Patents

Literature

396results about How to "Easy to scratch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

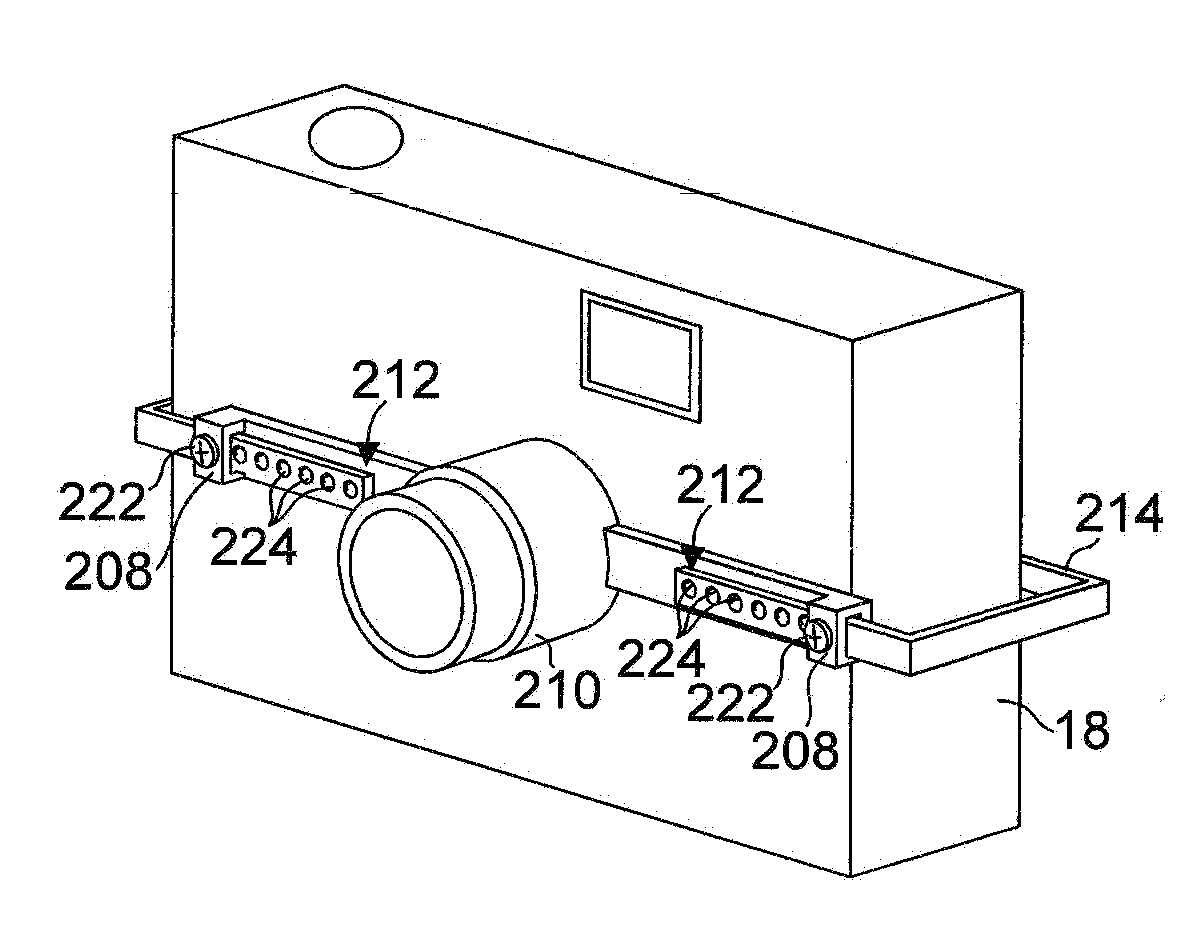

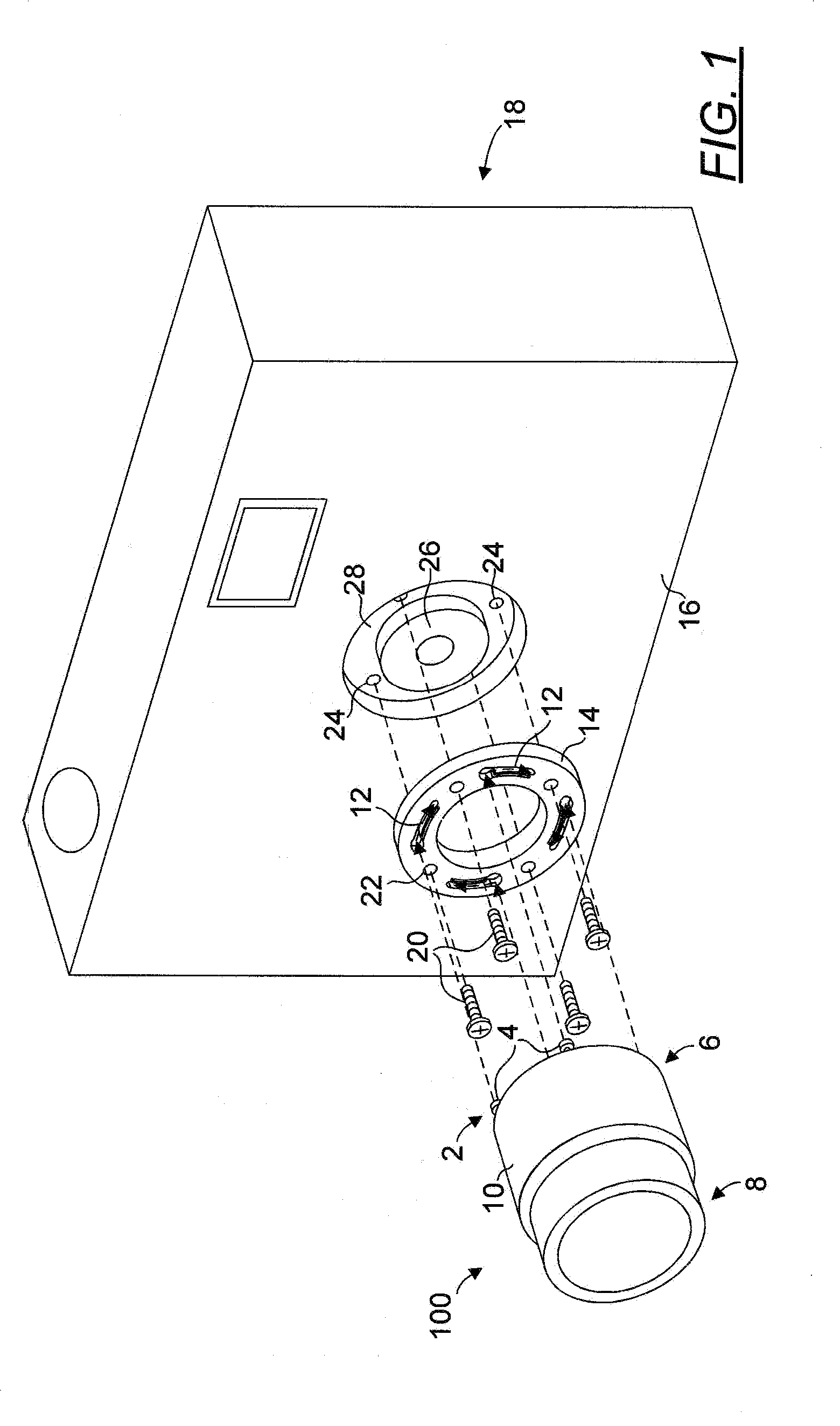

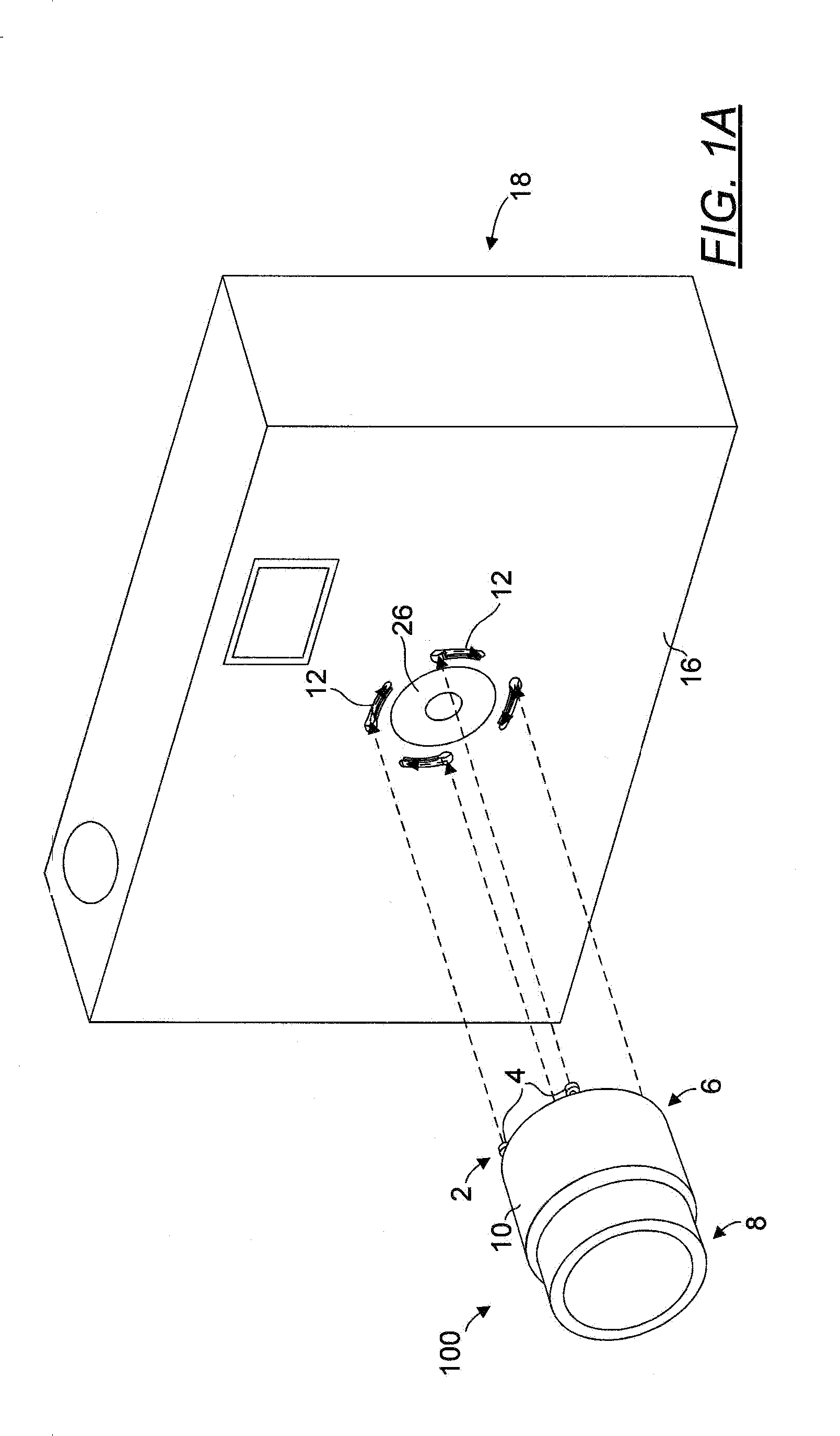

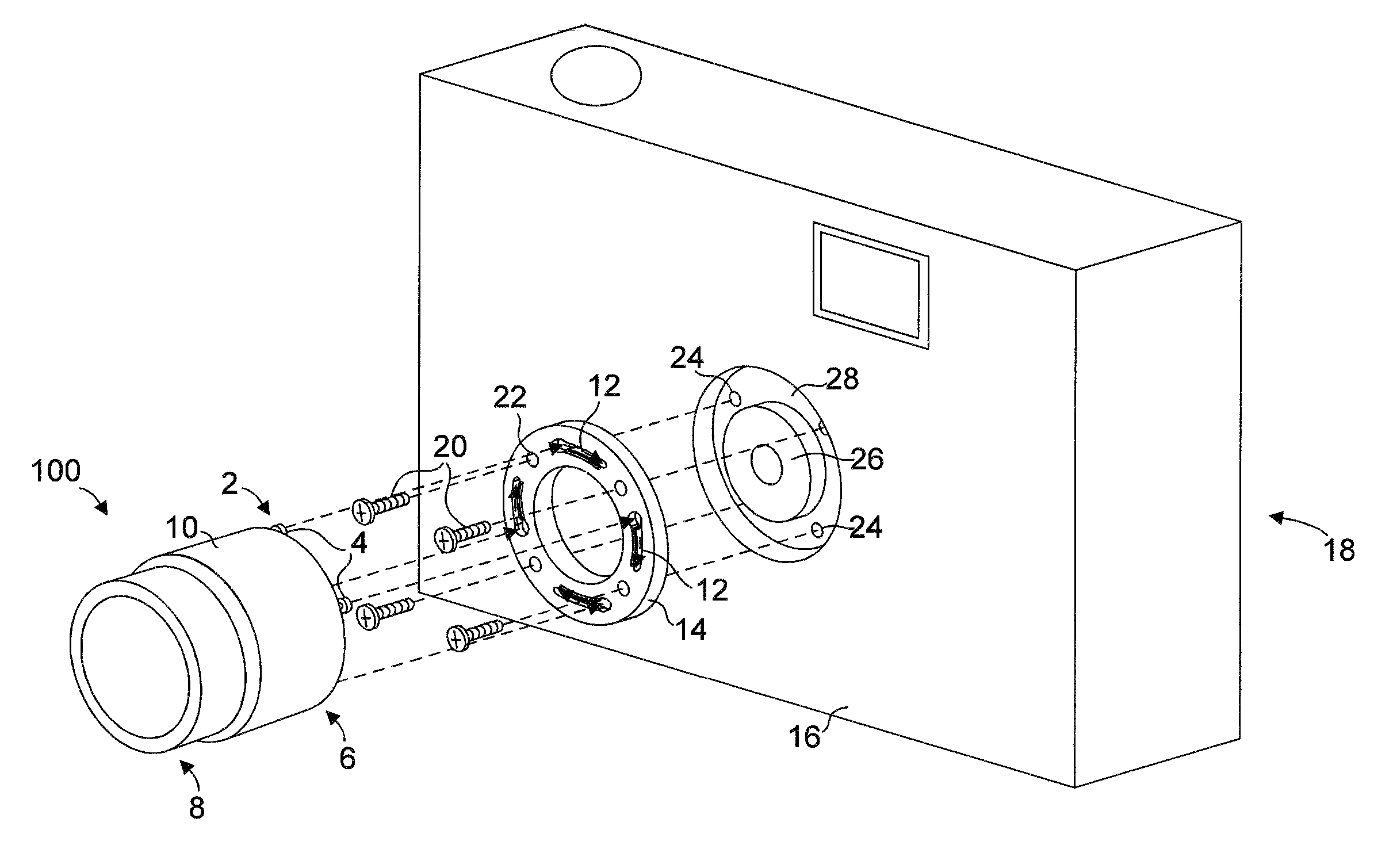

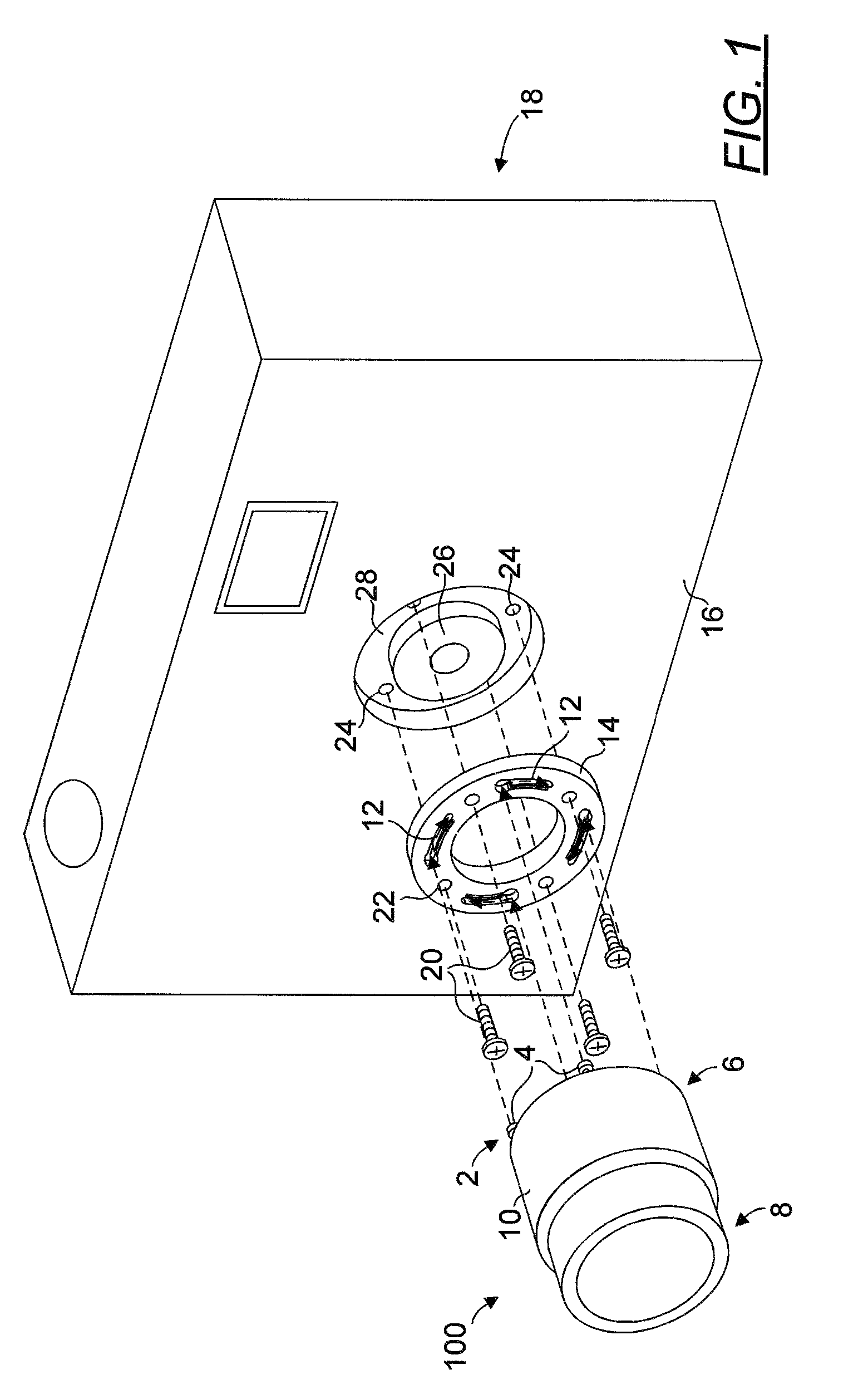

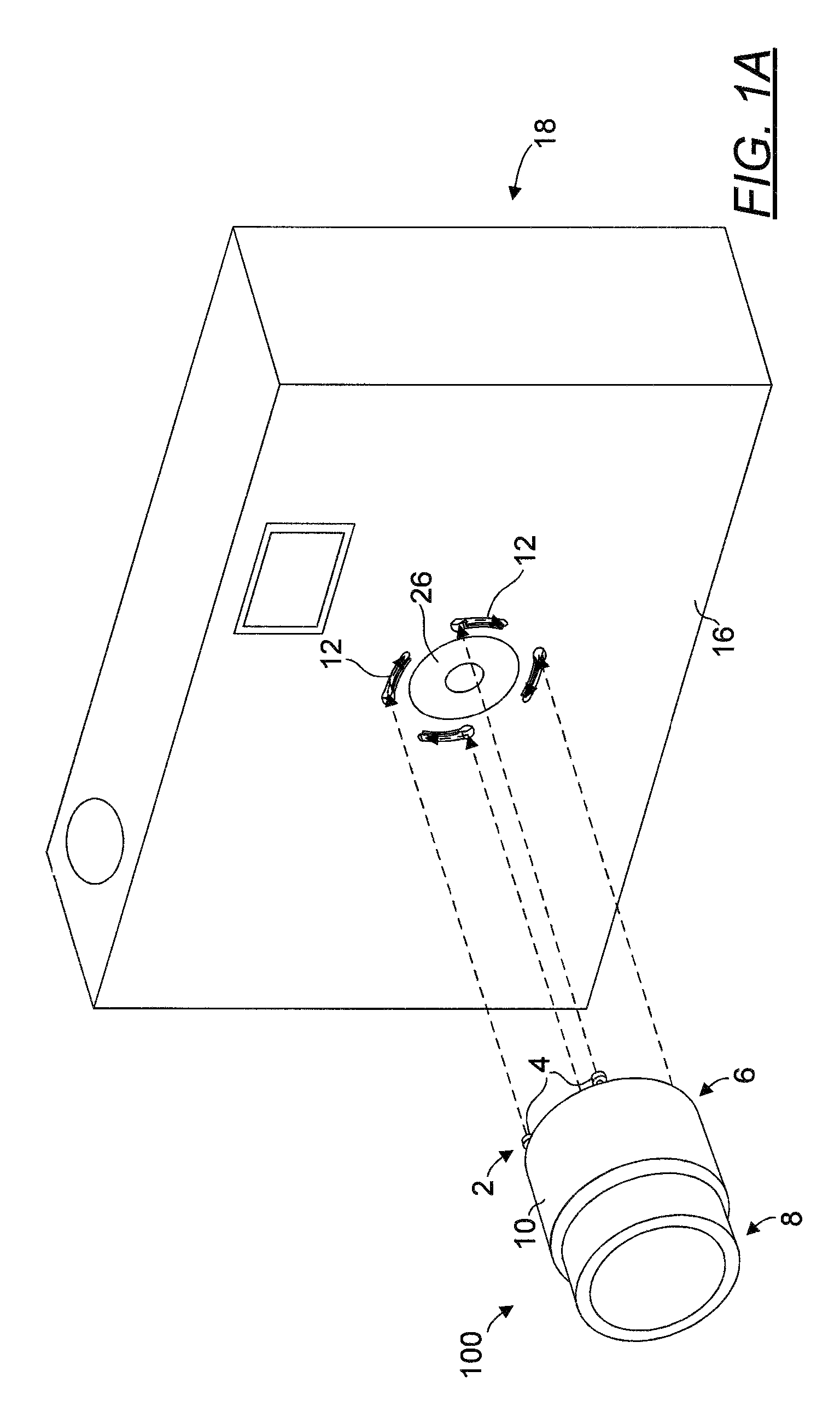

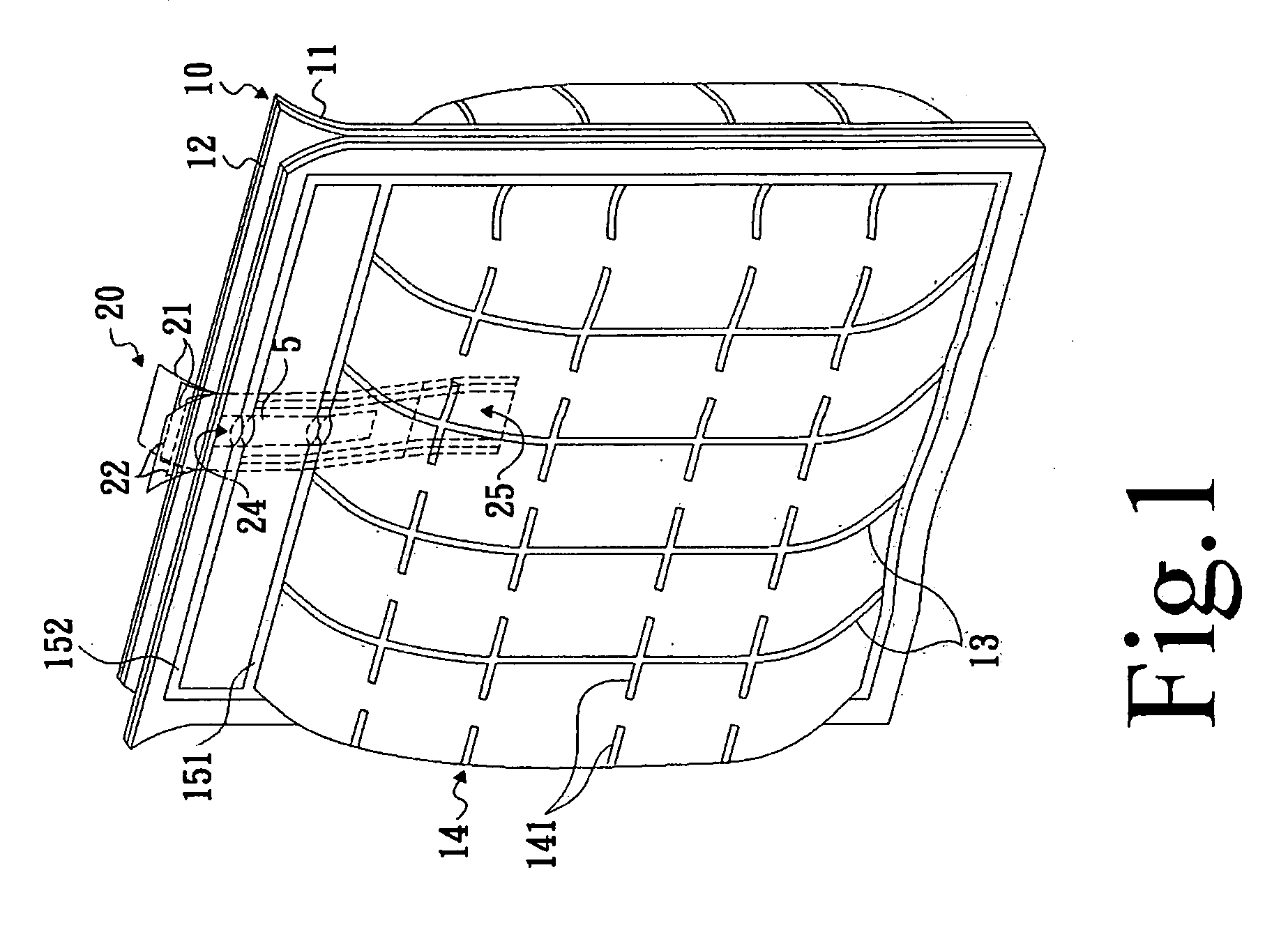

Lens And Display Accessory For Portable Imaging Device

The present invention relates to auxiliary detachable accessories associated with portable image capture and storage devices. Enhancements provided by the accessories include protective coverings for the integrated displays and integrated lenses, as well as the use of auxiliary conversion lenses that can be selectively attached to such devices to assist a user in enhancing in addition to creating artistic accentuations to the images.

Owner:GLENN F SCHAEFER

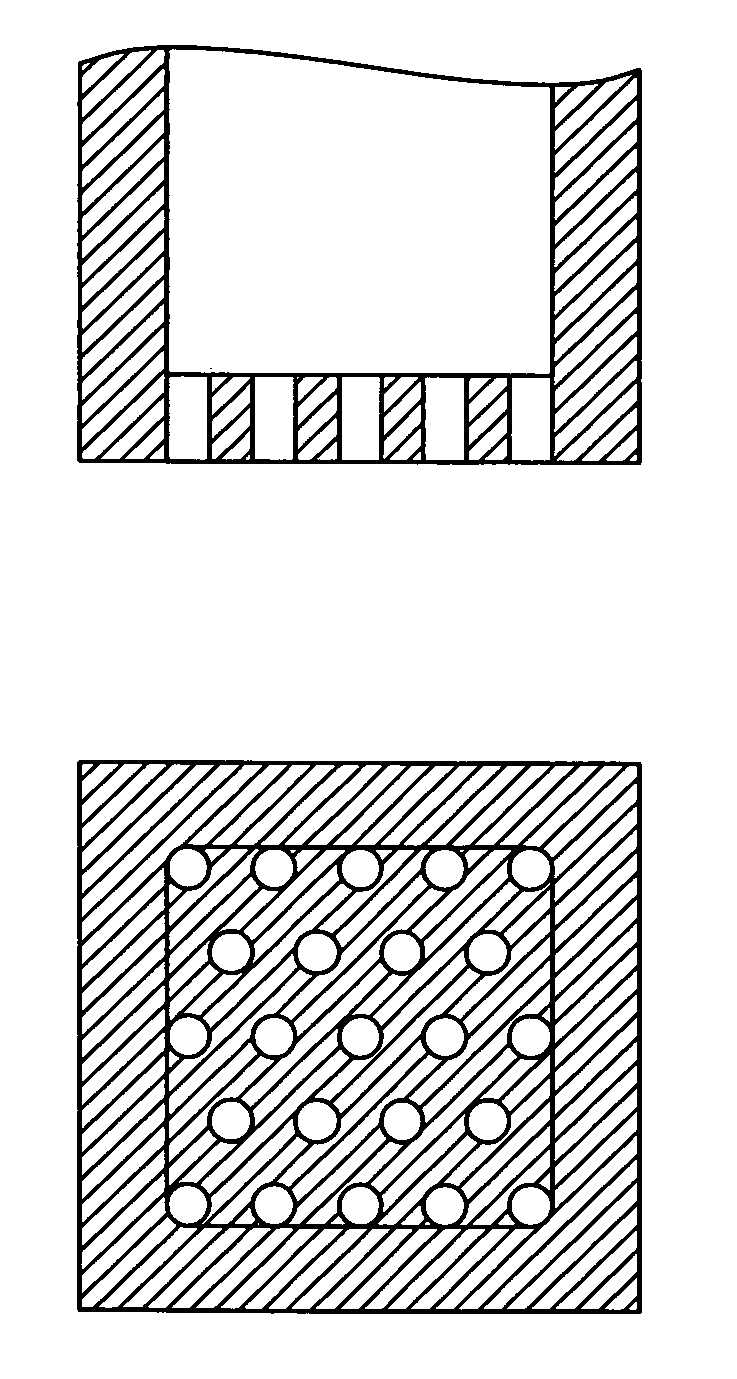

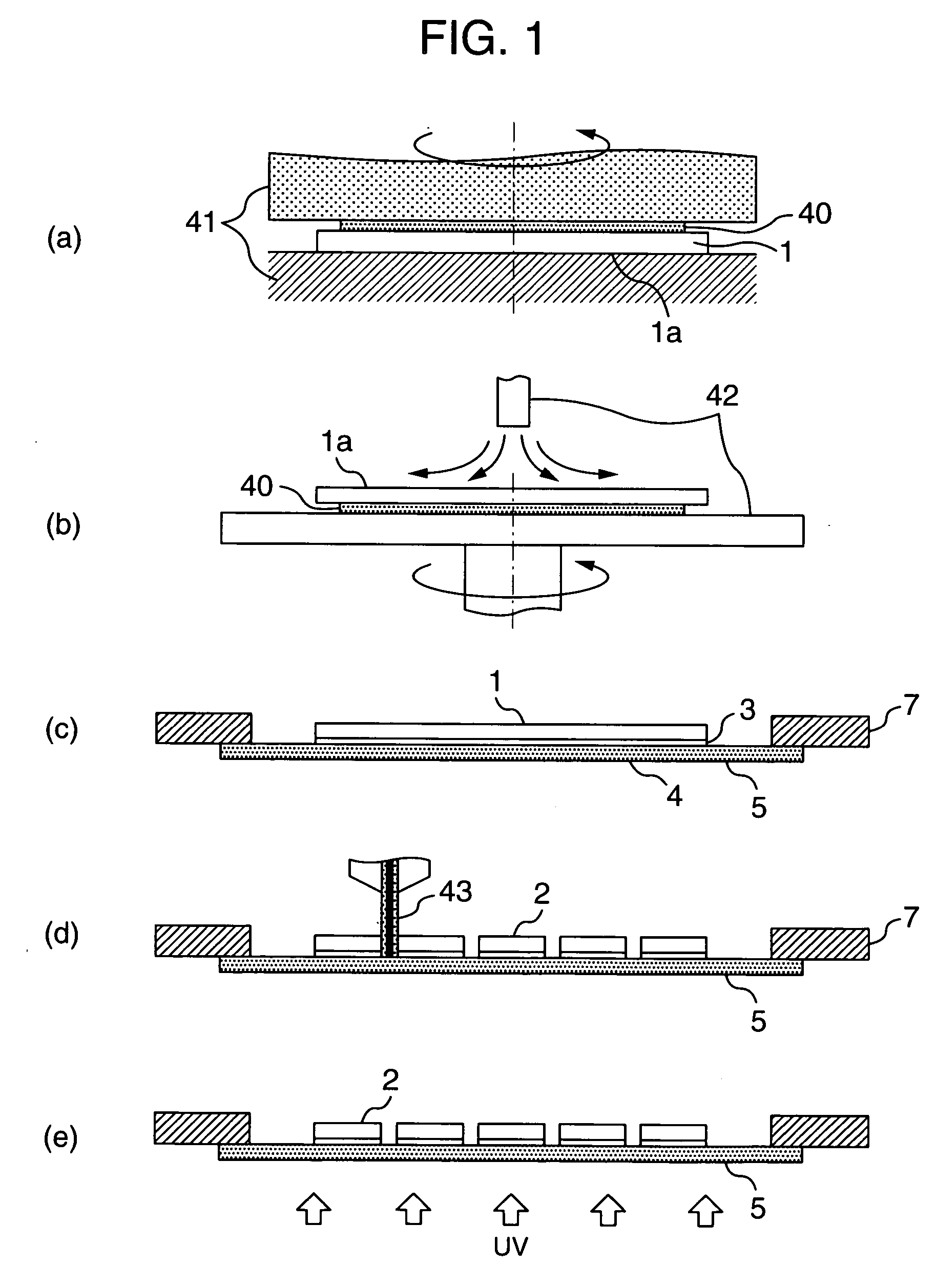

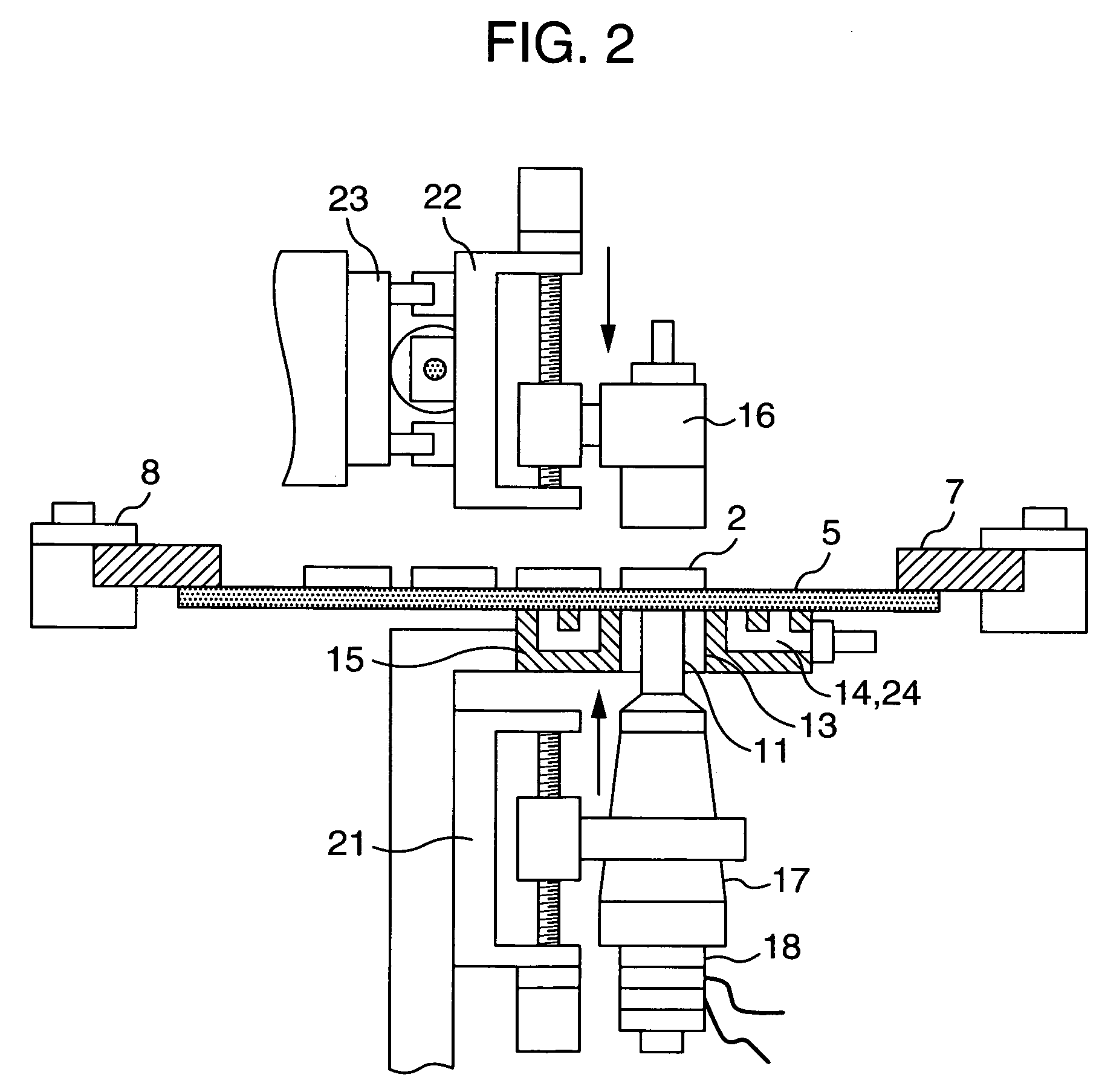

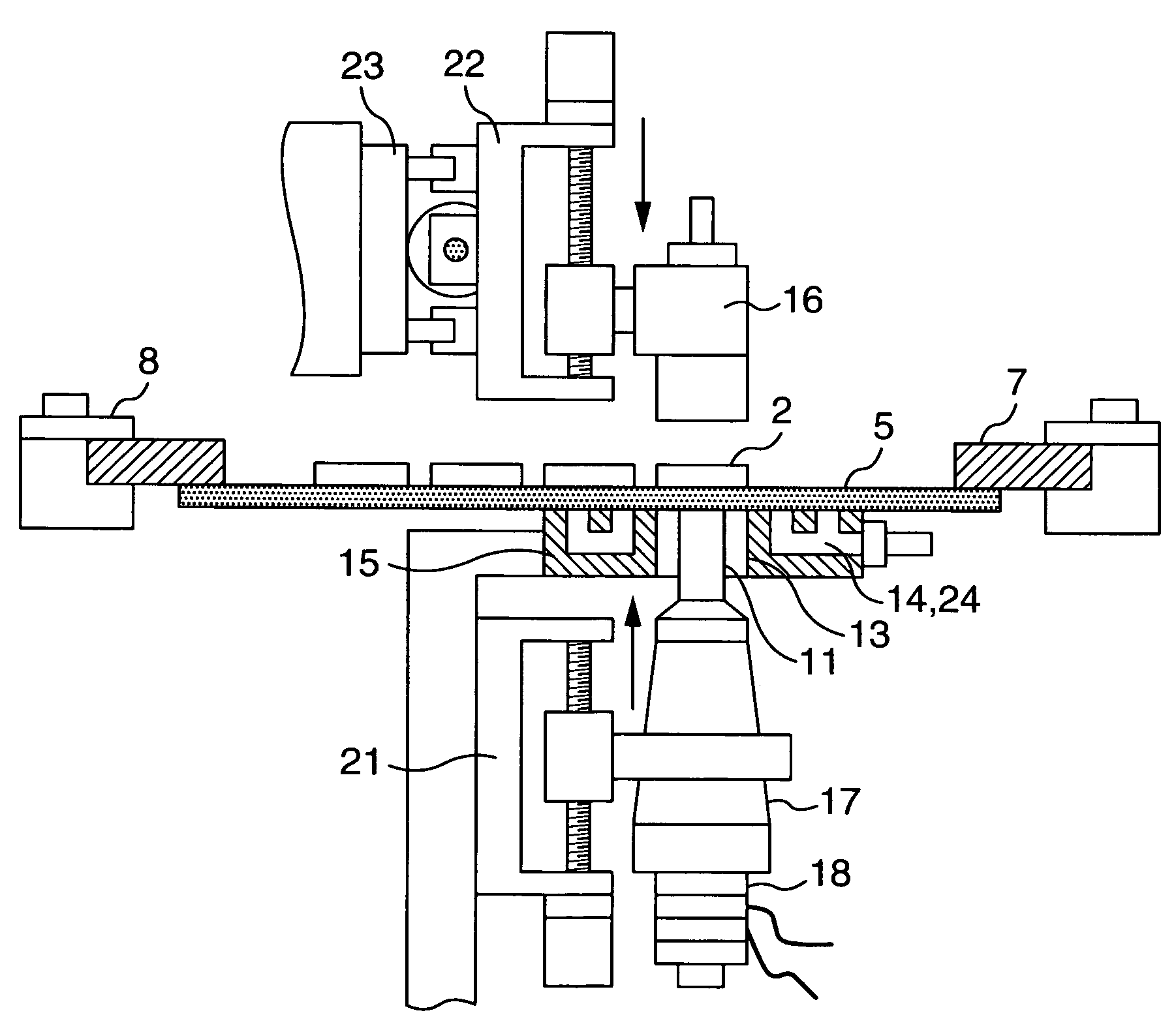

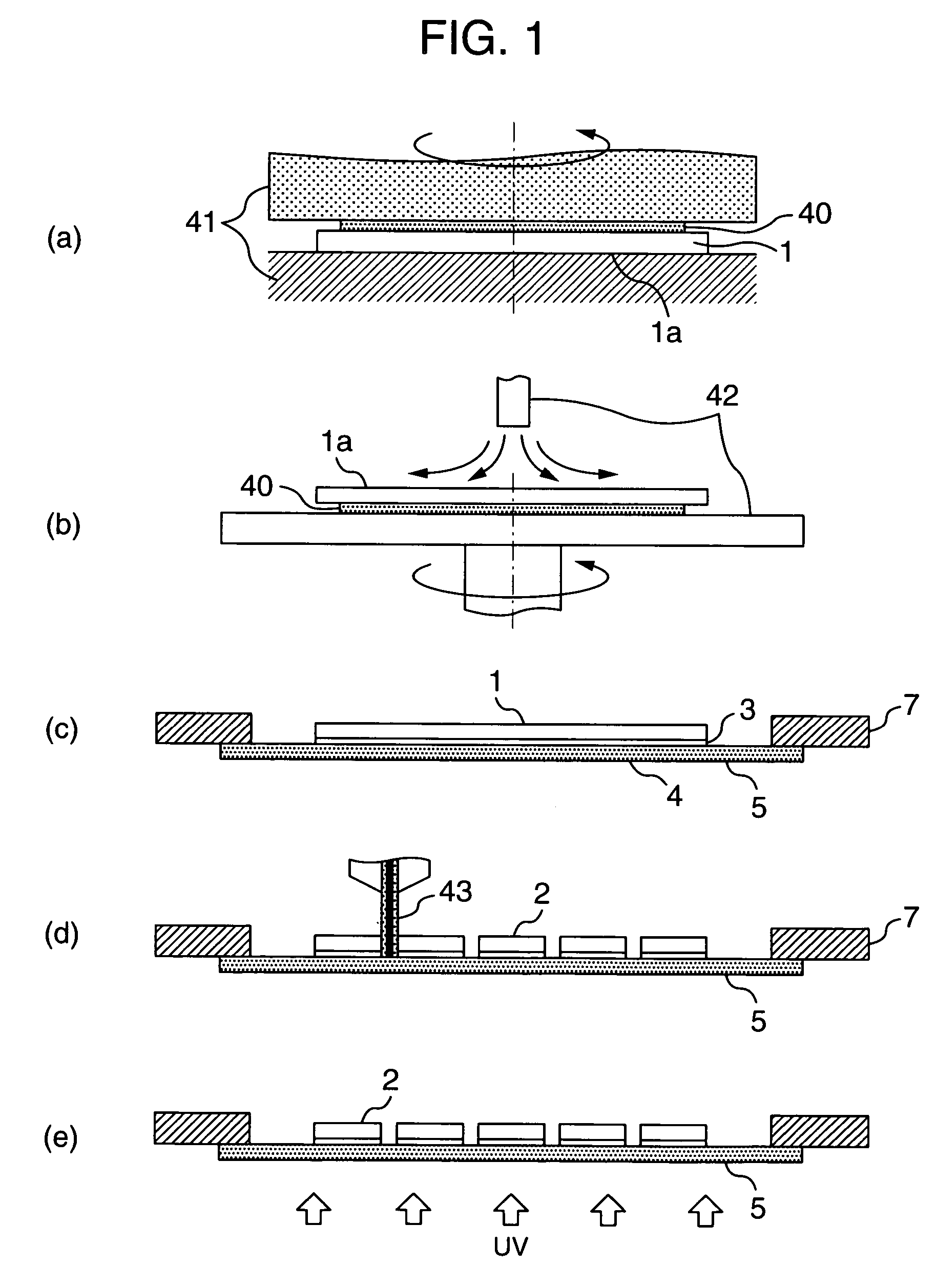

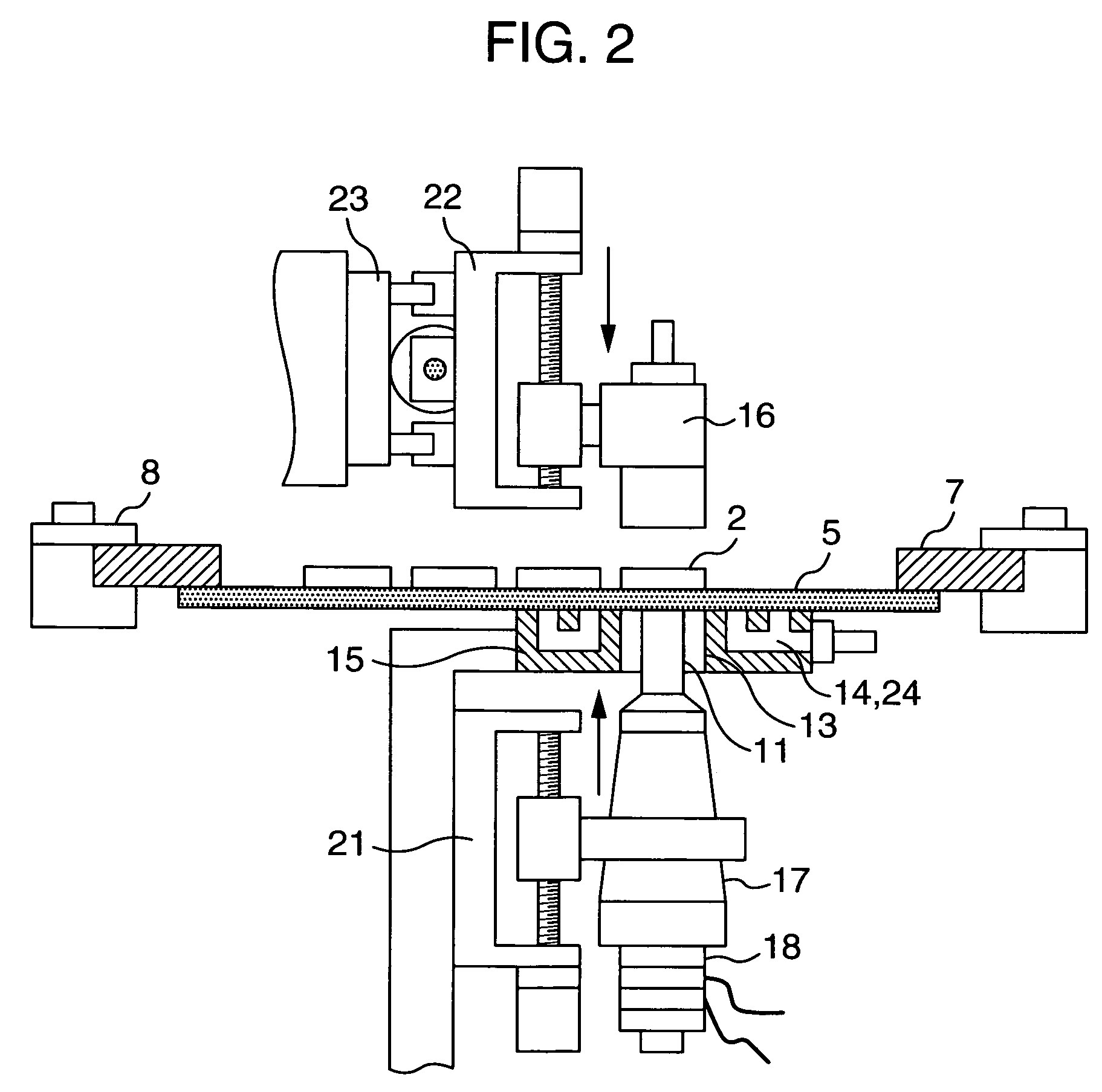

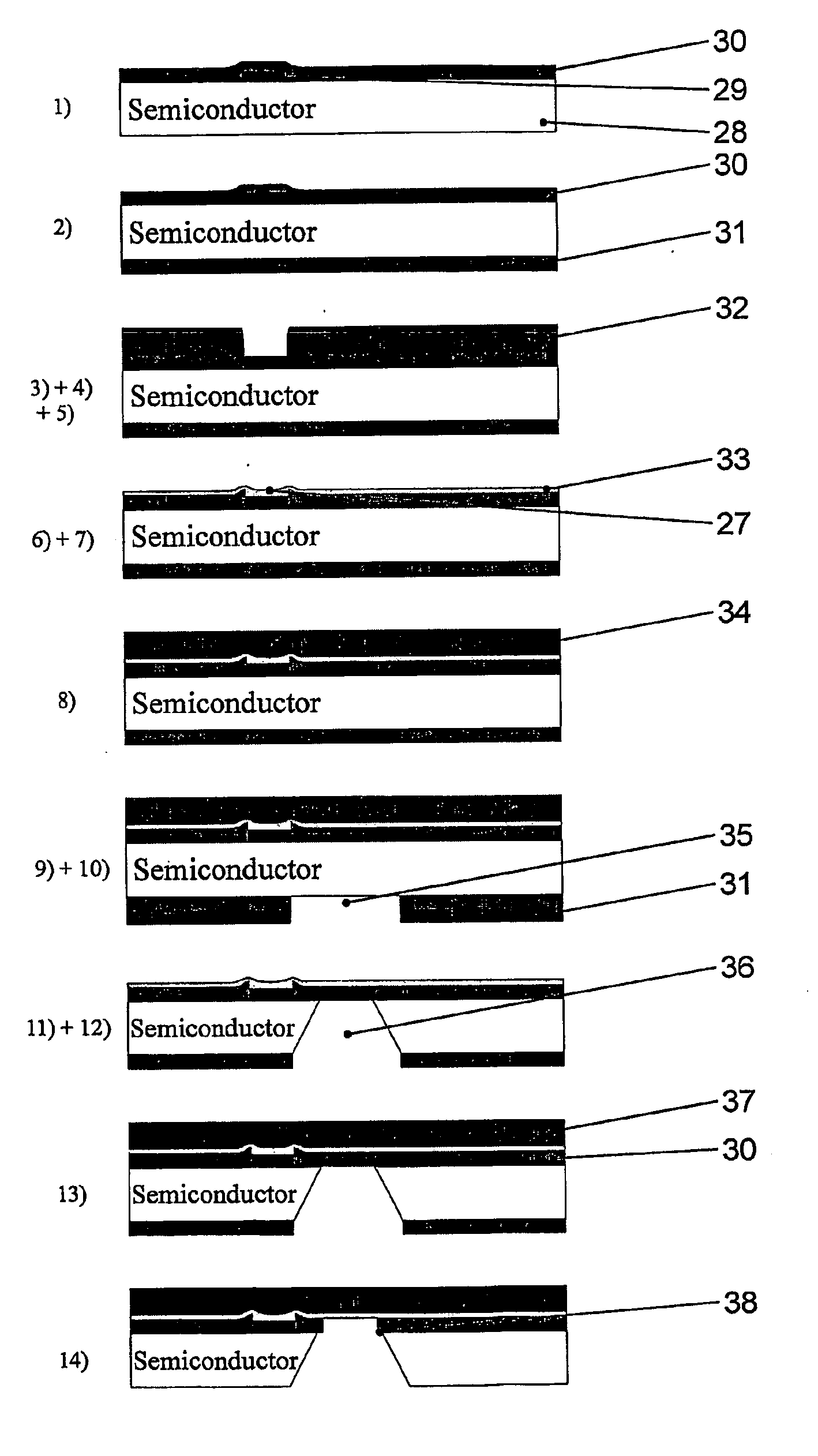

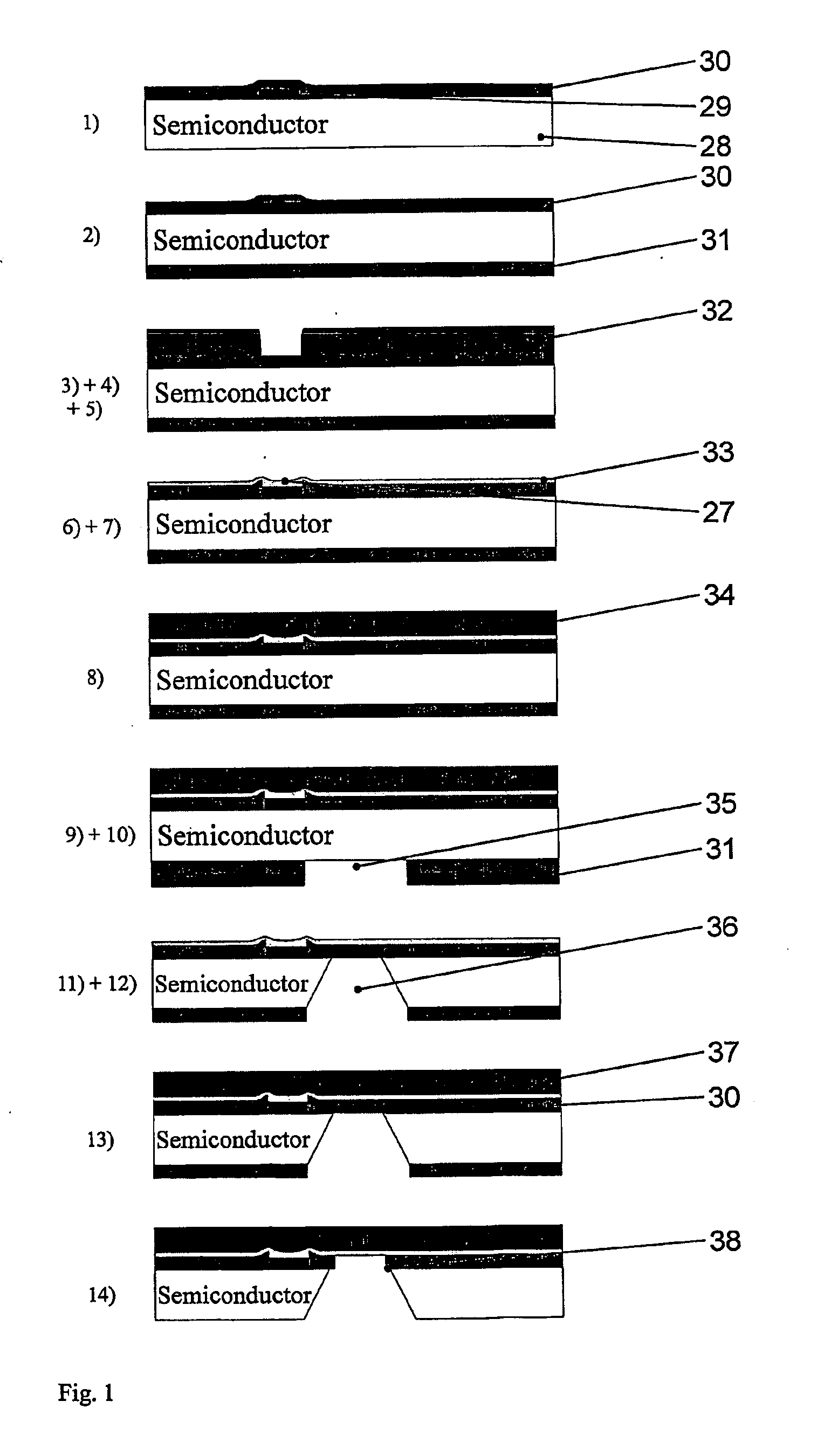

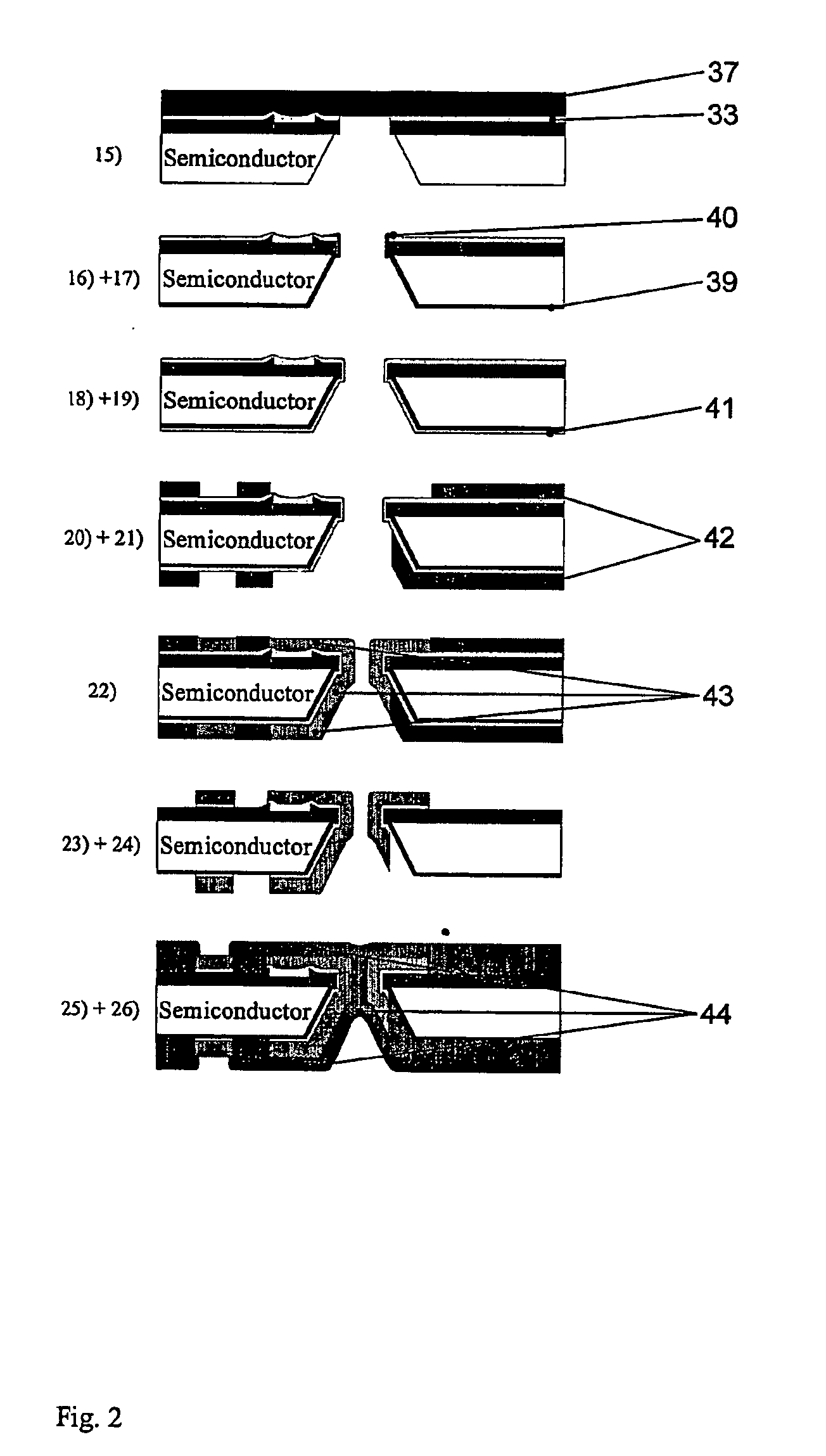

Semiconductor device and its manufacturing method

InactiveUS20060252233A1Small thicknessImprove reliabilityTransistorSolid-state devicesSemiconductor chipEngineering

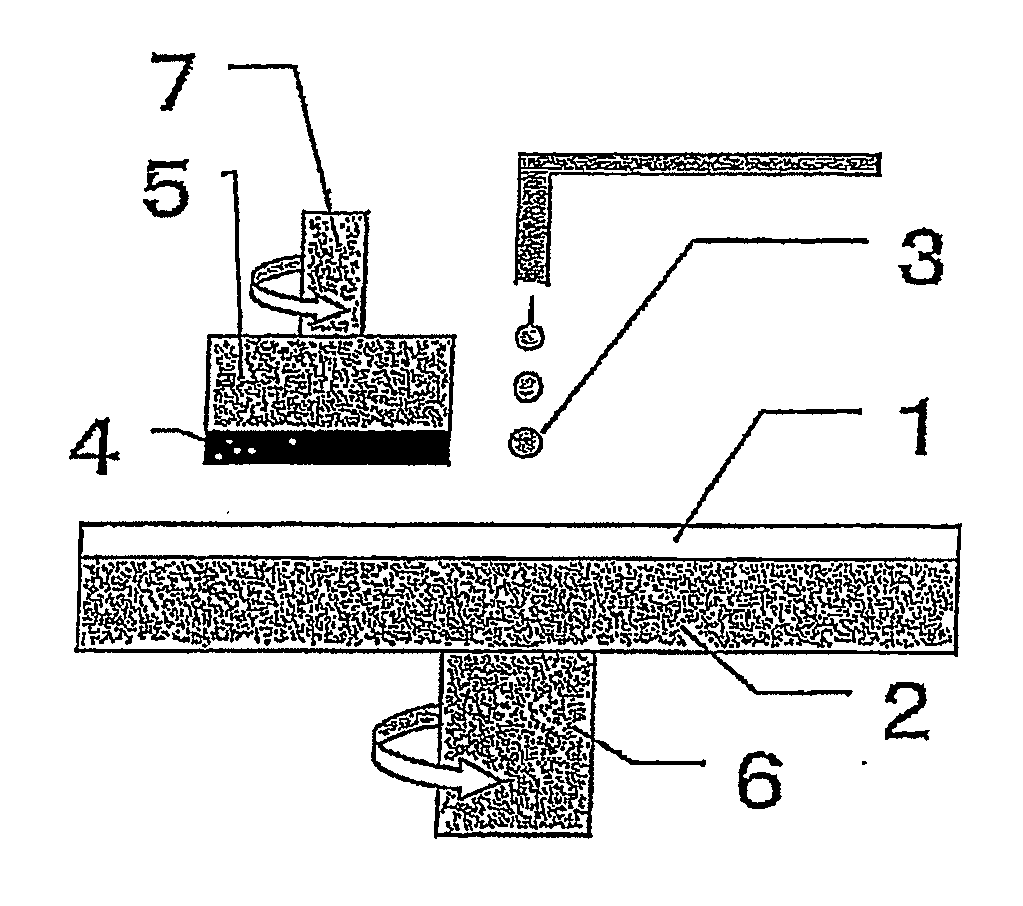

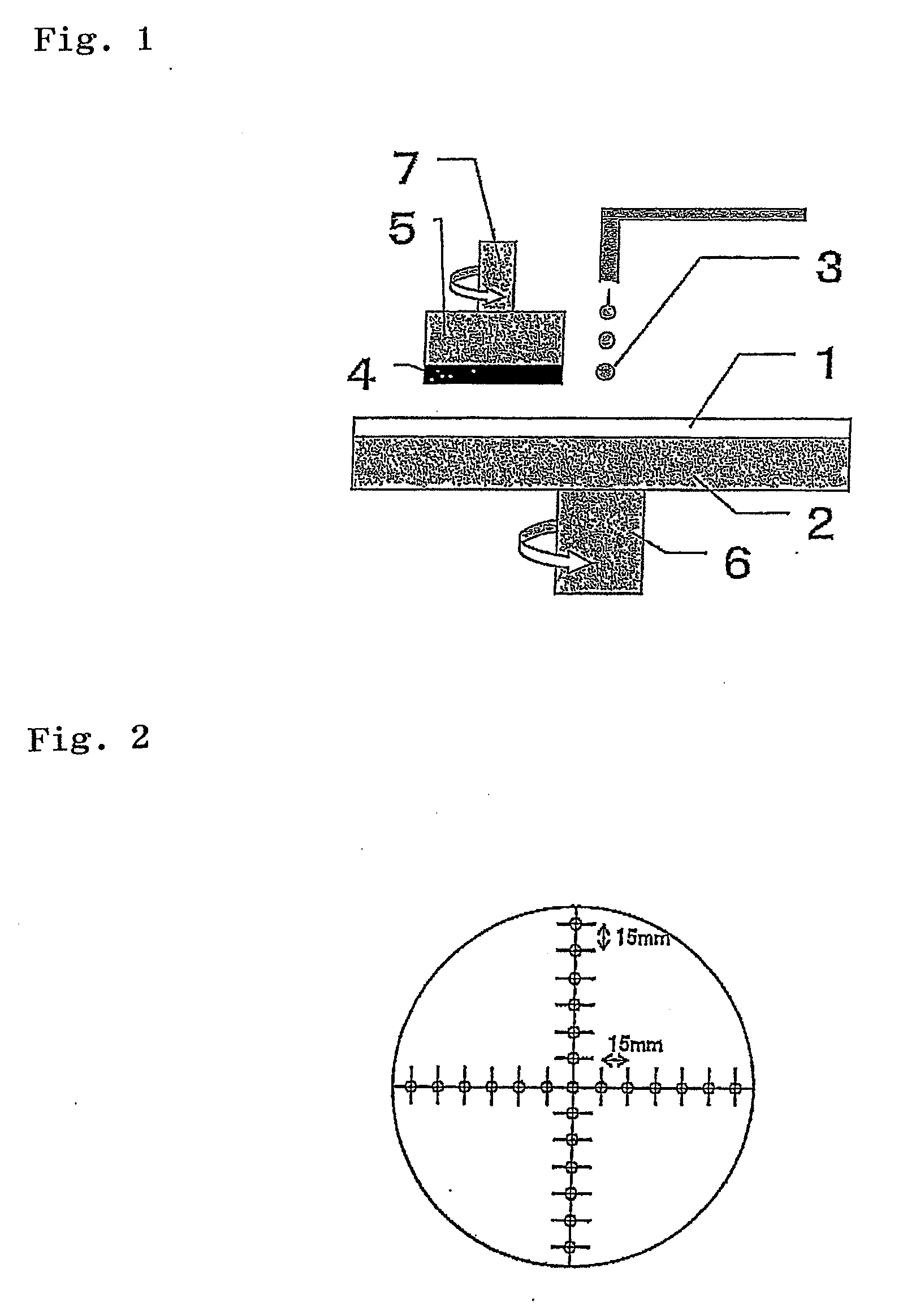

To improve the reliability and yield of a thin-type semiconductor device as used for a stack-type flash memory, the semiconductor device is manufactured by upheaving each of semiconductor chips (semiconductor devices) obtained by dicing a semiconductor wafer on an adhesive sheet from a backside via the adhesive sheet using an upthrow jig to which ultrasonic vibration is applied so as not to break through the adhesive sheet, and by picking up each semiconductor chip.

Owner:RENESAS ELECTRONICS CORP

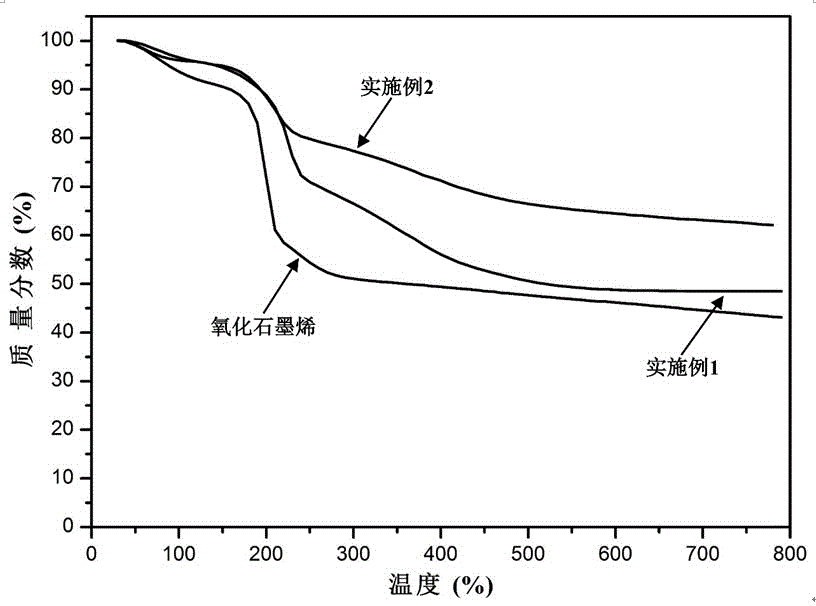

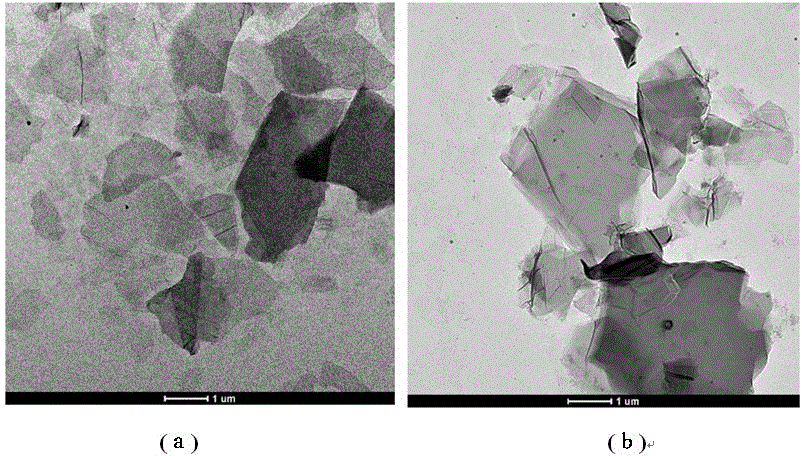

High-scratch-resistance abrasion-resistant coating material and preparation method thereof

InactiveCN106752923AIncrease elasticityAvoid scratch damageFireproof paintsAnti-corrosive paintsDispersityMechanical property

The invention provides a high-scratch-resistance abrasion-resistant coating material and a preparation method thereof. The preparation method comprises the following steps: modifying the graphene surface by using active groups by a chemical modification technique to obtain modified graphene, and blending the modified graphene with polysiloxane to obtain the high-scratch-resistance abrasion-resistant nano composite coating material. The surface modification is carried out to enhance the dispersity of the graphene and the interactions between the graphene and polysiloxane matrix, thereby enhancing the mechanical properties of the coating. No pigment or filler is added. The scratch resistance of the transparent graphene / polysiloxane composite coating is enhanced by 140% or above, and the abrasion loss is reduced by 60% or above. The transparent graphene / polysiloxane composite coating has excellent adhesion, heat resistance, weather resistance, flame retardancy and corrosion resistance. The graphene / polysiloxane composite coating can be used for surface protection and shielding of various metals, plastics, wood, concrete, glass and other substrates, and is applicable to the fields of automobile paints, photoelectric materials, precision instruments, marine heavy-corrosion protection, buildings and the like.

Owner:FUDAN UNIV

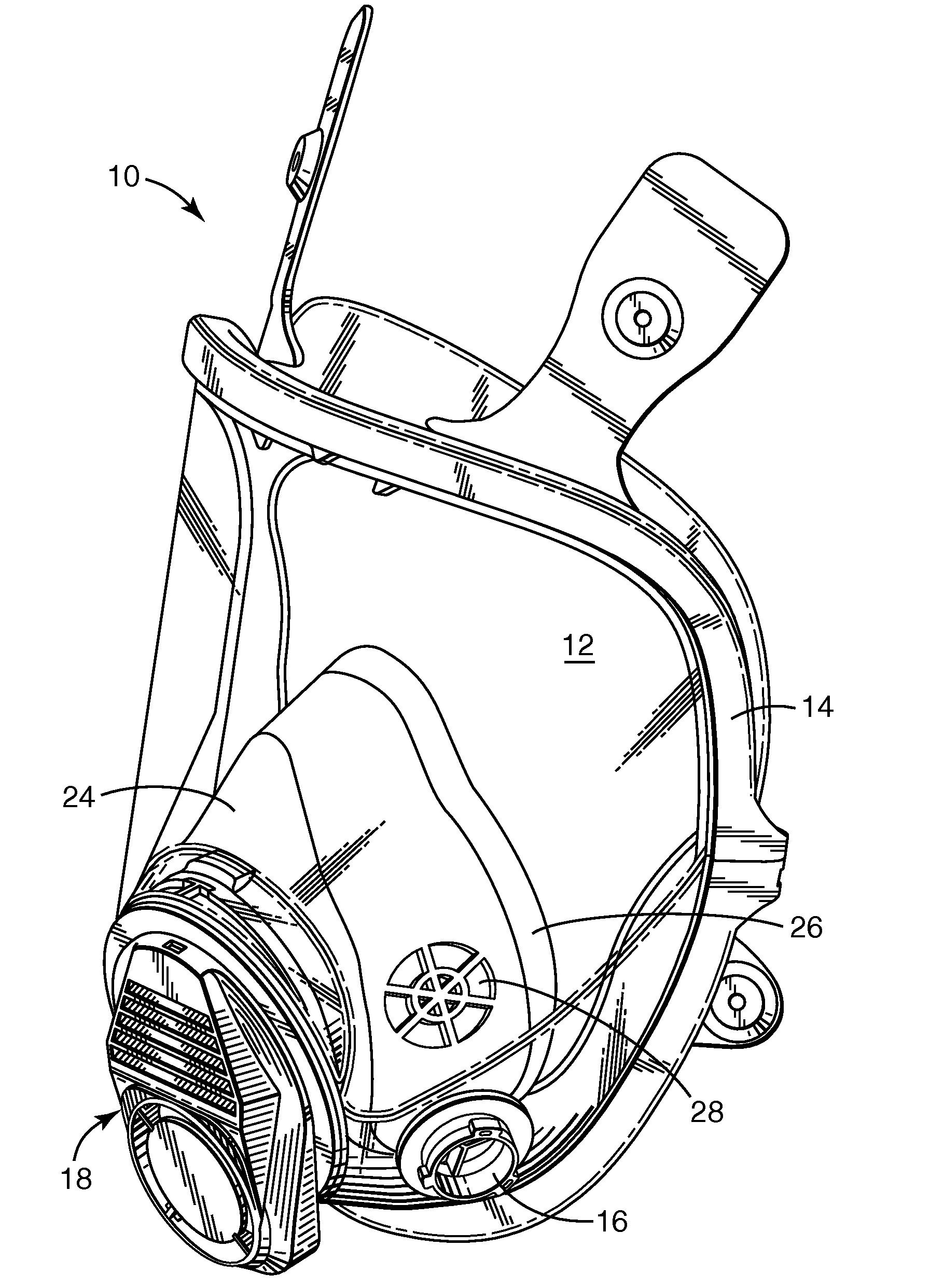

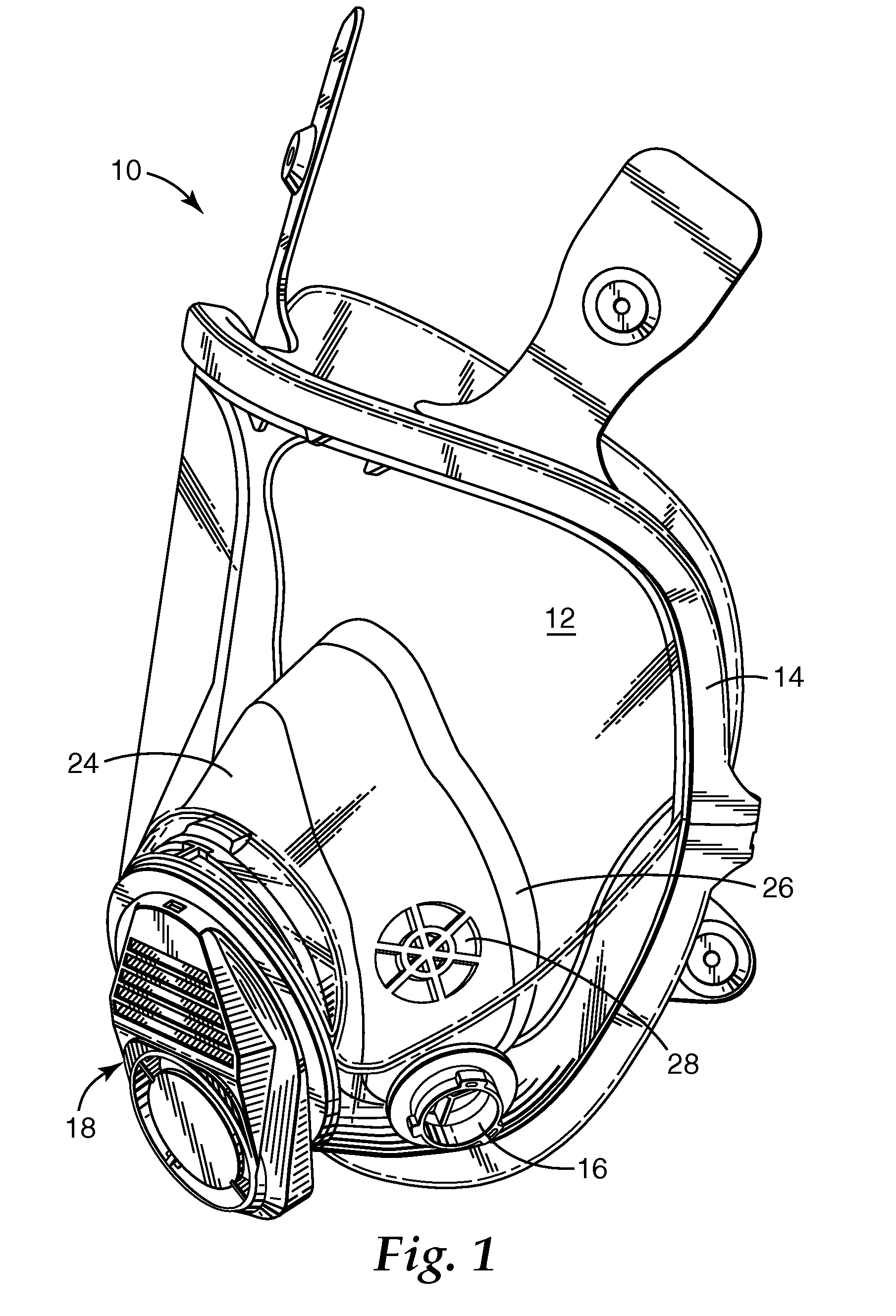

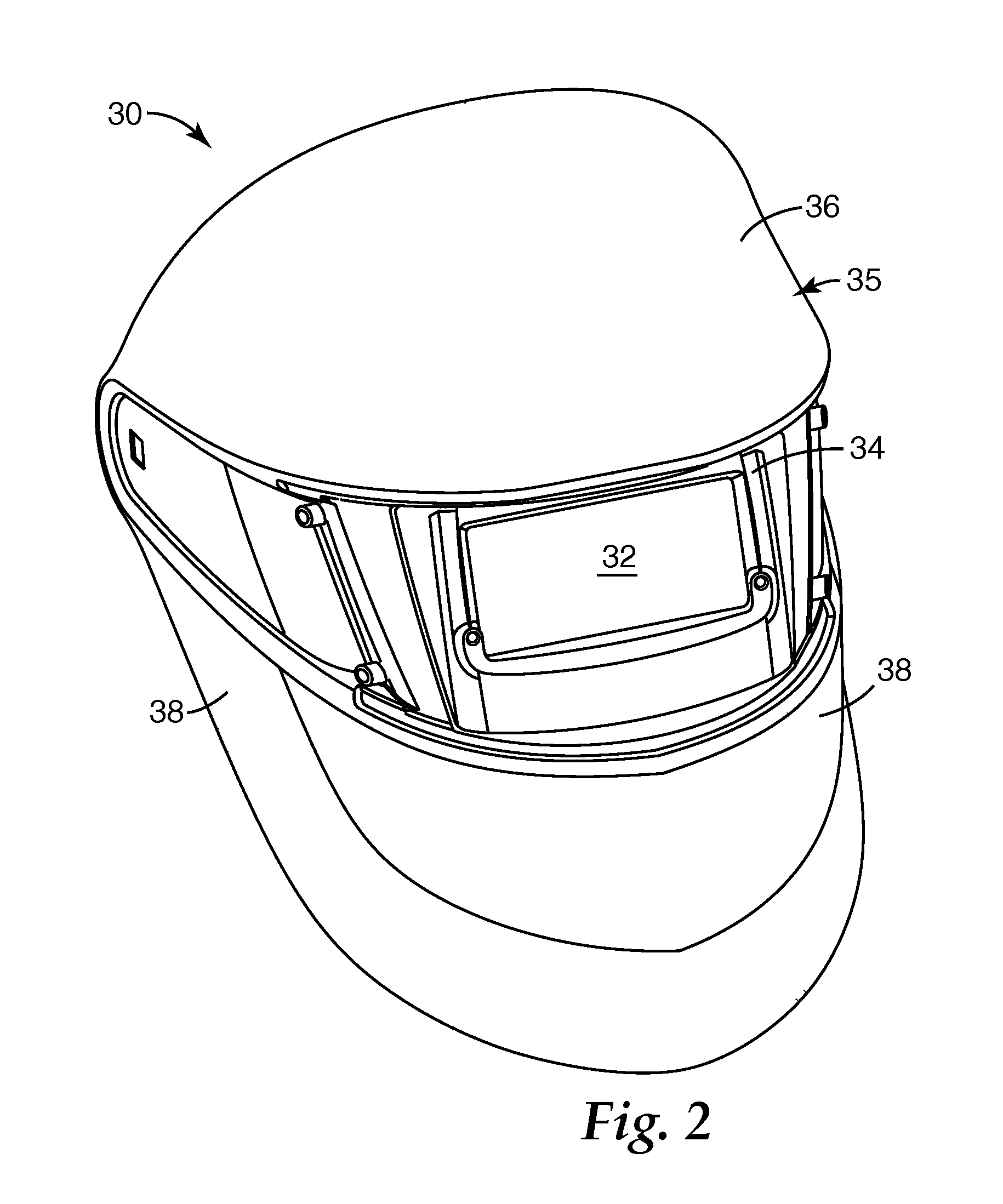

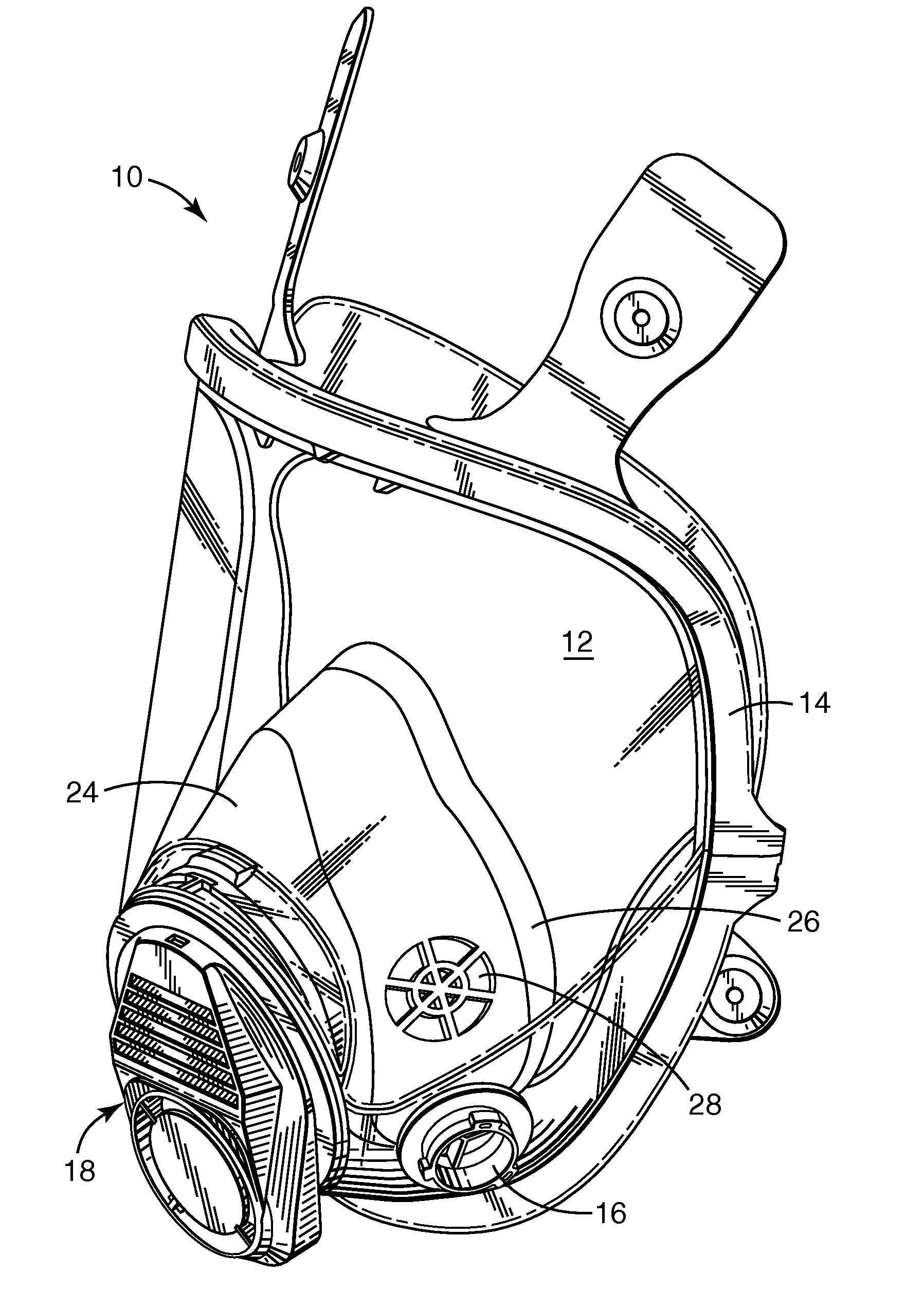

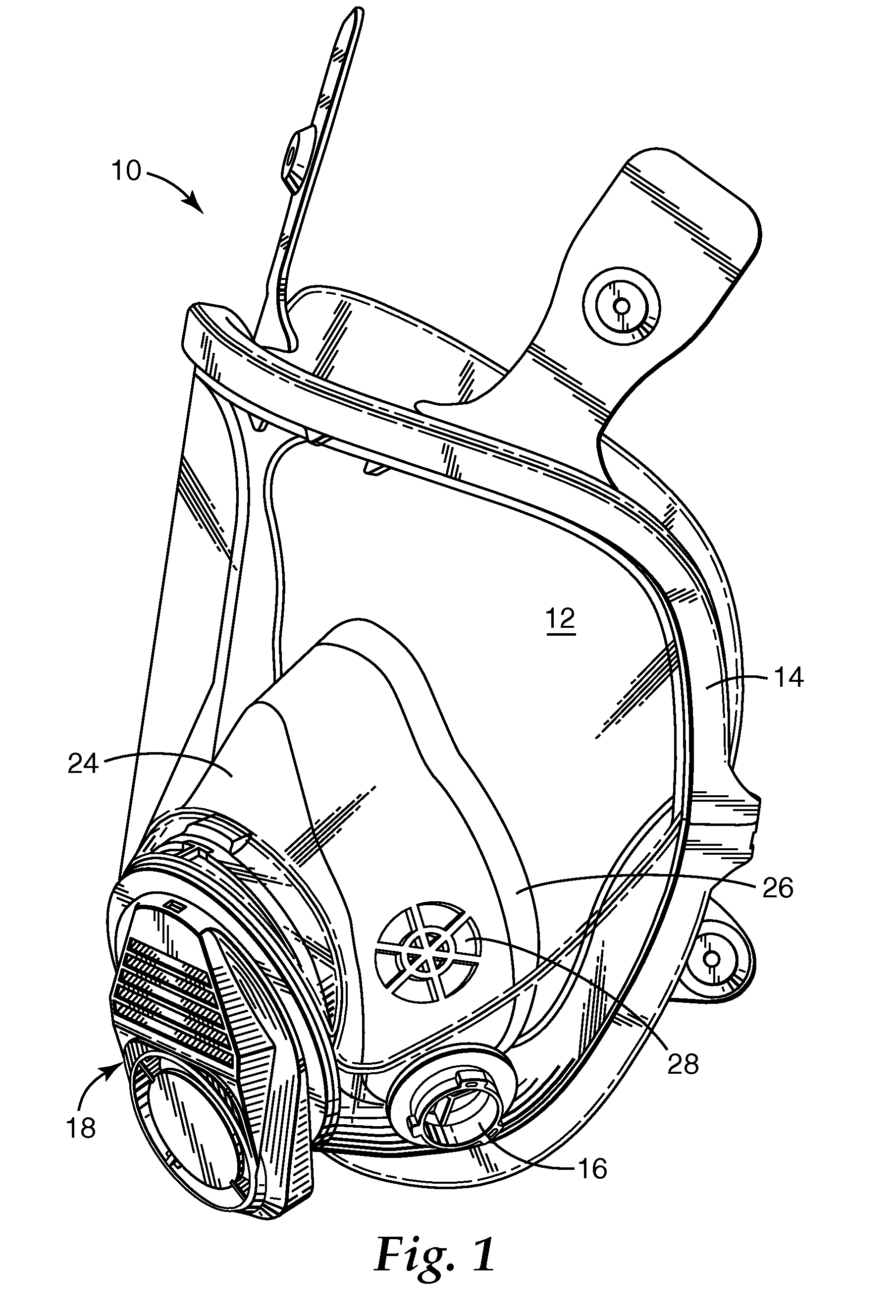

Respirator, welding helmet, or face shield that has low surface energy hard-coat lens

ActiveUS20090025727A1Good chemical-resistanceGood scratchChemical protectionHeat protectionPerfluoropolyetherRespirator

A personal safety protective device that includes a lens and a support structure onto which the lens is secured. The lens includes a substrate and a hard-coat layer located on the substrate of the lens. The hard-coat layer has a low surface energy outer surface that is derived from a) an additive that includes at least one of i) a perfluoropolyether urethane that includes hydrolysable silane groups, and ii) an acrylate polymer that includes at least one perfluoropolyether moiety and at least one hydrolysable silane group, and b) a silsesquioxane-based hard-coat composition. The provision of such a lens on a personal safety protective device enables the lens to be durable to abrasion and to be easily cleaned without use of solvents that could shorten the service life of the lens.

Owner:3M INNOVATIVE PROPERTIES CO

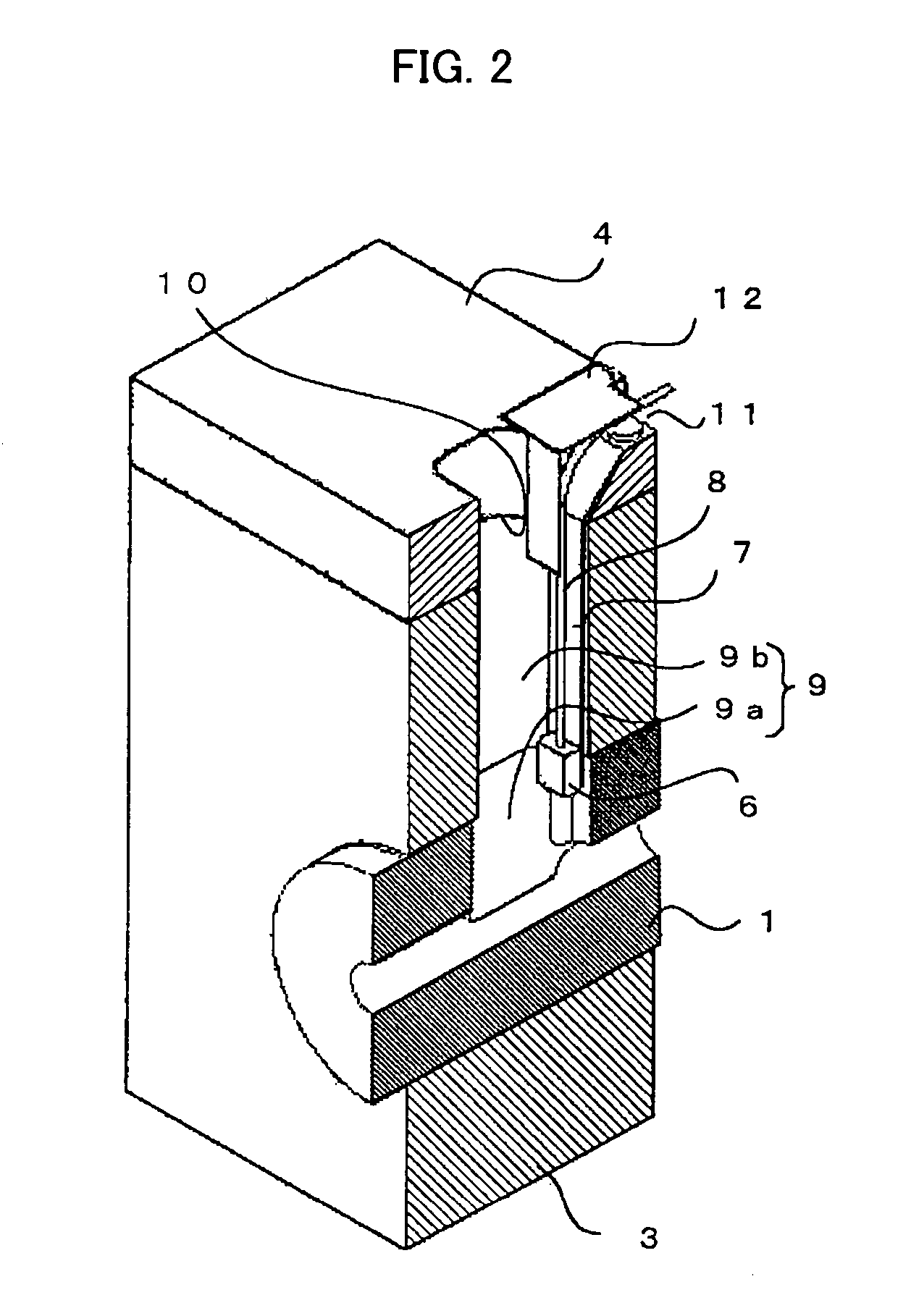

Semiconductor device and its manufacturing method

InactiveUS7265035B2Easy to scratchEasy to produceTransistorSolid-state devicesSemiconductor chipUltrasonic vibration

To improve the reliability and yield of a thin-type semiconductor device as used for a stack-type flash memory, the semiconductor device is manufactured by upheaving each of semiconductor chips (semiconductor devices) obtained by dicing a semiconductor wafer on an adhesive sheet from a backside via the adhesive sheet using an upthrow jig to which ultrasonic vibration is applied so as not to break through the adhesive sheet, and by picking up each semiconductor chip.

Owner:RENESAS ELECTRONICS CORP

Coated silica particles and method for production thereof

InactiveUS20030118824A1High depositionAdvantageous physicalMaterial nanotechnologyPigmenting treatmentSilica particleCerium oxide

Owner:AKZO NOBEL NV

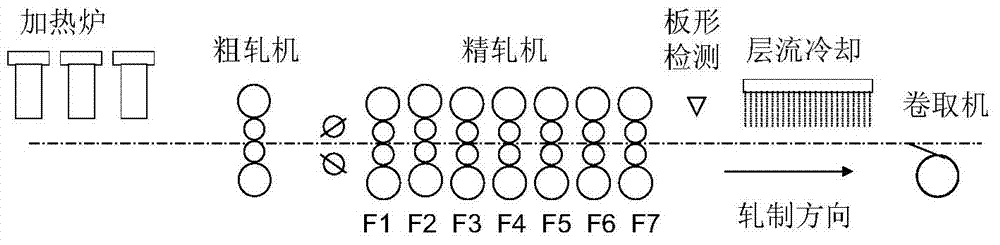

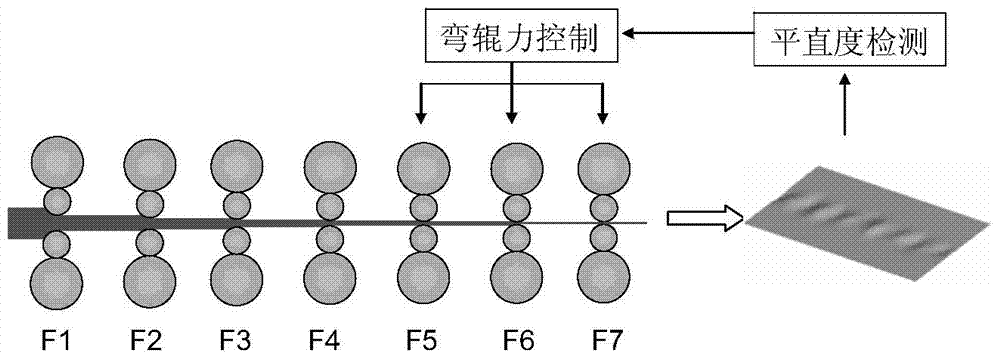

Slight center wave strip-shape control method of hot-rolled strip steel

ActiveCN104511484AFlat thickness distributionEasy to scratchProfile control deviceMartensitic stainless steelEngineering

The invention relates to a slight center wave strip-shape control method of hot-rolled strip steel. The method comprises the following steps: firstly, choosing a strip-shape feedback control frame; utilizing the adjusting manner of upstream frames, namely, adjusting the roll bending forces of the frames F2-F4 to realize the targeted slight center waves at a precision rolled outlet; secondly, controlling and adjusting the roll bending forces; detecting the flatness of the strip steel in real time by a strip-shape instrument and comparing it with a target value; if the deviation exists, adjusting the roll bending forces of the frames F2-F4. The slight center wave strip-shape control method of hot-rolled strip steel is applicable to overcoming strip-shape problems caused by the stages such as cooling and thermal treatment after hot rolling; the strip-shape quality of martensitic stainless steel strips is improved greatly and the scratching on the surface strip-shape in follow-up pickling and continuous annealing production is solved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

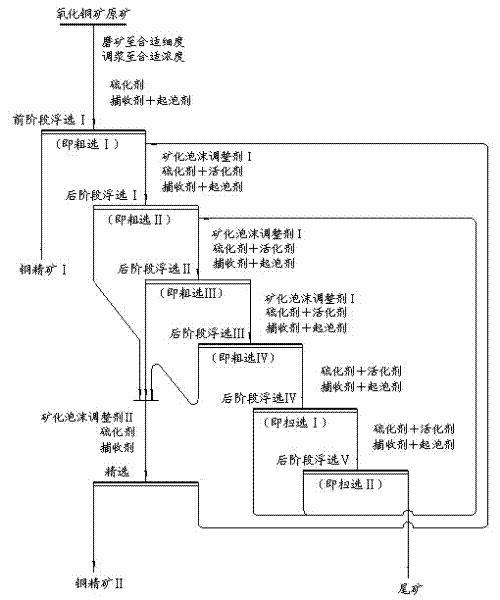

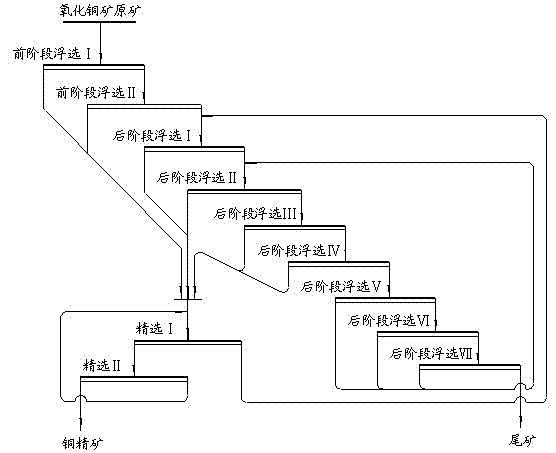

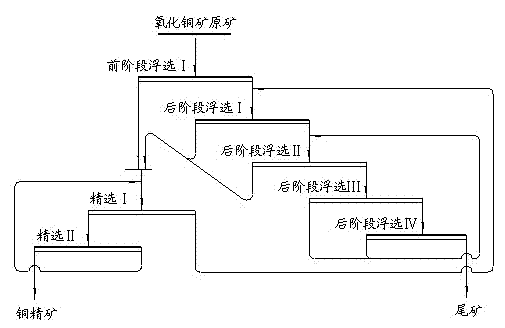

Method for activating and adjusting mineralized bubbles in vulcanizing flotation process of copper oxide ores

InactiveCN102366731AThe cumulative recovery rate is largeThe cumulative recovery rate increased greatlyFlotationFoaming agentCopper oxide

The invention provides a method for activating and adjusting mineralized bubbles in the vulcanizing flotation process of copper oxide ores. The method comprises pre-stage flotation, post-stage flotation and selection; after grinding and mixing, a vulcanizing agent, a collecting agent and a foaming agent are added in each sub-stage of the pre-stage flotation; the mineralized bubble adjusting agent I, a vulcanizing agent, an activating agent, a collecting agent and a foaming agent are added in each sub-stage of the post-stage flotation; and the mineralized bubble adjusting agent II, a vulcanizing agent and a collecting agent are added in each sub-stage of the selection so as to obtain copper concentrate and tailings. The method provided by the invention has the advantages that: the mineralized bubble adjusting agent is correspondingly added when the activating agent is added in the post-stage flotation so as to avoid excessively large bubbles caused by adding the activating agent only, and the production operation is convenient; and compared with the conventional vulcanizing flotation method and conventional activating flotation method, by adopting the medicine adding method and flow structure provided by the invention, the method can improve the recovery rate of copper concentrate by 8-14% while ensuring similar grades of the copper concentrate.

Owner:KUNMING UNIV OF SCI & TECH

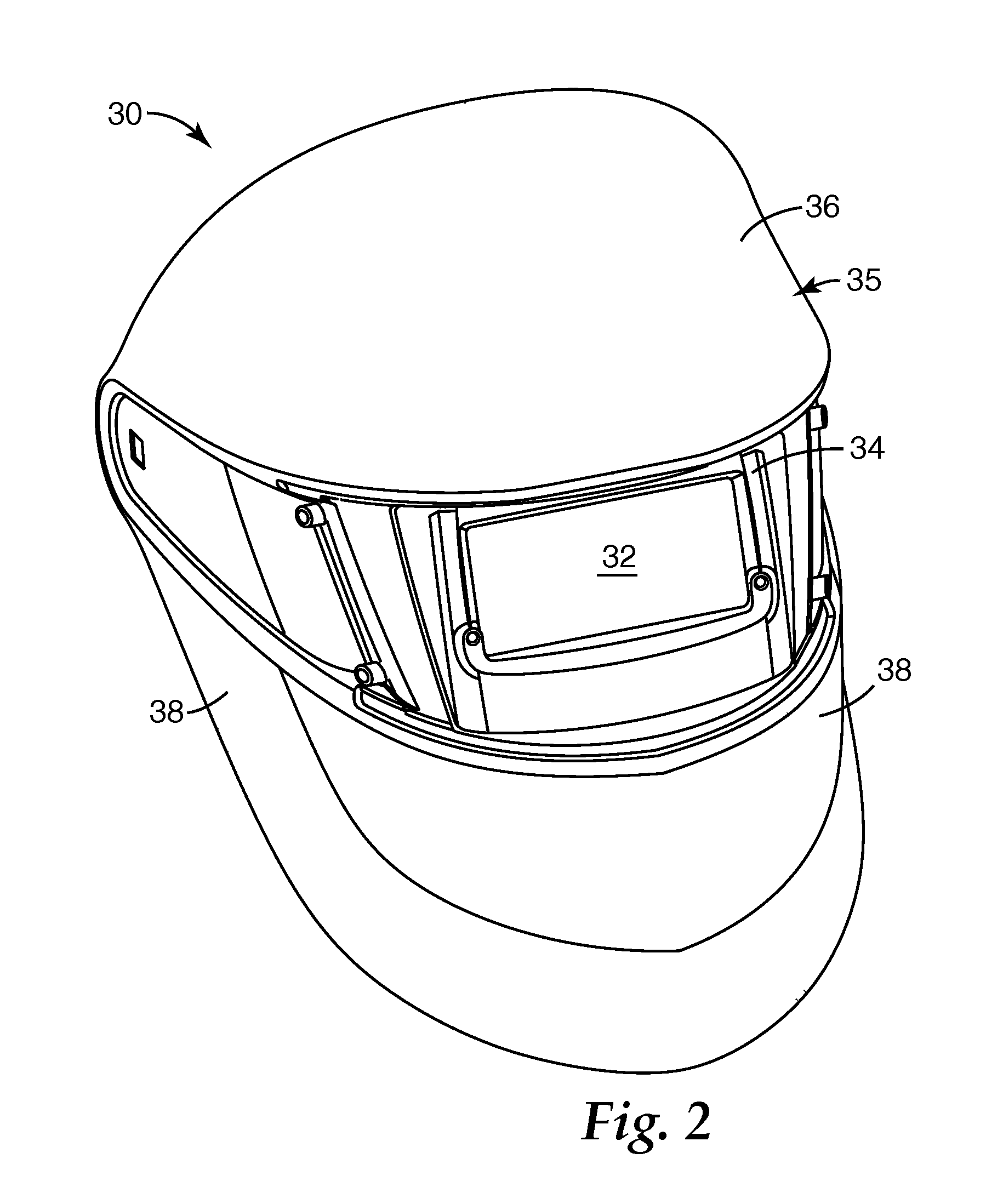

Air filling bag with outer film strengthening structure

Owner:LIAO CHIEH HUA

Glass material for mold pressing and method for manufacturing optical glass element

ActiveUS20090314033A1Avoid scratchesDegree of abrasion of becomes highGlass/slag layered productsGlass reforming apparatusShell moldingOptical glass

A glass material for mold pressing, comprising a core portion comprised of an optical glass with a degree of abrasion FA of 200 or higher and a covering portion comprised of a second glass covering at least a portion of the surface of said core portion. A method for manufacturing an optical glass element, wherein a glass material that has been preformed to a prescribed shape is heat softened and press molded with a pressing mold and the outer perimeter portion of the molded product obtained is removed by mechanical processing. The above-mentioned glass material for mold pressing is used as the glass material. To provide a means whereby an optical element does not bear scratches on optically functional surfaces through contact during handling after the press molding of press molded glass products despite being comprised of a glass material with a high degree of abrasion, and a means whereby even when scratched, the function of the optical element finally obtained is unaffected.

Owner:HOYA CORP

Polishing pad

ActiveUS20100048102A1Improve the level ofHigh polishing rateAbrasion apparatusSemiconductor/solid-state device manufacturingEndcappingPolyol

A polishing pad capable of maintaining a high level of dimensional stability upon moisture absorption or water absorption and providing high polishing rate includes a polishing layer of a polyurethane foam having fine cells, wherein the polyurethane foam includes a cured product of a reaction of (1) an isocyanate-terminated prepolymer (A) that includes an isocyanate monomer, a high molecular weight polyol (a), and a low molecular weight polyol, (2) an isocyanate-terminated prepolymer (B) that includes a polymerized diisocyanate and a polyethylene glycol with a number average molecular weight of 200 to 1,000, and (3) a chain extender.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

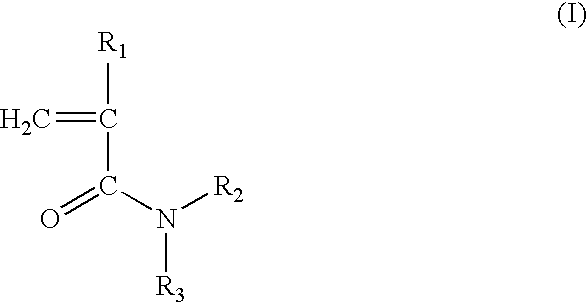

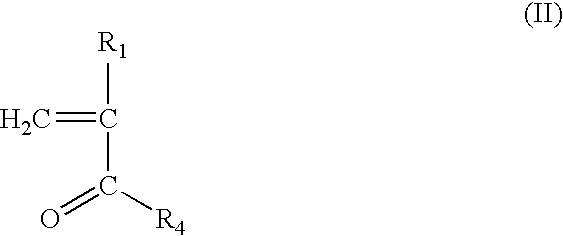

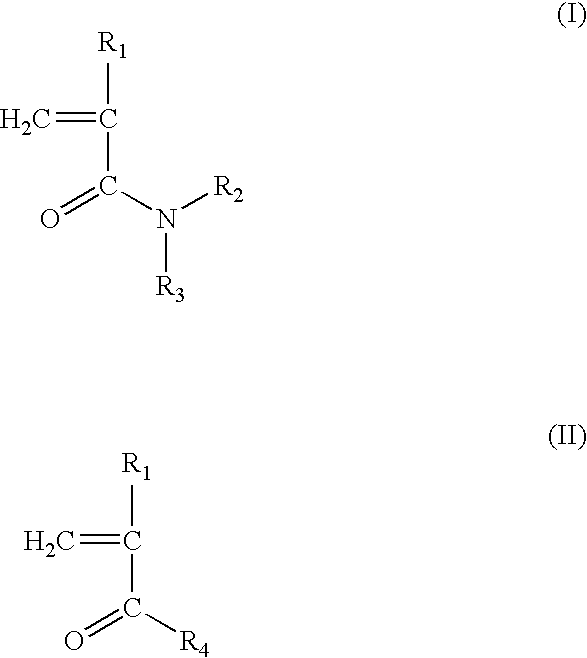

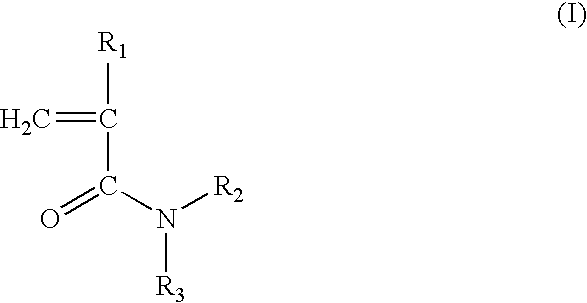

Cmp polishing compound and polishing method

ActiveUS20060148667A1Increase temperatureReduce the temperatureOrganic detergent compounding agentsOther chemical processesCompound (substance)Slurry

The present invention relates to a CMP polishing slurry, comprising cerium oxide particles, a dispersing agent, a water-soluble polymer and water, wherein the water-soluble polymer is a compound having a skeleton of any one of an N-mono-substituted product and an N,N-di-substituted product of any one selected from the group consisting of acrylamide, methacrylamide and α-substituted products thereof. The amount of the water-soluble polymer is preferably in the range of 0.01 part or more by weight and 10 parts or less by weight for 100 parts by weight of the polishing slurry. Thus it is possible to provide a polishing slurry and a polishing method which make it possible to polish a film made of silicon oxide or the like effectively and rapidly and further control the process therefor easily in CMP technique for flattening an interlayer insulating film, a BPSG film, an insulator film for shallow trench isolation, and other films.

Owner:RESONAC CORP

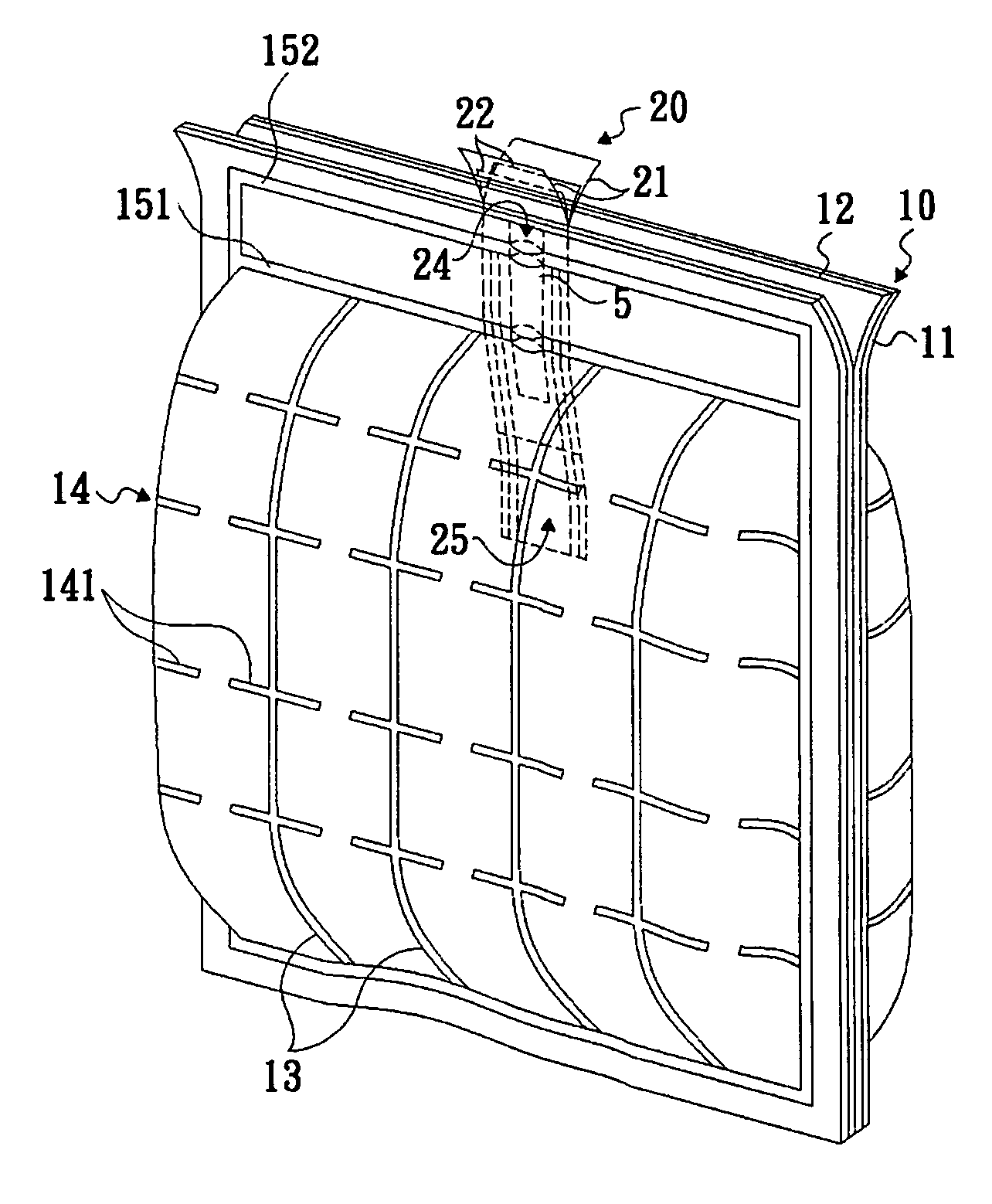

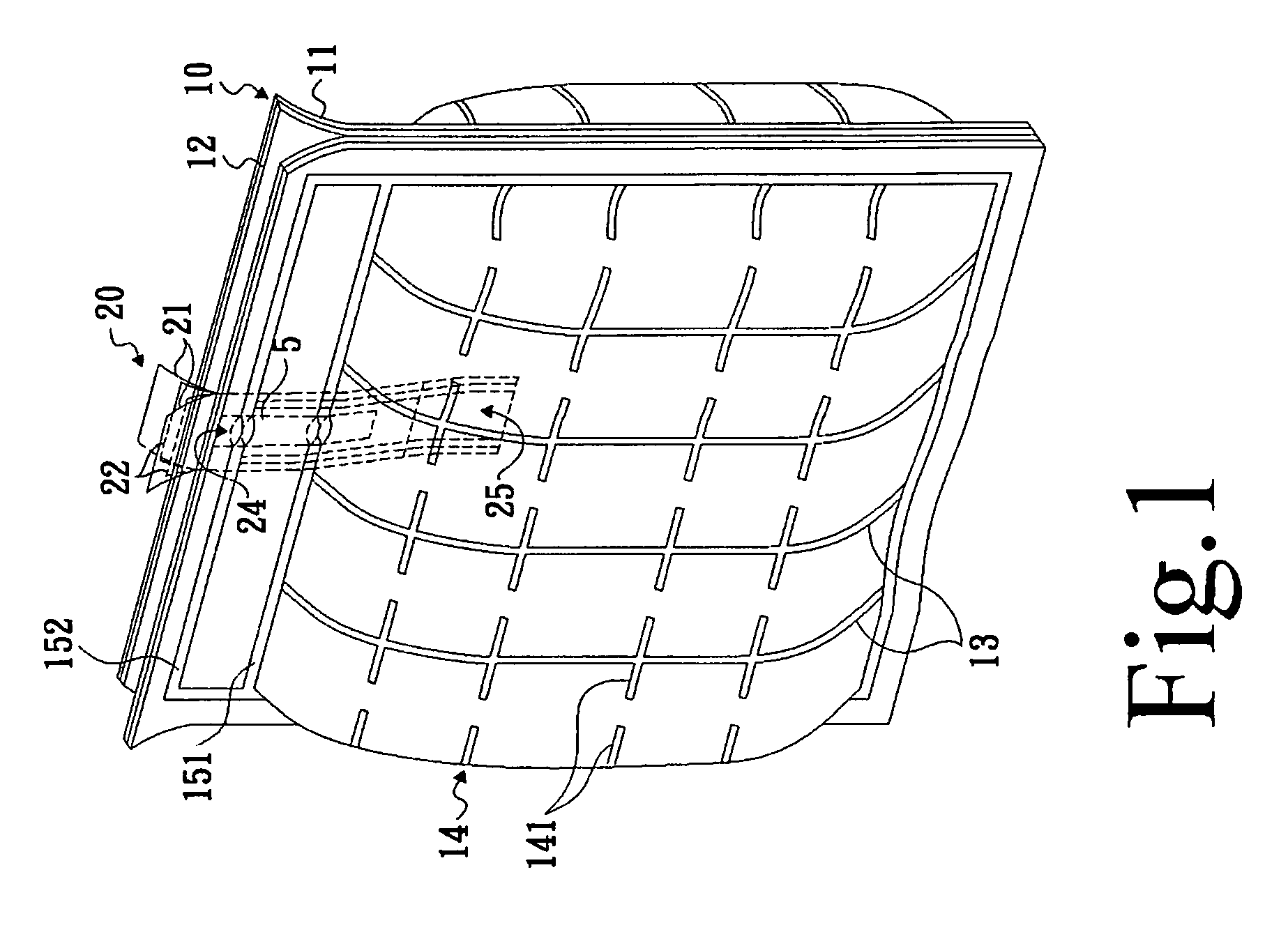

Lens and display accessory for portable imaging device

The present invention relates to auxiliary detachable accessories associated with portable image capture and storage devices. Enhancements provided by the accessories include protective coverings for the integrated displays and integrated lenses, as well as the use of auxiliary conversion lenses that can be selectively attached to such devices to assist a user in enhancing in addition to creating artistic accentuations to the images.

Owner:GLENN F SCHAEFER

Respirator, welding helmet, or face shield that has low surface energy hard-coat lens

ActiveUS8015970B2Good chemical-resistanceGood scratchChemical protectionHeat protectionPerfluoropolyetherRespirator

Owner:3M INNOVATIVE PROPERTIES CO

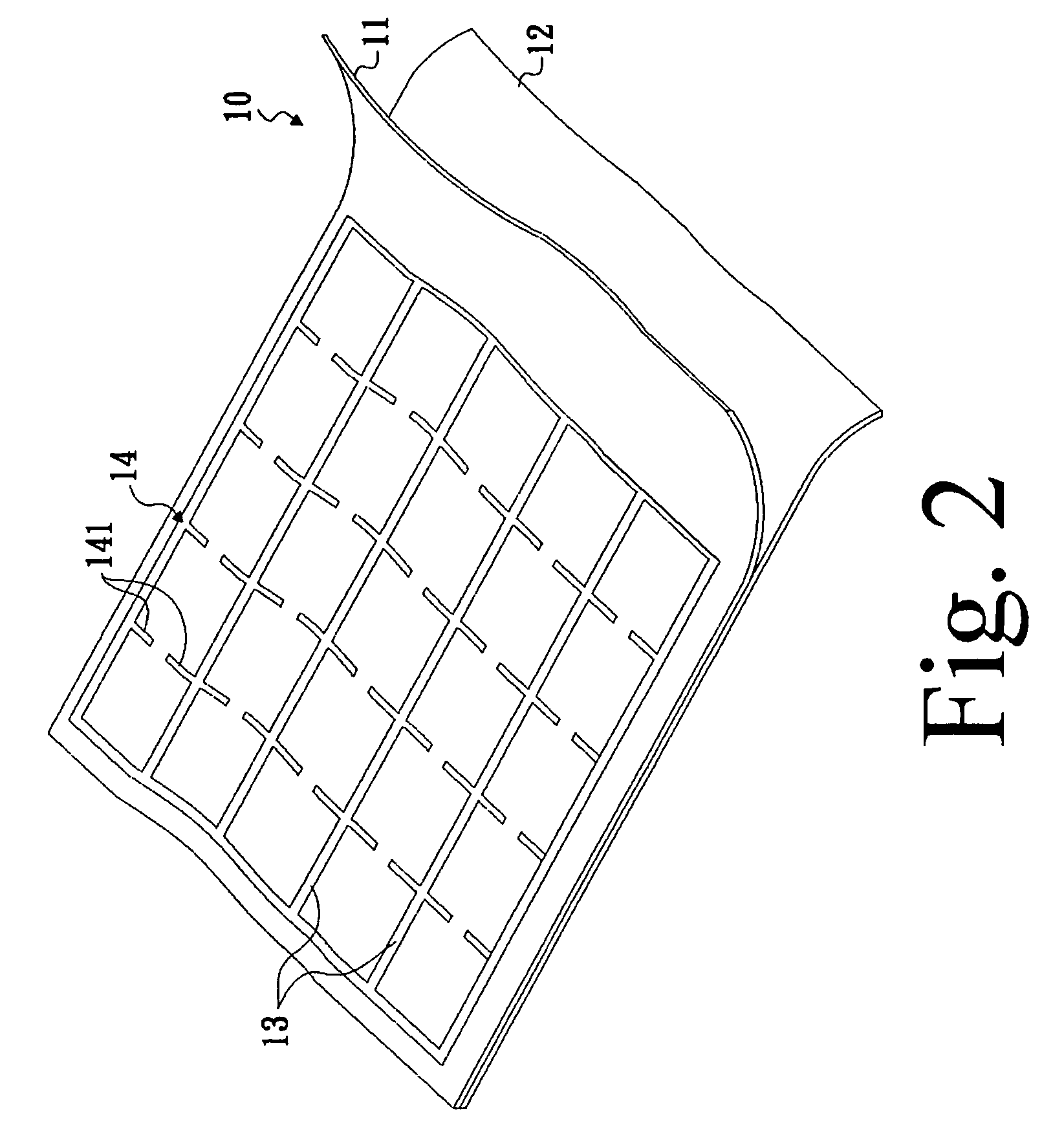

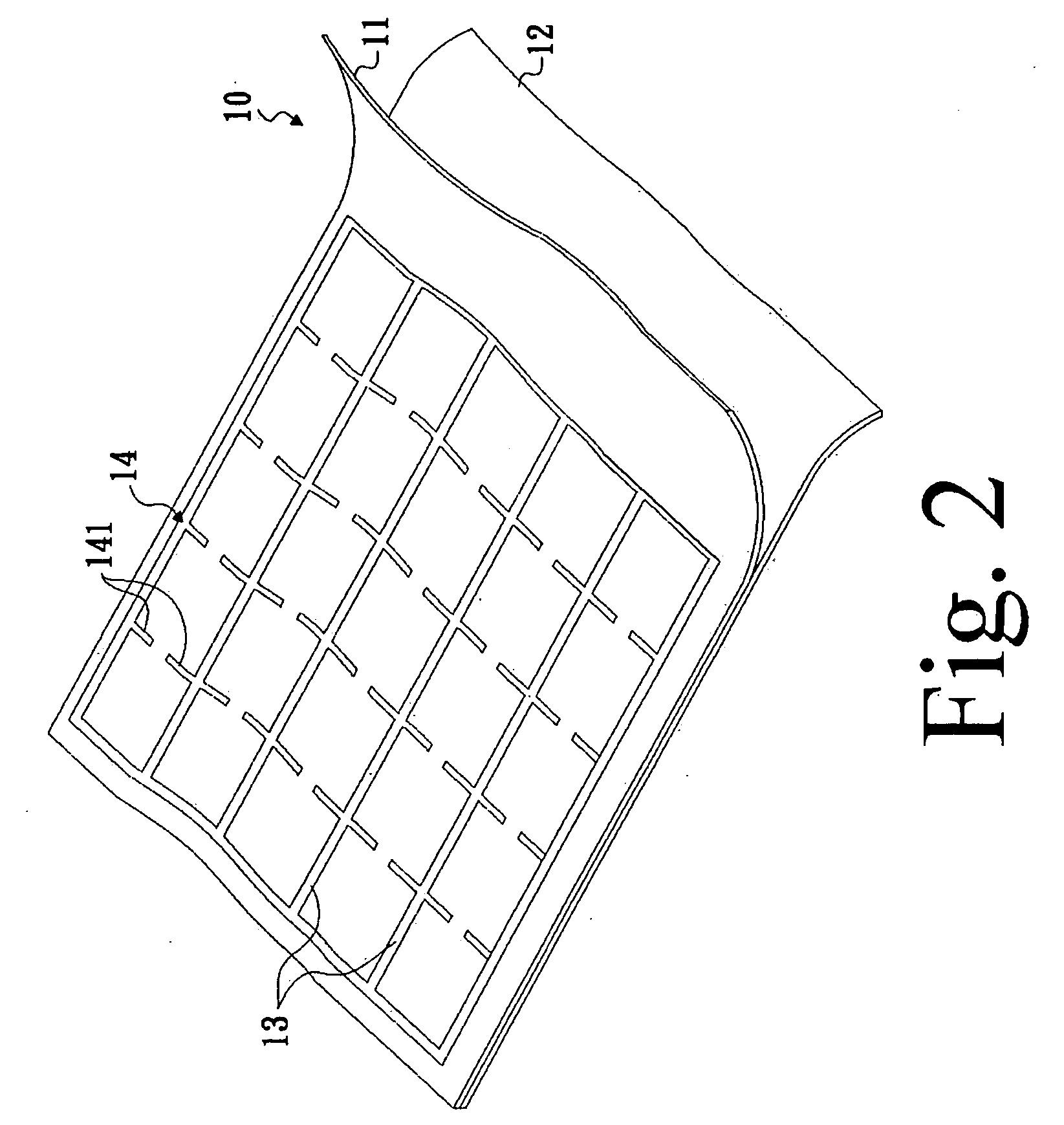

Air filling bag with outer film strengthening structure

An air filling bag with an outer film strengthening structure includes two outer films and a main check valve, where the two outer films are adhered to each other to form an air chamber by means of hot sealing, in which each outer film includes the first film sheet and the second film sheet stacked together, and a plurality of first hot sealing lines is formed by adhering the first film sheet to the second film sheet by means of hot sealing in a first direction together with a plurality of second hot sealing lines formed by adhering the first film sheet to the second film sheet by means of hot sealing in a second direction. The main check valve is positioned between the two outer films and one end thereof projects from the air chamber. Air in the air chamber can compress the main check valve to shield a first air passageway of the main check valve so as to prevent air from leaking out of the air chamber after outside air flows in the air chamber via the first air passageway.

Owner:LIAO CHIEH HUA

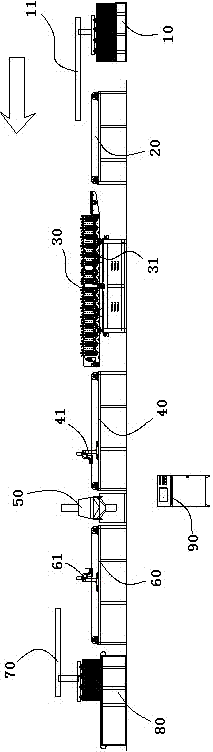

Panel bending automatic production line

ActiveCN104722610AFolding board is convenient and quickCompact structureMetal-working feeding devicesPositioning devicesProduction lineHydraulic cylinder

The invention discloses a panel bending automatic production line. The panel bending automatic production line comprises a feeding lifting table, a belt conveying platform, a cold bending molding machine, a first transition feeding table, a hydraulic panel bending machine, a second transition feeding table, a stacking mechanical arm, an output line and a control system which are sequentially arranged, wherein the control system is electrically connected the above mechanisms. The feeding lifting table is composed of four hydraulic cylinders, the first transition feeding table and the second transition feeding table are each composed of a conveying belt and a sensing positioning device, the stacking mechanical arm is composed of a sucker and a rotary arm, and the hydraulic panel bending machine is composed of a rack, a bending device, a panel pressing device and a hydraulic driving unit. By means of the panel bending automatic production line, panels in variable specifications and different modes can be bent so as to form a full-automatic production line, and can be bent in the modes such as a U type, a C type, a U type with turning edges and a C type with turning edges, mechanical automatic feeding and discharging devices and the accurate stacking device are arranged on the production line, and the aims of bending the panels in variable specifications and different modes and forming the full-automatic production line are achieved.

Owner:FOSHAN CITY NANHAI POPULA FAN

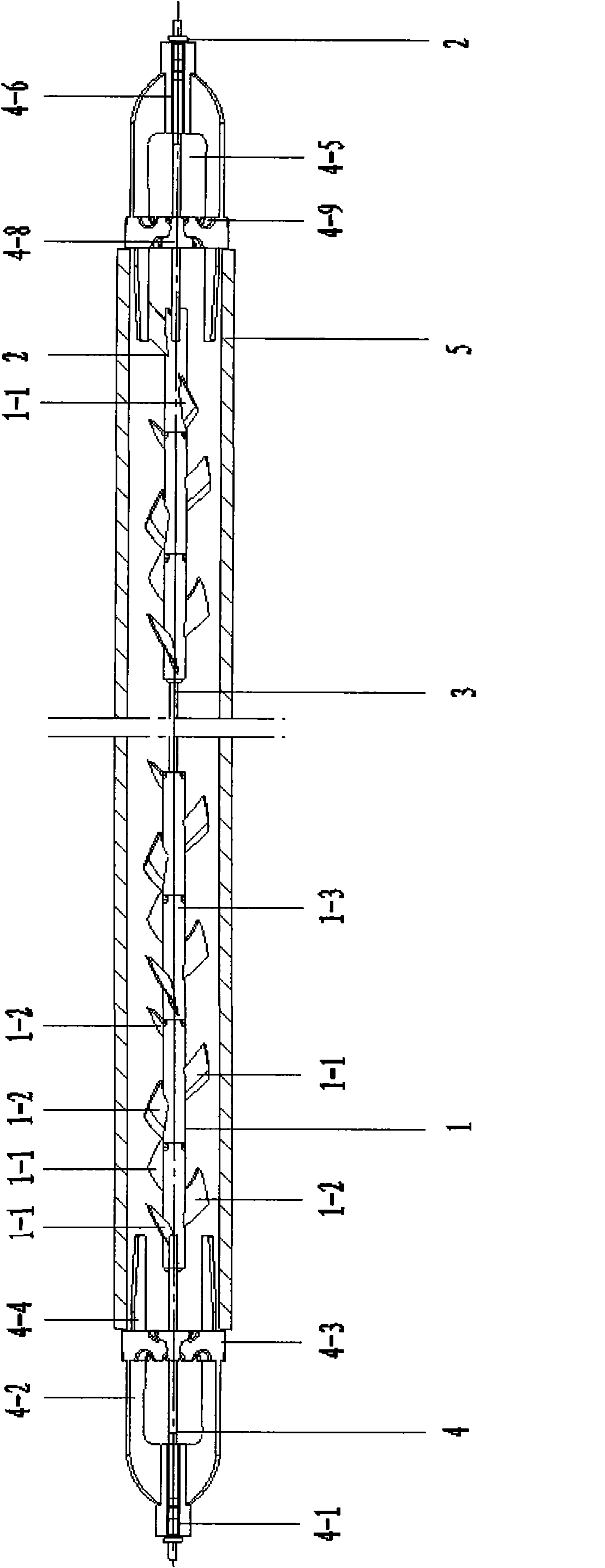

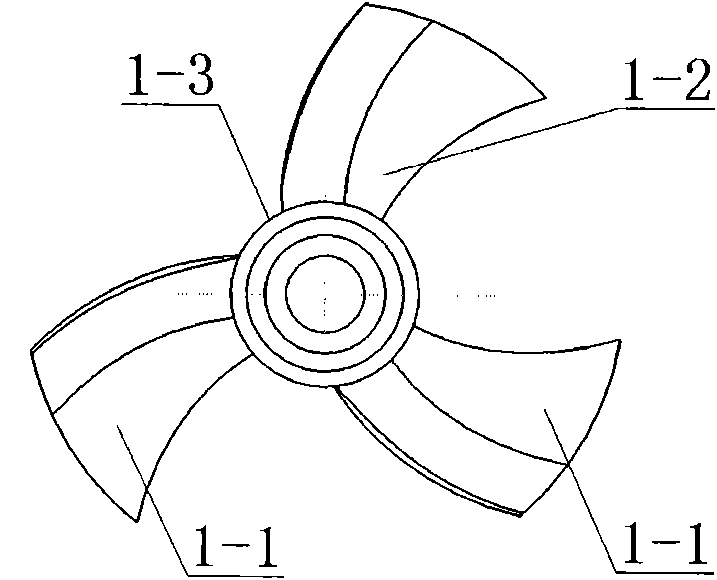

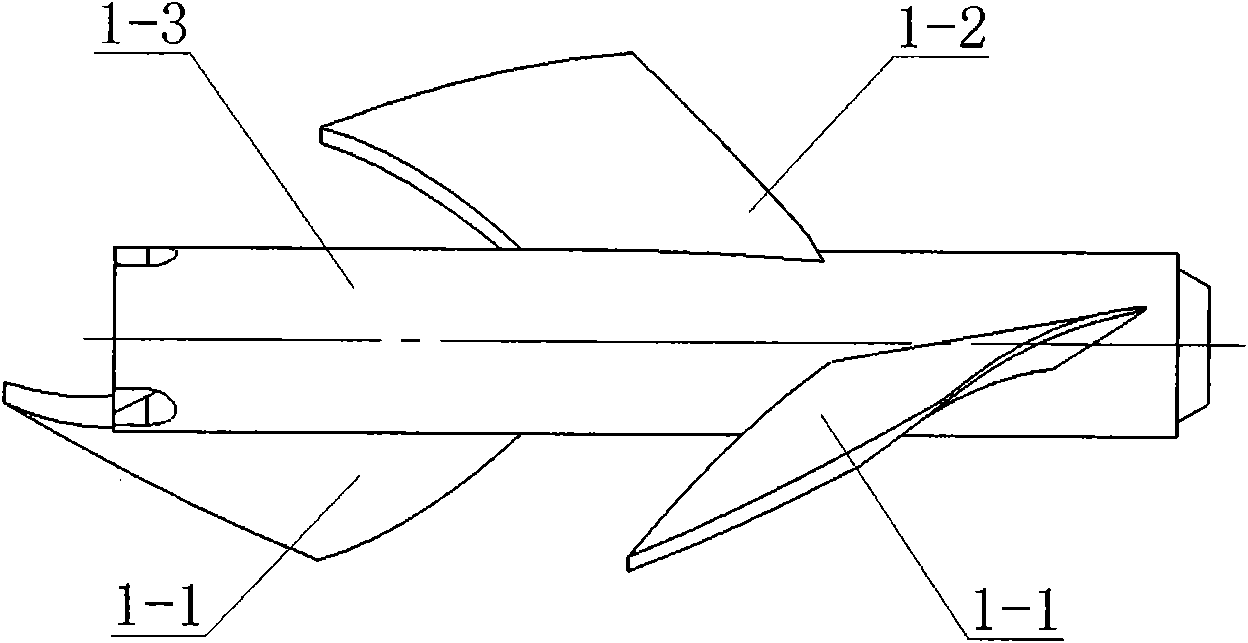

EHT (Extra High Tension) self-cleaning energy-saving environment-friendly device and manufacture method thereof

InactiveCN101968332AIncrease flexibilityReduce mutual interferenceHollow article cleaningCorrosion preventionEngineeringClean energy

The invention relates to an EHT (Extra High Tension) self-cleaning energy-saving environment-friendly device for strengthened heat transfer and descaling in a heat exchange pipe and a manufacture method thereof. The device comprises rotors, a rotating shaft, stoppers and hangers, wherein the plurality of rotors are fixed on the rotating shaft at segments, 2-200 rotors are arranged at each segment, rotors which are limited at each segment have the total length of 100-2000 mm, the rotating shaft is a flexible soft shaft, and the difference between the outside diameter of each rotor blade and the inside diameter of the heat exchange pipe is from 0.1 mm to 3 mm. The manufacture method comprises the following steps of: firstly, respectively manufacturing the rotors, the rotating shaft, the stoppers and the hangers; then, mounting the rotors on the rotating shaft segmentally; limiting the rotors with the stoppers at the tail ends of the rotors at each segment; penetrating the rotating shaft with the rotors into the heat exchange pipe; mounting the hangers at both ends of the heat exchange pipe; and fixing the rotating shaft on the hangers through the stoppers. The EHT (Extra High Tension) self-cleaning energy-saving environment-friendly device and the manufacture method thereof have the advantages of wide sphere of applications, remarkable strengthened heat transfer and descaling effects, convenient counting and measuring, high mounting efficiency and convenient and simple operation.

Owner:SINO ECO TECH

Preparation method for high-hardness waterborne polyurethane dispersion

ActiveCN104231209AImprove water resistanceImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method for high-hardness waterborne polyurethane dispersion. An inorganic nano material and waterborne polyurethane are grafted through an in-situ polymerization method, so that the hybridization reaction of inorganic materials and the organic materials is realized and complementary advantages are realized. The preparation method comprises the following operation steps: adding polyisocyanate, macromolecule polyol, a catalyst, a chain extender and a silane coupling agent according to certain weight ratio in a flask for reacting to obtain a polyurethane prepolymer; after the reaction is ended, sequentially adding a neutralizer, inorganic nano material dispersion liquid and deionized water under the condition of low-temperature and high-speed stirring; finally, heating under the vacuum condition for removing the solvent to obtain the high-hardness waterborne polyurethane dispersion. Compared with the traditional inorganic and organic blending process, the preparation method has the characteristics that products prepared through the preparation method have the advantages of good stability, excellent water resistance, long-time aging resistance, excellent and high adhesion, high drying speed, high hardness, good fullness, higher light transmittance and the like, and are wide in application range.

Owner:江苏日出化工有限公司

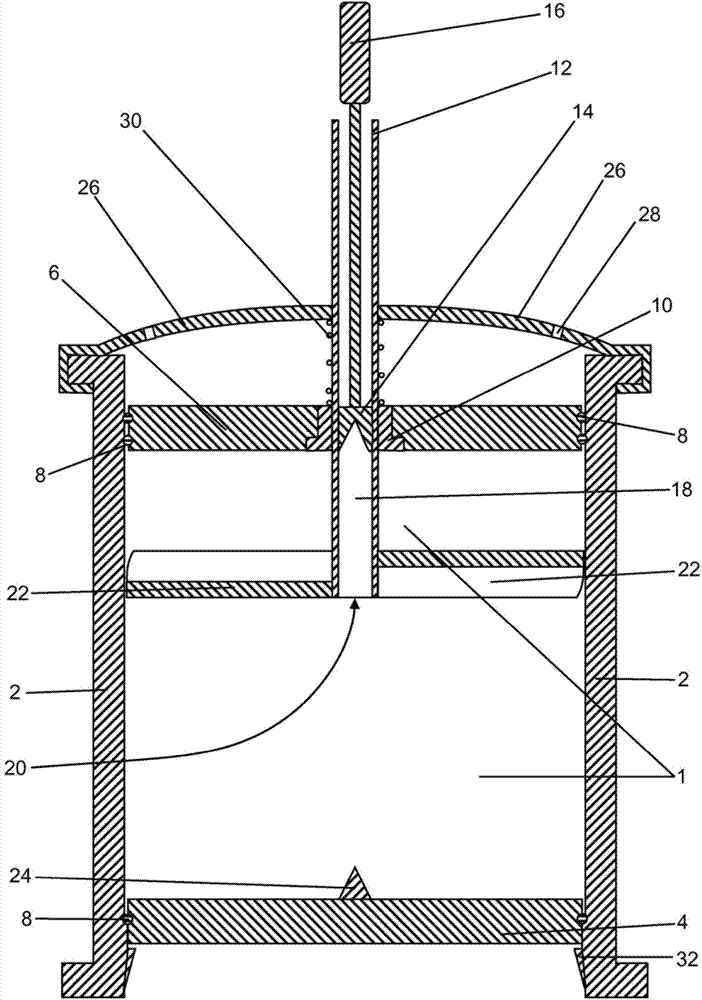

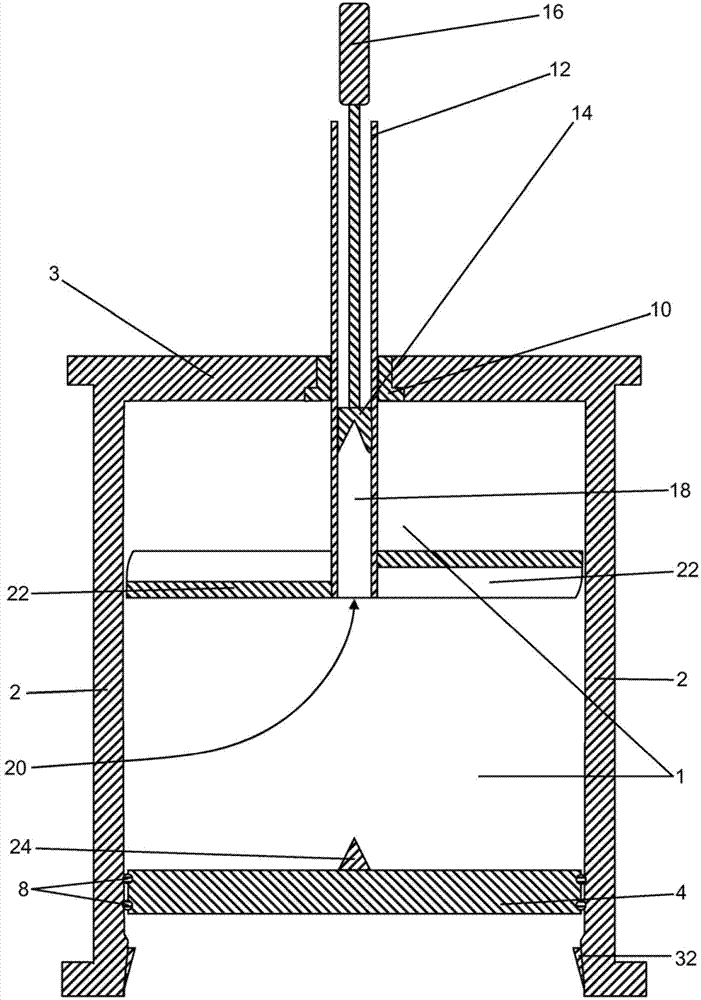

Device for storing and mixing bone cement

InactiveCN104276350AAvoid unevennessEasy to scratchShaking/oscillating/vibrating mixersMixer accessoriesEngineeringBone cement

A device stores, mixes, and applies polymethylmethacrylate bone cement. The device comprises a first container for a first pasty component of the bone cement, a dispensing plunger arranged in the first container such that it can be shifted and serves for pressing the content of the first container out of a dispensing opening, a mixing facility for mixing the content of the first container, whereby the mixing facility is arranged in the first container and the mixing facility can be moved in the first container from outside for mixing, and at least one second container for at least one second component of the bone cement is arranged in or on said first container. The second container can be opened, such that the contents of the first container and second container can be mixed with each other in the first container, whereby at least a boundary surface of the first container is formed by a mobile volume compensation element.

Owner:HERAEUS MEDICAL

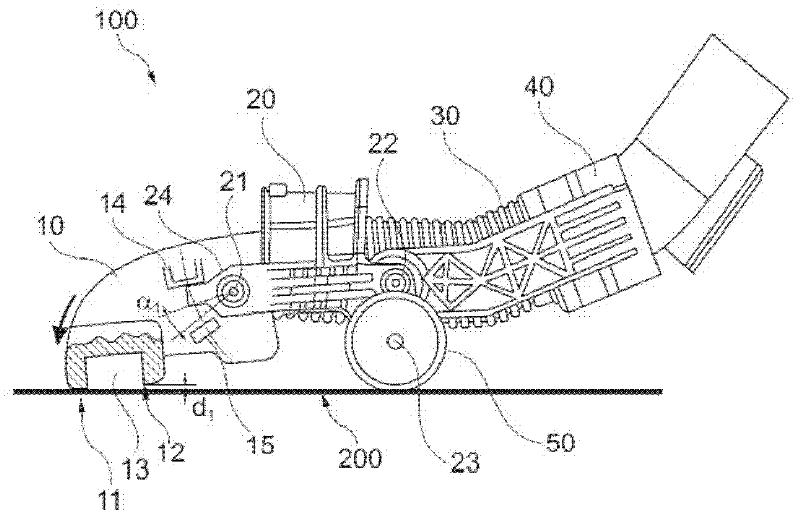

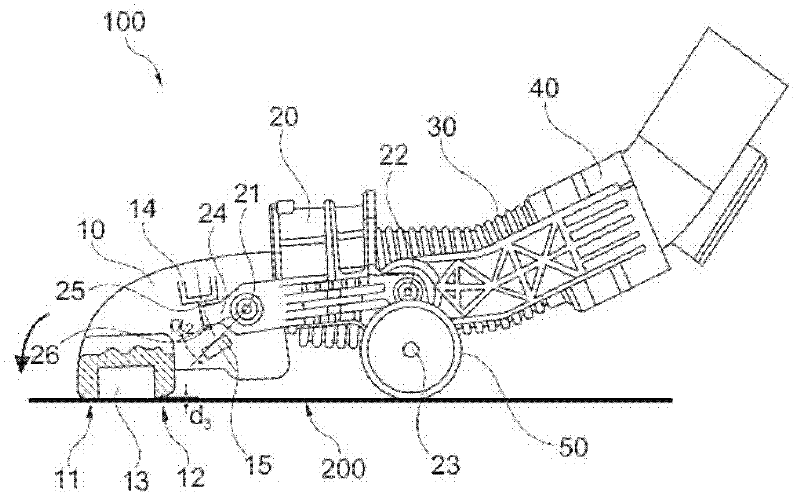

Vacuum cleaner nozzle with rotatably limited base plate

The nozzle (100) has a base plate (10) cleaning a floor with airflow-pressure and connected to a connecting rod (20). A limiting unit i.e. stop (14), limits rotation of the base plate to rotation angle (alpha1) with respect to the connecting rod, where the angle is a function of value of the airflow-pressure and proportional to the airflow-pressure. The stop unit is arranged on the connecting rod and on the base plate. The stop includes a cylindrical part fitted on the connecting rod and on the base plate, where the part possesses length representing a value of the angle.

Owner:SEB SA

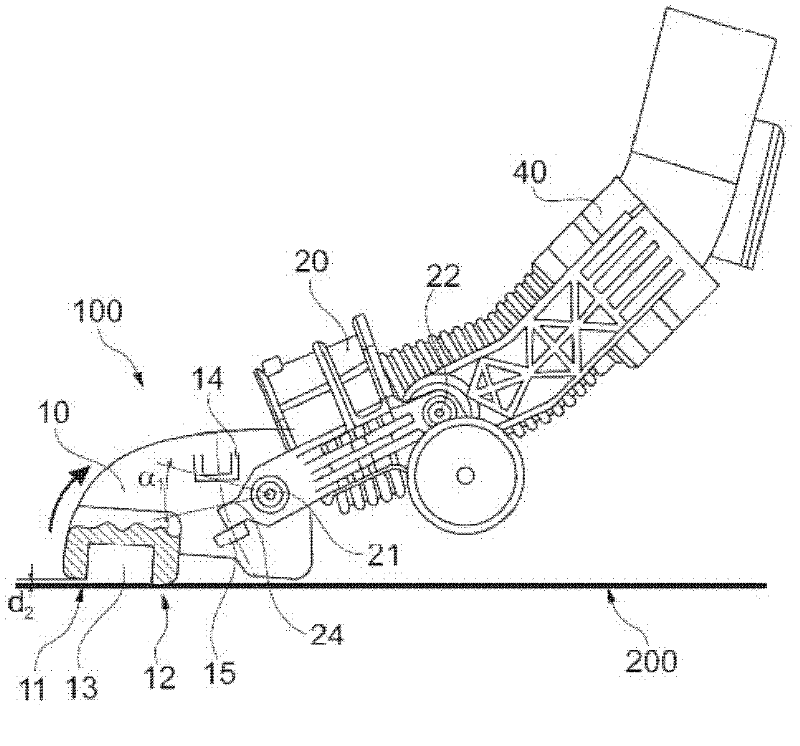

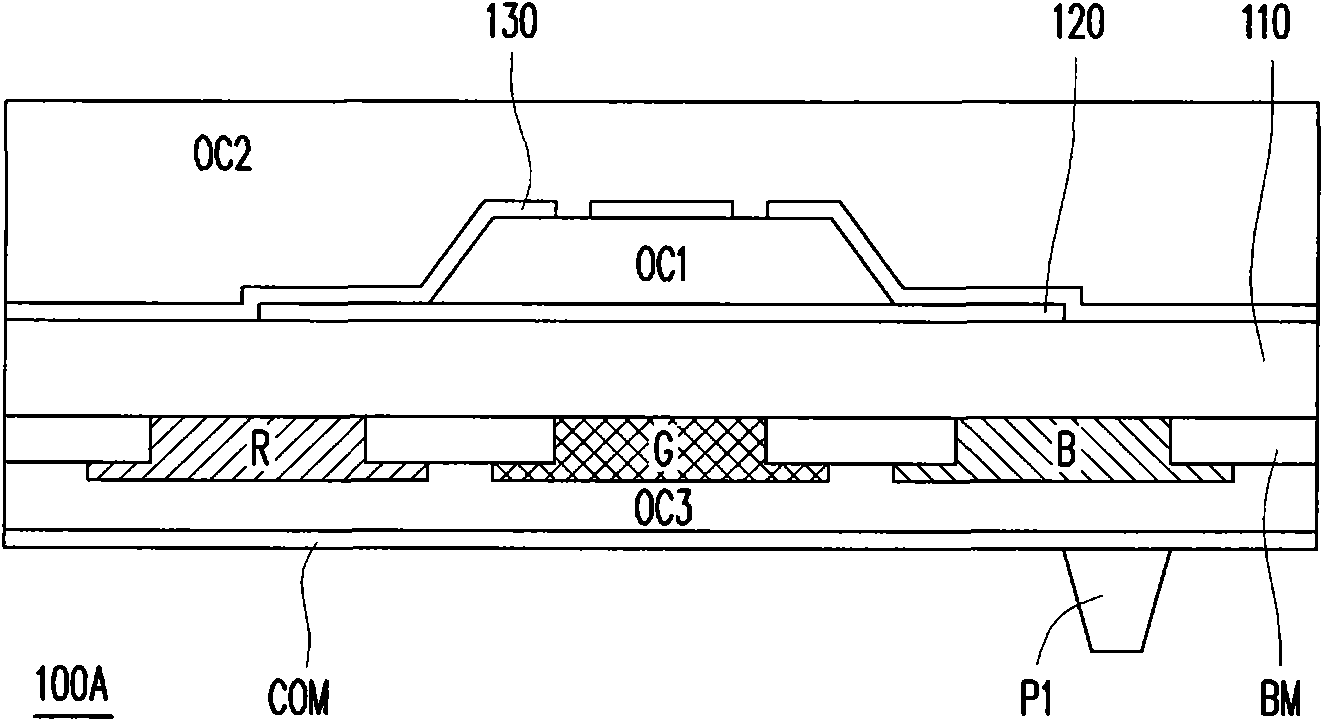

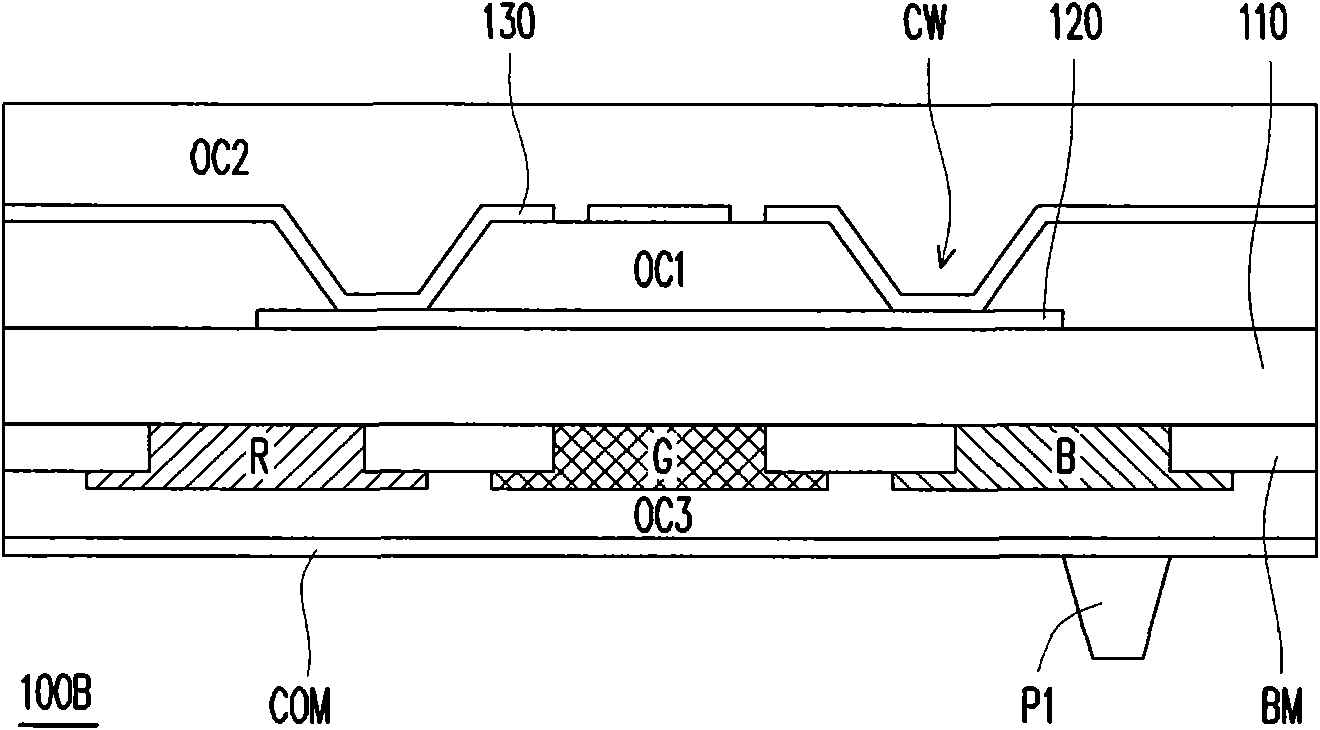

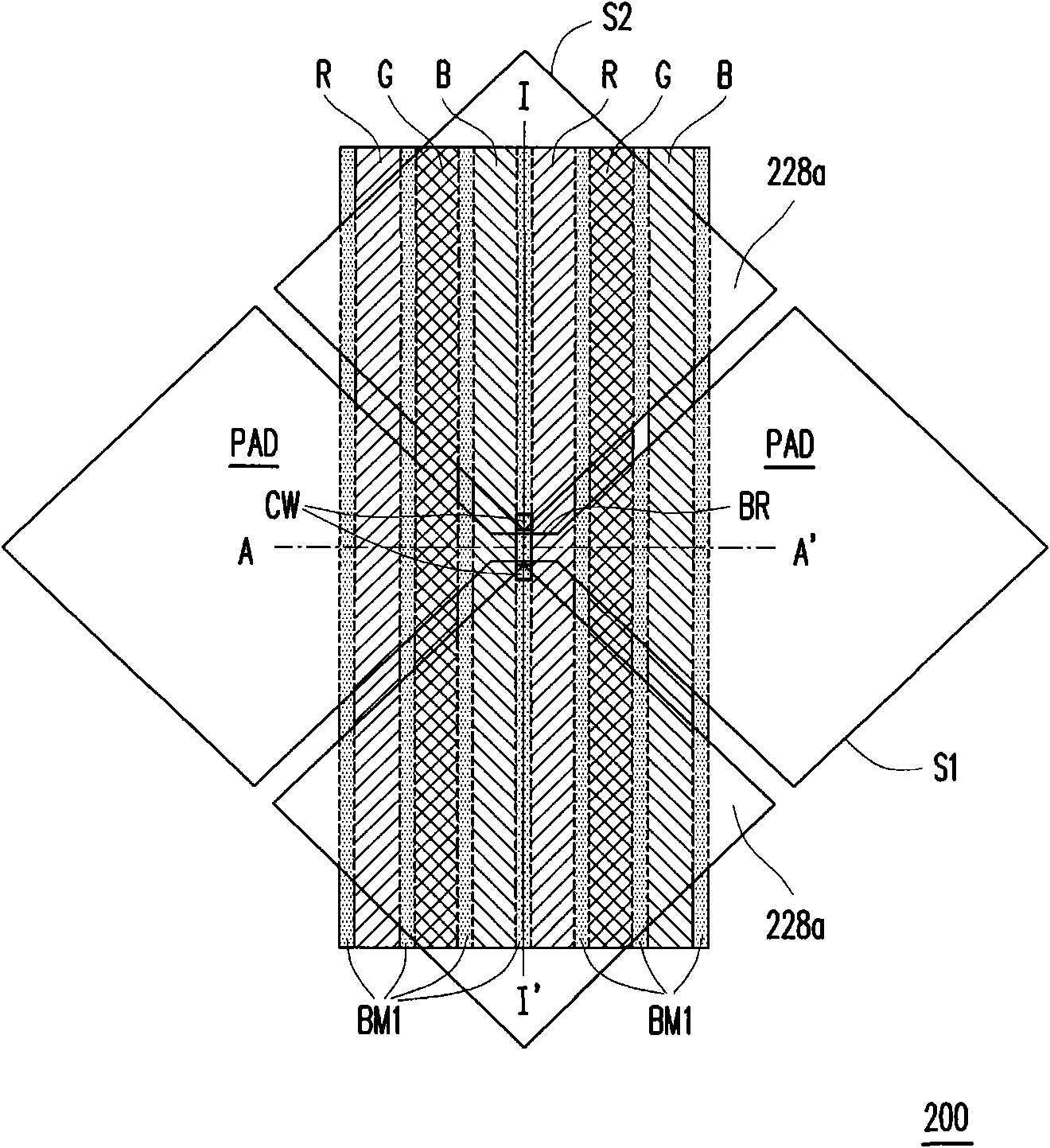

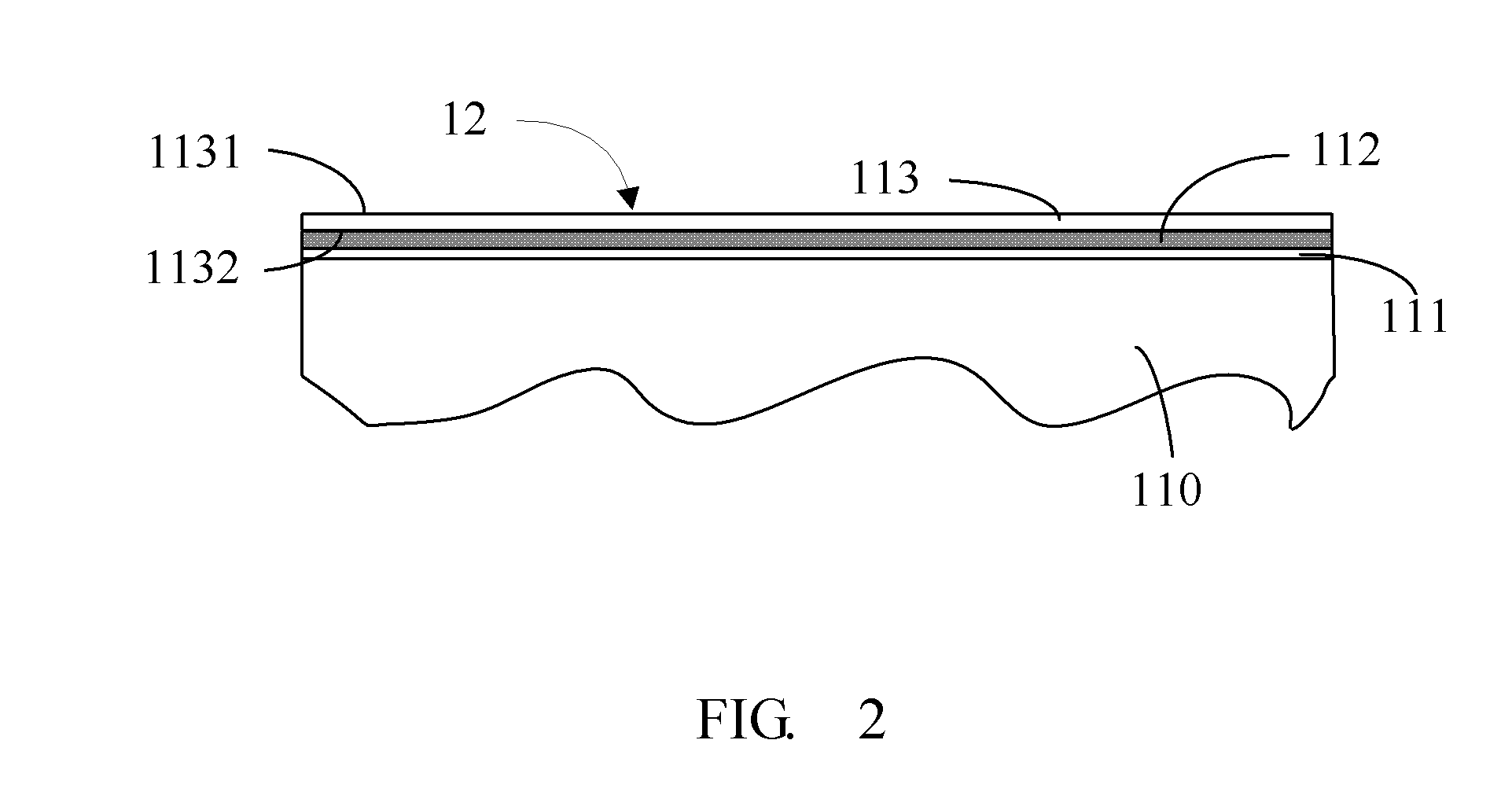

Touch plane display panel and manufacture method thereof

InactiveCN101943970AImprove scratches or damageImprove manufacturing yieldStatic indicating devicesInput/output processes for data processingLiquid crystalSurface plate

The invention relates to a manufacture method of a touch plane display panel, which comprises the steps of: providing a base plate provided with an outer surface and an inner surface relative to the outer surface; forming a plurality of bridge wires and a plurality of color filter films arranged in arrays on the outer surface, wherein the color filter films are provided with a plurality of touch openings; partial regions of each bridge wire are respectively exposed by two touch openings; forming a sensing line layer on the color filter films, wherein partial sensing line layers are electrically connected with the bridge wires through the touch openings; and assembling a liquid crystal layer between the inner surface of the base plate and an array base plate. At the same time, the invention discloses a touch plate display panel.

Owner:AU OPTRONICS CORP

Feed-through process and amplifier with feed-through

InactiveUS20050215054A1Improve applicationMounting of the sensitive wafer in an enclosure is avoidedSemiconductor/solid-state device manufacturingSemiconductor devicesAudio power amplifierEngineering

The invention concerns a process for generating a feed-through in a semiconductor wafer, which has electric circuitry embedded in a front surface whereby the hole for the feed-through is generated by the combined use of a front side protection layer and a wet KOH etch process etching the hole from the back side of the wafer, where a photomasking process is subsequently used do define the via followed by deposition of the via material.

Owner:OTICON

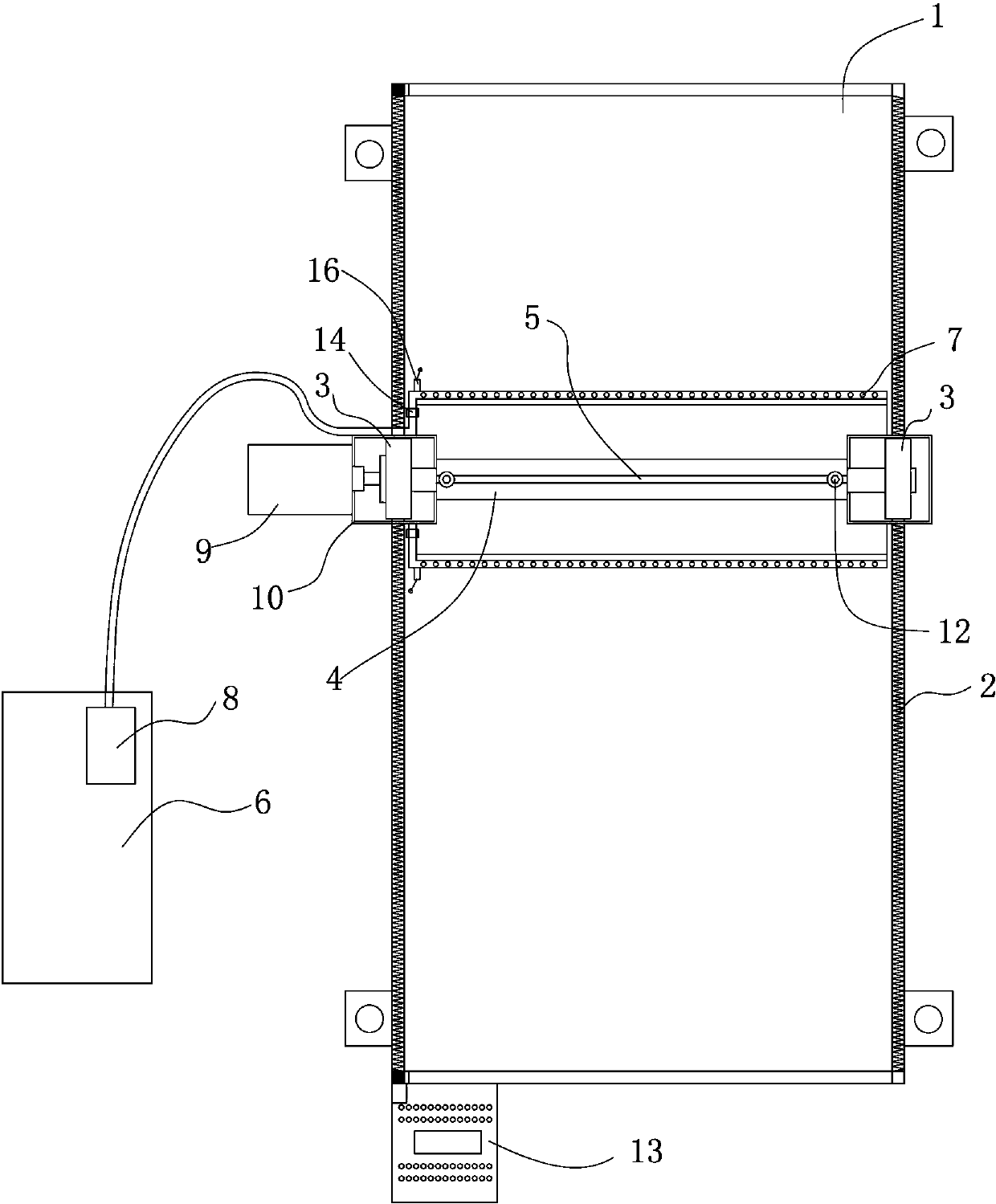

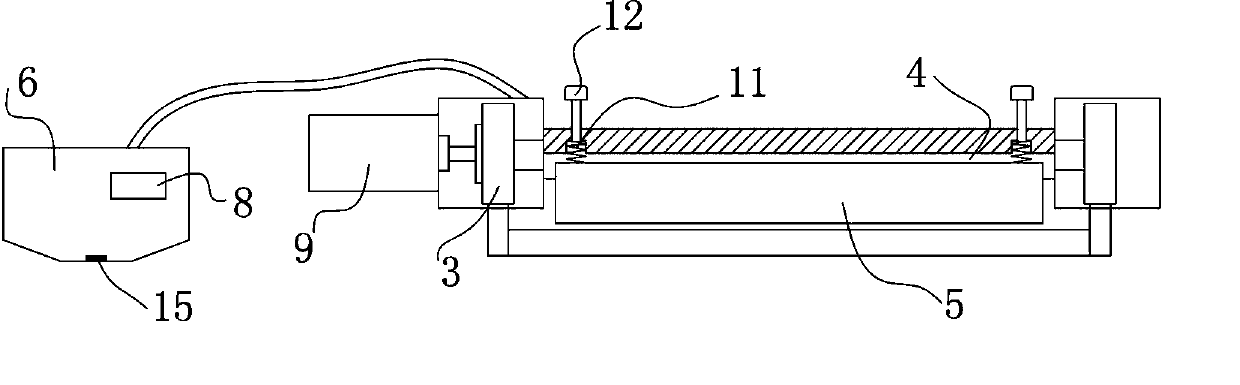

Cleaner for photovoltaic cell panel

InactiveCN104190668AIncrease power generationMediate contact pressureCleaning using toolsCleaning using liquidsCells panelReciprocating motion

The invention discloses a cleaner for a photovoltaic cell panel. The cleaner mainly comprises a cleaning unit and a walking unit. The walking unit comprises a pair of gear racks and two gears, wherein the pair of gear racks is fixed to the left edge and the right edge of the photovoltaic cell panel, and the two gears are meshed with the gear racks. The two gears are installed at the two ends of a gear shaft respectively, and bearings are arranged between the gears and the gear shaft. The cleaning unit comprises a scraping knife and a detergent containing box. The scraping knife is installed on the gear shaft, and two rows of spray heads are arranged on the two sides of the scraping knife respectively. A spray head pipeline is connected with the detergent containing box, a submerged pump gear is arranged in the detergent containing box and driven through a motor, and the motor is fixed to a gearbox of the outer side of one gear. The clockwise rotation and anticlockwise rotation of the motor are controlled to drive the scraping knife to move along the cell panel in a reciprocating mode, the spray heads are used for spraying detergent on the cell panel, then scraping is performed through the scraping knife, the structure is simple, automated cleaning is achieved, and the generating capacity of the cell panel is effectively increased.

Owner:吾满江·艾力 +2

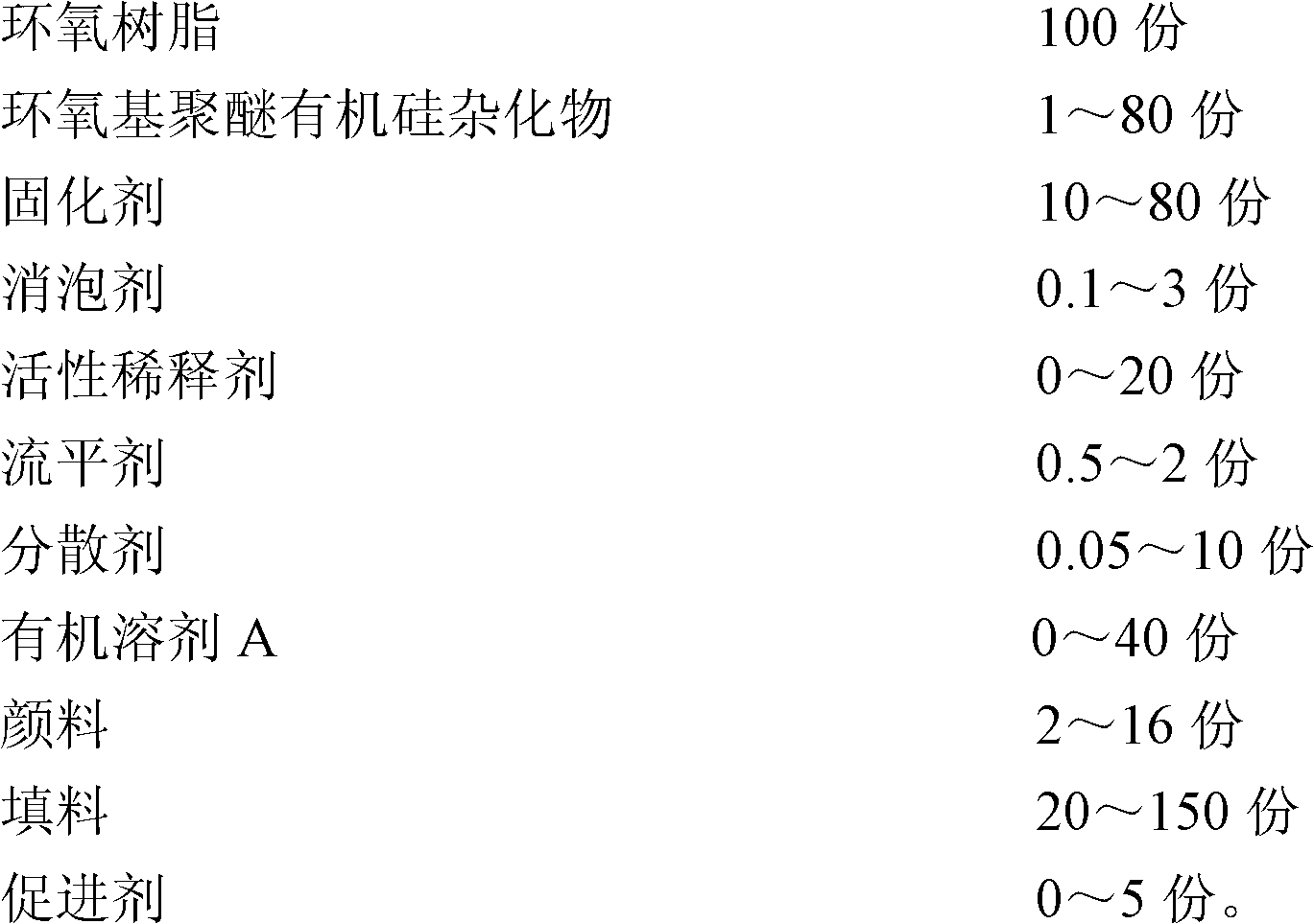

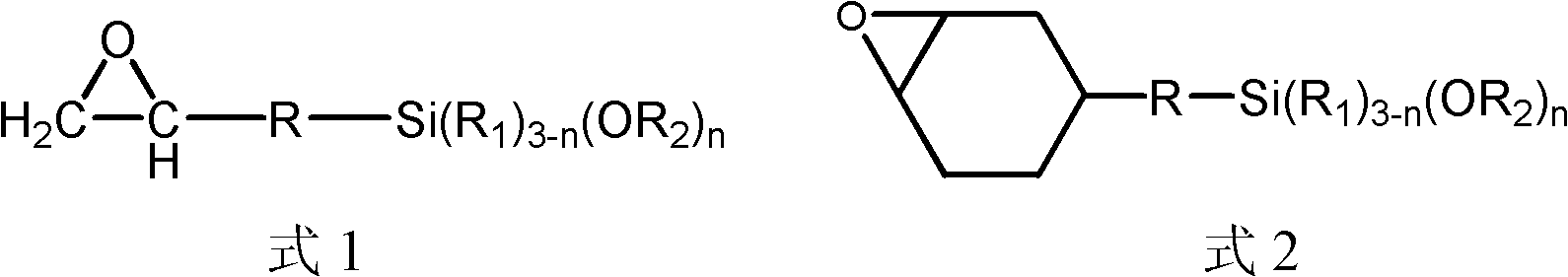

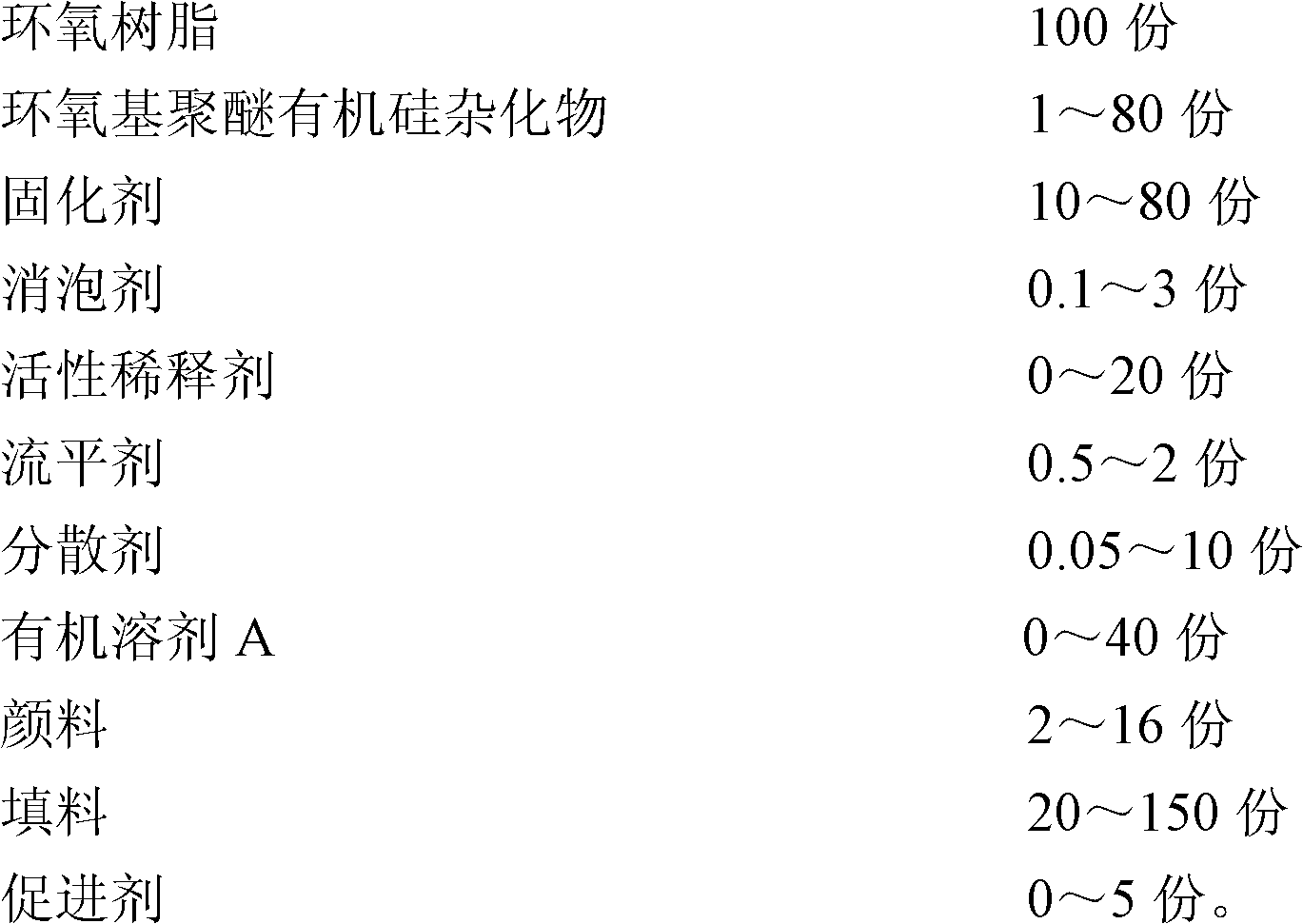

Epoxy floor coating containing epoxy polyether organosilicon hybrid and preparation method thereof

The invention discloses an epoxy floor coating containing epoxy polyether organosilicon hybrid and a preparation method thereof, belonging to the field of building materials. According to the method, the epoxy polyether organosilicon hybrid is prepared through hydrolytic polycondensation, and then 100 parts of an epoxy resin, 10 to 80 parts of a curing agent, 1 part to 80 parts of the epoxy polyether organosilicon hybrid, 0.1 part to 3 parts of an antifoaming agent, 0 to 20 parts of an active diluent, 0.5 part to 2 parts of a leveling agent, 0.05 part to 10 parts of a dispersant, 0 to 40 parts of an organic solvent, 2 to 16 parts of pigments, 20 to 150 parts of a filling material and 0 to 5 parts of a promoter are uniformly mixed so as to obtain the epoxy floor coating. Through modification by the epoxy polyether organosilicon hybrid, the epoxy floor coating provided in the invention has the following advantages compared to conventional epoxy floor coatings: a floor coated by the epoxy floor coating has a high hardness and good wear resistance, stain resistance and heat resistance; the preparation method has the advantages of a simple preparation process, easily available raw materials and convenient implementation, which enables production cost to be reduced and strong practicality to be obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Housing for electronic device and method for manufacturing the same

InactiveUS20120295045A1Great metallic lusterIncreasing the thicknessLamination ancillary operationsSynthetic resin layered productsPlastic materialsOptoelectronics

A method of manufacturing a housing includes steps of providing a transparent film including a first surface and an opposing second surface. Forming a patterned layer on the first surface of the transparent film, forming a metallic film layer on the first surface of the transparent film to cover the patterned layer, applying an adhesive material on the metallic film. Then placing the transparent film in the mold, the second surface of the transparent film attached to the inner molding surface of the mold. And at last injecting plastic material into the mold to form a plastic base adhered with the transparent film. The housing can have both predetermined patterns and metallic luster.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

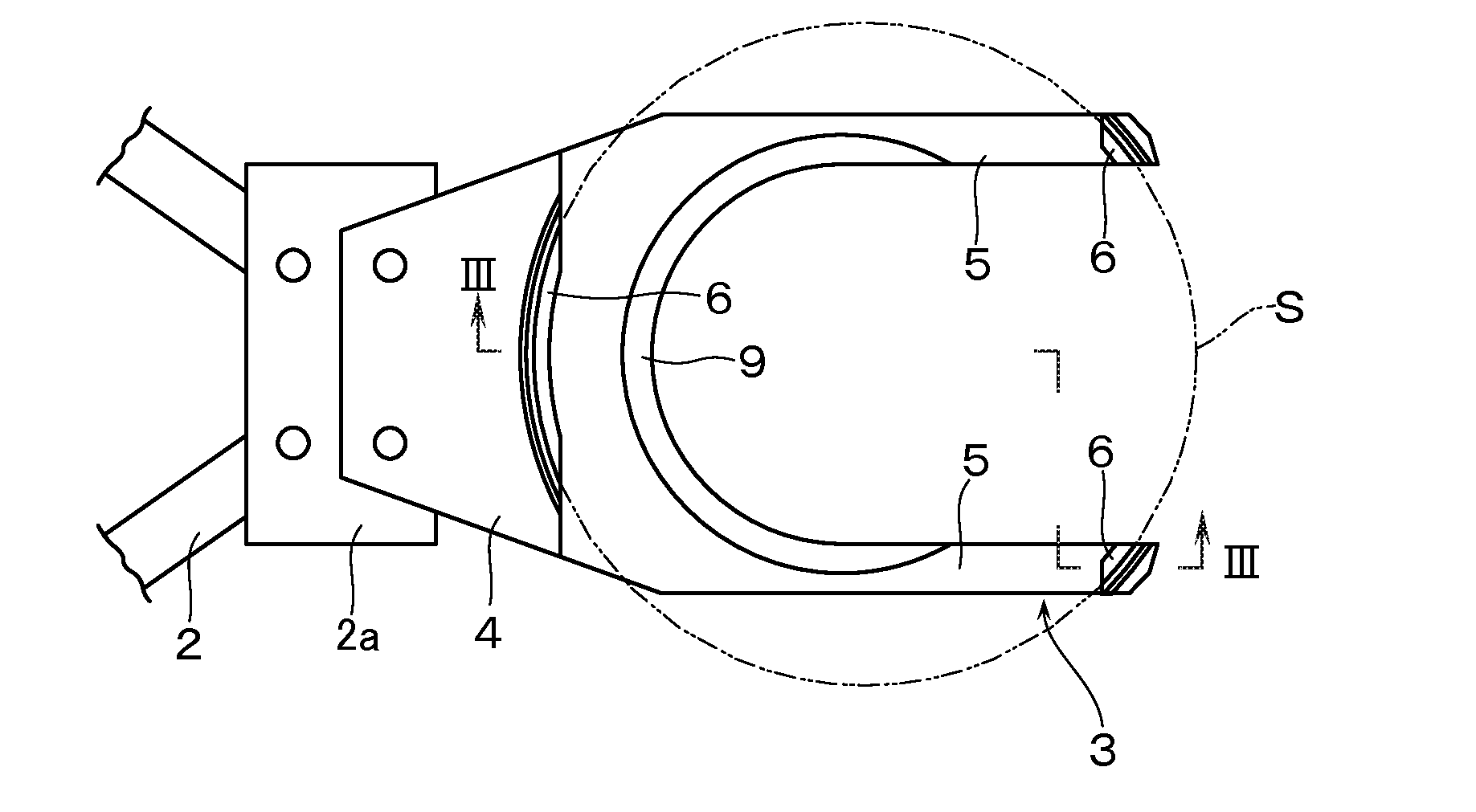

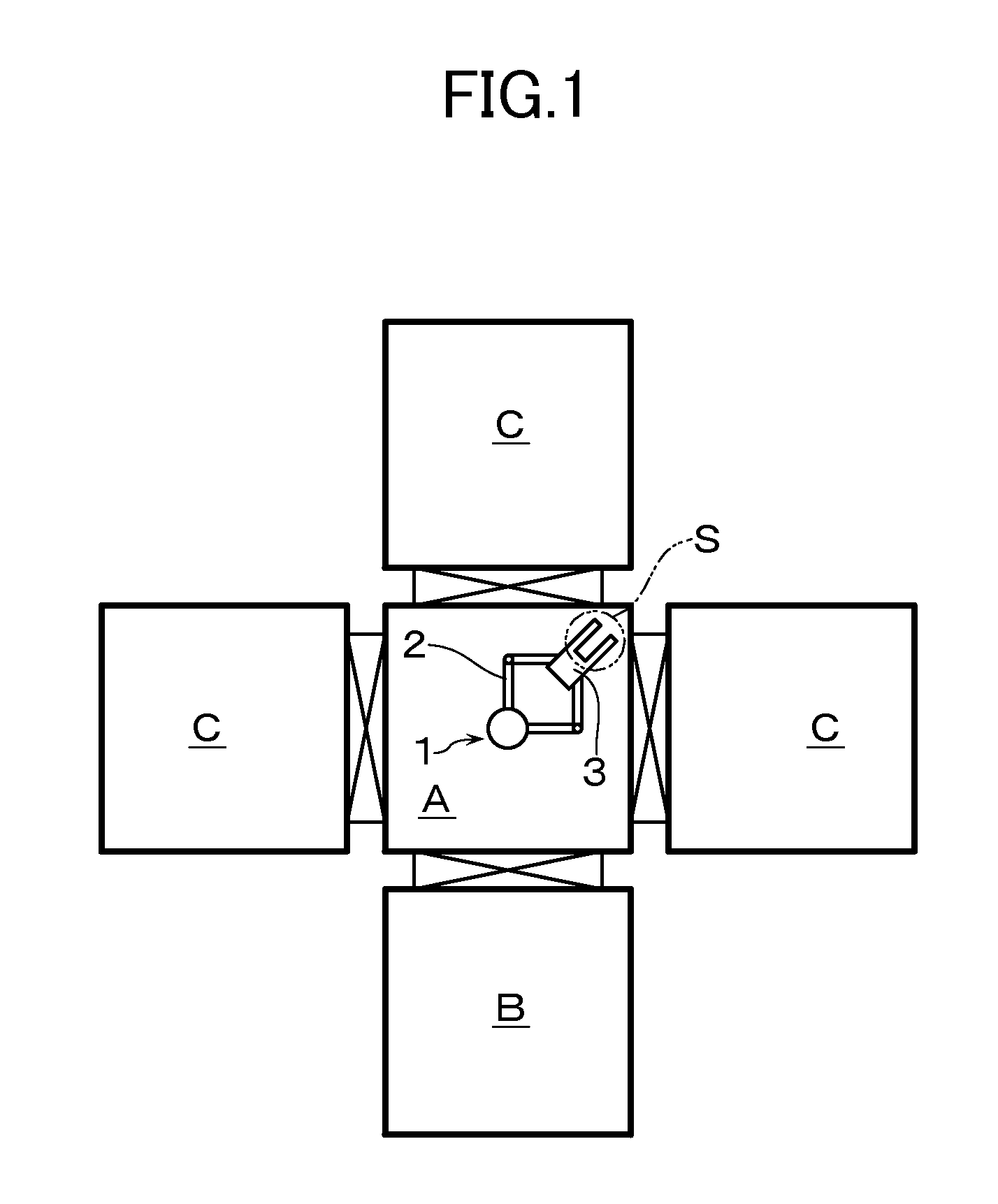

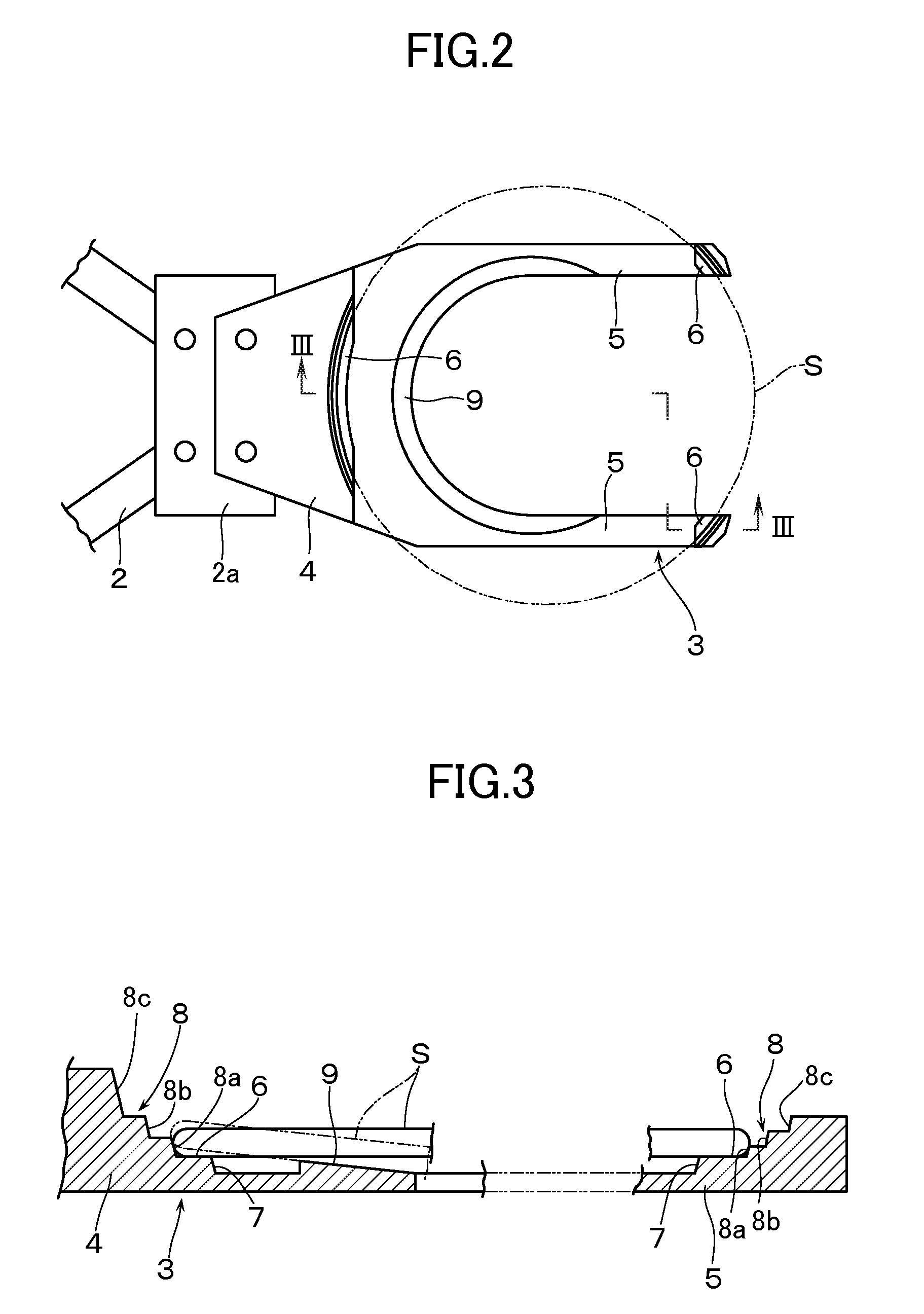

Robot hand for substrate transfer

ActiveUS20120049555A1Avoid position deviationSuppress position deviationProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingRobot handEngineering

There is provided a robot hand for substrate transfer in which the robot hand is so arranged that, even in case a substrate (S) gives rise to warping, the substrate (S) can be stably supported. On an upper surface of the robot hand there is formed a first seating surface on which is seated a lower-surface peripheral portion of the substrate (S) and, on a periphery thereof, there is formed an upwardly extended step. The step is provided with a plurality of stair-shaped stages. On an upper surface of the robot hand inwardly away from the first seating surface there is provided a second seating surface which is inclined downward toward the center of the substrate (S) such that a lower surface of the substrate (S) is seated on the second seating surface when the substrate (S) is warped downward into a concave shape.

Owner:ULVAC INC

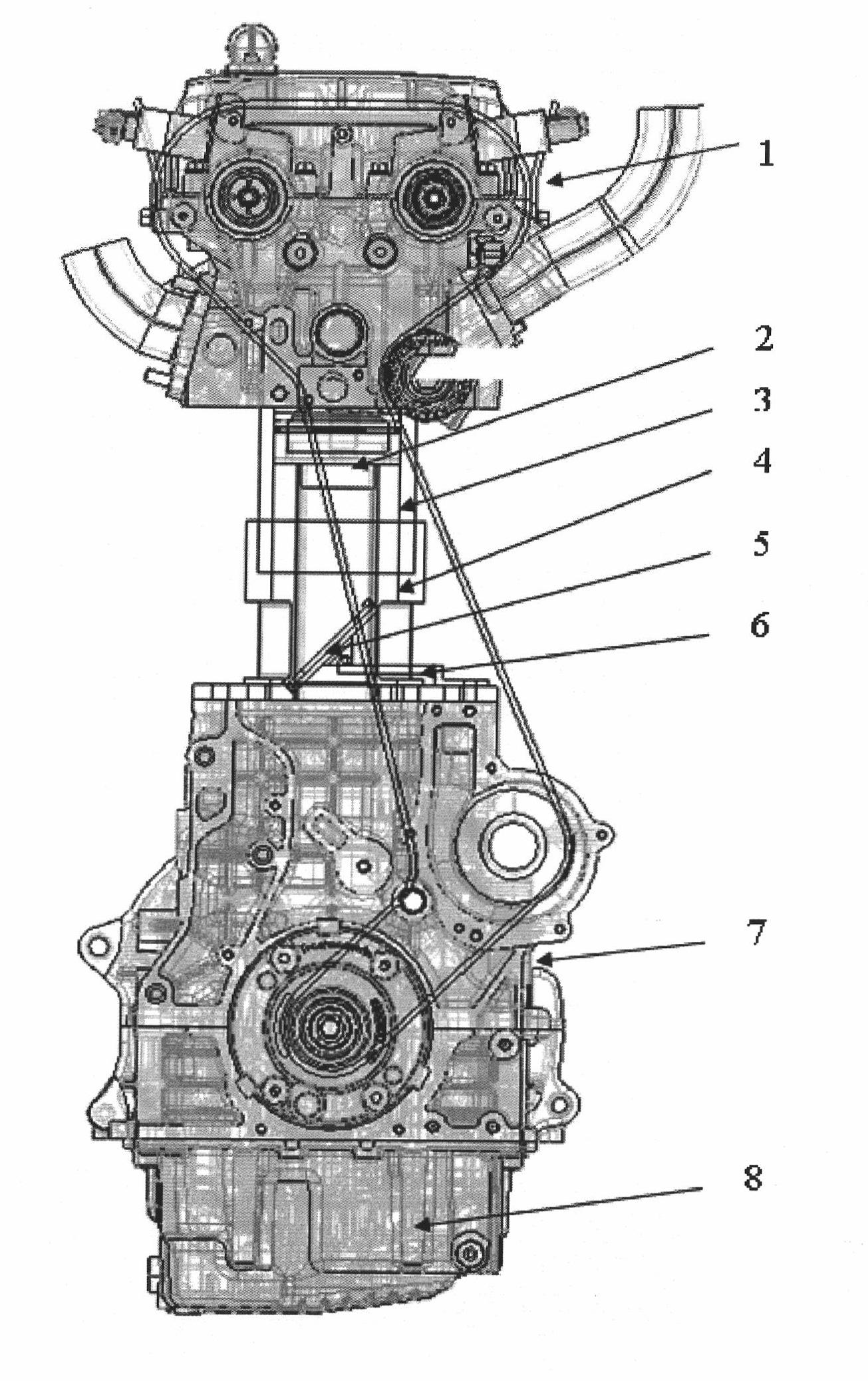

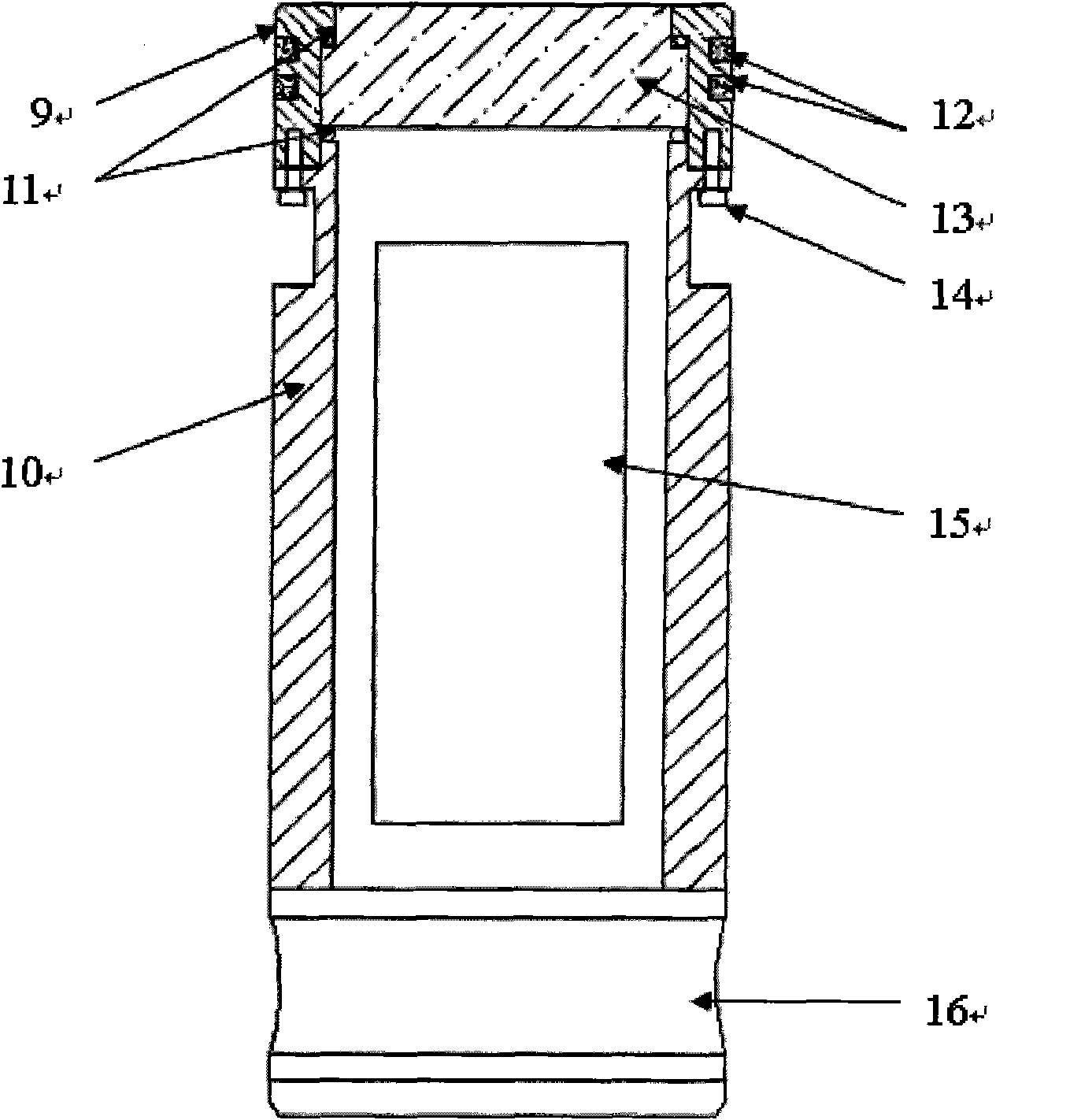

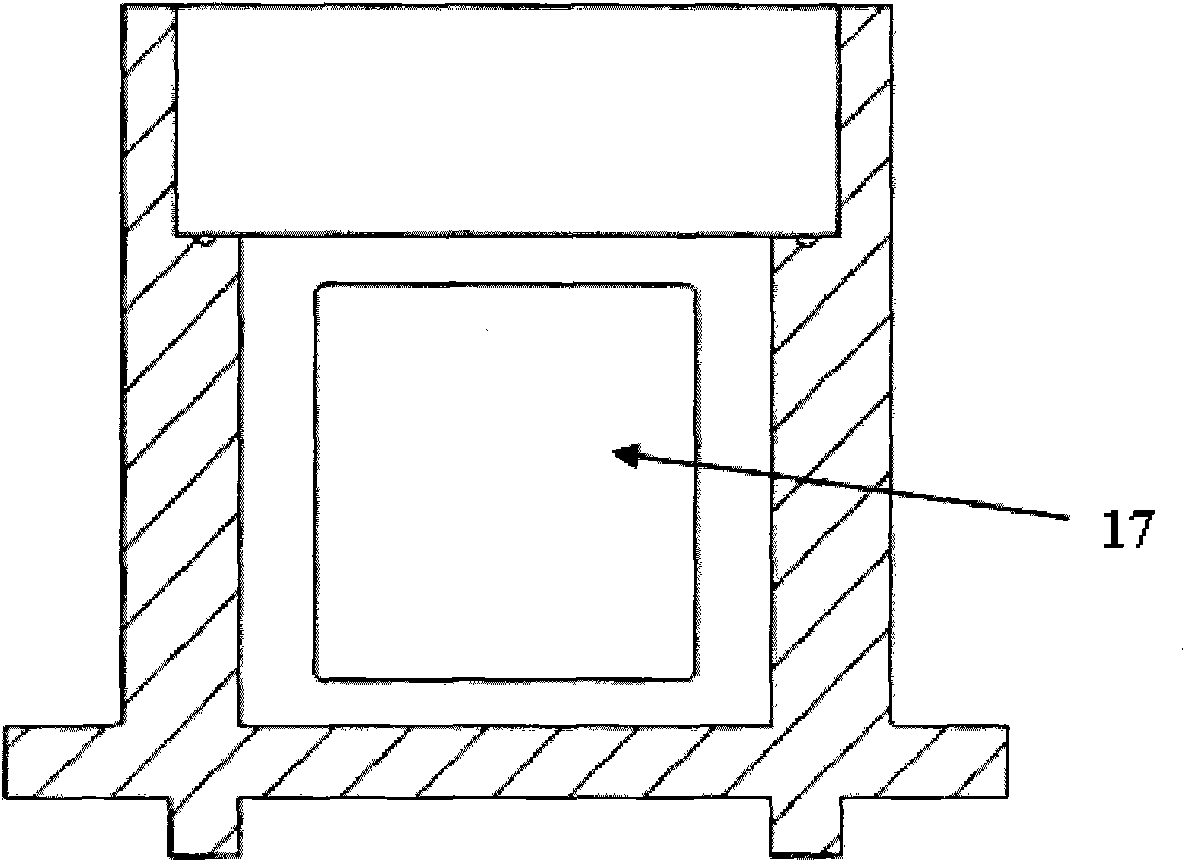

Optical engine

The invention relates to an optical engine which comprises a cylinder cover, an original cylinder casing and a piston; a transparent quartz glass cylinder casing is arranged between the cylinder cover and the original cylinder casing; the piston is an extended piston; the top of the extended piston is provided with a round window; transparent quartz glass is arranged in the round window; the length of the transparent quartz glass cylinder casing is more than the sum of the stroke of the engine and the distance between a ring at the bottommost of the piston and the top surface of the piston; and an engine cylinder body, the original cylinder casing, the cylinder cover and the transparent quartz glass cylinder casing are fixedly connected by bolts.

Owner:CHERY AUTOMOBILE CO LTD

CMP polishing compound and polishing method

ActiveUS7838482B2Easy to handleEasy to scratchOrganic detergent compounding agentsOther chemical processesSlurrySilicon oxide

The present invention relates to a CMP polishing slurry, comprising cerium oxide particles, a dispersing agent, a water-soluble polymer and water, wherein the water-soluble polymer is a compound having a skeleton of any one of an N-mono-substituted product and an N,N-di-substituted product of any one selected from the group consisting of acrylamide, methacrylamide and α-substituted products thereof. The amount of the water-soluble polymer is preferably in the range of 0.01 part or more by weight and 10 parts or less by weight for 100 parts by weight of the polishing slurry. Thus it is possible to provide a polishing slurry and a polishing method which make it possible to polish a film made of silicon oxide or the like effectively and rapidly and further control the process therefor easily in CMP technique for flattening an interlayer insulating film, a BPSG film, an insulator film for shallow trench isolation, and other films.

Owner:RESONAC CORP

Chemical mechanical polishing slurry, cmp process and electronic device process

InactiveUS20070270085A1Increase polishing speedSufficient polishing selectivityPigmenting treatmentOther chemical processesNegative potentialProcess capability

To provide a slurry for Chemical Mechanical Polishing, a Chemical Mechanical Polishing method using said slurry, and a method of producing electronic devices using said method that makes it possible to achieve a low scratch process capability in processing surfaces such as SiO2 film surfaces and the like and also to enable speed polishing to attain a high processing efficiency.Slurry for Chemical Mechanical Polishing characterized in comprising abrasive grains and water, wherein said abrasive grains are composite particles coated with ceria particles consisting of organic host particles and ceria particles, zeta potential of said composite particles being a negative potential, the organic host particles constituting the composite particles coated with ceria particles are organic host particles to which carboxyl groups and sulfonyl groups are introduced; the slurry is added with panarization additive; and the planarization additive is poly(methyl)acrylic acid ammonium salt.

Owner:HITACHI CHEM CO LTD

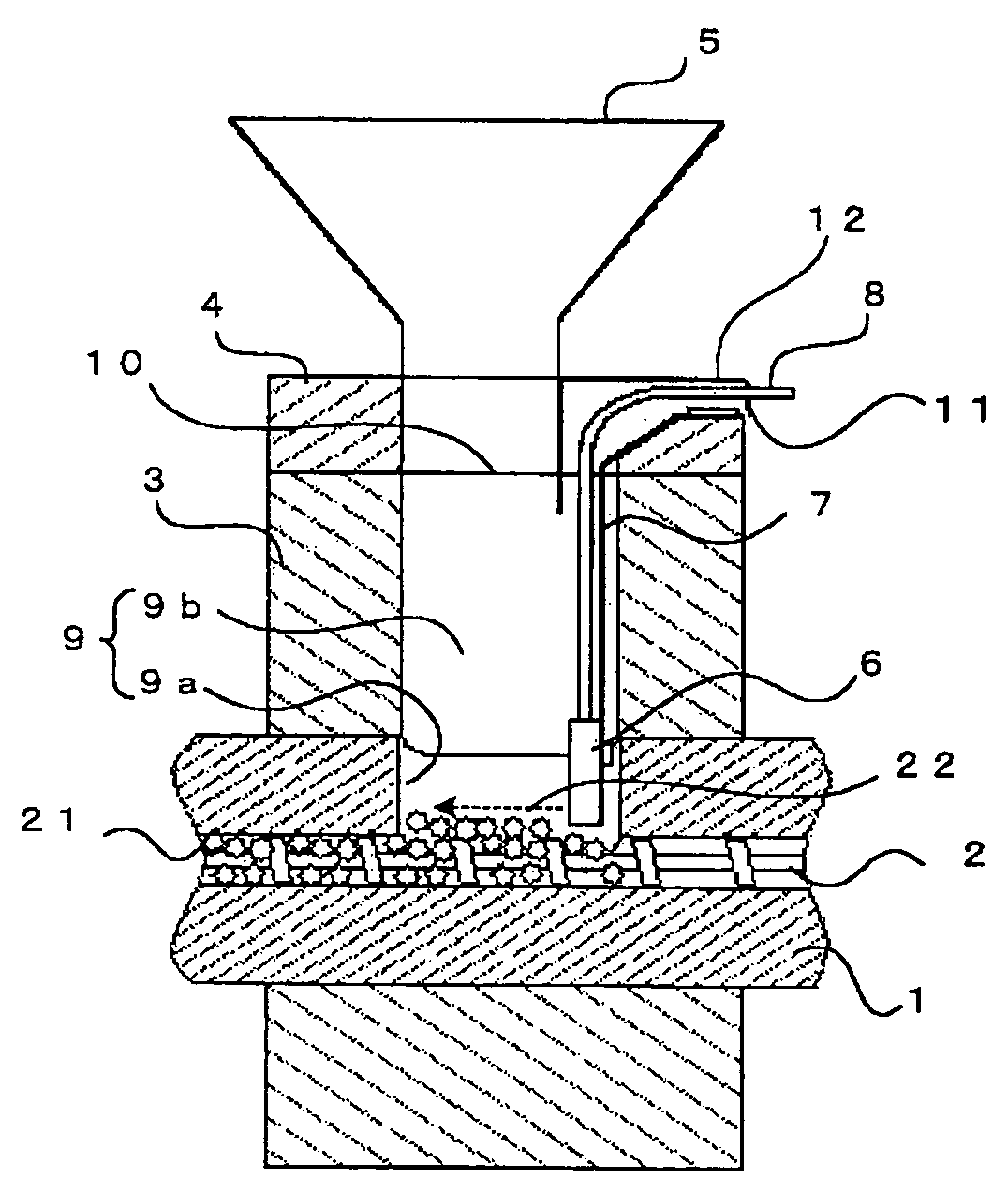

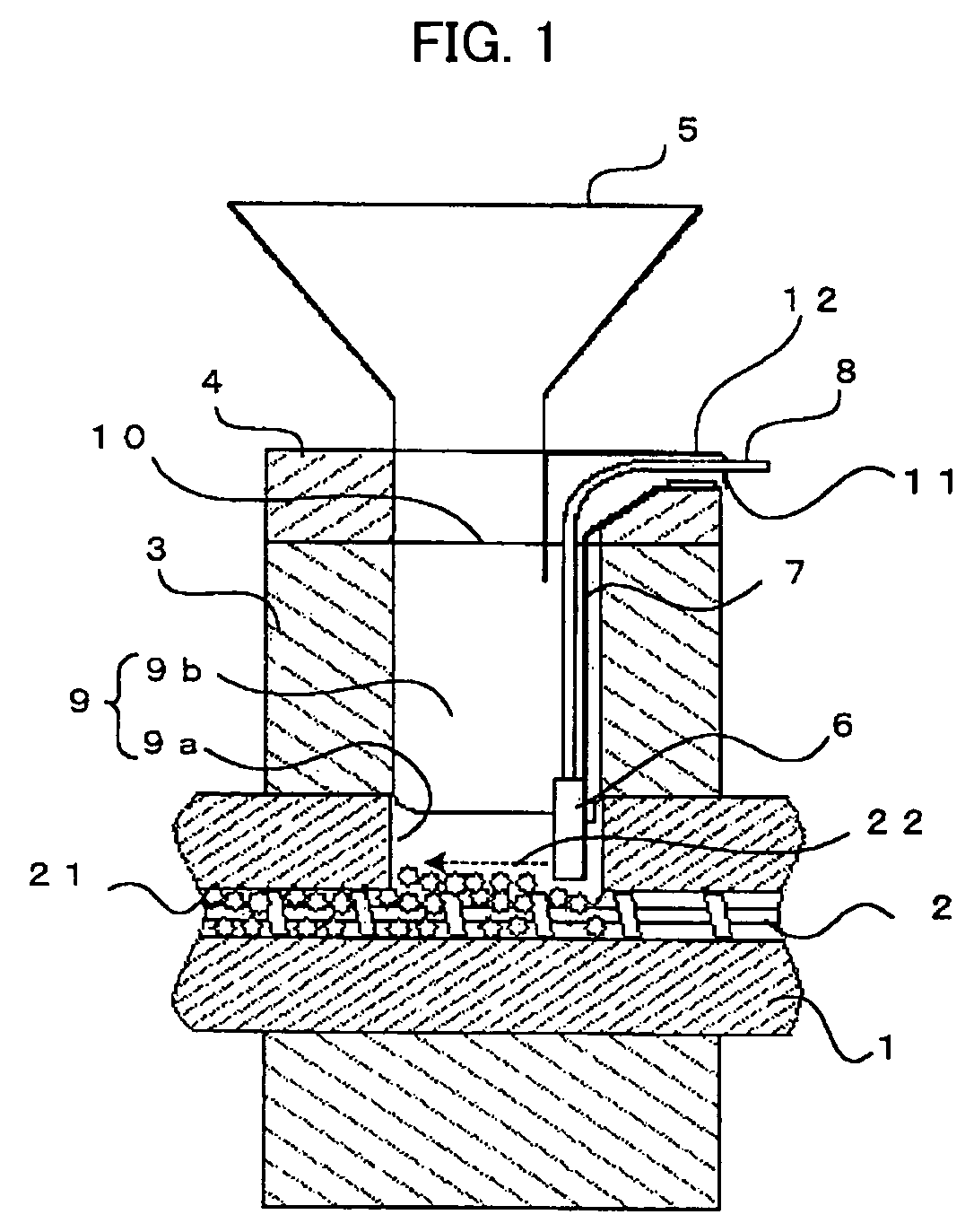

Injection molding machine

InactiveUS7431583B2Simple structureStructural economyAuxillary shaping apparatusDough mixing/kneading machinesEngineeringInjection molding machine

The invention provides an injection molding capable of adjusting a detection level with a simple structure and detecting a deposit level of the resin pellets near a plasticizing screw. A cooling jacket is mounted so that a resin supplying hole of the cooling jacket communicates with a resin supplying hole of a heating cylinder. A sensor head mounted on a sensor mounting plate is inserted into the resin supplying hole through a sensor insertion port provided on a hopper plate and a resin inlet and detects the deposit level of the resin pellets deposited in the resin supplying hole. Changing the extent of insertion of the sensor head enables the resin pellets deposit detection level to be changed, and further, enables the deposit level near the outer periphery of the screw to be detected. Setting the sensor detection direction perpendicular to the resin deposit direction enables dirtying of the sensor detection surface by the resin pellets to be reduced, thus enabling erroneous detection readings to be reduced.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com