Method for preparing ordered mesoporous aluminium oxide

An ordered mesoporous and alumina technology, applied in the direction of aluminum hydroxide preparation, alumina/hydroxide preparation, chemical/physical/physicochemical mobile reactors, etc., to achieve large specific surface area, rapid microscopic mixing, and operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A. With the 0.6mol / l aluminum nitrate solution of 2200ml preparation, add the polyethylene glycol of 0.9g as templating agent;

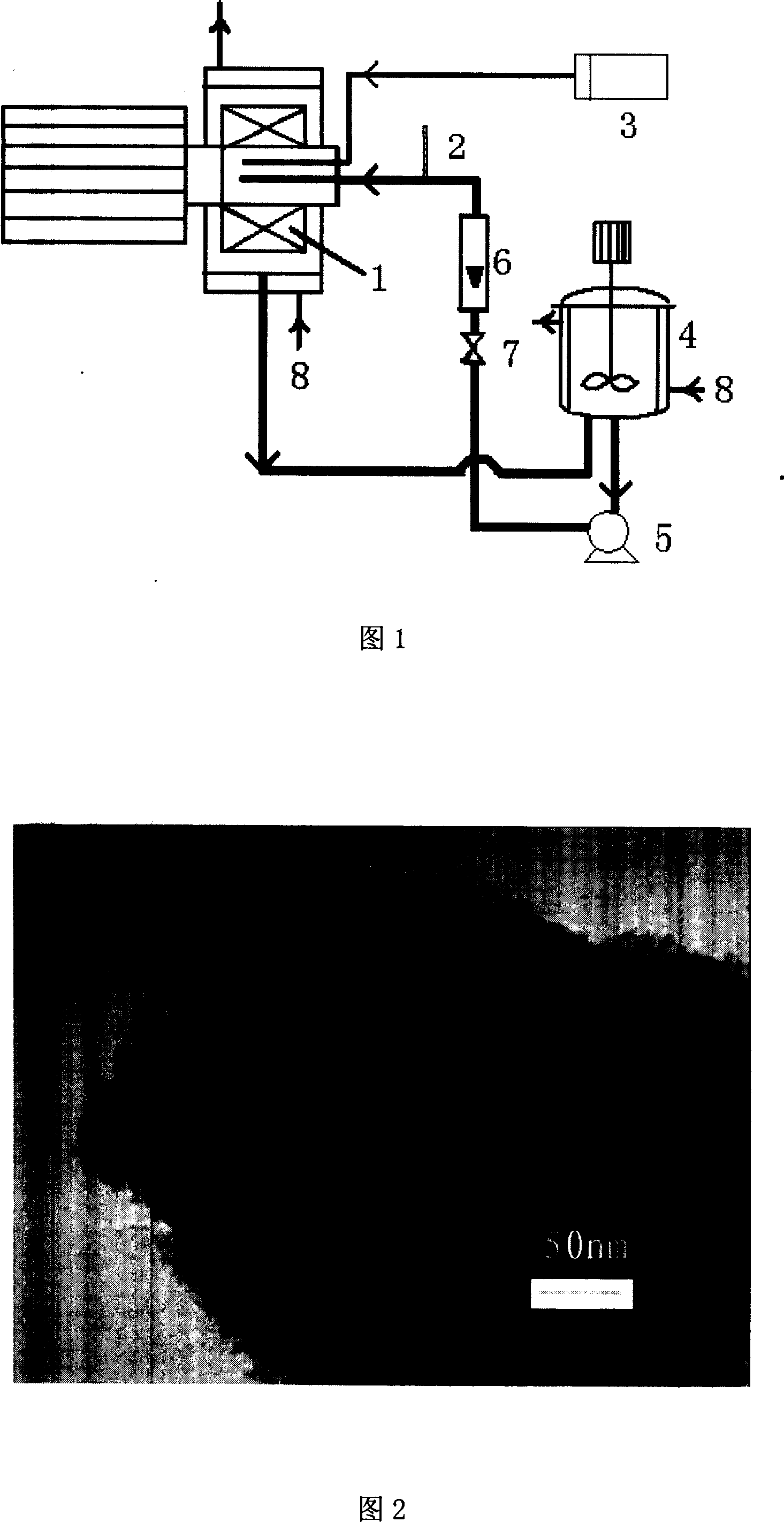

[0049] B. After dissolving, add it to the supergravity reactor (as shown in Figure 1), maintain the supergravity level at 140g, and the reaction temperature is 70°C, and add 1650ml / l of 0.6mol / l ammonium carbonate at a rate of 8ml / min solution, when the pH value at the end of the reaction reaches 7, an alumina hydrate sol is obtained.

[0050] C. Aging the obtained alumina hydrate sol at 70°C for 6 hours. The aged alumina hydrate sol is filtered by a vacuum pump, and the filter cake is washed with water for 2-3 times, and dried at 80°C to obtain aluminum hydrate powder.

[0051] D. Calcining the obtained alumina hydrate powder, the specific calcination process is: under the protection of nitrogen, the temperature is raised to 330°C at a speed of 3°C / min, and maintained for 3 hours, and then the temperature is raised to 550°C at a speed of 3°C...

Embodiment 2

[0054] A. With the 0.1mol / l aluminum nitrate solution of 2200ml preparation, add the polyethylene glycol of 0.9g as templating agent;

[0055] Other steps are with embodiment 1.

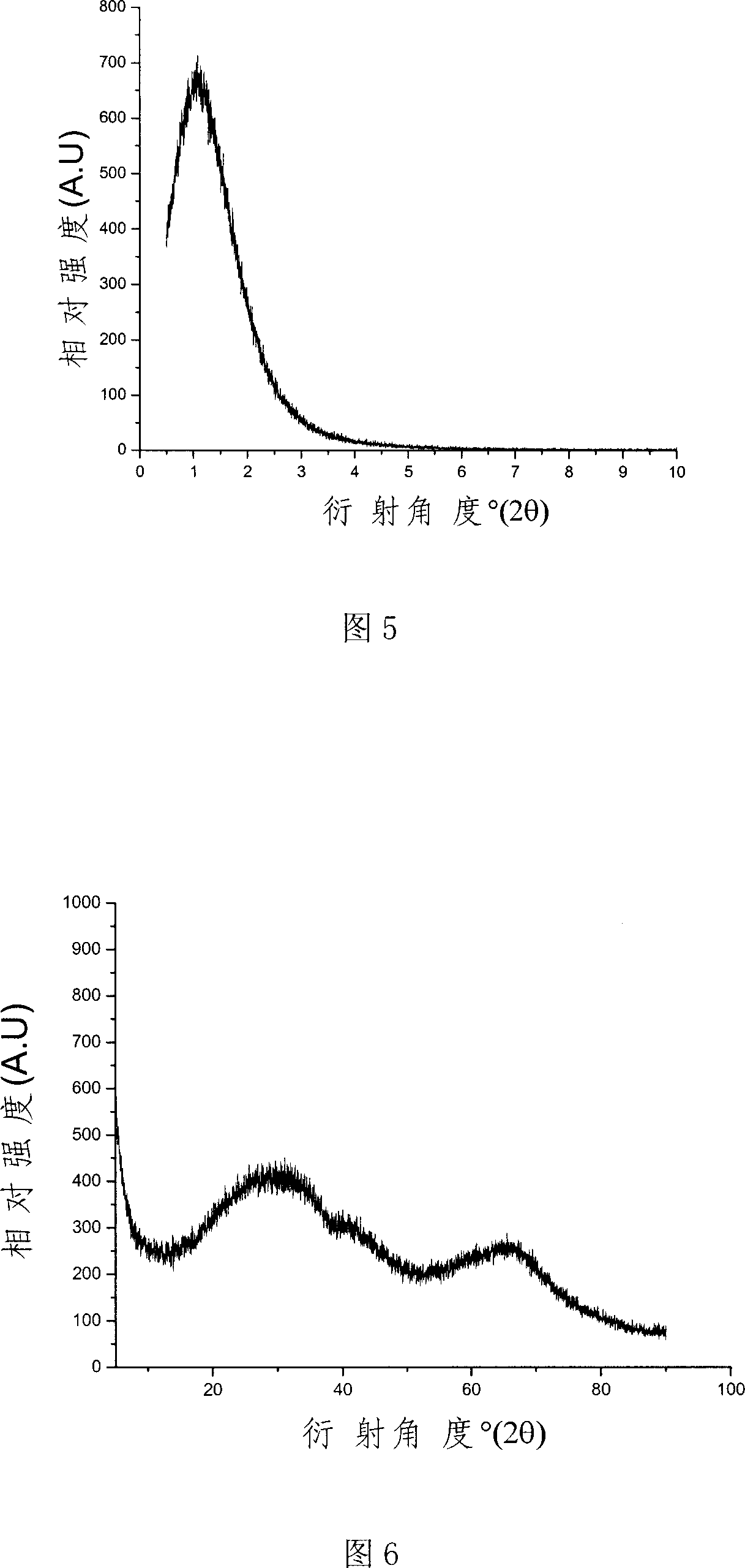

[0056] The prepared alumina has a specific surface area of 254m 2 / g, the pore volume is 0.28cm 3 / g, the pore size is 4.7nm. Through nitrogen isotherm adsorption-desorption curve analysis (shown in Figure 7), the adsorption curve is a VI-type curve, and Figure 8 shows that the pore size distribution is narrowed, indicating that its order is enhanced.

Embodiment 3

[0058] The operation is the same as in Example 1, except that the aging time is 12 hours and the aging temperature is 30°C.

[0059] The prepared alumina has a specific surface area of 301m 2 / g, the pore volume is 0.28cm 3 / g, the pore size is 5.4nm. Through nitrogen isotherm adsorption-desorption curve analysis (shown in Figure 9), the adsorption curve is a VI-type curve, and the obvious H ring becomes larger. Figure 10 shows that the pore size distribution is relatively narrow, and its mesoporous characteristics are obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com