Composition containing oxides of zirconium, cerium and another rare earth having reduced maximal reducibility temperature, and method for preparing and using same in the field of catalysis

A technology of rare earth elements and cerium oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve low-ratio surface area, difficulty in reconciliation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

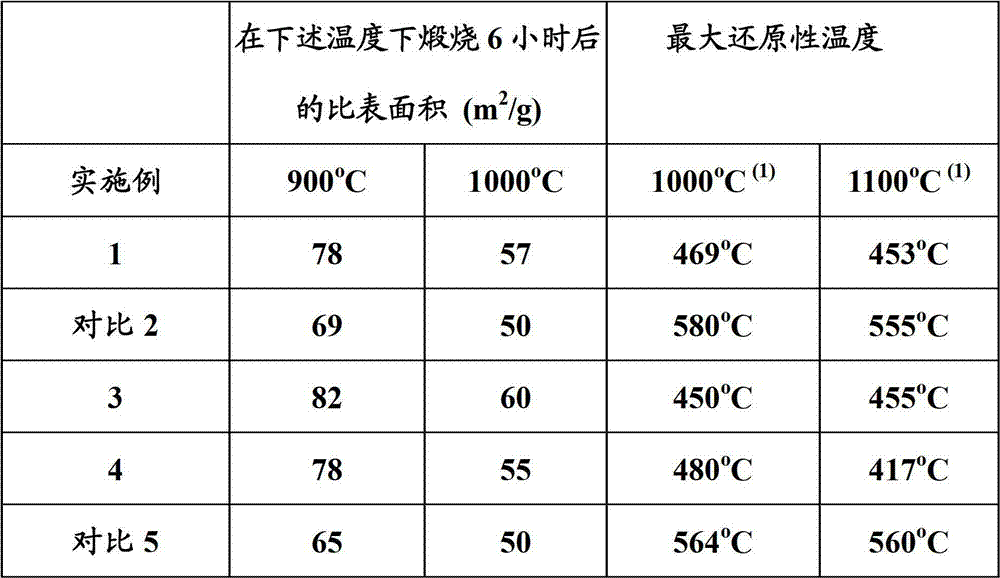

[0095] This example relates to a composition having 50% zirconium, 40% cerium, 5% lanthanum and 5% yttrium, the proportions being expressed as the oxide ZrO 2 , CeO 2 , La 2 o 3 and Y 2 o 3 expressed as a mass percentage.

[0096] The required amounts of zirconium nitrate, cerium nitrate, lanthanum nitrate, and yttrium nitrate were introduced into the stirred beaker. It is then topped up with distilled water to obtain 1 liter of a 120 g / l nitrate solution.

[0097] Ammonia solution (12 mol / l) was added to another stirred beaker and then made up with distilled water to obtain a total volume of 1 liter, and a 20% stoichiometric excess of ammonia relative to the cation to be precipitated.

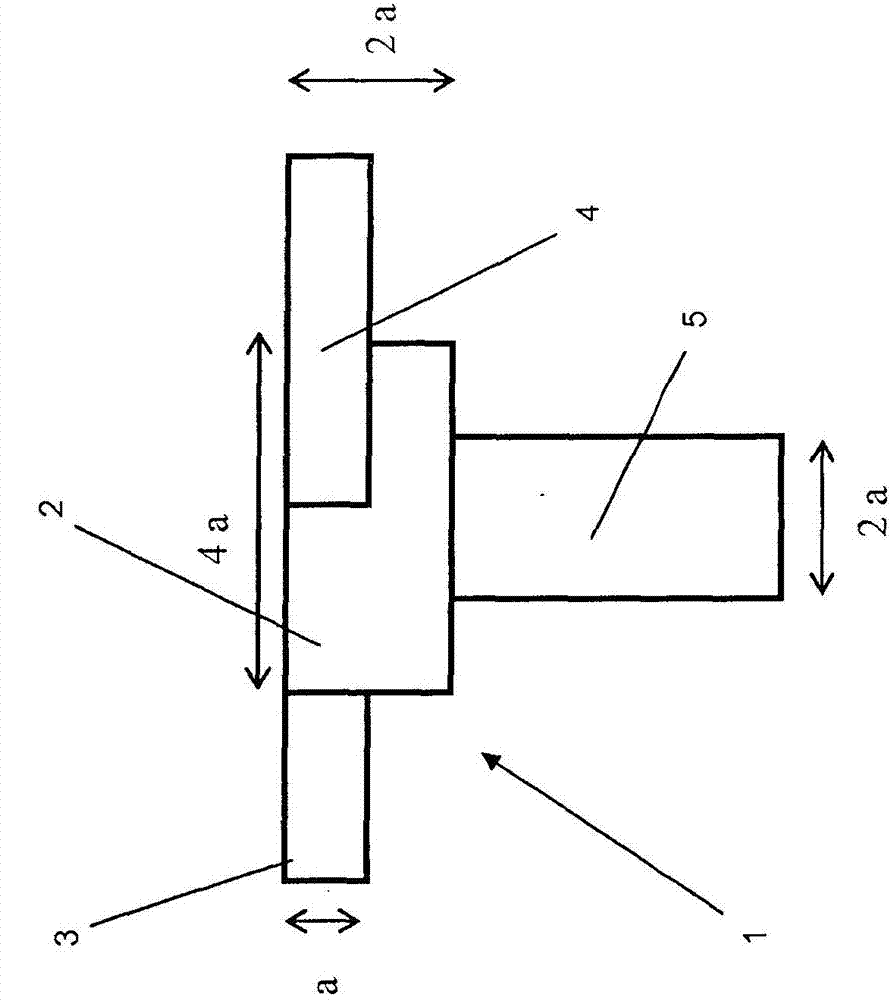

[0098] The two pre-prepared solutions were kept under constant stirring and were continuously added to figure 1 In a Hartridge-Roughton flash mixer of the type shown, the inlet height (a) is 2mm. The pH on leaving the mixer was 9.5. The flow rate of each reactant was 30 l / h and the re...

Embodiment 3

[0108] This example concerns the same composition as in Example 1, prepared under the same conditions, with the only difference that the initial ammonia solution was prepared with a 5% stoichiometric excess of ammonia relative to the cation to be precipitated.

Embodiment 4

[0110] This example relates to a composition having 72% zirconium, 21% cerium, 2% lanthanum and 5% neodymium, the proportions being expressed as the oxide ZrO 2 , CeO 2 , La 2 o 3 and Nd 2 o 3 expressed as a mass percentage.

[0111] The required amounts of zirconium nitrate, cerium nitrate, lanthanum nitrate, and neodymium nitrate were introduced into the stirred beaker. It is then topped up with distilled water to obtain 1 liter of a 120 g / l nitrate solution.

[0112] Ammonia solution (12 mol / l) was added to another stirred beaker and then made up with distilled water to obtain a total volume of 1 liter, and a stoichiometric excess of ammonia of 20% relative to the cation to be precipitated.

[0113] The two pre-prepared solutions were kept under constant stirring and were continuously added to figure 1 In a Hartridge-Roughton flash mixer of the type shown, the inlet height (a) is 2mm. The pH on leaving the mixer was 9.6. The flow rate of each reactant was 50 l / h an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com