Method of preparing good dispersion and high-purity ultra-fine alpha-Al2O3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

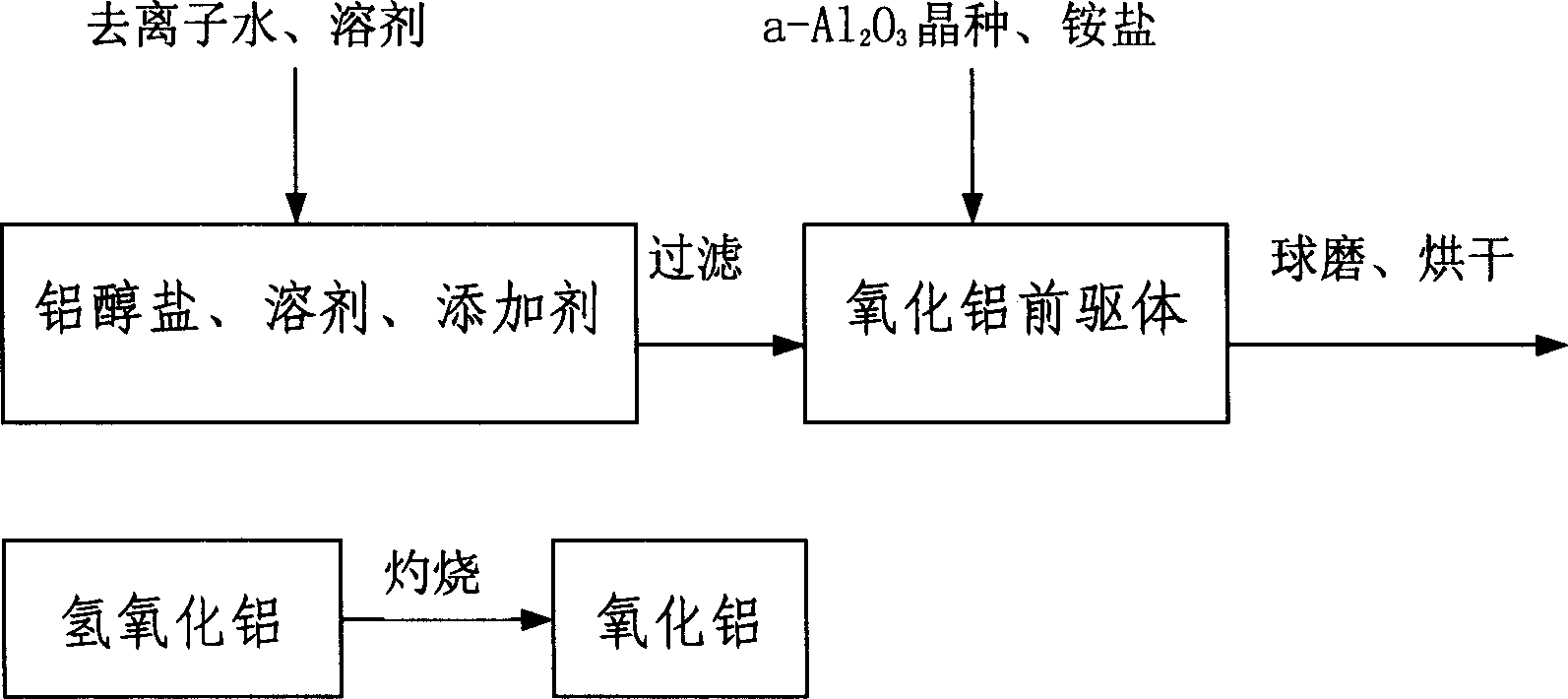

Method used

Image

Examples

Embodiment 1

[0018] Example 1: In a 1-liter three-necked flask, add 500 g of isopropanol solution with a mass concentration of 50% aluminum isopropoxide, place it in a water bath at 70° C., add 20 g of lauric acid as an additive while stirring, and continue stirring Mix well, then drop 80 g of isopropanol solution with a mass concentration of 75% deionized water while stirring, let stand for 10 hours after the reaction is completed, and filter for later use. The alumina precursor obtained after filtration is placed in a ball mill cylinder, and 2.5g a-Al is added at the same time 2 o 3 As a seed crystal and 20g of analytically pure ammonium citrate as an additive, an appropriate amount of deionized water was added as a dispersion medium and high-purity alumina balls were used as a ball milling medium, and ball milled for 5 hours, then dried in an oven at 70°C. The dried aluminum hydroxide is burned in a box furnace at 1050°C for 5 hours to obtain a-Al 2 o 3 Powder, the average particle s...

Embodiment 2

[0019] Example 2: In a 1-liter three-necked flask, add 500 g of isopropanol solution with a mass concentration of 50% aluminum isopropoxide, place it in a water bath at 70° C., and add 20 g of polyethylene glycol 200 as an additive while stirring , continue to stir and fully mix, and then drip 80 g of isopropanol solution whose mass concentration is 75% deionized water while stirring, let stand for 10 hours after the reaction is completed, and filter for subsequent use. The alumina precursor obtained after filtering is placed in a ball mill cylinder, and 2.5g a-Al is added 2 o 3 As a seed crystal and 20g of analytically pure ammonium carbonate as an additive, an appropriate amount of deionized water was added as a dispersion medium and high-purity alumina balls were used as a ball milling medium, and ball milled for 5 hours, then dried in an oven at 60°C. The final aluminum hydroxide is burned in a box furnace at 1050°C for 5 hours to obtain a-Al 2 o 3 Powder, the average p...

Embodiment 3

[0020] Example three: In a 1-liter three-neck flask, add 500 g of isopropanol solution with a mass concentration of 50% aluminum isopropoxide, place it in a water bath at 70° C., and add 20 g of Tween-80 as an additive while stirring, Continue to stir and mix thoroughly, then drop 80 g of isopropanol solution with a mass concentration of 75% deionized water while stirring, let stand for 10 hours after the reaction is completed, and filter for later use. The alumina precursor obtained after filtering is placed in a ball mill cylinder, and 2.5g a-Al is added 2 o 3 As crystal seeds and 20g of analytically pure ammonium nitrate as additives, at the same time add appropriate amount of deionized water as dispersion medium and high-purity alumina balls as ball milling medium, ball mill for 5 hours, then dry in an oven at 75°C, and dry The final aluminum hydroxide is burned in a box furnace at 1050°C for 6 hours to obtain a-Al 2 o 3 Powder, the average particle size is 120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com