Patents

Literature

53 results about "Electroceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroceramics is a class of ceramic materials used primarily for their electrical properties. While ceramics have traditionally been admired and used for their mechanical, thermal and chemical stability, their unique electrical, optical and magnetic properties have become of increasing importance in many key technologies including communications, energy conversion and storage, electronics and automation. Such materials are now classified under electroceramics, as distinguished from other functional ceramics such as advanced structural ceramics.

Nanoparticles of rare earth oxides

ActiveUS20070104629A1Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

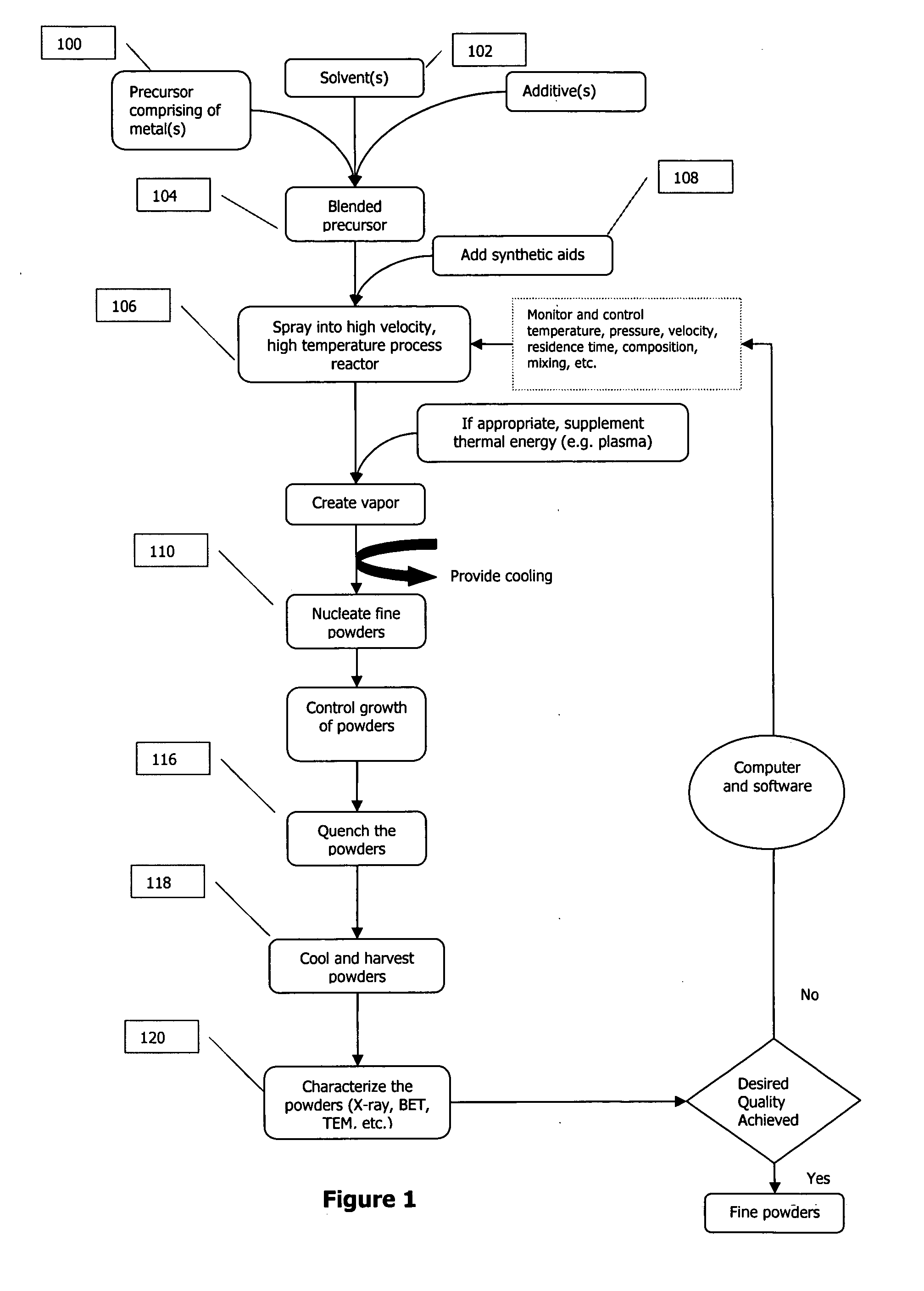

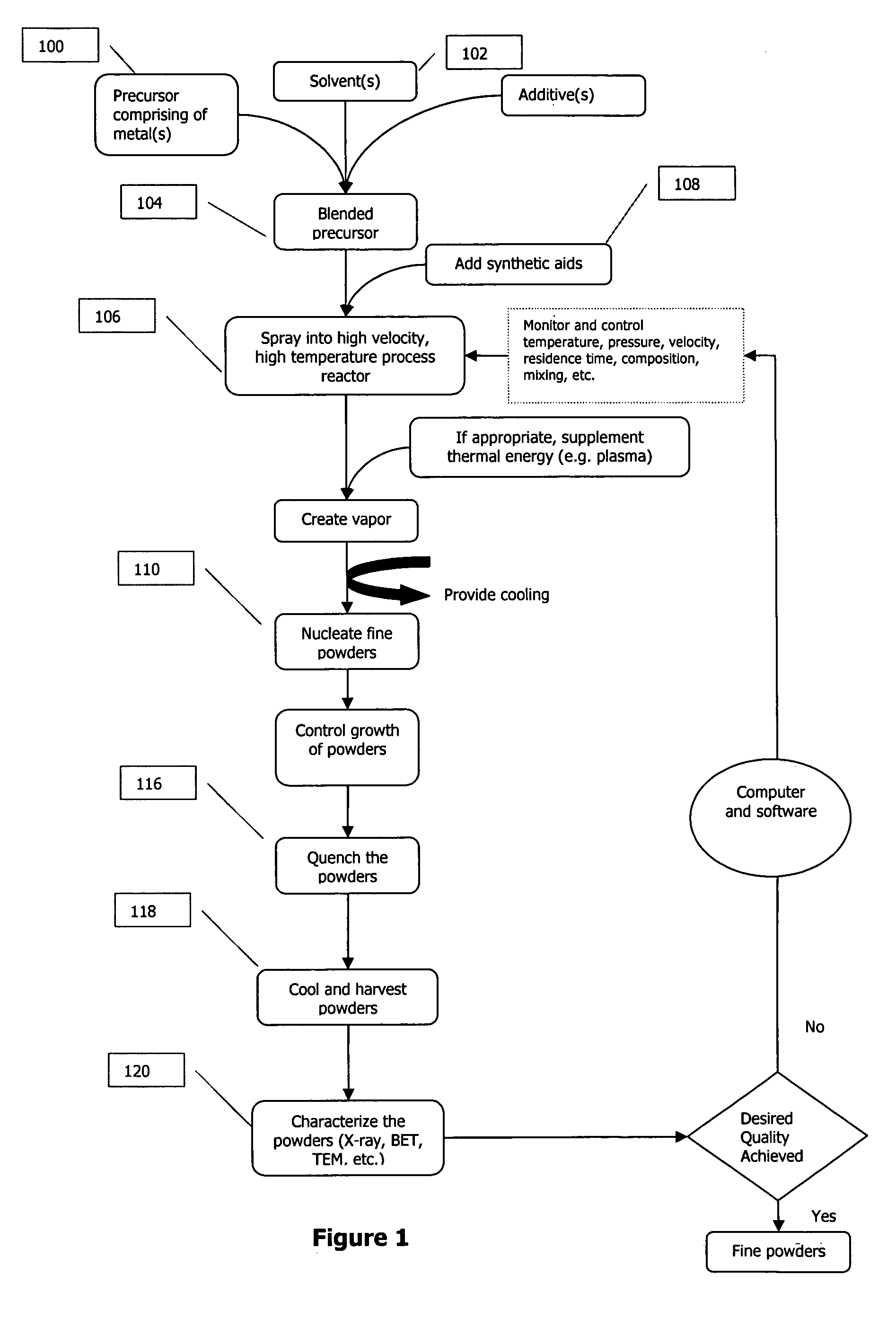

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum(La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium(Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

Magnetically mounted vibration impact transducer

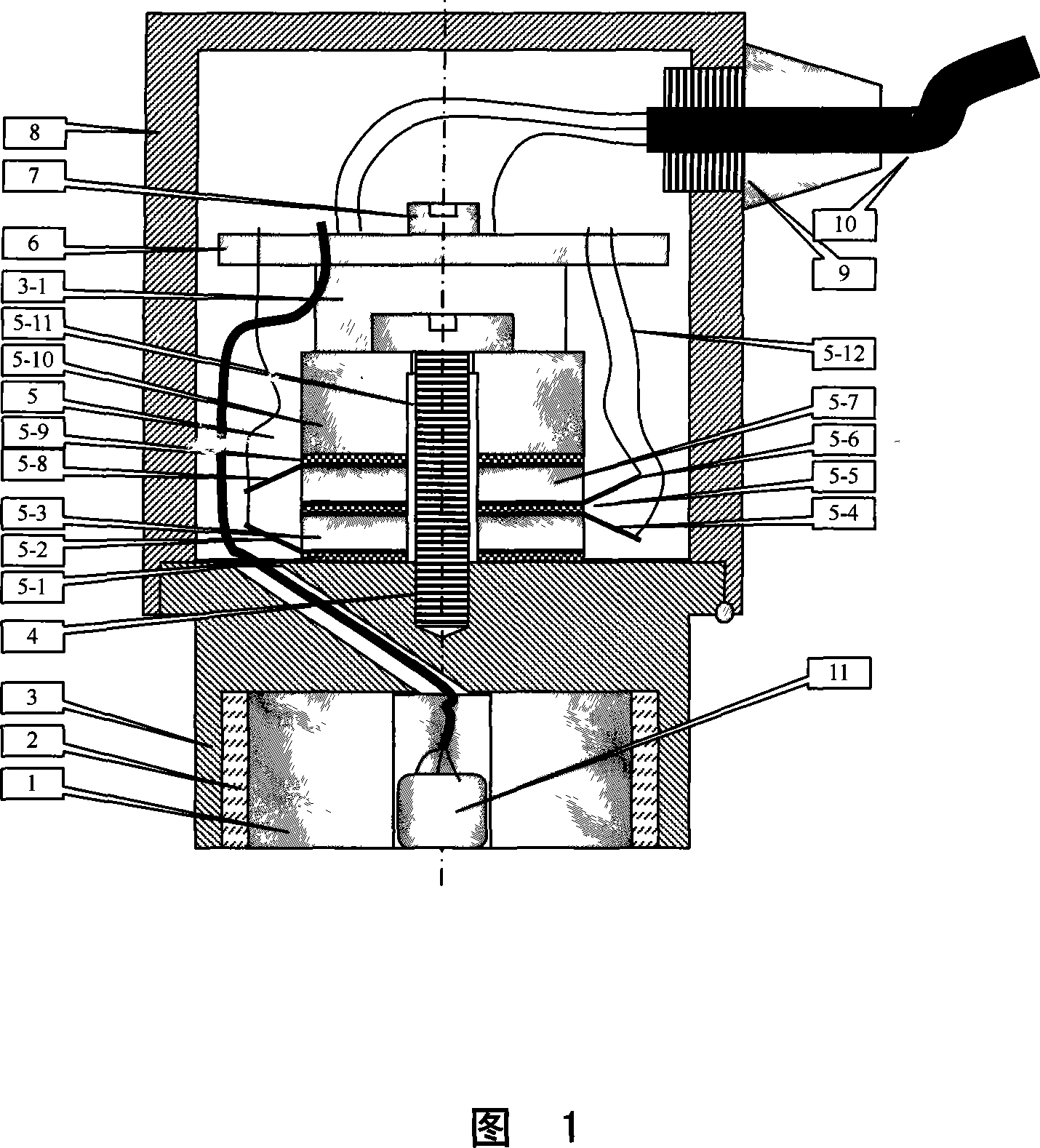

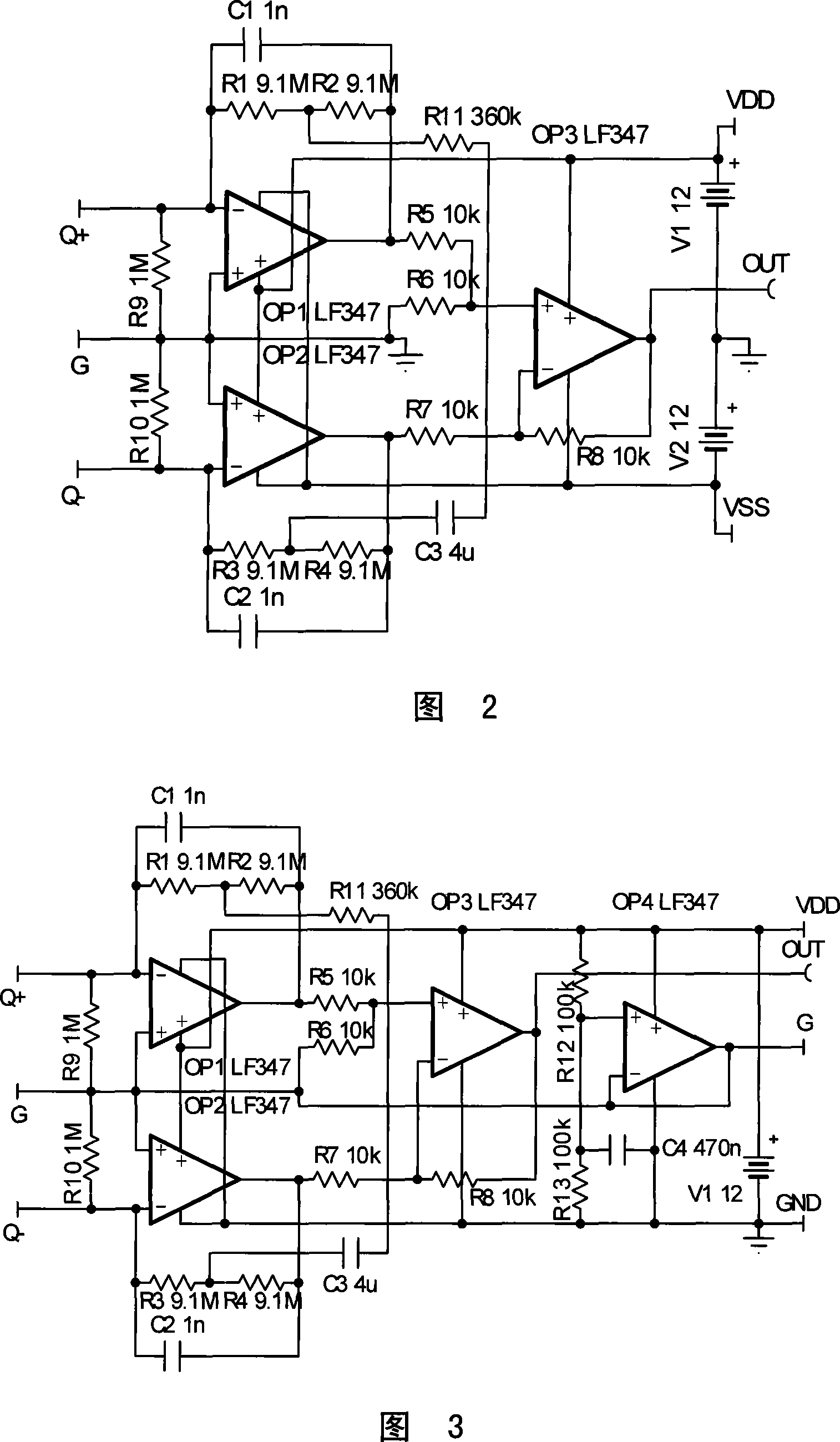

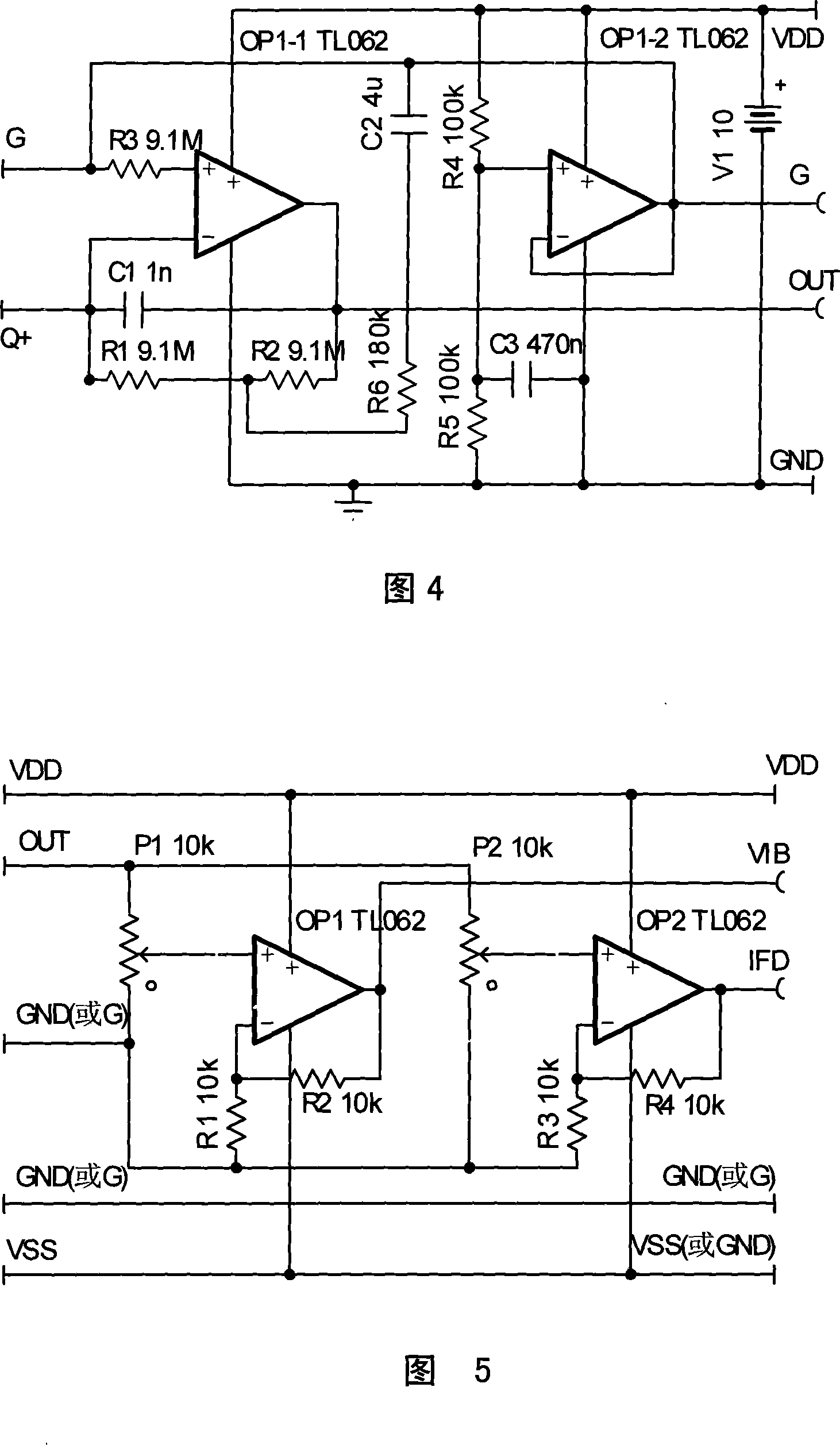

A magnetic arranged vibration shook sensor comprises a shell, permanent magnetic steel, a diamagnetism spacer ring, a base, piezoelectricity component and a signal conditioner, wherein, the shell and the base are closely fitted, assembled, and, after welded, combined to form a closed installation space wherein the piezoelectricity component and the signal conditioner are arranged at the upper part, and form a installation space for permanent magnetic steel in the base; the piezoelectricity component consists of an insulation sheet, an upper conducting strip, a lower conducting strip, an upper electroceramics, a lower electroceramics, a positive conducting strip, a negative conducting strip and a quality block, and is connected to the base through screws; the signal conditioner is arranged on a supporting frame of the piezoelectricity component; the diamagnetism spacer ring, the excircle of which is coated with glue, is firstly pressed into the bottom hole of the base made of ferromagnetic material, then the permanent magnetic steel with high parallelism, finish and planeness is pressed into the center hole of the base, a thin layer of spirit glue with high intensity and high hardness is filled coordinately, the inner disk of the diamagnetism spacer ring is provided with a plurality of equally distributed small grooves which are connected with the magnetic steel and the spacer ring hard through glue; meanwhile, various electric sensing circuits are arranged according to requirements in order to form the magnetic arranged vibration shook sensor.

Owner:北京唐智科技发展有限公司

Nanoparticles of rare earth oxides

ActiveUS7229600B2Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

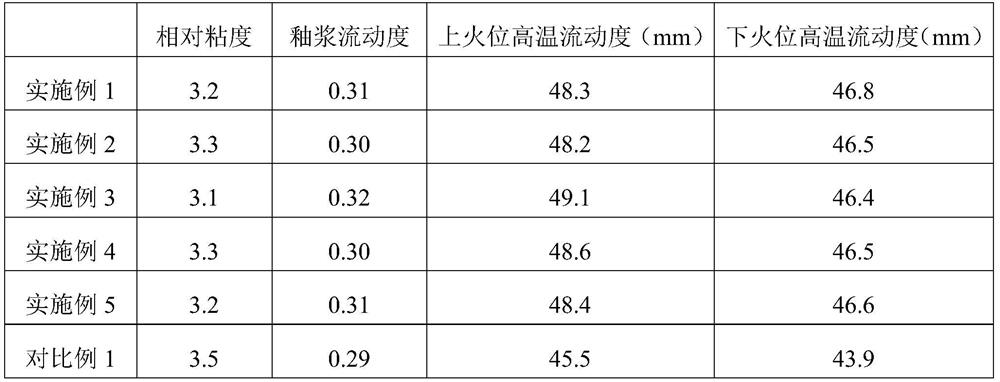

High-strength electroceramics ash glaze formulation and preparation method thereof

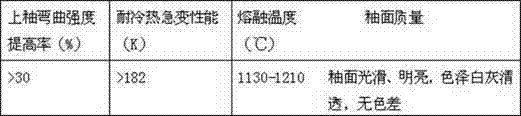

The invention relates to a high-strength electrotechnical porcelain ash glaze formulation which comprises white glaze base materials and coloring materials with mass of 15 to 35% of that of the white glaze base materials, wherein the white glaze base material comprises the following components in parts by weight: 23 to 27 parts of potassium feldspar, 25 to 29 parts of quartz, 8 to 15 parts of Xinhui powder, 4 to 9 parts of washed kaolin, 5 to 8 parts of Xingzi kaolin, 8 to 15 parts of talc, 4 to 7 parts of limestone, 3 to 8 parts of Zuoyun earth, 2 to 6 parts of zirconium silicate, and 5 to 15 parts of alumina. The preparation method comprises the following steps of: roasting three colorant raw materials at a high temperature firstly; grinding finely; and then milling in a wet way along with white glaze based on the ratio until the size fineness reaches to 325 meshes; and finally sieving to residue of 4 to 6%. The electrotechnical porcelain ash glaze prepared based on the formulation is suitable for various porcelain blank bodies, and can be coated to form a good intermediate layer which can be combined with the porcelain body well, thus, the mechanical performance of the porcelain can be greatly improved, and the bending strength of the porcelain can be increased by more than 30%; and meanwhile, the glazed surface of a porcelain component is smooth, the color is white gray and clear, and the surface has no defect, and the market demand can be met.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

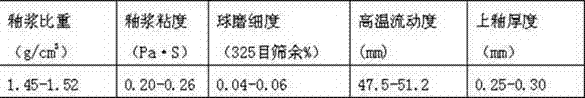

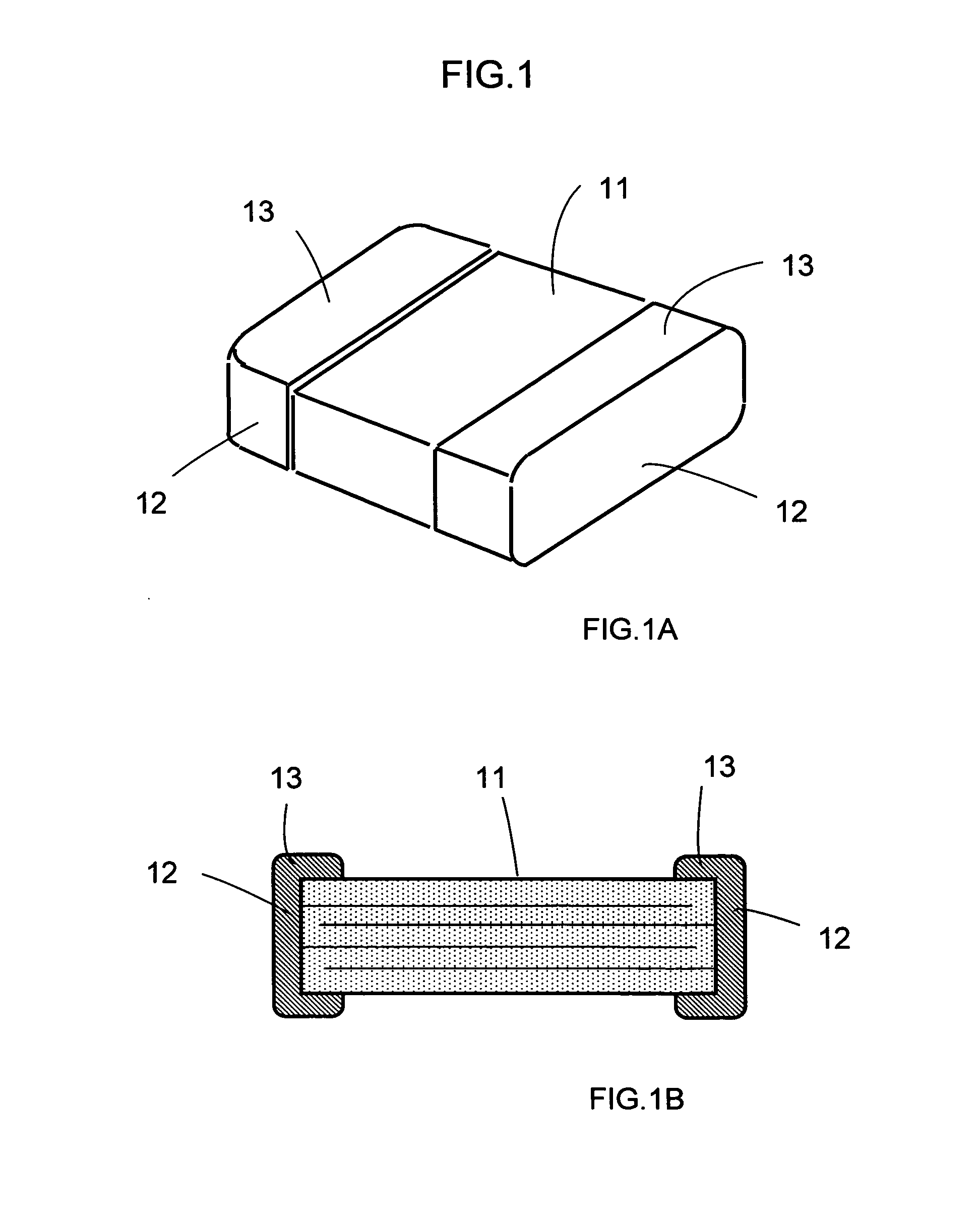

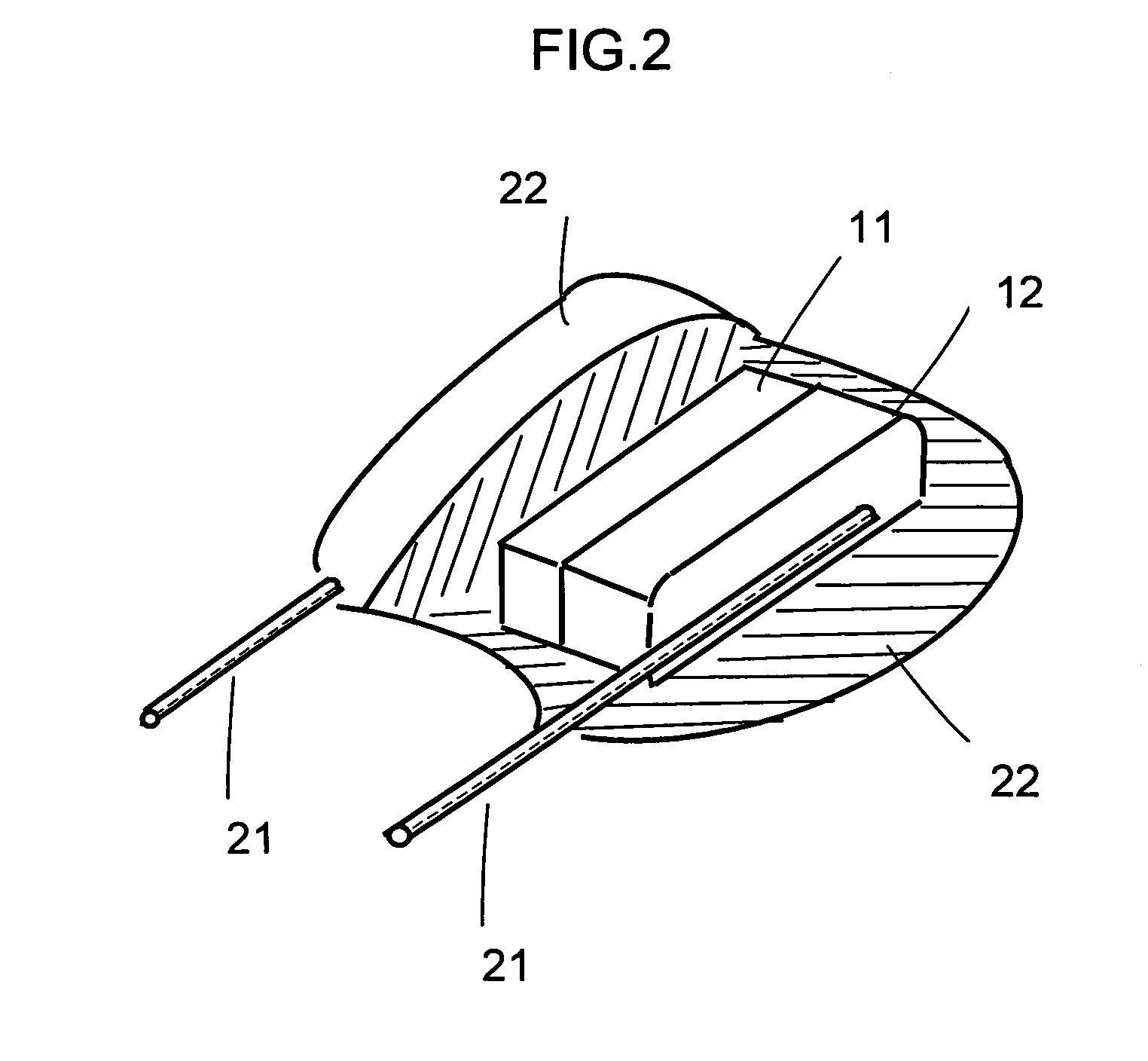

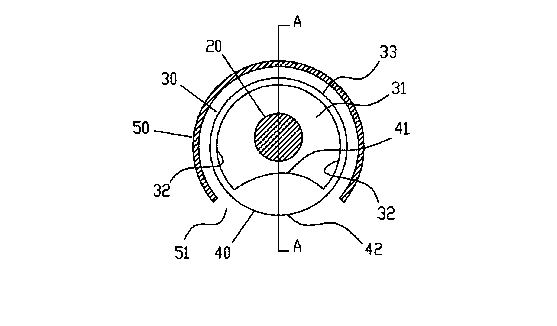

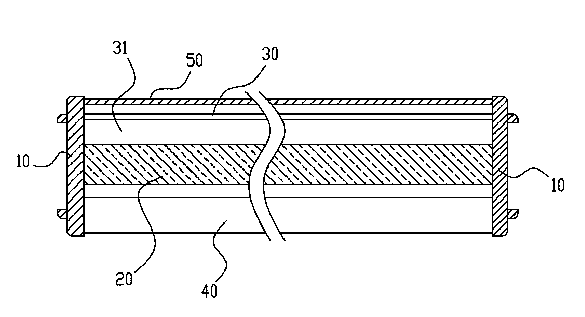

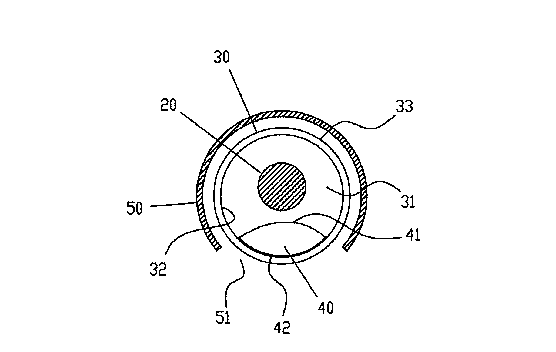

Partial conformal coating of electronic ceramic component and method making the same

InactiveUS20120223798A1Improve surface conditionDifficult to wetTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectricitySolderability

A partial conformal coating covers the ceramic portion of leadless type electroceramic component but not the metalized terminals to improve the surface condition without altering the solderability of the component. And the methods to form the partial conformal coating to cover the desired area of the electroceramic component in simple processes suitable for mass production.

Owner:WEIS INNOVATIONS

High-strength alkali-resistant refractory castable

The invention discloses a high-strength alkali-resistant refractory castable, including refractory aggregate, powder, binder, additive and water. Waste electroceramics and waste tiles are processed into a refractory aggregate of 1-5mm; chamotte, waste electroceramics, waste tiles, mullite and silicon powder are mixed and processed into a powder; and binder and additive are added into the refractory aggregate and the powder. The invention selects waste electroceramics and waste tiles with excellent alkali resistance to produce a castable with excellent alkali resistance; the waste electroceramics and the waste tiles has characteristics of wide source, large quantity and no environmental pollution, so as to reduce costs on raw material consumption and harm to the environment, and realize abundant raw material, energy saving and environmental protection. The mullite powder and silicon powder fill gaps of the castable, and improve the casting material pressure resistance and bending strength; and chamotte and CA50-G6 cement better bond the refractory aggregate and the powder.

Owner:浙江恒丰建材有限公司

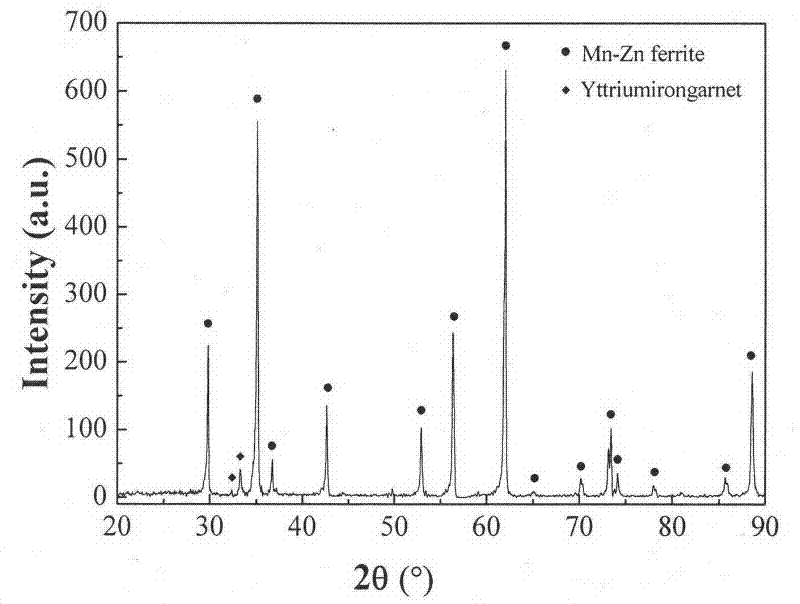

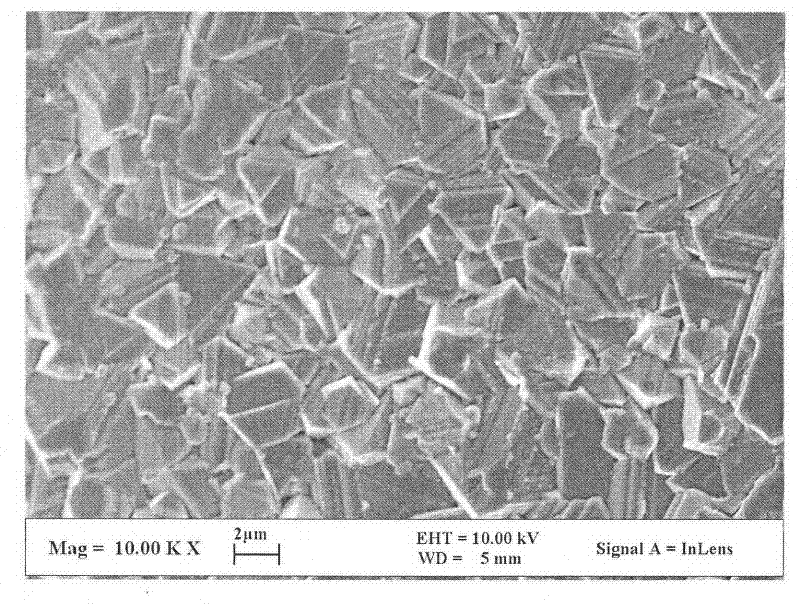

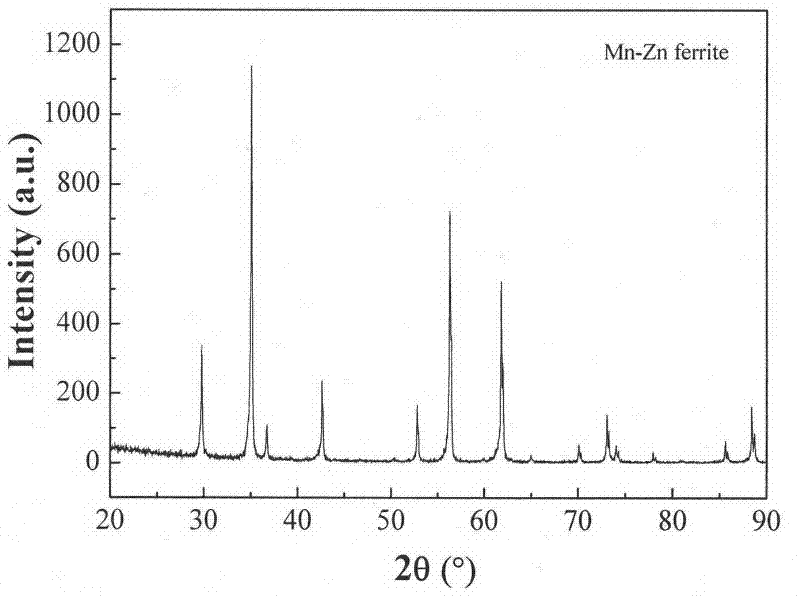

Novel MnZn-doped ferrite material and preparation method thereof

The invention which relates to a novel MnZn-doped ferrite material and a preparation method thereof belongs to the technical field of preparations and applications of electron ceramics. The material comprises main materials and an additive, wherein the main material comprises, by mole, 45-55mol% of Fe2O3, 22-26mol% of ZnO, 23-29mol% of MnO2; and the additive comprises one or more of Y2O3, Sb2O3 and Cr2O3, each formula contains CaCO3, and each additive which is additionally added respectively accounts for 0.05-5.0mol% of the total mole of the main materials. The preparation method of the material which sequentially comprises processes and steps of main material burdening, ball milling, drying, preburning, crushing, doping, secondary ball milling, sieving, compression molding, sintering and the like has the advantages of economy, simplicity and reliability. The material which has the advantages of high saturation magnetization and initial magnetic permeability, low loss and coercive force, and excellent comprehensive electromagnetic performance is especially applied to high frequency devices with small volume, light mass, and high sensitivity.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High-strength corrosion-resistant refractory castable

The invention discloses a high-strength corrosion-resistant refractory castable which comprises the following raw materials in parts by weight: 50-60 parts of aggregate, 20-35 parts of powder, 5-6 parts of binding agent, 5-10 parts of zirconia fibers and 5-10 parts of yttrium oxide, wherein the aggregate consists of waste electroceramics, waste tiles and coal gangue; the powder consists of coal gangue, waste electroceramics, waste tiles, flint clay and silica powder; the binding agent refers to aluminate cement; and the additive refers to alpha-alumina fine powder.

Owner:宁夏胜金水泥有限公司

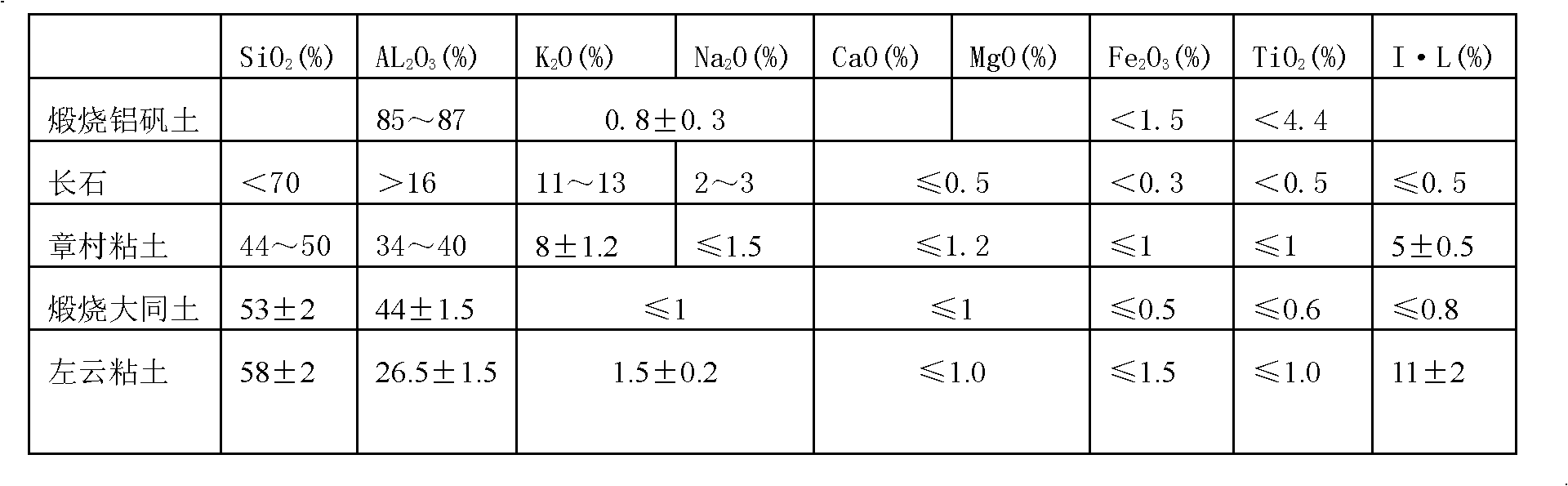

1100KV rod post porcelain insulator

The invention relates to a 1100KV rod post porcelain insulator and belongs to the technical field of electroceramics. The 1100KV rod post porcelain insulator is prepared by compounding, grinding, molding and sintering. The 1100KV rod post porcelain insulator comprises the following components in weight percentage: 45-53 percent of calcined bauxite, 8-15 percent of feldspar, 5-12 percent of Zhangcun clay, 7-13 percent of calcined Datong clay and 16-25 percent of Zuoyun clay. According to the 1100KV rod post porcelain insulator, the strength of a test strip reaches up to 220MPa, and the requirement of the 1100KV rod post porcelain insulator on the material strength can be well met.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

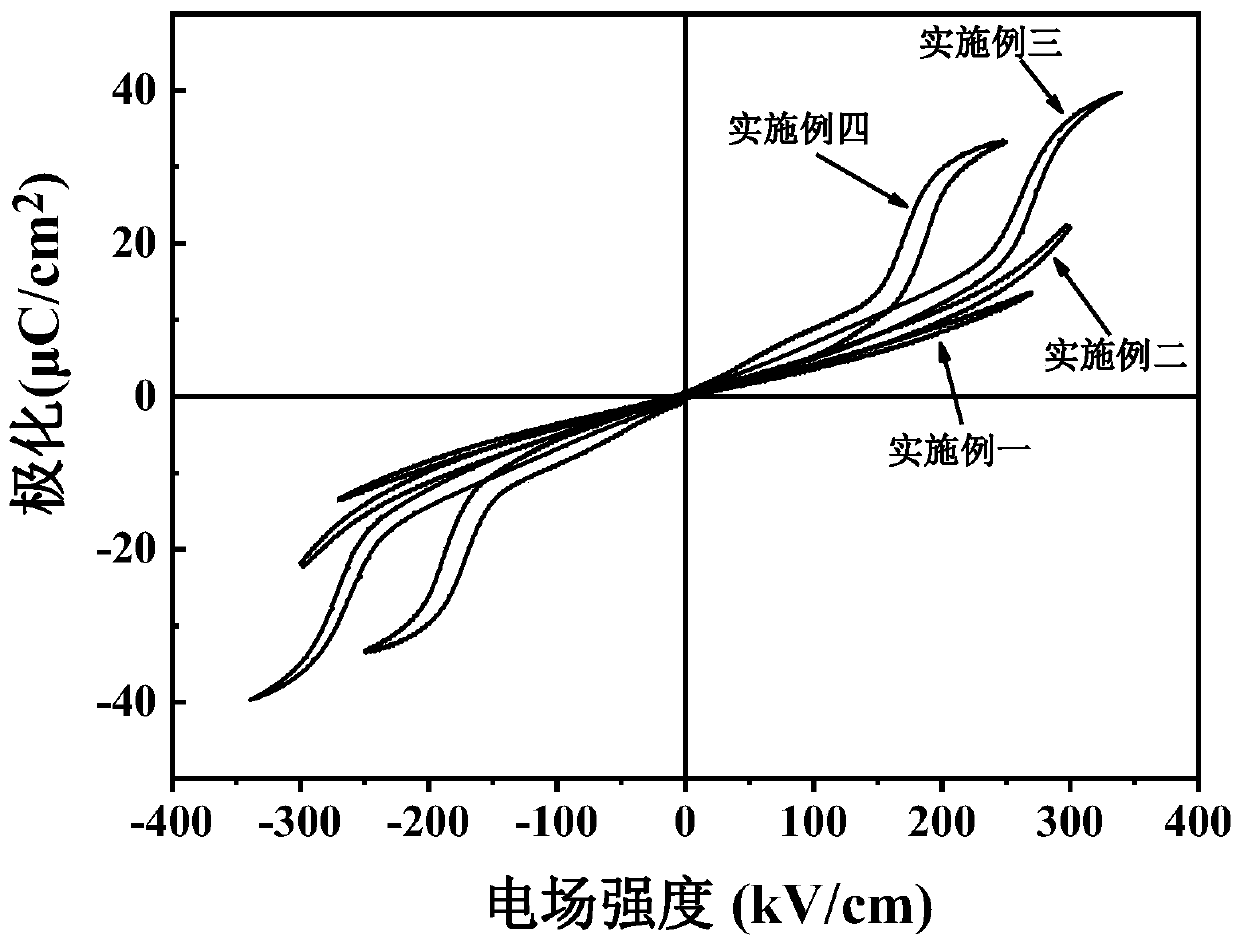

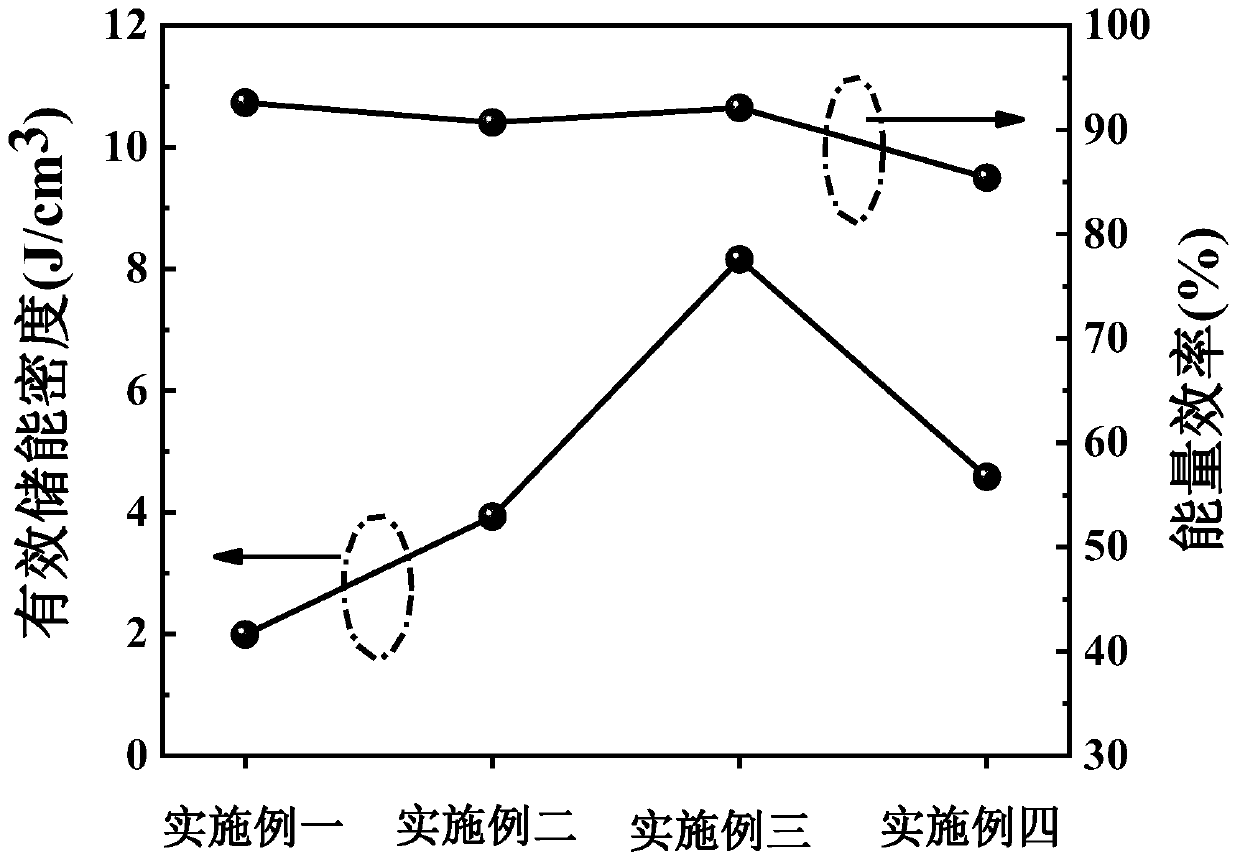

Anti-ferroelectric ceramic material and preparation method thereof

The invention relates to an anti-ferroelectric ceramic material and a preparation method thereof. The chemical general formula of the anti-ferroelectric ceramic material is (Pb<0.91>Ba<x>La<0.06-2x / 3>) (Zr<y>Sn<1-y>) O<3>, wherein 0<x<0.09, and 0<y<1. Compared with the prior art, the anti-ferroelectric ceramic material prepared by a traditional electronic ceramic preparation process has the characteristics of high energy storage density, small hysteresis, high energy storage efficiency and excellent charge discharge performance, and is of great significance for the development of pulse power capacitors with high energy storage density and high energy storage efficiency with long cycle charge discharge life.

Owner:TONGJI UNIV

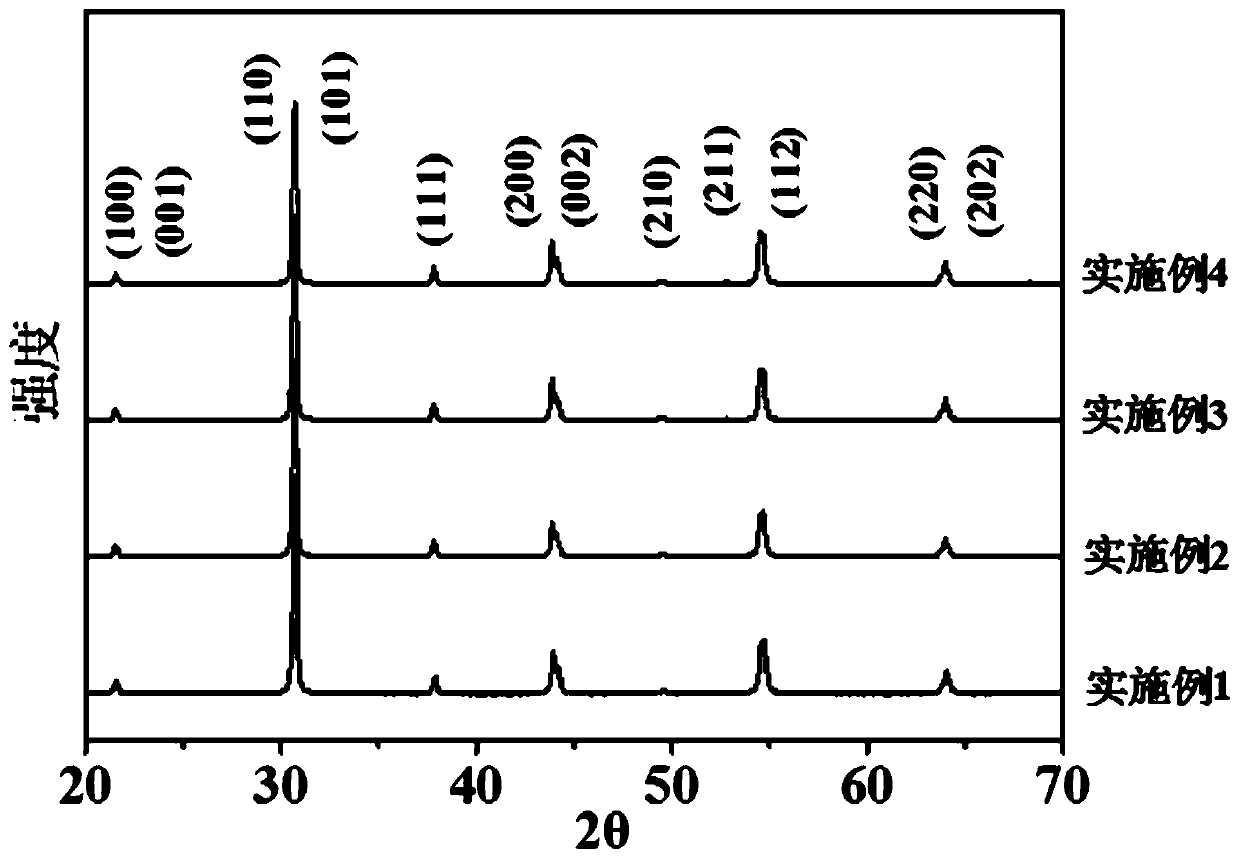

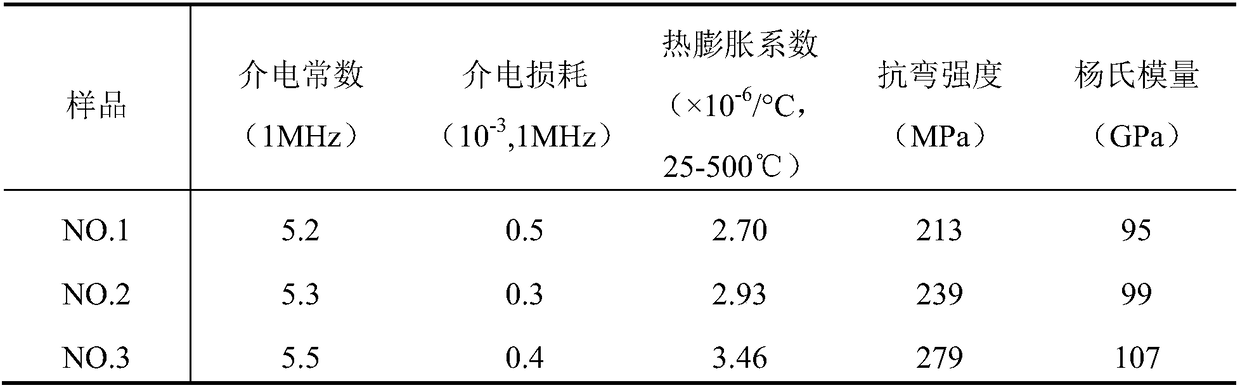

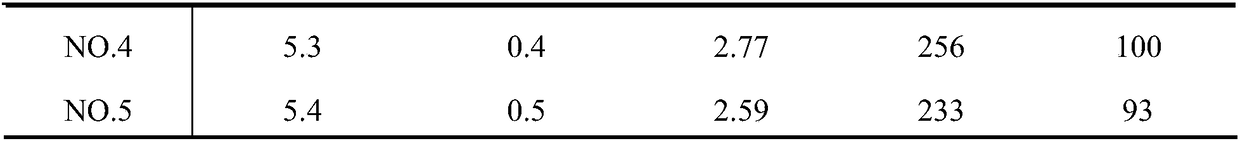

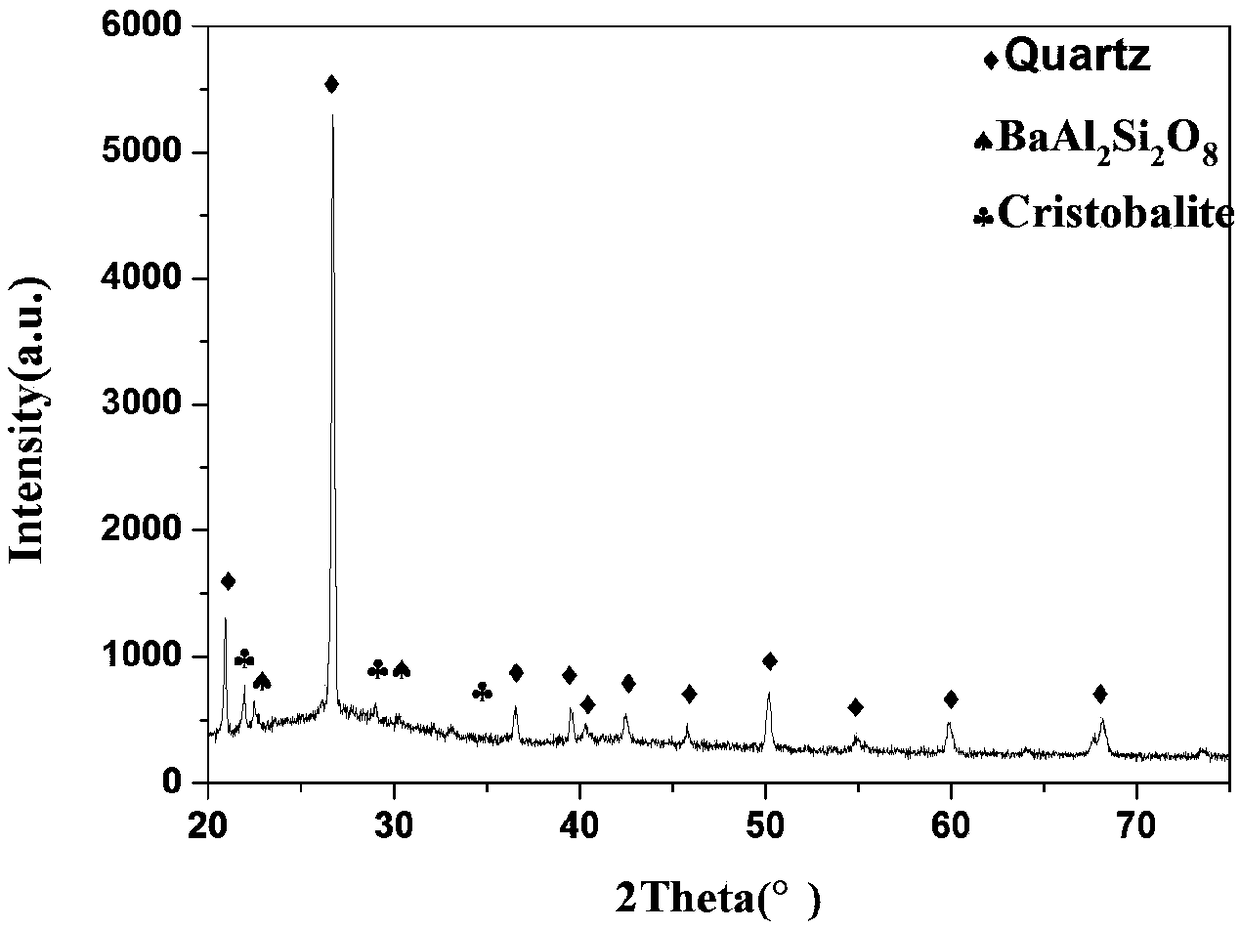

High-strength low-thermal-expansion-coefficient microcrystalline glass and preparation method thereof

InactiveCN108558215AMeet material requirementsImprove flexural strengthGlass shaping apparatusDielectric lossYoung's modulus

The invention belongs to the field of electronic ceramic materials, and particularly provides high-strength low-thermal-expansion-coefficient microcrystalline glass and a preparation method thereof. The microcrystalline glass is used for solving the problems that an existing ceramic material is high in thermal expansion coefficient (poor in matching degree with a silicon chip), low in bending strength, high in dielectric constant, large in dielectric loss and the like. The high-strength low-thermal-expansion-coefficient microcrystalline glass which is low in thermal expansion coefficient (2.5-3.5*10<-6> / DEG C), high in bending strength (200-280 MPa), high in Young modulus (90-110 GPa), low in dielectric constant (5.0-5.5@1MHz), low in dielectric loss (0.3-0.5*10<-3>@1MHz), insulating and reliable can be prepared from the components and through the preparation technology, and requirements of LTCC electronic packaging substrate materials are met; meanwhile, the microcrystalline glass issimple in process, high in stability, low in production cost and suitable for industrial batch production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

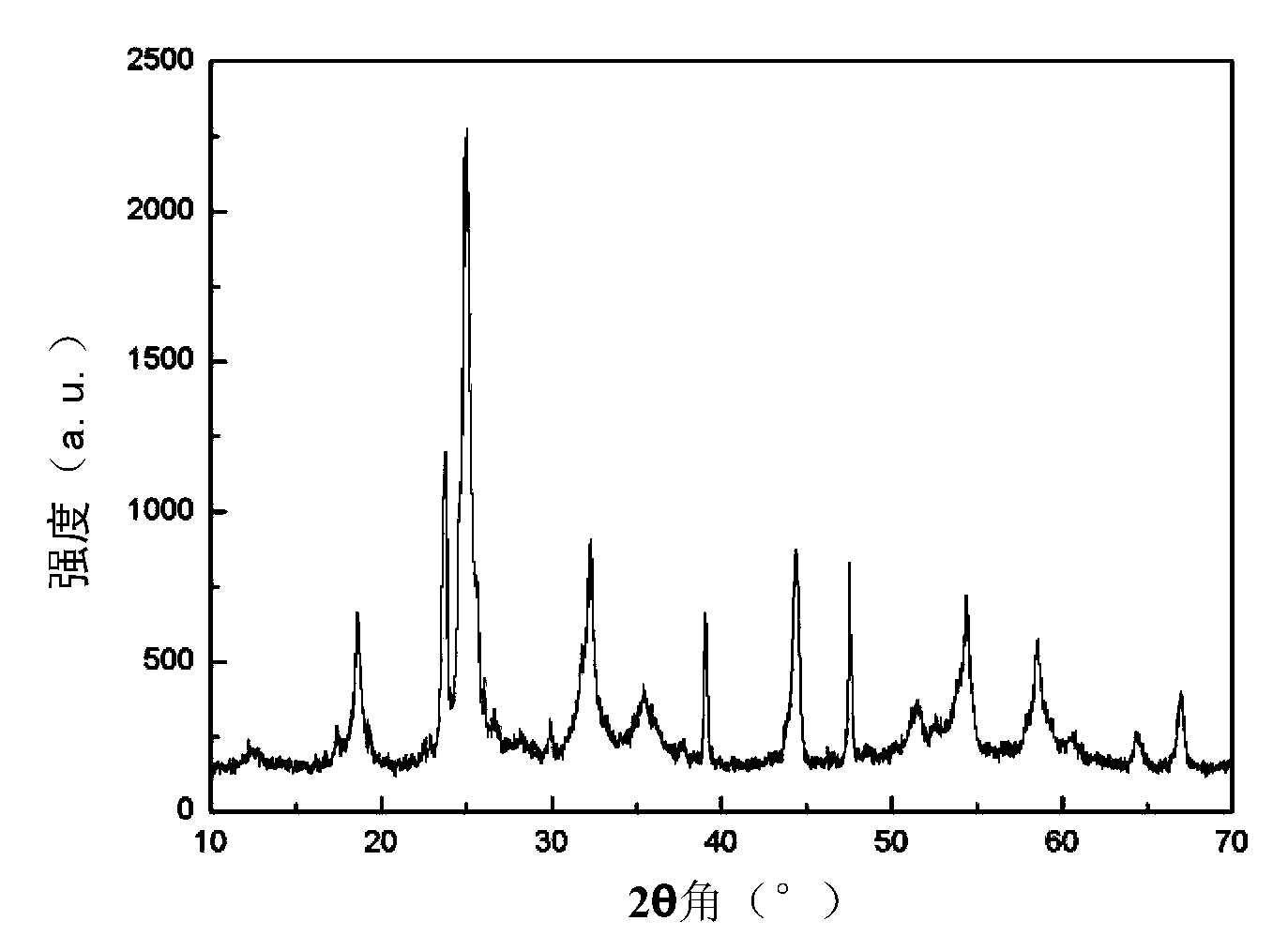

Rod-like niobium pentoxide template grain and preparation method thereof

ActiveCN103449520AEasy to manufactureSimple preparation processNiobium compoundsMicron scaleDiameter ratio

The invention relates to a rod-like niobium pentoxide template grain and a preparation method thereof. The grain is rod-like with a length of 10-20 microns, a diameter of 2-10 microns and a length-diameter ratio of 10-15; the grain is anisotropic. According to the rod-like niobium pentoxide powder grain disclosed by the invention, the grain is rod-like, obviously anisotropic in structure and micron-scale in size; the rod-like niobium pentoxide template grain is an effective template capable of guiding the grain to directionally grow so as to prepare textured ferrocolumbium-containing electroceramics, and is very suitable for orienting various ferrocolumbium-containing electroceramics so as to improve the piezoelectric property.

Owner:江苏先进无机材料研究院

Raw material formula of wire-post type sand-coating glaze

The invention relates to a raw material formula of wire-post type sand-coating glaze, and relates to processing powder used for preparing ceramic product glaze. With the raw materials, electroceramics with higher mechanical properties and dielectric properties can be prepared. A purpose of the invention is achieved through the following measures: the raw material formula of wire-post type sand-coating glaze is characterized in that the glaze comprises substances of, by mass: 27-31 parts of potash feldspar, 14-18 parts of quartz powder, 3-6 parts of Xu earth, 4-7 parts of limestone, 16-20 parts of calcined talcum, 3-5 parts of spodumene, 1-3 parts of barium carbonate, 10-15 parts of a high-strength blank material, 6-12 parts of a common blank material, and 0.2-0.5 parts of carboxymethyl cellulose (OM6-1). Compared with prior art, the technical scheme provided by the invention is characterized in that with the formula, the prepared glaze is advantaged in uniform ceramic sand distribution, no sand stacking or sand lacking phenomenon, and firm ceramic sand adhesion. After a sand-coating process, the strength is improved by 20%. The glaze is convenient to use, and can be used as wire-post type sand-coating special-purposed glaze.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Raw material formula and method for manufacturing high-alumina porcelain insulator

The invention relates to a raw material formula and method for manufacturing a high-alumina porcelain insulator, and belongs to the technical field of electric porcelain. The formula comprises bauxite, kaolinite, feldspar, mullite, illite, clay, Zuoyun soil, nacrite, garnet and white carbon black, and the high-alumina porcelain insulator is prepared by a sintering process comprising the followingsteps: using a plurality of raw materials and adding a small amount of garnet, white carbon black and methyl silicone resin, grinding into powder with two different particle sizes in the preparation process, mixing, heating in stages, cooling and heating again. And the obtained porcelain insulator has excellent mechanical properties and meets the requirements of the field of electroceramics at present.

Owner:江西省萍乡市宇翔电瓷制造有限公司

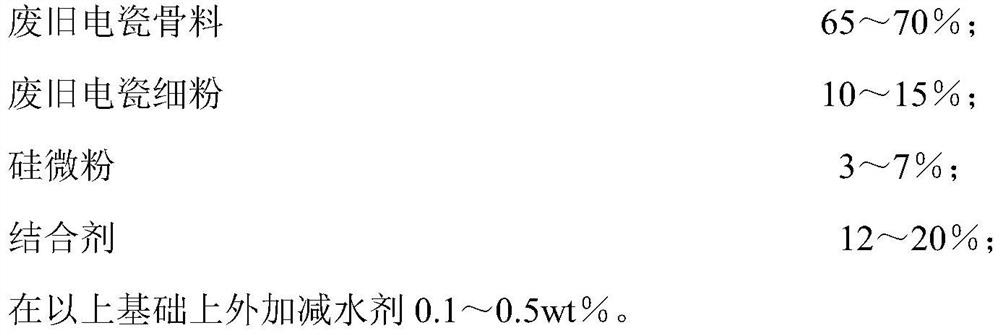

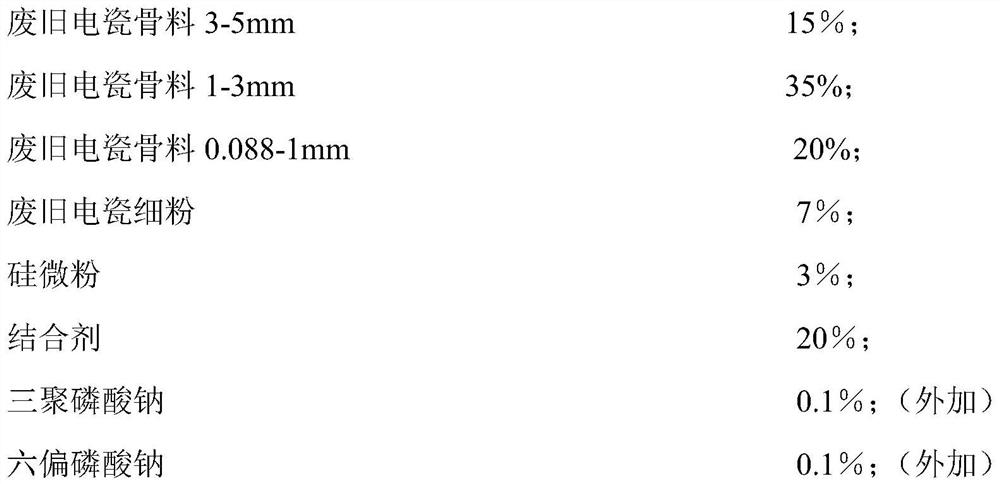

Self-flowing heat-resistant concrete utilizing waste electric porcelain

InactiveCN112079608ALow impurity contentUniform particle distributionEnvironmental engineeringElectroceramics

The invention discloses self-flowing heat-resistant concrete utilizing waste electric porcelain. The self-flowing heat-resistant concrete contains the following components in percentage by weight: 65-70% of waste electric porcelain aggregate; 10%-15% of waste electric porcelain fine powder; 3-7% of silica powder; 12-20% of a binding agent; and 0.1-0.5 wt% of a water reducing agent is added on thebasis. The invention provides the self-flowing heat-resistant concrete for the high-temperature parts of the blast furnace foundation and the casting house platform; meanwhile, the waste electroceramics can be recycled, the content of the waste electroceramics in the obtained self-flowing heat-resistant concrete is 70wt% or above, and the use temperature can reach 1,300 DEG C or above. The high strength and good sintering stability of the waste high-voltage electric porcelain are fully utilized, secondary utilization of solid waste resources is achieved, and the cost is reduced. By adopting the zirconium-removed silica powder, impurities are few, the fluidity is good, the water consumption is greatly reduced, the material can be pumped for construction, and the construction efficiency is greatly improved.

Owner:中冶武汉冶金建筑研究院有限公司

High-strength alkali-resisting refractory castable

The invention relates to a high-strength alkali-resisting refractory castable which is prepared from the following raw materials in parts by weight: 51-62 parts of aggregates, 30-38 parts of powder, 3-5 parts of an adhesive and 5-6 parts of an additive, wherein the aggregates are prepared from waste electroceramics, waste tiles and coal gangues; the powder is prepared from coal gangues, waste electroceramics, flint clays, silicon micropowder, aluminum oxide and magnesium oxide; the adhesive is aluminate cement; and the additive is alpha-aluminum oxide fine powder.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

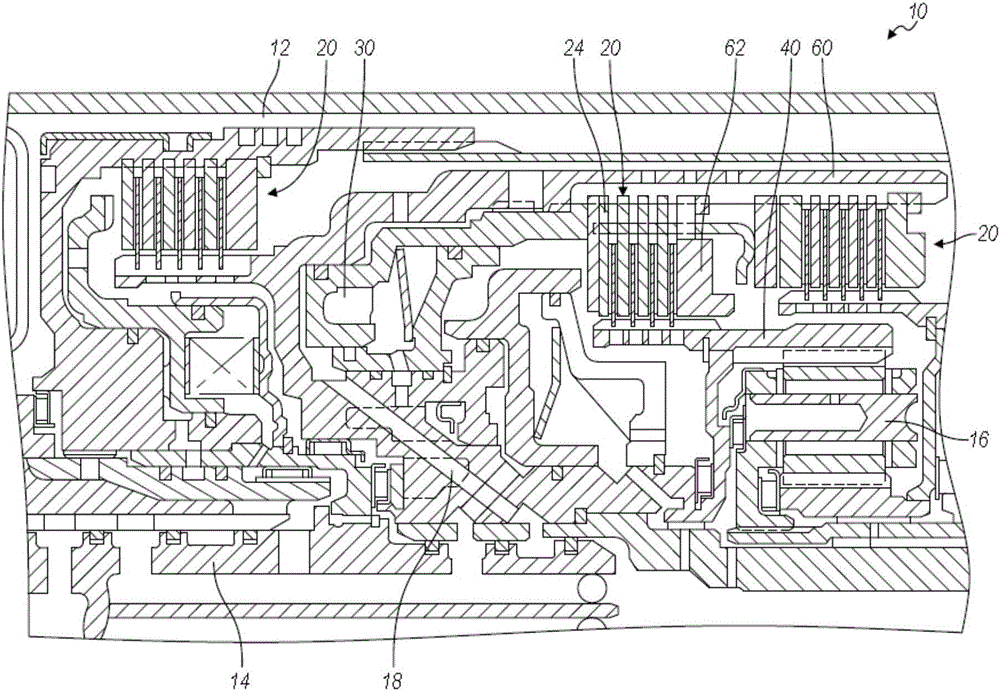

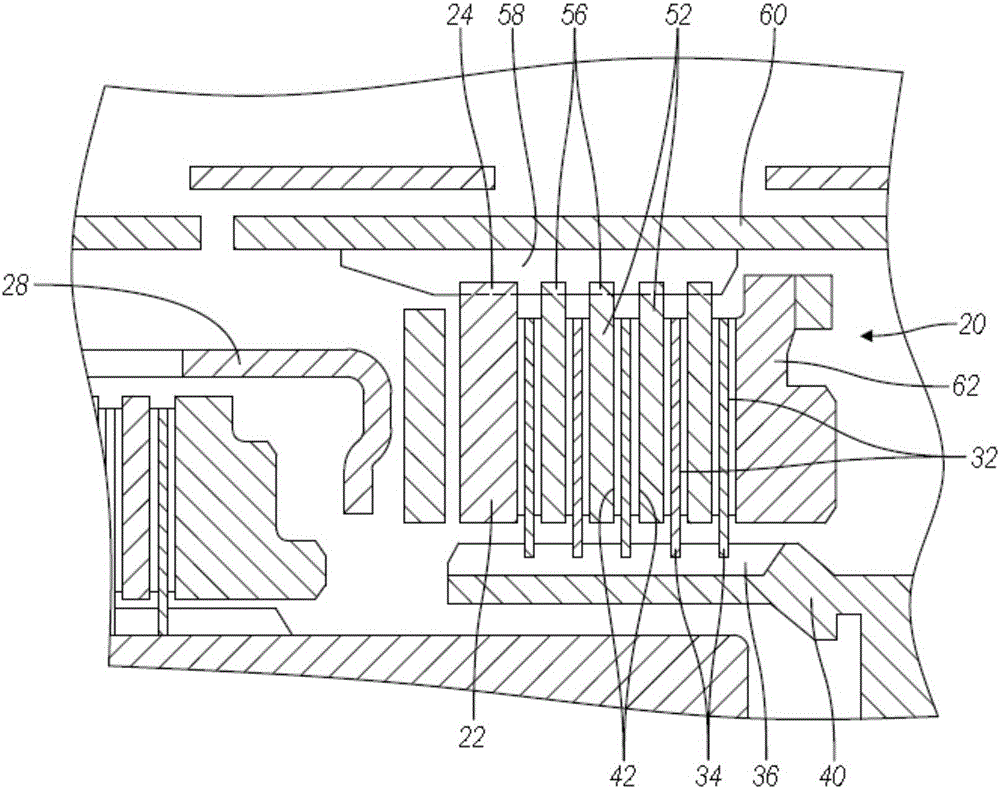

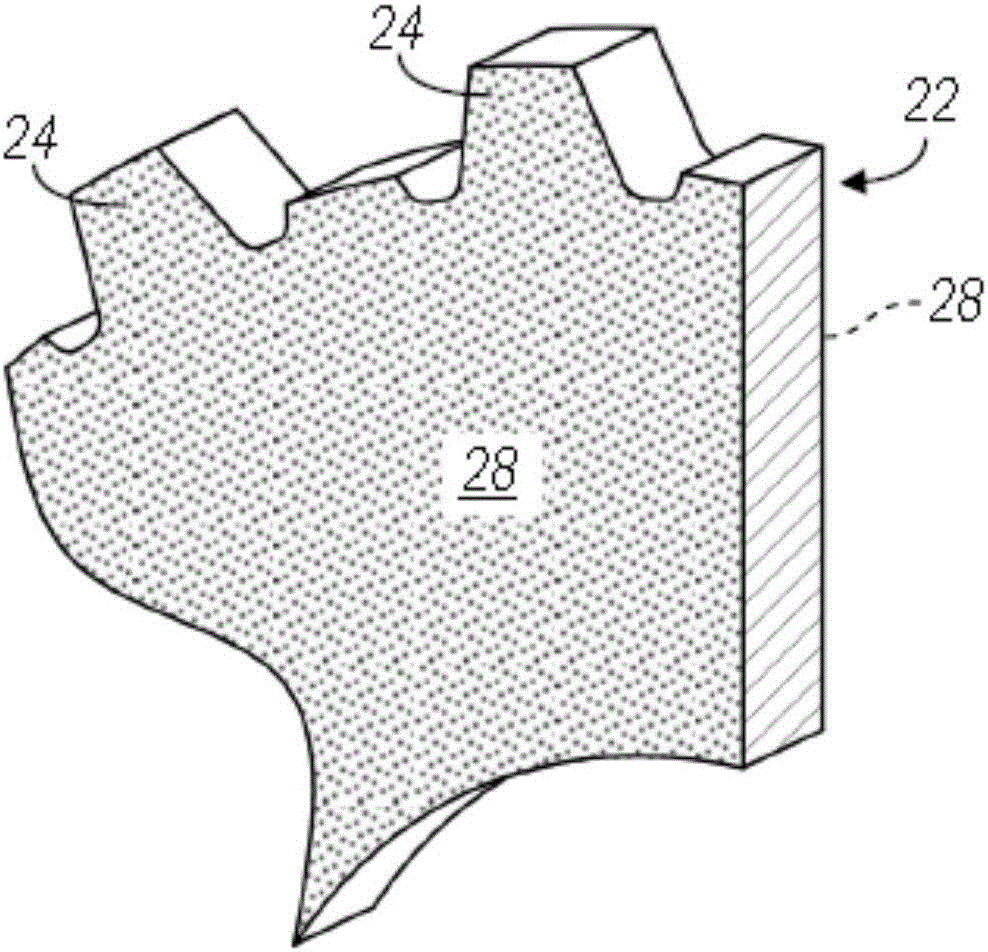

Electro ceramic coated aluminum transmission components

The present invention is directed to apply plates, clutch plates, reaction plates and backing plates utilized of friction clutch packs, brake housings, clutch hubs, clutch housings, accumulators, spline sets, valve bodies and wear surfaces against which bushings, seals, springs and similar components slide and contact which are utilized in motor vehicle automatic transmissions, are fabricated of aluminum and include an electro ceramic coating deposited thereon. Such components exhibit reduced weight relative to similar components fabricated of steel as well as extended service life due to both the hardness and porosity of the ceramic coating.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rod-shaped porcelain insulator and preparation method thereof

PendingCN110911062AHigh tensile strengthHigh compressive strengthInorganic insulatorsSupporting insulatorsKaoliniteMullite

The invention discloses a rod-shaped porcelain insulator and a preparation method thereof, and relates to the field of electroceramics technology. The insulator is prepared from the following raw materials in parts by mass: 10-30 parts of Zuoyun soil, 20-30 parts of mullite powder, 3-8 parts of titanium dioxide, 5-10 parts of kaolinite, 1-3 parts of lanthanum trioxide, 1-5 parts of Farkui clay, 4-10 parts of zirconium oxide and 2-8 parts of nano cerium borate. The rod-shaped porcelain insulator and the preparation method have the beneficial effects that the components and the proportion of theraw materials of the porcelain insulator are changed on the basis of the traditional preparation process, and the prepared porcelain insulator has more excellent tensile strength and compressive strength compared with the porcelain insulator in the prior art, and maintains good insulativity.

Owner:萍乡恒邦电力器材有限公司

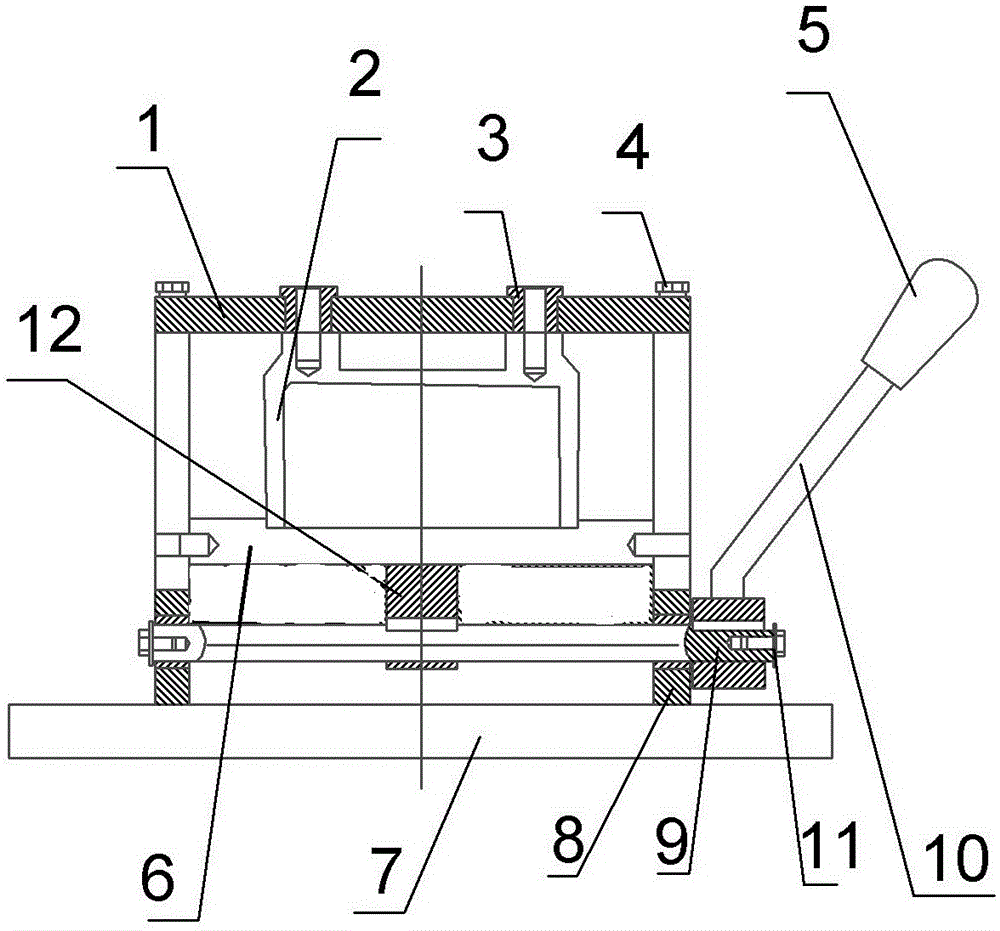

Hardware fitting flange tool clamp

InactiveCN105108207AEasy and stable connectionConvenient serial productionDrill jigsEngineeringElectroceramics

The invention discloses a hardware fitting flange tool clamp, belongs to the workpiece clamp field, and comprises a drill jig device, a drill jig support and a clamp device; the drill jig device comprises a drill jig plate and a drill sleeve, wherein the drill sleeve is arranged on the drill jig plate; the drill jig support comprises a support plate and a pedestal plate, wherein the support plate is arranged on the pedestal plate, and the support plate is provided with a guide slot hole; the drill jig plate is connected with the drill jig support; the clamp device comprises a slide seat, an eccentric sheave, an eccentric sheave shaft and a handle; two ends of the slide seat are respectively connected with the support plate; the surface of the eccentric sheave abuts against the slide seat; the eccentric sheave is connected with the eccentric sheave shaft; one end of the handle is connected with the eccentric sheave shaft. The hardware fitting flange tool clamp can conveniently drill an electroceramics insulator flange and a disc form flange.

Owner:CHONGQING HANGFEI MACHINERY MFG

Blank formula of fuse ceramic shell using waste material recycled from isostatic pressing electroceramics and preparation method thereof

The invention relates to a blank formula of a fuse ceramic shell using a waste material recycled from isostatic pressing electroceramics and a preparation method thereof. The blank comprises following components in parts by mass: 85-90 parts of waste material recycled from isostatic pressing electroceramics, 10-15 parts of feldspar, 0.3-0.5 part of water reducing agent and 0.8-1.2 parts of additive. The fuse ceramic shell is prepared from the raw materials through steps of grinding, sieving, deironing and so on. Due to adoption of the waste material recycled from isostatic pressing electroceramics, the water reducing agent and additive as well as the feldspar as the fluxing agent, the performance of the ceramics is effectively guaranteed, the costs of the raw materials and manufacture are lowered, the performance requirements of the ceramics are met, and excellent effects of the ceramics are achieved.

Owner:CHINA XD ELECTRIC CO LTD

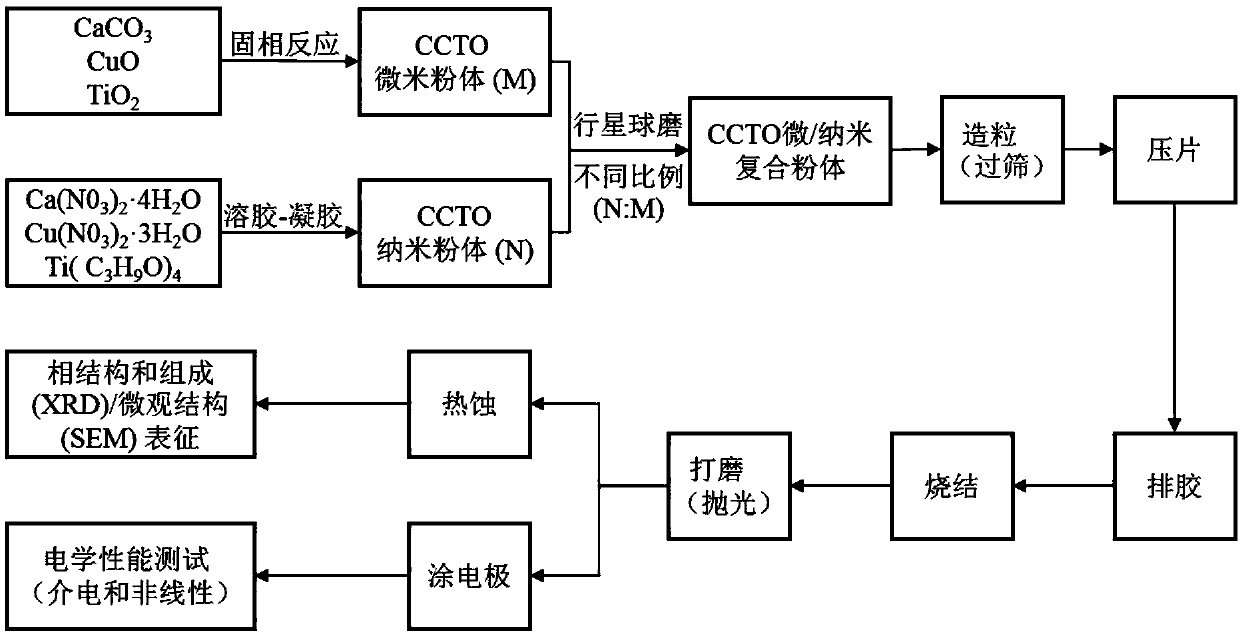

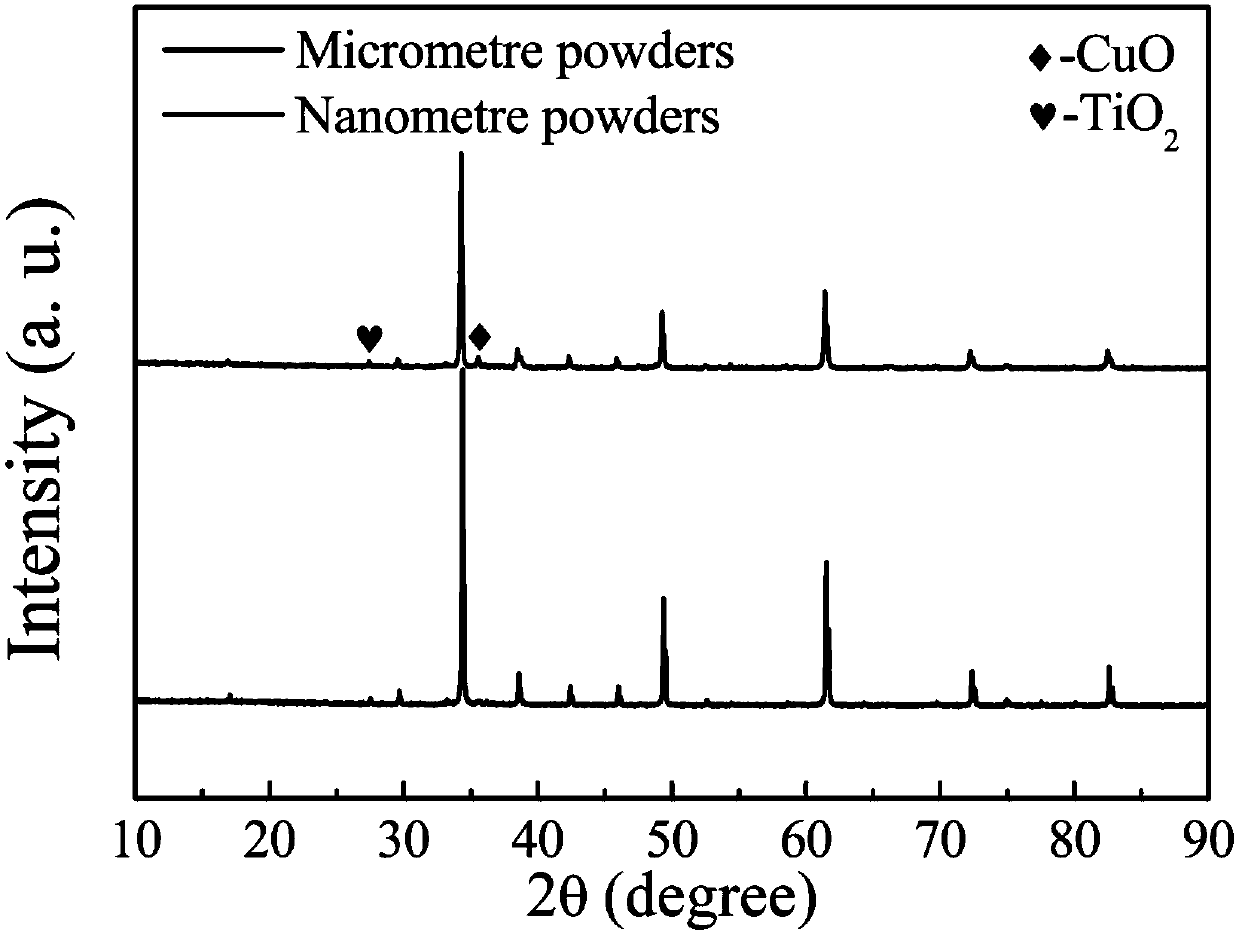

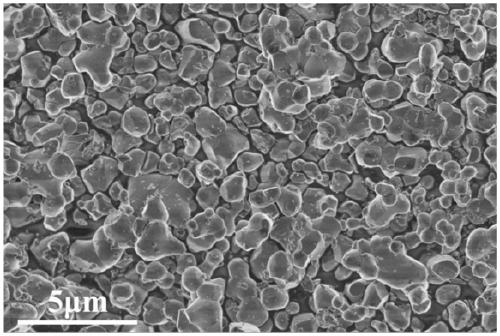

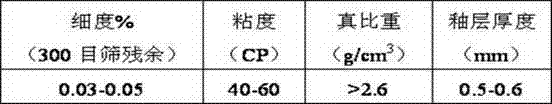

Giant dielectric composite ceramic copper calcium titanate material and preparation method and application thereof

ActiveCN109650875AThe preparation process is simple and controllableImprove yieldFixed capacitor dielectricStacked capacitorsHigh energyComposite ceramic

The invention discloses a giant dielectric composite ceramic copper calcium titanate material and a preparation method and application thereof and belongs to the technical field of electronic ceramicmaterial preparation. According to the method, micro powder and nano powder which are synthesized by a solid-phase method and a sol-gel method are mixed for preparing the composite ceramic copper calcium titanate material, and the preparation process is simple, controllable and high in repeatability and yield. Moreover, by changing the composite ratio of the micro and nano powder, the crystal grain size and range of the composite ceramic copper calcium titanate material can be regulated and controlled, and therefore, the compact composite ceramic copper calcium titanate material with a high dielectric constant (5*104), low loss (0.051), high breakdown field strength (2,374V / cm) and high energy storage density (20kJ / m<3>) is obtained, wherein the energy storage density of the composite ceramic material is 12.7 times higher than that of ceramics prepared from micro powder and 12.1 times higher than that of ceramics prepared from nano powder. The composite ceramic copper calcium titanatematerial prepared by the method has high practicability, can be used as a dielectric material for preparing high-dielectric multilayer ceramic capacitors and dynamic random access memories, and can also serve as a pressure-sensitive ceramic material in the fields of electric power, electronic systems and the like.

Owner:XI AN JIAOTONG UNIV

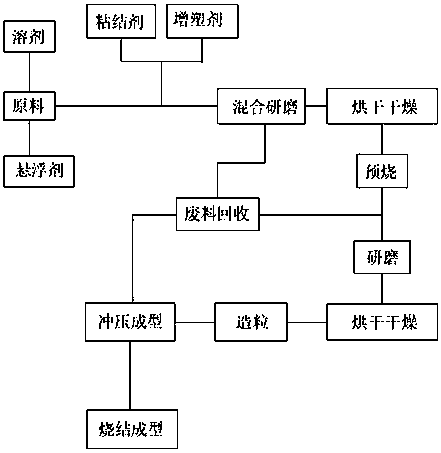

Preparation method of low-temperature sintered electronic ceramic material

The invention discloses a preparation method of a low-temperature sintered electronic ceramic material. The preparation method comprises the following steps: mixing a plurality of preparation raw materials according to the proportions; grinding the raw materials and adding the ground raw materials into a solvent; preparing suspension by adding a suspending agent, and enabling suspension slurry toflow to a stably-rotating annular steel strip through a casting nozzle by means of gravity; carrying out circular drying for multiple times to obtain a raw material thin film; adding a binder and a plasticizer into the raw material thin film; carrying out first-time mixing and grinding by a ball mill to obtain mixed material powder; putting the mixed material powder into a drying oven. According to the preparation method disclosed by the invention, the density of a blank body is more uniform; the quality of the obtained electronic ceramic material is high, and the electronic ceramic material can be prepared by low-temperature sintering forming; when the obtained electronic ceramic material is cofired, metals with better properties such as silver with better conductive property can be used;meanwhile, a formula is simple and low in price, so that the preparation cost of the low-temperature sintered electronic ceramic material is reduced.

Owner:HUNAN JIAYEDA ELECTRONICS

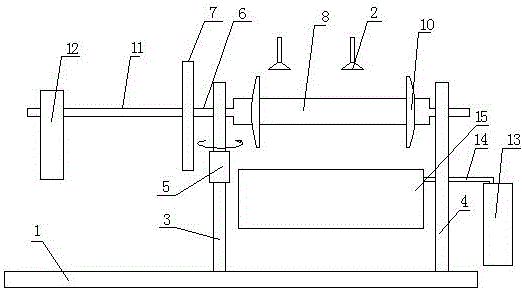

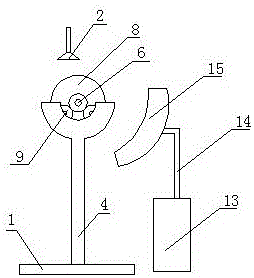

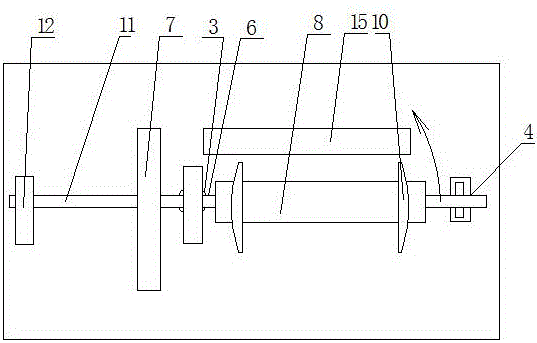

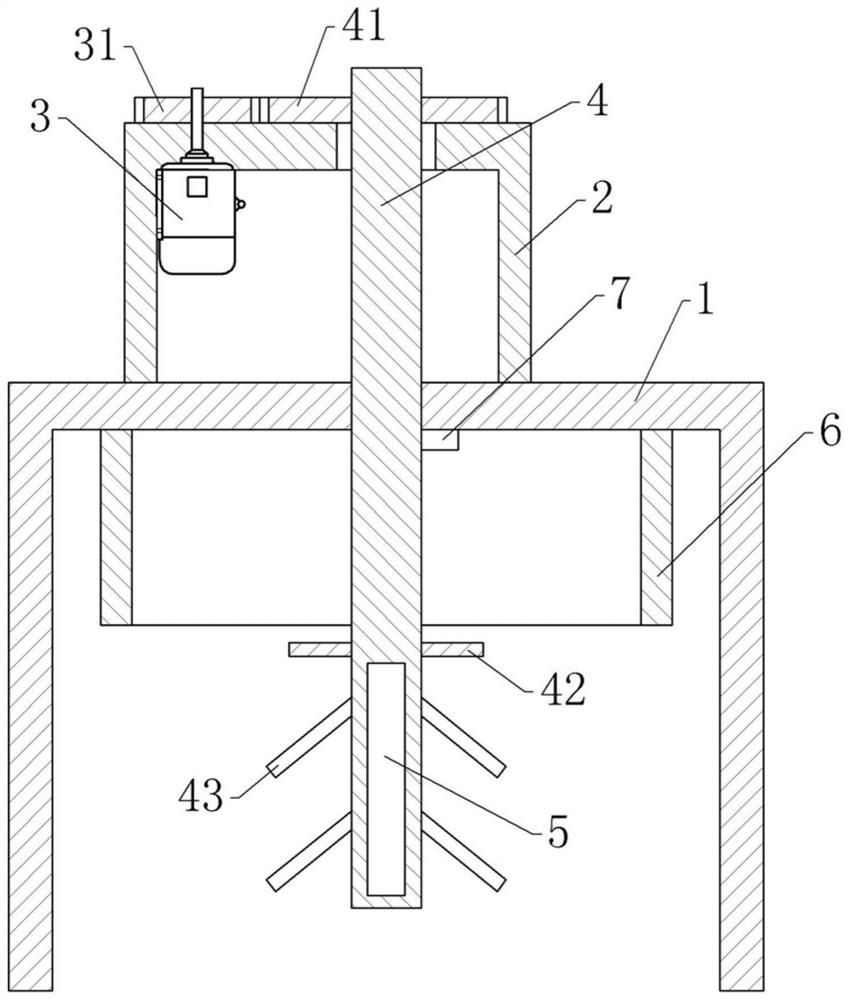

Inserting type porcelain insulator blank glazing device

The invention relates to equipment of the technical field of electroceramics production, specifically to an inserting type porcelain insulator blank glazing device. The inserting type porcelain insulator blank glazing device comprises a frame, which is provided with a mobile glazing nozzle; the inserting type porcelain insulator blank glazing device also comprises two support racks including a first support rack and a second support rack. The inserting type porcelain insulator blank glazing device is characterized in that the first support rack is provided with a rotating shaft which is connected with a cross bar through a bearing, the cross bar is provided with a rotating disc outside the first support rack and provided with a rubber shaft sleeve on the circumference of one side of the first support rack; the second support rack is provided with a groove, the bearing is arranged inside the groove, and the end portion of the cross bar can be arranged onto the bearing,; the cross bar is provided with two chucks which can clamp the end surfaces of a blank to be glazed; the cross bar is provided with an extension rod on one side of the rotating disc, and the extension rod is provided with a balance weight. The inserting type porcelain insulator blank glazing device can avoid sinking of the blank during glazing and has the advantage of being convenient to use.

Owner:河南鑫海电力设备有限公司

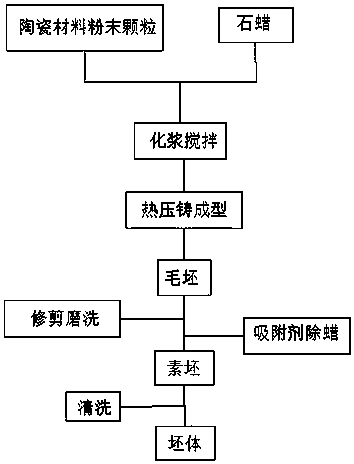

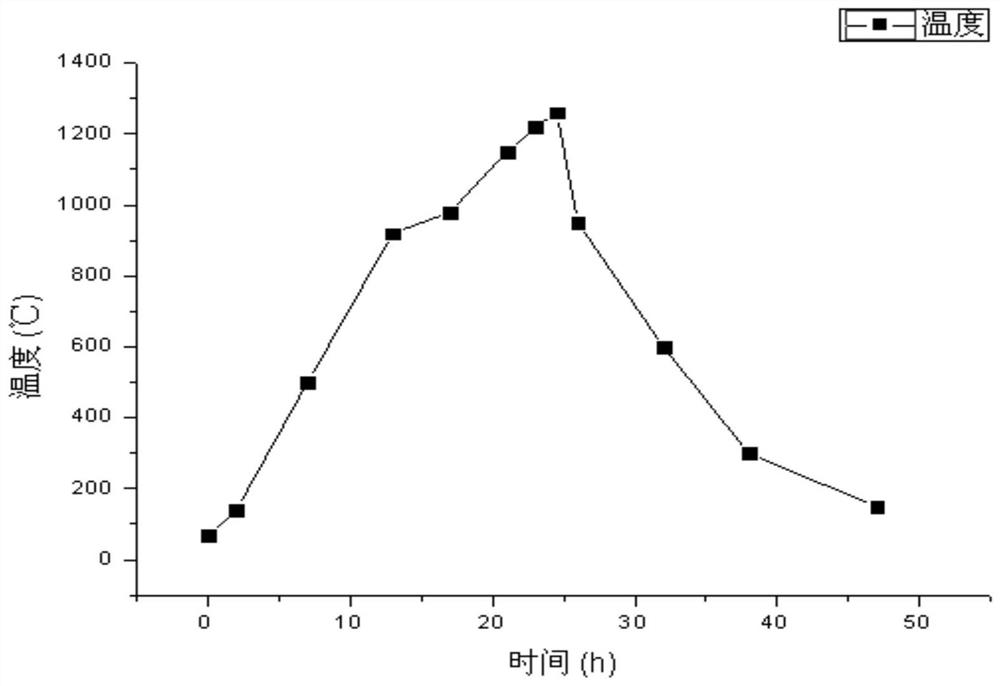

Preparation method of ceramic capacitor

The invention belongs to the technical field of electronic equipment, and more specifically relates to a preparation method of a ceramic capacitor. The preparation method comprises following steps: 1, ingredients of an electronic ceramic composition are subjected to uniform wet grinding and drying; 2, the dried electronic ceramic composition is mixed with a ceramic molding adhesive at a certain ratio, and an obtained mixture is stirred to be uniform, and is subjected to pressure casting and moulding so as to obtain a green body; 3, the green body is subjected to adhesive removing, sintering, and ultrasonic cleaning successively; and 4, the green body is subjected to sorting, silver printing, reduction, measuring, and encapsulating; wherein adhesive removing temperature is controlled to be 280 to 400 DEG C, sintering temperature is controlled to be 1350 to 1430 DEG C, and sintering time is controlled to be 3 to 4h. The ceramic capacitor obtained via the preparation method possesses relatively high dielectric constant, high capacitor stability, and excellent voltage withstand characteristics; the preparation method is simple; equipment requirement is low; production cost is low; and profit rate is high.

Owner:ZHANGJIAGANG HONGJIA DIGITAL TECH

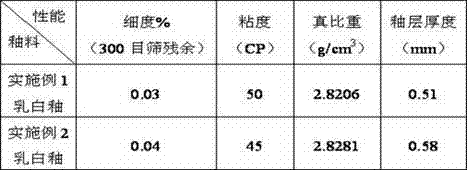

Opal glaze for electroceramics and glazing process thereof

InactiveCN102775194AGood water reduction effectGood glaze performanceElectroceramicsMaterials science

The invention discloses an opal glaze for electroceramics and a glazing process thereof. The opal glaze comprises the following components in percentage by weight: Datong sand, talcum powder, limestone, Faku clay, white drystone, feldspar, silica powder, barium carbonate, zirconium silicate and SP-100 dispersing agent. The glazing process comprises the steps of (1) glaze dipping; (2) primary and secondary glaze spraying; and (3) roasting, and the like. The opal glaze and glazing process thereof disclosed by the invention have the following characteristics and advantages: 1, the glazing process belongs to a creative process, and is a novel glazing process implemented by carrying out optimized combination on different glazing modes such as glaze dipping, glaze spraying and the like; 2, for adapting to the novel process and realizing good glaze slip performance, in the invention, while the process is adjusted, a dispersing agent with a better water reducing effect is used in a formula; and 3, the surface of an opal glaze product produced according to the invention is smooth, no glaze peeling and massing phenomena are caused, and more serious quality problems that the opal glaze product has yellow edges and water edges and the like are mainly solved, so that the surface quality of the product is greatly increased.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

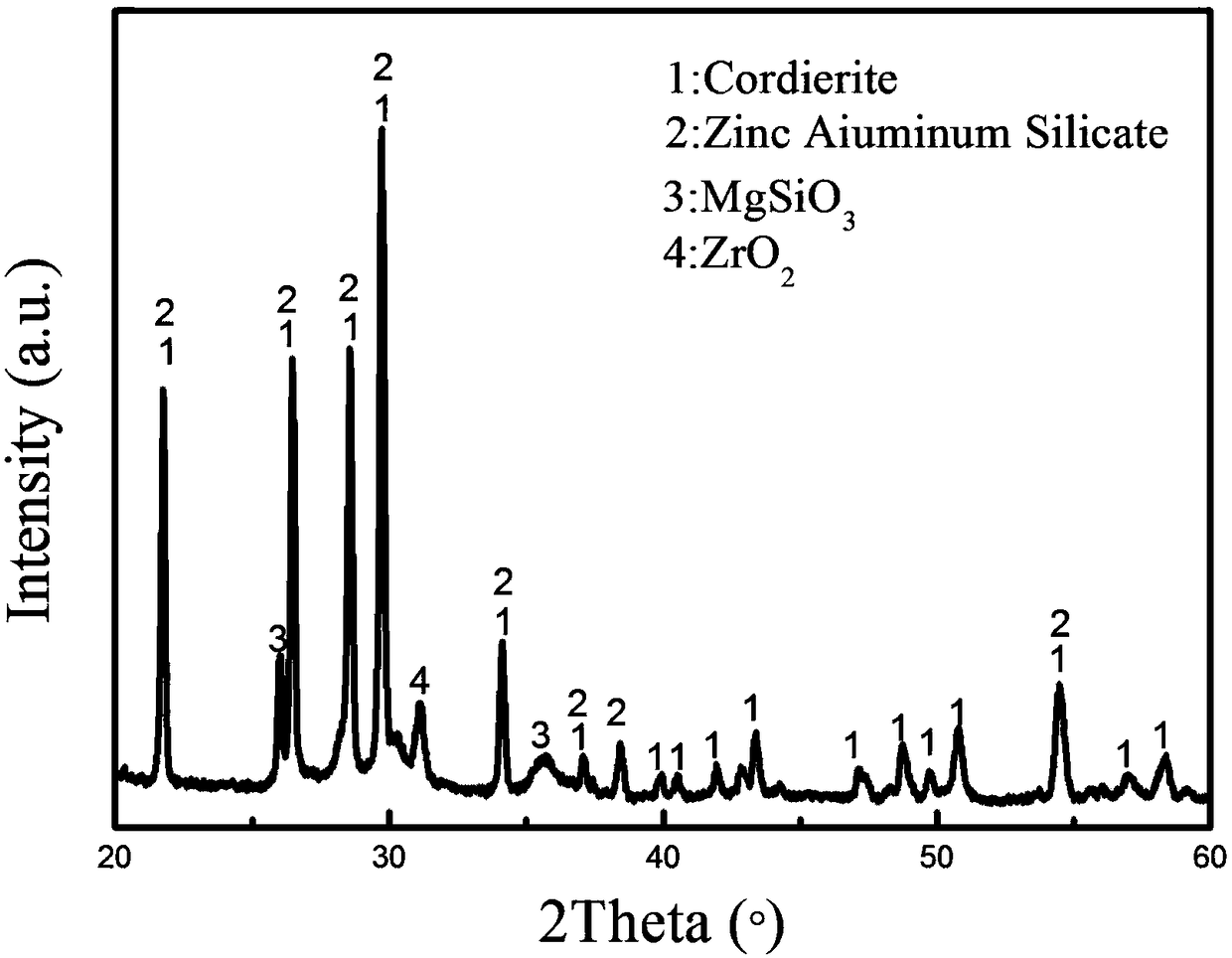

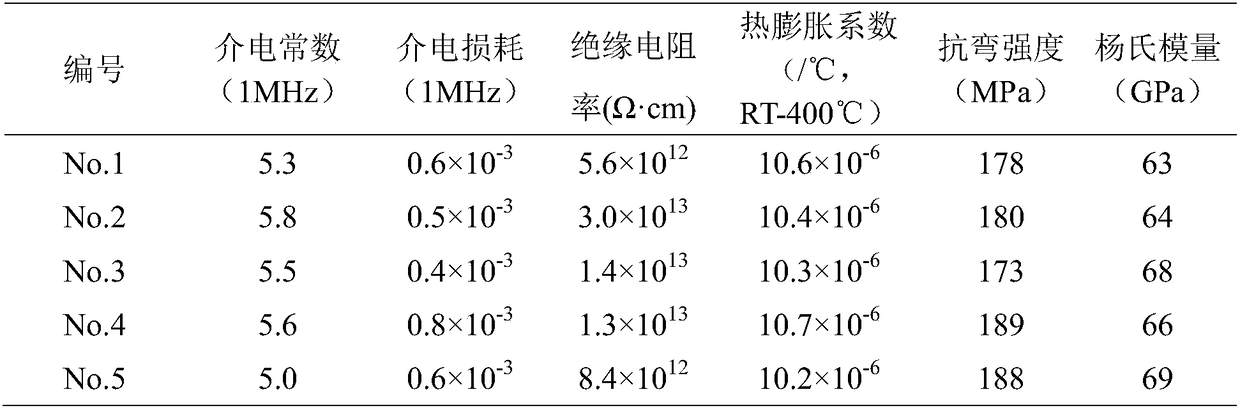

Ceramic substrate material with high strength and high thermal expansion and preparation method of ceramic substrate material

The invention belongs to the field of electronic ceramic packaging materials, particularly relates to a ceramic substrate material with high strength and high thermal expansion and a preparation method of the ceramic substrate material, and is suitable for ceramic packaging of large-scale integrated circuit chips, in particular for CBGA (ceramic ball grid array) packaging. A low-temperature co-firing process is adopted and is simple and easy to implement, raw materials are green and environmentally friendly and do not contain pollutants defined in RoHS (Restriction of the use of certain Hazardous Substances), and material performance is stable. By redesign of the material formula, the ceramic substrate material with high strength and high coefficient of thermal expansion has excellent dielectric properties: the dielectric constant is 5-6, and the dielectric loss is less than 1.0*10<-3>, bending strength is 170-190 MPa, Young's modulus is as high as 60-70 GPa and the coefficient of thermal expansion is (10-11)*10<-6> / DEG C; perfect thermal matching with a PCB with a specific thermal expansion coefficient can be realized, and an excellent ceramic substrate material is provided for ICdevice packaging; besides, the substrate material has low production cost and has industrial promotion benefits.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Opal glaze for electroceramics as well as preparation method and glazing process of opal glaze

The invention discloses opal glaze for electroceramics as well as a preparation method and application of the opal glaze. The opal glaze for the electroceramics is prepared from the following raw materials in percentage by weight: 5-10% of Datong sand, 8-12% of talc, 1-3% of limestone, 4-7% of Faku clay, 9-12% of Baigan stone, 26-34% of feldspar, 17-22% of silica powder, 1-4% of barium carbonate,10-15% of zirconium silicate, 3-4% of Suzhou soil, 1-3% of aluminum oxide and 0.05-0.2% of a dispersing agent. The preparation method comprises the steps of glaze dipping, glaze spraying and roasting.The components in the opal glaze are reasonably matched, aluminum oxide is added on the basis of the prior art to improve the precision of the glaze, and limestone and Suzhou soil are added to increase the high-temperature viscosity of the glaze to adjust the fluidity of the glaze in the high-temperature stage in order to overcome the problems of yellow edges and white edges. The color differenceof white exposure and yellow exposure of the edge part of the product due to too strong fluidity of the glaze in a high-temperature stage is avoided or increased.

Owner:河北宣化新迪电瓷股份有限公司

Copper clad welding rod and manufacturing method thereof

InactiveCN104889607AAvoid residueImprove conductivityWelding/cutting media/materialsSoldering mediaCopper platingRare earth

The invention discloses a copper clad welding rod and a manufacturing method thereof, wherein the copper clad welding rod comprises a metal core and a welding flux covering; the metal core comprises a working part and a holding part that are fixedly connected with each other; the welding flux covering is covered outside the working part; the working part is an iron alloy wire; and the holding part is a copper-plated aluminum wire; the length ratio between the holding part and the working part is 1:7-8; and the welding flux covering comprises the following components: 20-25 parts by weight of albite, 10-12 parts by weight of potassium carbonate, 6-10 parts by weight of calcium carbonate, 20-25 parts by weight of sodium silicate, 1-3 parts by weight of nanometer titanium dioxide, 2-3 parts by weight of nanometer ferric oxide, 1-1.5 parts by weight of manganese dioxide, 0.5-1 part by weight of rare earth lanthanum, 8-12 parts by weight of kaolin, and 6-10 parts by weight of Zuoyuntu (a raw material for electroceramics originating in Zuoyun County, Shanxi Province, China). The method comprises the steps of frictionally welding the working part with the holding part, and then coating the welding flux covering. By employing the contact interface design of the working part and the holding part of the welding rod, and utilizing the different characteristics of the metal and the welding flux covering, automatically releasing the welding rod head is achieved when the welding rod is about to run out, thereby thoroughly avoiding the residual of the welding rod head.

Owner:赵兰

High-performance glaze

The invention belongs to the technical field of preparation of glazes from inorganic materials, and discloses a high-performance glaze. The high-performance glaze comprises high-potassium low-sodium feldspar, high-sodium low-potassium feldspar, ball clay, hard kaolin, calcined talc, limestone, quartz powder and sodium carboxymethyl cellulose. A preparation method for the high-performance glaze comprises the following steps: weighing the raw materials according to a desired ratio, putting the raw materials into a ball mill, adding water, and carrying out ball milling to obtain primary slurry; sieving the primary slurry to filtering out impurities and raw material particles with large particle sizes, thereby obtaining secondary slurry; and finally, aging the secondary slurry to obtain the high-performance glaze. According to the invention, the problem of high production cost of electroceramics due to low first-pass yield of the electroceramics prepared from conventional glazes is solved.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Heating device

InactiveCN103687108ACan focus firepowerSave energyDomestic stoves or rangesLighting and heating apparatusEngineeringElectroceramics

A heating device comprises an electric heating wire, a quartz tube, a collecting mirror and a reflecting shade, wherein the electric heating wire is integrally fixed by electroceramics heads arranged at two ends, and is mounted in a tube body of the quartz tube; the reflecting shade is arc-shaped, and is arranged at the periphery of the quartz tube in an opening manner; the collecting mirror is mounted close to the opening. The design construction of the heating device is achieved by the shape, the structure, and the combination of the shape and the structure.

Owner:李文庆

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com