Patents

Literature

126results about "Lanthanum oxide/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

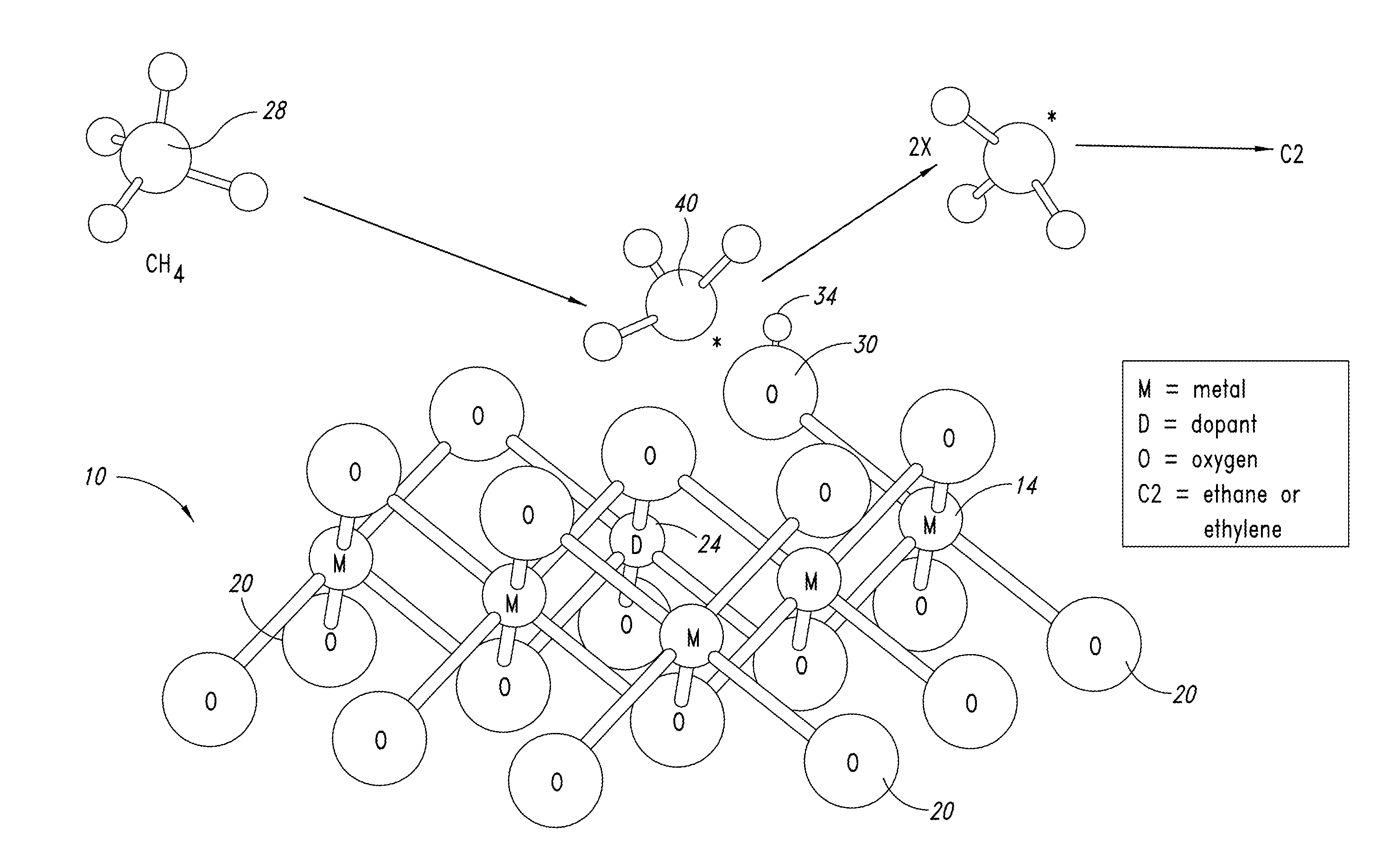

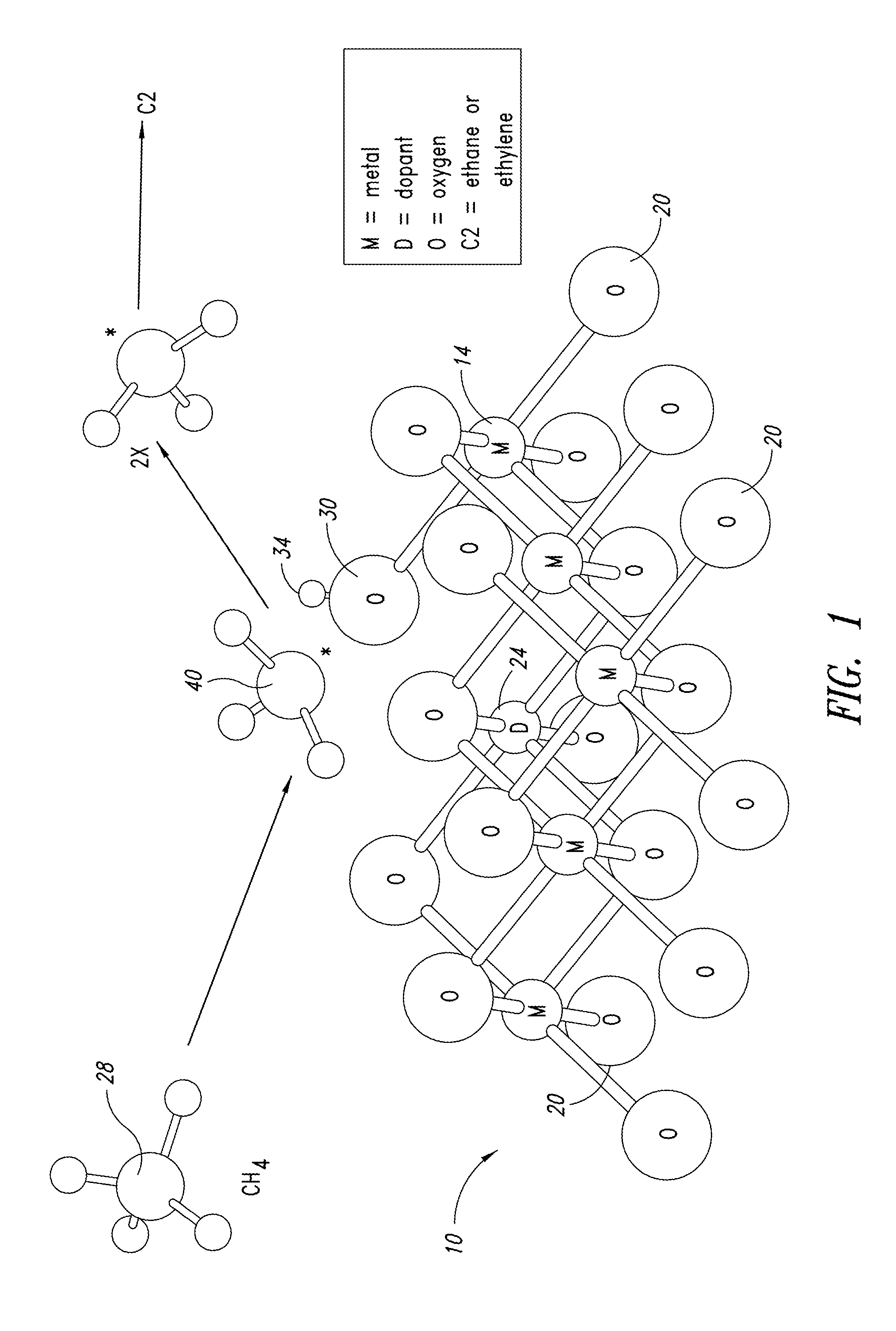

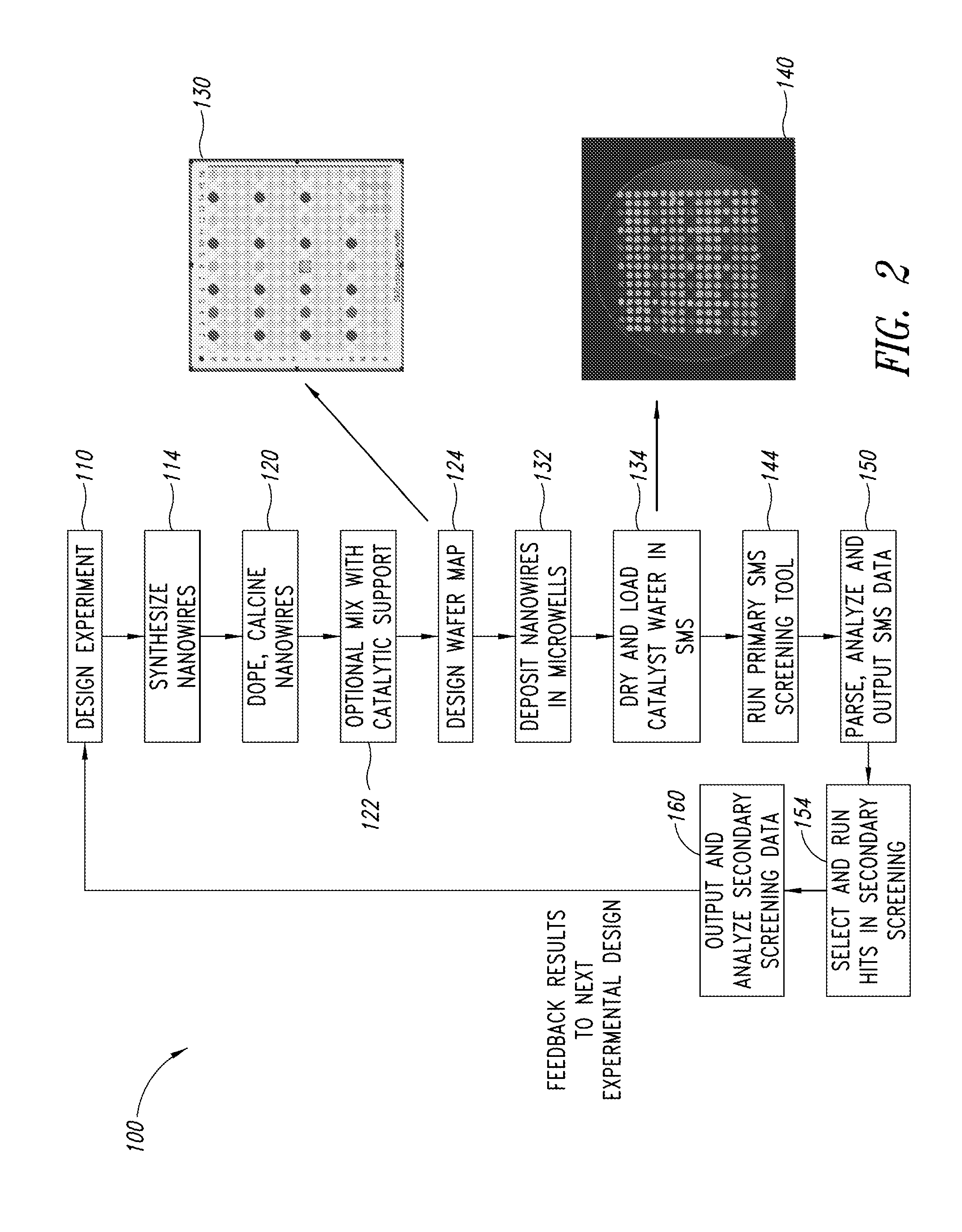

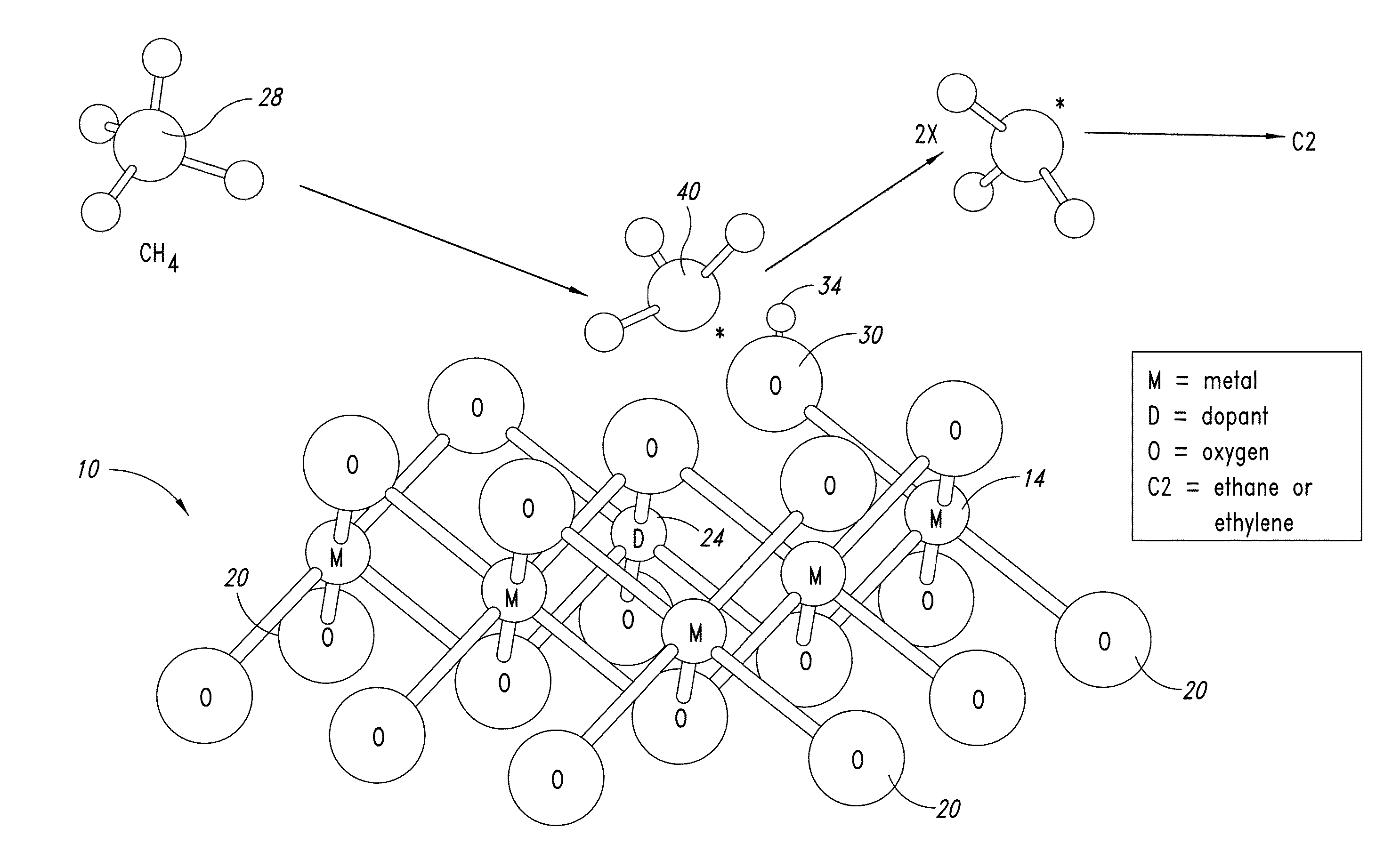

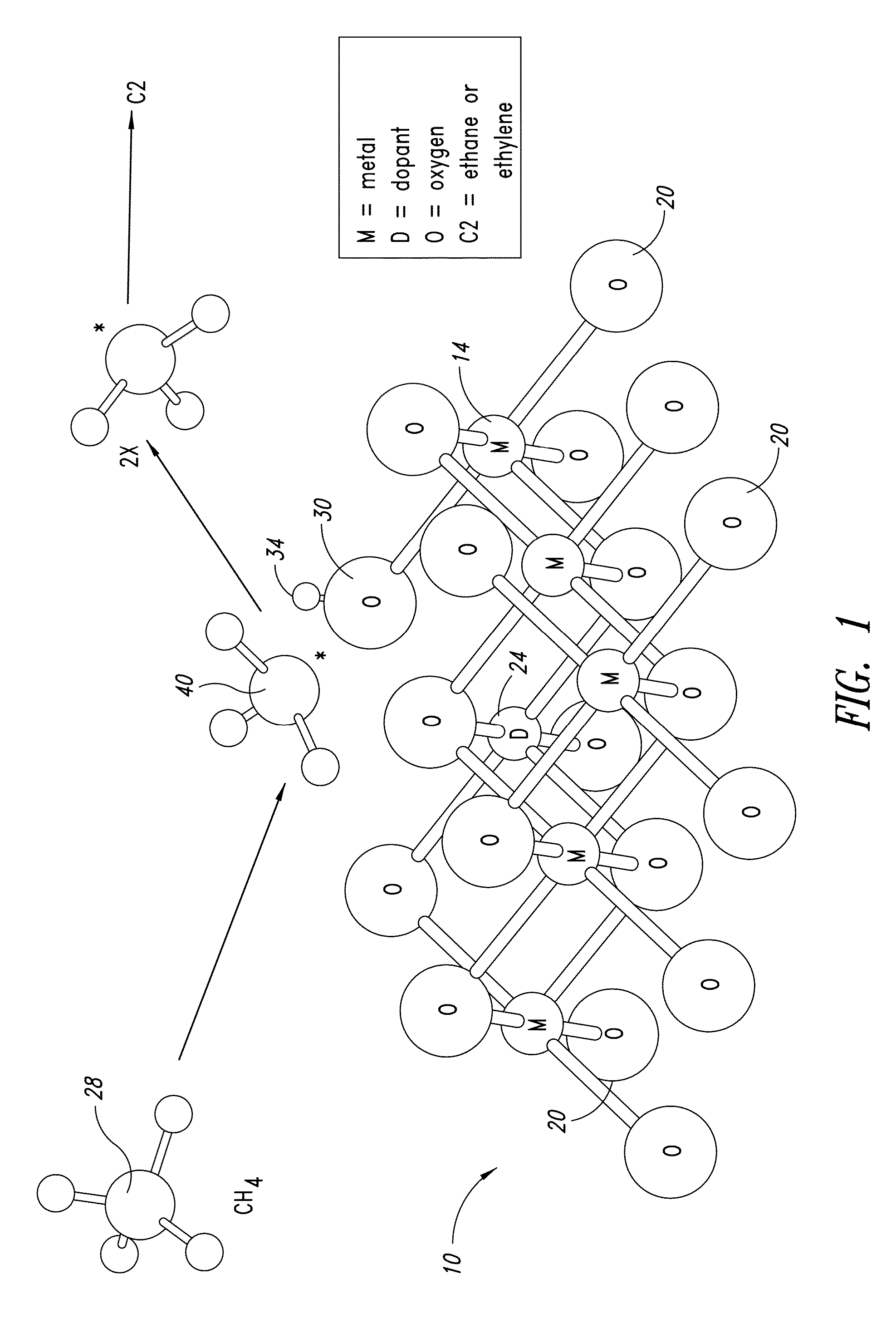

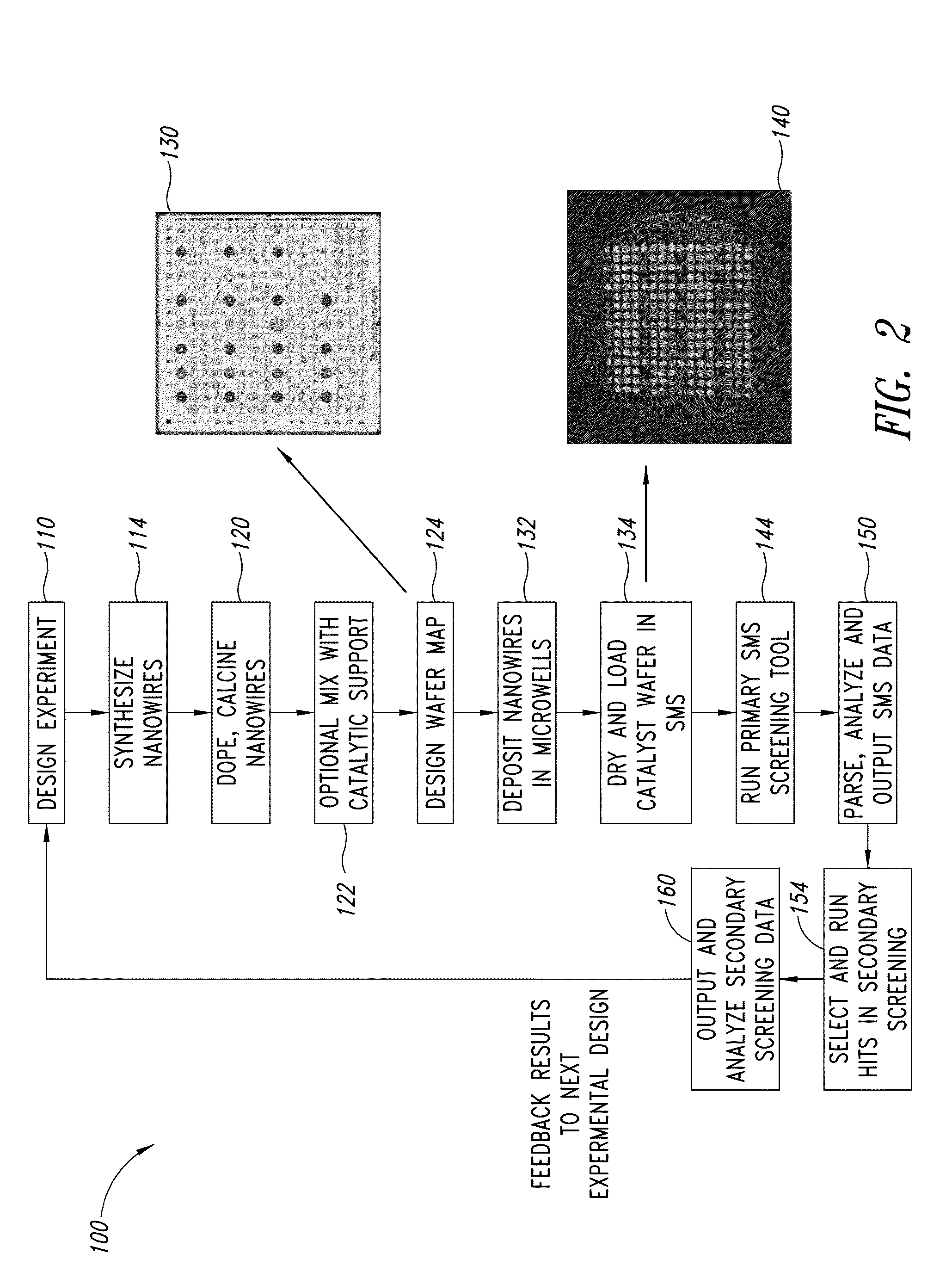

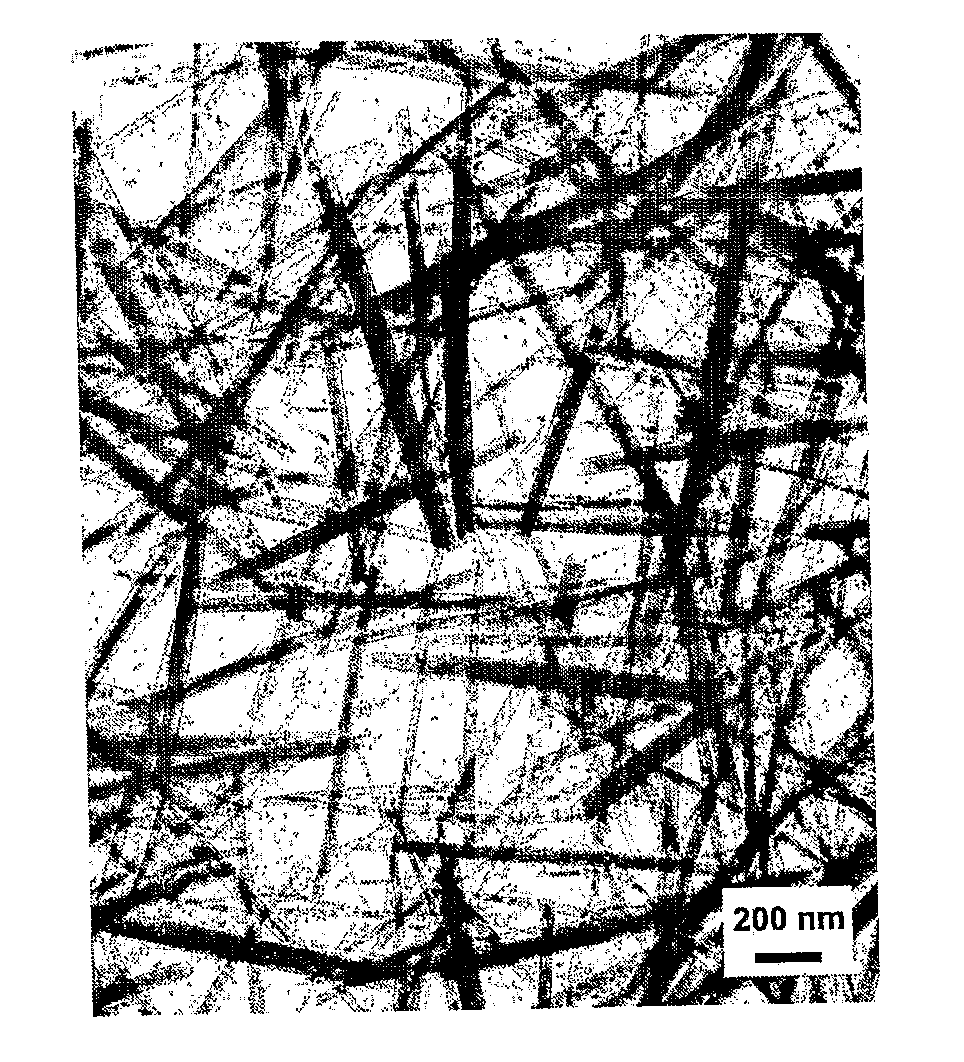

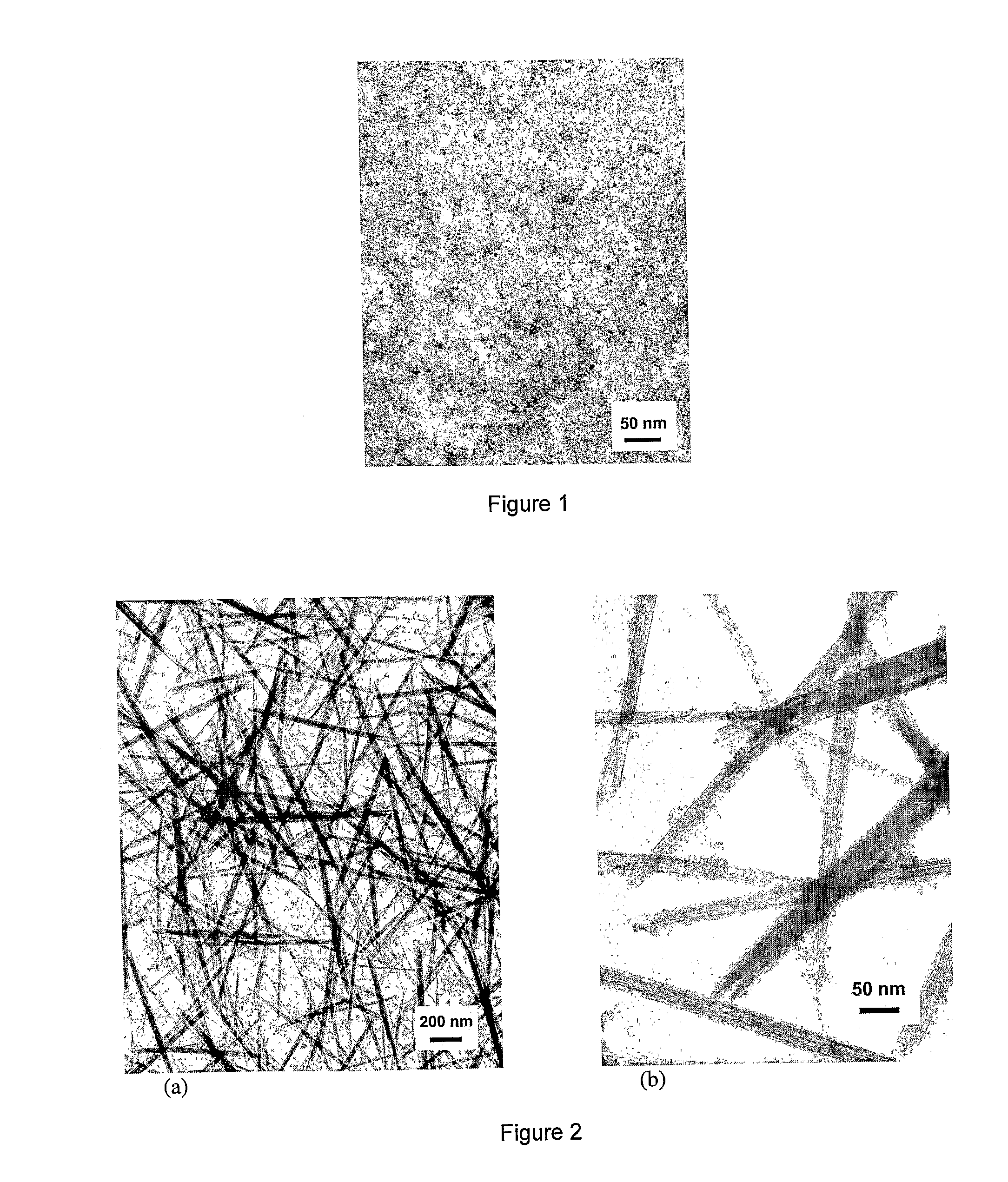

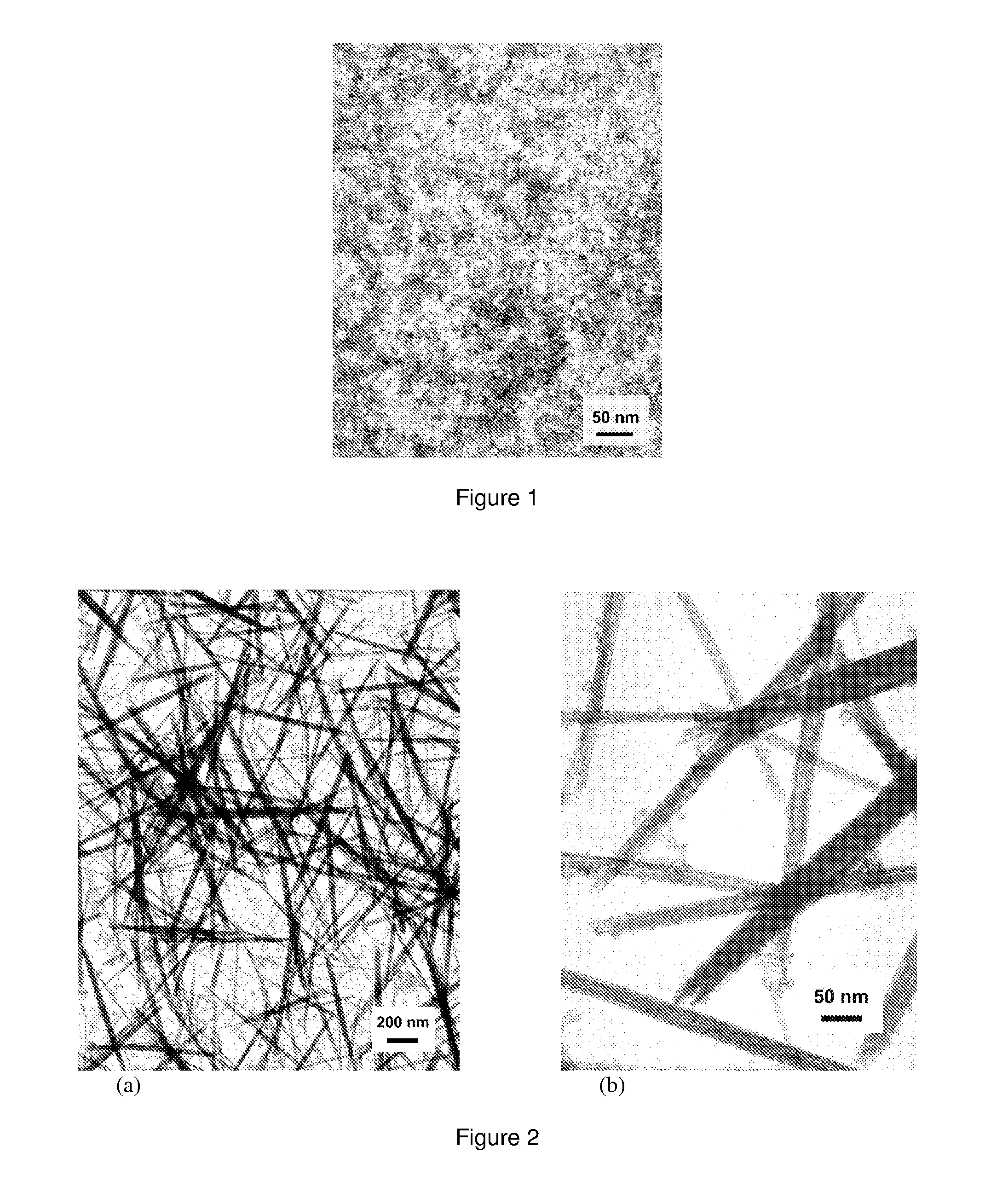

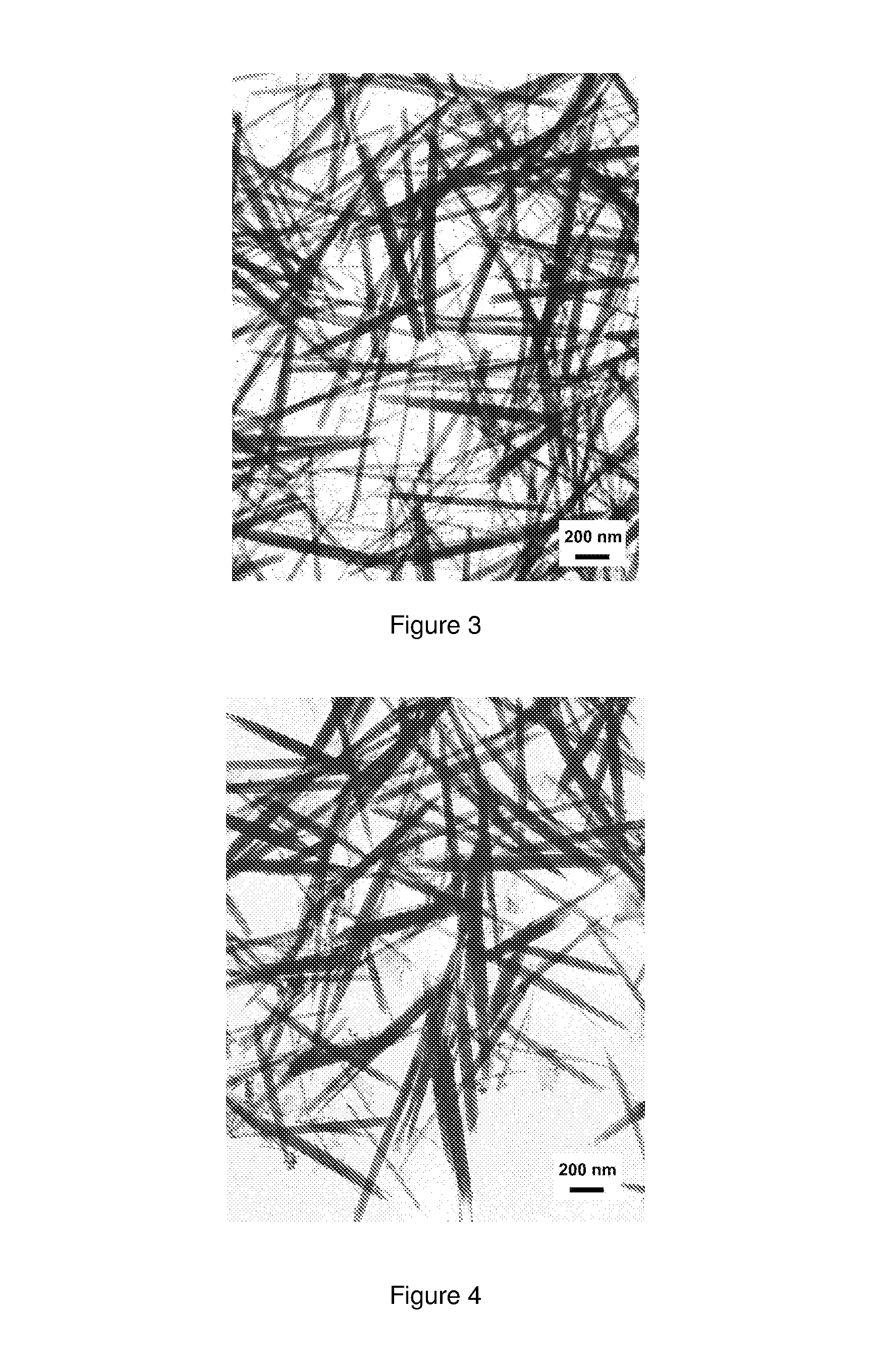

Nanowire catalysts and methods for their use and preparation

ActiveUS20130165728A1Material nanotechnologyManganese oxides/hydroxidesNanowireOxidative coupling of methane

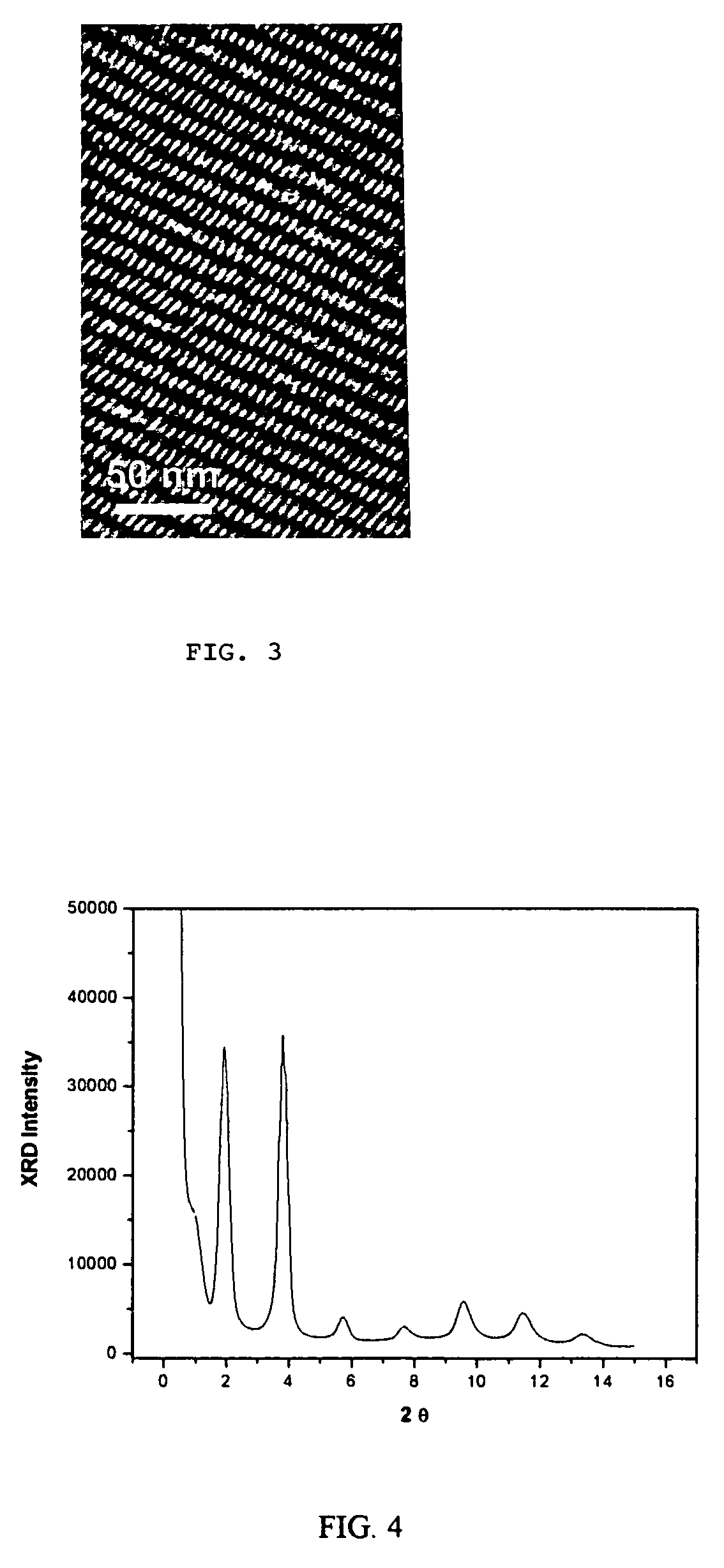

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

Polymer templated nanowire catalysts

InactiveUS20130158322A1Improve drawing legibilityMaterial nanotechnologyManganese oxides/hydroxidesNanowirePolymer science

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are prepared by polymer templated methods and are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethane and / or ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

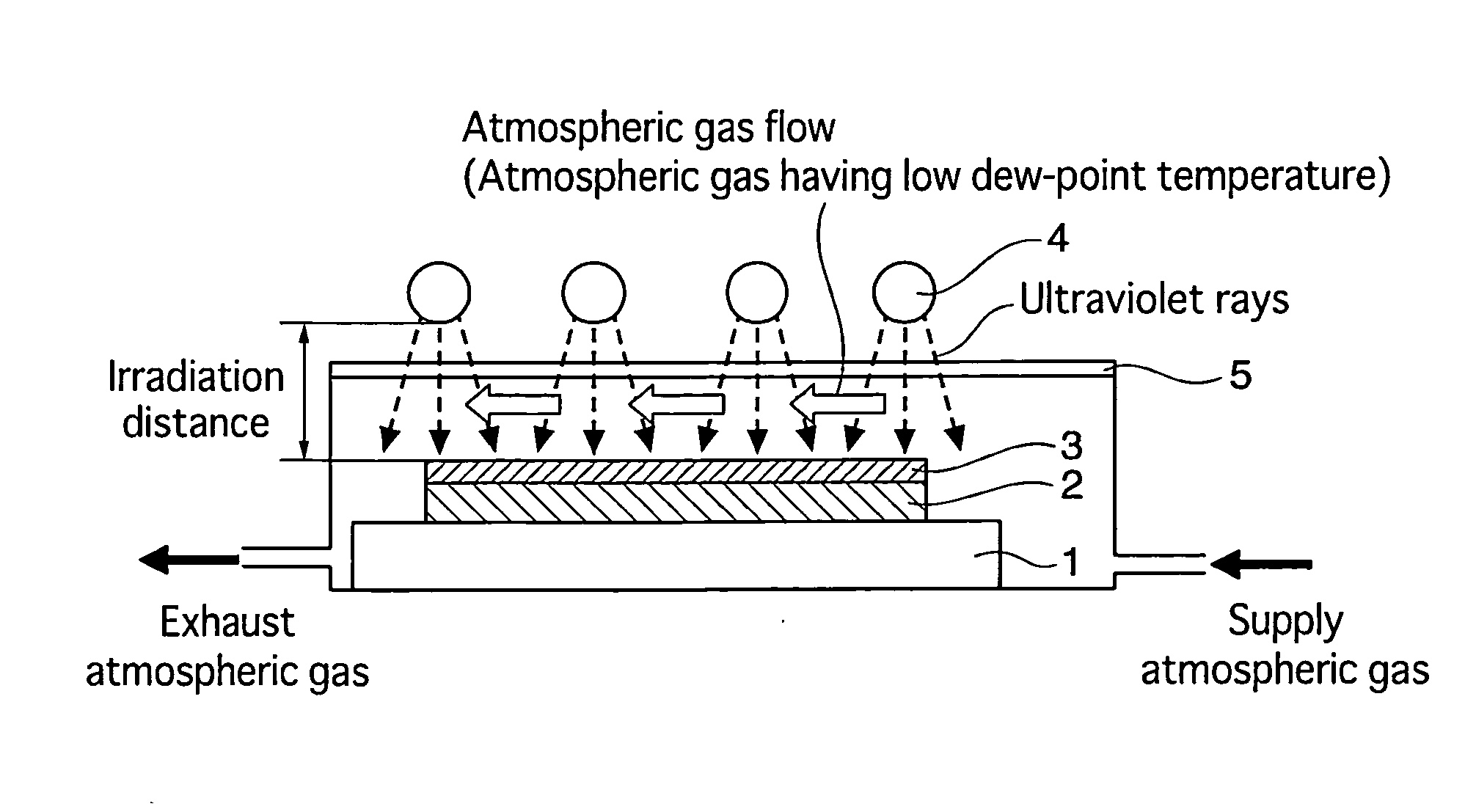

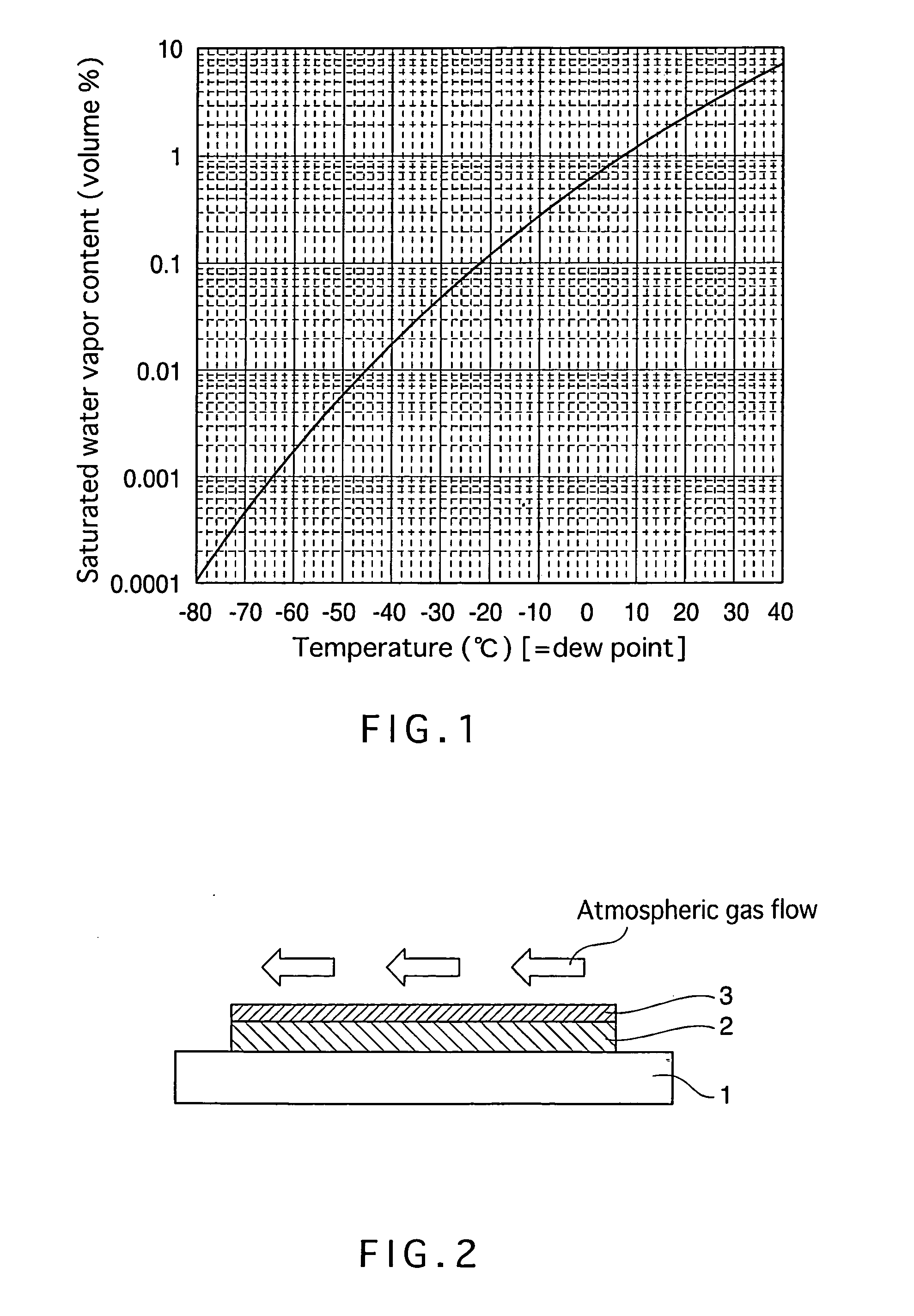

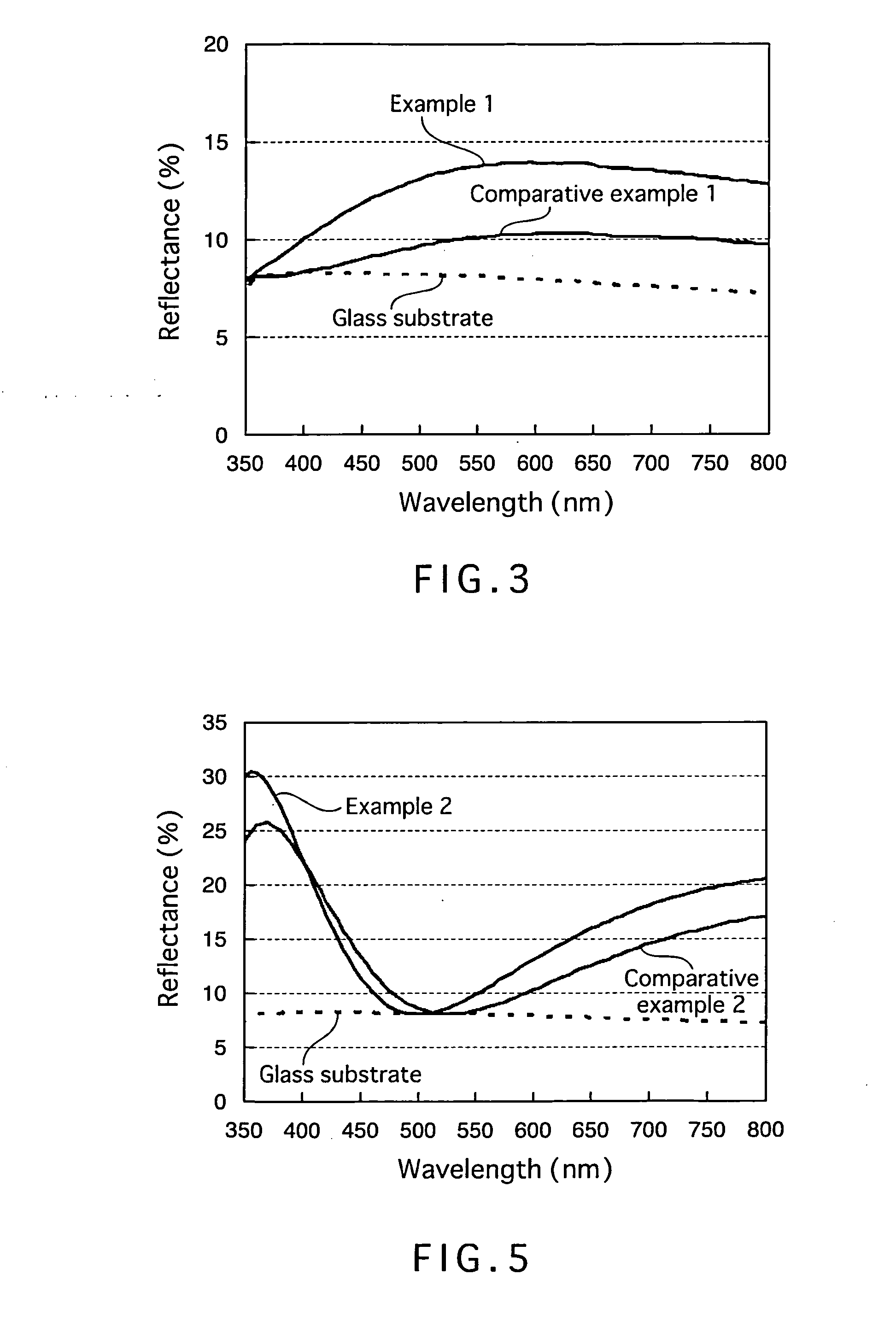

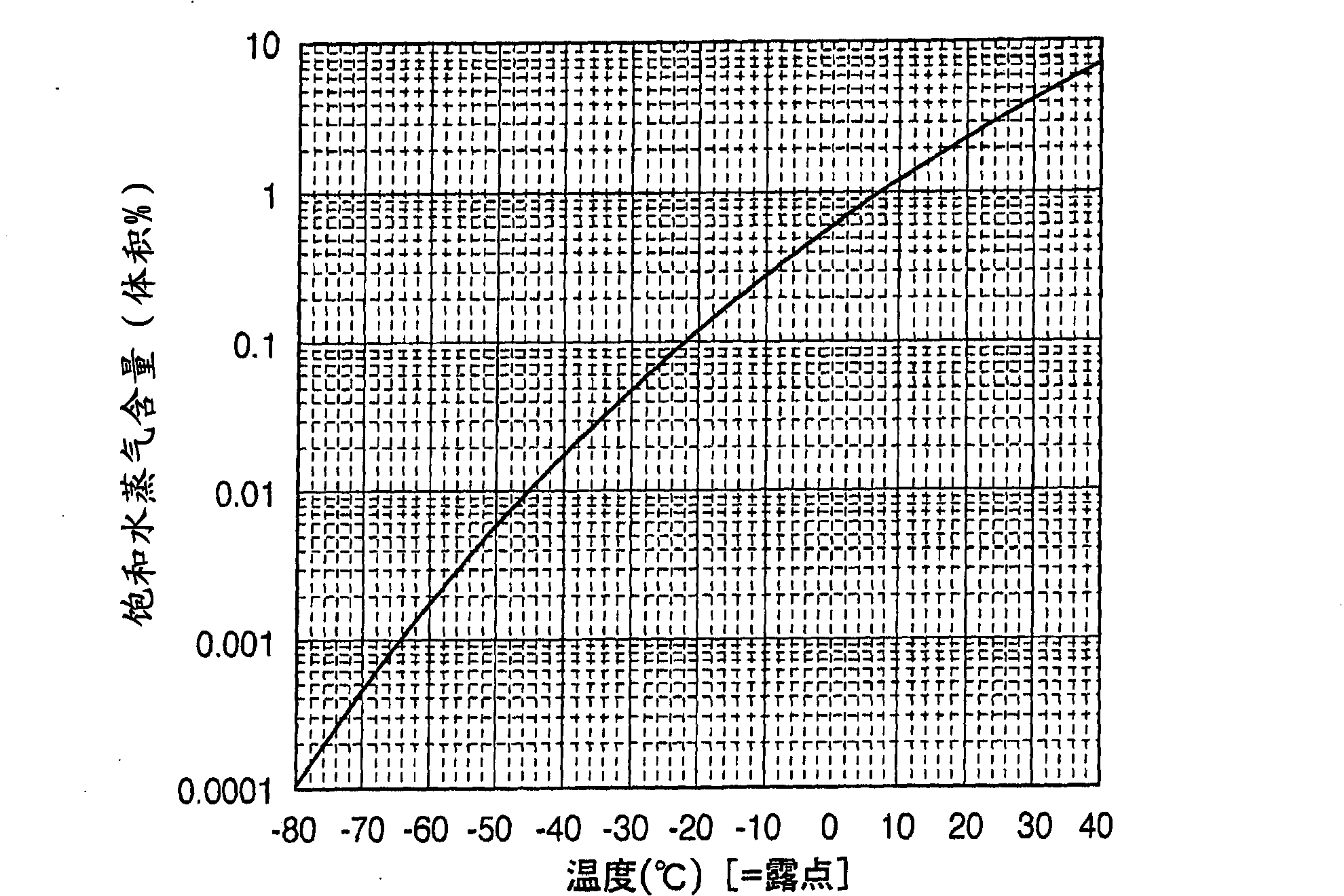

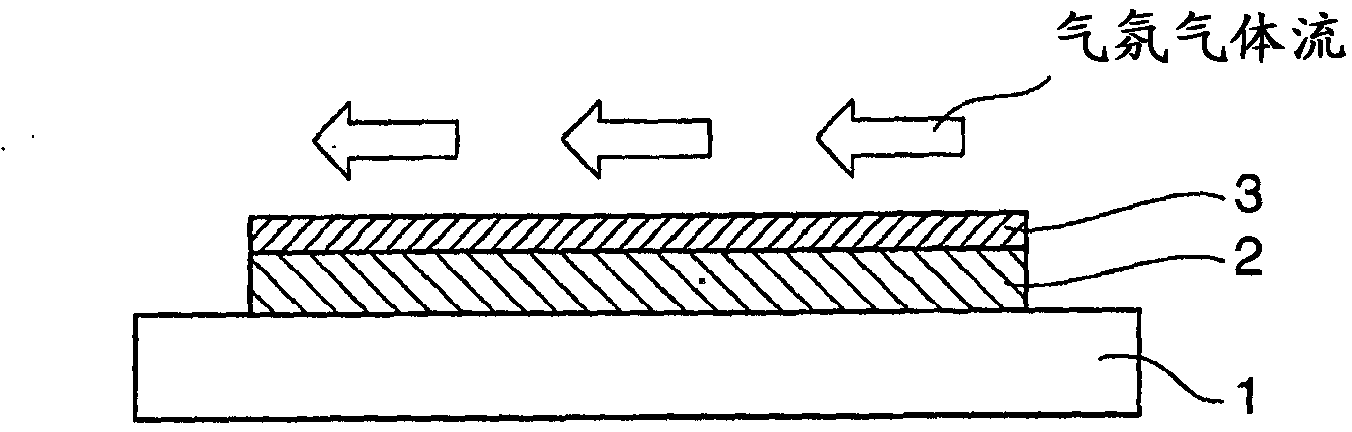

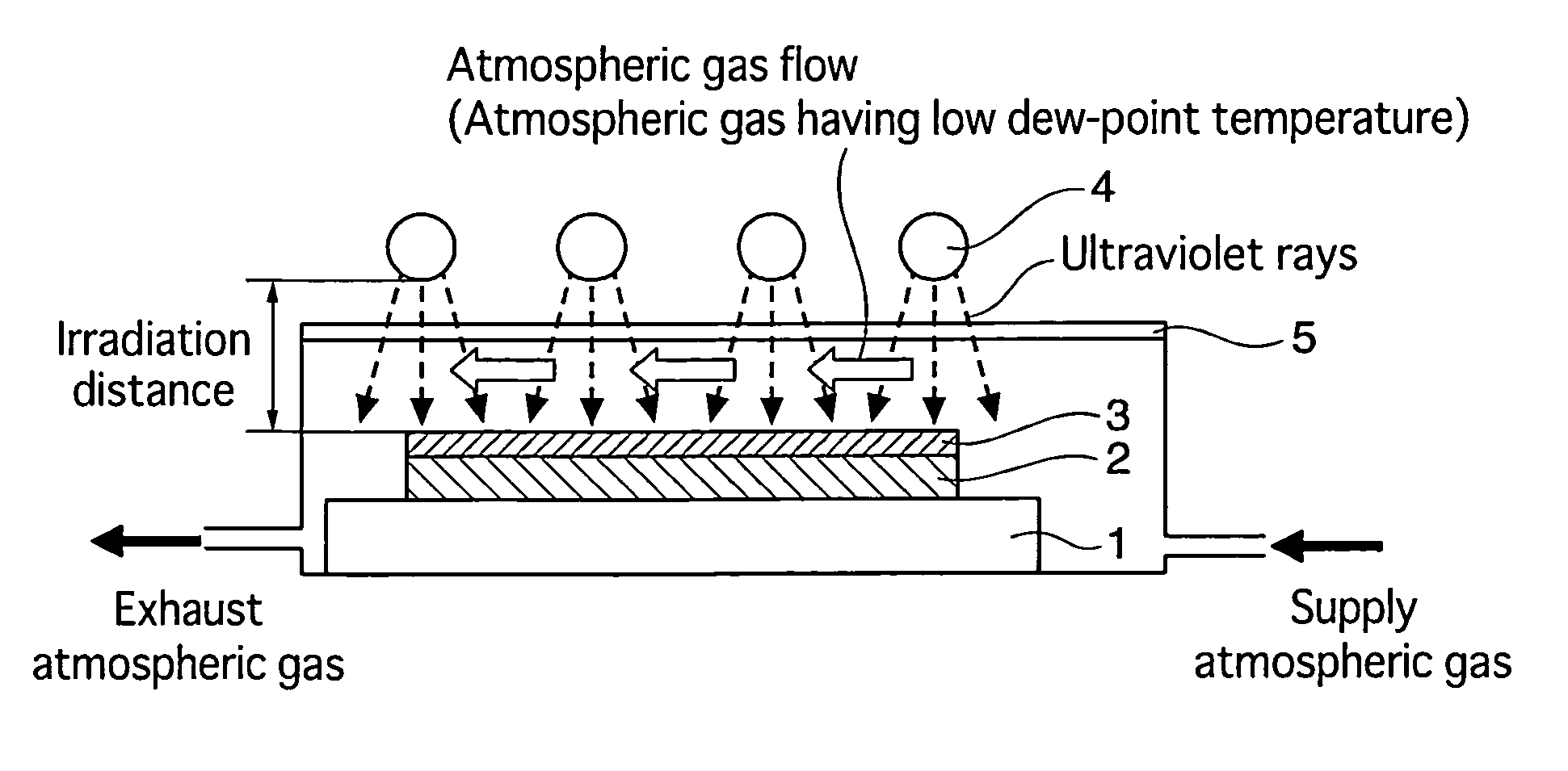

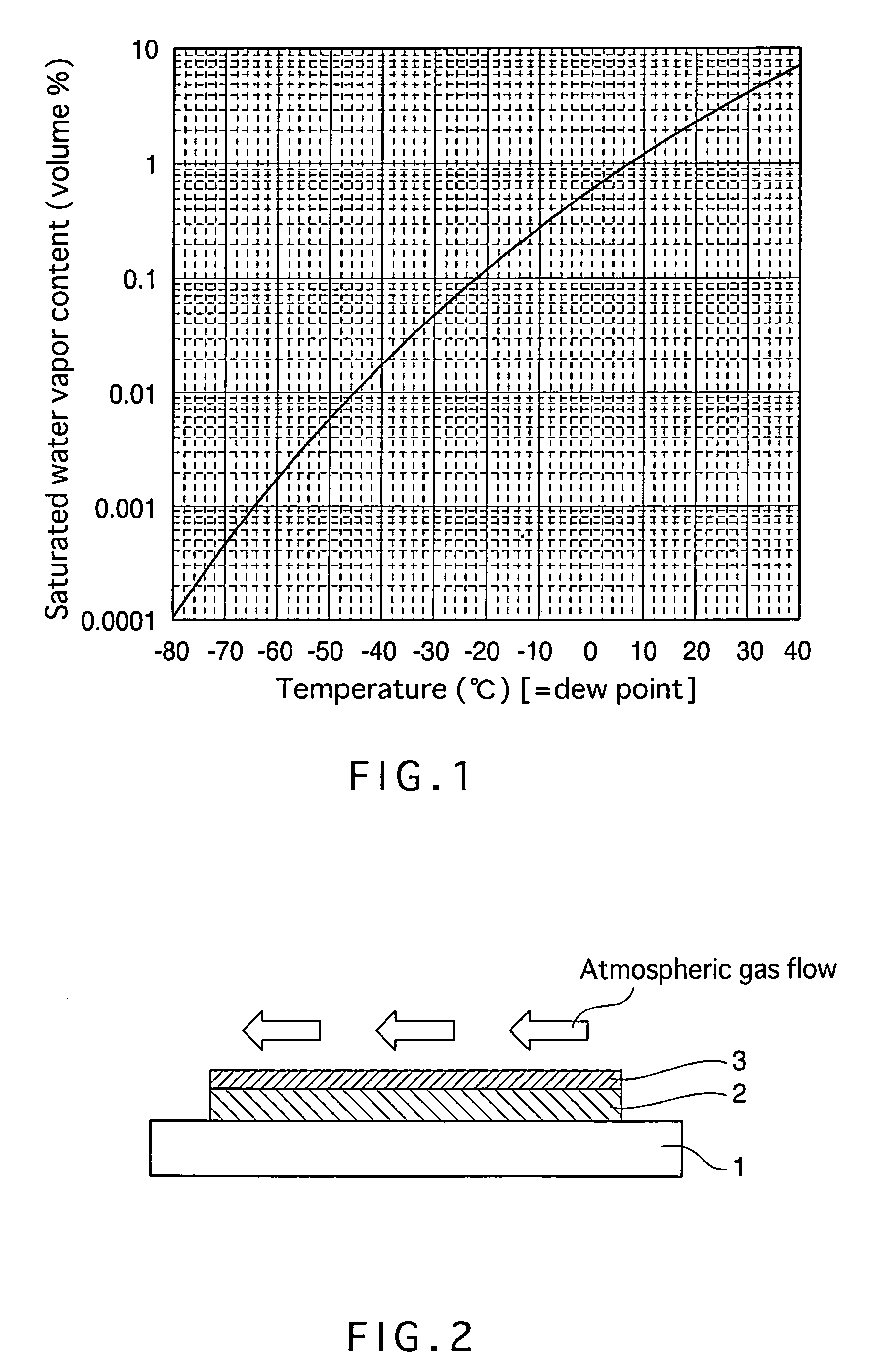

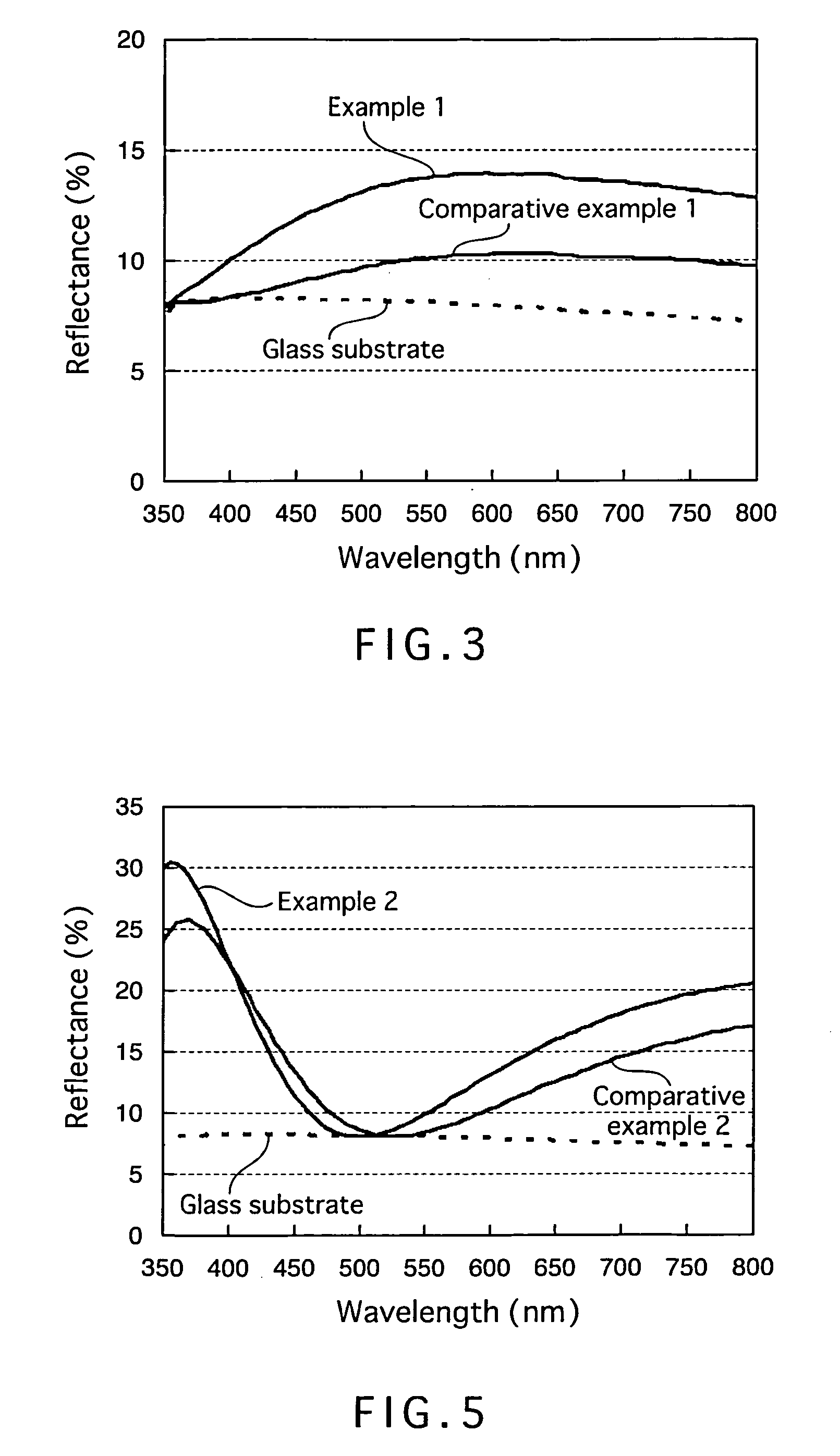

Method of manufacturing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveUS20130101867A1High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device detailsOxygenMaterials science

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

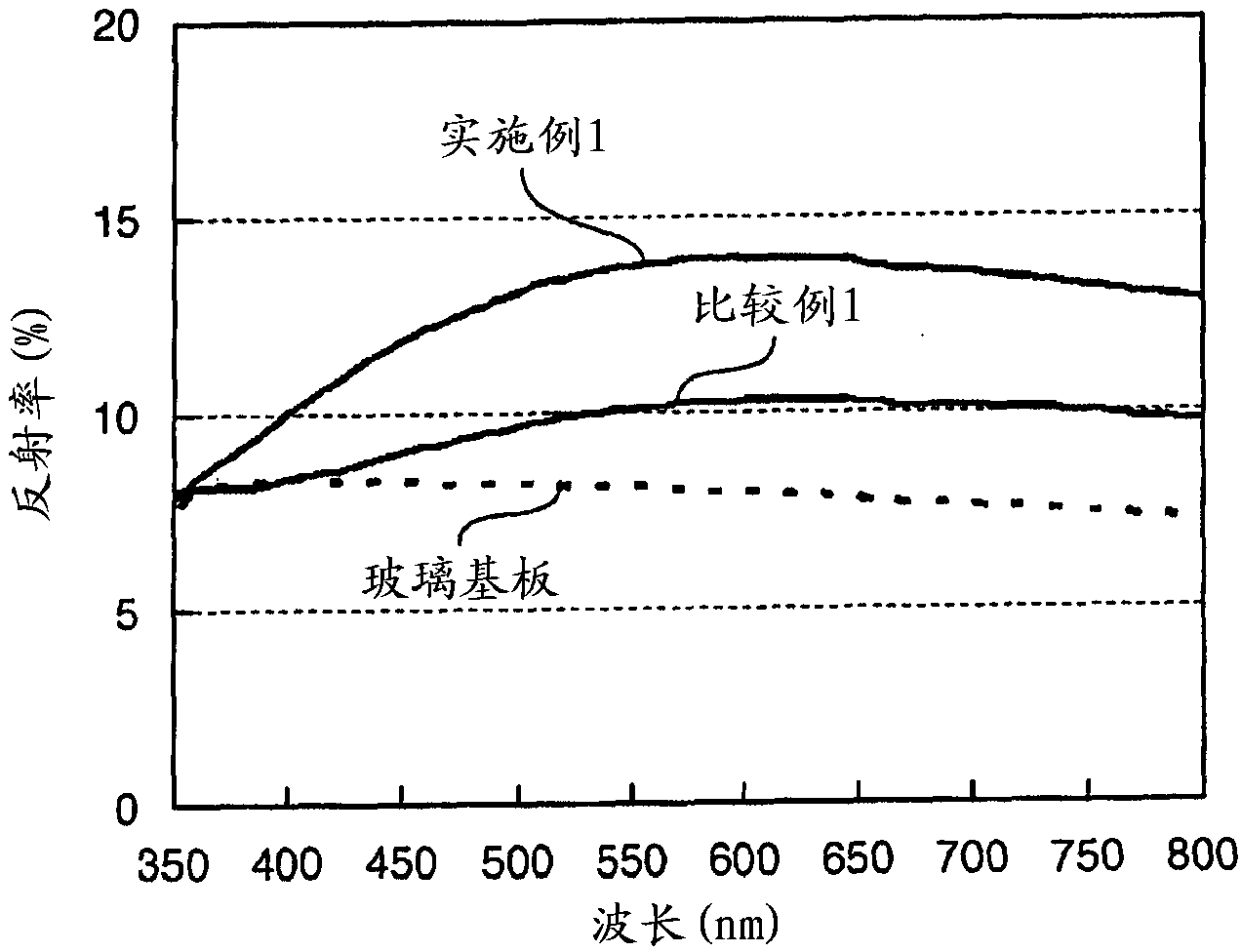

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

Process For Metal Recovery From Catalyst Waste

InactiveUS20120156116A1Lanthanum oxide/hydroxidesGroup 3/13 element organic compoundsPregnant leach solutionRare earth

A method for recovering rare earth metals from zeolite-containing waste FCC catalysts comprises an acid leaching step to remove the rare earth metals from the catalyst to form a leachate containing dissolved rare earth metals and separating the rare earth metals from the leachate such as by precipitation.

Owner:BASF CORP

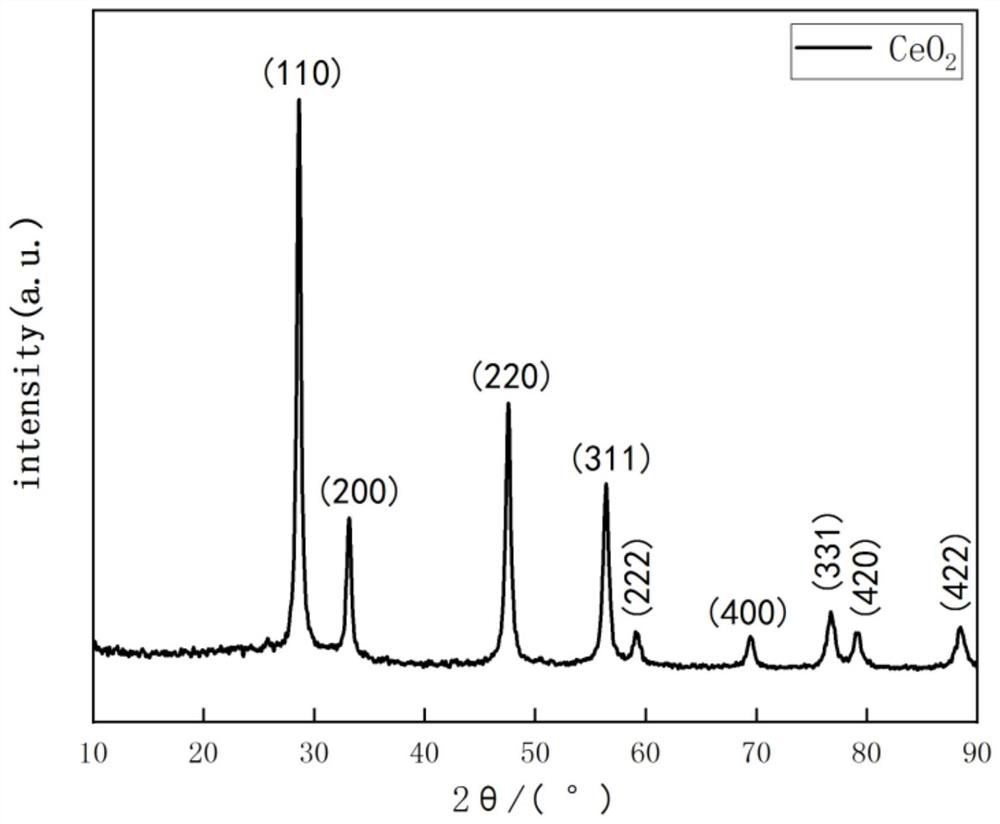

Nanoparticles of rare earth oxides

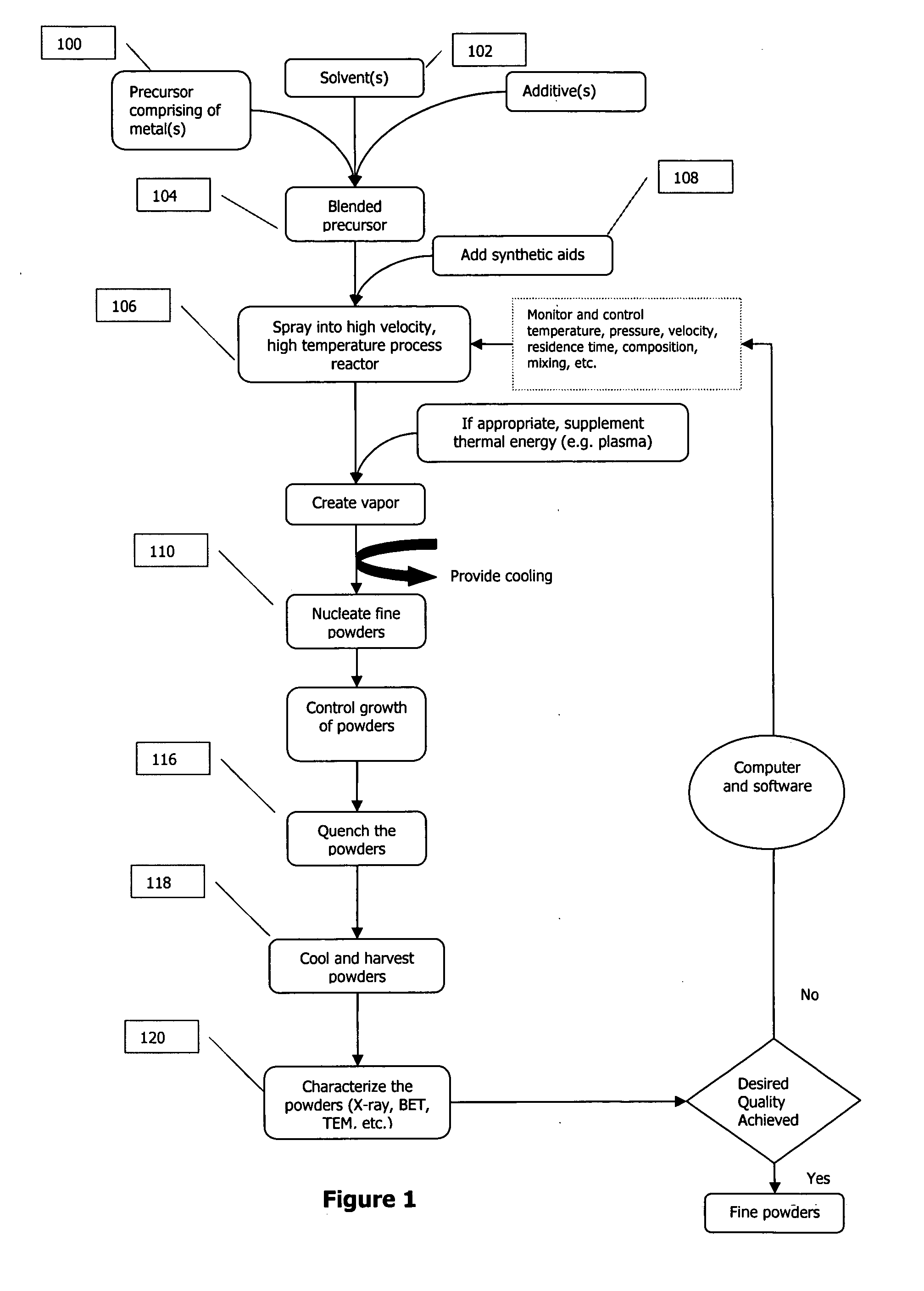

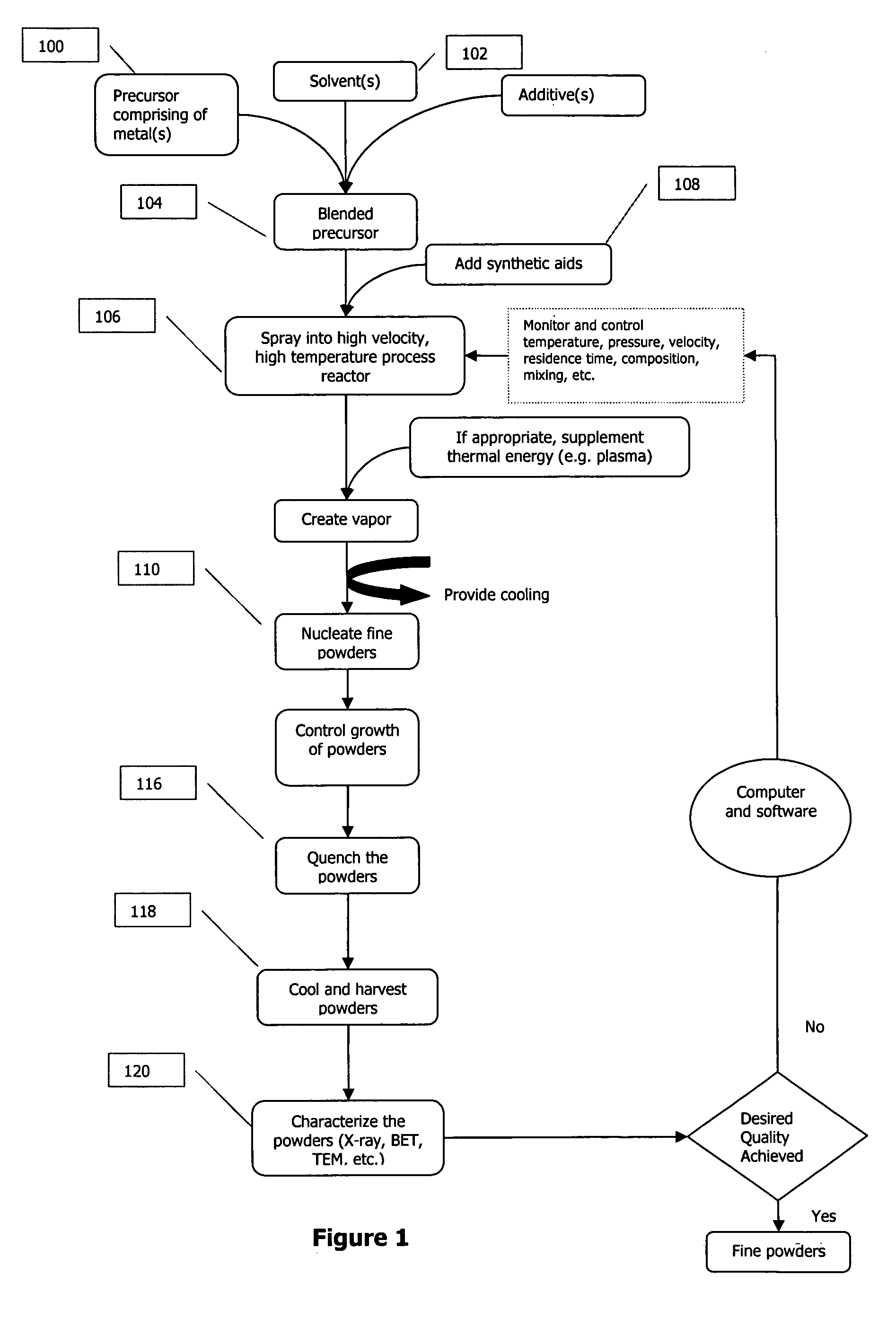

ActiveUS20070104629A1Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum(La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium(Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

Nanoparticles of rare earth oxides

ActiveUS7229600B2Increase volumeLow cost productionMaterial nanotechnologyLanthanum oxide/hydroxidesCeriumScandium

Rare earth compositions comprising nanoparticles, methods of making nanoparticles, and methods of using nanoparticles are described. The compositions of the nanomaterials discussed may include scandium (Sc), yttrium (Y), lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), and lutetium (Lu). The nanoparticles can be used to make organometallics, nitrates, and hydroxides. The nanoparticles can be used in a variety of applications, such as pigments, catalysts, polishing agents, coatings, electroceramics, catalysts, optics, phosphors, and detectors.

Owner:PPG IND OHIO INC

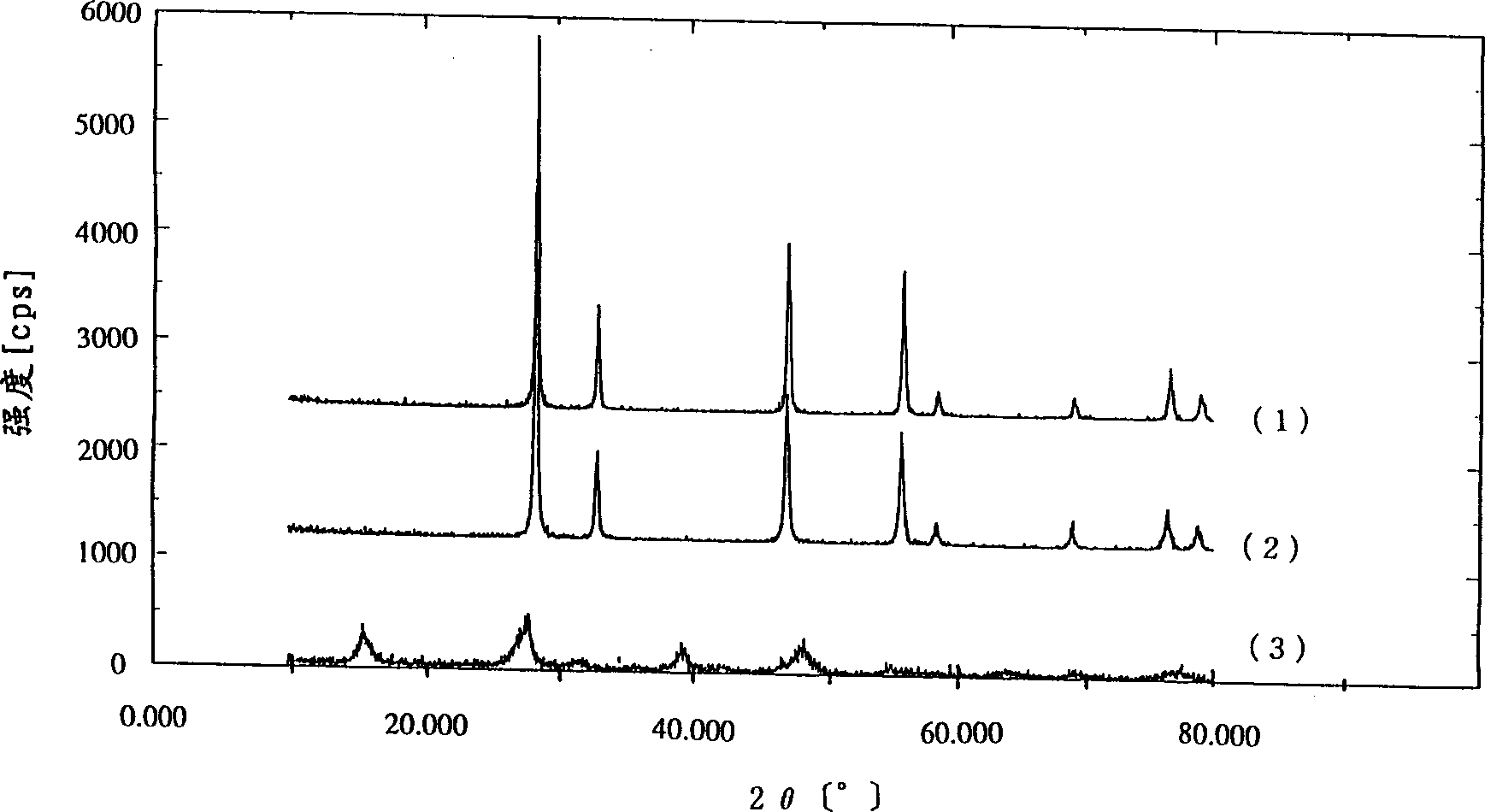

Method for producing cerium-based abrasive and cerium-based abrasive produced thereby

InactiveUS6901684B2High-accuracy polished surfaceImprove wear resistancePigmenting treatmentDrying using combination processesCeriumCe element

This invention is a method for producing a cerium-based abrasive which includes: a step of grinding raw material for the cerium-based abrasive; a step of roasting the ground raw material; and a step of subjecting the roasted raw material to wet processing, the method being characterized in that it further includes a lower-temperature re-roasting step of heating the wet-processed raw material at 200 to 700° C. In the invention disclosed in this application, an abrasive with particularly preferable properties can be produced by fully drying the wet-processed raw material in a drying step, and subsequently subjecting the dried raw material to the lower-temperature re-roasting step.

Owner:MITSUI MINING & SMELTING CO LTD

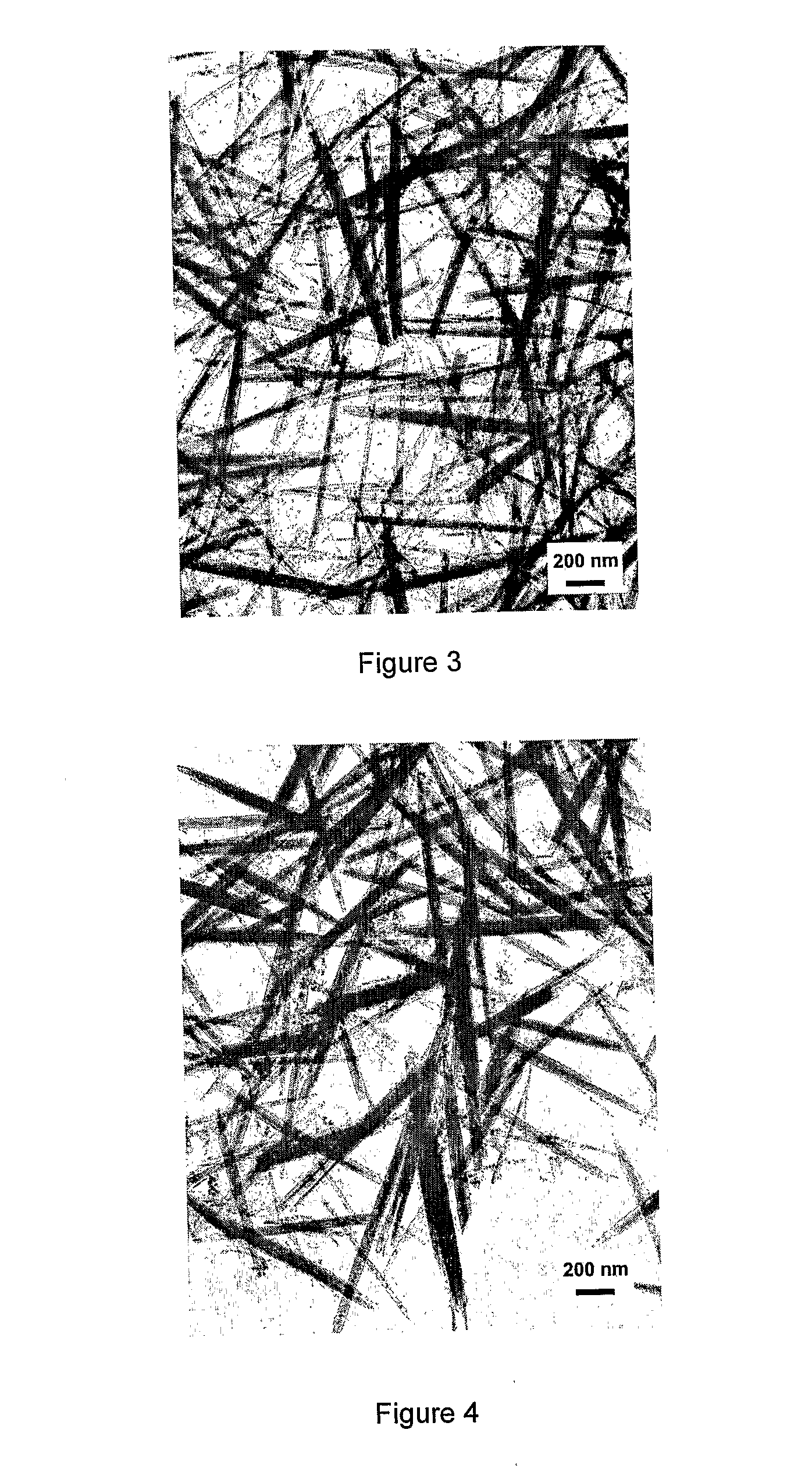

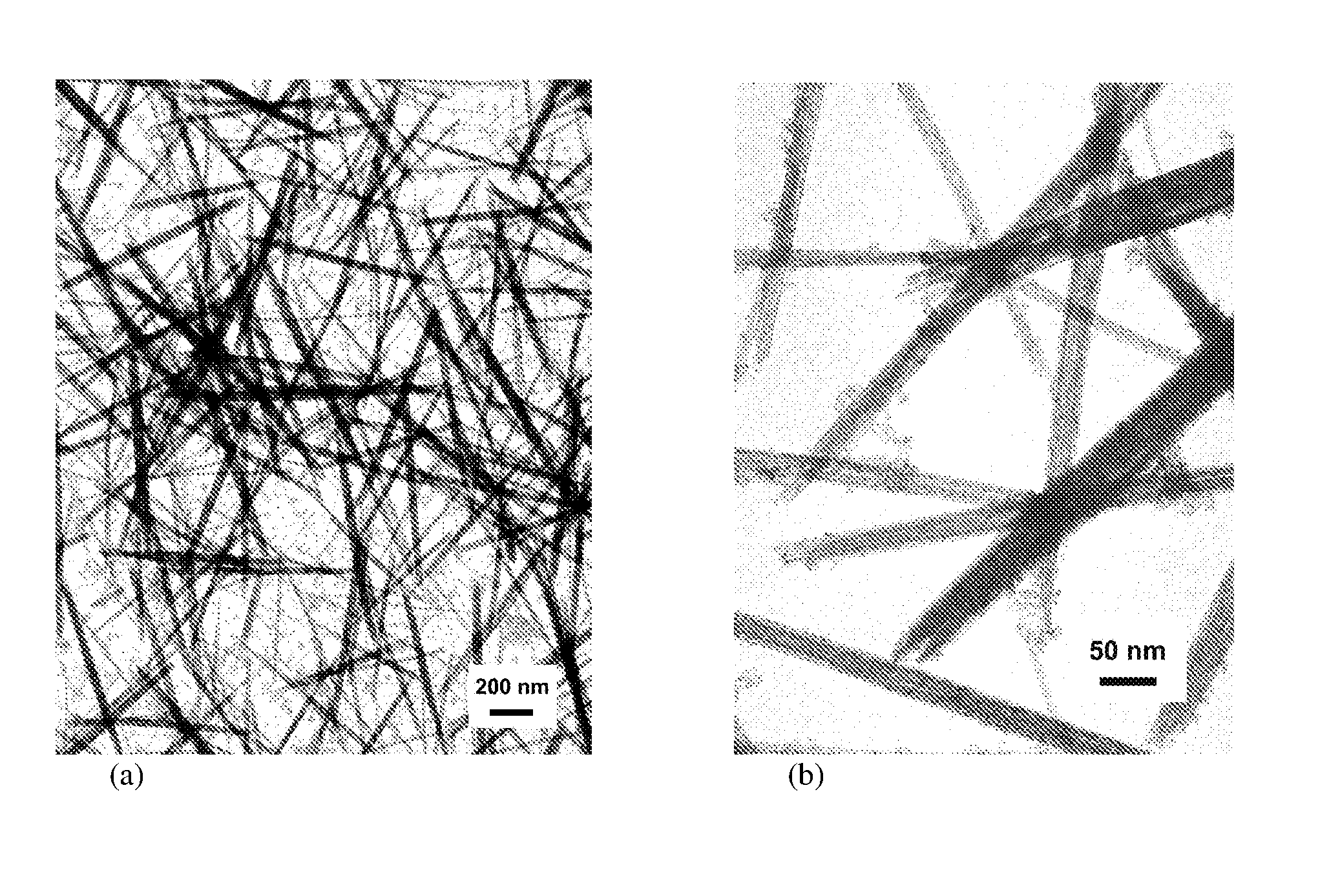

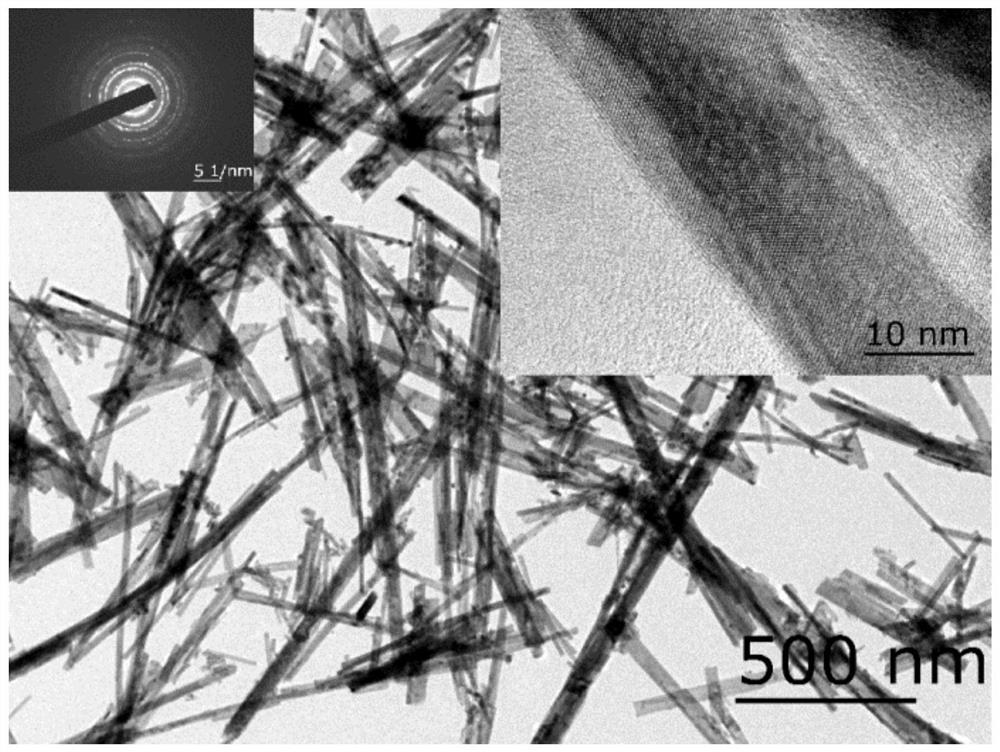

Rare Earth Nanorods

ActiveUS20080279744A1Reduce expenditureMaterial nanotechnologyPolycrystalline material growthNanoparticleRare earth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Rare earth nanorods

ActiveUS7943106B2Reduce expenditureMaterial nanotechnologyPolycrystalline material growthRare-earth elementAnisotropic growth

A process for the production of nanorods containing a rare earth metal is disclosed. The process comprises the steps of: (a) increasing the pH of an aqueous solution of the formula MX3, where M is a trivalent rare earth metal cation and X is a monovalent anion so as to produce a reaction product containing X anions in solution and a precipitate in the form of trivalent rare earth hydroxide nanoparticles of the formula M(OH)3, the nanoparticles having a hexagonal crystal structure; and, (b) ageing the nanoparticles of step (a) in the presence of the reaction product containing X anions in solution so as to cause rod-like anisotropic growth of the nanoparticles and form rare earth hydroxide nanorods.

Owner:ADVANCED NANO TECH

Doped anionic clays

The present invention is directed to a process for the preparation of a doped anionic clay. In said process a trivalent metal source is reacted with a divalent metal source, at least one of the metal sources being either doped boehmite, doped MgO or doped brucite, to obtain a doped anionic clay. Suitable dopants are compounds containing elements selected from the group of alkaline earth metals (for instance Ca and Ba), alkaline metals, transition metals (for example Co, Mn, Fe, Ti, Zr, Cu, Ni, Zn, Mo, W, V, Sn), actinides, rare earth metals such as La, Ce, and Nd, noble metals such as Pt and Pd, silicon, gallium, boron, titanium, and phosphorus.

Owner:AKZO NOBEL NV +1

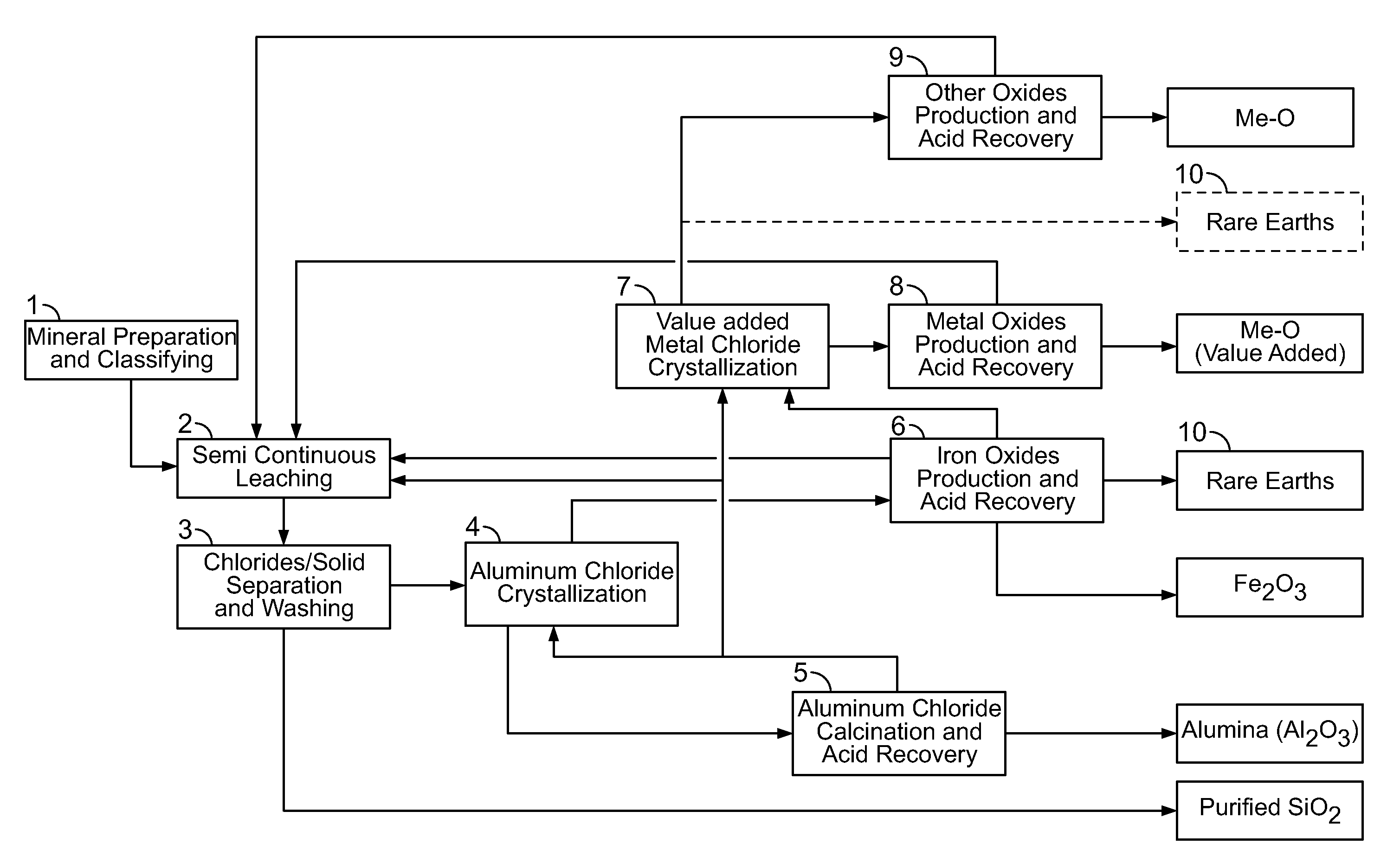

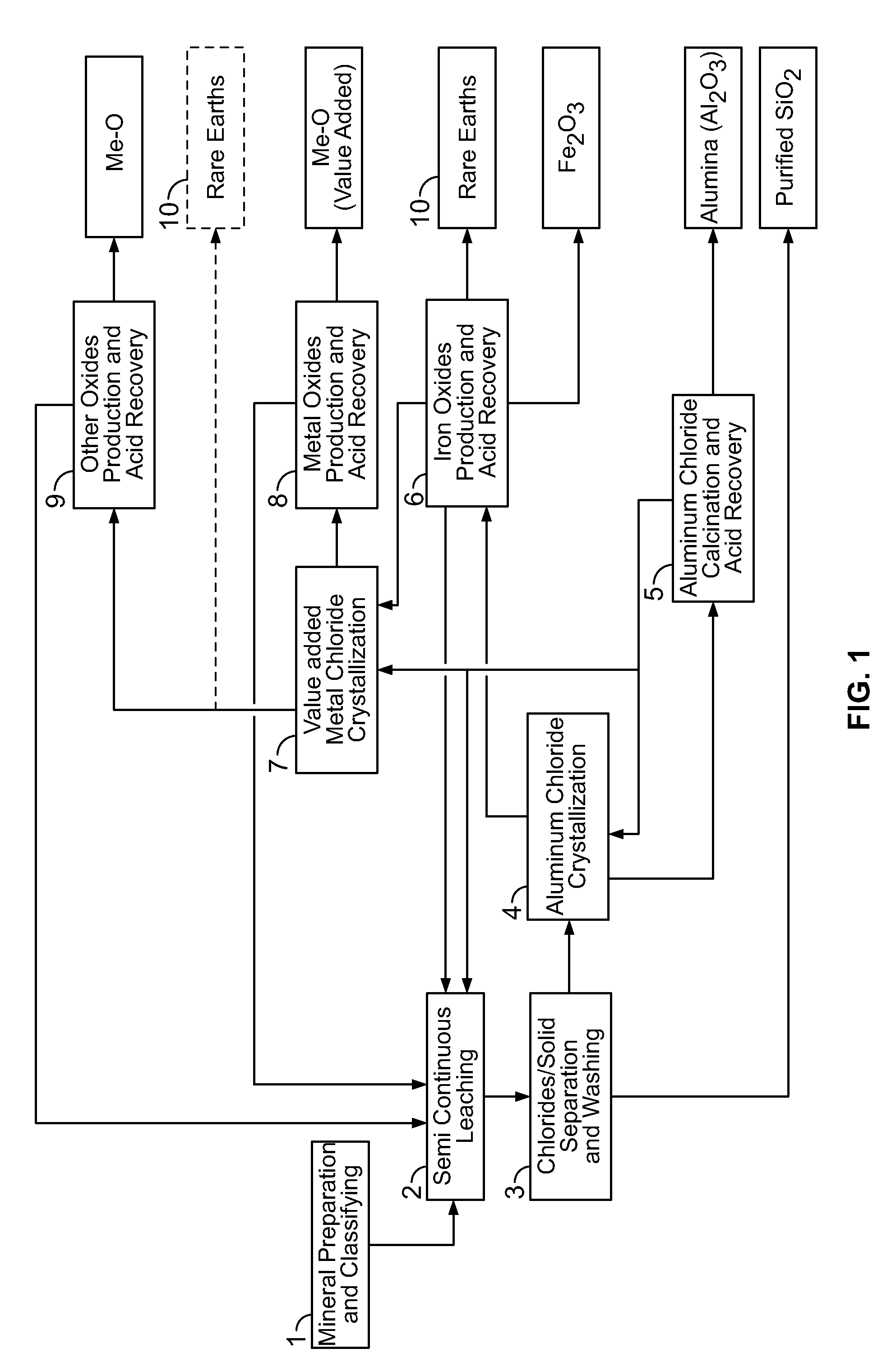

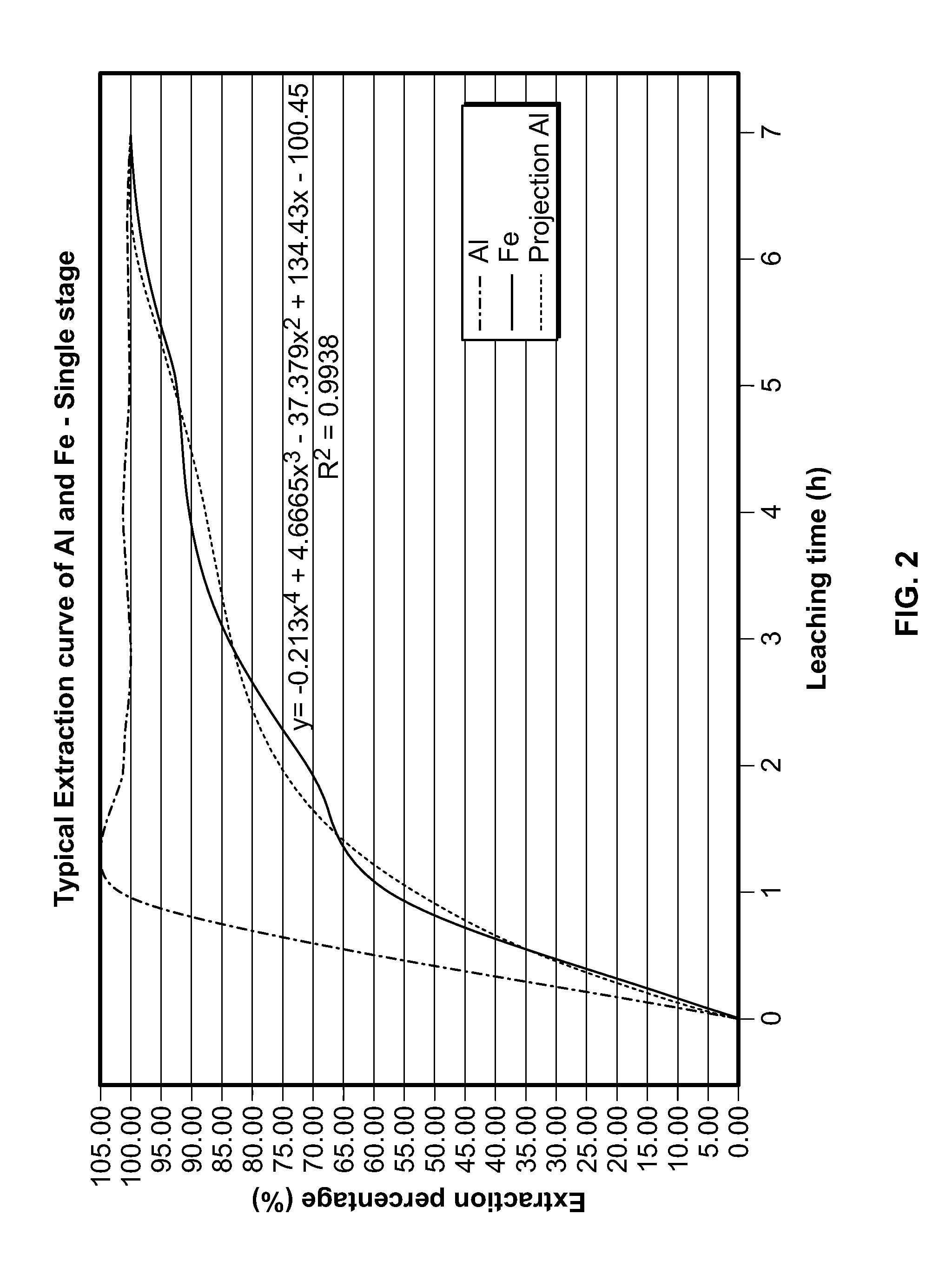

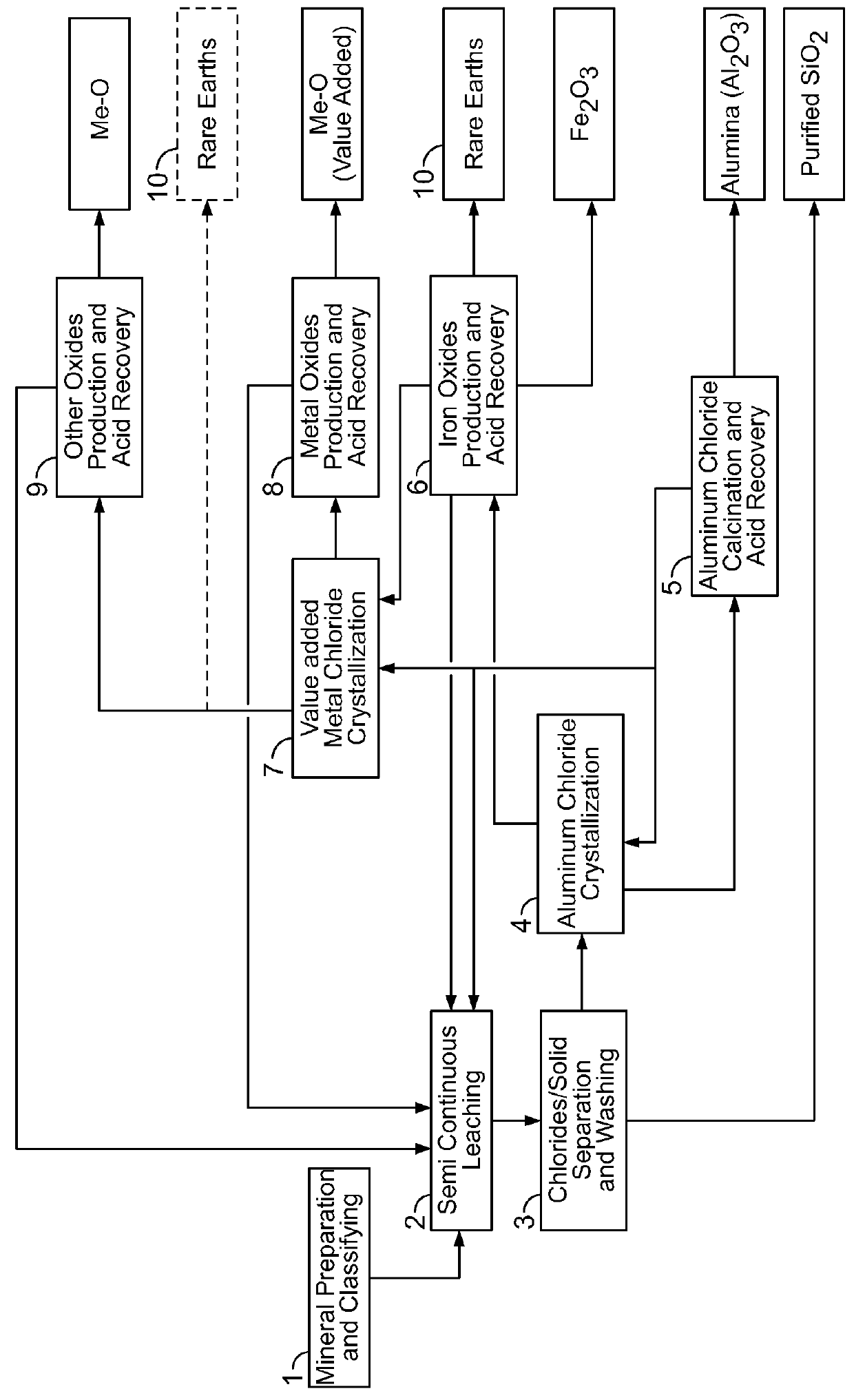

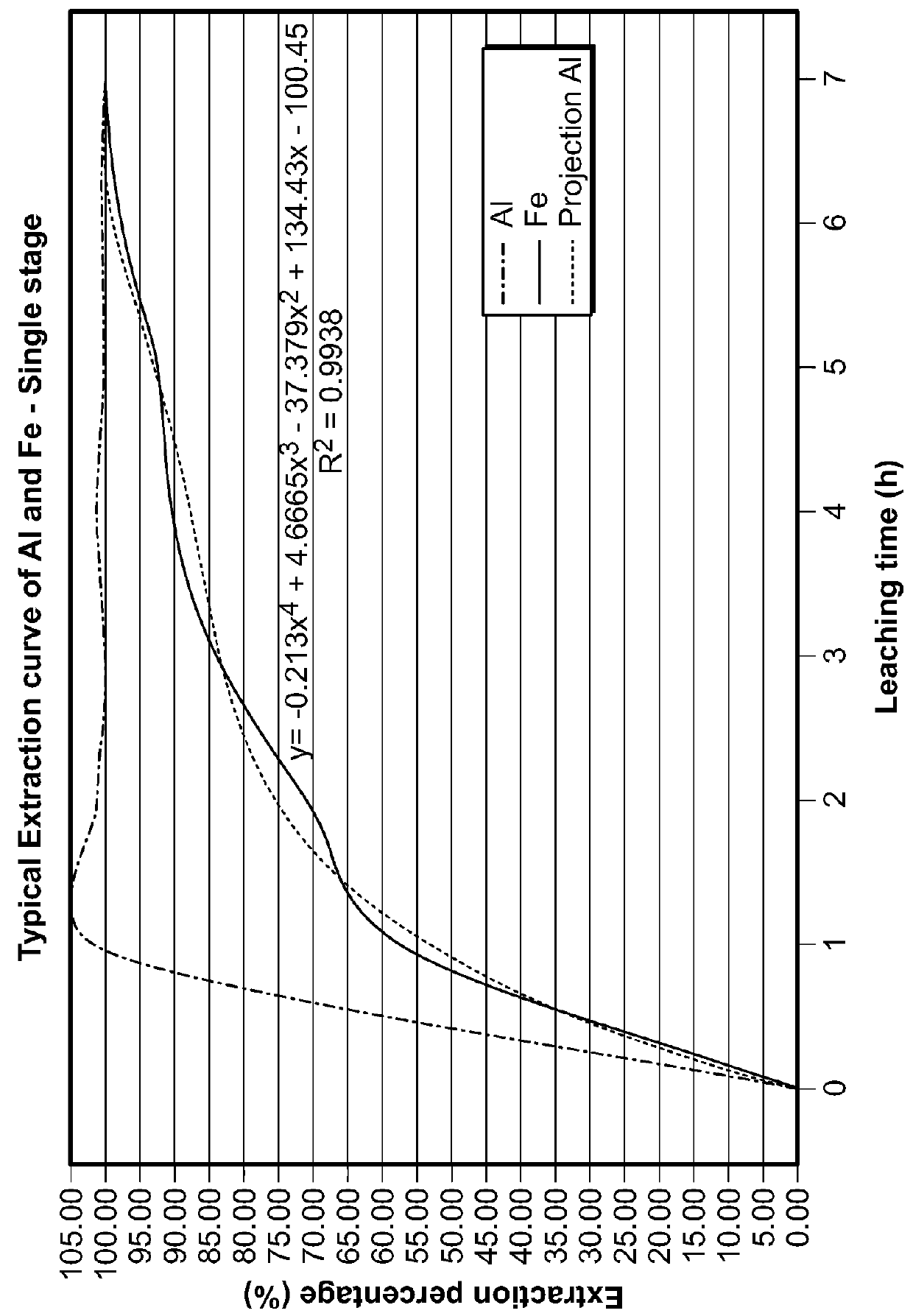

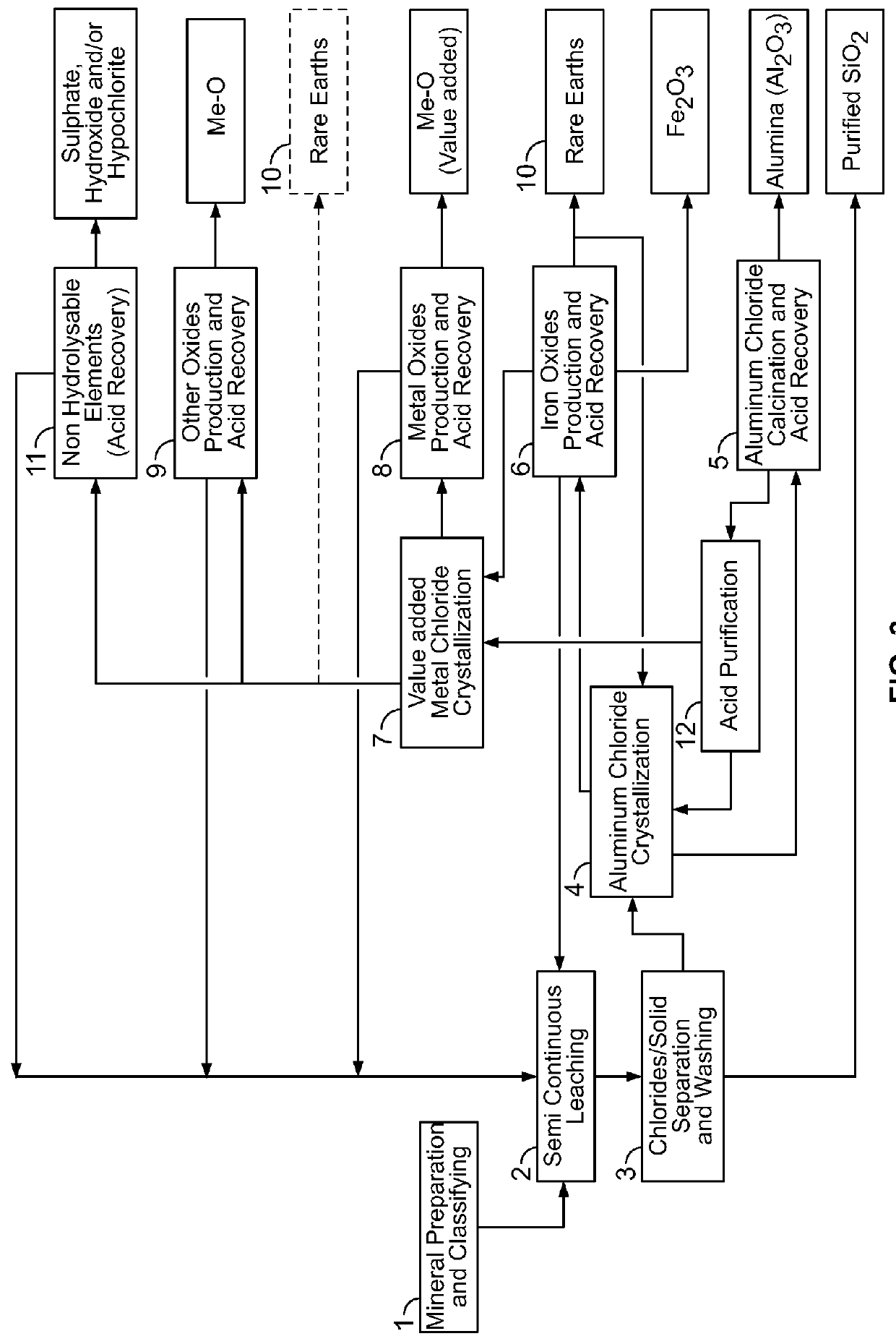

Processes for preparing alumina and various other products

There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides of various metals, sulphates and chlorides of various metals, as well as rare earth elements, rare metals and aluminum.

Owner:ORBITE ALUMINAE INC

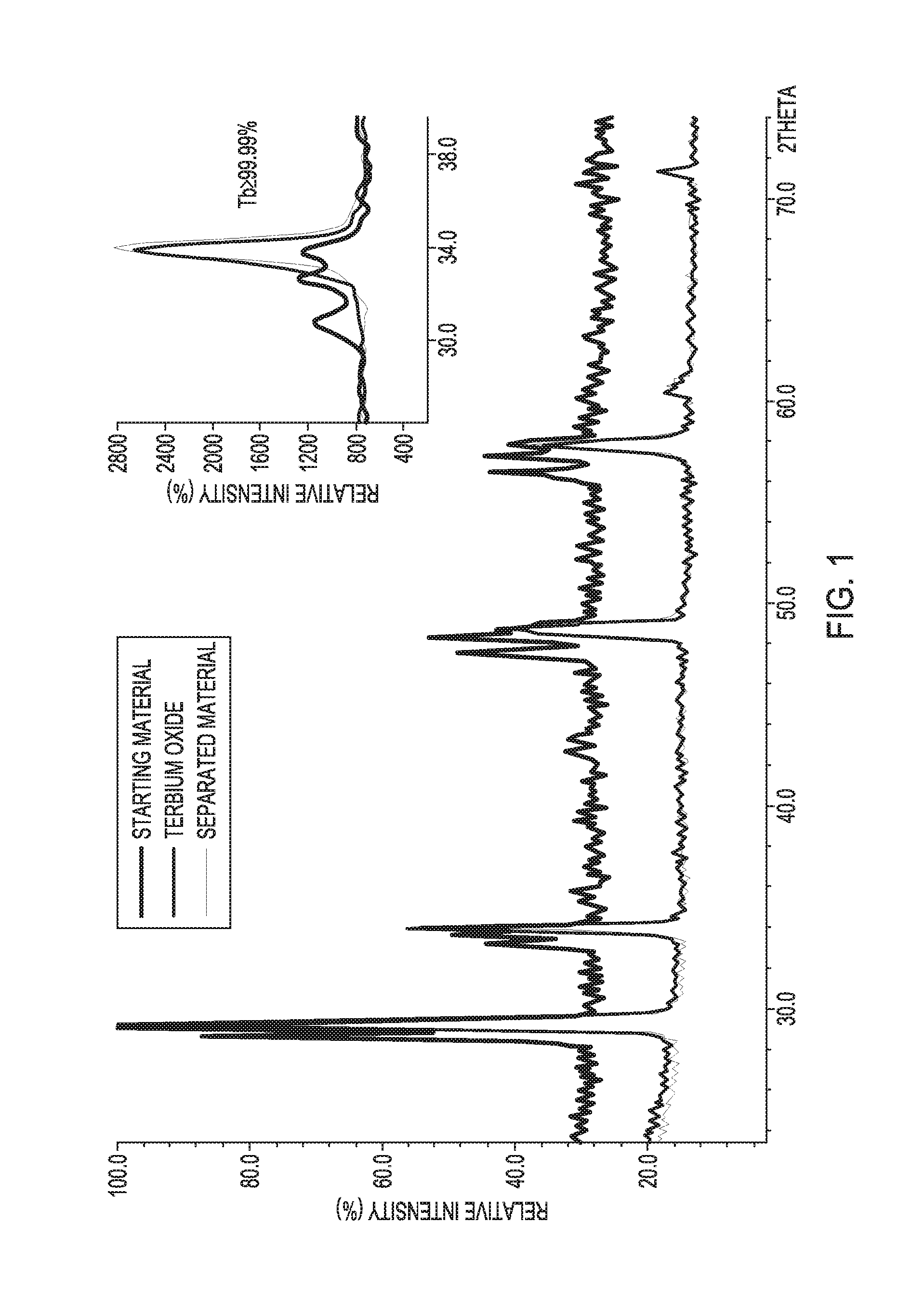

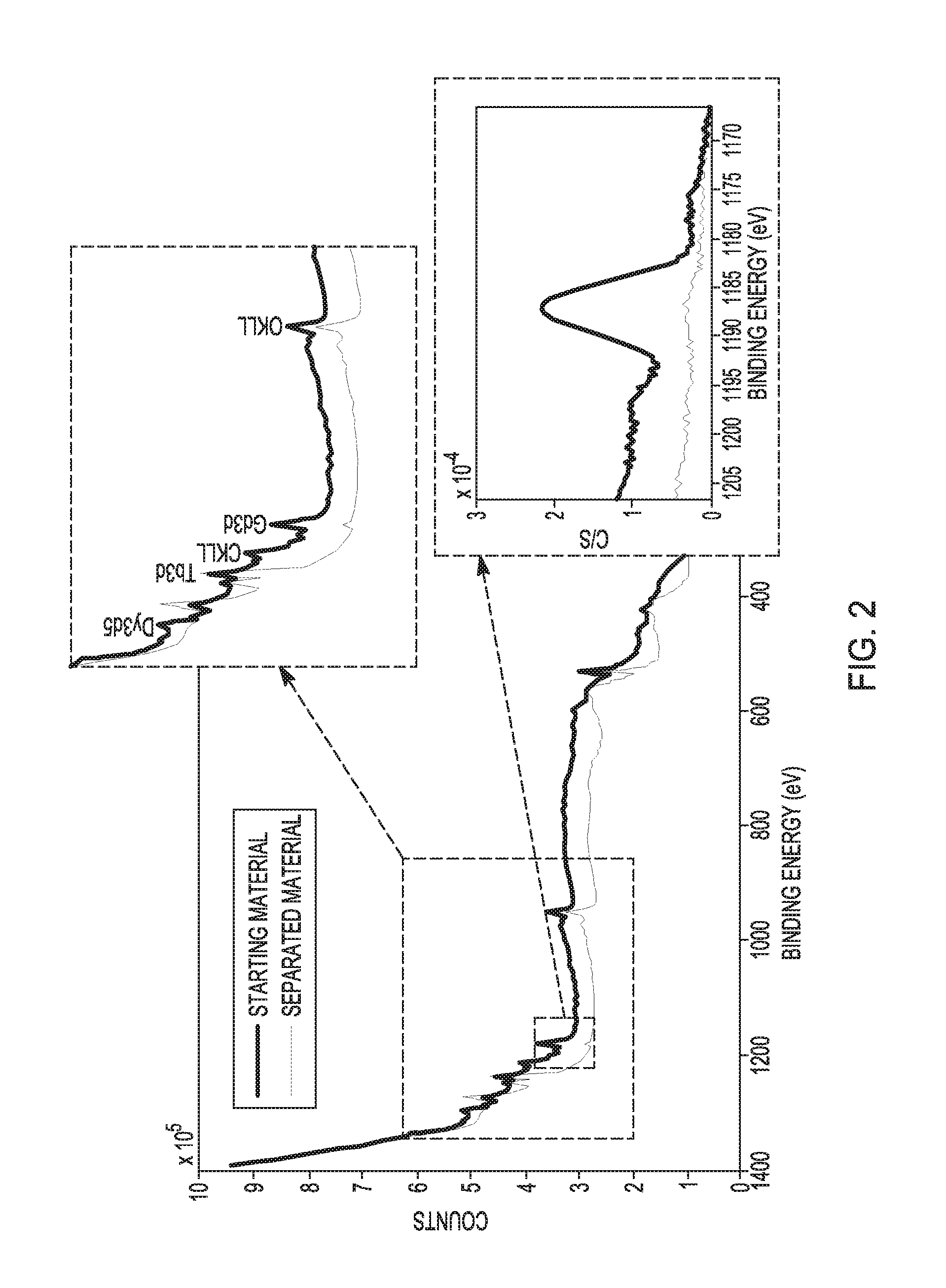

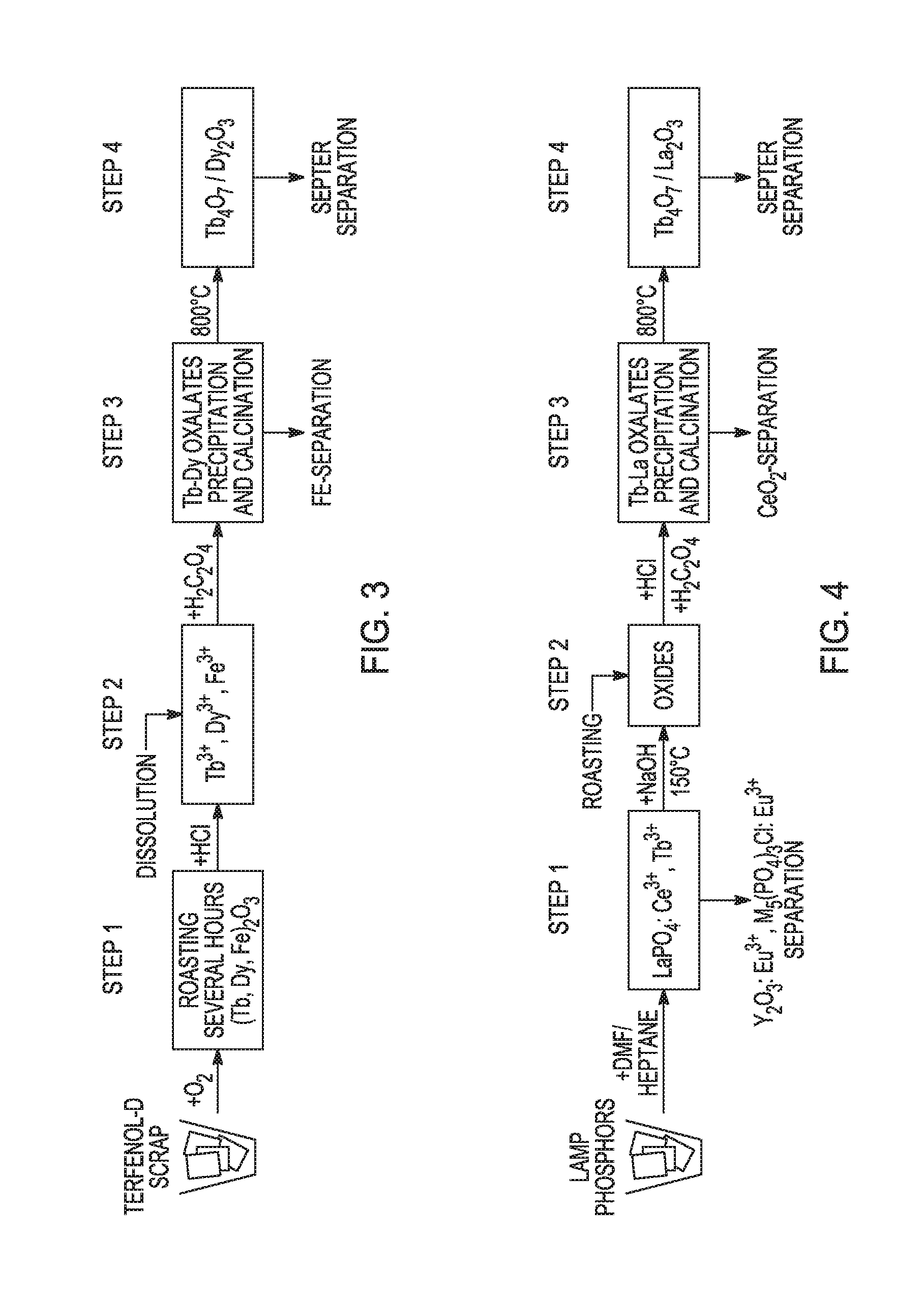

Separation of terbium(iii,iv) oxide

ActiveUS20170022071A1Little and no waste generationHigh purityPhosphatesLanthanum oxide/hydroxidesAcetic acidRare earth

Various embodiments relate to separation of terbium(III,IV) oxide. In various embodiments, present invention provides a method of separating terbium(III,IV) oxide from a composition. The method can include contacting a composition including terbium(III,IV) oxide and one or more other trivalent rare earth oxides with a liquid including acetic acid to form a mixture. The contacting can be effective to dissolve at least some of the one or more other trivalent rare earth oxides into the liquid. The method can include separating undissolved terbium(III,IV) oxide from the mixture, to provide separated terbium(III,IV) oxide.

Owner:IOWA STATE UNIV RES FOUND

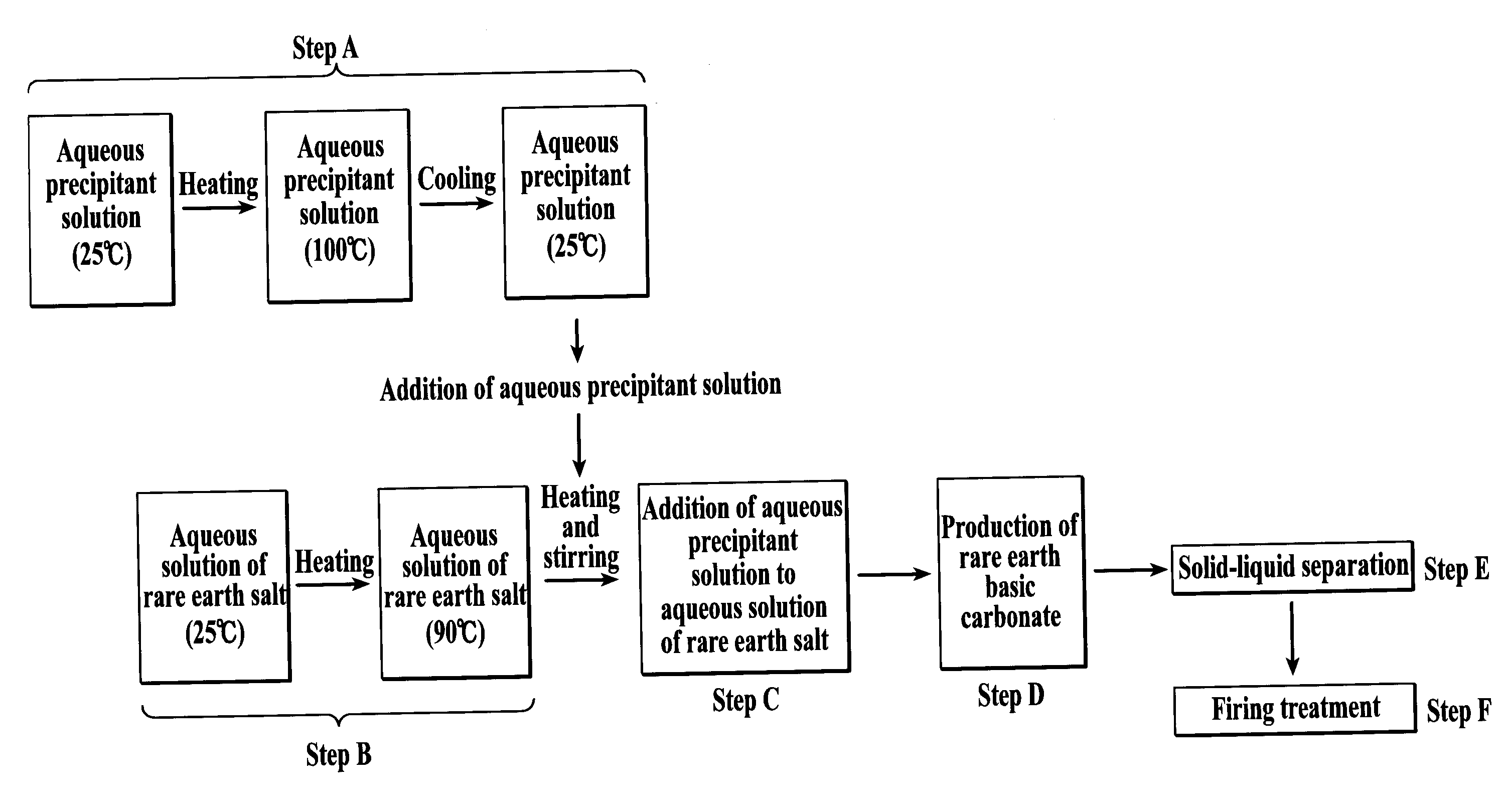

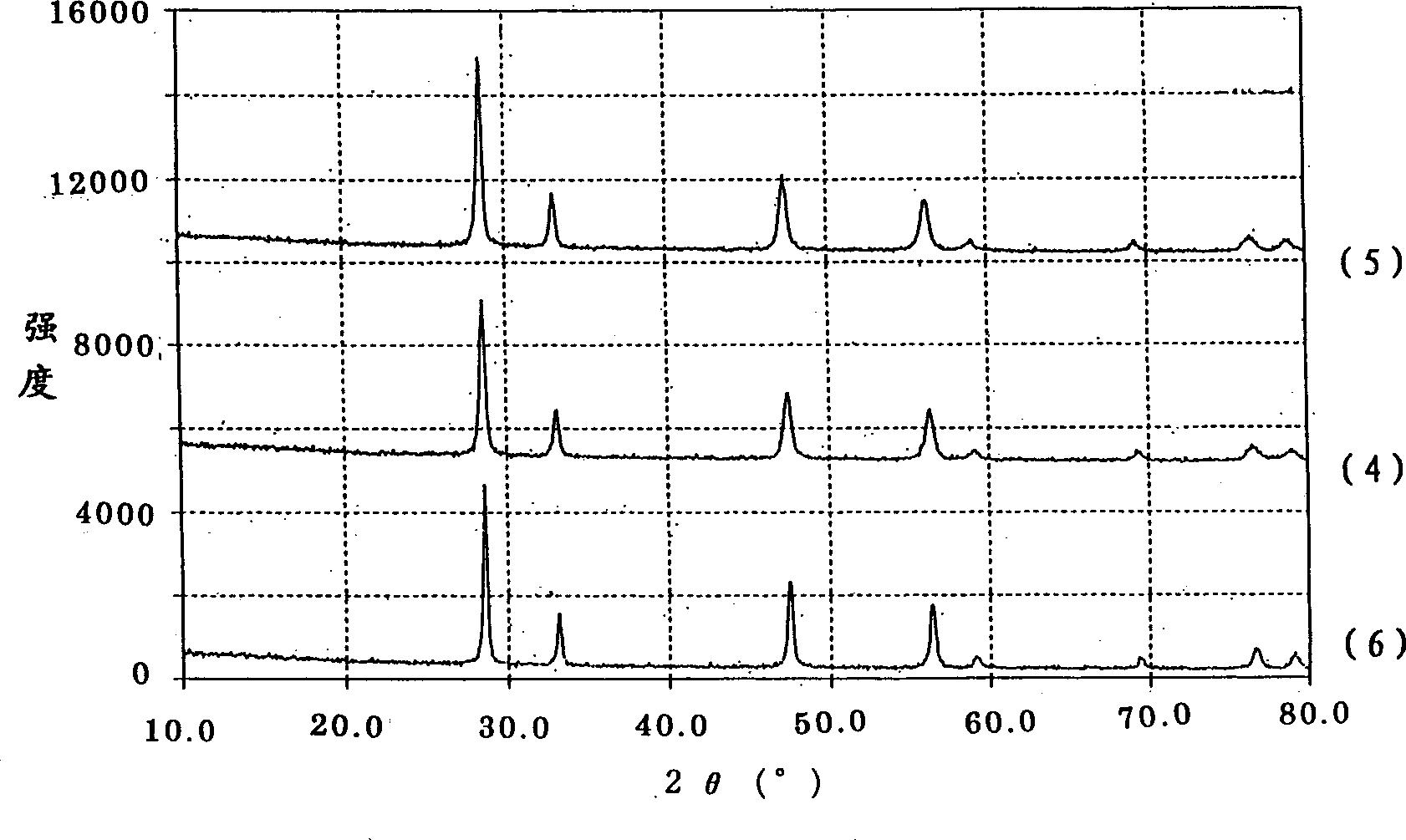

Cerium Oxide Abrasive, Method for Producing Cerium Oxide Abrasive, and Polishing Method

ActiveUS20160272860A1Improve polishing effectEasy to scratchOther chemical processesLanthanum oxide/hydroxidesRare-earth elementSpherical shaped

An object of the present invention is to provide a cerium oxide abrasive material containing cerium oxide abrasive particles prepared by a synthetic method using an aqueous solution of a salt of a rare earth element and a precipitant, the cerium oxide abrasive particles having a spherical shape and high polishing performance (polishing rate and polishing precision of the polished surface), a method for producing the cerium oxide abrasive material, and a polishing method. The cerium oxide abrasive material according to the present invention comprises spherical cerium oxide abrasive particles prepared by a synthetic method using an aqueous solution of a salt of a rare earth element and a precipitant, wherein the cerium oxide abrasive particles have a spherical shape having an average aspect ratio within the range of 1.00 to 1.15.

Owner:KONICA MINOLTA INC

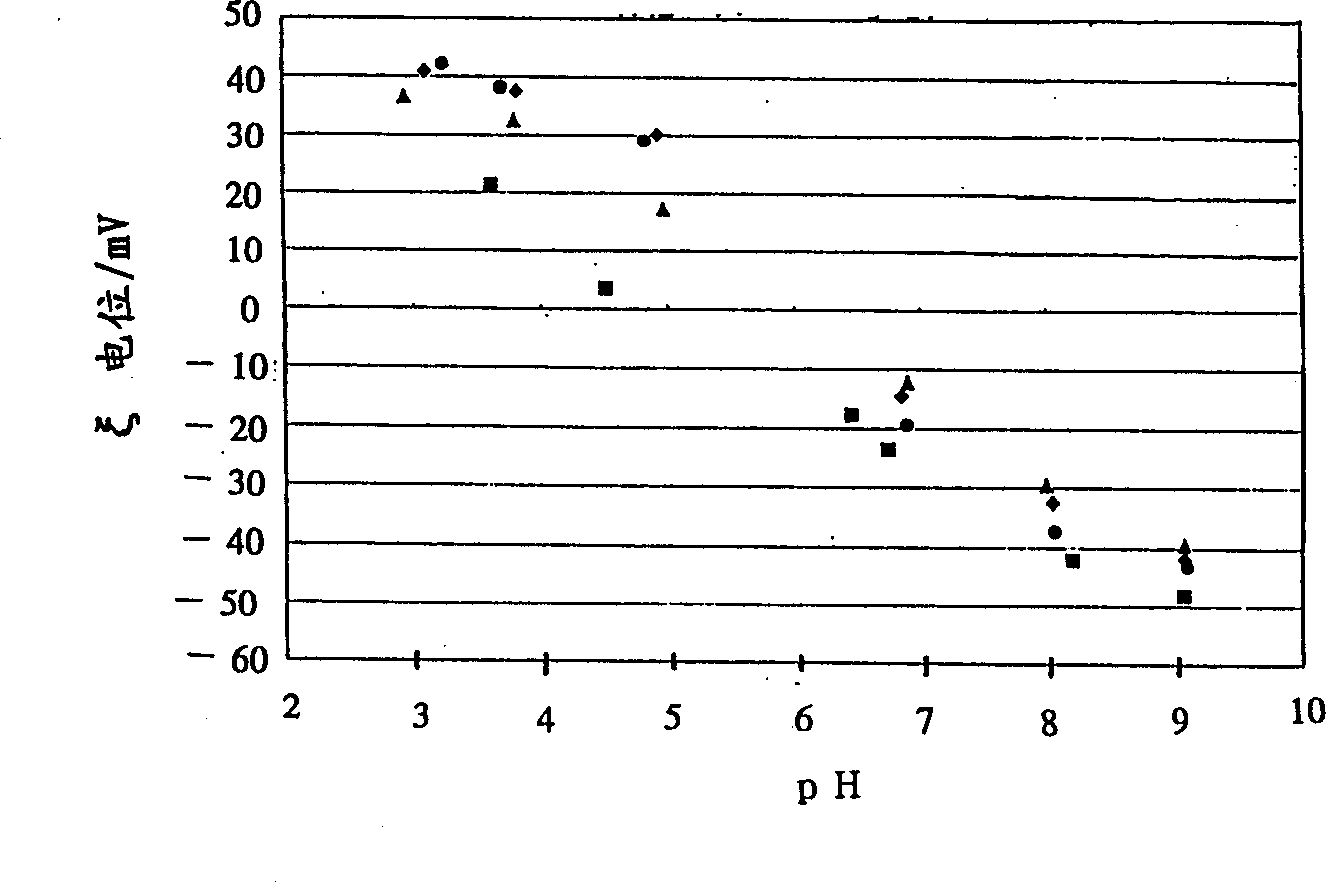

Cerium oxide sol and abrasive

There is provided an abrasive used for polishing a substrate which comprises silica as a main component. The abrasive contains a sol inwhich particles are dispersed in a medium, wherein the particles have a particle size of 0.005 to 1 mum and comprise as a main component crystalline cerium oxide of the cubic system and as an additional component a lanthanum compound, a neodymium compound or a combination thereof, wherein the additional component is contained in X / (Ce + X) molar ratio of 0.001 to 0.5 in which X is lanthanum atoms, neodymium atoms or a combination thereof. High speed polishing and high quality glazed surface can be obtained by application of this abrasive.

Owner:NISSAN CHEM IND LTD

Thermal spray powder and method for forming thermal spray coating

ActiveUS20080112873A1Increase resistanceLiquid surface applicatorsMolten spray coatingRare-earth elementThermal spray coating

A thermal spray powder contains particles composed of an oxide of any of the rare earth elements having an atomic number of 39 or from 59 to 70. The crushing strength of the particles is 80 MPa or greater. The ratio of bulk specific gravity to true specific gravity of the thermal spray powder is 0.15 or greater. The particles are preferably granulated and sintered particles. The average particle size of primary particles constituting the granulated and sintered particles is preferably 6 μm or less.

Owner:FUJIMI INCORPORATED

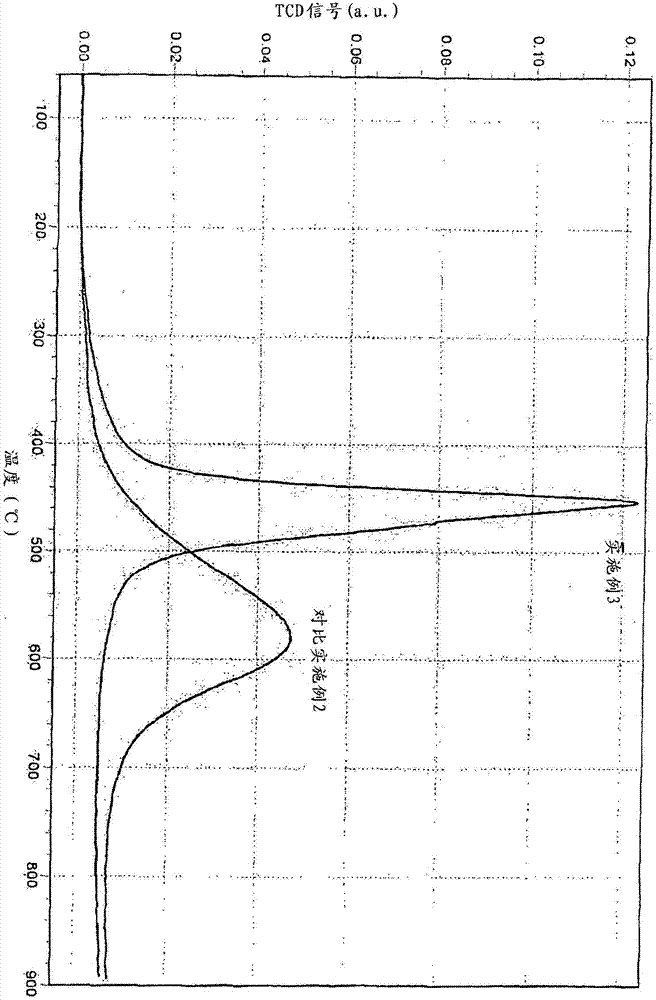

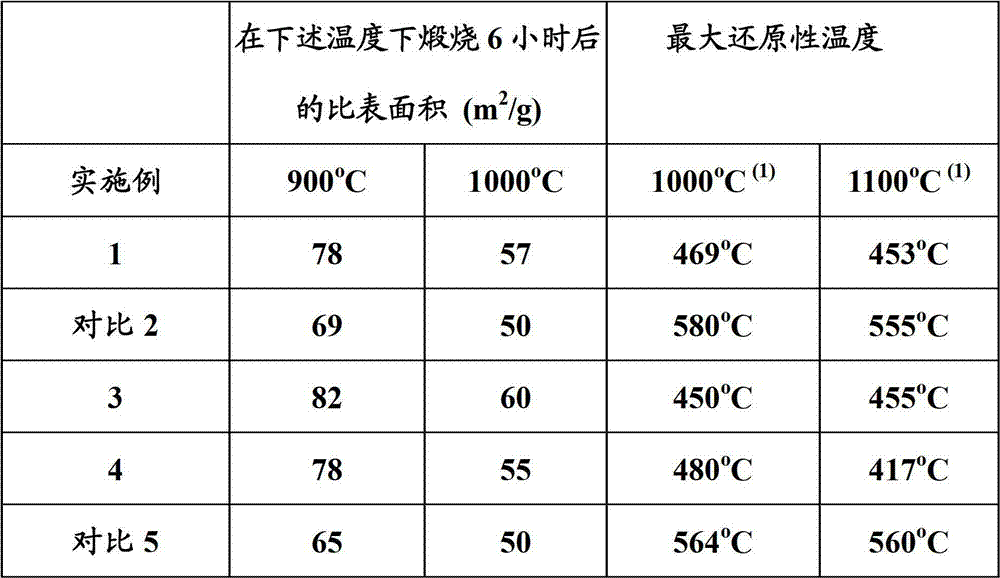

Composition containing oxides of zirconium, cerium and another rare earth having reduced maximal reducibility temperature, and method for preparing and using same in the field of catalysis

The invention relates to a composition containing oxides of zirconium, cerium and another rare earth different from cerium, having a cerium oxide content not exceeding 50 wt% and, after calcination at 1000 DEG C for 6 hours, a maximal reducibility temperature not exceeding 500 DEG C and a specific surface of at least 45 m2 / g. The composition is prepared according to a method that comprises continuously reacting a mixture containing compounds of zirconium, cerium and another rare earth having a basic compound for a residence time not exceeding 100 milliseconds, wherein the precipitate is heated and contacted with a surfactant before calcination.

Owner:RHODIA OPERATIONS SAS

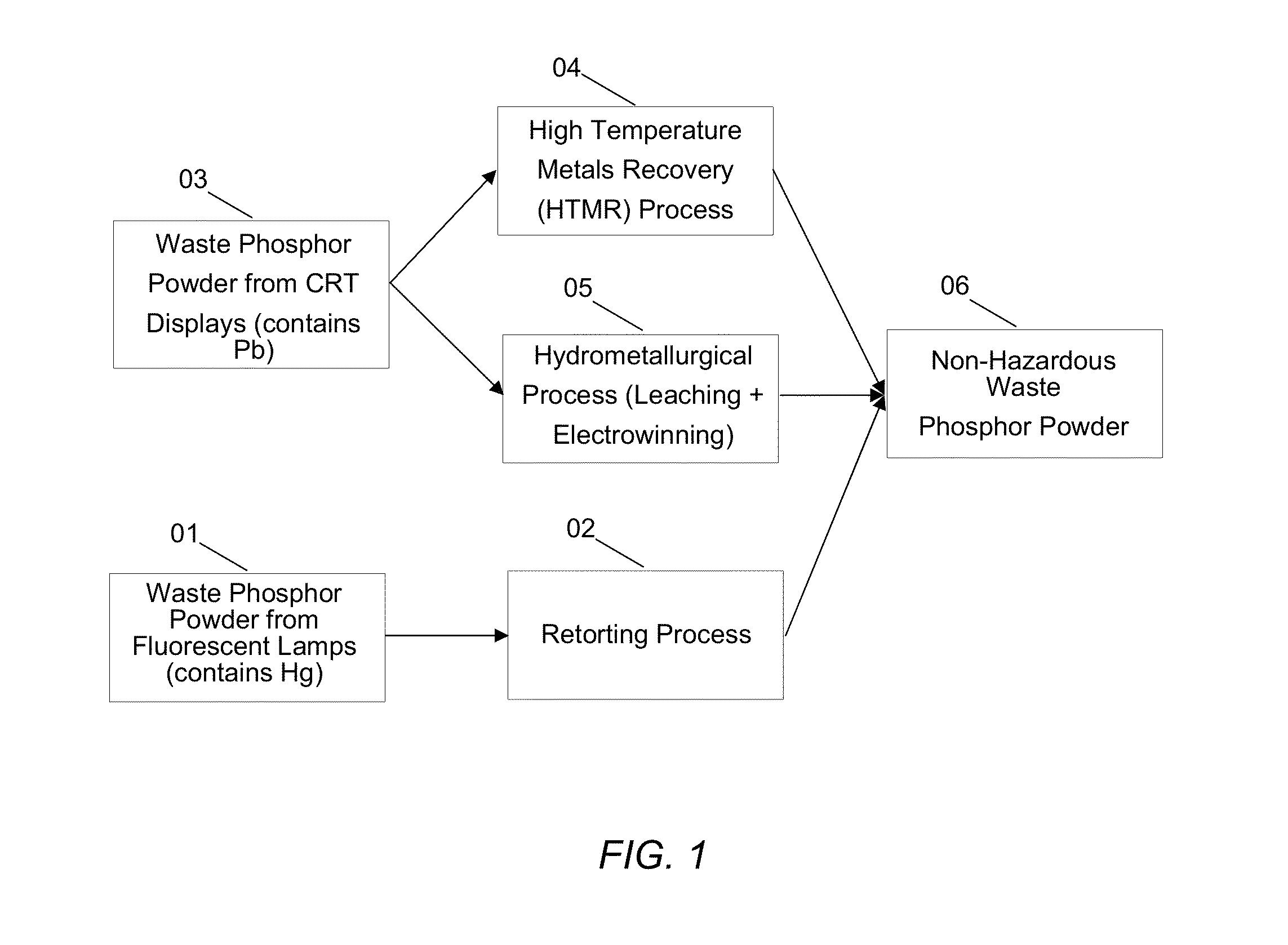

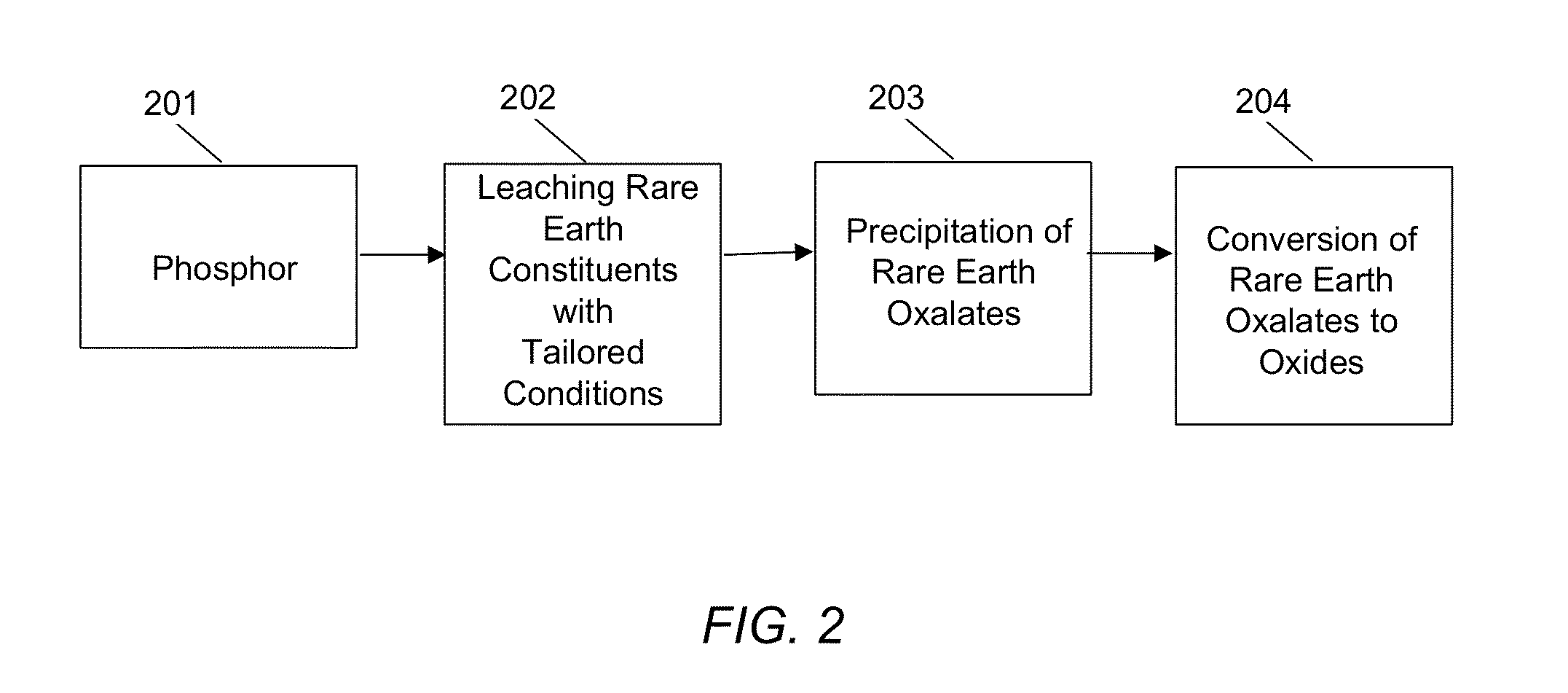

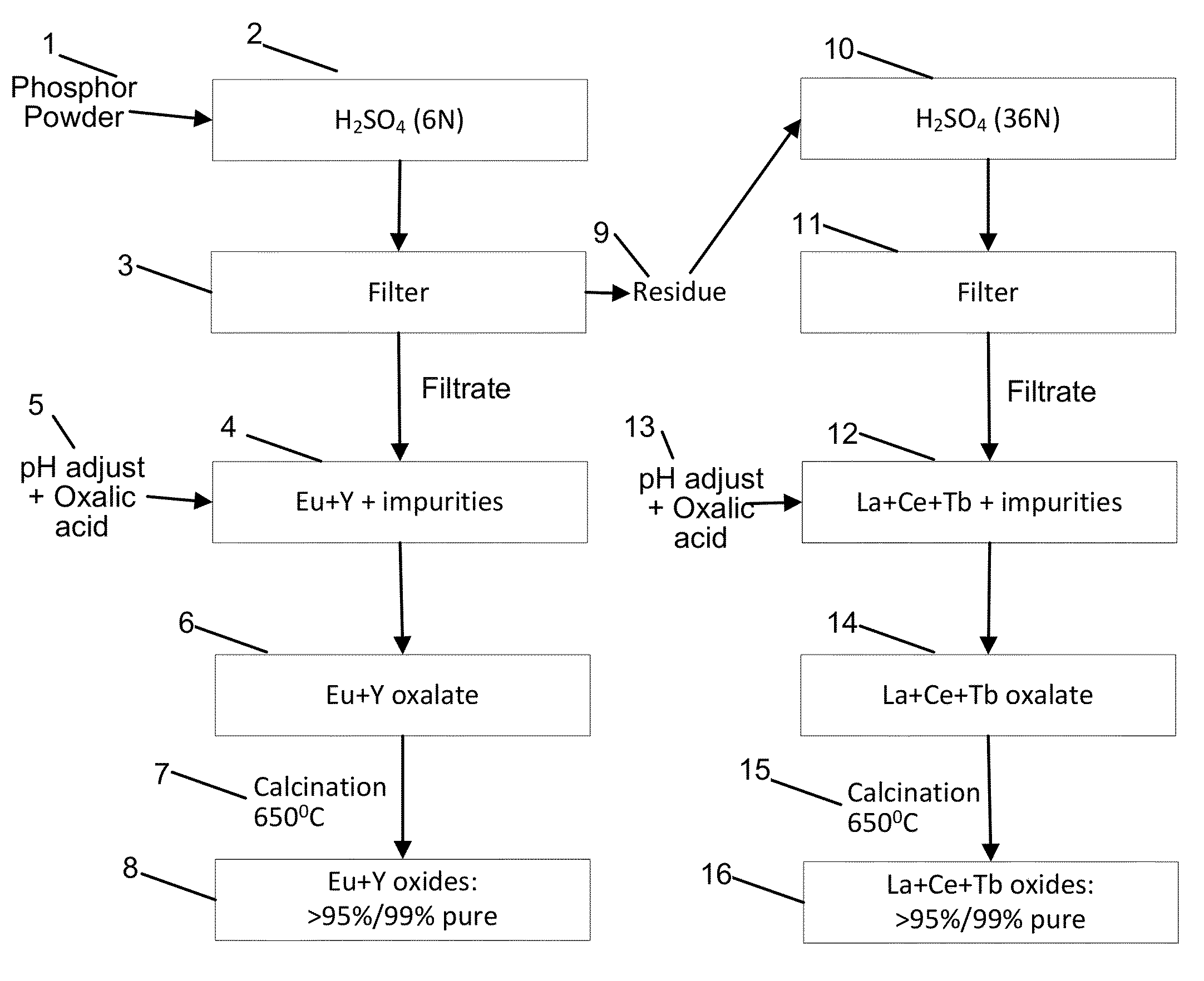

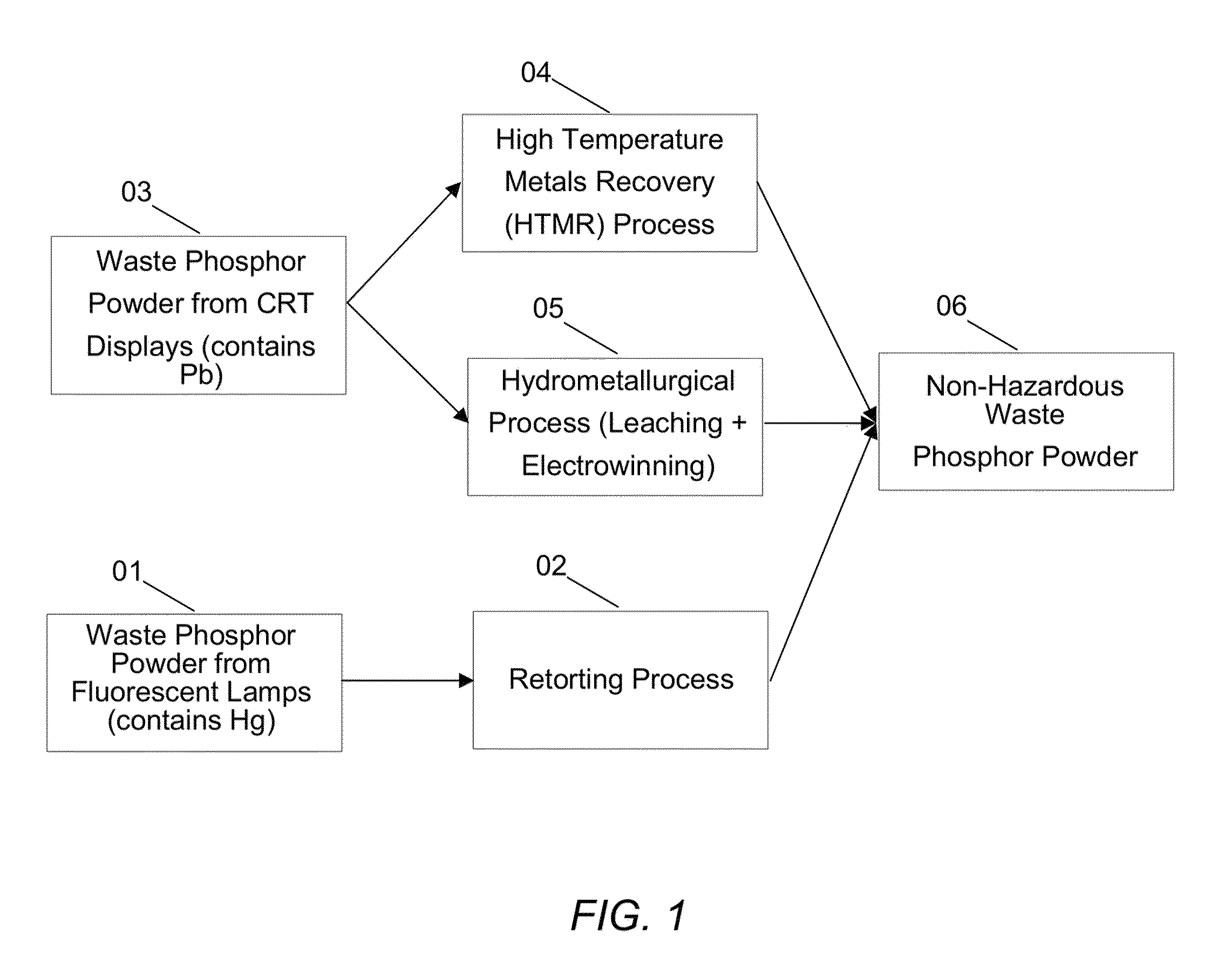

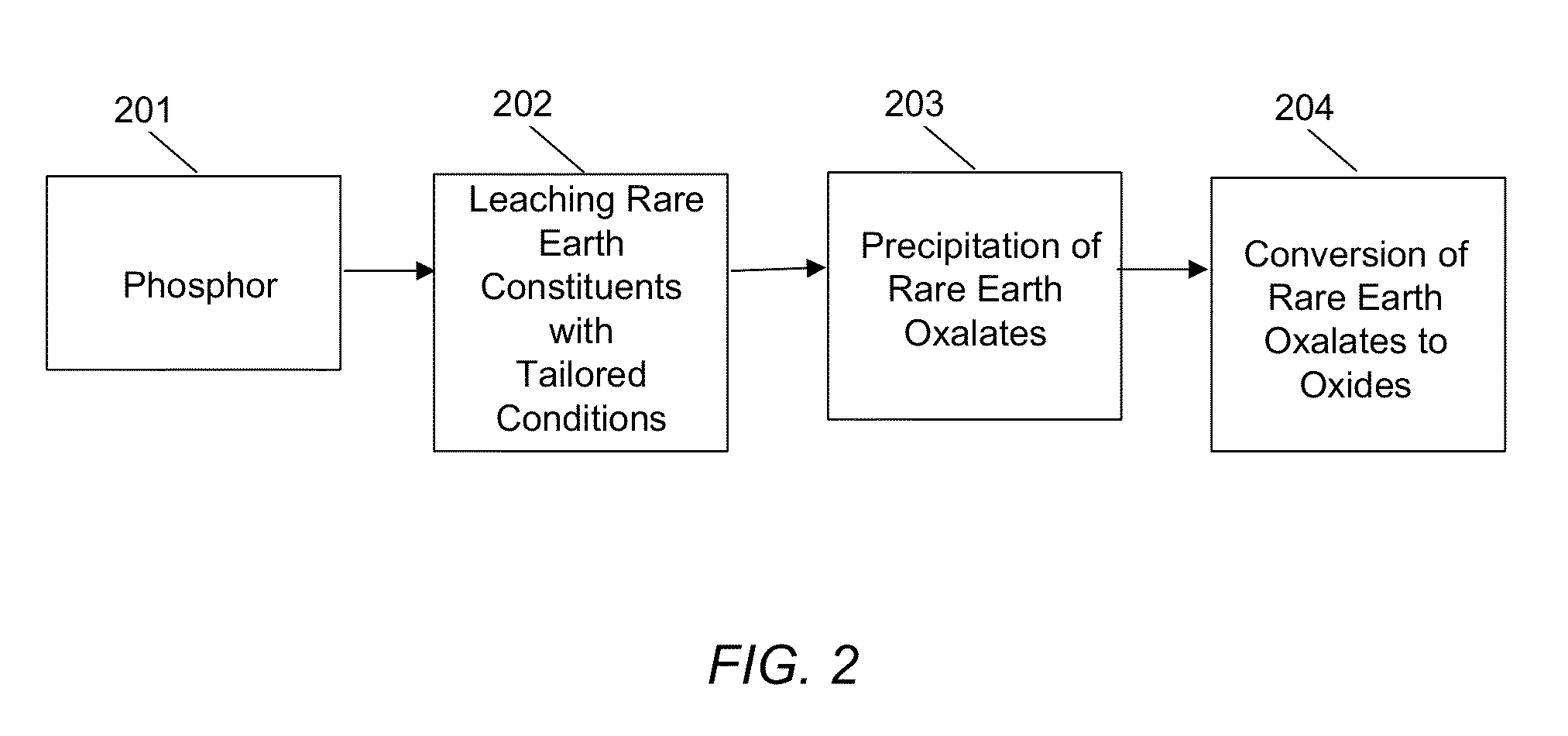

Rare earth recovery from phosphor

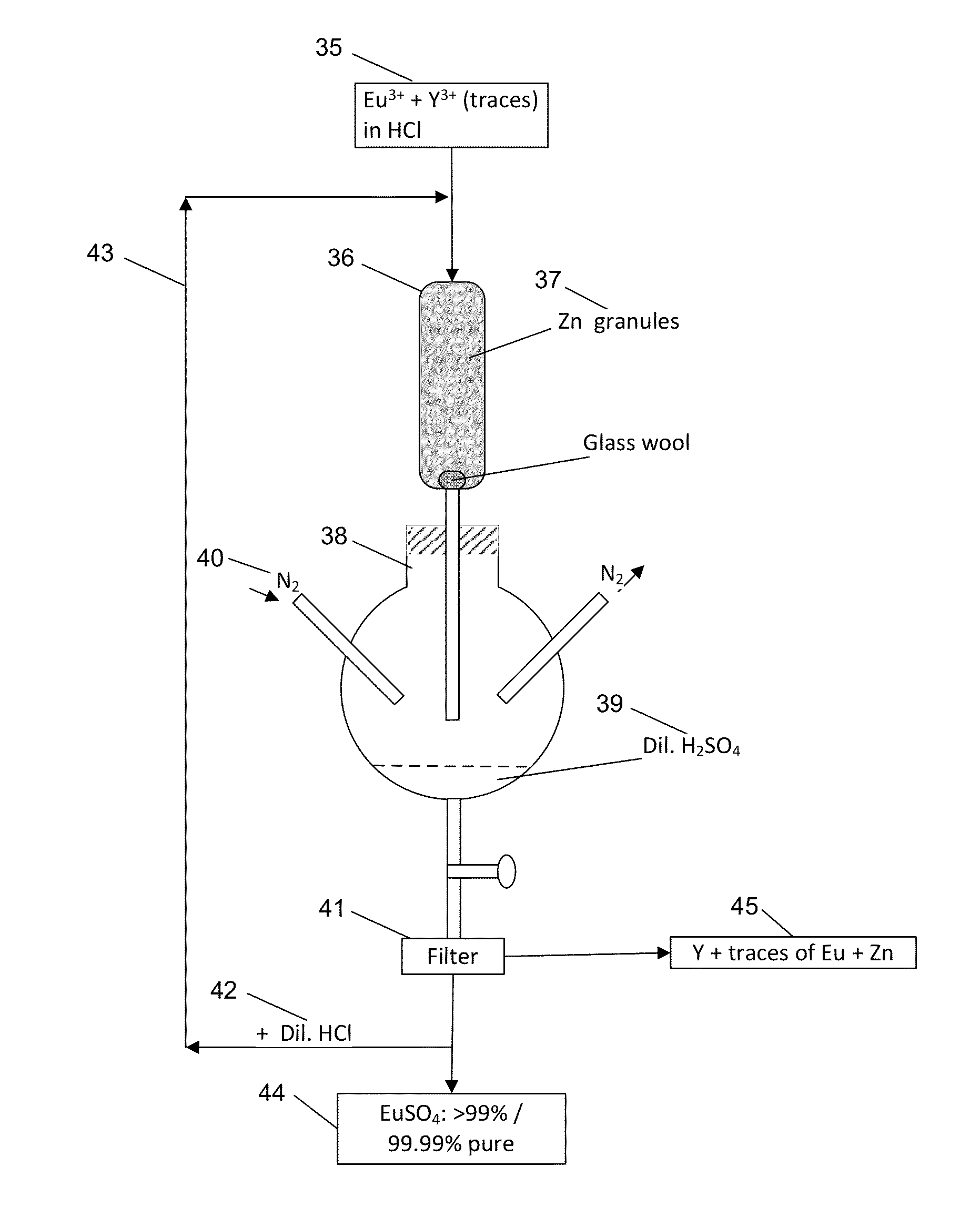

InactiveUS20130156660A1Efficient methodEfficient and effectivePhysical/chemical process catalystsRare earth metal chloridesPhosphorRare earth

A method is described to produce high purity rare earth oxides of the elements La, Ce, Tb, Eu and Y from phosphor, such as waste phosphor powders originating in various consumer products. One approach involves leaching the powder in two stages and converting to two groups of relatively high purity mixed rare earth oxides. The first group containing Eu and Y is initially separated by solvent extraction. Once separated, Eu is purified using Zn reduction with custom apparatus. Y is purified by running another solvent extraction process using tricaprylmethylammonium chloride. Ce is separated from the second group of oxides, containing La, Ce and Tb by using solvent extraction. Subsequently, La and Tb are separated from each other and converted to pure oxides by using solvent extraction processes. A one-stage leaching process, wherein all rare earths get leached into the solution and subsequently processed, is also described.

Owner:REENEWAL

Method of manufacturing metal oxide film

InactiveUS8753987B2High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device manufacturingOxygenMetal

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

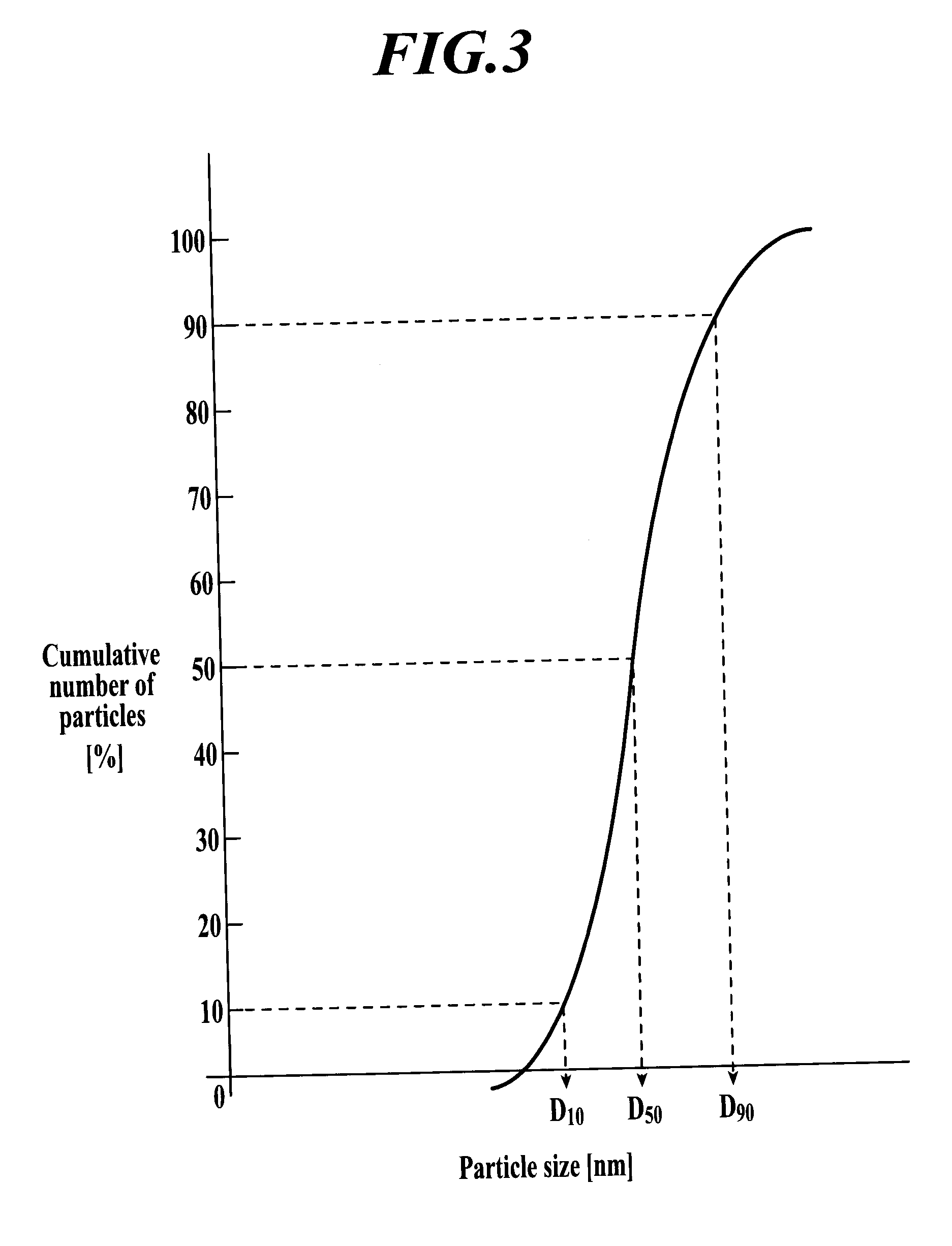

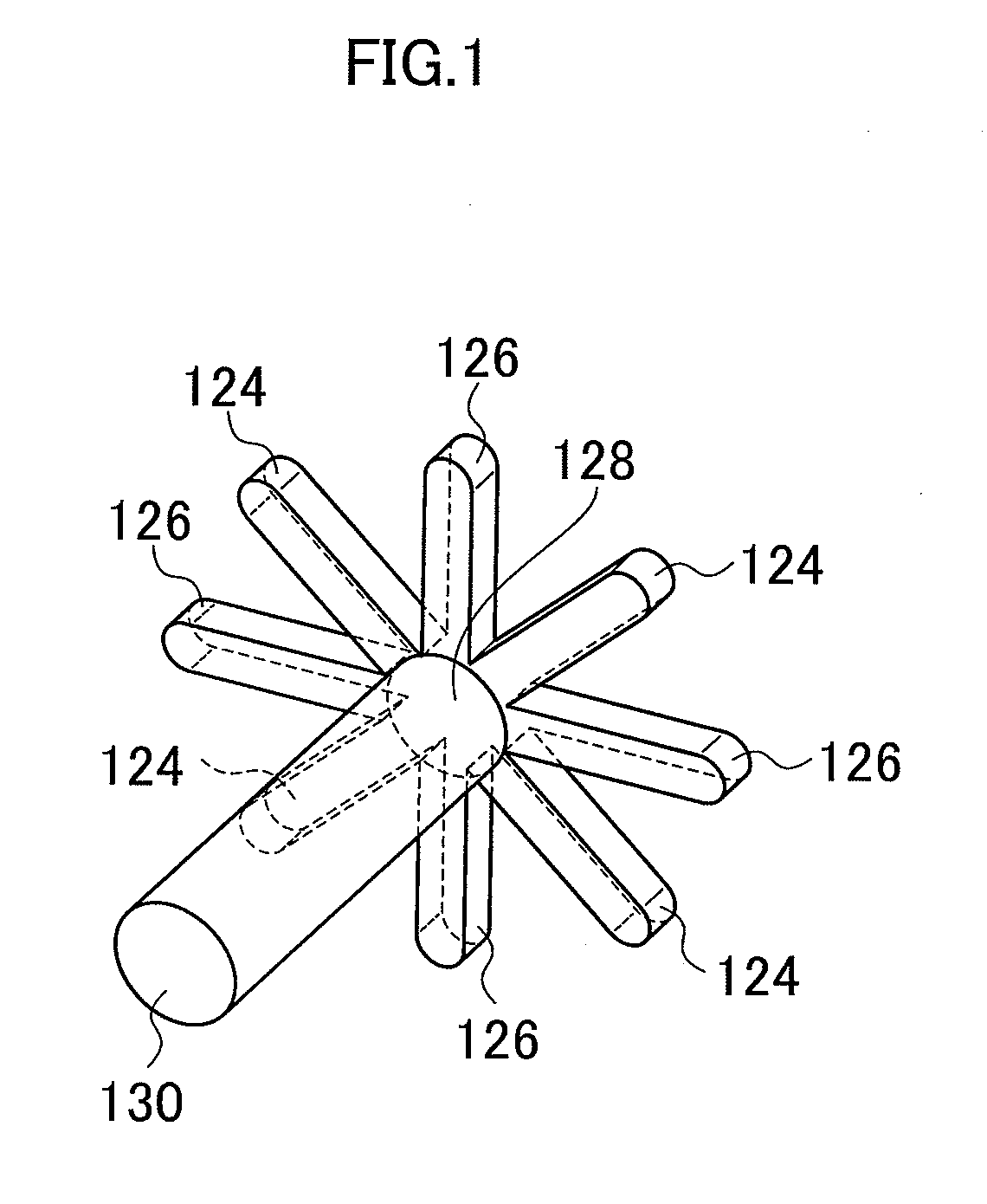

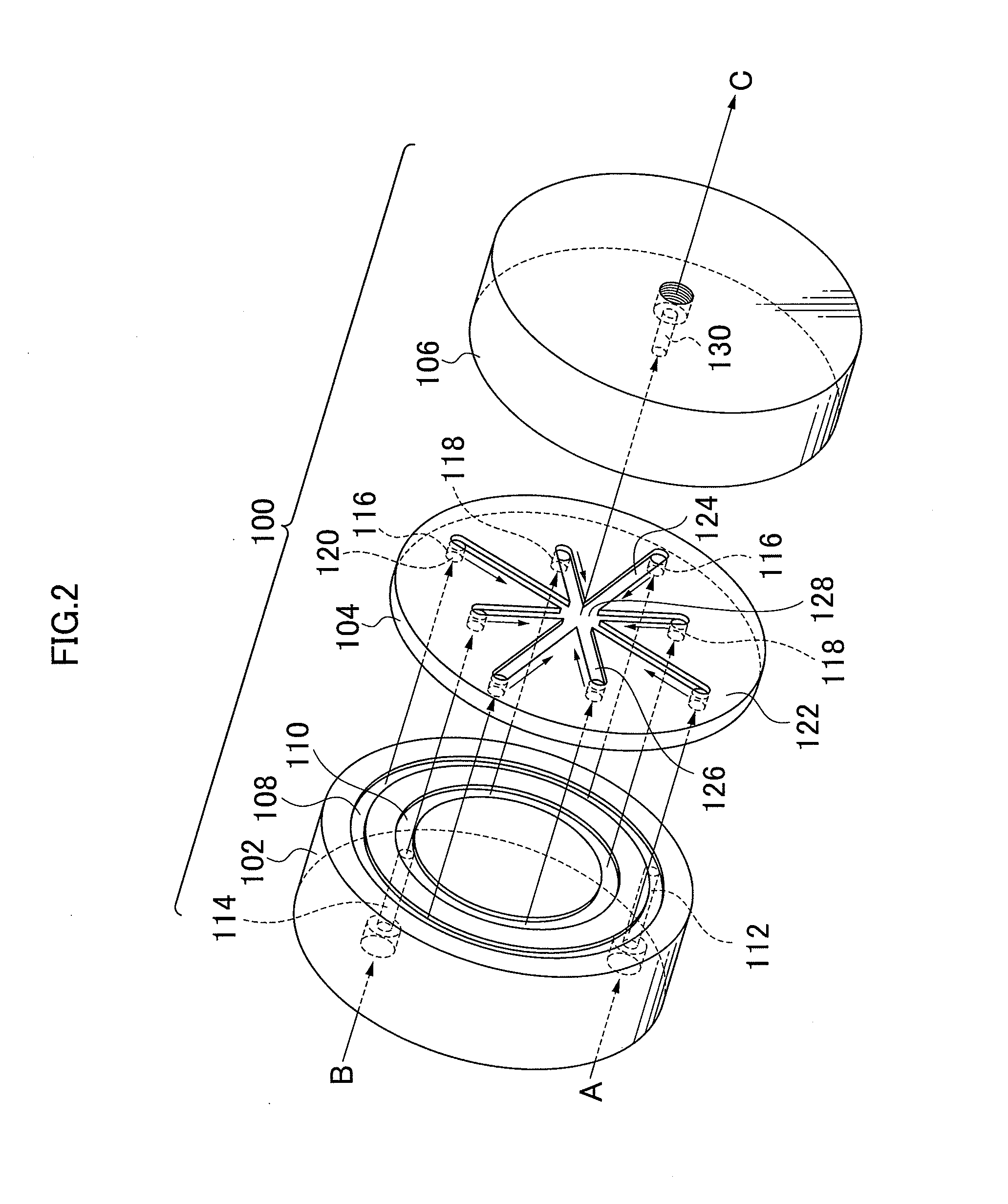

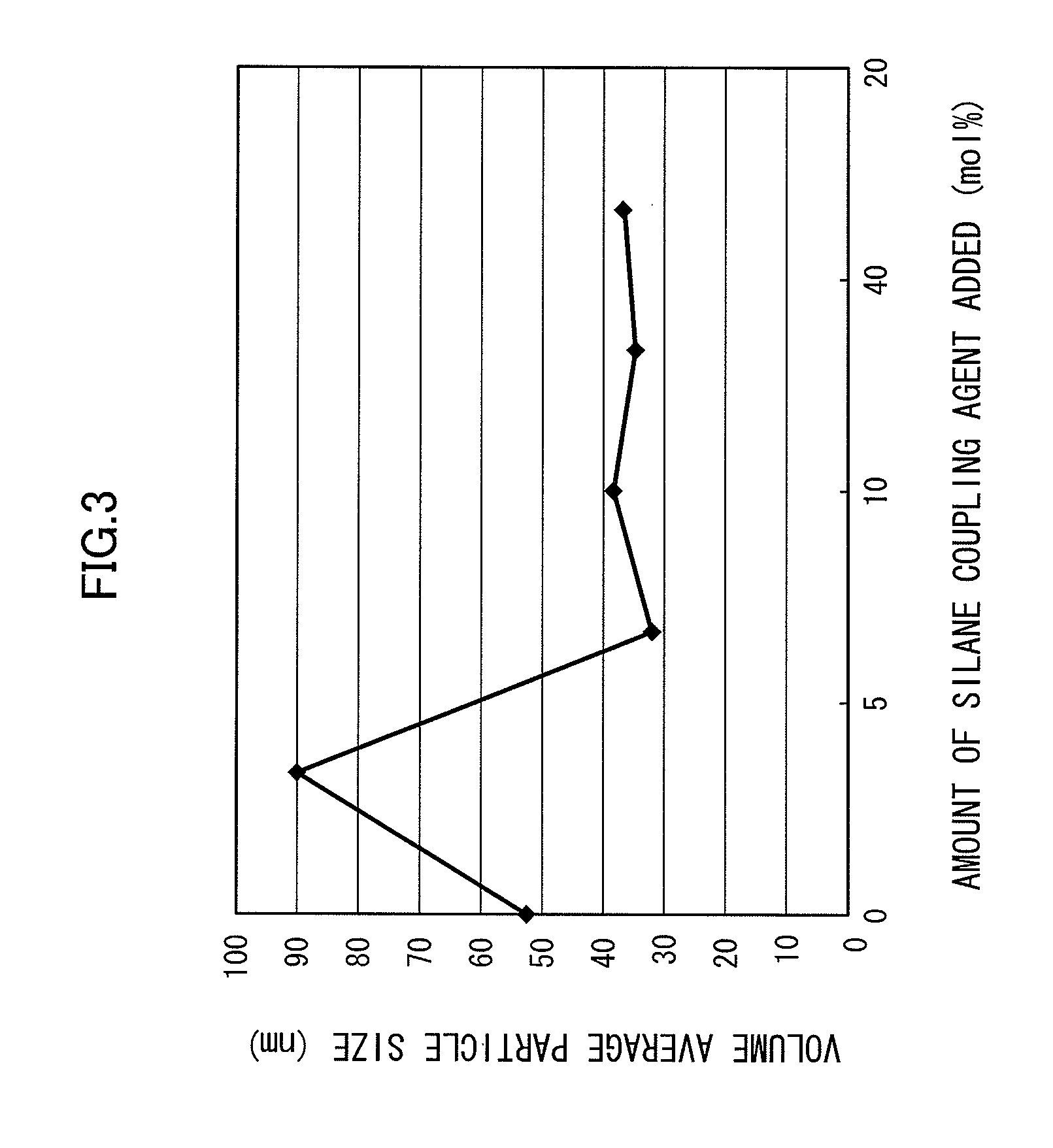

Method for producing metal hydroxide fine particle

InactiveUS20110236285A1Eliminate needInhibit aggregationMaterial nanotechnologyOxide/hydroxide preparationReaction fieldCrystallinity

An object of the present invention is to provide a method for producing a metal hydroxide fine particle, which can produce metal hydroxide fine particles with favorable crystallinity and small particle sizes. The present invention provides a method for producing a metal hydroxide fine particle by reacting a metal ion with a hydroxide ion in a solvent, which includes a mixing and reacting step of supplying the metal ion, the hydroxide ion, and a silane coupling agent to a reaction field to mix and react the ions.

Owner:FUJIFILM CORP

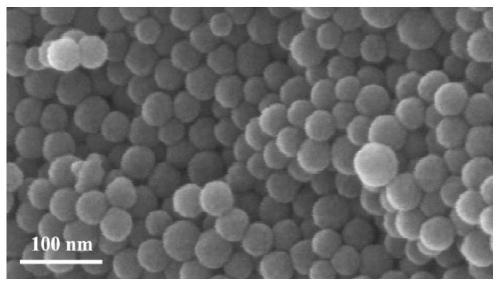

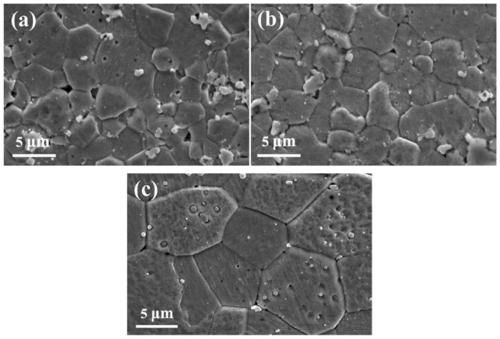

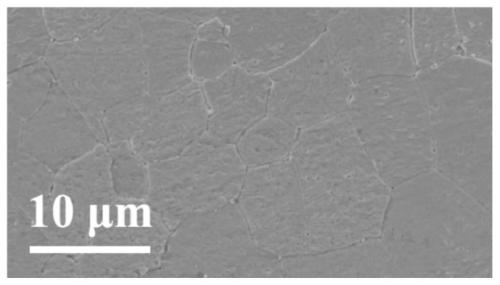

Preparation method of high-performance ultra-fine grain molybdenum and lanthanum alloy

ActiveCN111206164AEvenly distributedEasy accessLanthanum oxide/hydroxidesNanotechnologyStress concentrationBreaking strength

The invention discloses a preparation method of a high-performance ultra-fine grain molybdenum and lanthanum alloy. The preparation method comprises the following steps that 1) spherical nano La2O3 isprepared; 2) molybdenum powder is prepared; 3) mixed powder is prepared; and 4) a molybdenum alloy is prepared, and namely, after the mixed powder is subjected to weight balancing, SPS rapid sintering is performed to obtain the La2O3-Mo molybdenum alloy. According to the preparation method, a La2O3 second phase is prepared by using a water bath method, the purpose of controlling the size and theappearance of the second phase can be achieved by controlling the time length of the water bath and the size of the cooling speed, so that the very fine spherical La2O3 is obtained, particles of the second phase are smaller, so that the distribution is more uniform, and the particles are easier to enter the interiors of the Mo alloy grains, and more obvious strengthening effect is achieved. The strengthening effect of the spherical La2O3 is best, the possibility of micro-cracks is small due to the fact that the tendency of the stress concentration is small, the breaking strength can be furtherimproved, the cracks will deviate from the original main expansion direction, dislocation loops are formed, and therefore, the yield strength and tensile strength are improved.

Owner:CENT SOUTH UNIV

Processes for preparing alumina and various other products

There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides of various metals, sulphates and chlorides of various metals, as well as rare earth elements, rare metals and aluminum.

Owner:ORBITE ALUMINAE INC

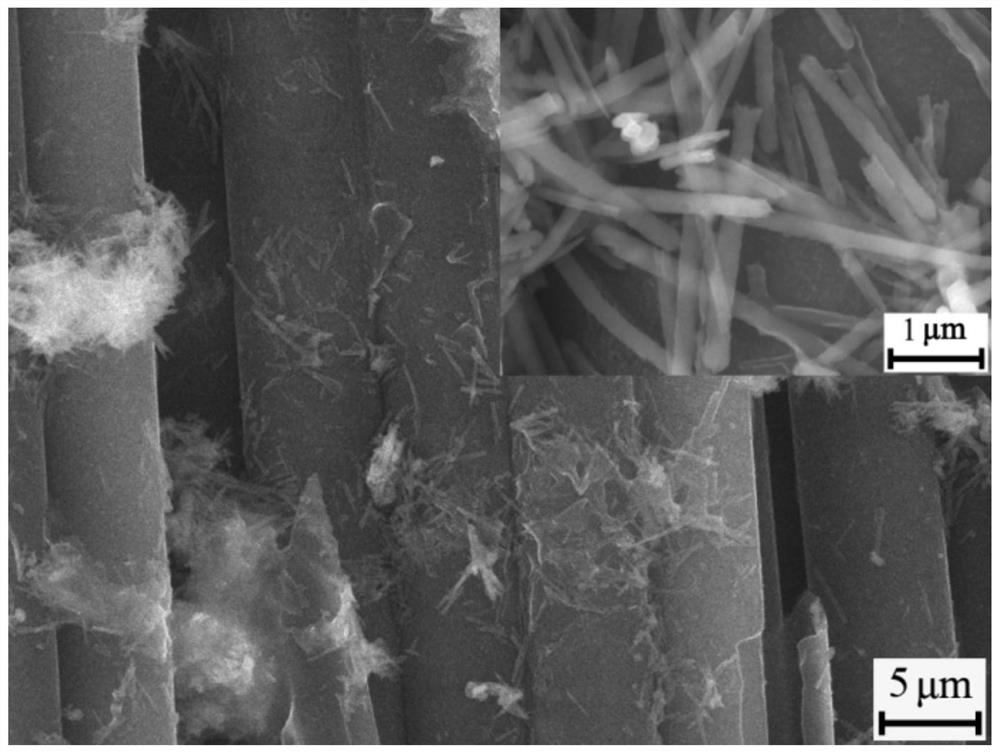

Preparation method of carbon fiber/rare earth oxide nanowire mixed reinforcement, as well as obtained material and application of carbon fiber/rare earth oxide nanowire mixed reinforcement

InactiveCN113846482AScientific and reasonable designControl compositionLanthanum oxide/hydroxidesCarbon fibresCarbon fibersNanowire

The invention belongs to the technical field of composite materials, and particularly relates to a preparation method of a carbon fiber / rare earth oxide nanowire mixed reinforcement, as well as an obtained material and application of the carbon fiber / rare earth oxide nanowire mixed reinforcement. The preparation method comprises the following steps of placing a carbon fiber preform in a rare earth salt reaction solution, magnetically stirring, performing high-temperature and high-pressure in-situ synthesis reaction, cleaning, drying and calcining to obtain the carbon fiber / rare earth oxide nanowire mixed reinforcement. According to the preparation method provided by the invention, reagents which are high in cost and pollute the environment are not used, the preparation process is simple and controllable, the reaction temperature is low, and the composition, the content and the like of rare earth oxide nanowires can be controlled through design of the reaction solution proportion and reaction conditions; and the mixed reinforcement prepared by the preparation method disclosed by the invention can give consideration to the cross-scale synergistic reinforcement advantage of carbon fibers and nanowires on an interface and a matrix and the modification effect of rare earth on the surface of the carbon fibers, and can be used for reinforcing polymers, carbon and ceramic-based composite materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

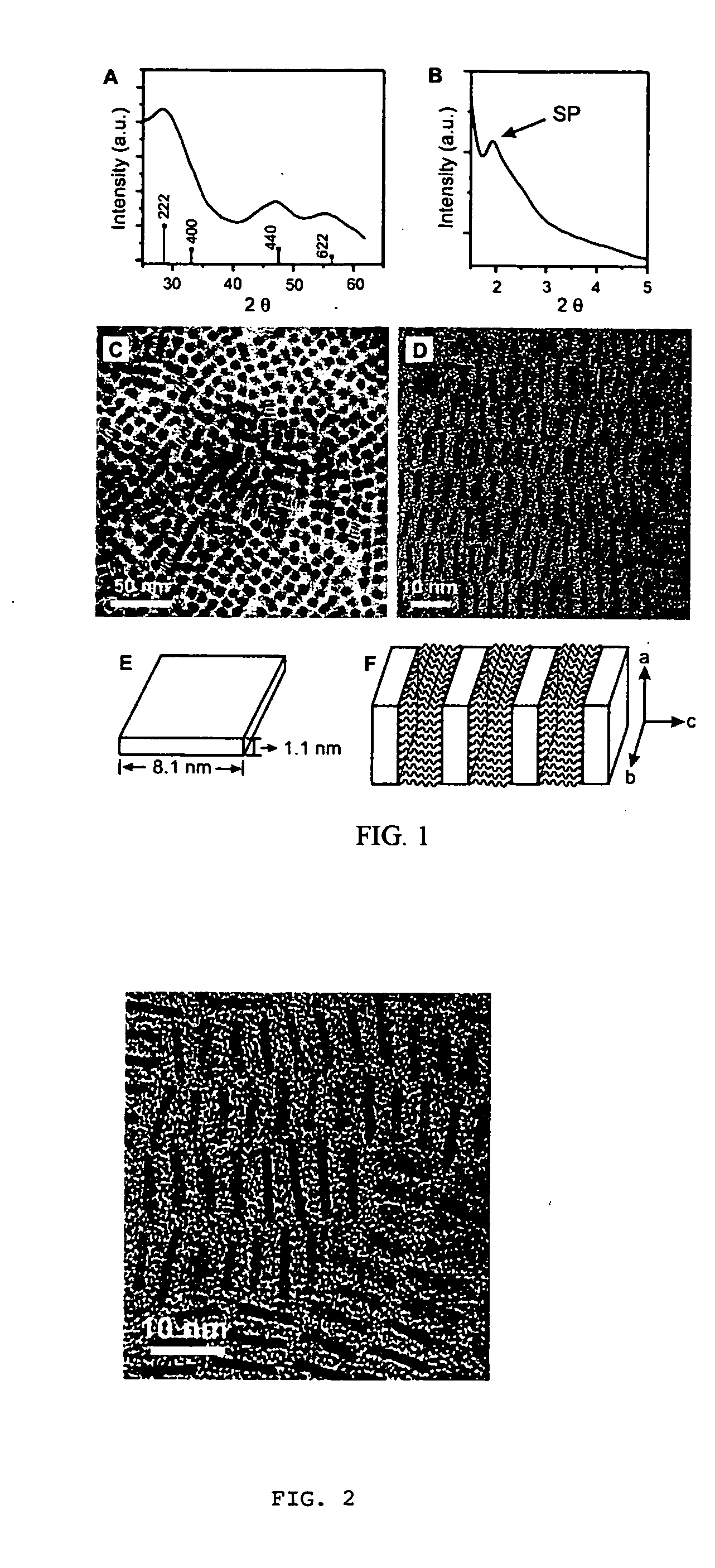

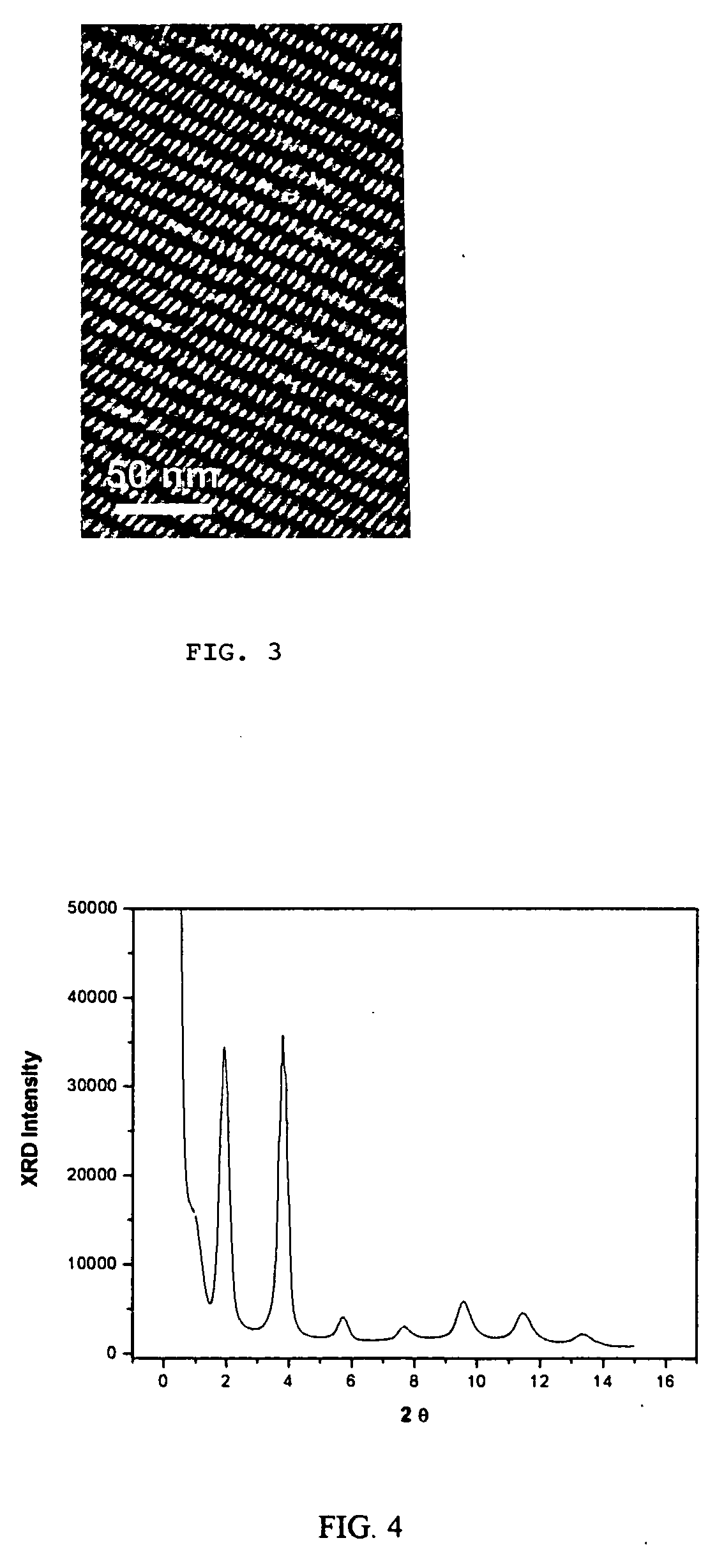

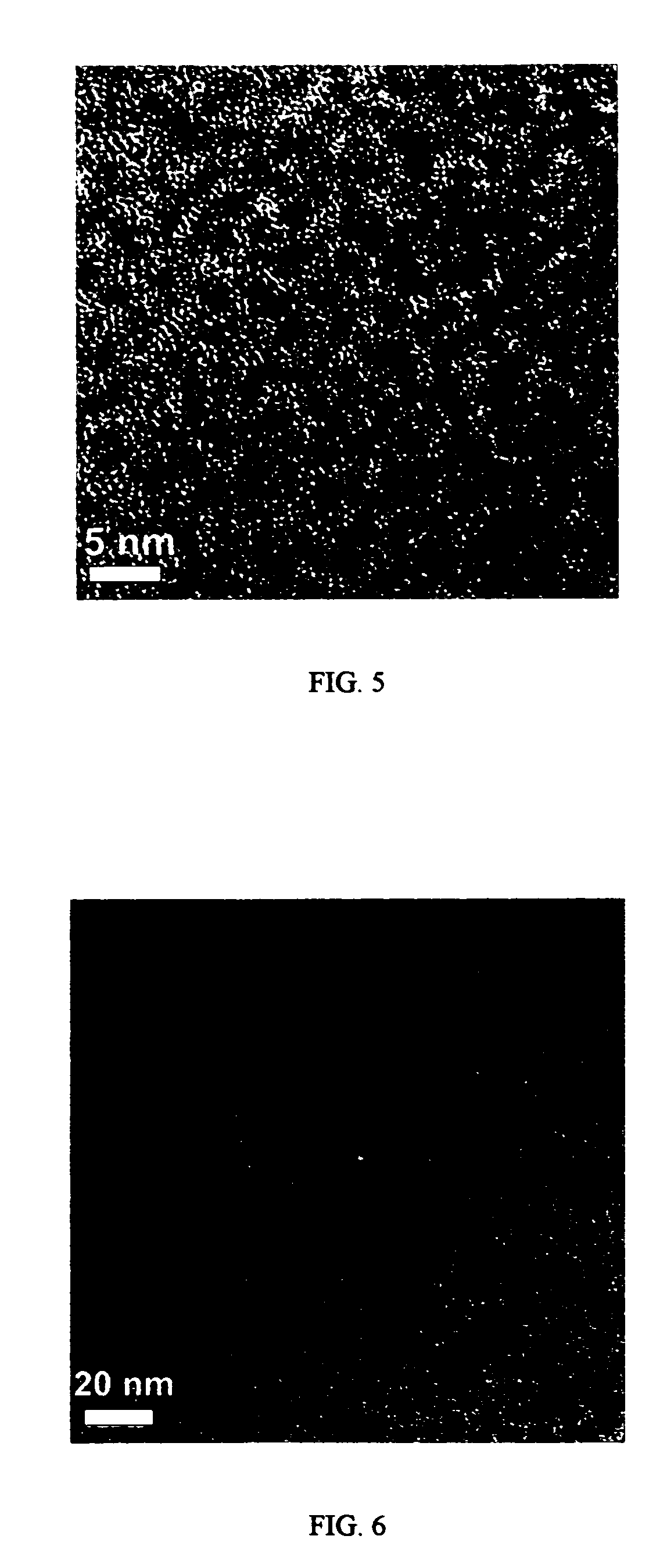

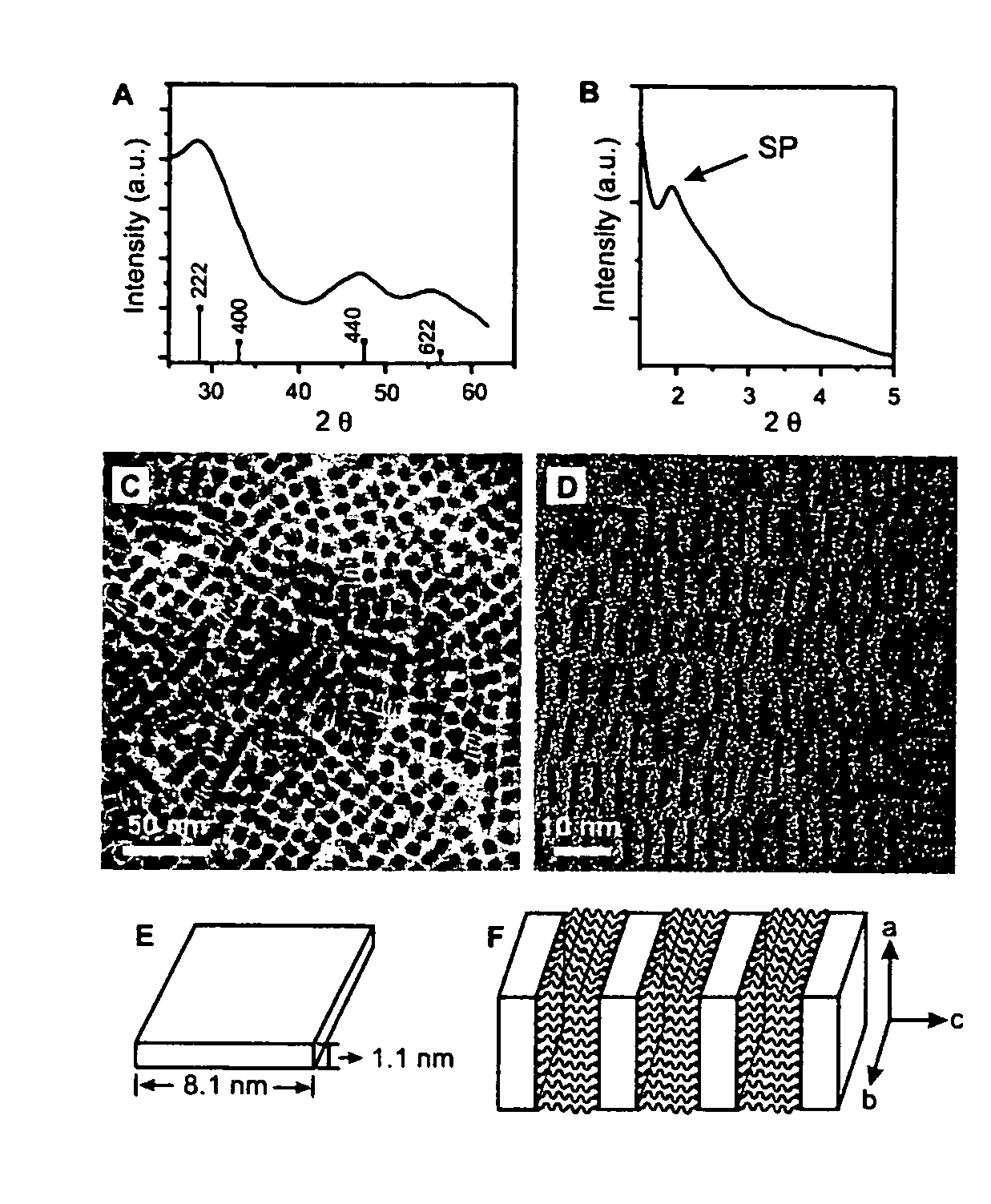

Rare earth oxide nanocrystals and methods of forming

InactiveUS20080175779A1Simple processLow variabilityMaterial nanotechnologyFrom normal temperature solutionsOrganic solventDecomposition

A method of forming rare earth oxide nanocrystals include the steps of dissolving a rare earth including compound in a solution containing at least one organic solvent, heating the solution to a temperature of at least 160° C., wherein a concentration of the rare earth including compound provided upon decomposition is sufficient to provide critical supersaturation of at least one active intermediate in the solution to nucleate a plurality of rare earth oxide nanocrystals. The plurality of rare earth nanocrystals are then grown, wherein the growing step proceeds at least in part in the absence of critical supersaturation of the active intermediate. The rare earth nanocrystals can assemble into at least one close-packed, ordered nanocrystal superlattice.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Complex oxide, method for producing same, and exhaust gas purifying catalyst

InactiveUS20120309614A1Large hole volumeImprove heat resistanceGas treatmentLanthanum oxide/hydroxidesHeat resistanceCerium

Disclosed are a composite oxide which is capable of maintaining a large volume of pores even used in a high temperature environment, and which has excellent heat resistance and catalytic activity, as well as a method for producing the composite oxide and a catalyst for exhaust gas purification employing the composite oxide. The composite oxide contains cerium and at least one element selected from aluminum, silicon, or rare earth metals other than cerium and including yttrium, at a mass ratio of 85:15 to 99:1 in terms oxides, and has a property of exhibiting a not less than 0.30 cm3 / g, preferably not less than 0.40 cm3 / g volume of pores with a diameter of not larger than 200 nm, after calcination at 900° C. for 5 hours, and is suitable for a co-catalyst in a catalyst for vehicle exhaust gas purification.

Owner:ANAN KASEI CO LTD

Rare earth recovery from phosphor

InactiveUS8524176B2Efficient and effectiveRare earth metal chloridesPhysical/chemical process catalystsPhosphorRare earth

A method is described to produce high purity rare earth oxides of the elements La, Ce, Tb, Eu and Y from phosphor, such as waste phosphor powders originating in various consumer products. One approach involves leaching the powder in two stages and converting to two groups of relatively high purity mixed rare earth oxides. The first group containing Eu and Y is initially separated by solvent extraction. Once separated, Eu is purified using Zn reduction with custom apparatus. Y is purified by running another solvent extraction process using tricaprylmethylammonium chloride. Ce is separated from the second group of oxides, containing La, Ce and Tb by using solvent extraction. Subsequently, La and Tb are separated from each other and converted to pure oxides by using solvent extraction processes. A one-stage leaching process, wherein all rare earths get leached into the solution and subsequently processed, is also described.

Owner:REENEWAL

Thermal spray powder and method for forming thermal spray coating

ActiveUS7837967B2Increase resistanceLiquid surface applicatorsMolten spray coatingRare-earth elementThermal spraying

A thermal spray powder contains particles composed of an oxide of any of the rare earth elements having an atomic number of 39 or from 59 to 70. The crushing strength of the particles is 80 MPa or greater. The ratio of bulk specific gravity to true specific gravity of the thermal spray powder is 0.15 or greater. The particles are preferably granulated and sintered particles. The average particle size of primary particles constituting the granulated and sintered particles is preferably 6 μm or less.

Owner:FUJIMI INCORPORATED

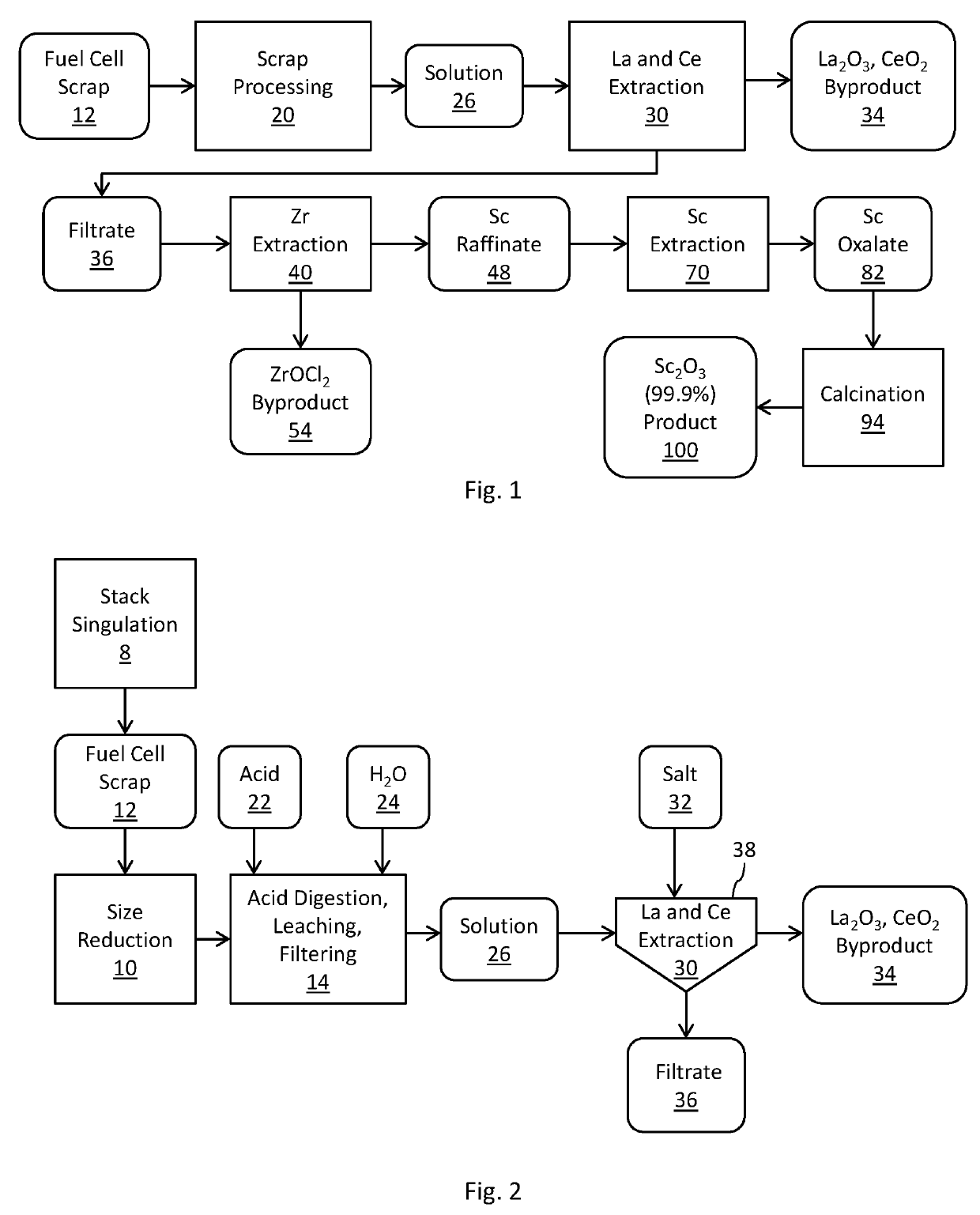

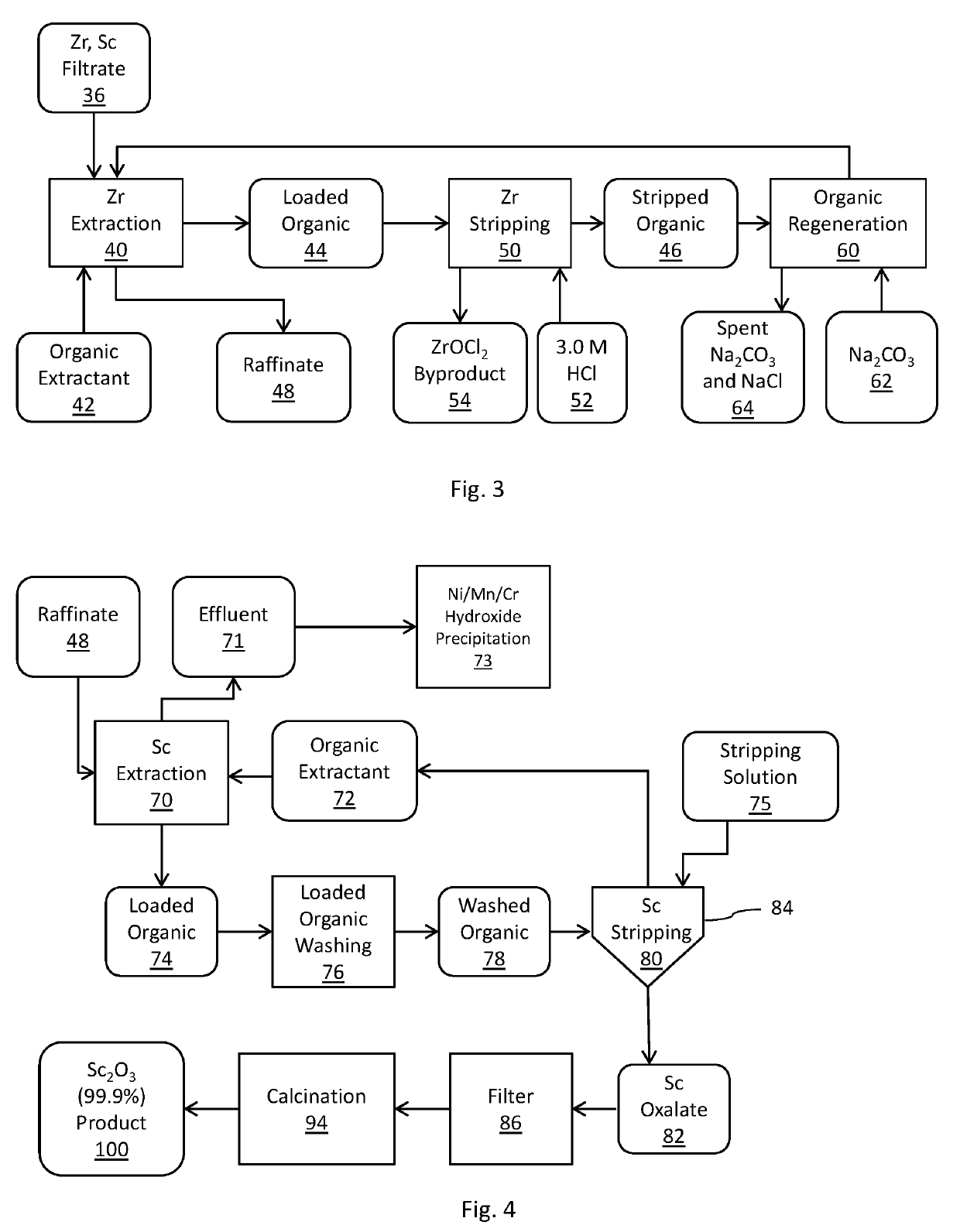

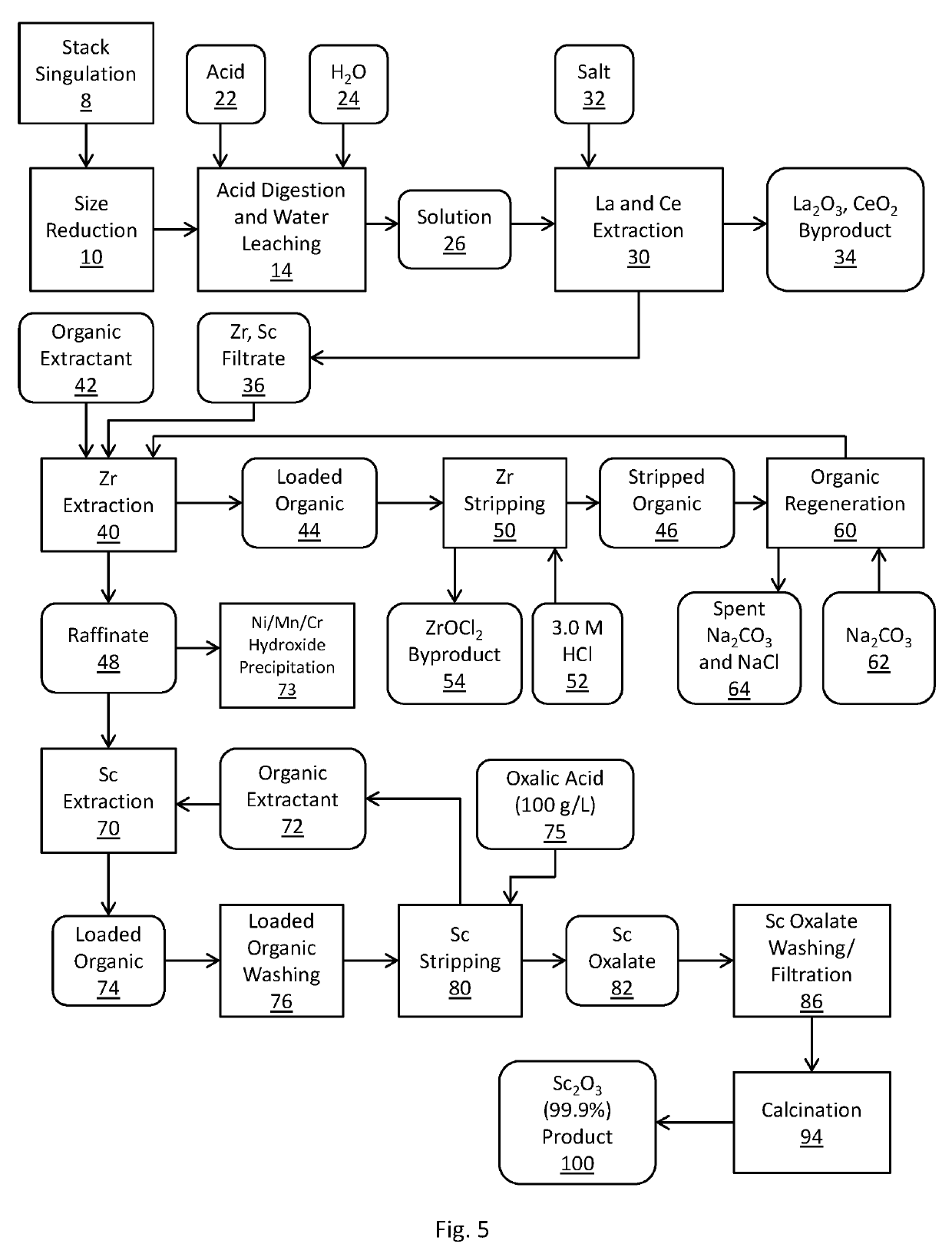

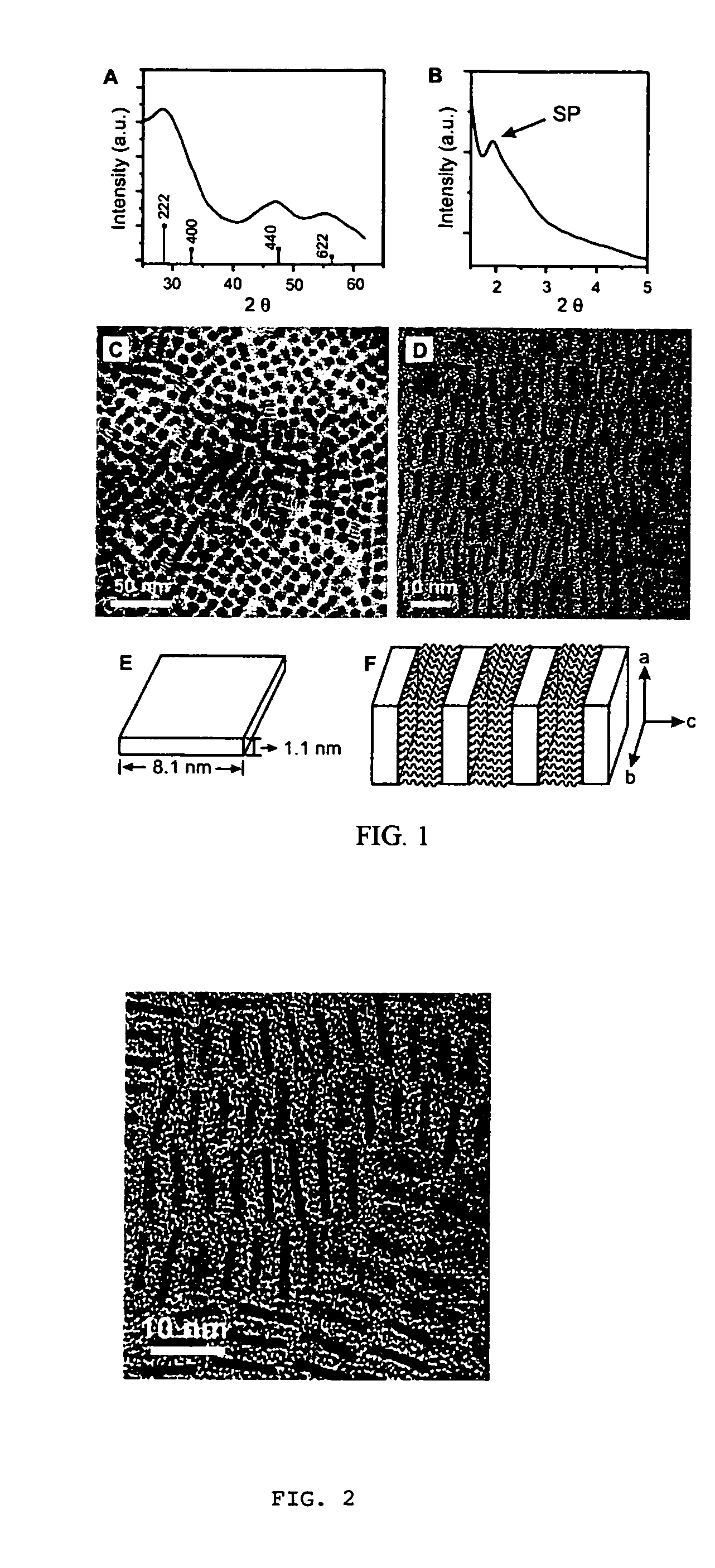

Method of recovering metal compounds from solid oxide fuel cell scrap

A method of recovering metal compounds from solid oxide fuel cell scrap includes processing the solid oxide fuel cell scrap to form a powder, digesting the processed scrap, extracting lanthanum oxide and cerium oxide from a solution containing the digested processed scrap, extracting a zirconium compound from the solution after extracting the lanthanum oxide and cerium oxide, and extracting scandium compound from the solution extracting the zirconium compound from the solution.

Owner:BLOOM ENERGY CORP

Rare earth oxide nanocrystals and methods of forming

InactiveUS7527773B2Simple processLow variabilityMaterial nanotechnologyX-ray/infra-red processesOrganic solventDecomposition

A method of forming rare earth oxide nanocrystals include the steps of dissolving a rare earth including compound in a solution containing at least one organic solvent, heating the solution to a temperature of at least 160° C., wherein a concentration of the rare earth including compound provided upon decomposition is sufficient to provide critical supersaturation of at least one active intermediate in the solution to nucleate a plurality of rare earth oxide nanocrystals. The plurality of rare earth nanocrystals are then grown, wherein the growing step proceeds at least in part in the absence of critical supersaturation of the active intermediate. The rare earth nanocrystals can assemble into at least one close-packed, ordered nanocrystal superlattice.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

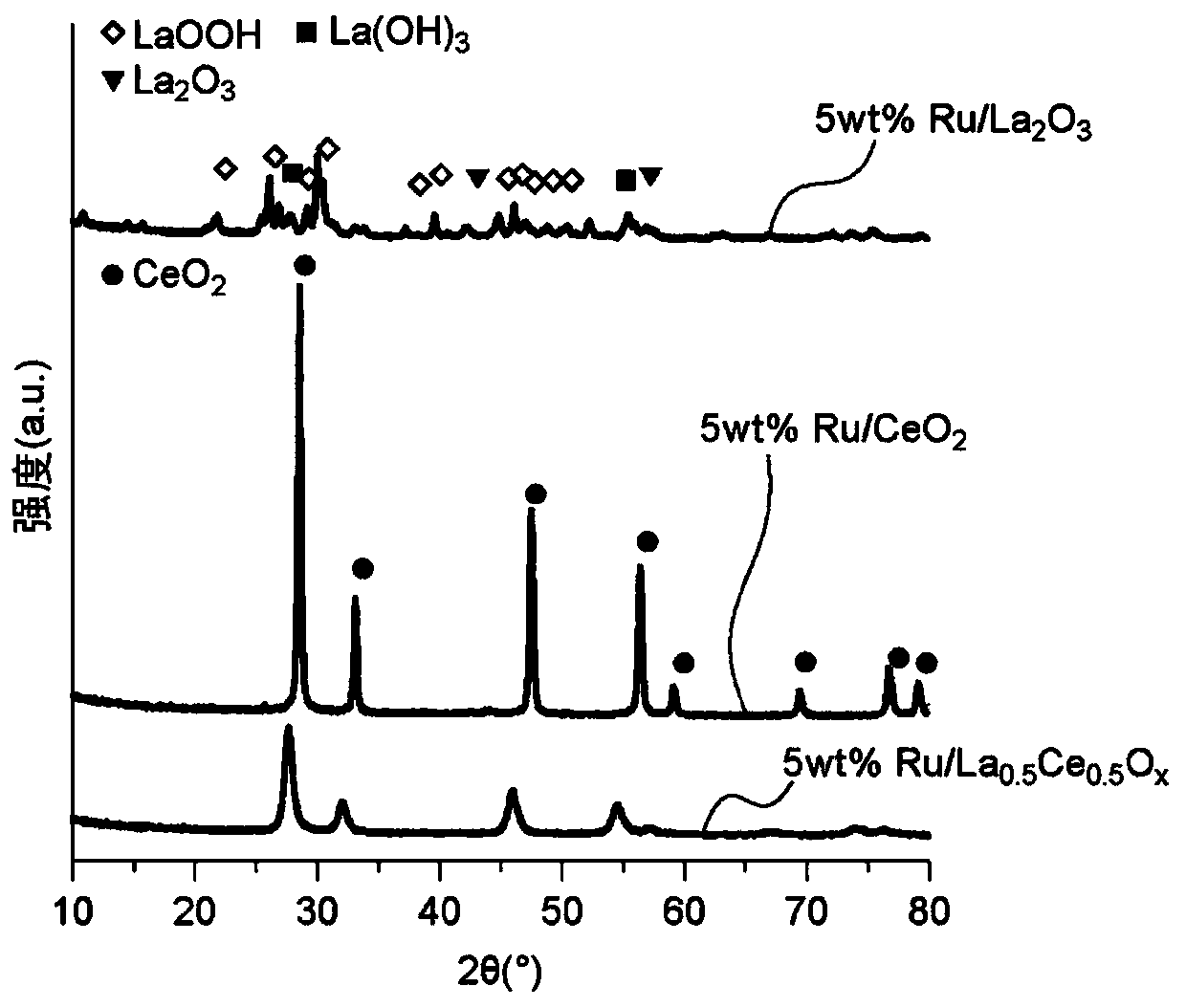

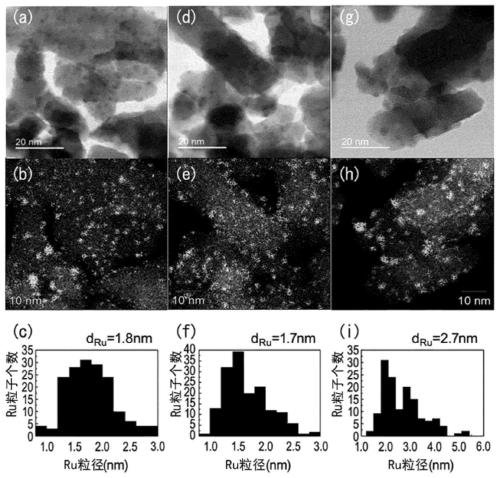

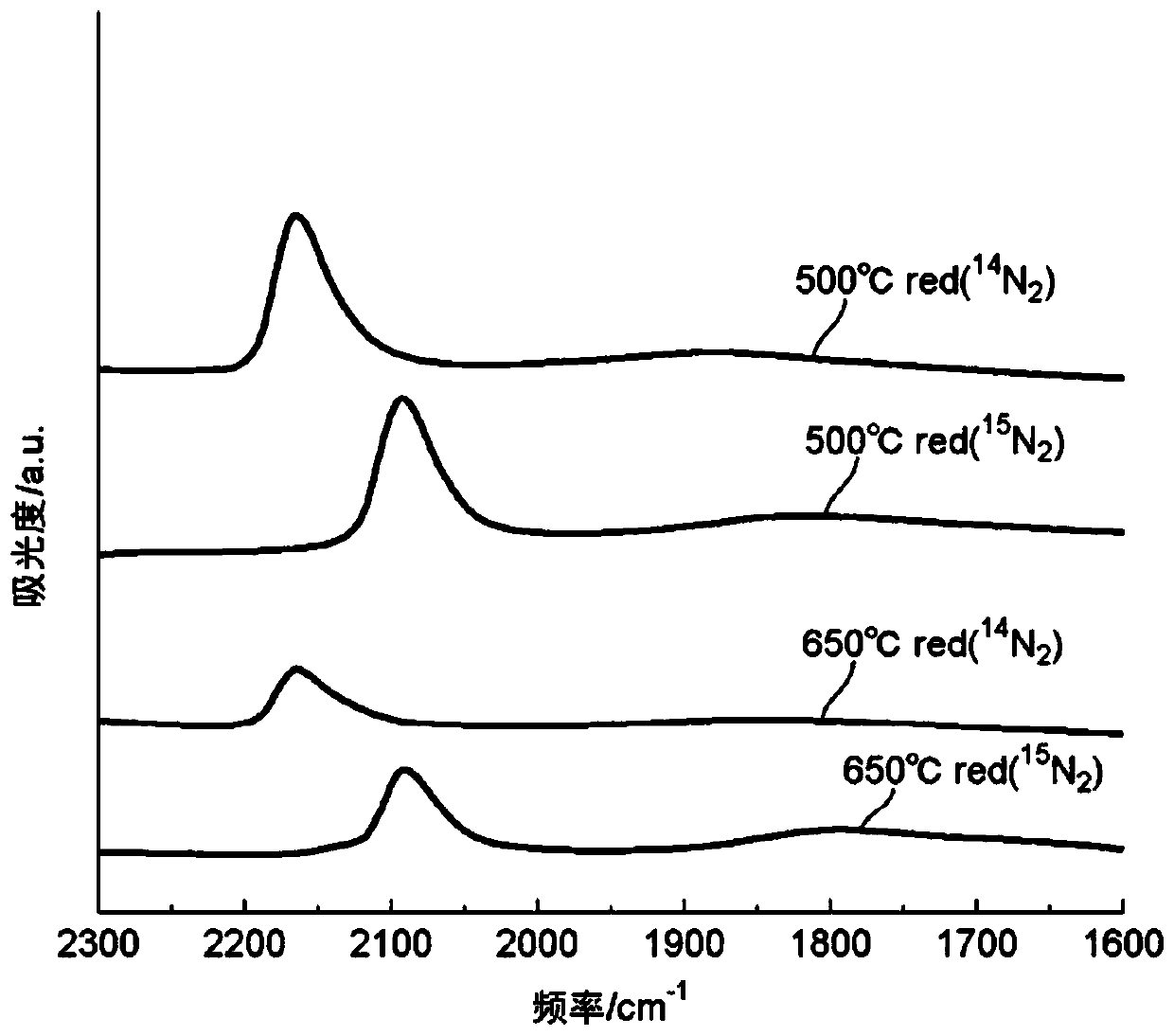

Composite oxide, metal-supporting material and ammonia synthesis catalyst

ActiveCN111183115AThe preparation method is simple and easyLanthanum oxide/hydroxidesZirconium compoundsPtru catalystPhysical chemistry

The composite oxide according to the present invention is a composite oxide that contains metal elements and has a composition represented by general formula (1). AnXyMm (1) [wherein: A represents a lanthanoid characterized by being partly or entirely in the III valence state; X represents a group 2 element in the periodic table selected from the group consisting of Ca, Sr and Ba or a lanthanoid,provided that X is an element different from A; M represents a group 1 element in the periodic table, a group 2 element selected from the group consisting of Ca, Sr and Ba or a lanthanoid, provided that M is an element different from A and X; and n is more than 0 and less than 1, y is more than 0 and less than 1, and m is 0 or more and less than 1, provided that n+y+m is 1].

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com