Optical engine

An optical engine, engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as uneven motion, incomplete observation, limited observation, etc., to maintain consistency, avoid adverse effects, and reduce temperature Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

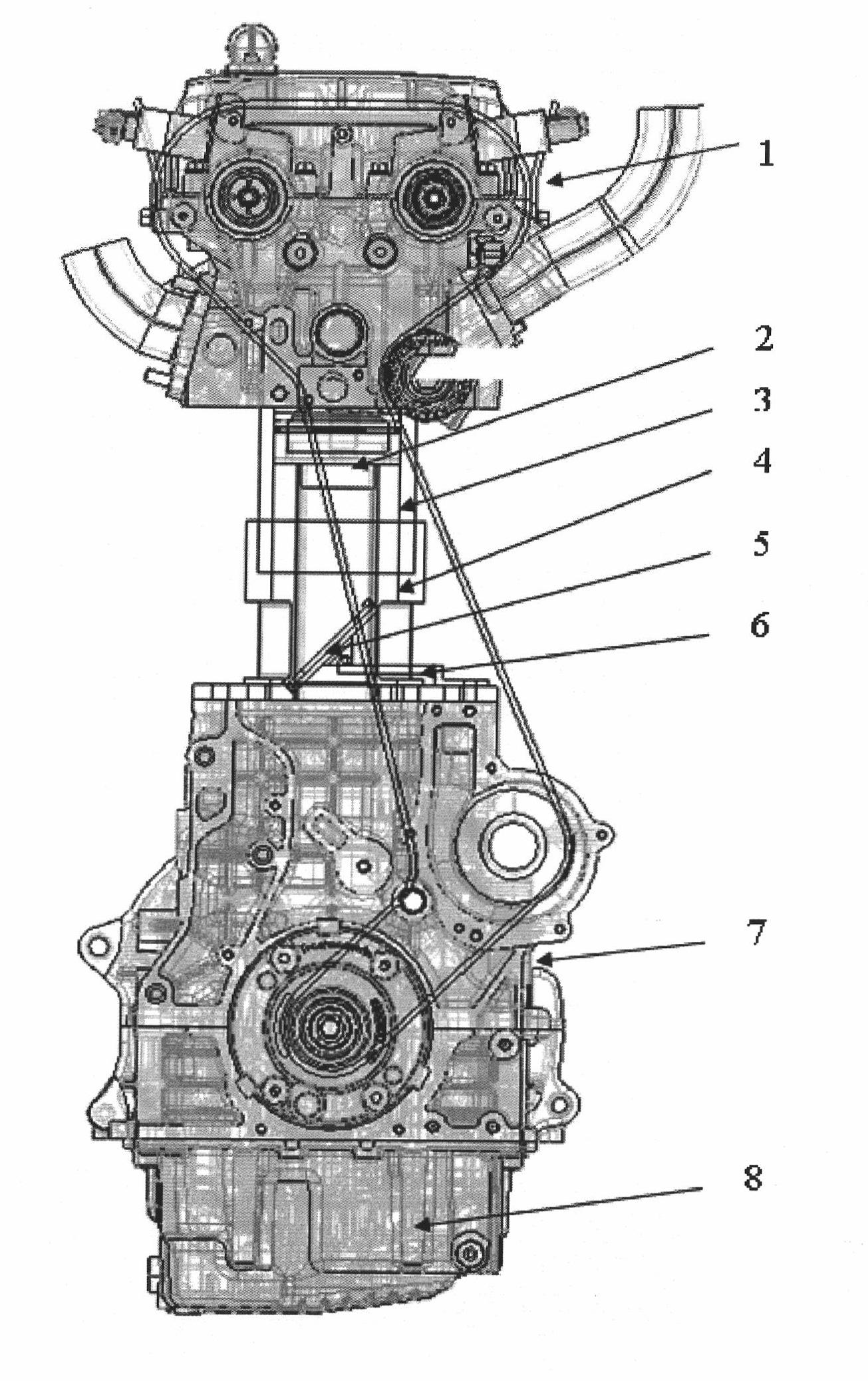

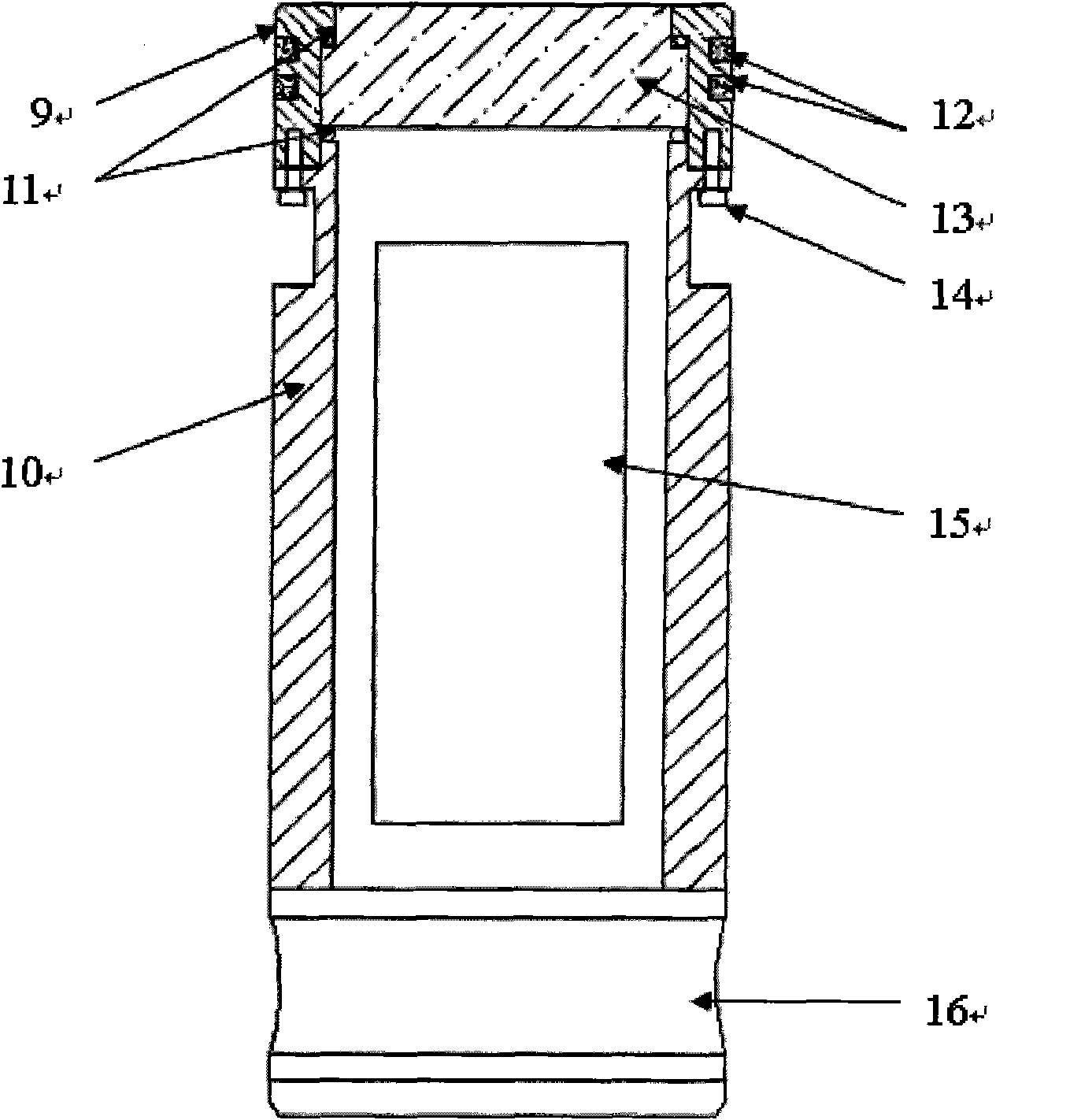

[0022] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

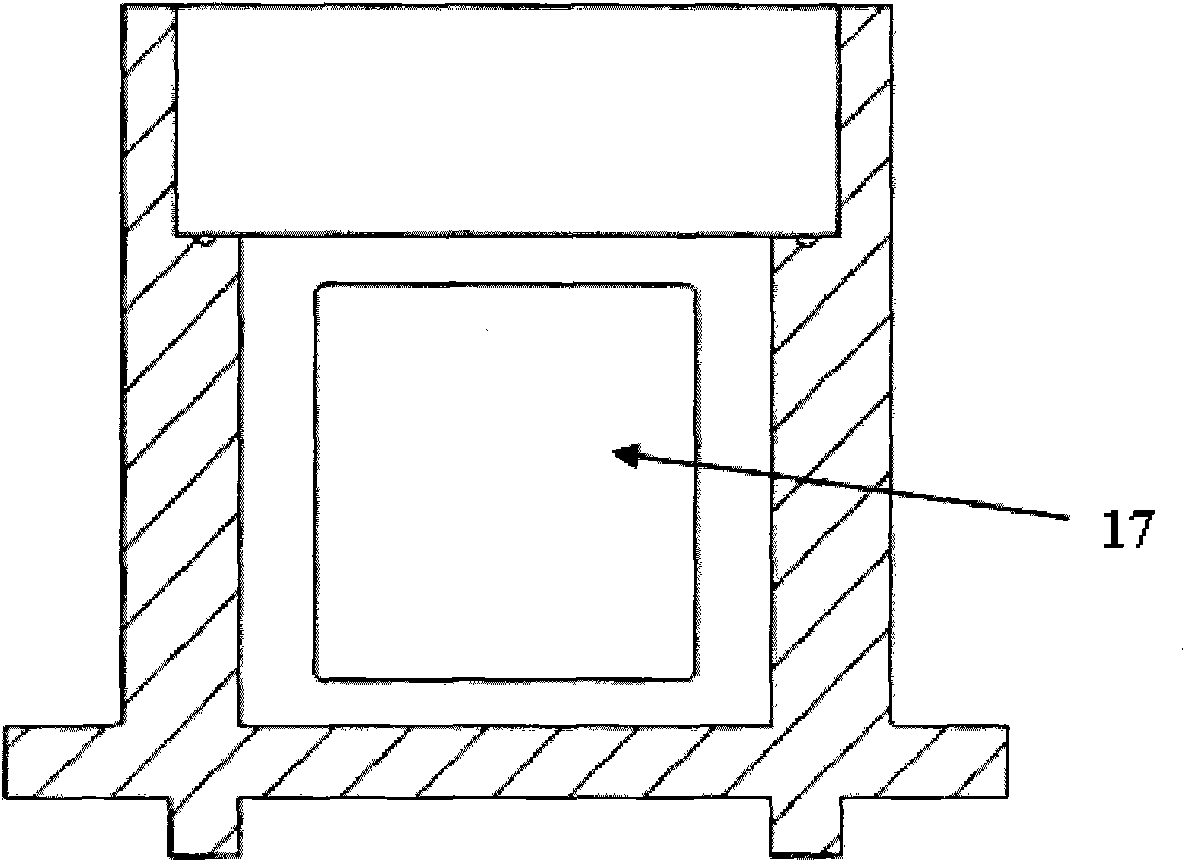

[0023] In the preferred embodiment, parts such as the original engine cylinder head, cylinder block, crankcase system and connecting rod remain unchanged, the piston is lengthened, and the head of the extended piston is equipped with transparent quartz glass, and the side of the extended piston has a window, and the window The height is greater than the stroke of the engine (to prevent the piston from bumping into the reflector when moving up and down), the window is equipped with a reflector, and a transparent quartz glass cylinder liner is added between the cylinder block and the cylinder head. Through the reflector at the bottom of the piston and the transparent cylinder liner, it can be detected The flow field, spray and the formation of mixed gas in the cylinder; the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com