Preparation method of high-performance ultra-fine grain molybdenum and lanthanum alloy

A molybdenum-lanthanum alloy and ultra-fine-grained technology, which is applied in the field of molybdenum alloy materials, can solve the problems of low yield strength, tensile strength, reducing the bonding force between grain boundaries, and reducing the performance of molybdenum alloys, so as to reduce the sintering temperature and Effects of sintering time, grain refinement, and improvement of sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

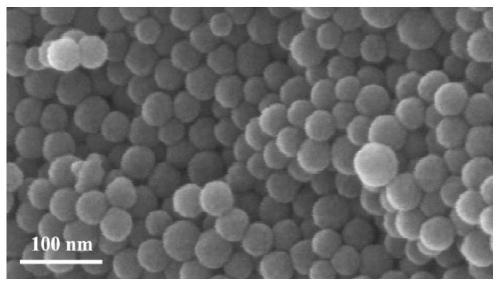

[0029] Weigh 0.325g of lanthanum nitrate with a particle size of 0.8-1.2μm and 18g of urea, dissolve them in 150mL of water and stir them evenly with a magnetic force. The temperature of the water bath is 85°C and keep warm for 1h. After filtering and washing, a white powder is obtained. Put the white powder into a tube furnace, heat up to 950°C at 10°C / min for calcination, keep it warm for 2 hours, and take out the sample to form a spherical La 2 o 3 , the spherical La in this example 2 o 3 Microscopic appearance such as figure 1 As shown, it can be seen from the figure that it is a regular spherical shape, and its average particle diameter is measured to be 85nm.

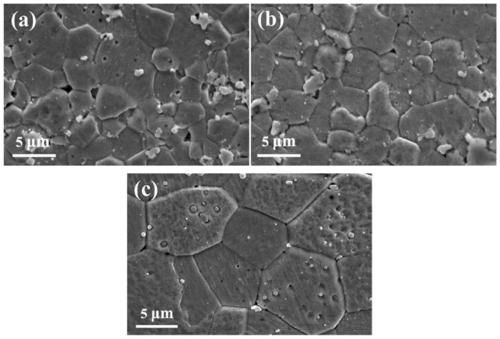

[0030] Grind industrial ammonium paramolybdate to an average particle size of 0.8 μm, then place it in a muffle furnace, raise the temperature to 550°C under a hydrogen atmosphere, and perform the first reduction for 1 hour; the first reduction is completed Afterwards, the temperature is raised to 900° C. for ...

Embodiment 2

[0034] All the process parameters in the preparation process are basically the same as in Example 1, only the SPS sintering temperature is 1500°C.

Embodiment 3

[0056] Weigh 0.2g of lanthanum nitrate with a particle size of 0.8-1.2μm and 16g of urea, dissolve them in 400mL of water and stir evenly with a magnetic force. The temperature of the water bath is 80°C, keep warm for 1.5h, filter and wash to obtain a white powder. Put the white powder into a tube furnace, heat it up to 900°C at 11°C / min for calcination, keep it warm for 1.5 hours, take out the sample and it will be a spherical La 2 o 3 , The average particle size was measured to be 70nm.

[0057] Grind industrial ammonium paramolybdate to an average particle size of 0.8 μm, then place it in a muffle furnace, raise the temperature to 500°C under a hydrogen atmosphere, and perform the first step of reduction, the reduction time is 1.2h; the first step of reduction After the end, the temperature is raised to 850°C for the second step of reduction, and the reduction time is 1.2 hours; after the end of the reaction, molybdenum powder with a thickness of about 560nm is obtained, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com