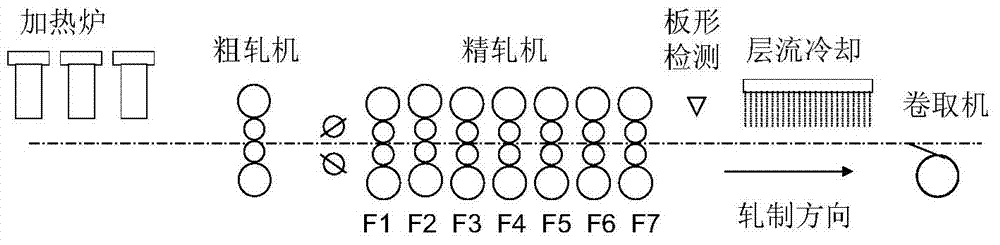

Slight center wave strip-shape control method of hot-rolled strip steel

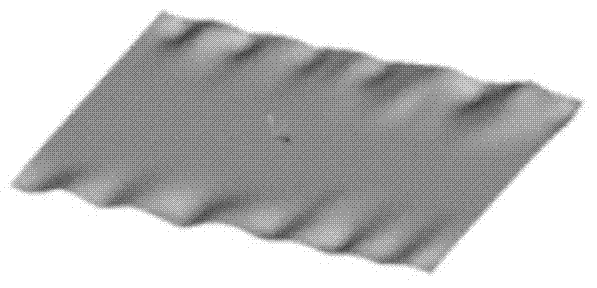

A hot-rolled strip steel and control method technology, applied in the direction of contour control, etc., can solve problems such as residue, affecting hot-rolled production, rolling instability, etc., to improve the problem of strip shape scratches, and improve strip shape quality and thickness The effect of distribution flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

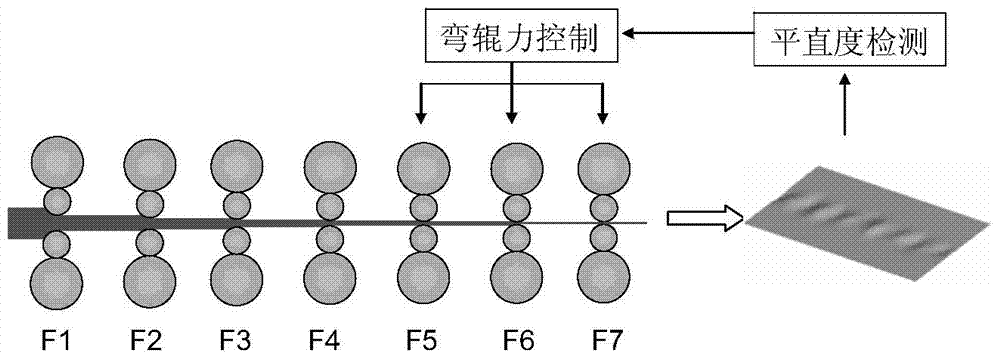

Method used

Image

Examples

Embodiment 1

[0051] For a hot-rolled steel strip product with a specification of 2.3×1250mm, the target micro wave control amount is 0.6%. According to the method in this paper, when there is a certain deviation between the measured micro-medium wave value and the target value, the bending force adjustment of F2-F4 is used to control, so that the measured micro-medium wave reaches the target value. The related control parameter of bending force is α 2 =0.015,α 3 =0.041,α 4 =0.072. The control of the plate shape before and after the implementation of this method is shown in Table 1.

[0052] Table 1 The shape control situation under the old method and the new method

[0053] Test times

Embodiment 2

[0055] For a hot-rolled steel strip product, the specification is 3.0×1250mm, and the target micro wave control amount is 0.8%. According to the method in this paper, when there is a certain deviation between the measured micro-medium wave value and the target value, the bending force adjustment of F2-F4 is used to control, so that the measured micro-medium wave reaches the target value. The related control parameter of bending force is α 2 =0.017, α 3 =0.049,α 4 =0.087. The control of the plate shape before and after the implementation of this method is shown in Table 2.

[0056] Table 2 The shape control situation under the old method and the new method

[0057] Test times

Embodiment 3

[0059] For a hot-rolled strip product, the specification is 4.0×1460mm, and the target micro wave control amount is 1.1%. According to the method in this paper, when there is a certain deviation between the measured micro-medium wave value and the target value, the bending force adjustment of F2-F4 is used to control, so that the measured micro-medium wave reaches the target value. The related control parameter of bending force is α 2 =0.022,α 3 =0.050,α 4 =0.093. The control of the plate shape before and after the implementation of this method is shown in Table 3.

[0060] Table 3 The shape control situation under the old method and the new method

[0061] Test times

Number of rolls produced

Number of rolls with bad shape

defective rate

Before implementation

47

16

34.0%

after implementation

61

4

6.6%

[0062] The content to be protected by the present invention is as follows:

[0063] (1) The micro-medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com