Synthesis process of nanostring and nanopowder of RE hydroxide or oxide

A rare earth hydroxide and rare earth oxide technology, which is applied in the synthesis of rare earth hydroxide or oxide nanowires and their nanoparticles, and the synthesis of rare earth compounds, can solve problems such as preparation method reports, and achieves simple process and cost The effect of low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

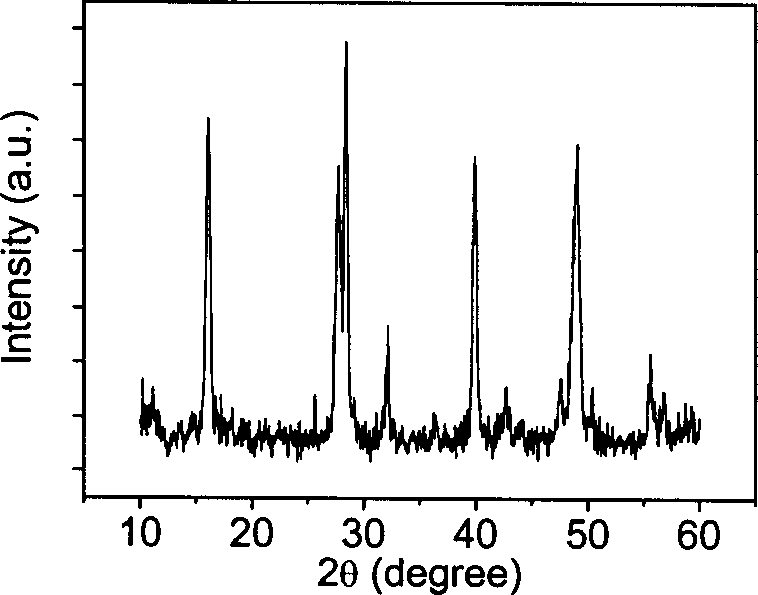

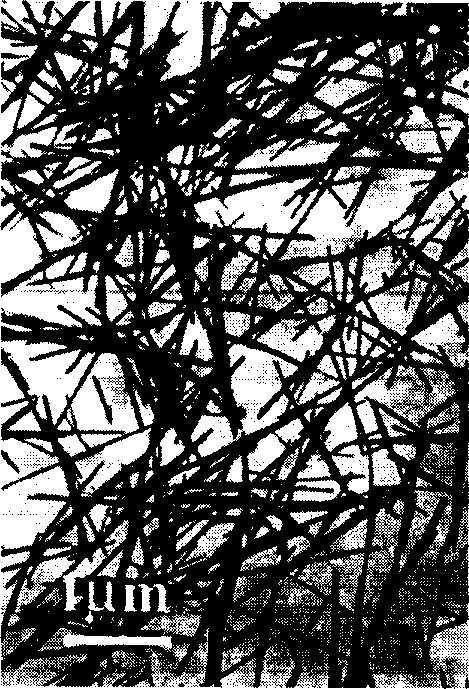

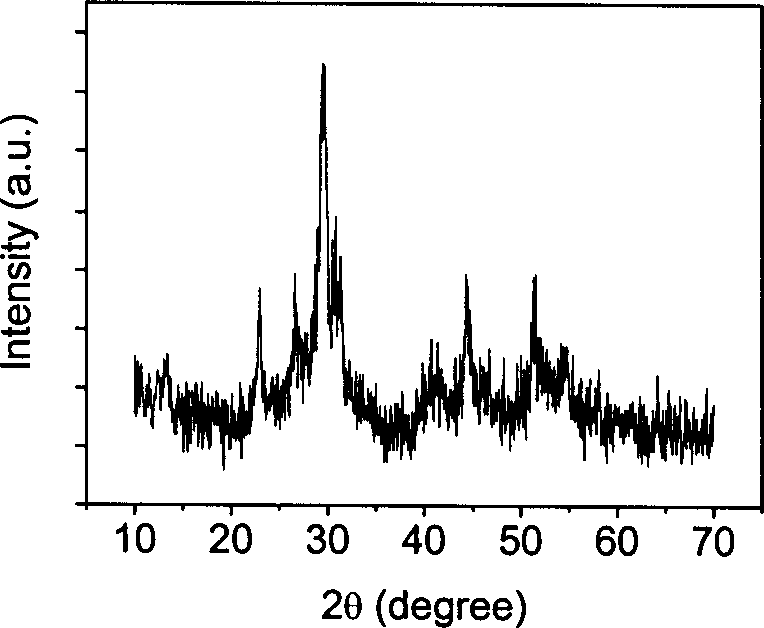

[0035] Weigh 0.001mol of analytically pure lanthanum oxide and place it in a 40ml stainless steel pressure-resistant reactor, dissolve it with a small amount of concentrated nitric acid, then quickly adjust the pH value to 13 with 20% concentrated potassium hydroxide solution, then add deionized water, and The reaction was carried out at 180° C. for 12 hours in the reaction kettle. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a white powder. The product is identified as hexagonal phase lanthanum hydroxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 10-20 nanometers, and the length is 2.5-4.0 microns. Single nanowire electron diffraction proves that the product is a single crystal. Under the same conditions, the reaction temperature is controlled at 100, 120, 160, 200, and 250°C, and within 8 to 24 hours of reaction time, one-dimen...

Embodiment 2

[0037] Weigh 0.0015mol of analytically pure samarium oxide and place it in a 40ml stainless steel pressure-resistant reactor, dissolve it with a small amount of concentrated nitric acid, then quickly adjust the pH value to 9 with 10% concentrated potassium hydroxide solution, then add deionized water, React at 100°C for 24 hours in the reactor. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a white powder. The product is identified as hexagonal phase samarium hydroxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 10-20 nanometers, and the length is 2.5-4.0 microns. Single nanowire electron diffraction proves that the product is a single crystal. Under the same conditions, the reaction temperature is controlled at 120°C, 160°C, 180°C, 200°C, 250°C, and one-dimensional single-crystal nanowires of samarium hydroxide can be obtained with...

Embodiment 3

[0039] Weigh 0.0005mol of analytically pure gadolinium oxide and place it in a 40ml stainless steel pressure-resistant reactor, dissolve it with a small amount of concentrated nitric acid, then quickly adjust the pH value to 14 with 20% concentrated potassium hydroxide solution, then add deionized water, and React at 180°C for 15 hours in a closed reactor. Then cool to room temperature, open the reaction kettle, filter with Buchner funnel, and wash with deionized water to obtain a white powder. The product is identified as hexagonal gadolinium hydroxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 10-20 nanometers, and the length is 2.5-3.0 microns. Single nanowire electron diffraction proves that the product is a single crystal. Under the same conditions, the reaction temperature is controlled at 100, 120, 160, 200, and 250°C, and within 8 to 24 hours of reaction time, one-dimensional single-crystal nanowires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com