Cerium oxide sol and abrasive

A cerium oxide and sol technology, applied in the direction of cerium oxide/cerium hydroxide, lanthanum oxide/lanthanum hydroxide, lanthanide oxide/hydroxide, etc., can solve the problem of irregular particle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

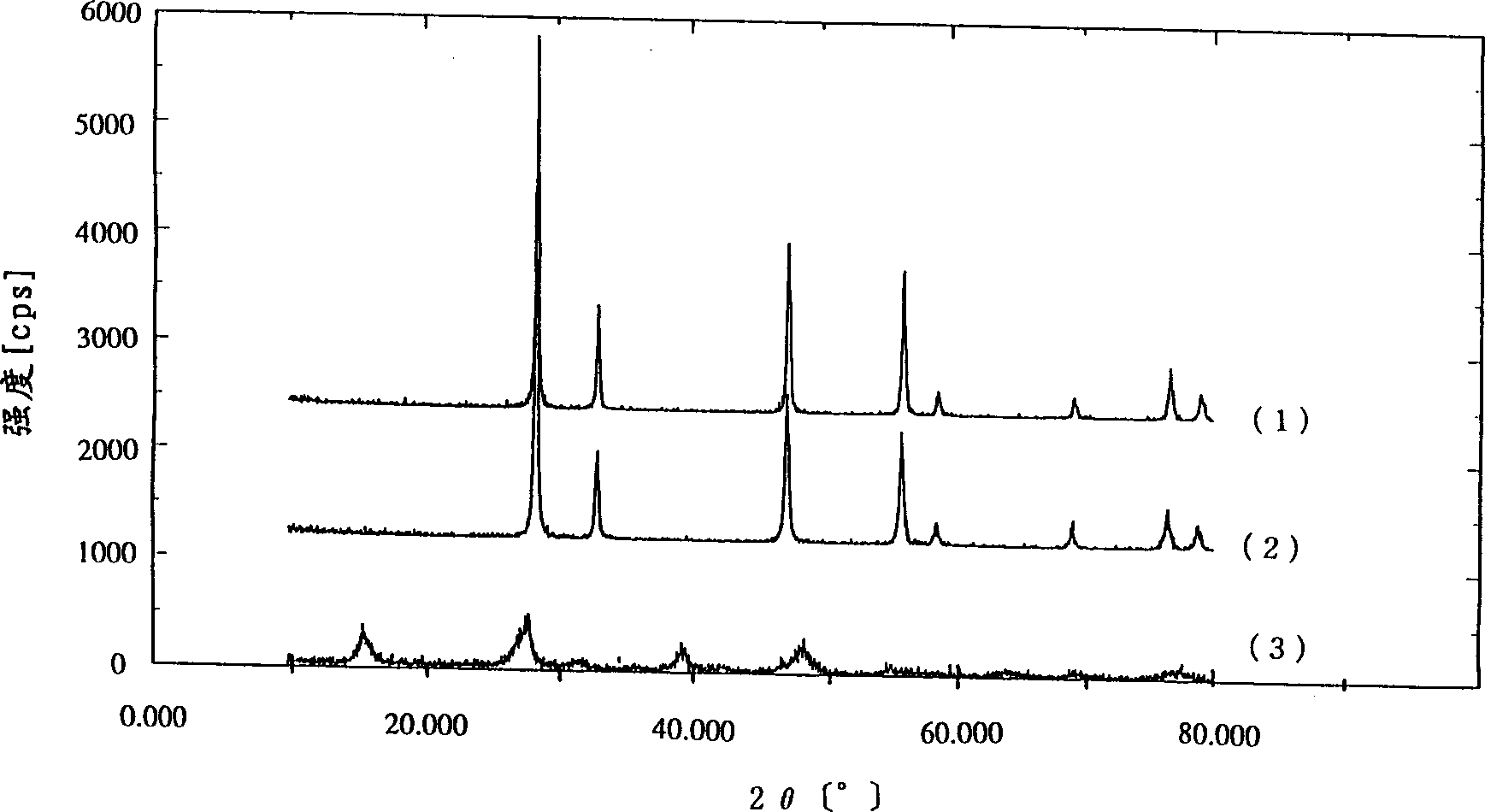

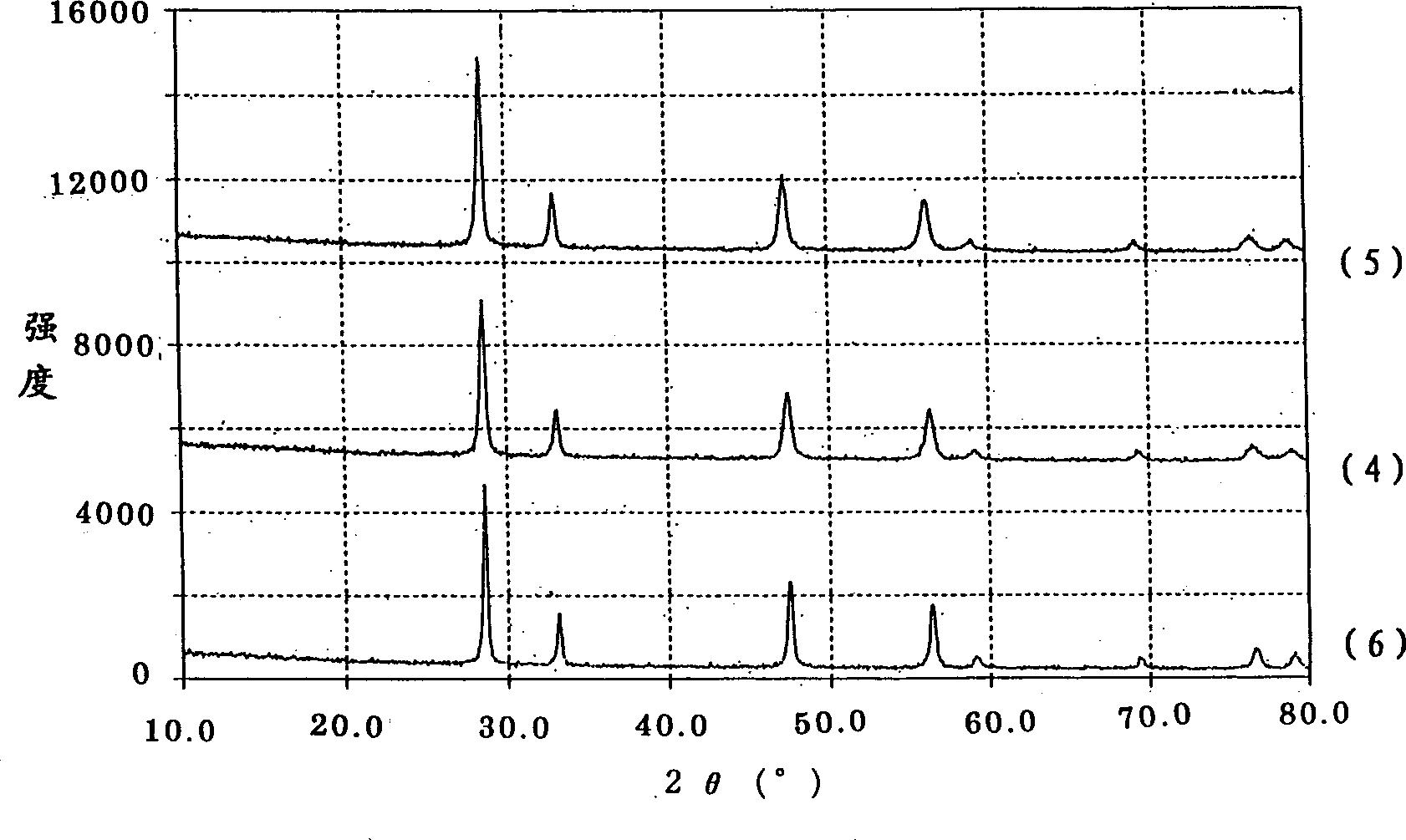

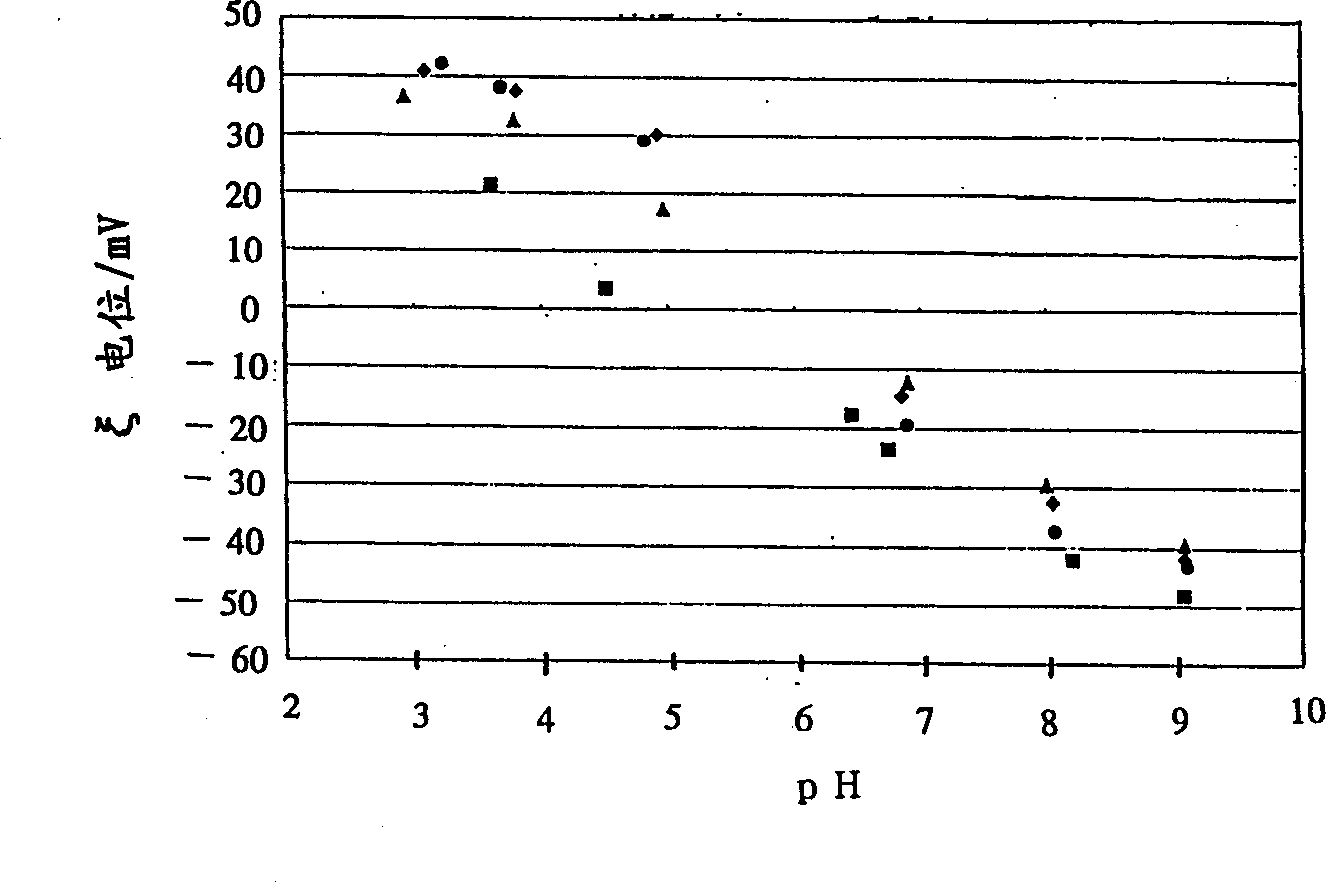

Embodiment 1

[0073] In a 2L glass reaction tank, add the equivalent of NH 3 / (Ce 3+ +La 3+ )=8 (mol ratio) of 25% ammonia solution 253g, from the glass nozzle whose liquid temperature is kept at 30° C., 0.5 L / min of nitrogen gas is introduced. In a 1L glass container, convert to CeO 2 The concentration is 11.5% by weight, the purity is 693g of cerium nitrate (III) aqueous solution of 99.9%, and conversion into La 2 o 3 28.5 g of an aqueous solution of lanthanum (III) nitrate having a concentration of 14.0% by weight and a purity of 99.99% or higher was mixed. This mixed aqueous solution contained lanthanum in such a ratio that the molar ratio in terms of La / (Ce+La) was 0.05. While stirring this mixed aqueous solution, it was slowly added to a 2 L glass reaction vessel over 30 minutes to obtain a hydroxide suspension. Next, after raising the temperature of the suspension to 80° C., the gas flow from the glass nozzle was switched from nitrogen to 0.5 L / min of air to start the oxidation...

Embodiment 2

[0077] In a 2L glass reaction tank, add the equivalent of NH 3 / (Ce 3+ +La 3+) = 8 (mol ratio) of 25% ammonia solution 253g, blowing 0.5L / min of nitrogen gas from the glass nozzle whose liquid temperature was kept at 30°C. In a 1L glass container, convert to CeO 2 The concentration is 11.5% by weight, the cerium nitrate (III) aqueous solution 693g of purity 99.9%, and conversion into La 2 o 3 28.5 g of an aqueous solution of lanthanum (III) nitrate having a purity of 99.99% or higher at a concentration of 14.0% by weight was mixed. This mixed aqueous solution contained lanthanum in such a ratio that the molar ratio in terms of La / (Ce+La) was 0.05. This mixed aqueous solution was slowly added to a 2 L glass reaction tank over 30 minutes while stirring, to obtain a hydroxide suspension. Next, after raising the temperature of the suspension to 80° C., the gas blowing from the glass nozzle was switched from nitrogen to 0.5 L / min of air to start the oxidation reaction of ceri...

Embodiment 3

[0082] In a 2L glass reaction tank, add the equivalent of NH 3 / (Ce 3+ +La 3+ ) = 8 (mol ratio) of 25% ammonia solution 253g, blowing 0.5L / min of nitrogen gas from the glass nozzle whose liquid temperature was kept at 30°C. In a 1L glass container, convert to CeO 2 The concentration is 11.5% by weight, the cerium nitrate (III) aqueous solution 693g of purity 99.9%, and conversion into La 2 o 3 56.8 g of an aqueous solution of lanthanum (III) nitrate having a purity of 99.99% or higher at a concentration of 14.0% by weight was mixed. This mixed aqueous solution contained lanthanum in such a ratio that the molar ratio in terms of La / (Ce+La) was 0.10. This mixed aqueous solution was slowly added to a 2 L glass reaction vessel over 30 minutes while stirring, to obtain a hydroxide suspension. Next, after raising the temperature of the suspension to 80° C., the gas blowing from the glass nozzle was switched from nitrogen to 0.5 L / min of air to start the oxidation reaction of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com