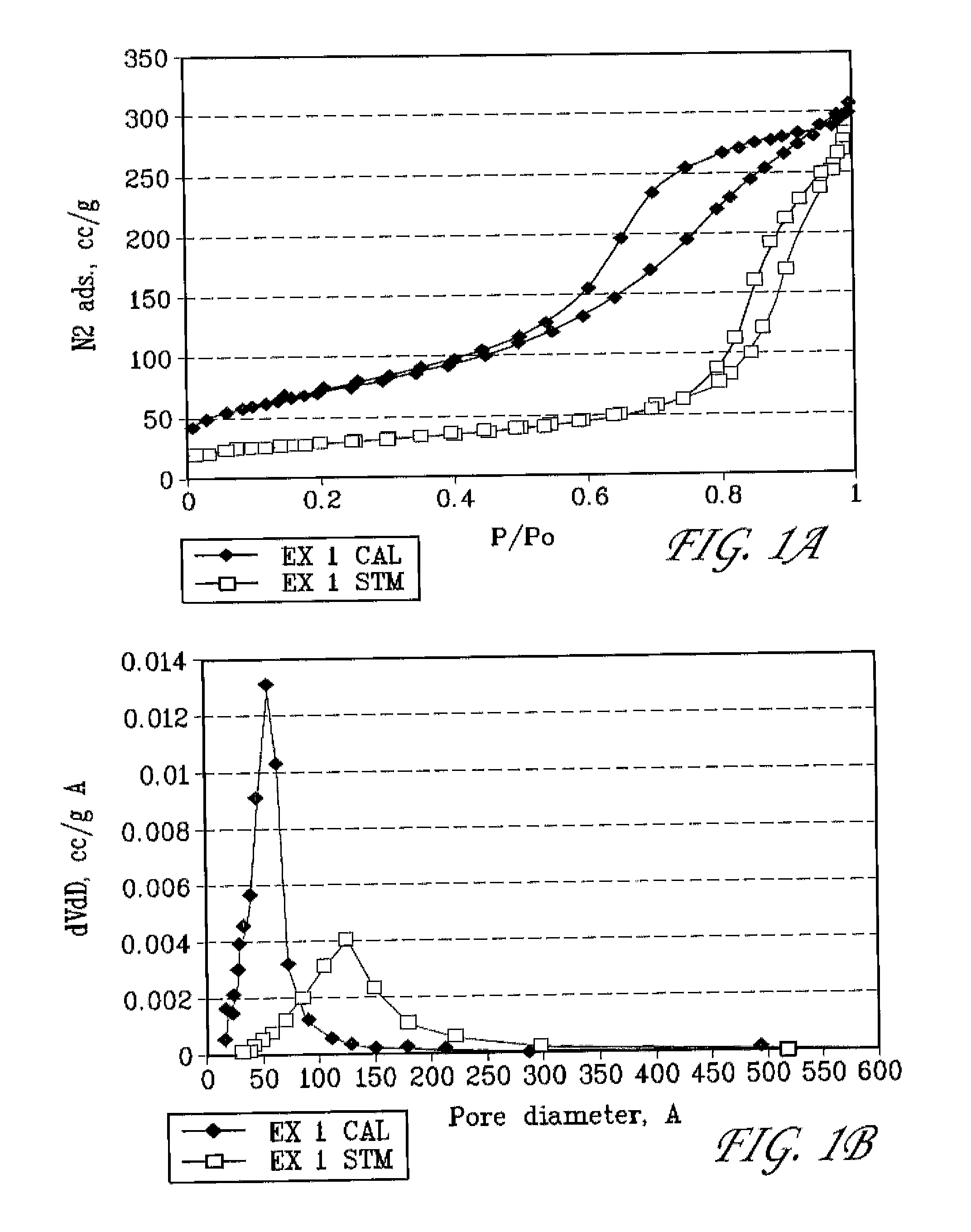

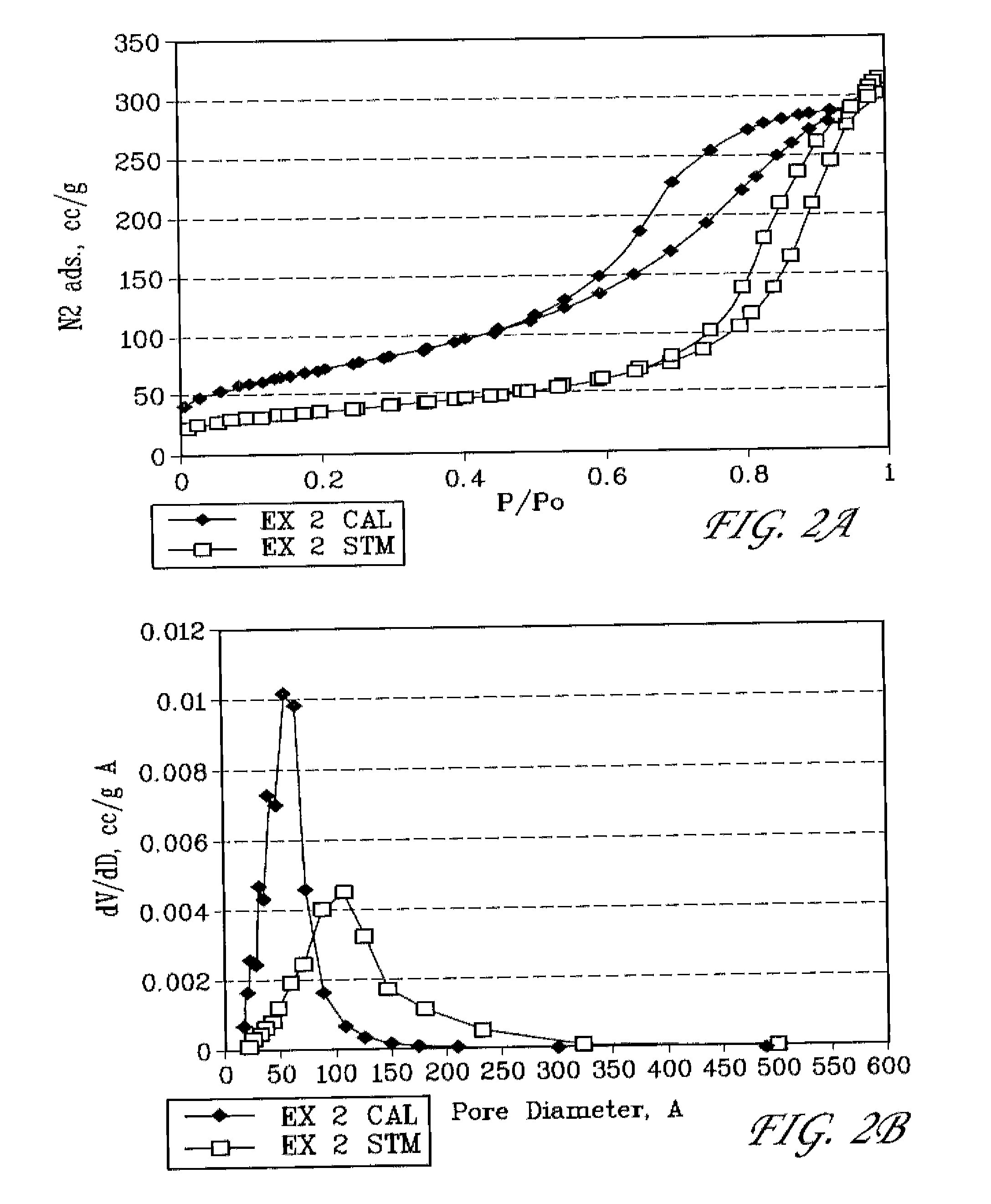

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

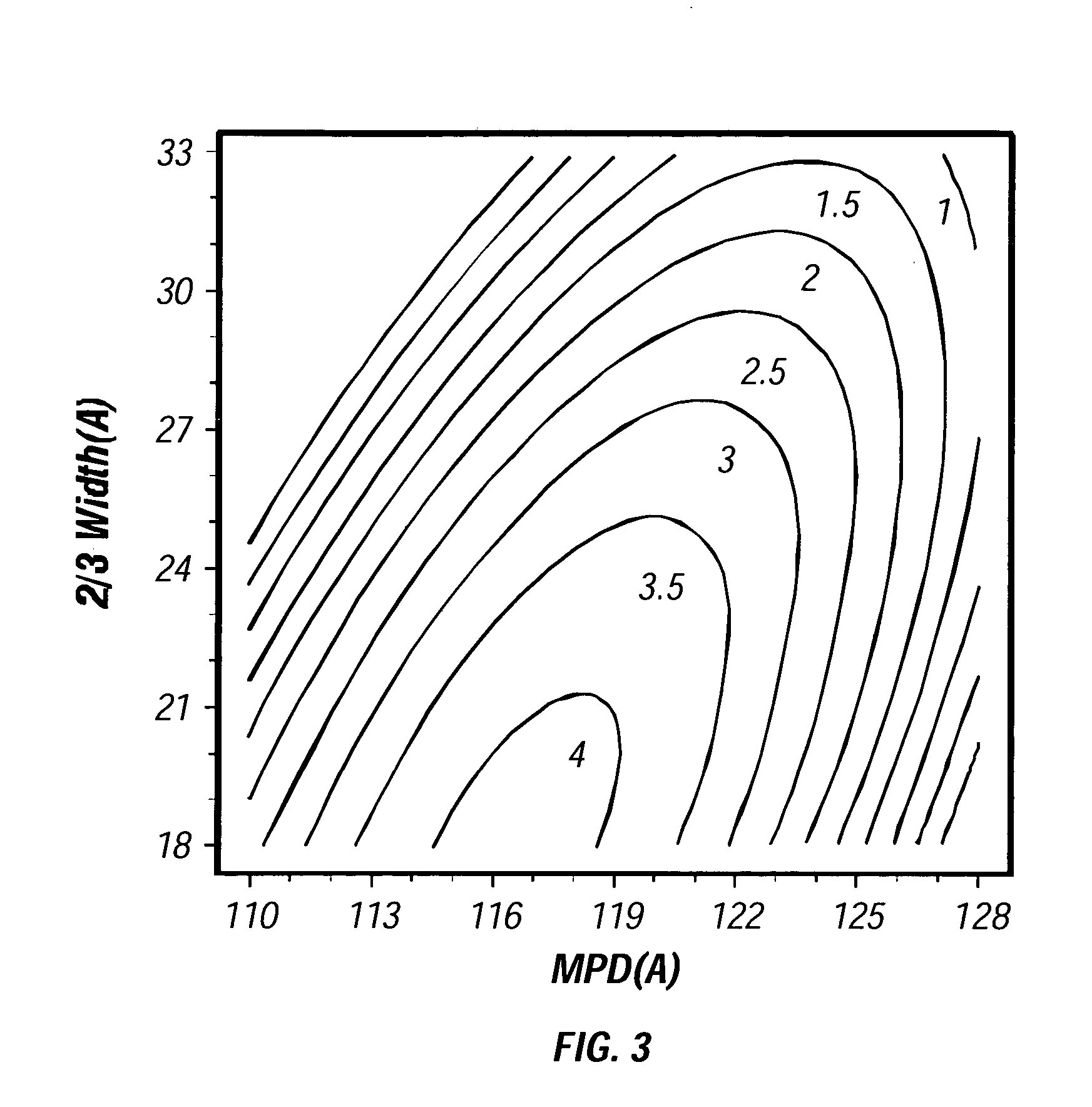

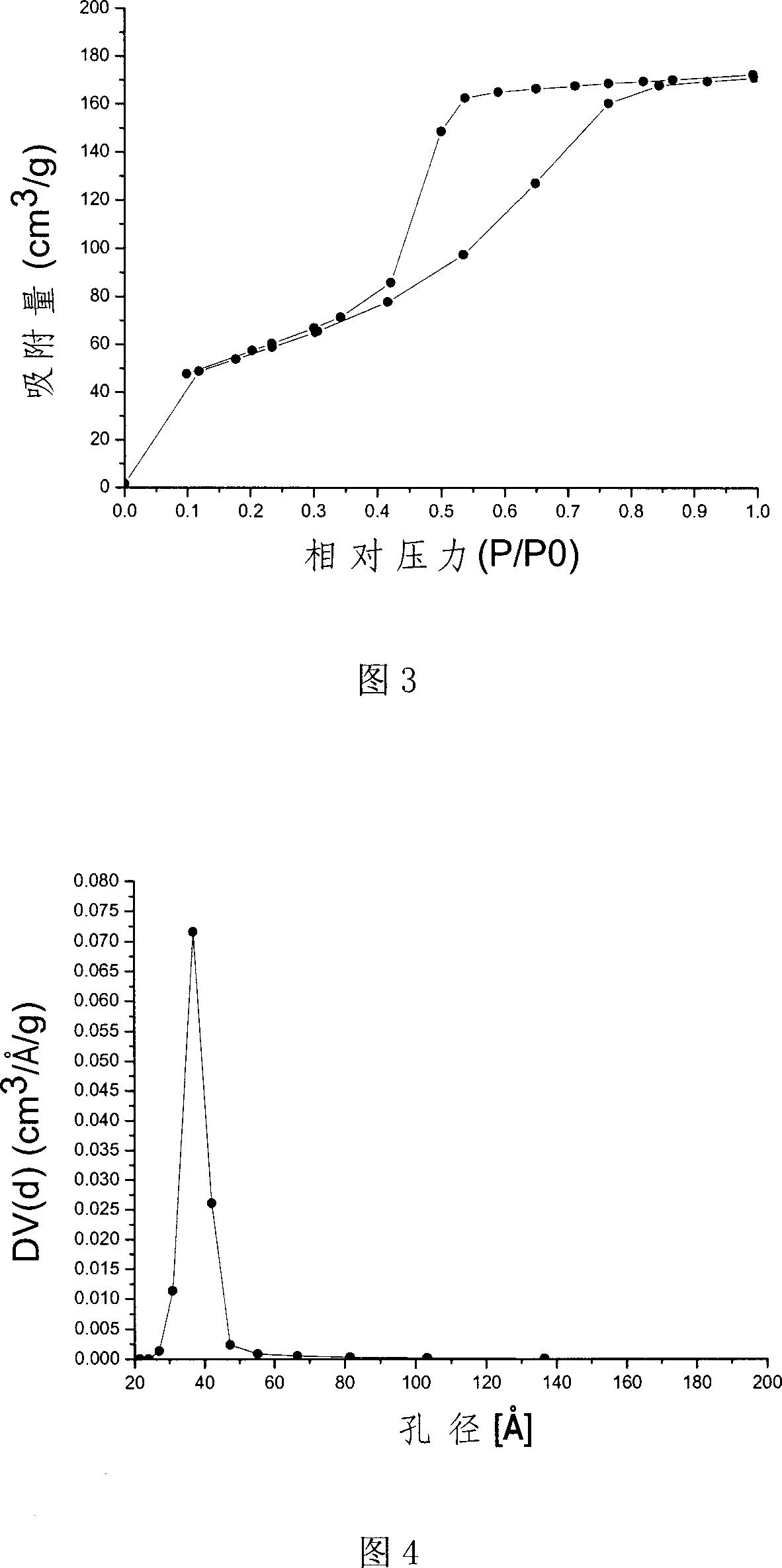

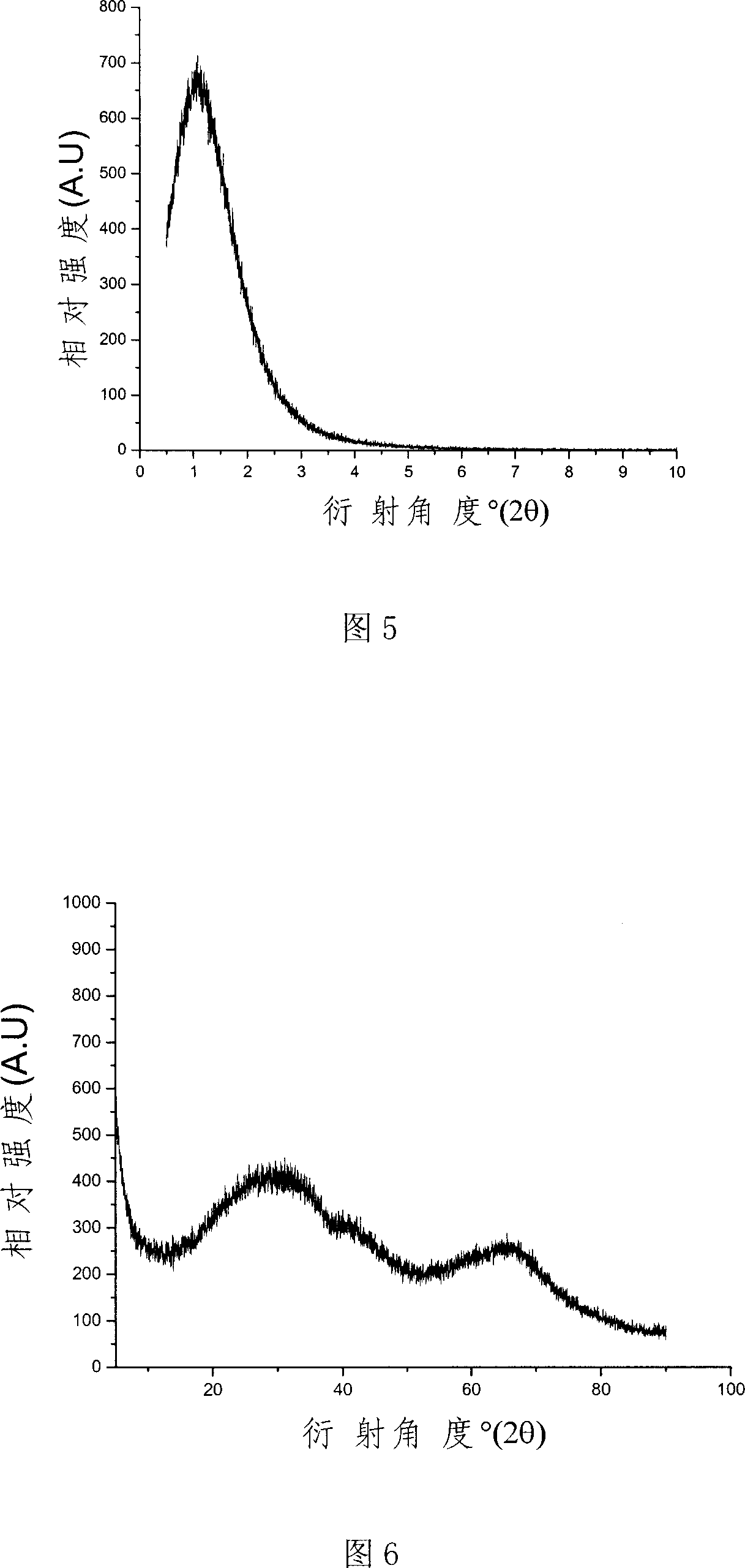

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

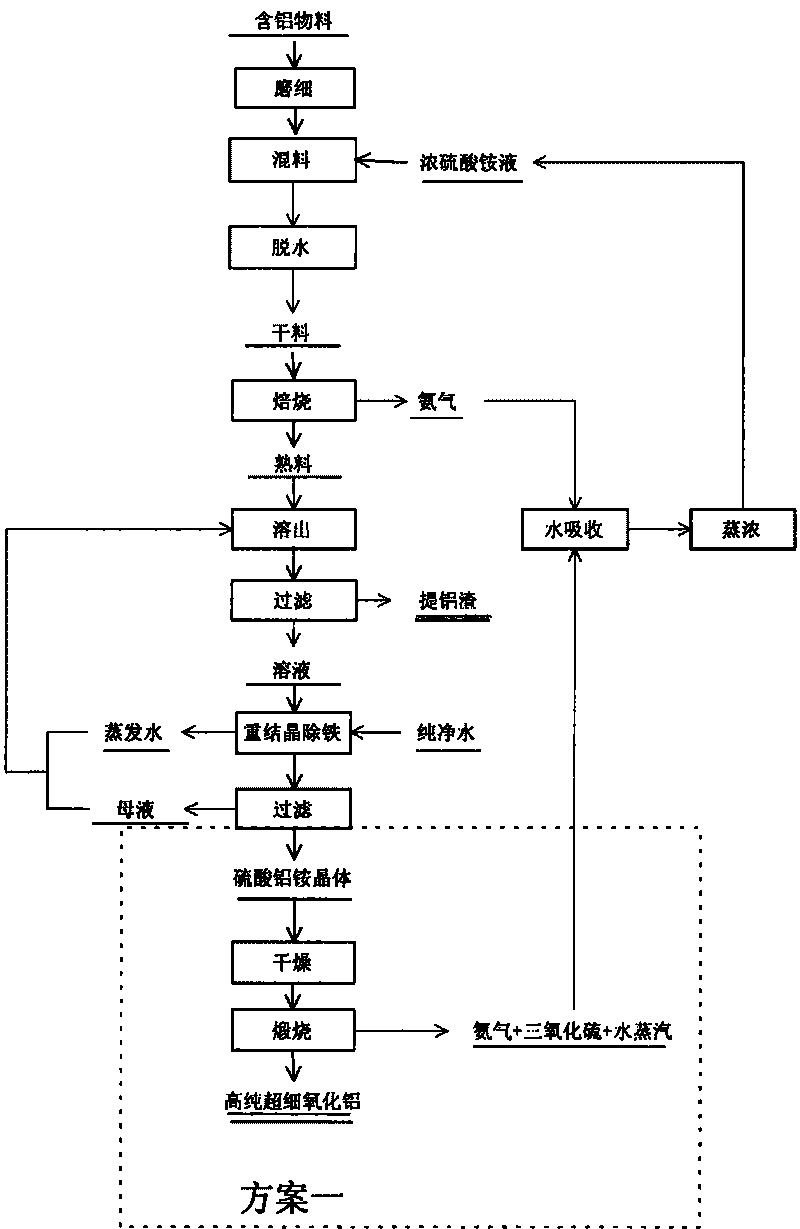

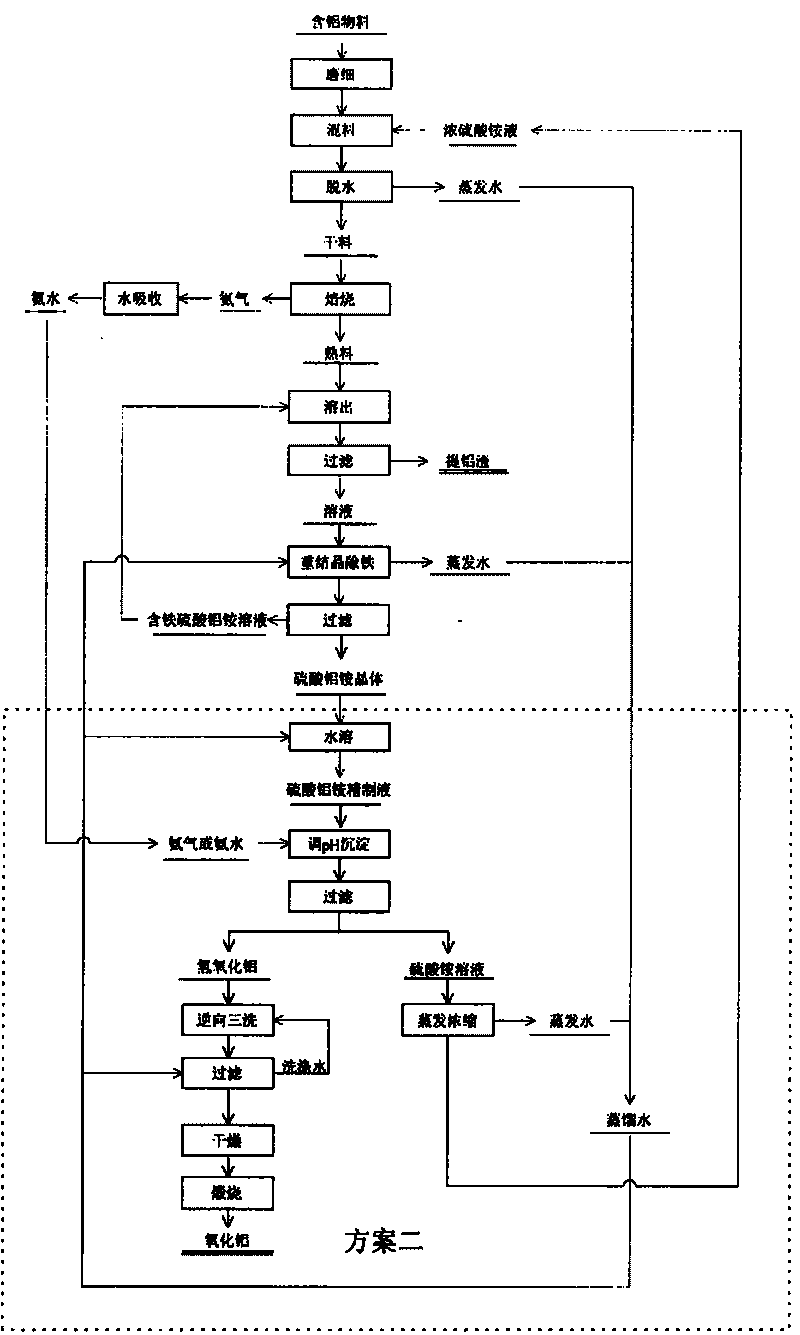

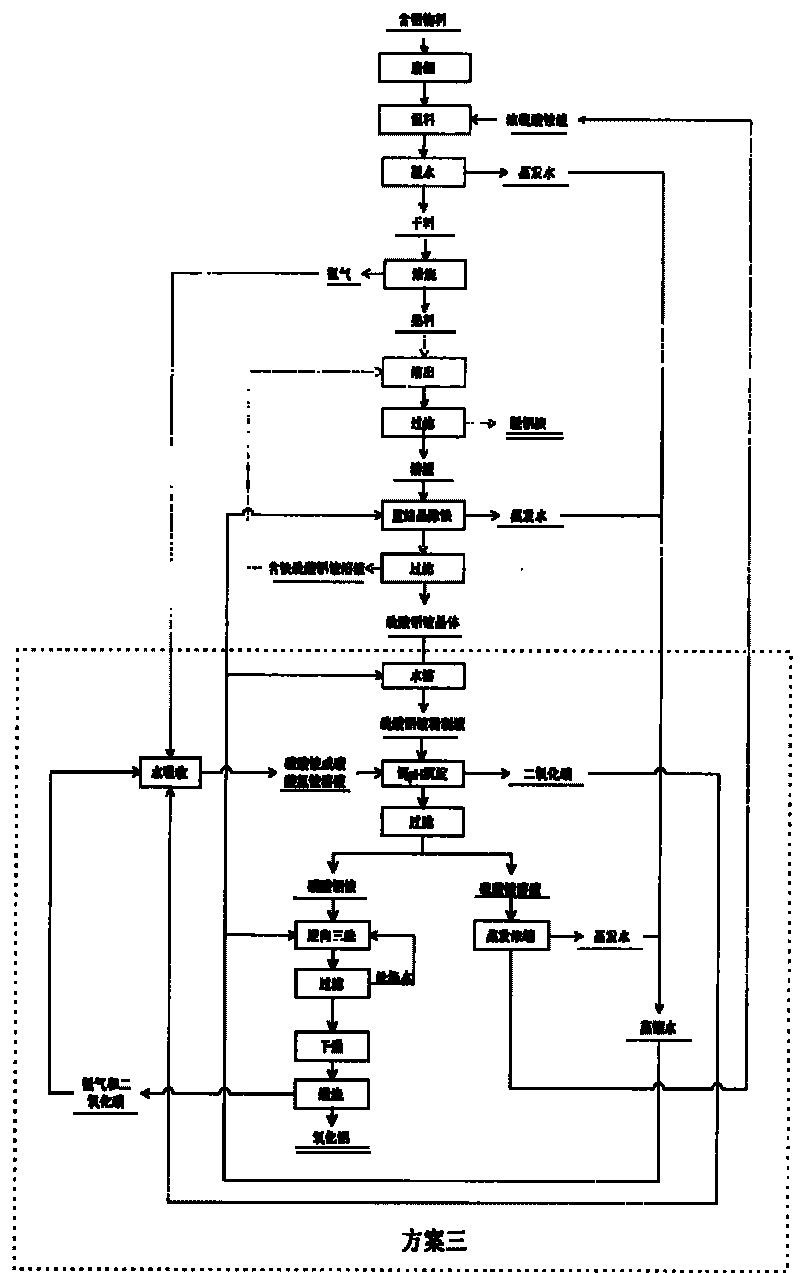

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

Alpha alumina (corundum) whiskers and fibrous-porous ceramics and method of preparing thereof

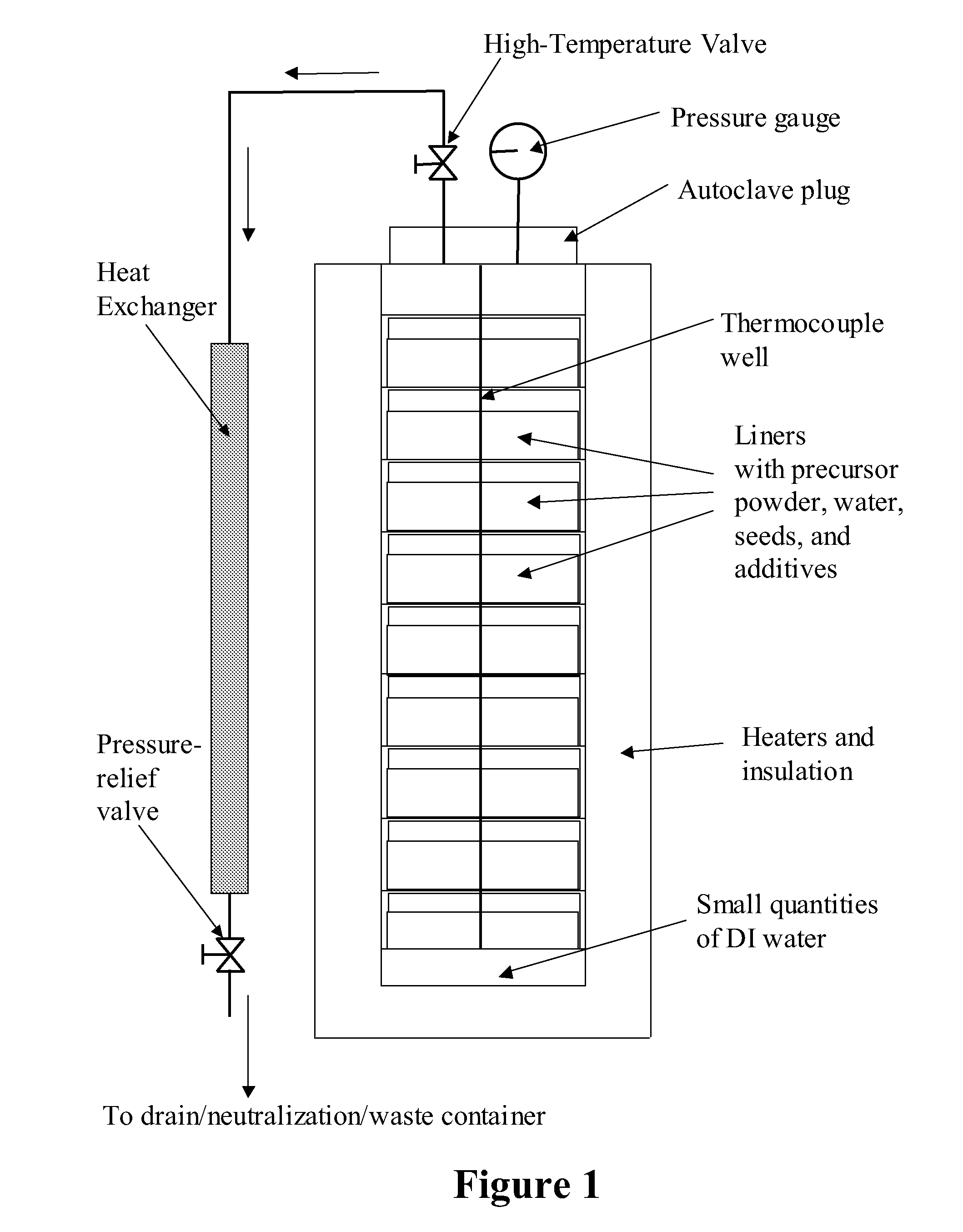

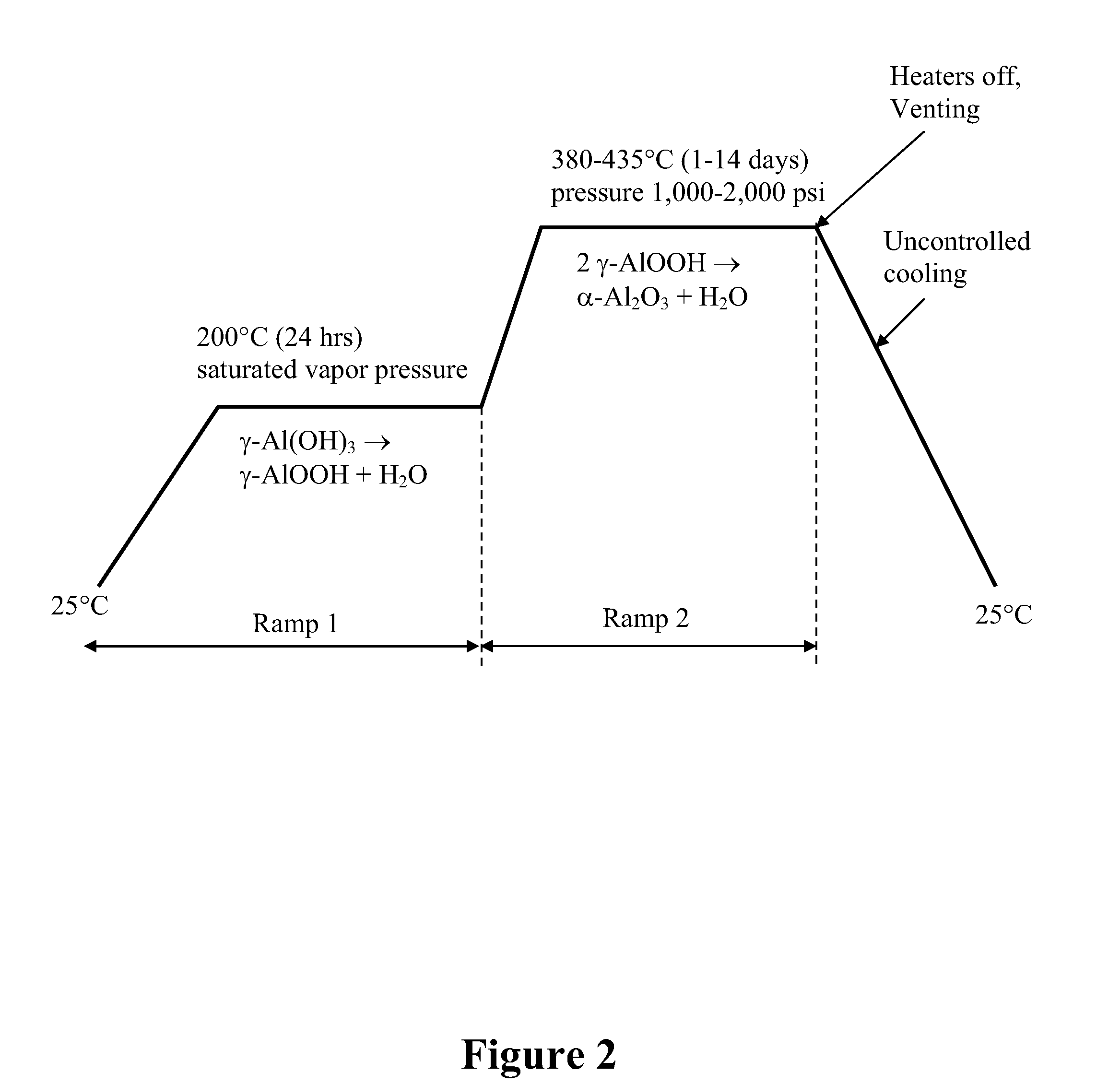

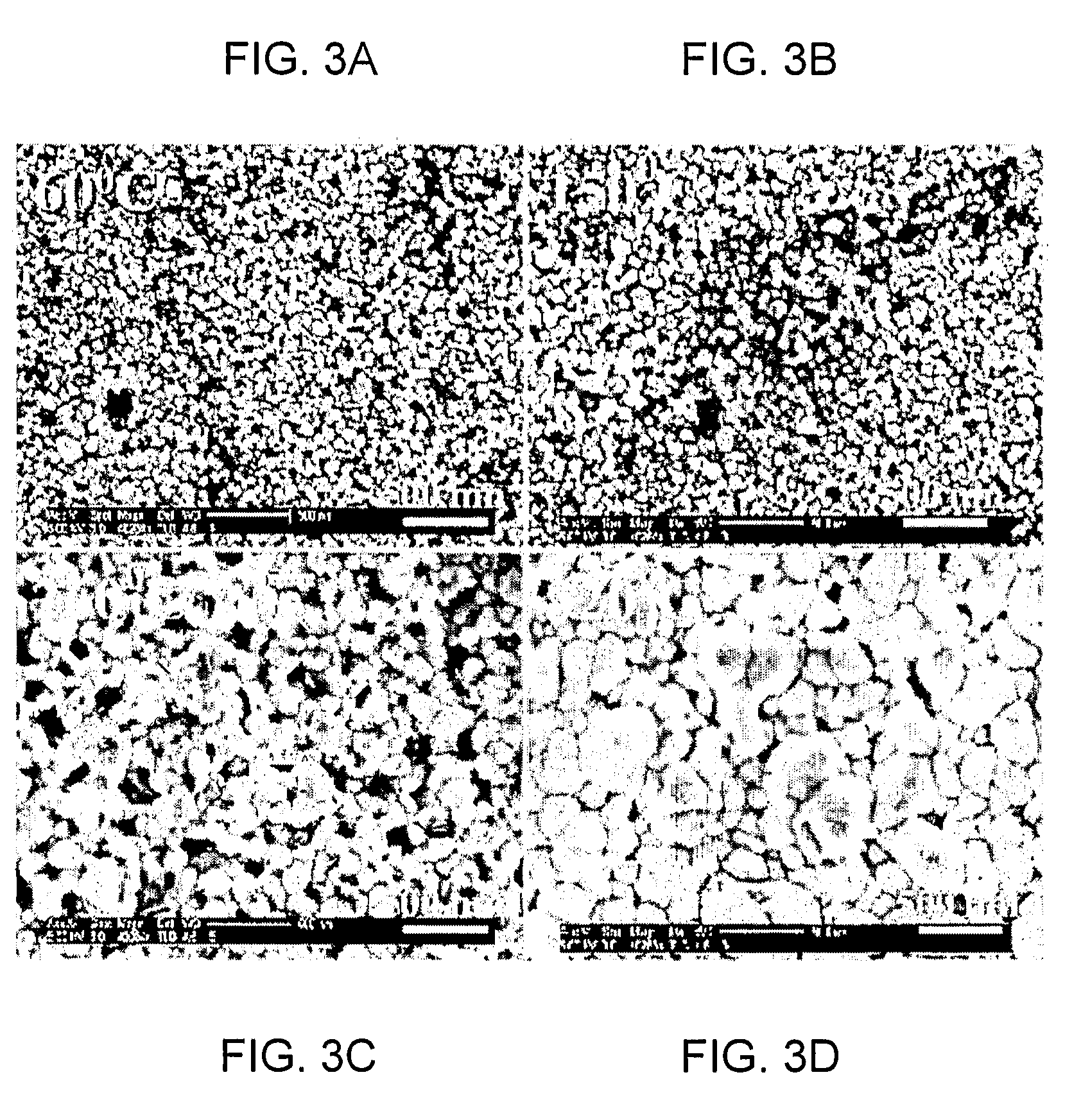

InactiveUS20120189833A1High mechanical strengthHigh porosityAluminium oxide/hydroxide preparationAluminium hydroxide preparationWhiskersPorous ceramics

Materials and associated processes for making the materials. For example the material may include alpha alumina crystalline whiskers. The process may include conducting the process as hydrothermal, and producing the whiskers to have a length to diameter aspect ratio of at least two.

Owner:SAWYER TECHN MATERIALS

THERMALLY STABLE DOPED AND UNDOPED POROUS ALUMINUM OXIDES AND NANOCOMPOSITE CeO2-ZrO2 AND Al2O3 CONTAINING MIXED OXIDES

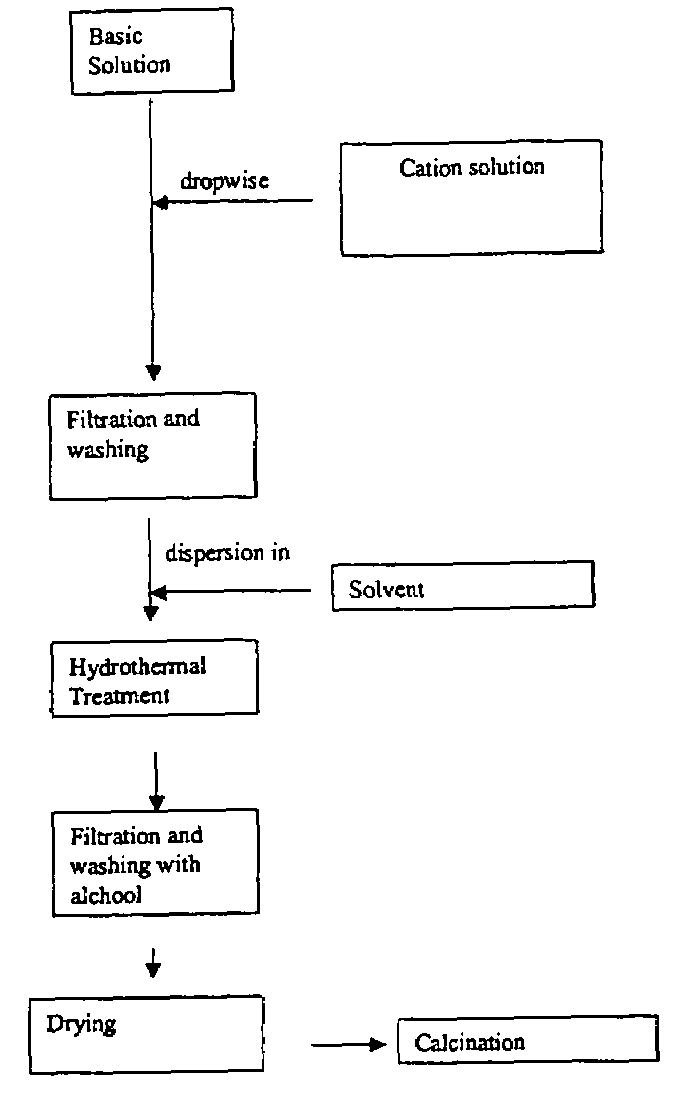

InactiveUS20090023581A1Improve thermal stabilityImproved oxygen storageMaterial nanotechnologyBarium aluminatesDopantMixed oxide

The present invention relates to doped or undoped aluminas having after calcination at 1200° C. for 5-24 hours a pore volume ≧0.5 ml / g and a BET surface area greater then 35 m2 / g. The invention also relates to a method for preparing these aluminas comprising the steps of: a. preparing an aqueous solution of an aluminum salt with optional co-dopants, b. treating the aqueous solution with hydrogen peroxide, c. precipitating the alumina using a base, and d. filtering, drying and calcining the alumina.

Owner:MAGNESIUM ELETRON LTD

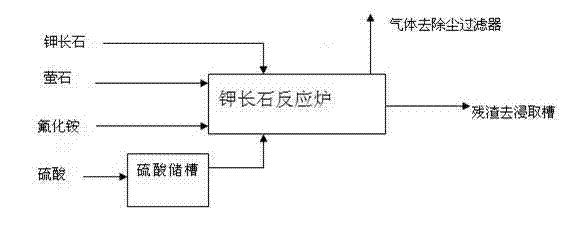

Method of producing aluminum oxides and products obtained on the basis thereof

InactiveUS6841497B1Increase contentMaterial nanotechnologyPretreated surfacesNanoparticleCrystal structure

The invention relates to the field of technical ceramics and specifically relates to a method of synthesis for aluminum oxides of different crystalline structure and to the products obtained by the method. The aim of the invention is to provide a method of producing redispersible nanoparticulate corundum and nanoporous Al2O3 sintered products, the method using precursors and being viable on a commercial scale. To this aim, inter alia, a method of producing redispersible nanoparticulate corundum of an average particle size of D50<100 nm is used which method includes the addition of crystal nuclei. According to the method, organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 650° C. and is then further heated by increasing the temperature to ≦950° C. The aim of the invention is also attained by using a method of producing nanoporous Al2O3 sintered products according to which organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 750° C.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

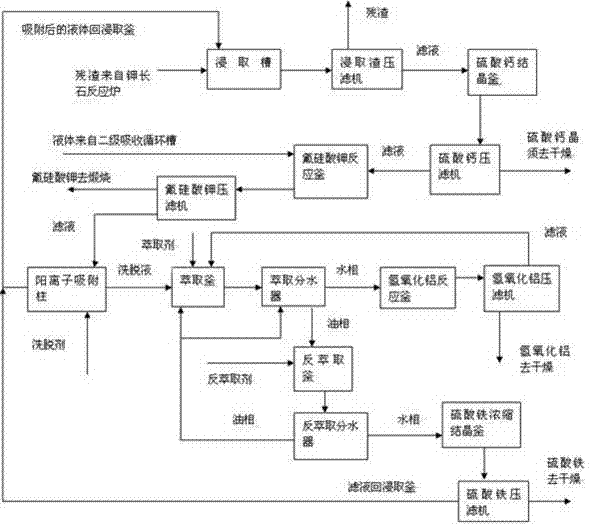

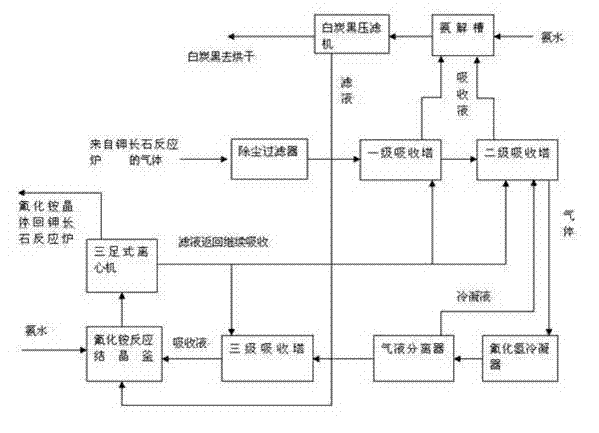

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

Oil ammonia column shaping method of spherical aluminium oxide

InactiveCN1493524AAvoid pollutionEasy to manufactureCatalyst carriersAluminium hydroxide preparationOil phaseSurfactant free

A process for preparing spherical alumina by oil-ammonia column includes dripping the alumina sol in the oil-ammonia column composed of upper oil phase and lower electrolyte solution phase to generate spherical gel particles, ageing in electrolyte solution for 0.5-10 hr, drying and calcining. Its advantage is high purity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of forming aqueous-based dispersions of metal nanoparticles

The invention relates to a method for preparing an aqueous-based dispersion of metal nanoparticles comprising: (a) providing an aqueous suspension of a metal salt; (b) pre-reducing the metal salt suspension by a water soluble polymer capable of metal reduction to form a metal nuclei; and (c) adding a chemical reducer to form metal nanoparticles in dispersion. The invention further relates to aqueous-based dispersions of metal nanoparticles, and to compositions such as ink comprising such dispersions.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

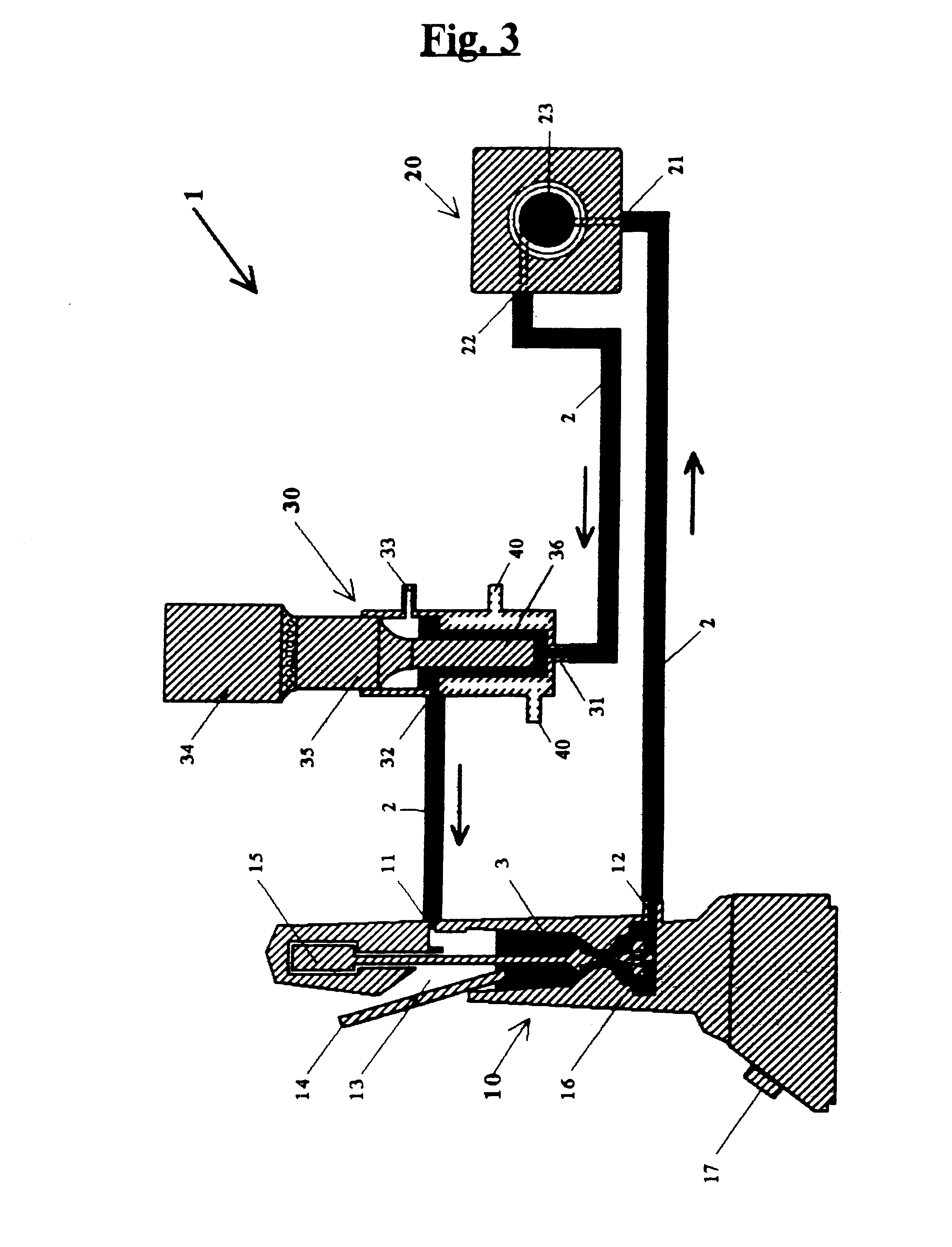

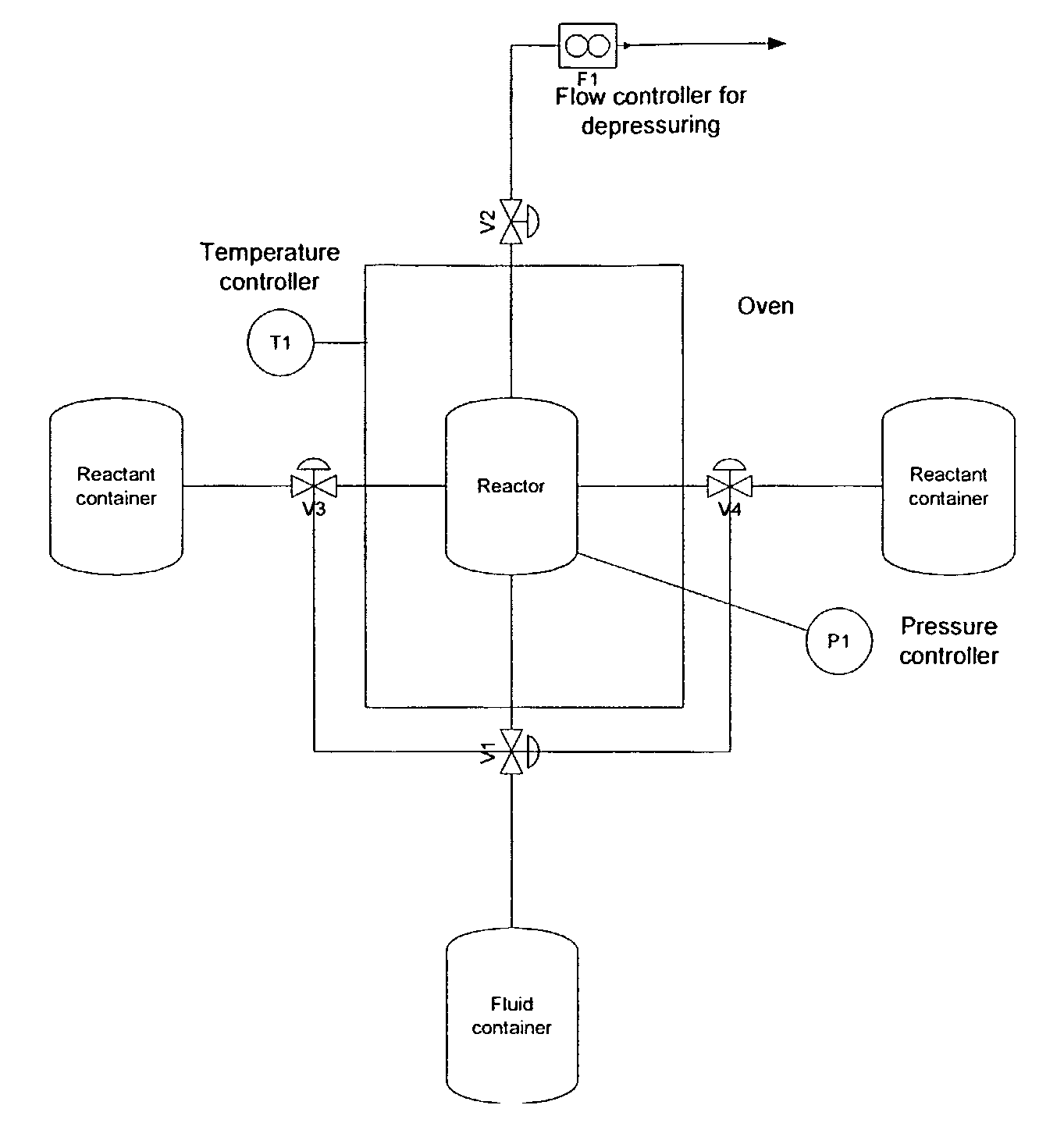

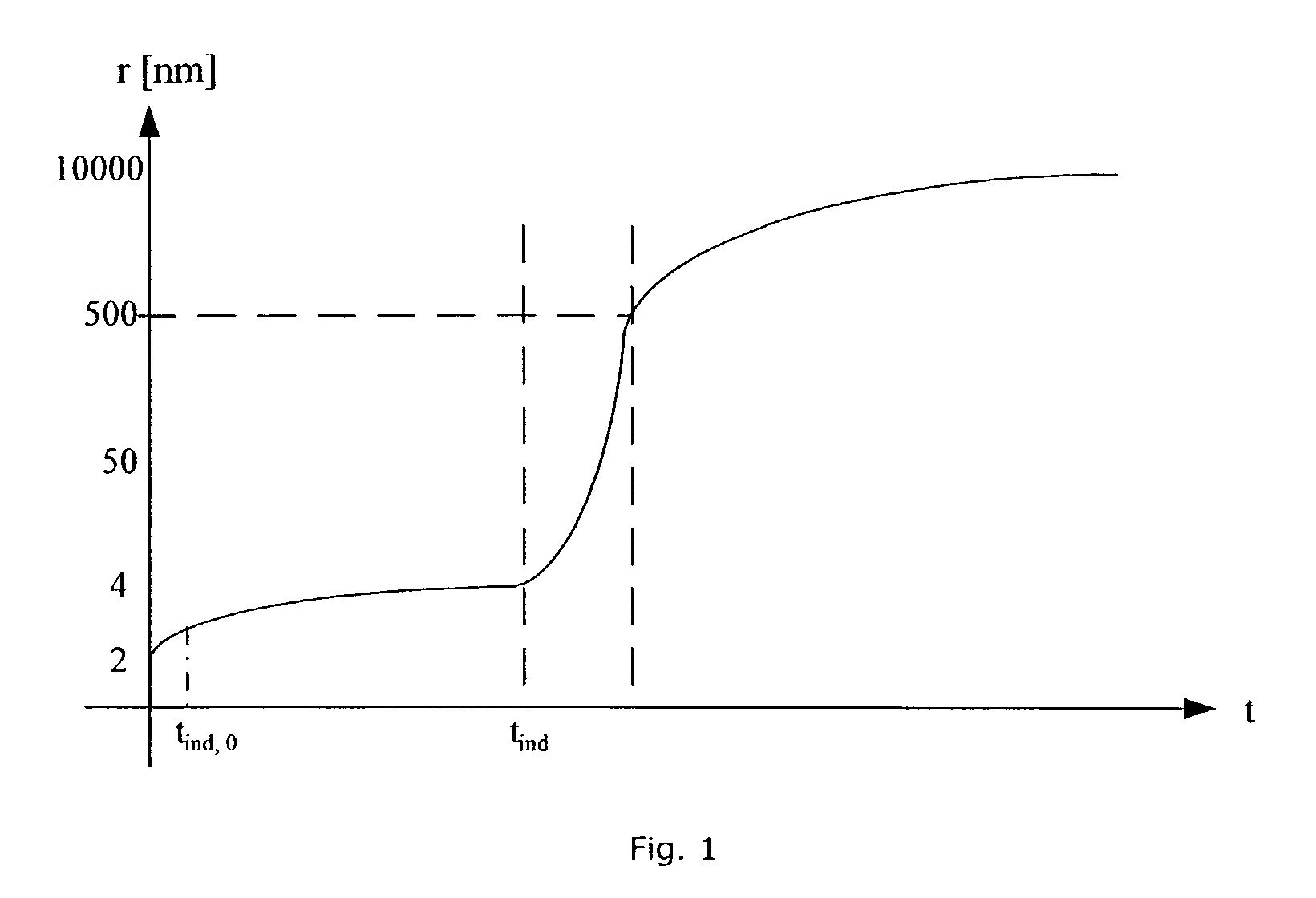

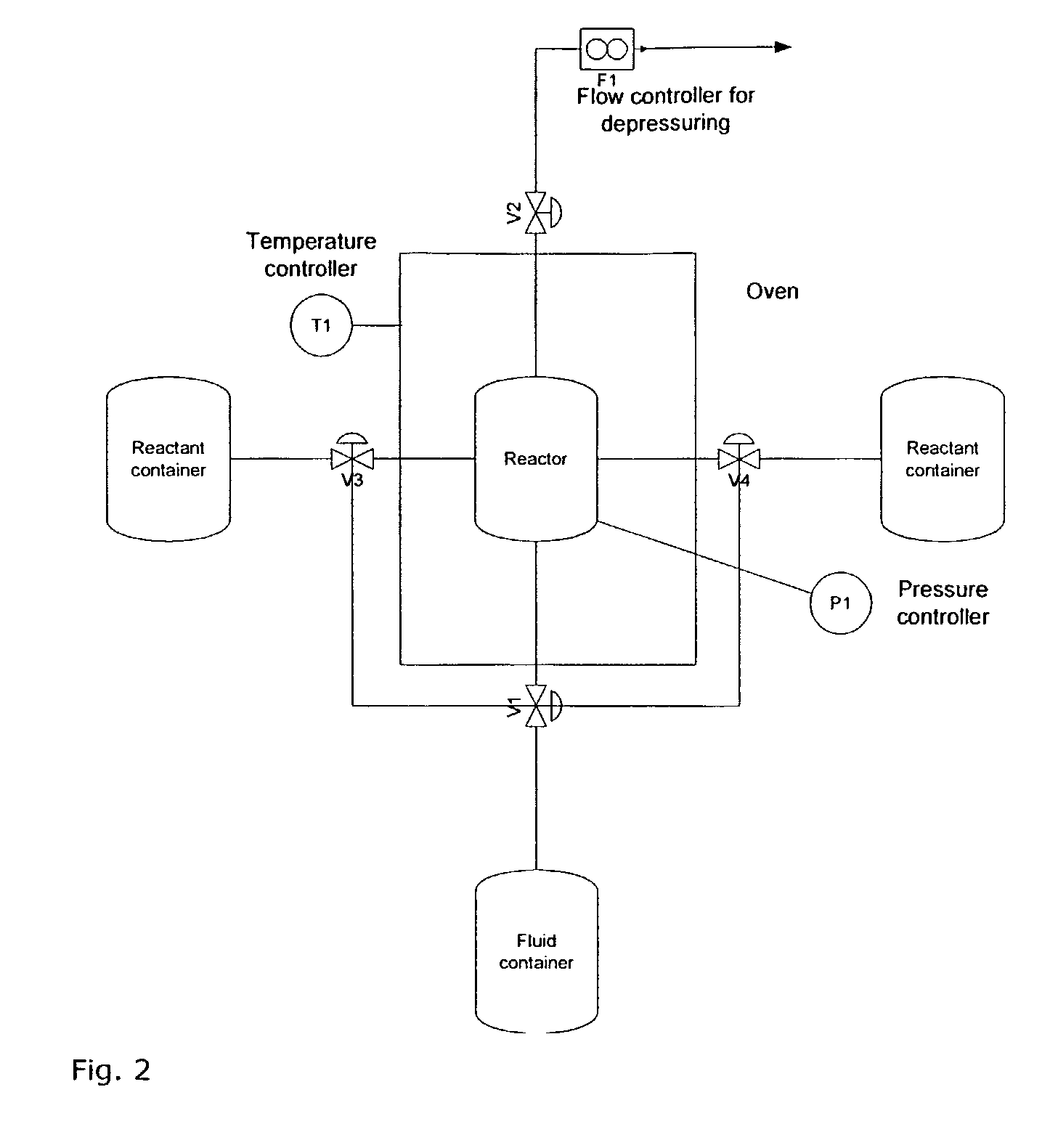

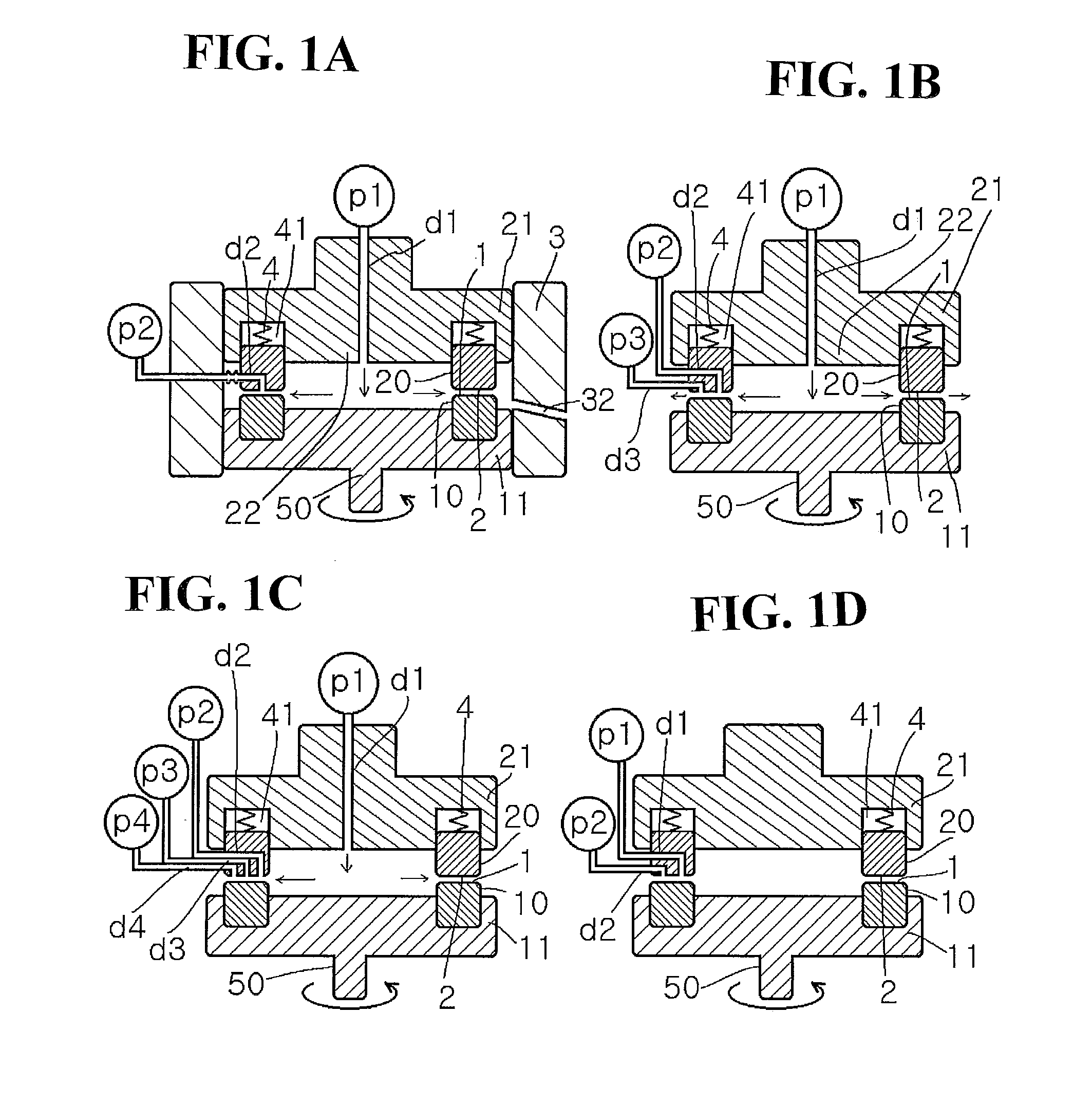

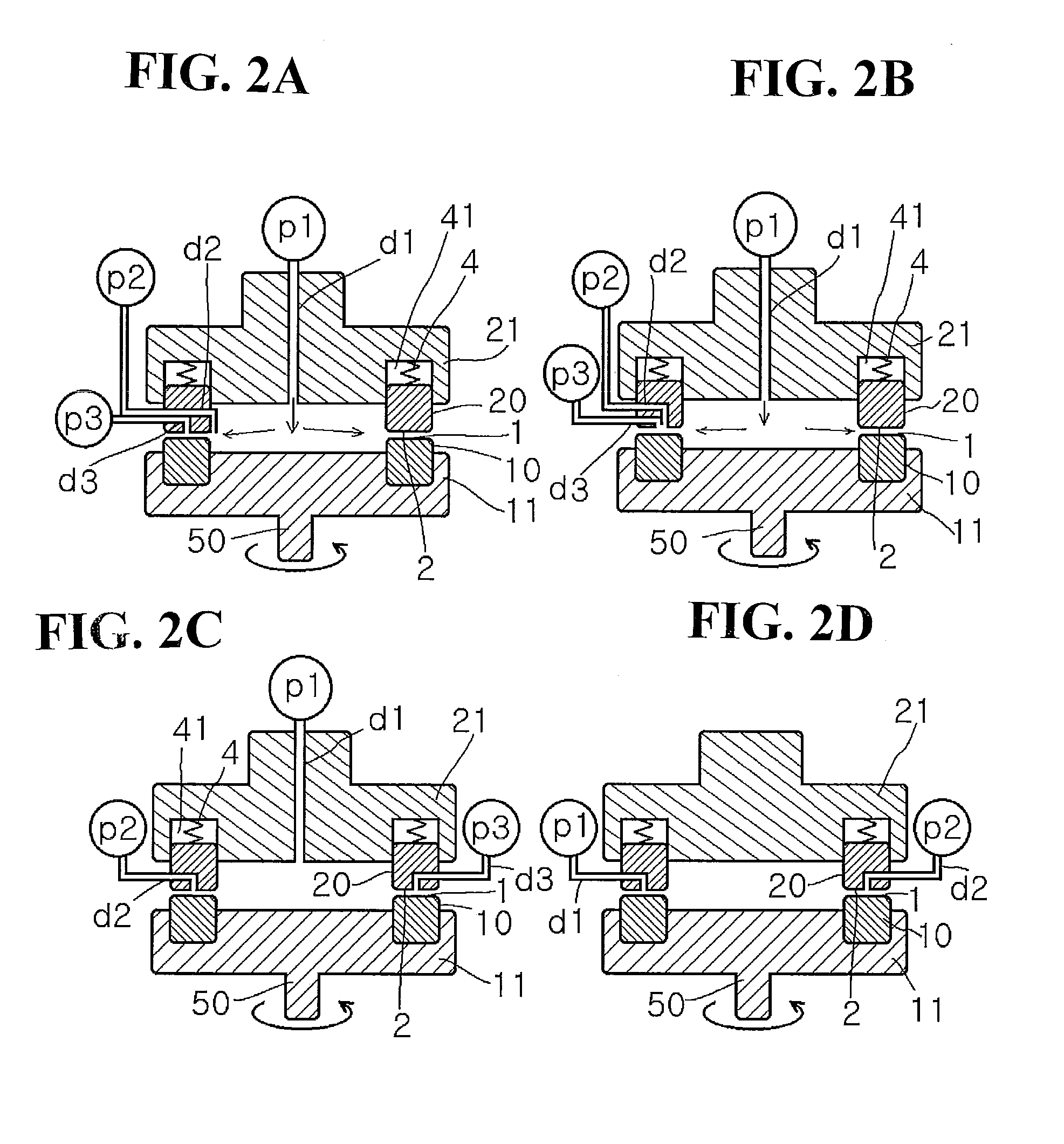

Method and apparatus for production of a compound having submicron particle size and a compound produced by the method

InactiveUS20080026929A1Low costBudget is minimisedMaterial nanotechnologyAuxillary shaping apparatusFilling materialsCarbide

The invention relates to an improved method of manufacturing a compound having a sub-micron primary particle size such as a metal compound such as metal oxides, metaloxy hydroxides metal hydroxides, metal carbides, metal nitrides, metal carbonitrides, metal borides, electroceramics and other such compound, said method comprising the steps of: introducing a solid reactor filling material in a reactor, introducing a metal-containing precursor, a semi-metal-containing precursor, a metal-containing oxide or a semi-metal-containing oxide in said reactor, introducing a reactant or a substitution source into the said reactor, and introducing a supercritical solvent into the said reactor. These steps result in the formation of said compound in the proximity of the said solid reactor filling material.

Owner:AALBORG UNIV

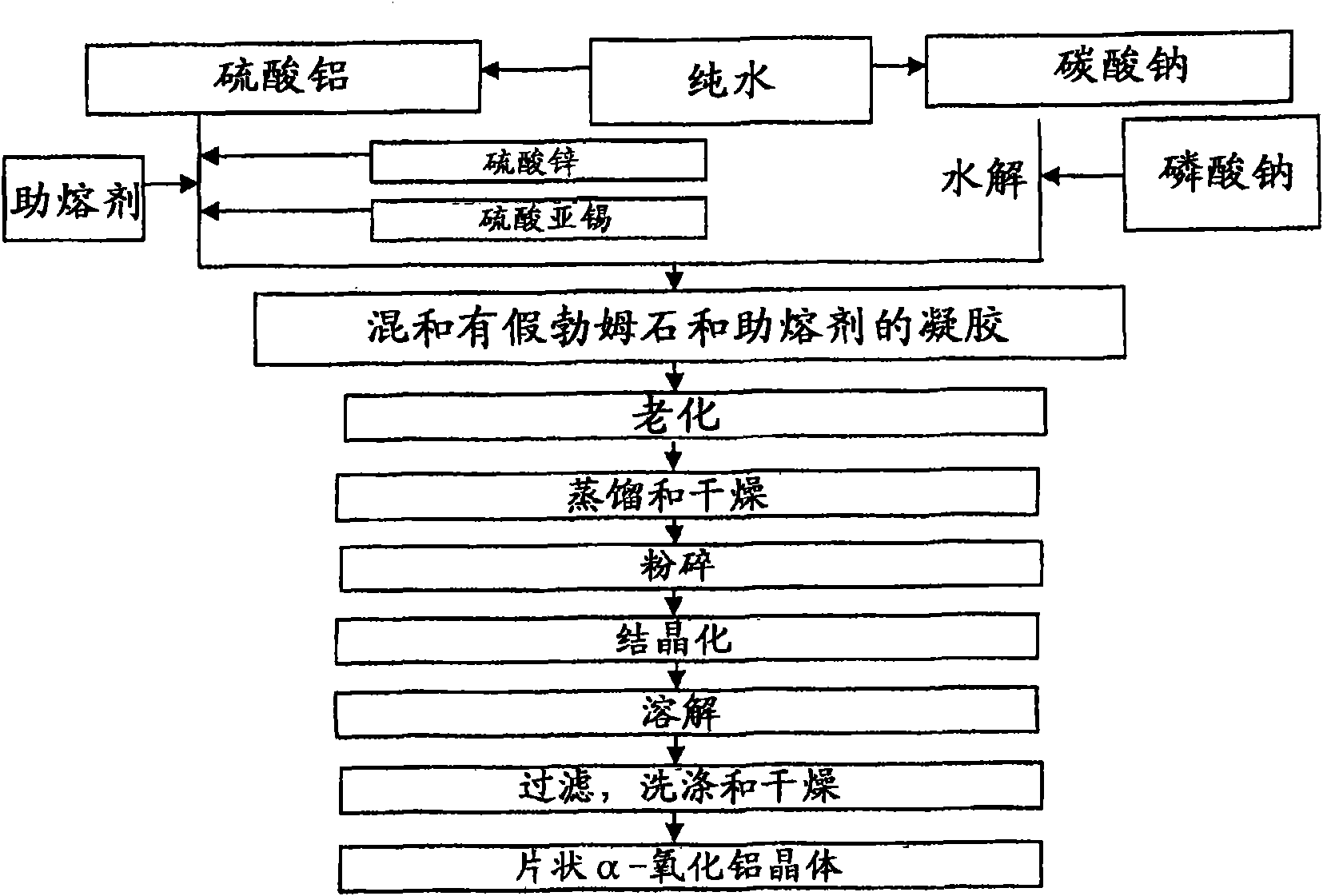

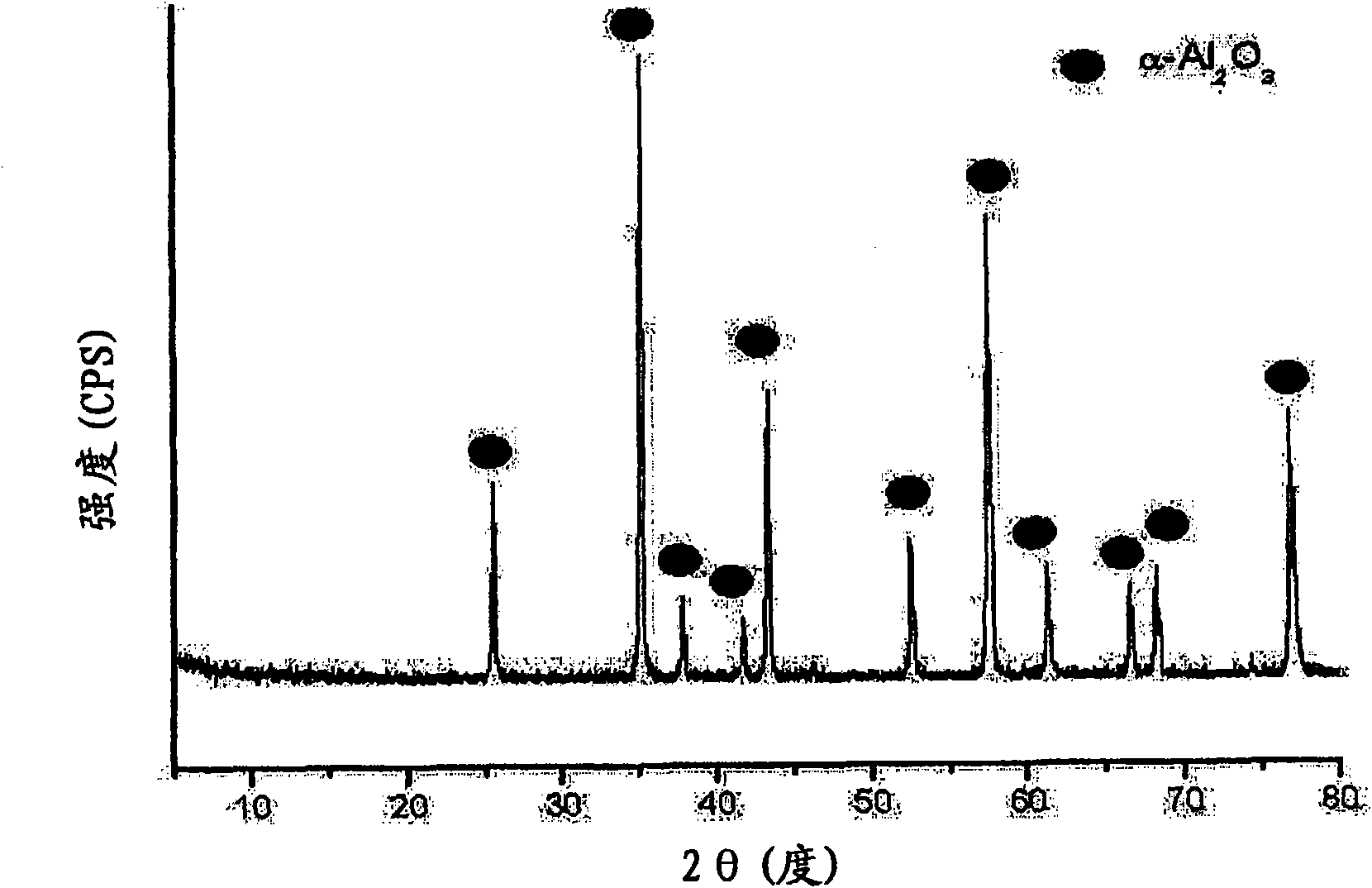

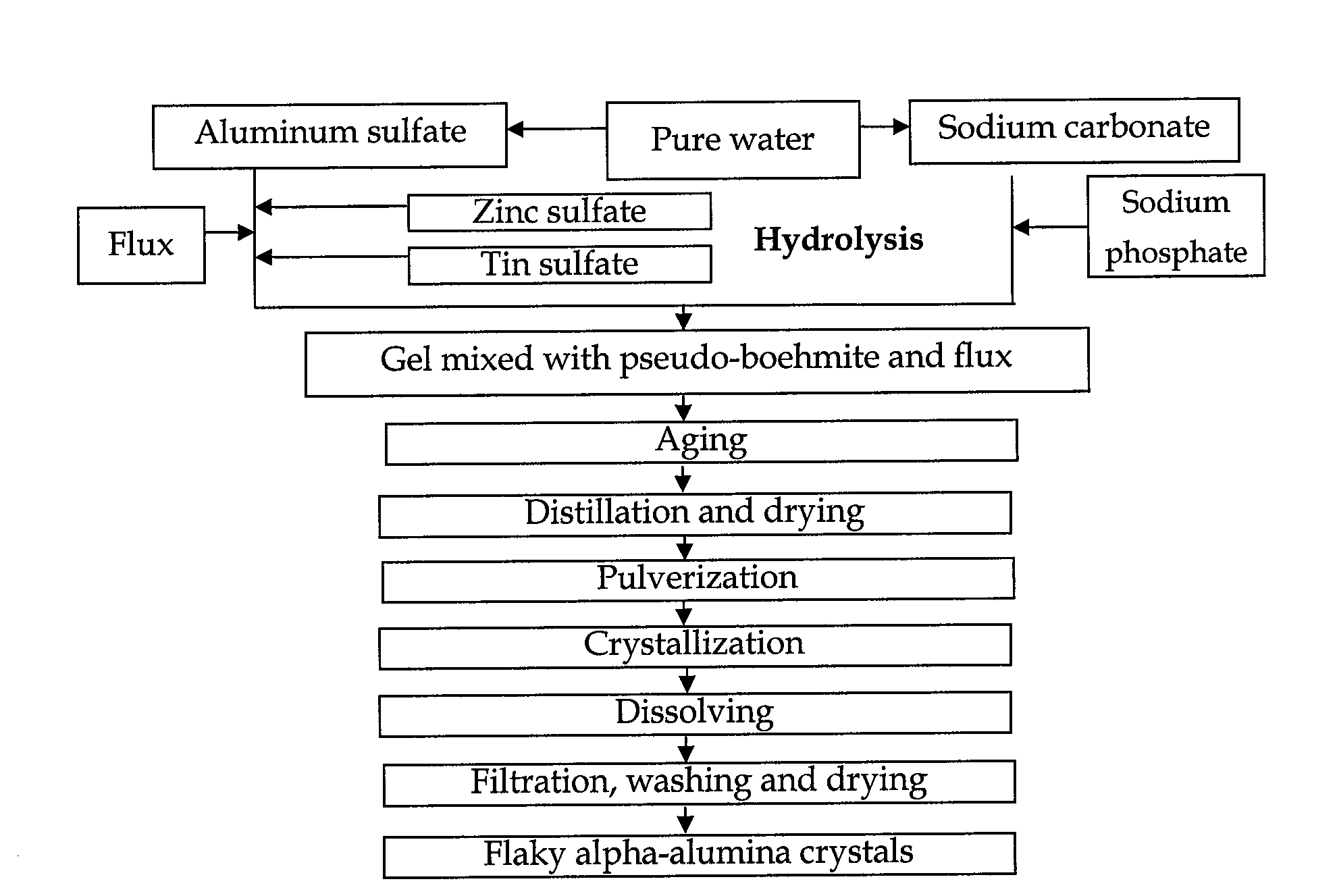

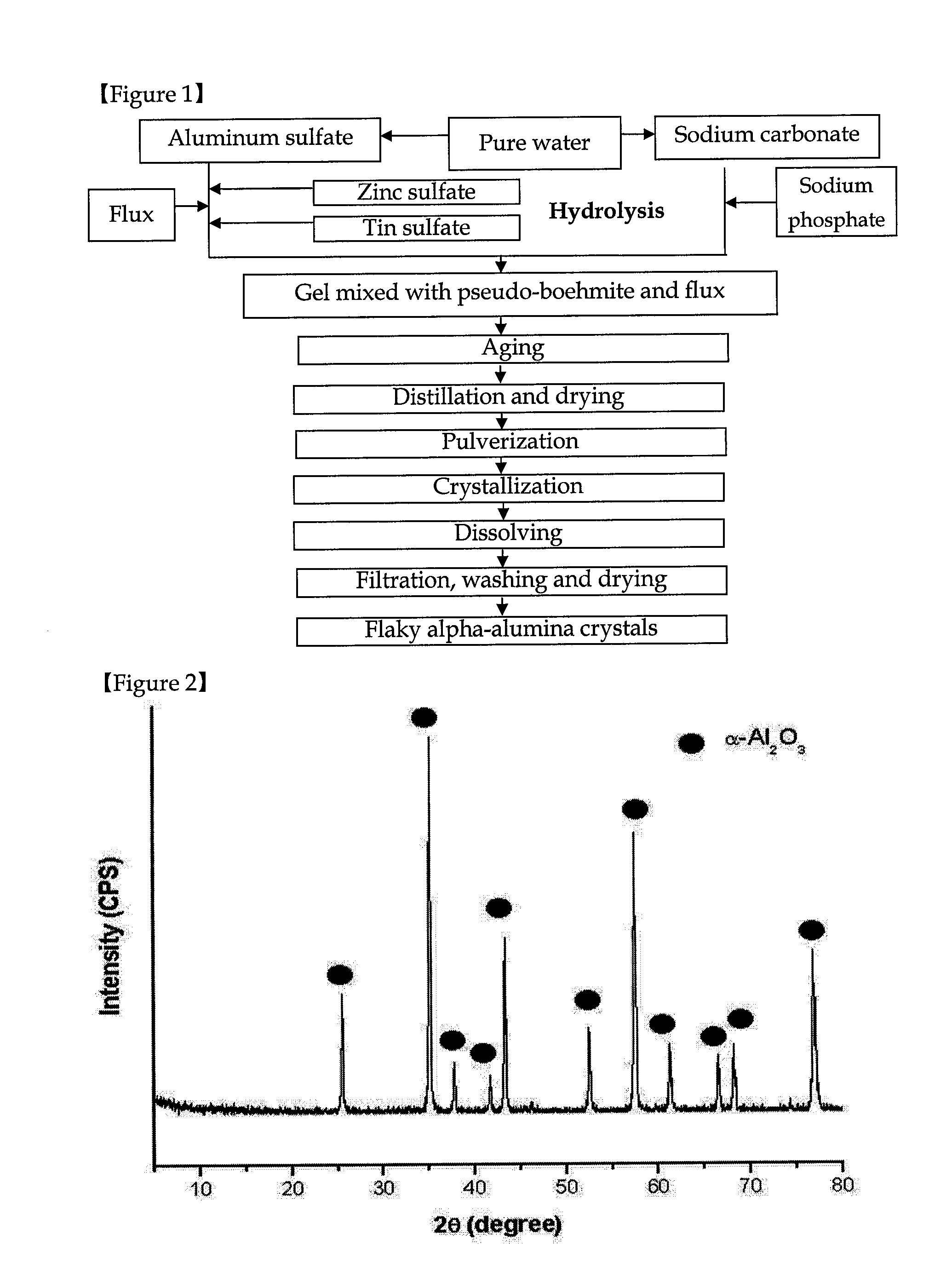

Flaky alpha-alumina crystals with large aspect ratio and a preparation method of the same

The present invention relates to flaky alpha-alumina crystals with large aspect ratio and its preparation method, and particularly to flaky alpha-alumina crystals comprising aluminum oxide, zinc oxide and tin oxide, which are prepared by obtaining a mixed gel which are prepared by obtaining a mixed gel by means of hydrolysis of an aqueous aluminum precursor solution comprising aqueous flux, aqueous zinc precursor solution and tin precursor aqueous solution, followed by aging, drying and crystallization processes. The crystals herein have an average particle thickness of 0.5 [mu]m or less, an average particle diameter of 30 [mu]m or higher and an aspect ratio of 100 or higher, thus being useful as a substrate of high quality pearlescent pigments, an abrasive, ceramic material and a filling material.

Owner:KOREA RES INST OF CHEM TECH +1

Mesoporous aluminas stabilized with rare earth and phosphorous

A mesoporous oxide composition includes, other than oxygen, a major amount of aluminum and lesser amounts of phosphorus and at least one rare earth element. The compositions have high surface area and excellent thermal and hydrothermal stability, with a relatively narrow pore size distribution in the mesoporous range. These compositions may be prepared by a hydrothermal co-precipitation method using an organic templating agent. These mesoporous oxide compositions may be used as catalysts or as supports for catalysts, for example, in a fluid catalytic cracking process.

Owner:EXXON RES & ENG CO

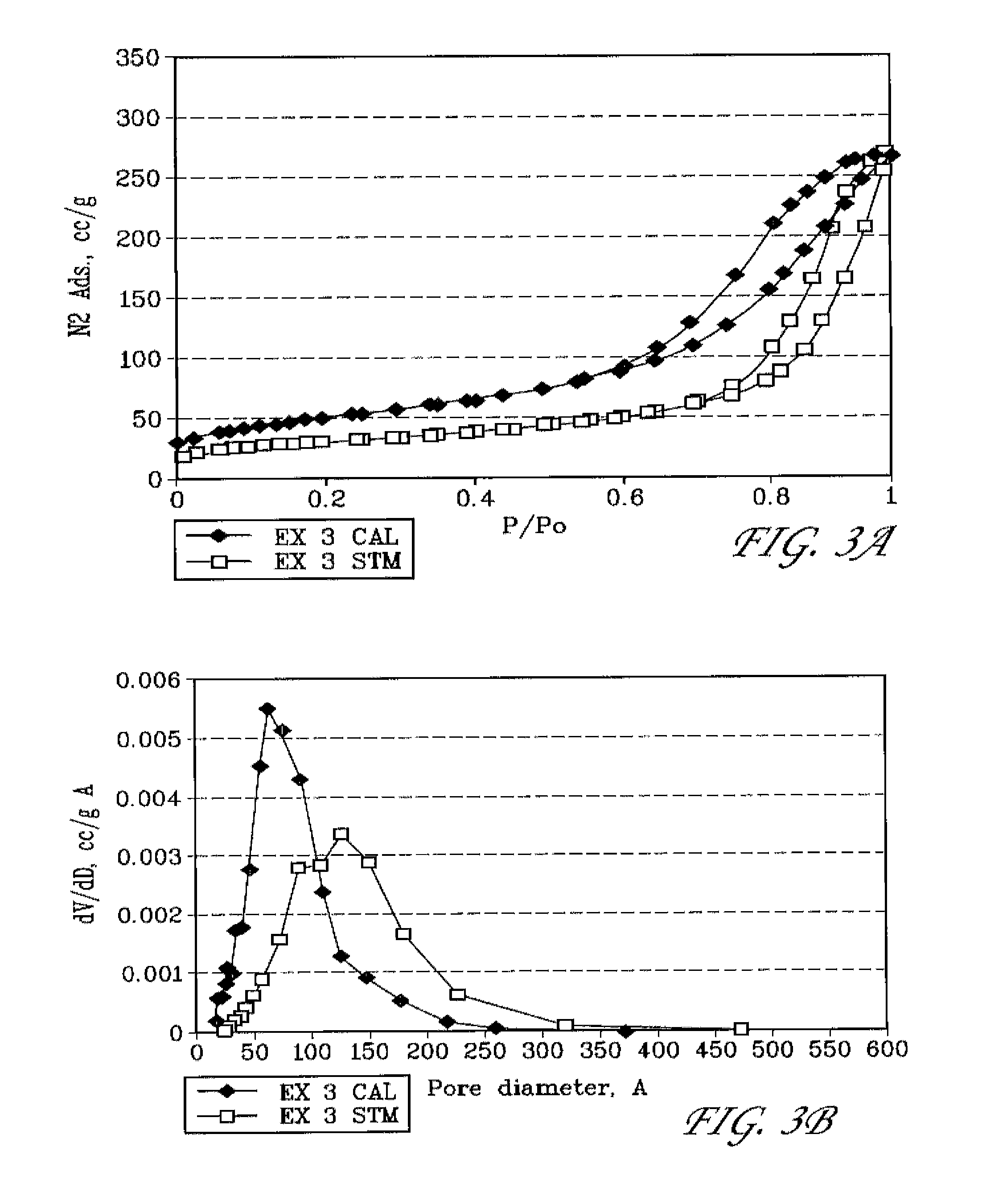

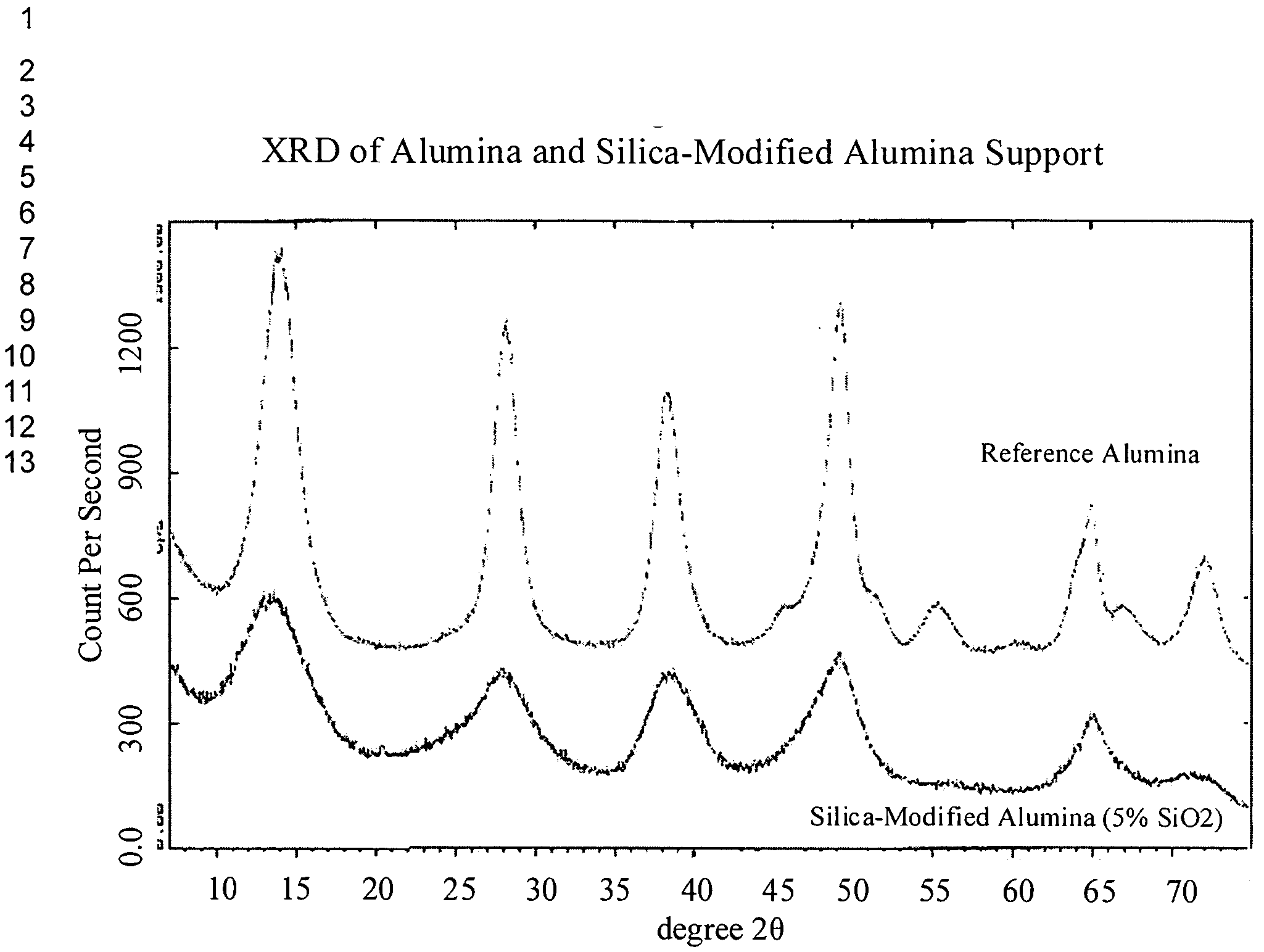

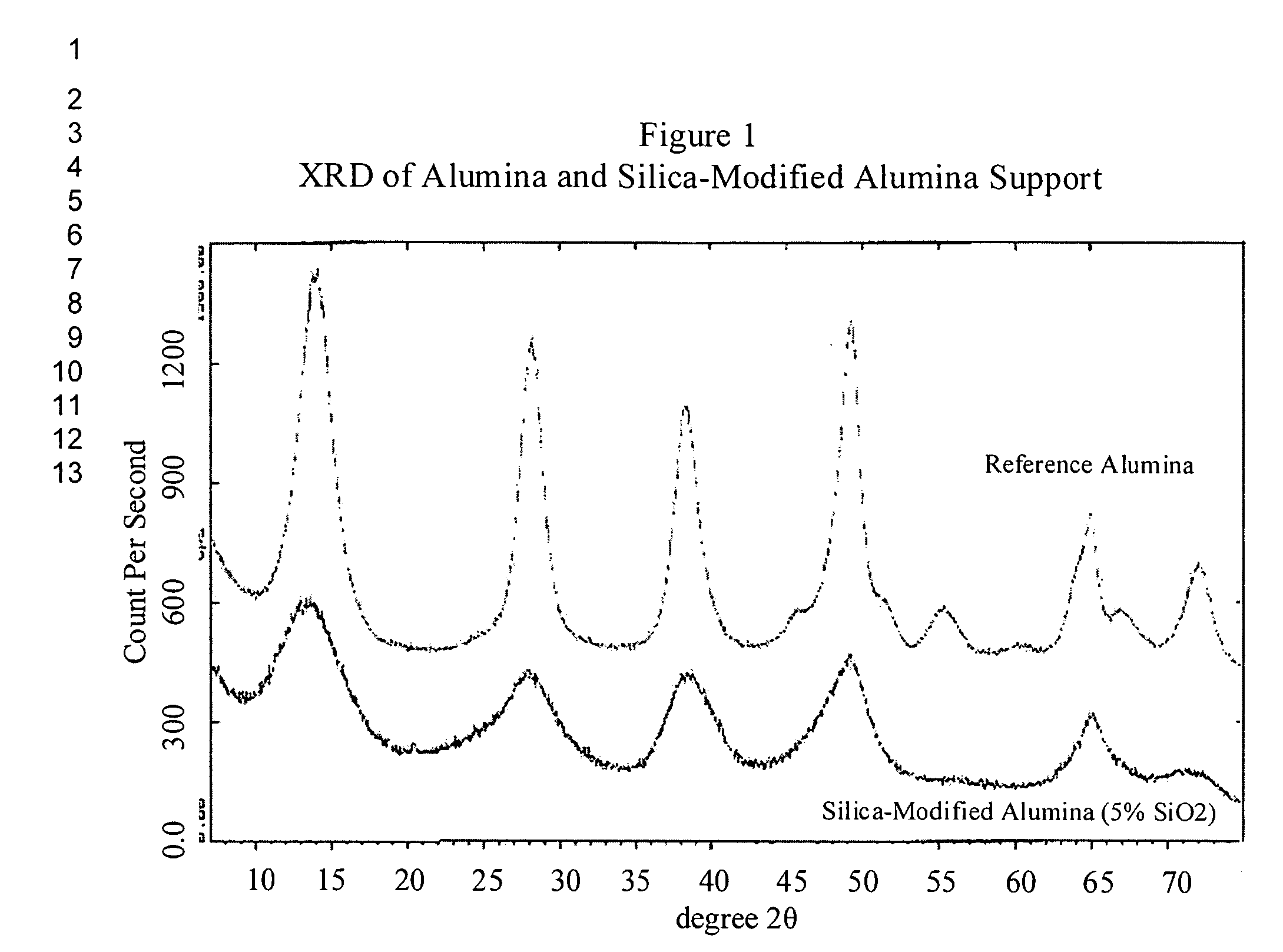

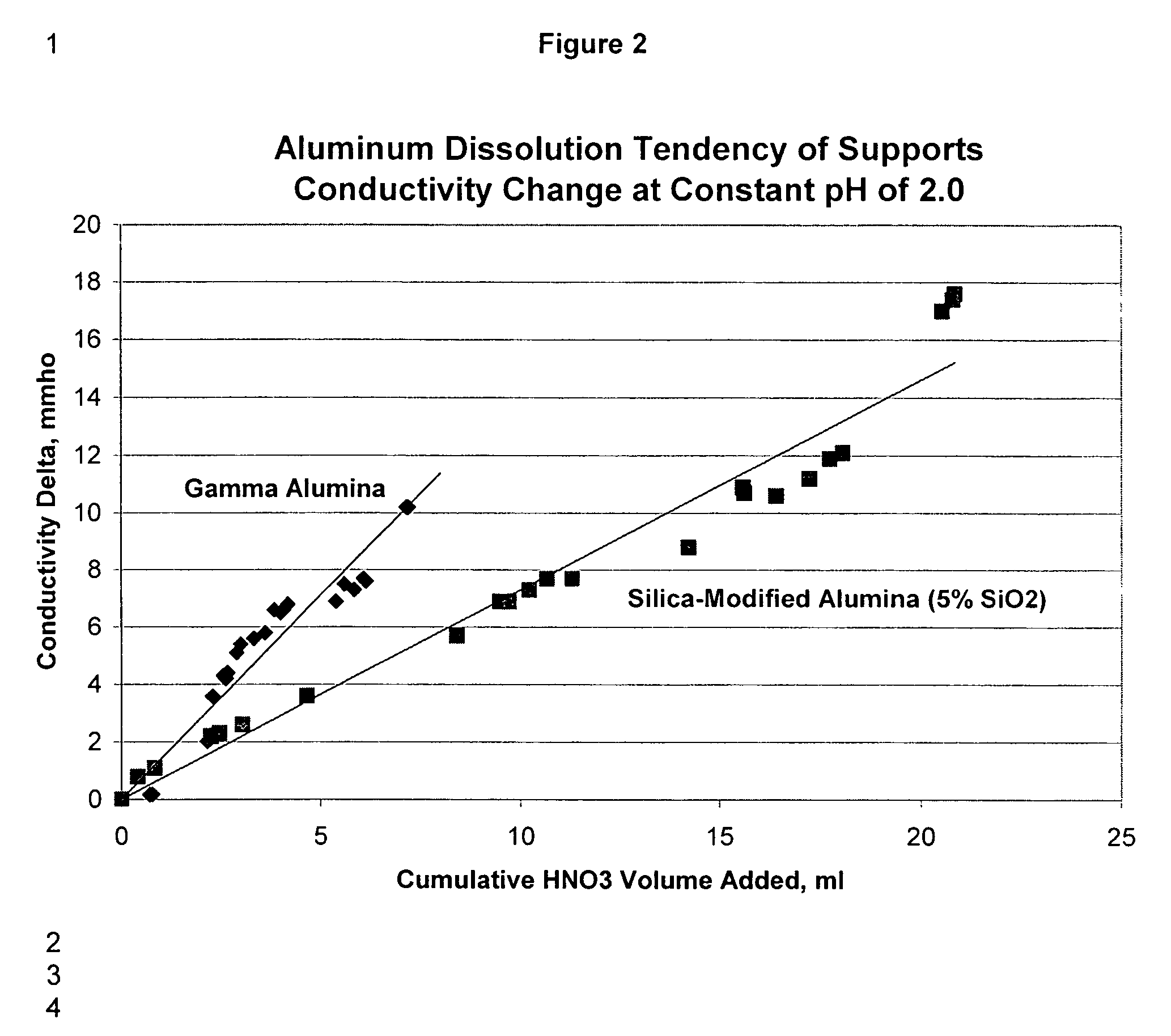

Homogeneous modified-alumina Fischer-Tropsch catalyst supports

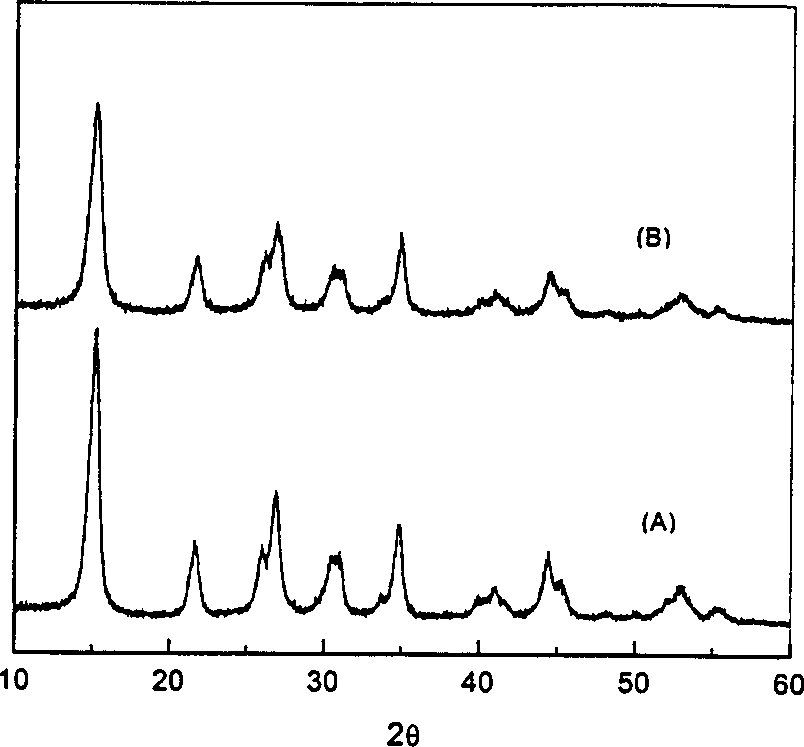

InactiveUS7348293B2Other chemical processesCatalyst activation/preparationHigh resistanceAlkali metal oxide

A homogeneous, amorphous catalyst support comprising a modifying-metal-oxide and a base-metal oxide, the catalyst support having a Surface to Bulk modifying-metal / base-metal atomic ratio of from about 0.6 to about 1.3 and exhibiting an X-ray diffraction having broader line width and lower intensity than is exhibited by the base-metal oxide is disclosed. More specifically, a homogeneous, amorphous silica-modified-alumina catalyst support useful in the Fischer-Tropsch process is disclosed. A silica-modified-Alumina catalyst support of the present invention maintains the desirable properties of alumina and exhibits higher resistance to acid than unmodified alumina.

Owner:CHEVROU USA INC

Reinforcing aluminum-based filler and rubber composition Comprising such a filler

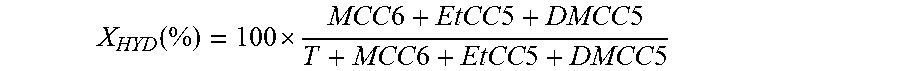

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers): Al(OH)aOb, with 0<a<=3 and b=(3-a) / 2, (I) the specific BET surface area of which is between 30 and 400 nm<2> / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10<-3 >mum<-1> / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

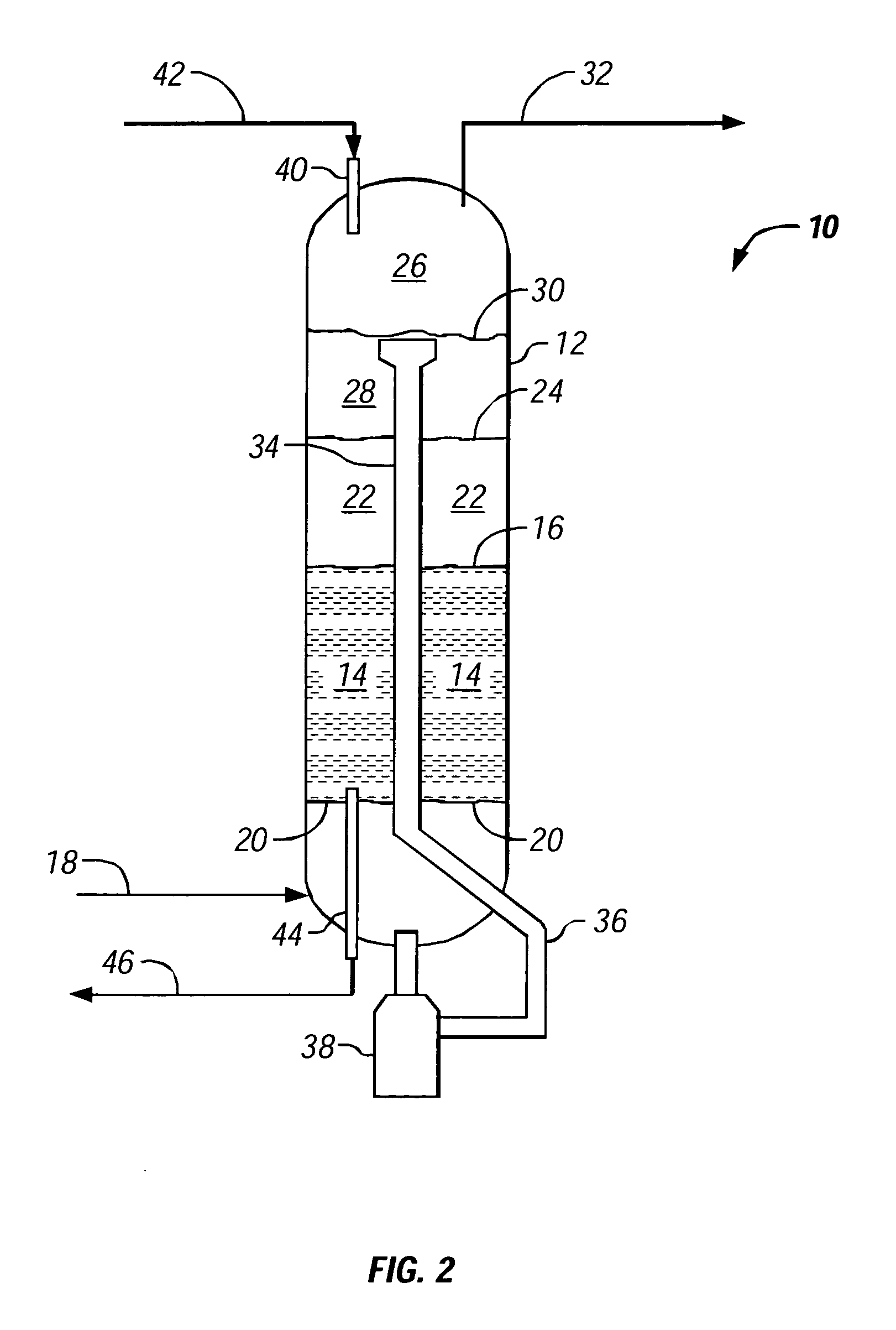

Active phase bimodal commixed catalyst, process for its preparation and use in hydrotreating residue

InactiveUS20170120229A1Reduce manufacturing costCatalyst activation/preparationAluminium hydroxide preparationHydrogenOxide matrix

A hydroconversion catalyst with a bimodal pore structure:an oxide matrix predominantly of calcined aluminium;a hydro-dehydrogenative active phase of at least one group VIII metal being at least partly commixed within the said oxide matrix mainly made up of calcined aluminium, an SBET specific surface greater than 100 m2 / g, a mesoporous median diameter in volume between 12 and 25 nm inclusive, a macroporous median diameter in volume between 250 and 1500 nm inclusive, a mesoporous volume as measured by mercury intrusion porosimeter greater than or equal to 0.55 ml / g and a total measured pore volume by mercury porosimetry greater than or equal to 0.70 ml / g;a method for preparing a residue catalyst for hydroconversion / hydroprocessing by commixing the active phase with a particular alumina,the use of the catalyst in hydroproces sing, including hydroproces sing heavy feeds.

Owner:INST FR DU PETROLE

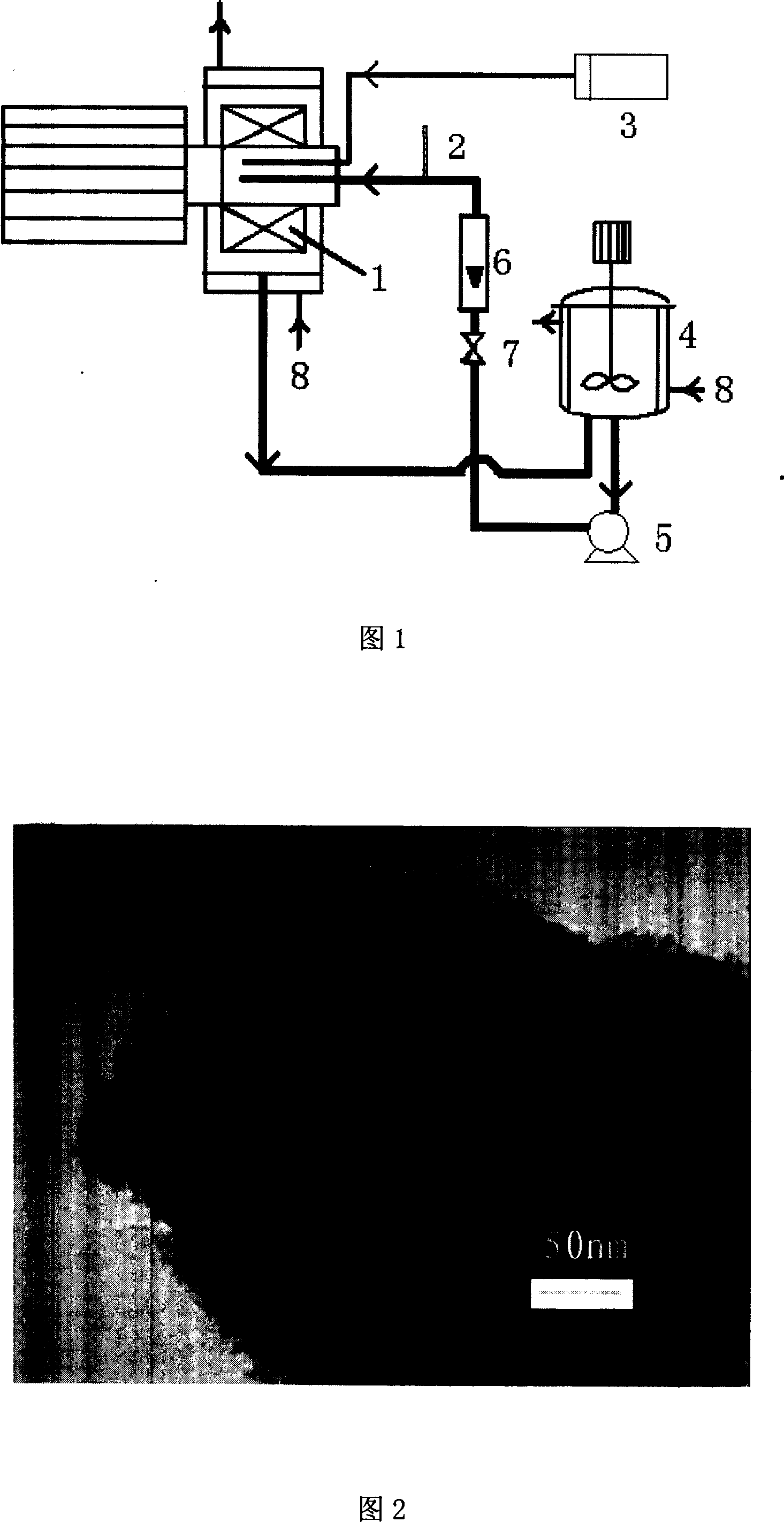

Method for preparing ordered mesoporous aluminium oxide

InactiveCN101024503AGood dispersionUniform shapeAluminium oxide/hydroxide preparationAluminium hydroxide preparationSalt solutionMaterials science

The invention relates to a manufacturing method for ordered medium aperture alumina that includes the following steps: adding surface activator into inorganic aluminum salt as template agent, making precipitant solution, adding inorganic aluminum salt solution into hypergravity reactor, adding precipitant, when the reacting solution reaching a certain pH value, the precursor sol would be gained; taking aging, filtering, washing, and drying to the precursor sol to gain precursor powder. The powder could be made into ordered medium aperture alumina after taking sintering. The invention has the advantages of simple technology, safe to operate, low cost, etc. The specific surface of the product reaches 250-300m2 / g, and the shape has certain orderliness. It has crucial application value in adsorption and catalyzing process.

Owner:BEIJING UNIV OF CHEM TECH

Process for producing metal oxide flakes

InactiveUS20070243337A1Material nanotechnologyPigment preparation by wet methodsDielectric layerMaterials science

The present invention relates to a process for the preparation of a plane-parallel structure (a platelet-shaped body, or flake), comprising at least one dielectric layer consisting of oxides of one or more metal selected from groups 3 to 15 of the periodic table, which method comprises: (a) optionally applying a layer of release material on a substrate, (b) applying a composition comprising one or more precursors of one or more desired metal oxides to said release layer, or directly to a substrate with no layer of release material, (c) subjecting the one or more precursors of one or more desired metal oxides to microwave radiation to form a metal oxide layer on the substrate or on the layer of release material; and (d) separating the resulting metal oxide layer from the substrate as plane-parallel structures.

Owner:BASF AG

Method for producing ceramic nanoparticles

ActiveUS20110015054A1Improve production efficiencyIncrease in sizeMaterial nanotechnologyAlkaline earth titanatesMetallurgyNanoparticle

The invention provides a method for producing ceramic nanoparticles, which comprises hydrolyzing a ceramic material in a thin film fluid formed between processing surfaces arranged to be opposite to each other so as to be able to approach to and separate from each other, at least one of which rotates relative to the other.

Owner:M TECHN

Process for preparing active aluminium oxide

InactiveCN1425612AUniform temperatureUniform concentrationAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The present invention relates to the preparation process of active gamma-Al2O3. The mixed water solution of materials including aluminum chloride, ammonia water, pore expander ammonium oxalate or ammonium citrate, etc. is heated and concentrated to produce aluminum hydroxide precipitate; the precipitate is dried and heated to obtain solid powder and to decompose its NH4Cl, which is recovered from hot gas flow through cooling and crystallization; and the solid powder is roasted at 400-800 deg.c for 3-6 hr to convert into gamma-Al2O3. The present invention produces aluminum hydroxide through evaporation and concentration, rather than neutralization, and aluminium hydroxide is precipitated and separated in a stable and balanced solid-liquid state, and this is favorable to producing aluminium hydroxide grains with homogeneous size.

Owner:XIAMEN UNIV

Method for preparing hydrated alumina

ActiveCN103043694AIncrease spawn rateSmall particle sizeAluminium hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateHydrated alumina

The invention discloses a method for preparing hydrated alumina. The method comprises the following process that: (1) bottom water is added into a neutralization reactor and is heated to 50-95 DEG C, an acid aluminium salt water solution is added at the same time so as to control the pH value between 2 and 4, and the pH value is stabilized for a while; (2) the acid aluminium salt water solution and alkali metal aluminate (or alkaline precipitator) solution to regulate the pH value between 6 and 8, and the pH value is stabilized for a while; the alkaline precipitator solution (or the alkaline precipitator solution) is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; (4) the acid aluminium salt water solution is added to regulate the pH value to be between 2 and 4, and the pH value is stabilized for a while; (5) the alkaline precipitator solution or the alkaline precipitator solution is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; the steps (4) and (5) are repeated for 1-4 times; (7) after gelatinizing is completed, aging, filtering, washing and drying are carried out to obtain the hydrated alumina; and the steps (1)-(3) are carried out under the action of ultrasonic waves, and the frequencies of the ultrasonic waves are10-80 kHZ. The hydrated alumina which is prepared through the method is distributed in a centralized manner and has high crystallinity and large pore volumes and pore diameters.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing alumina powder with high sinter activity

InactiveCN1369434AImprove sintering performanceLow costAluminium hydroxide preparationAluminium chlorideInorganic salts

A process for preparing alumine powder with high sinter activity includes reaction of Al-contained inorganic salt chosen from aluminium nitrate, aluminium chloride and aluminium ammonium sulfate on ammonium bicarbonate at 5-50 deg.C to generate NH4Al(OH)2CO3, depositing and ageing for 2-24 hrs, washing with deionized water, baking at 50-150 deg.C and sintering at 1100-1200 deg.C to obtain alpha-Al2O3 particles less than 400 nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

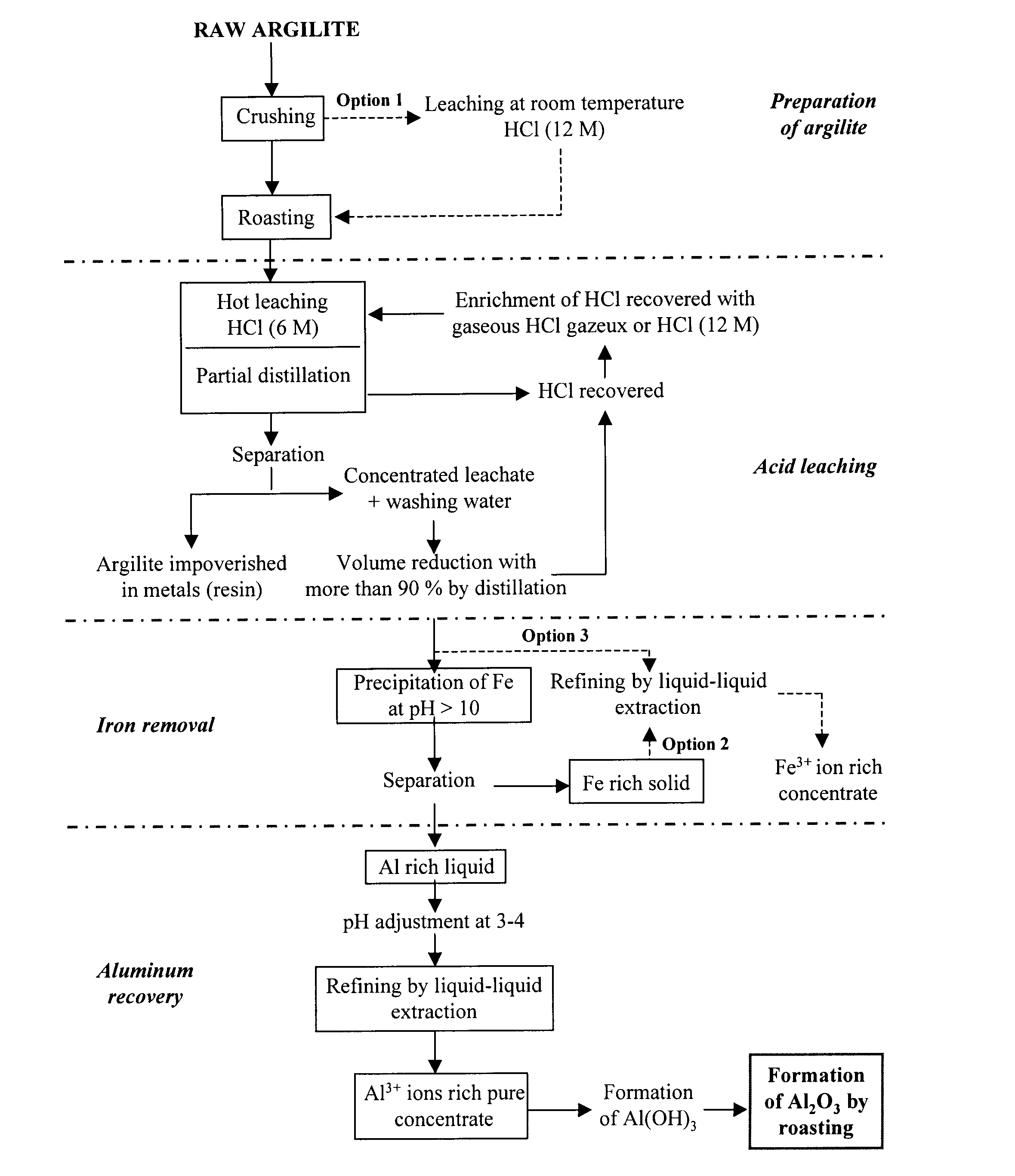

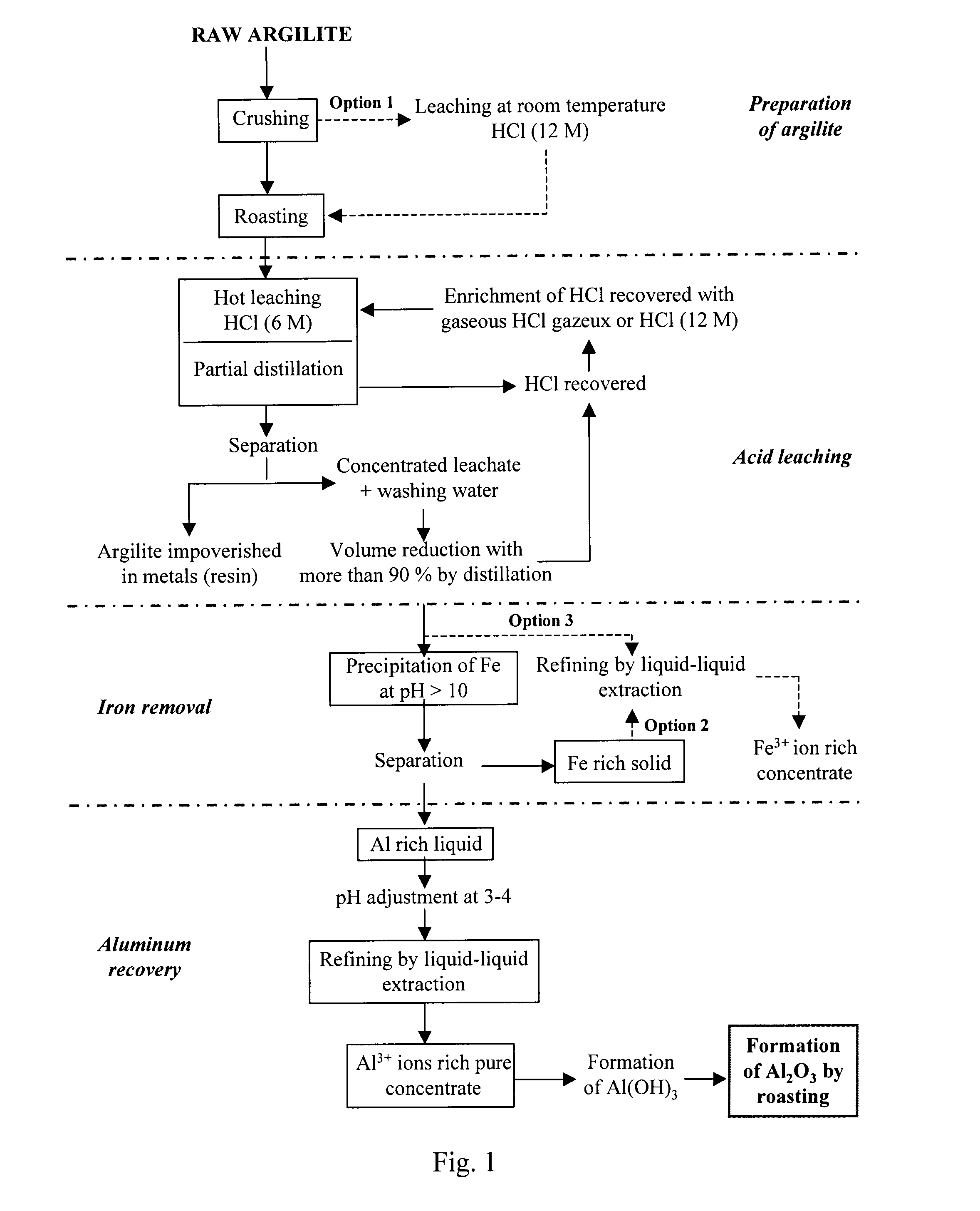

Processes for extracting aluminum and iron from aluminous ores

Owner:ORBITE ALUMINAE INC

Method of preparing good dispersion and high-purity ultra-fine alpha-Al2O3

InactiveCN1919737AGood dispersionUniform particle size distributionAluminium hydroxide preparationAluminium oxides/hydroxidesAlcoholUltra fine

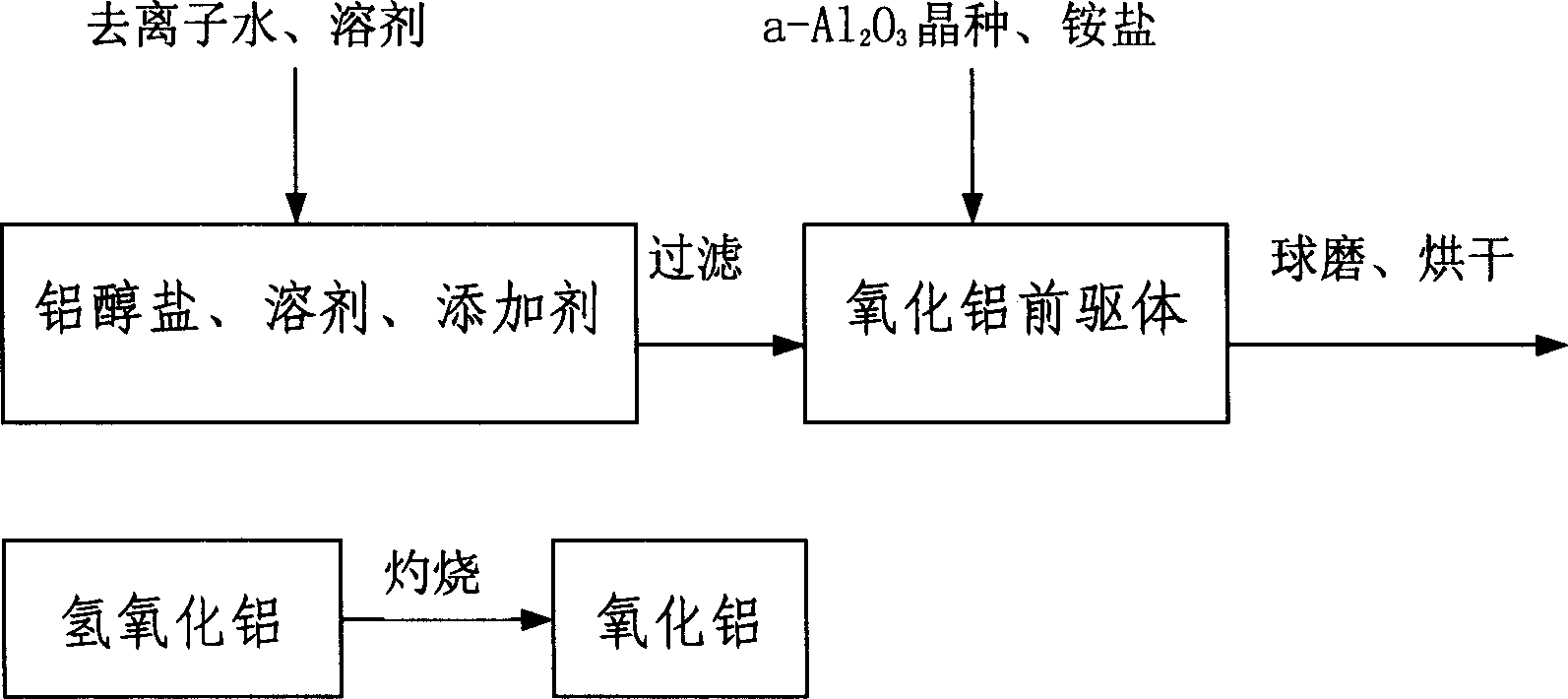

The invention discloses a preparing method of excellent dispersing high-pure ultra-fine alpha-Al2O3, which comprises the following steps: adopting analytic pure aluminium-alcohol salt hydrating reaction; balling; drying; sintering; adding one carboxyl acid or surface activator in the dehydrating course; adding alpha-Al2O3 seed and additive ammonium salt in the balling course.

Owner:DALIAN LUMING SCI & TECH GROUP

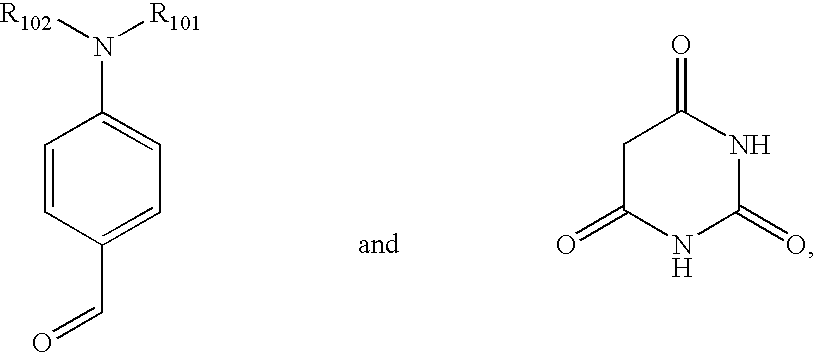

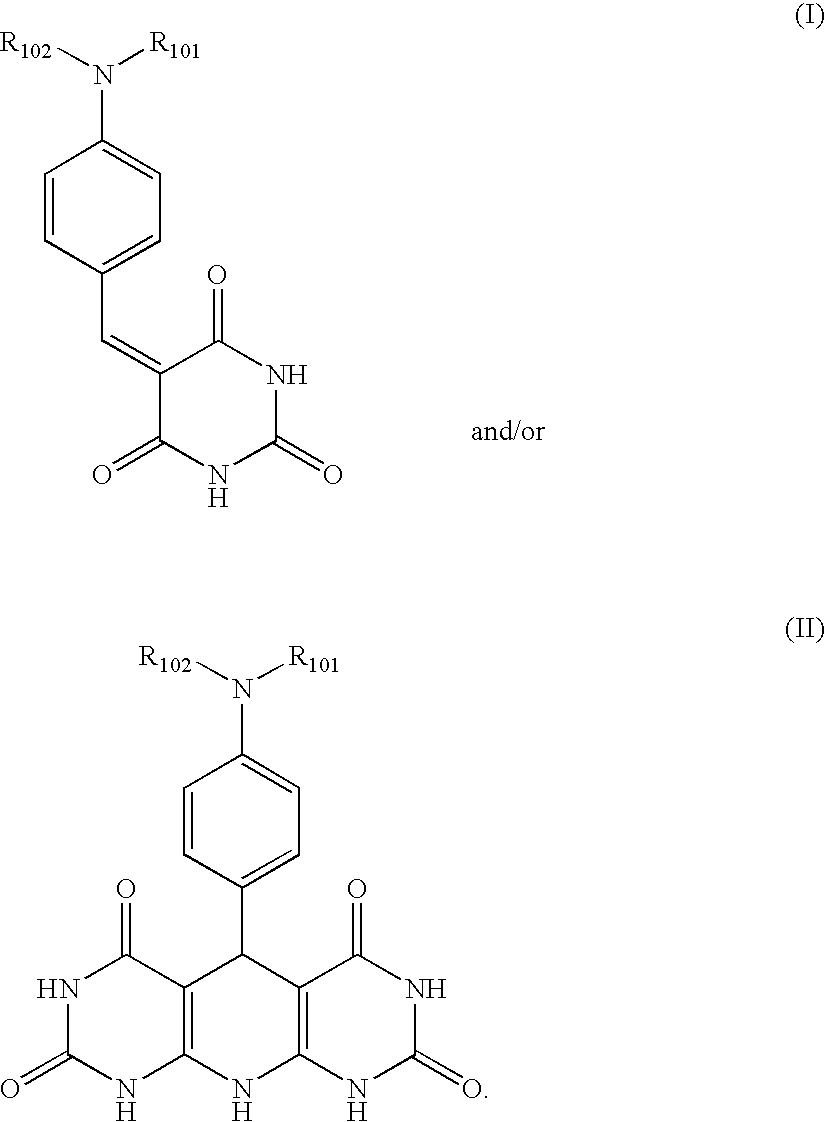

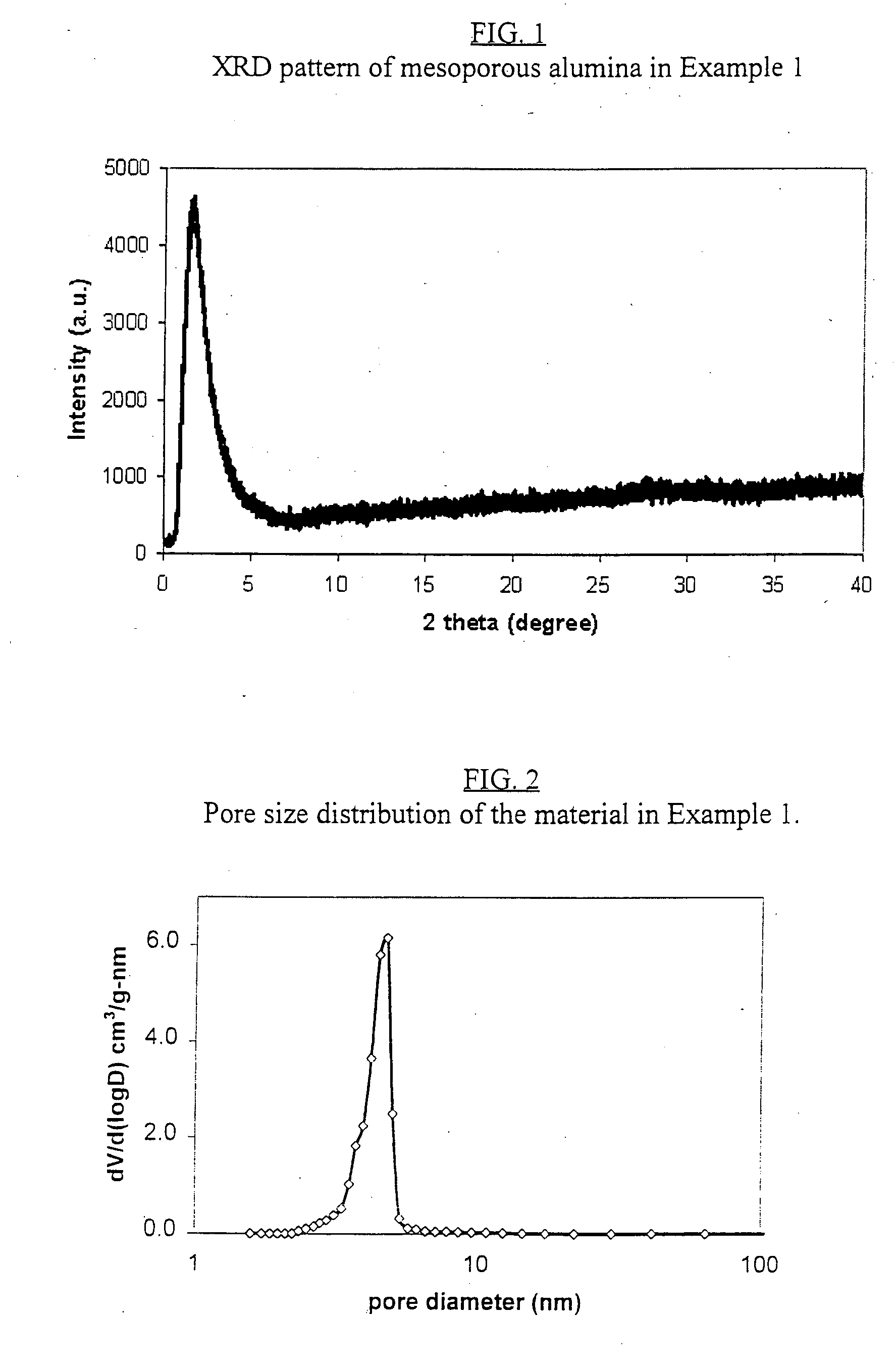

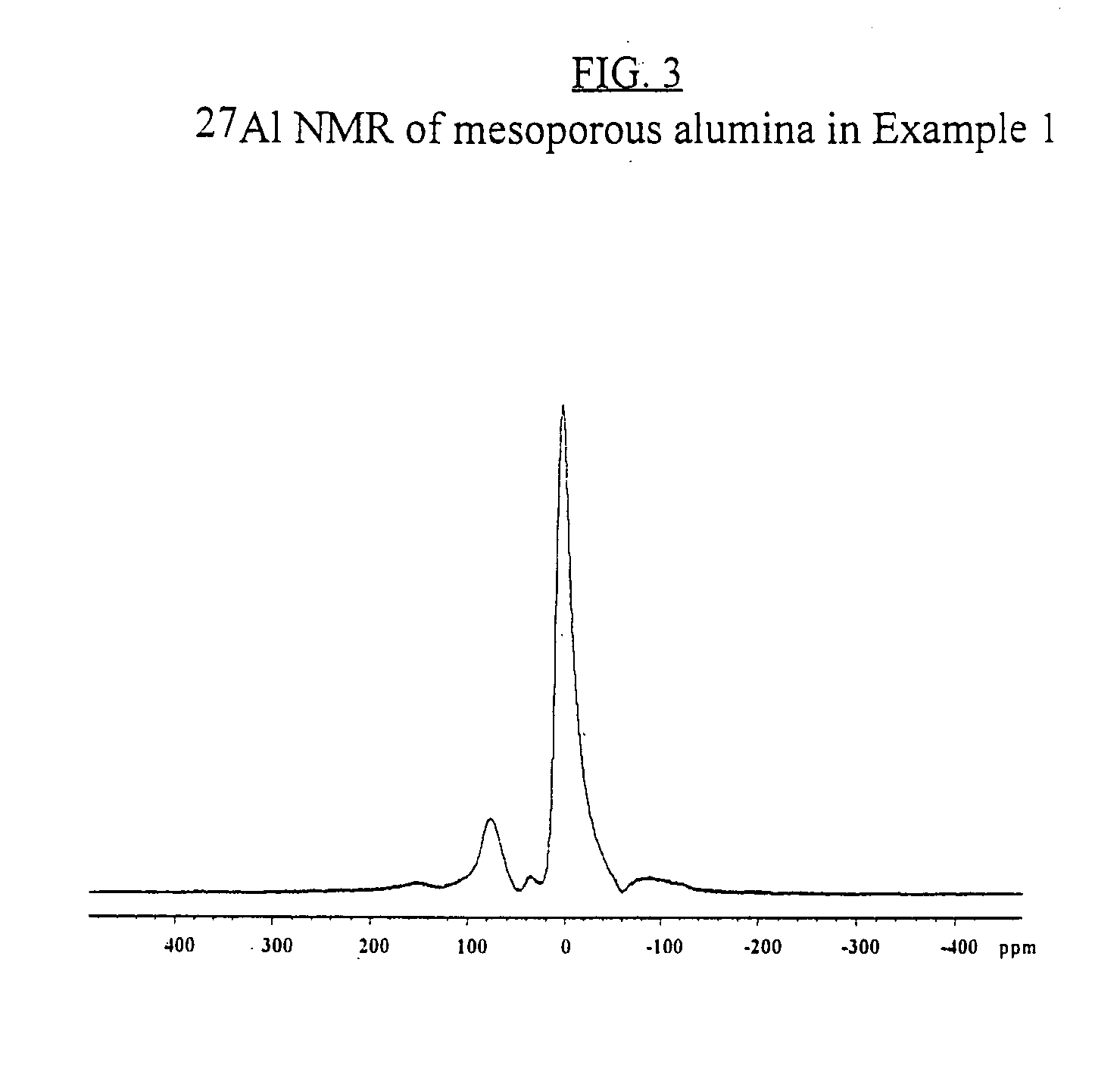

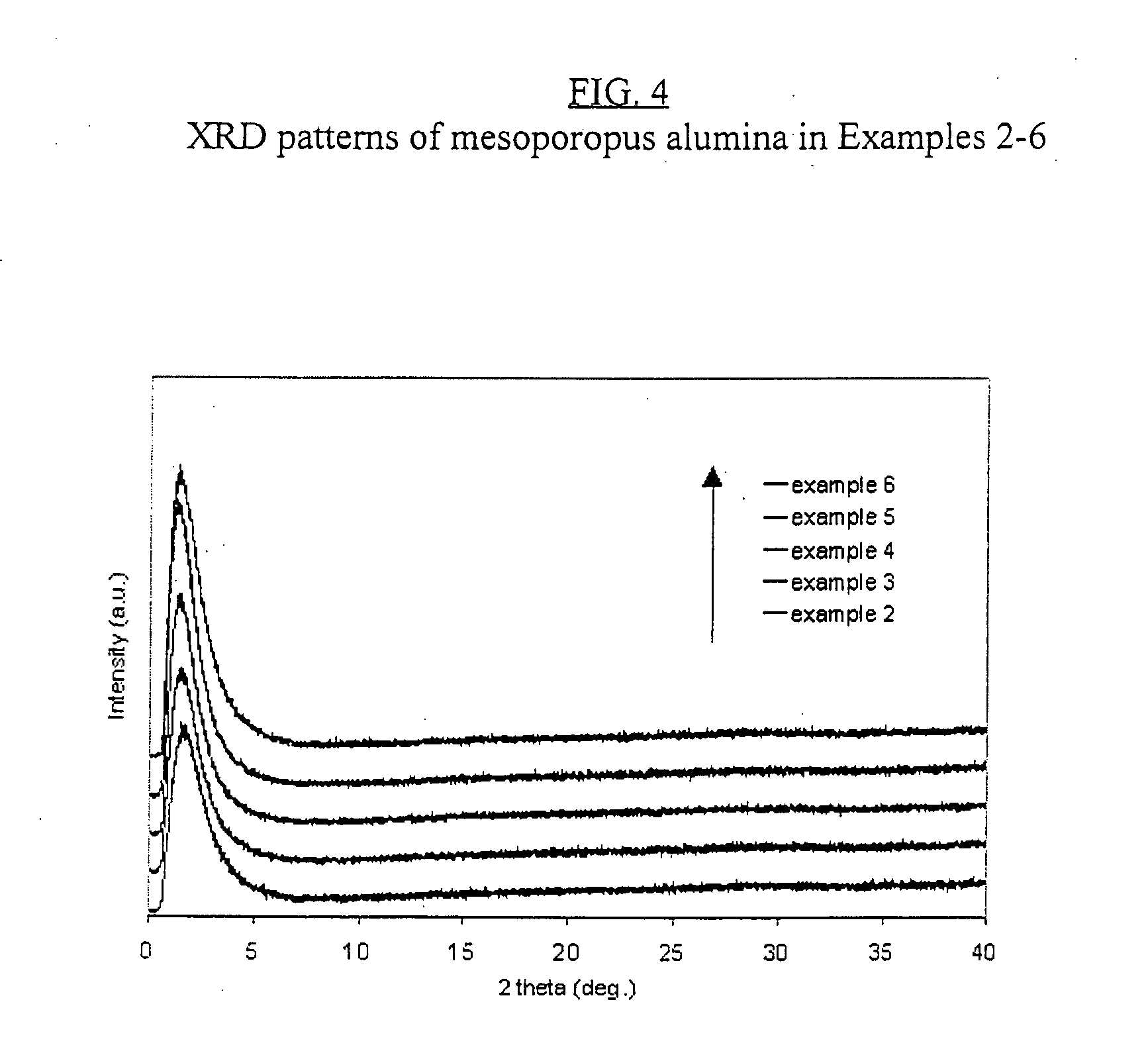

Mesoporous aluminum oxide, preparation and use thereof

InactiveUS20070170096A1Cost-effectiveEasy to operateHydrogenCatalytic naphtha reformingSteam reformingCatalytic reforming

Mesoporous aluminum oxides with high surface areas have been synthesized using inexpensive, small organic templating agents instead of surfactants. Option-ally, some of the aluminum can be framework-substituted by one or more other elements. The material has high thermal stability and possesses a three-dimensionally randomly connected mesopore network with continuously tunable pore sizes. This material can be used as catalysts for dehydration, hydrotreating, hydrogenation, catalytic reforming, steam reforming, amination, Fischer-Tropsch synthesis and Diels-Alder synthesis, etc.

Owner:LUMMUS TECH INC

Method for producing alpha-alumina powder

A method for producing α-alumina powder is described. The method comprises the steps of removing water from a compound containing the following (1), (2), (3) and (4), and calcining the results: (1) α-alumina precursor, (2) seed crystal, (3) water, (4) nitrate ion in an amount of from 2.8 to 3.3 mol per mol of aluminum (Al) contained in the α-alumina precursor and the seed crystal.

Owner:SUMITOMO CHEM CO LTD

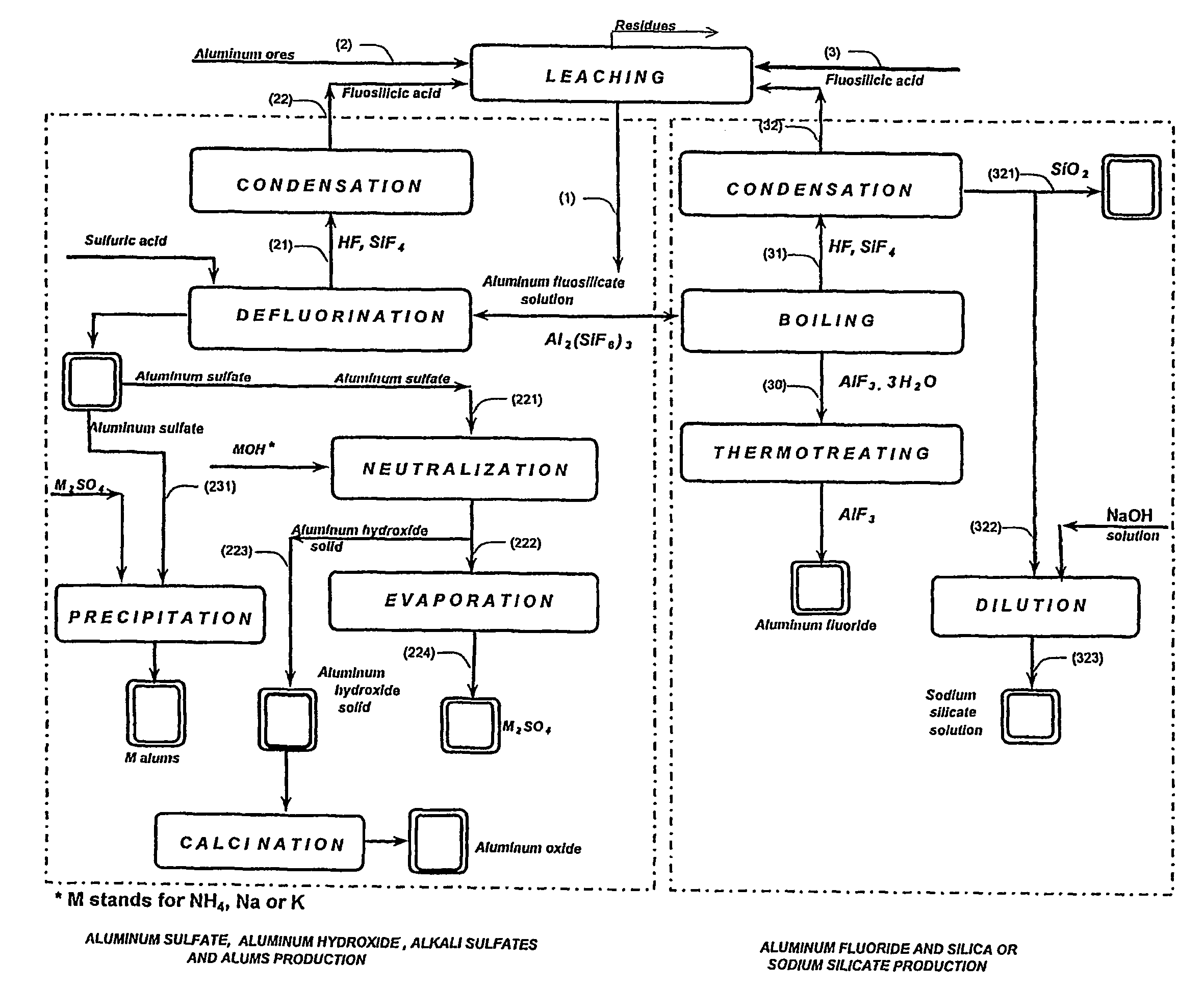

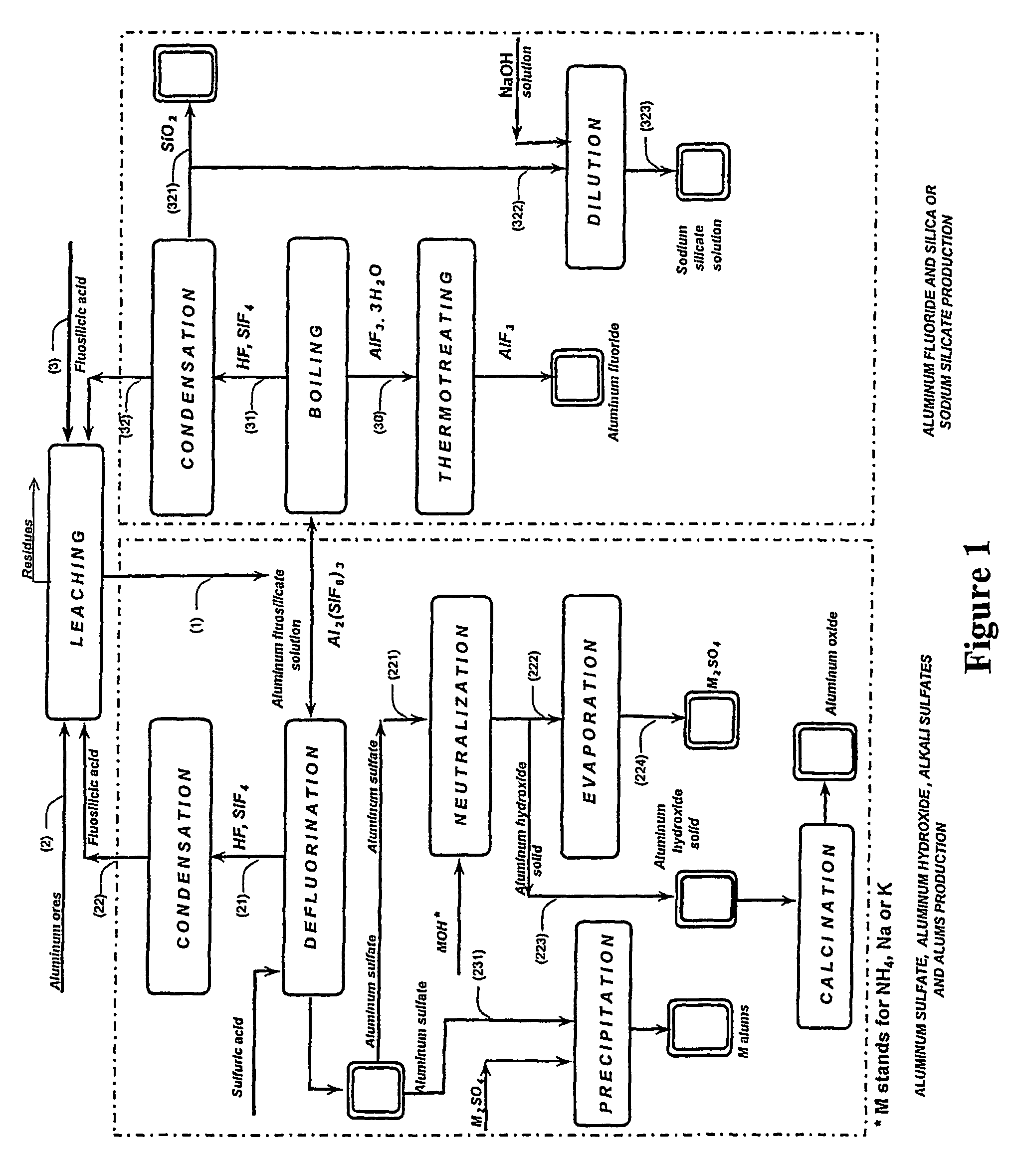

Production of aluminum compounds and silica from ores

A method for the production of inorganic aluminum substances and amorphous silica from aluminum oxide containing ores, comprising: (a) leaching of said ores with fluorosilicic acid to obtain aluminum fluosilicate solution; (b) filtering said leached solution from insoluble materials; and (c) washing said insoluble materials.

Owner:ATI ALUMINUM TECH ISRAEL

Flaky alpha-alumina crystals with large aspect ratio and a preparation method of the same

ActiveUS20100015445A1High aspect ratioOvercome problemsPigmenting treatmentSynthetic resin layered productsHydrolysisTin

The present invention relates to flaky alpha-alumina crystals with large aspect ratio and its preparation method, and particularly to flaky alpha-alumina crystals comprising aluminum oxide, zinc oxide and tin oxide, which are prepared by obtaining a mixed gel which are prepared by obtaining a mixed gel by means of hydrolysis of an aqueous aluminum precursor solution comprising aqueous flux, aqueous zinc precursor solution and tin precursor aqueous solution, followed by aging, drying and crystallization processes. The crystals herein have an average particle thickness of 0.5 um or less, an average particle diameter of 30 μm or higher and an aspect ratio of 100 or higher, thus being useful as a substrate of high quality pearlescent pigments, an abrasive, ceramic material and a filling material.

Owner:KOREA RES INST OF CHEM TECH +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com