Patents

Literature

153results about How to "Improve application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

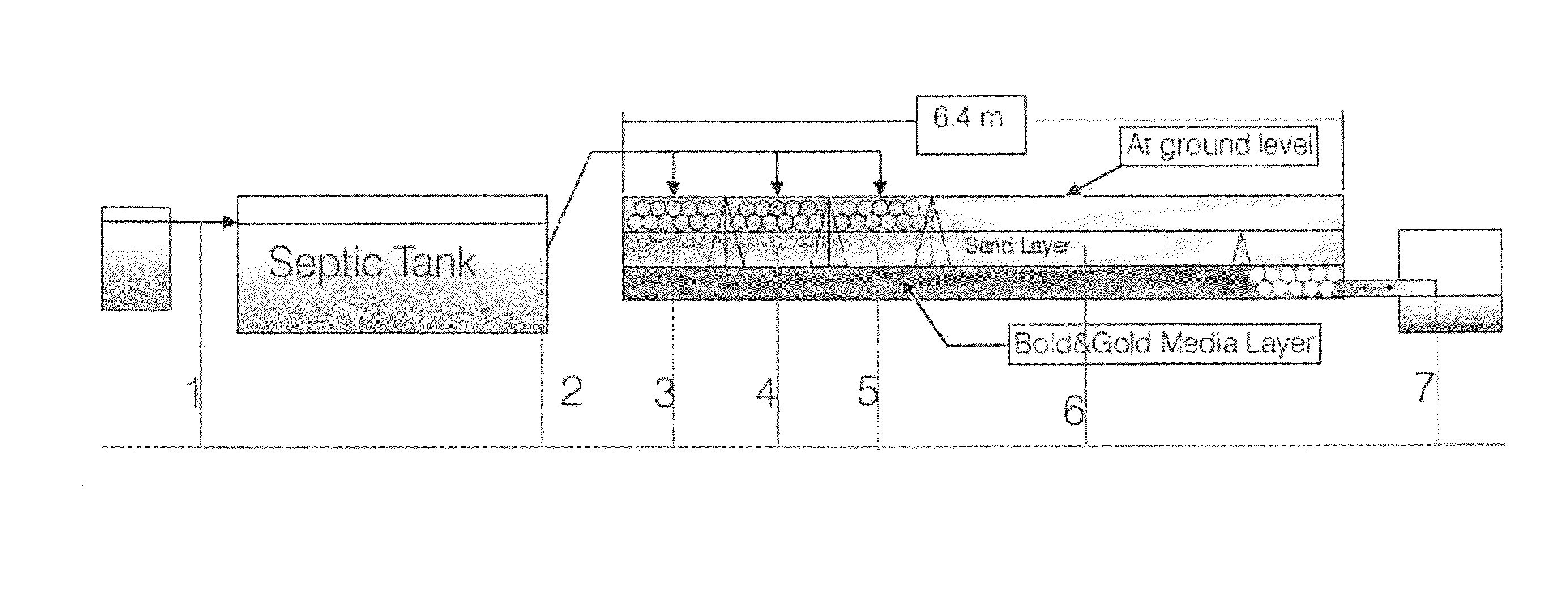

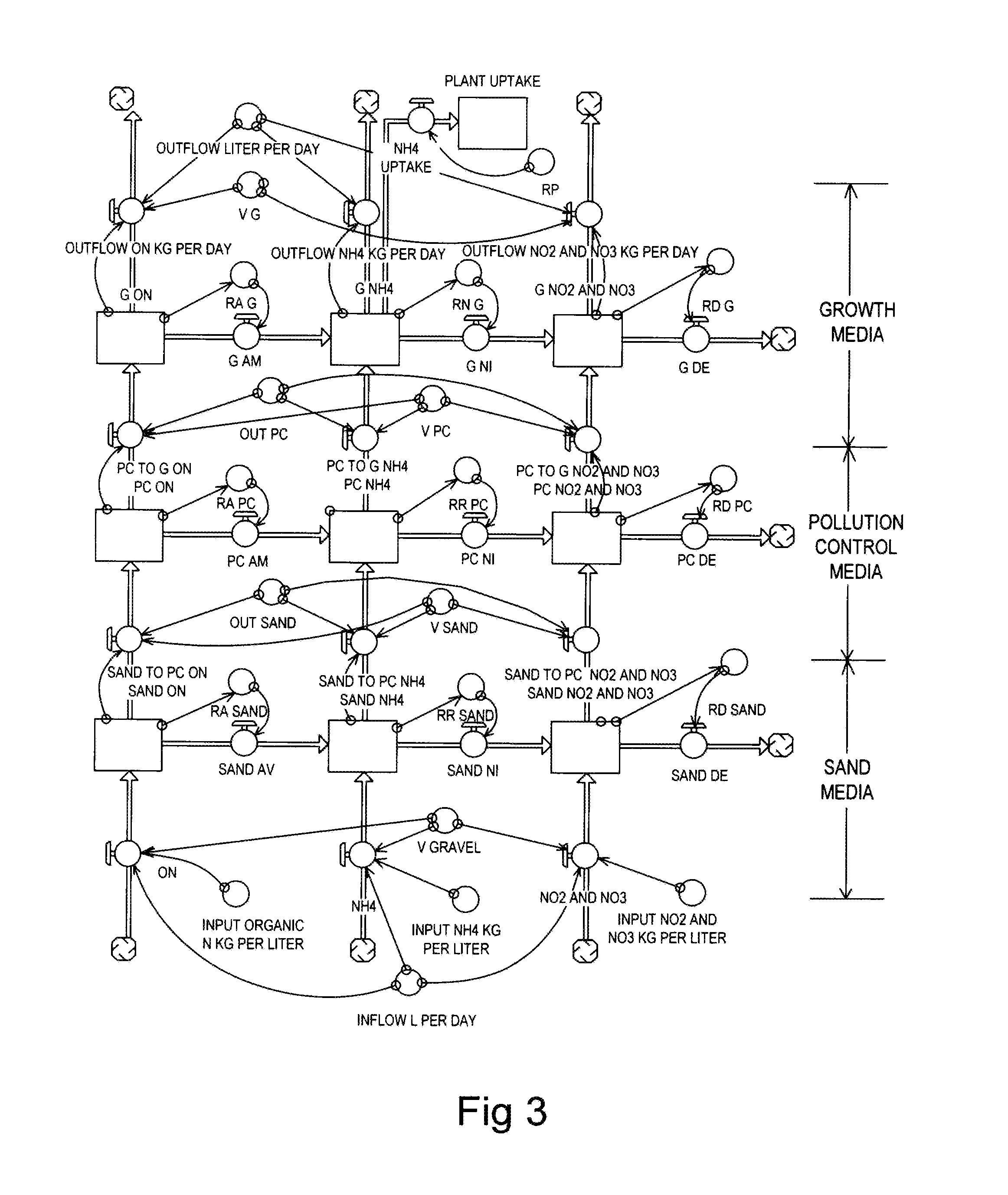

Subsurface upflow wetland system for nutrient and pathogen removal in wastewater treatment systems

ActiveUS8252182B1Low maintenance burdenHigh benefit cost ratioWater cleaningContaminated soil reclamationFecesTotal suspended solids

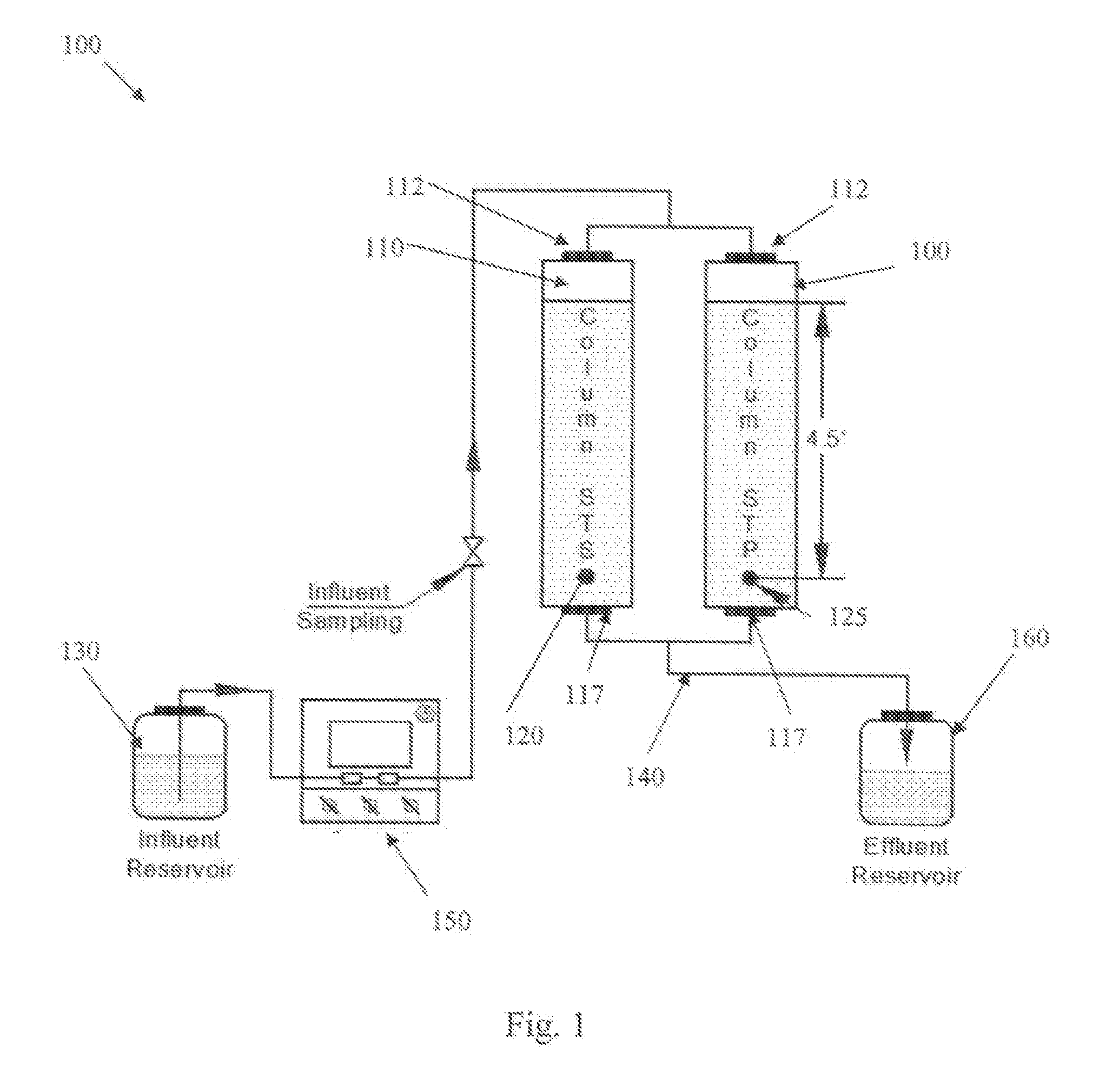

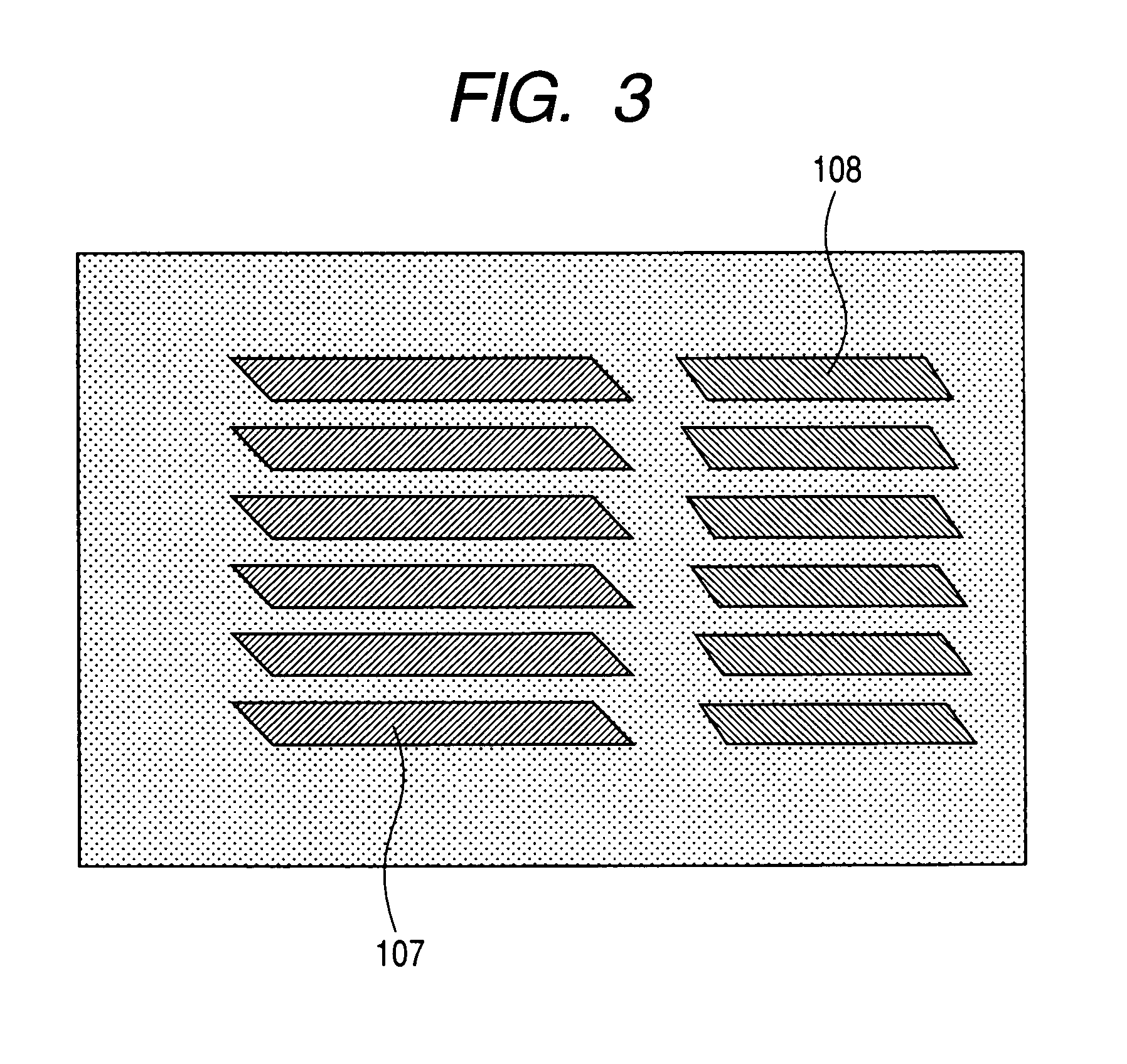

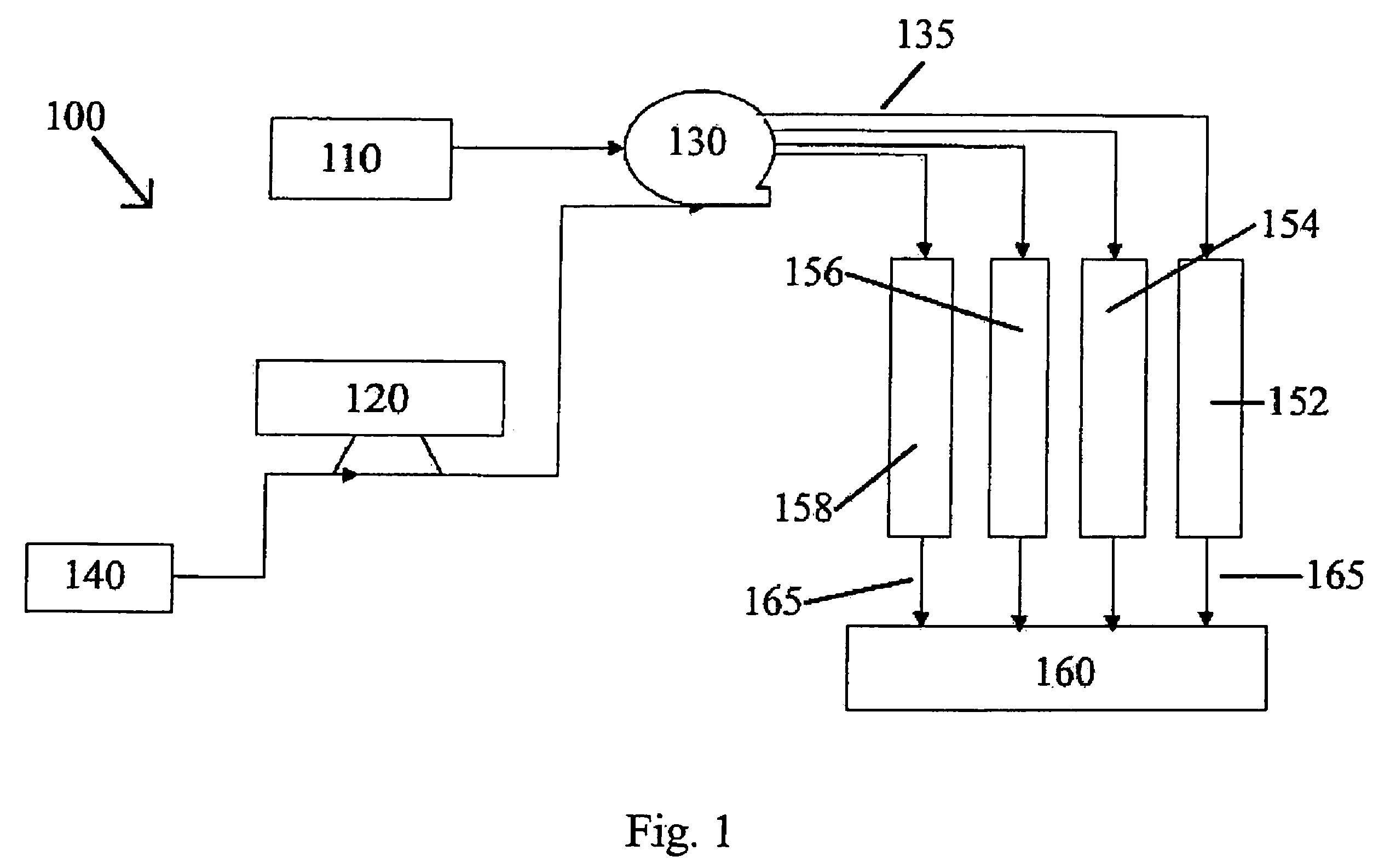

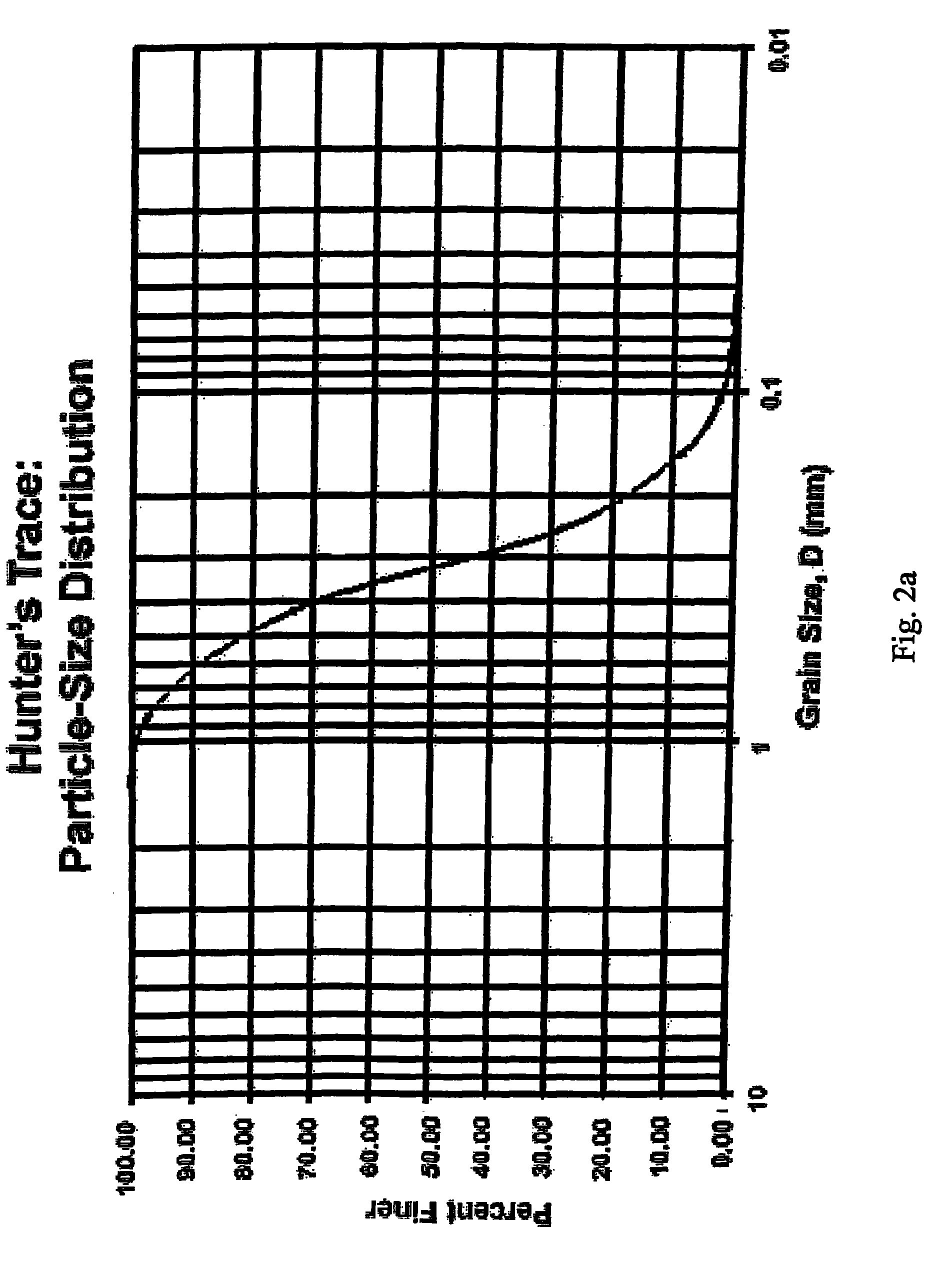

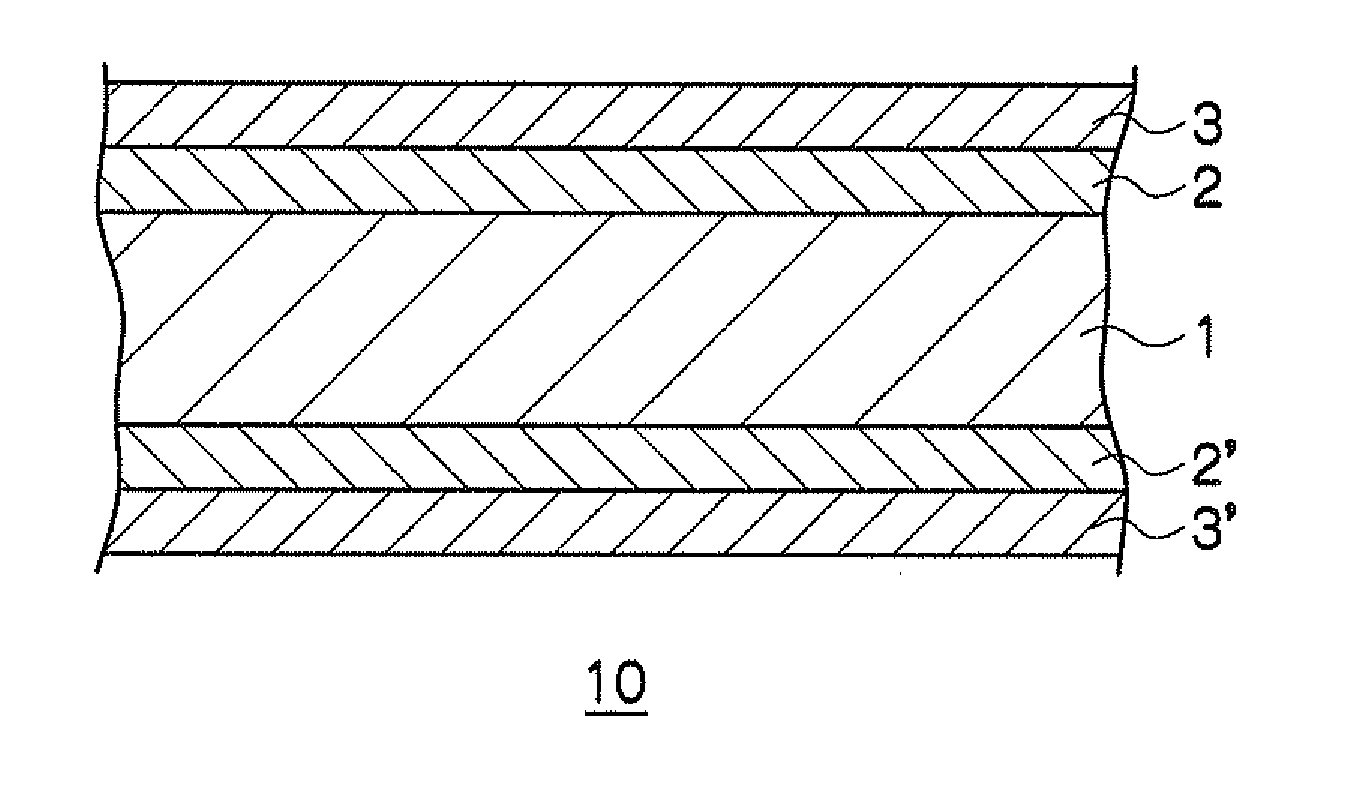

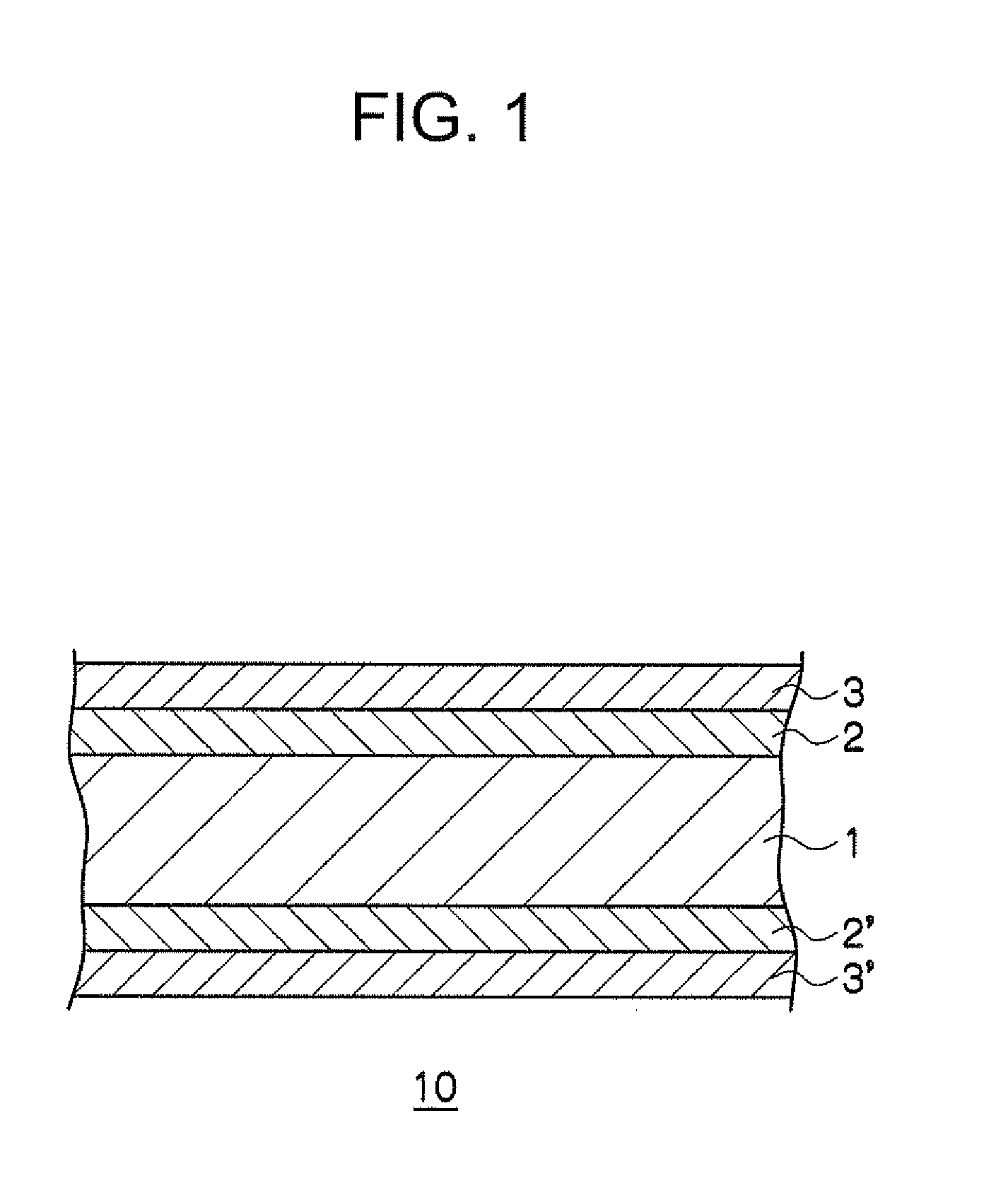

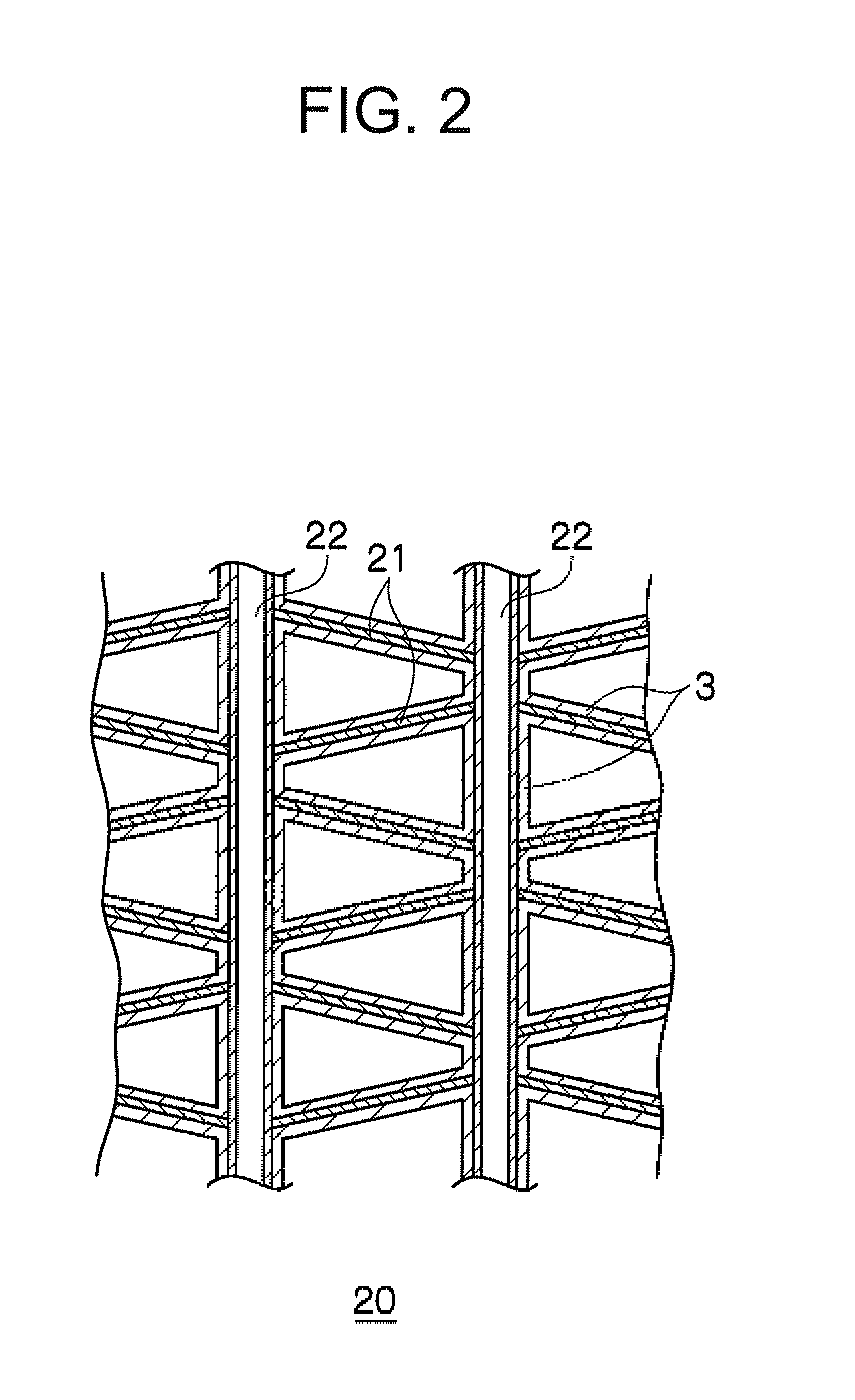

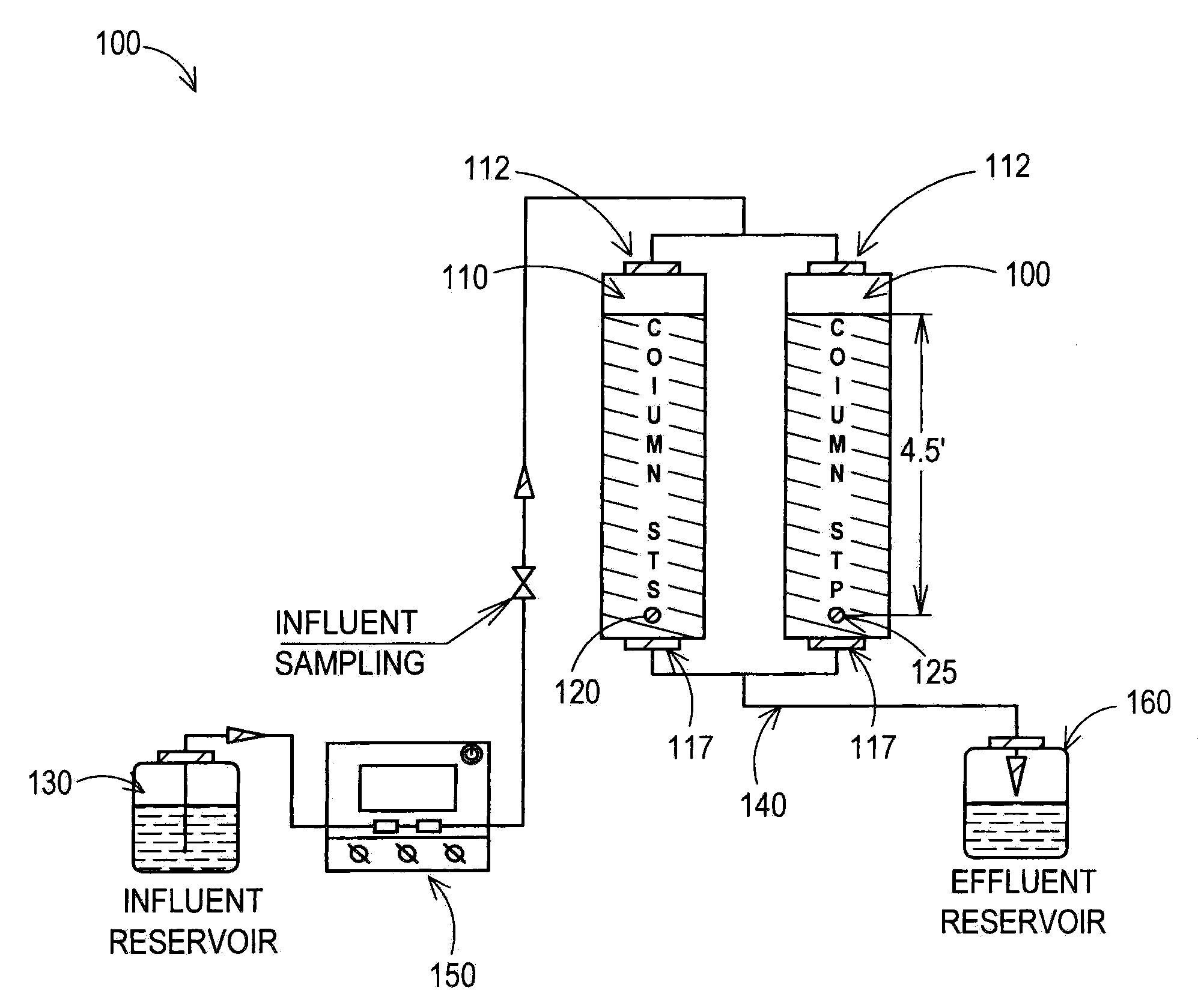

Methods and systems for a subsurface upflow wetland for wastewater treatment that includes a series of parallel treatment cells, each cell including from bottom to top, a layer of gravel, a layer of sand over the gravel to remove pathogens from a septic effluent, a pollution control medium above the sand layer to remove nutrients, total suspended solid, and biochemical oxygen demand and a growth media mixture layered on top of the pollution control media to grow plants, and a gravity distribution system to distribute effluent to the series of parallel treatment cells. The pollution control medium includes at least one recycled material and at least one naturally occurring material. In an embodiment it includes recycled tire crumb, sand and limestone or recycled tire crumb, compost, sand and limestone.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

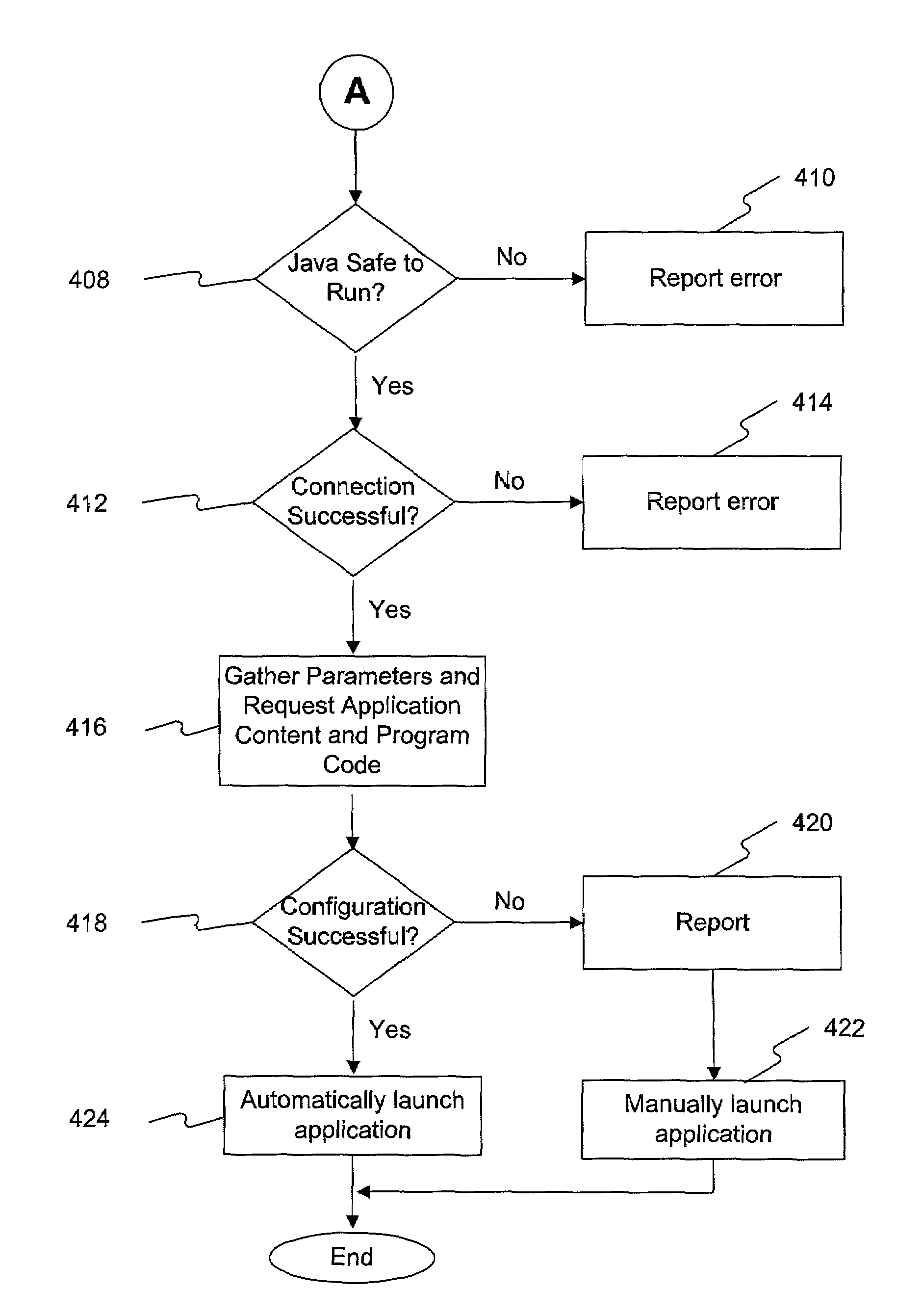

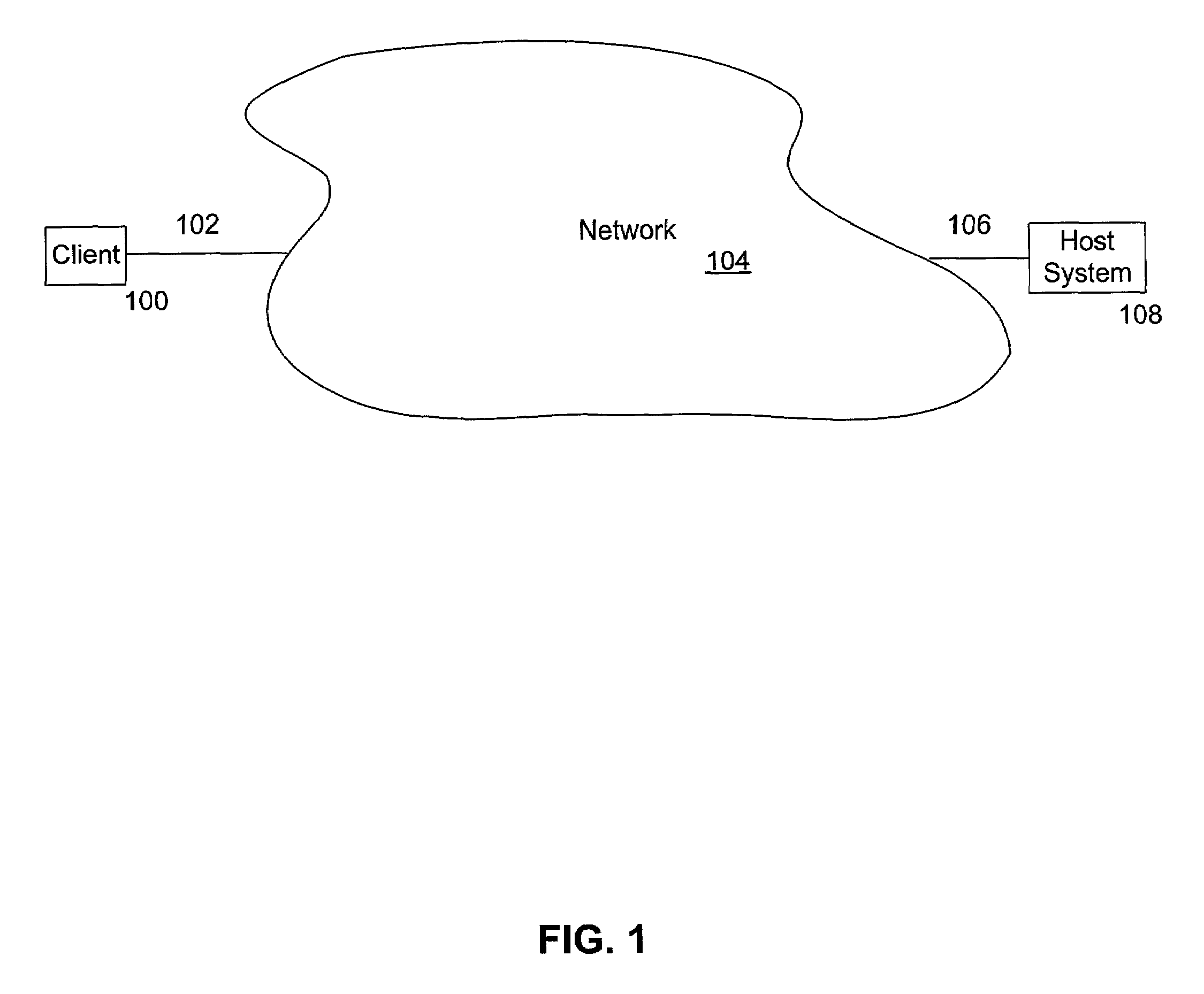

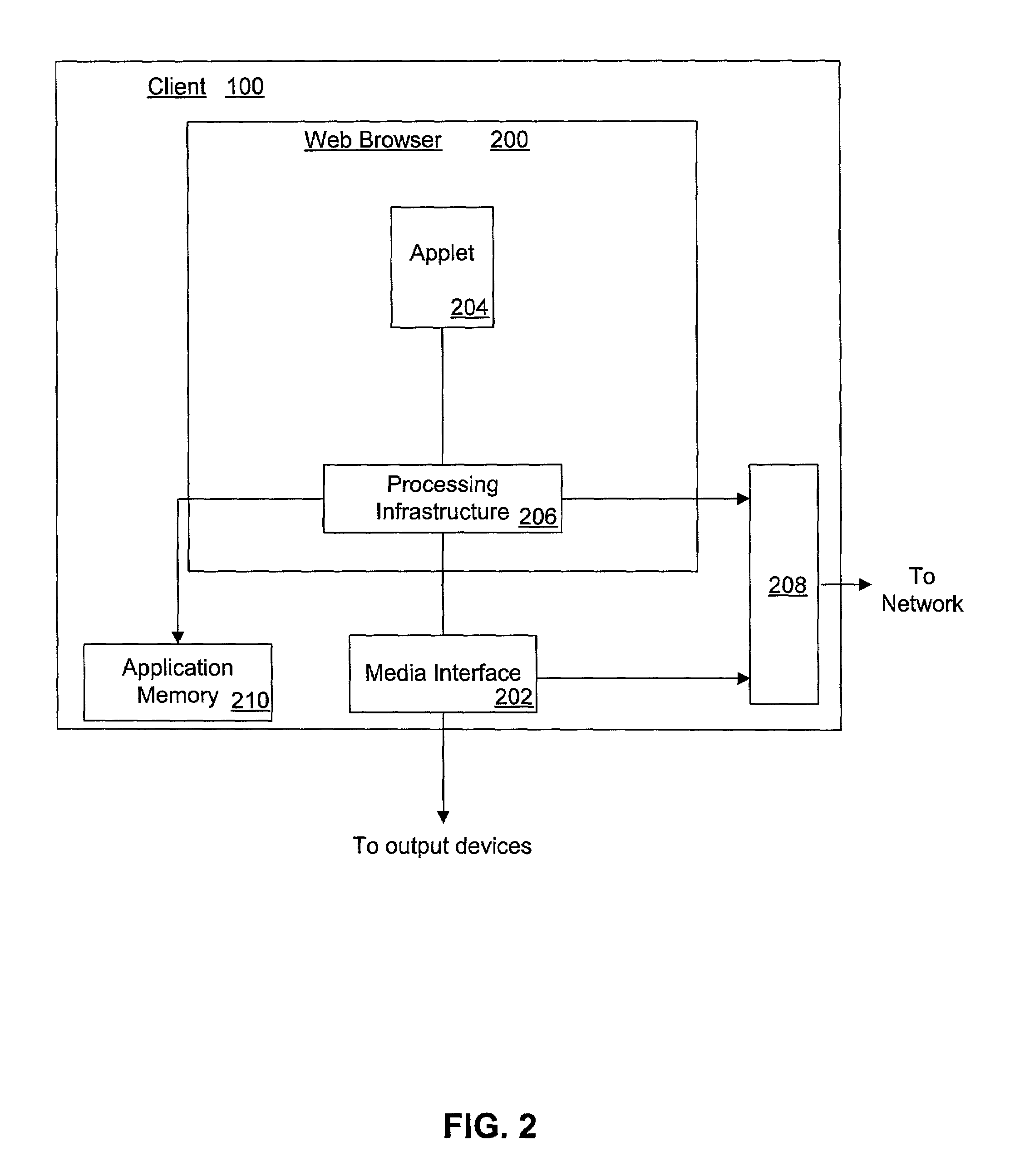

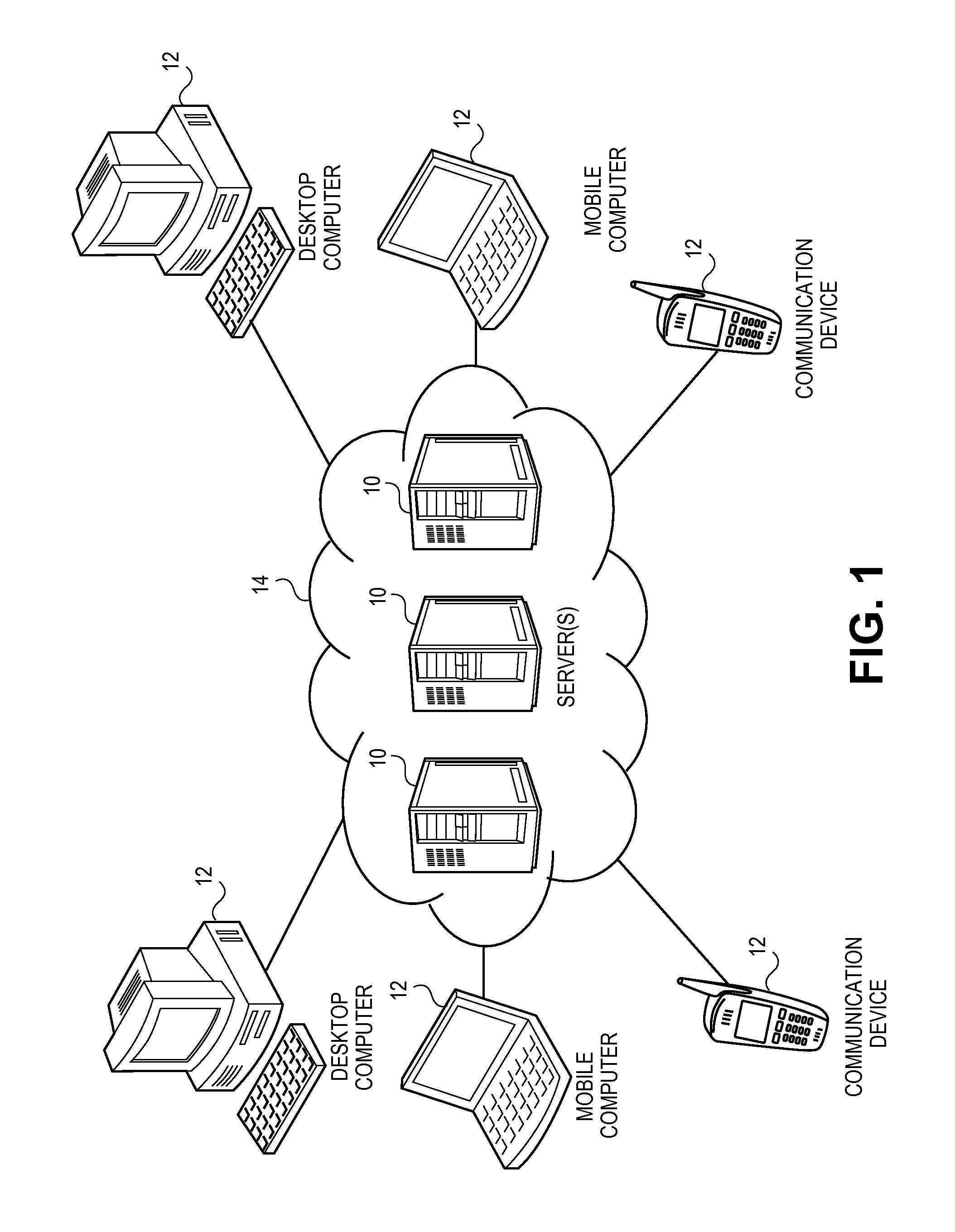

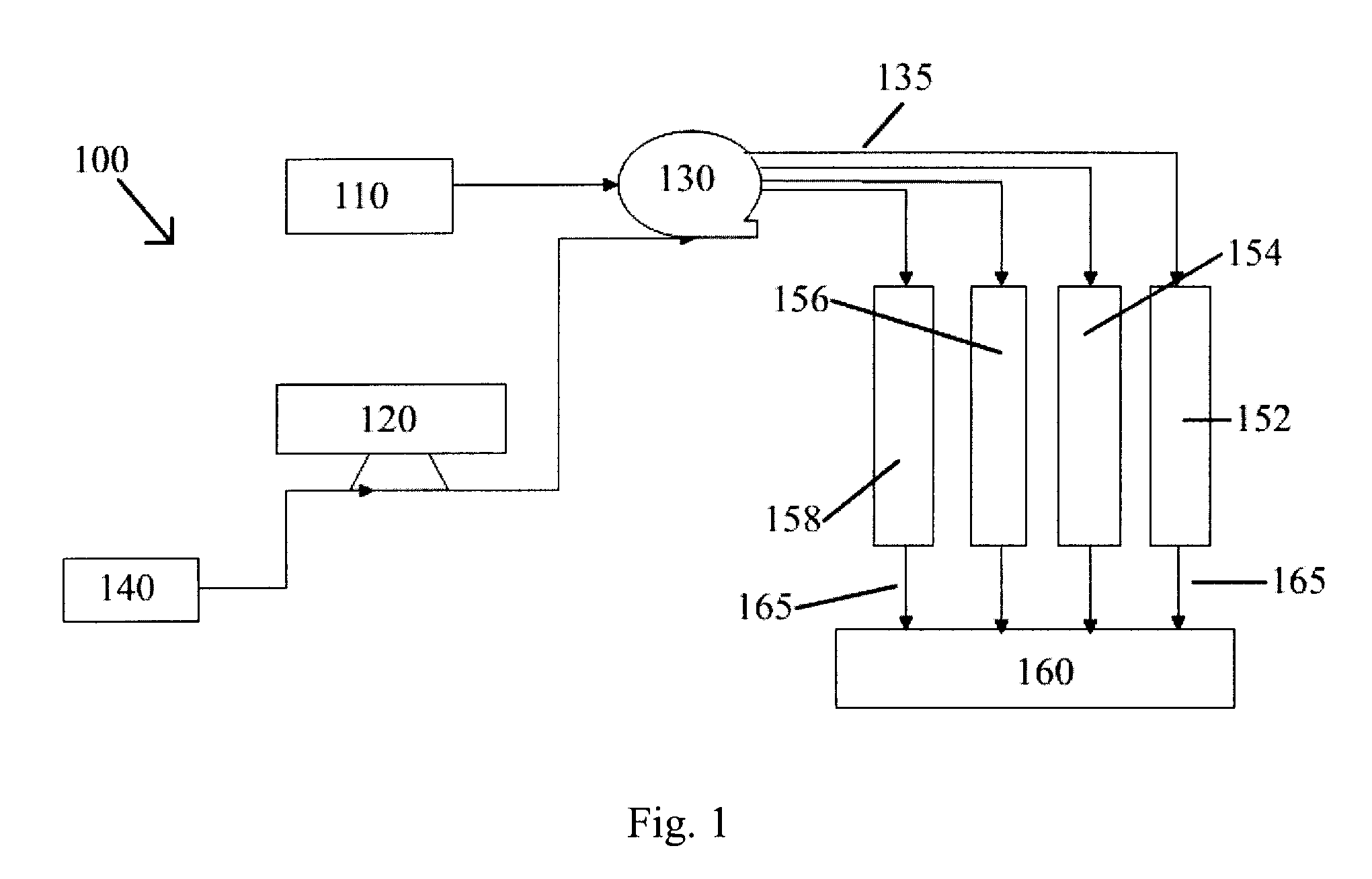

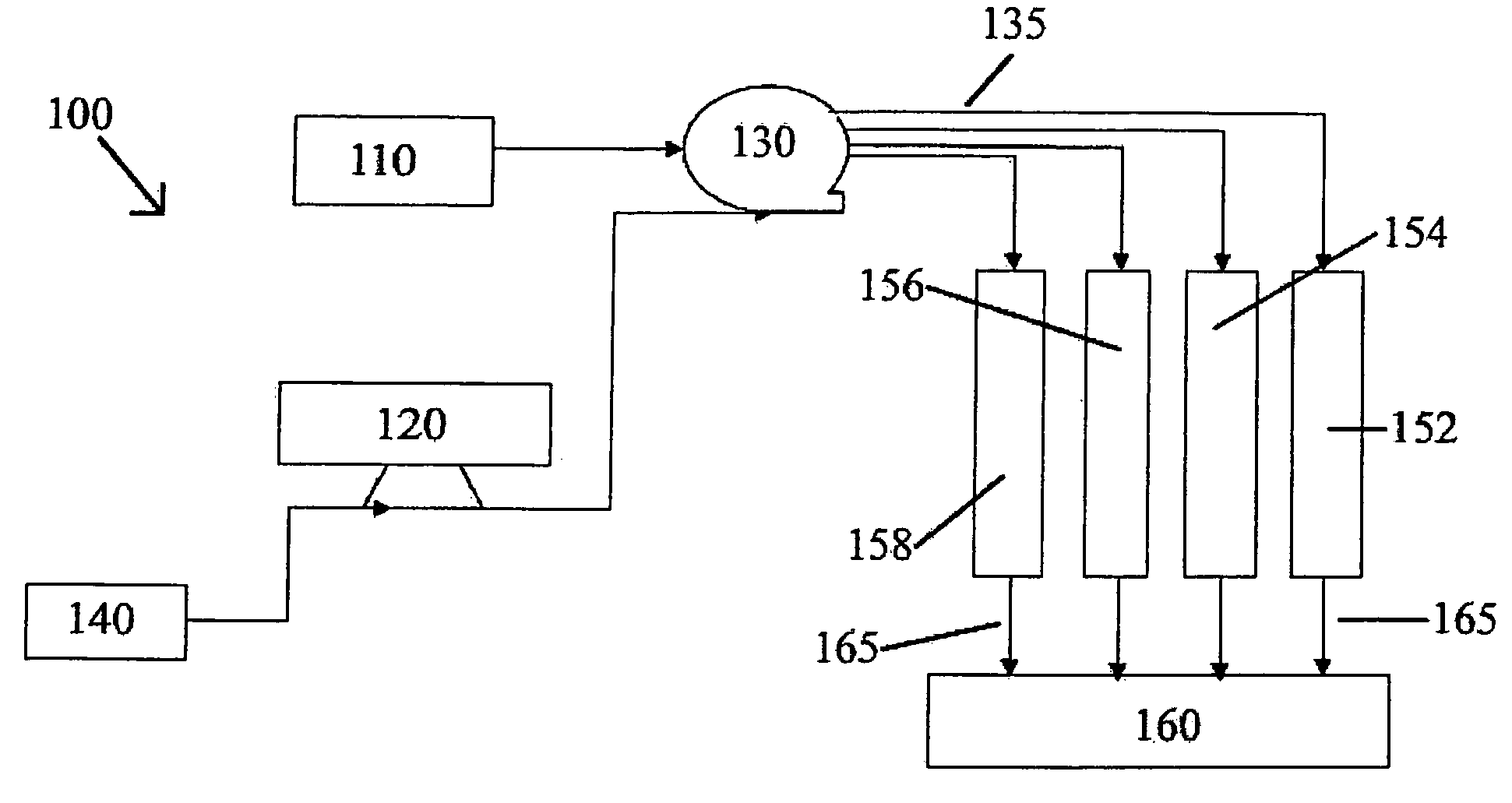

Methods and systems for adaptation, diagnosis, optimization, and prescription technology for network-based applications

ActiveUS7665082B2Improve applicationSoftware engineeringInterprogram communicationClient-sideApplication software

The present invention adapts, diagnoses, optimizes, and prescribes a network-based application between a client and a host system. Some or all components of the network-based application, including configuration information may be installed on the client. The components and configuration information may be installed as the network-based application is executed. Alternatively, the components and configuration information may be installed in advance of the network-based application. To launch the network-based application, a user via the client sends an application request to the host system. The host system sends program code to the client. Upon executing the program code, the client attempts to establish a session with the host system and determines configuration information for the network-based application. Upon establishing the session and determining the configuration information, the client then launches the network-based application.

Owner:MICROSOFT TECH LICENSING LLC

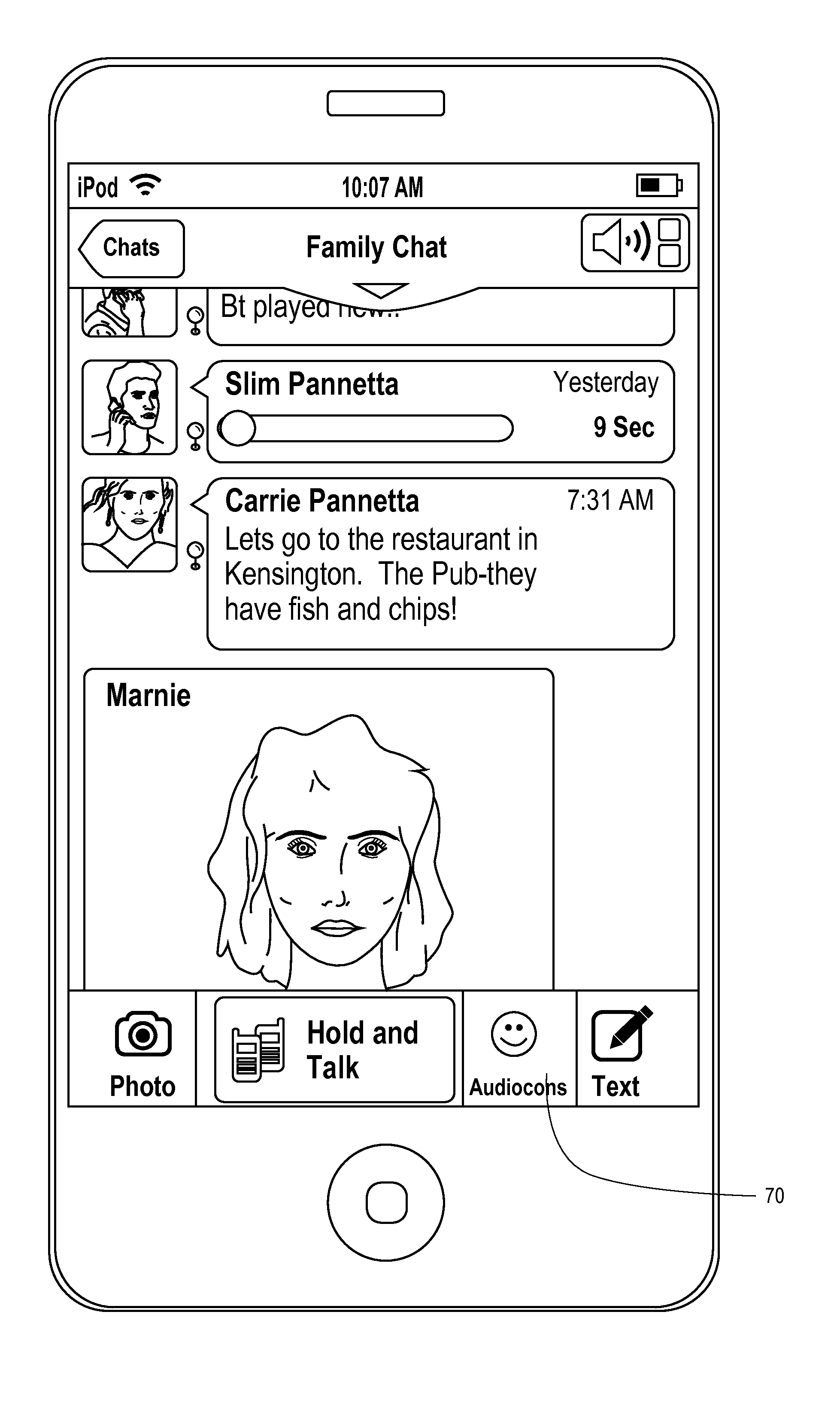

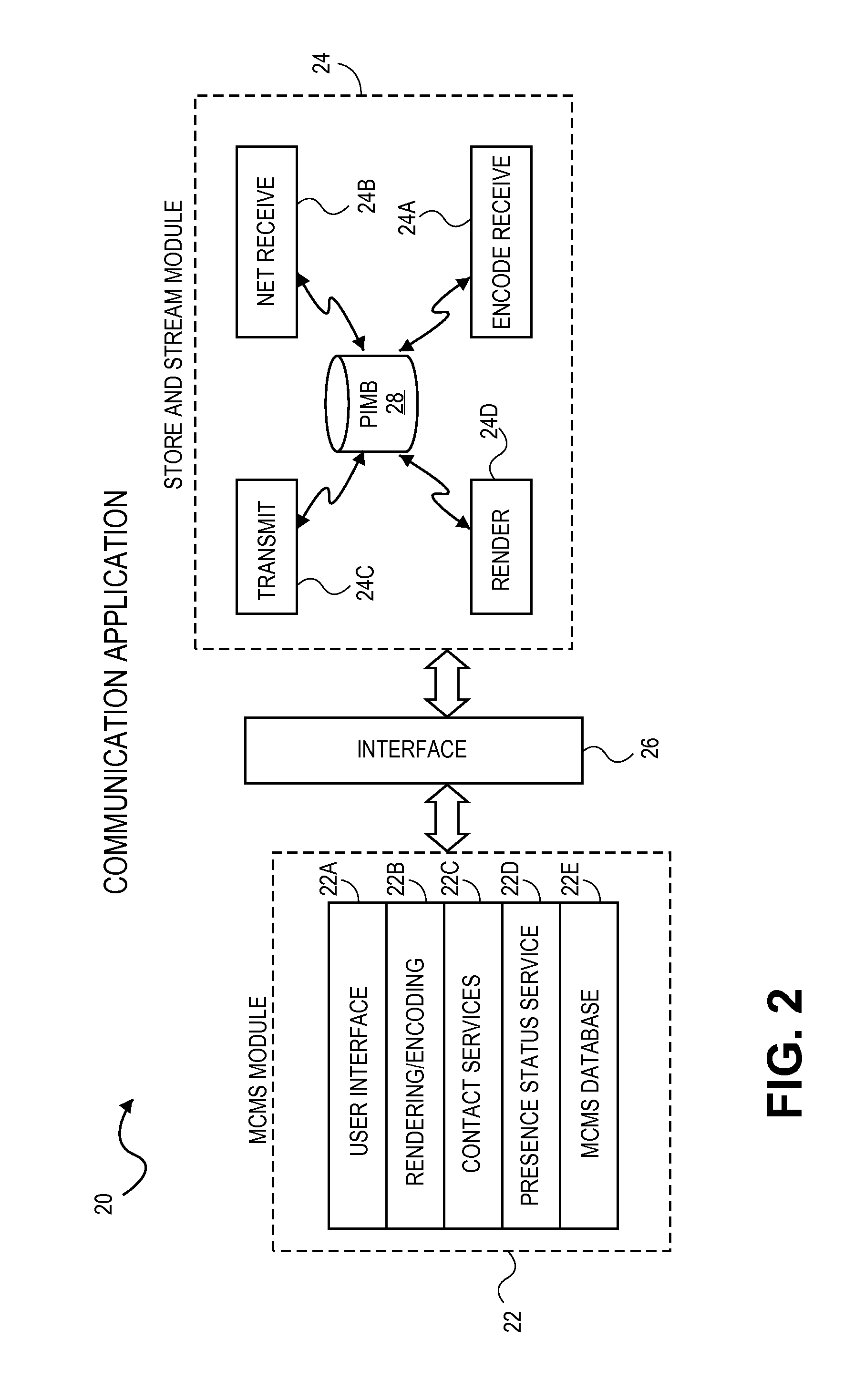

Audiocons

InactiveUS20120162350A1Improve applicationSubstation equipmentTwo-way working systemsMessage passingText messaging

A messaging application supports a mode of communication in which users can add audio effects to text messages in order to express emotions. These audio effects are described as audiocons. The audiocons may also alternatively include visual effects. In one implementation the message application supports system-defined audiocons, user-defined audiocons, and text-to-speech audiocons. Additionally, the audiocons may be inserted into a communication stream having a mixture of calls, text messaging, and instant messaging including a system having a real-time mode for time-based media and a time-shifted mode.

Owner:VOXER IP

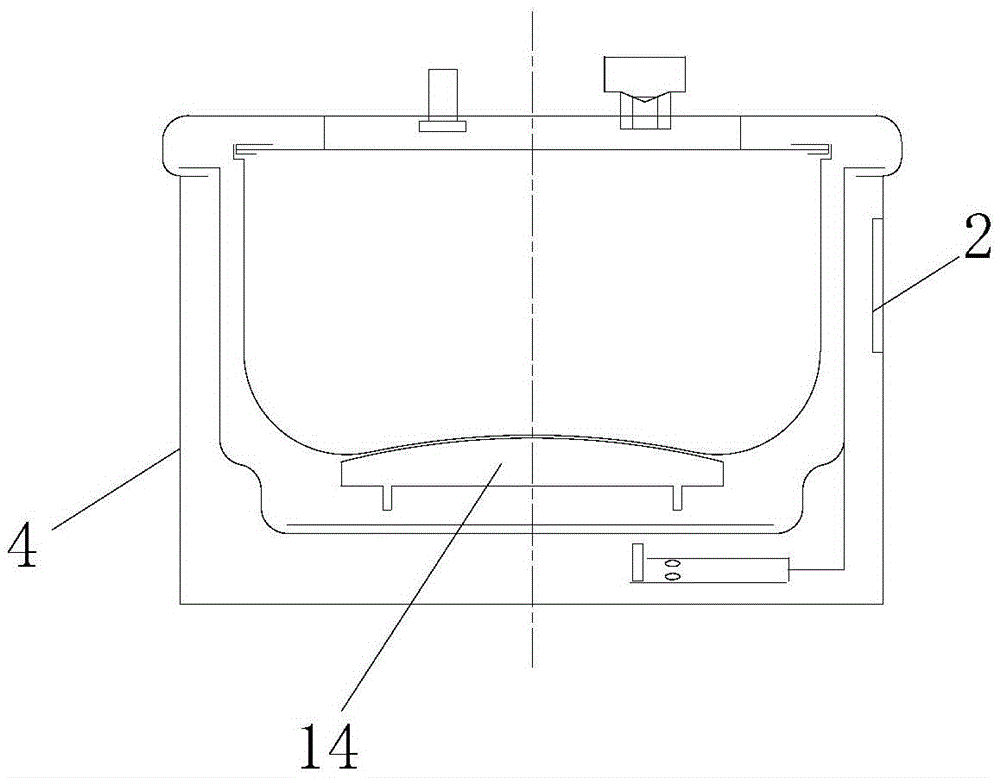

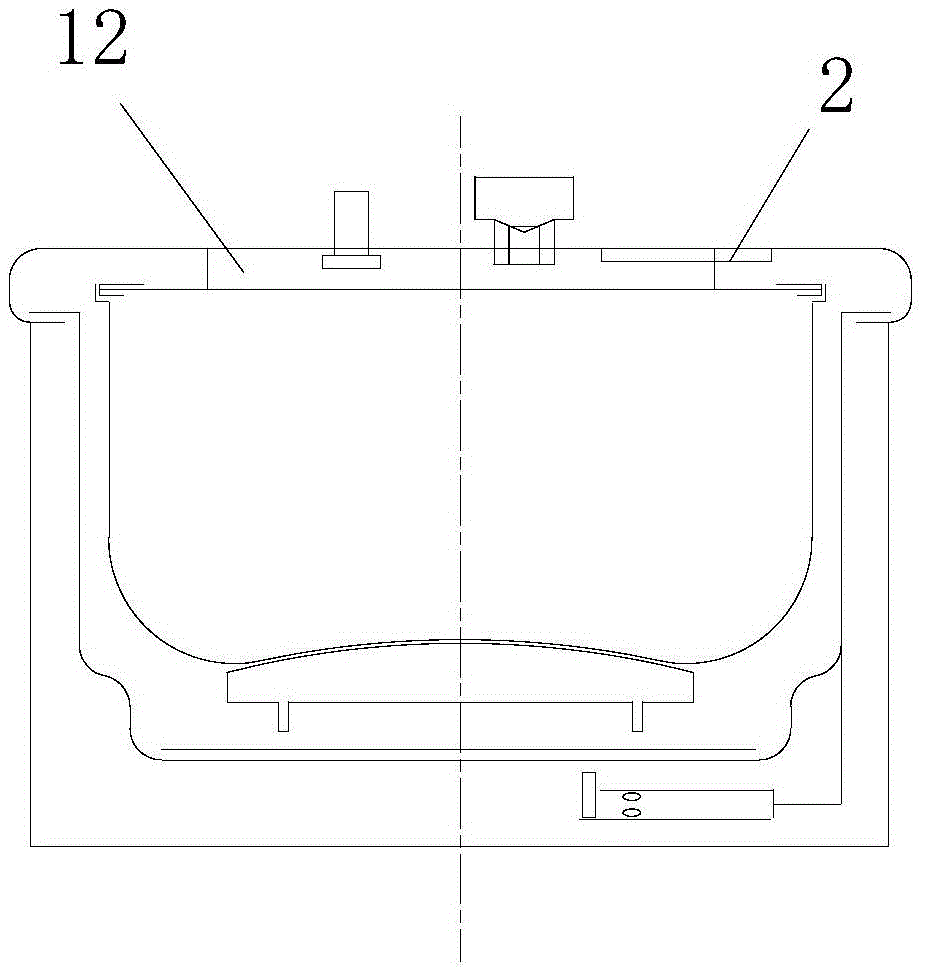

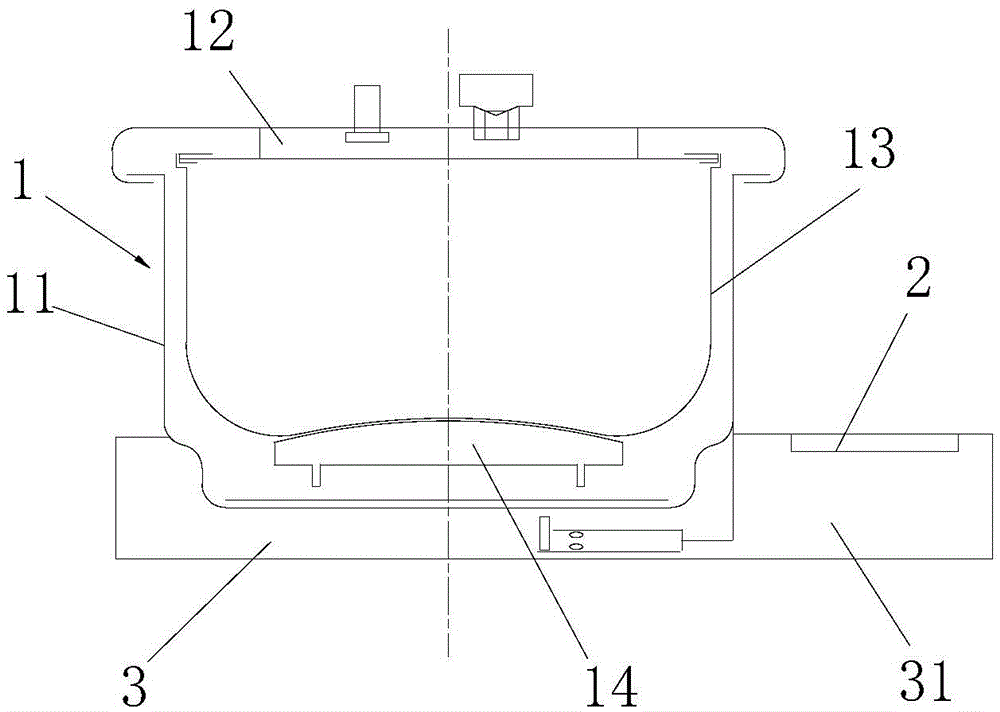

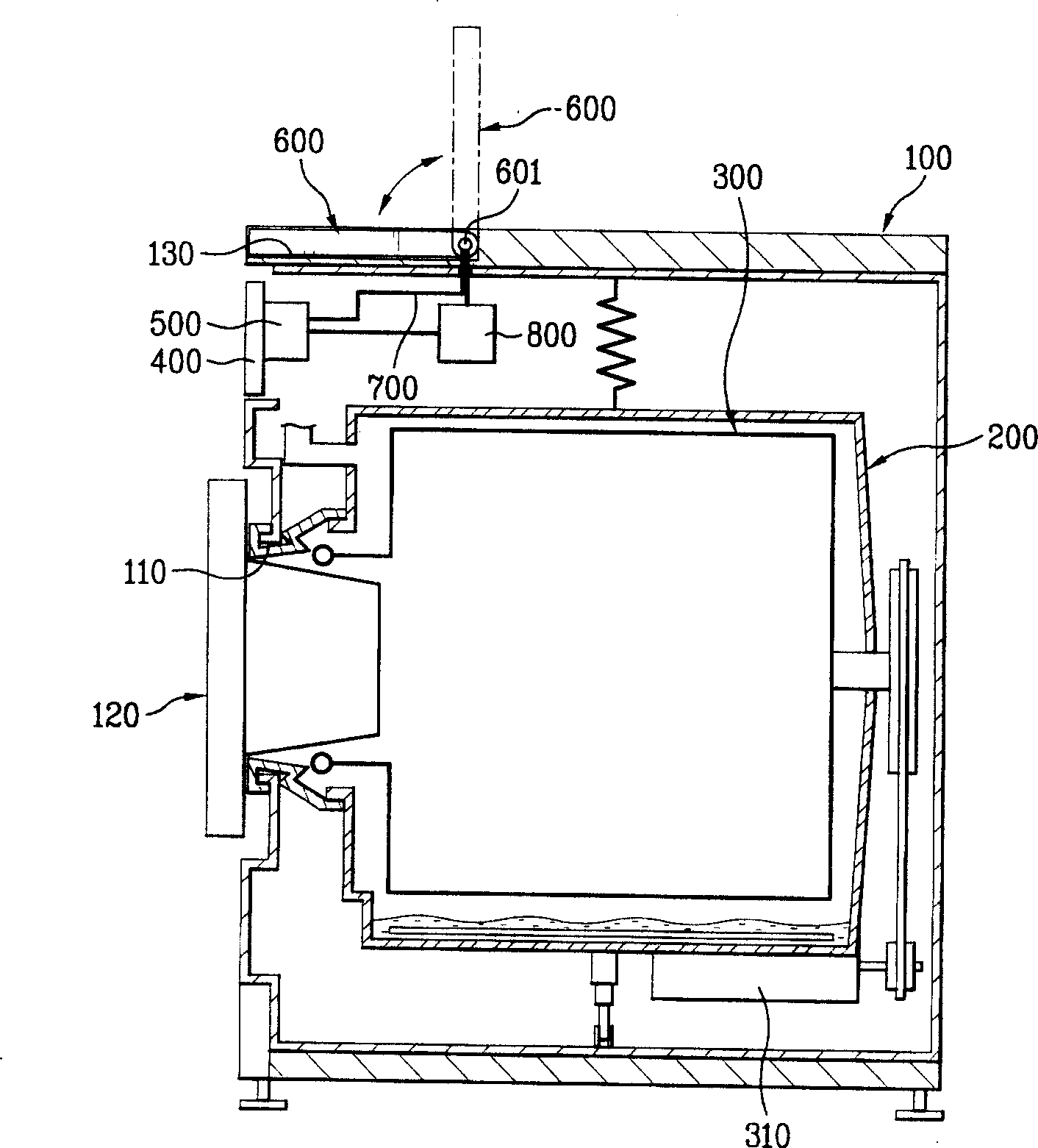

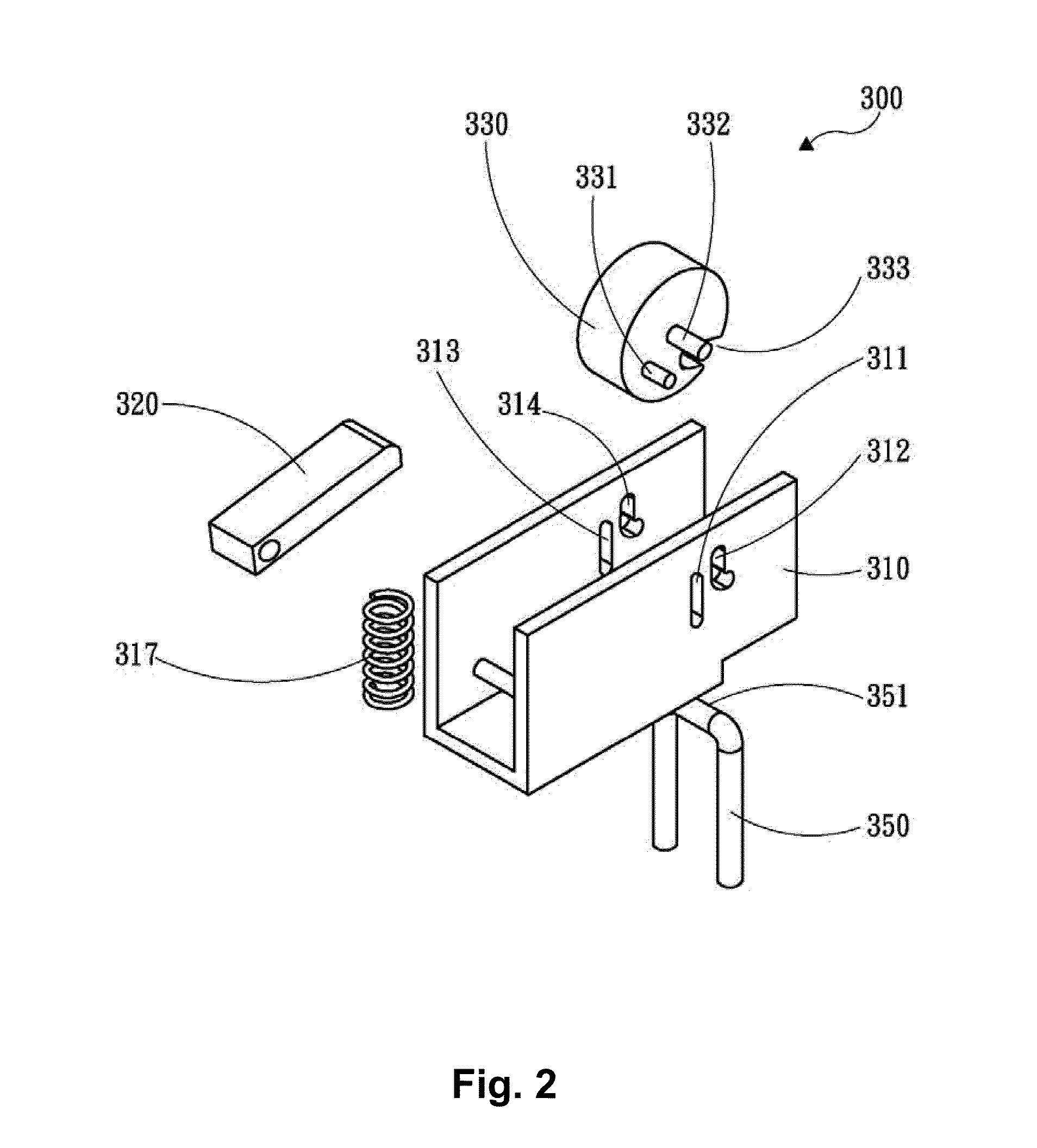

Pressure cooker component

The invention provides a pressure cooker component. The pressure cooker component comprises a pressure cooker body (1) and a control device (2) electrically connected with the pressure cooker body (1), wherein the pressure cooker body (1) comprises an outer cooker (11) and also comprises a base (3) which is arranged under the pressure cooker body (1) to contain the pressure cooker body (1); the base (3) also comprises an extending part (31) which extends outwards along the horizontal direction from the position of the base (3) corresponding to any radial periphery of the outer cooker (11); and the control device (2) is arranged at the position of the upper surface of the extending part (31). The pressure cooker component provided by the invention has the advantages that the base is arranged at the bottom part of the pressure cooker body, the extending part extends horizontally and outwards from the position of the base corresponding to any radial periphery of the outer cooker, the control device is arranged on the position of the upper surface of the extending part and can be controlled from the upper surface of the extending part, so that the operation is convenient, completely-effective sealing for the inner part of the pressure cooker can be realized and further the potential hazards of electric safety can be prevented.

Owner:GREE ELECTRIC APPLIANCES INC

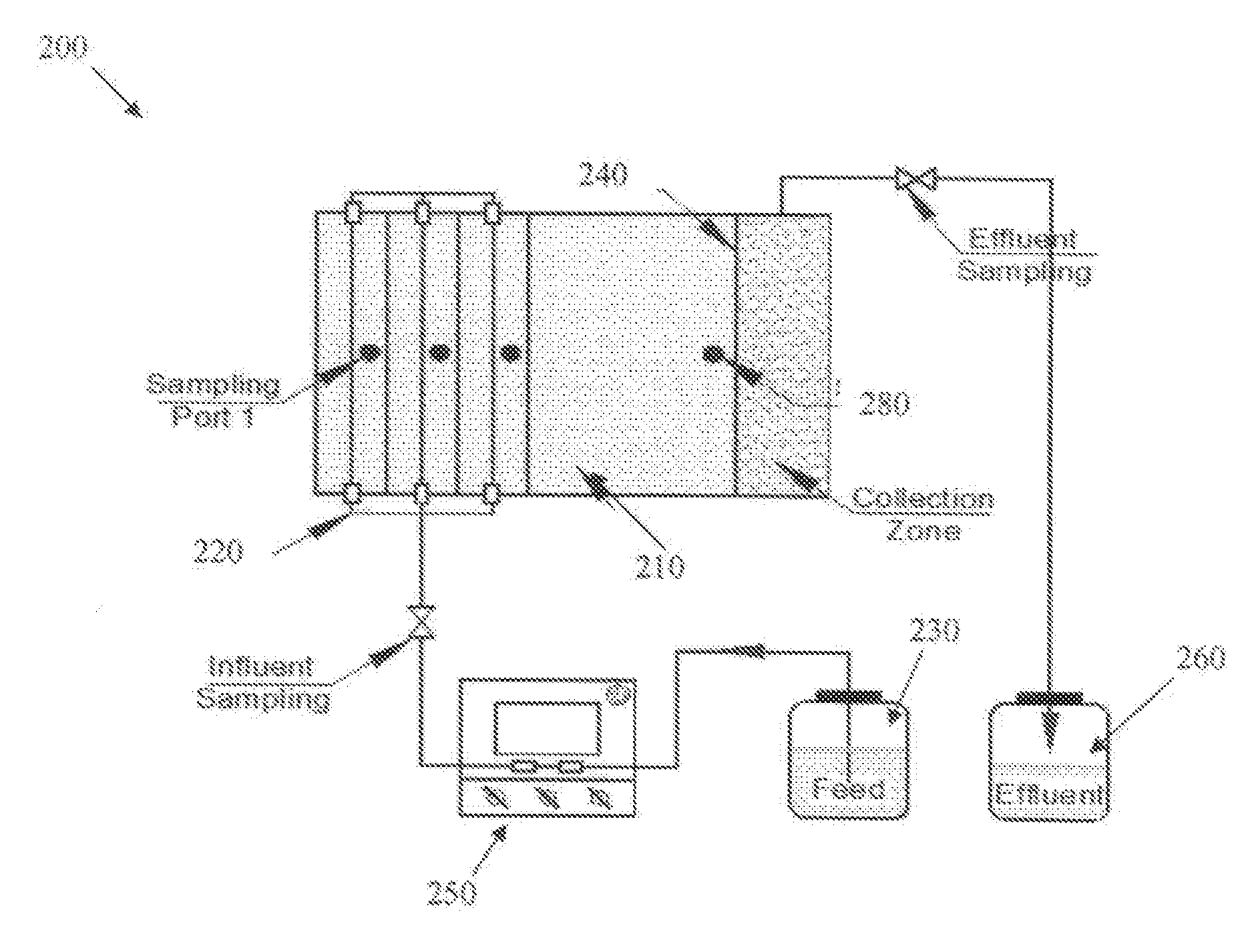

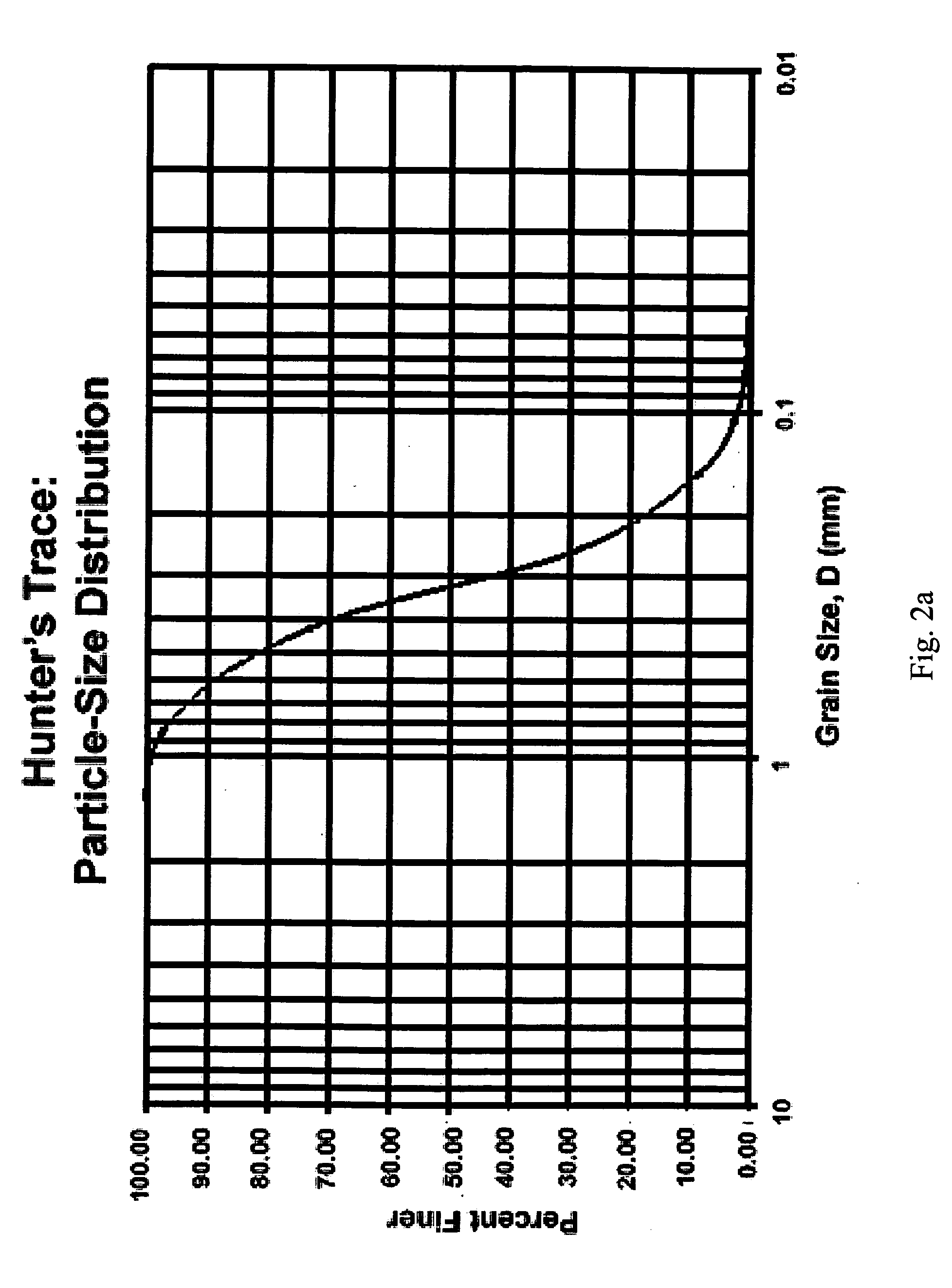

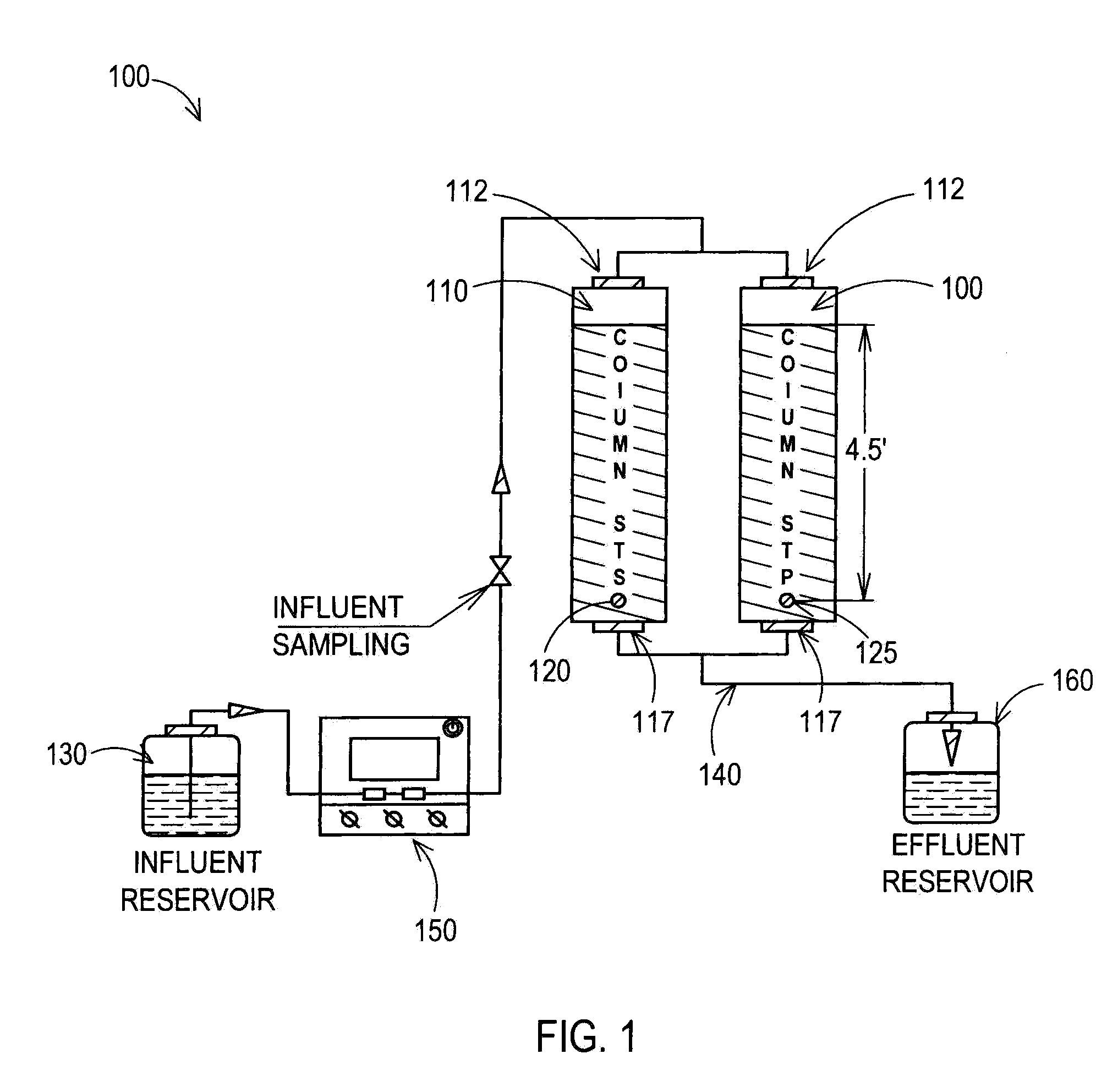

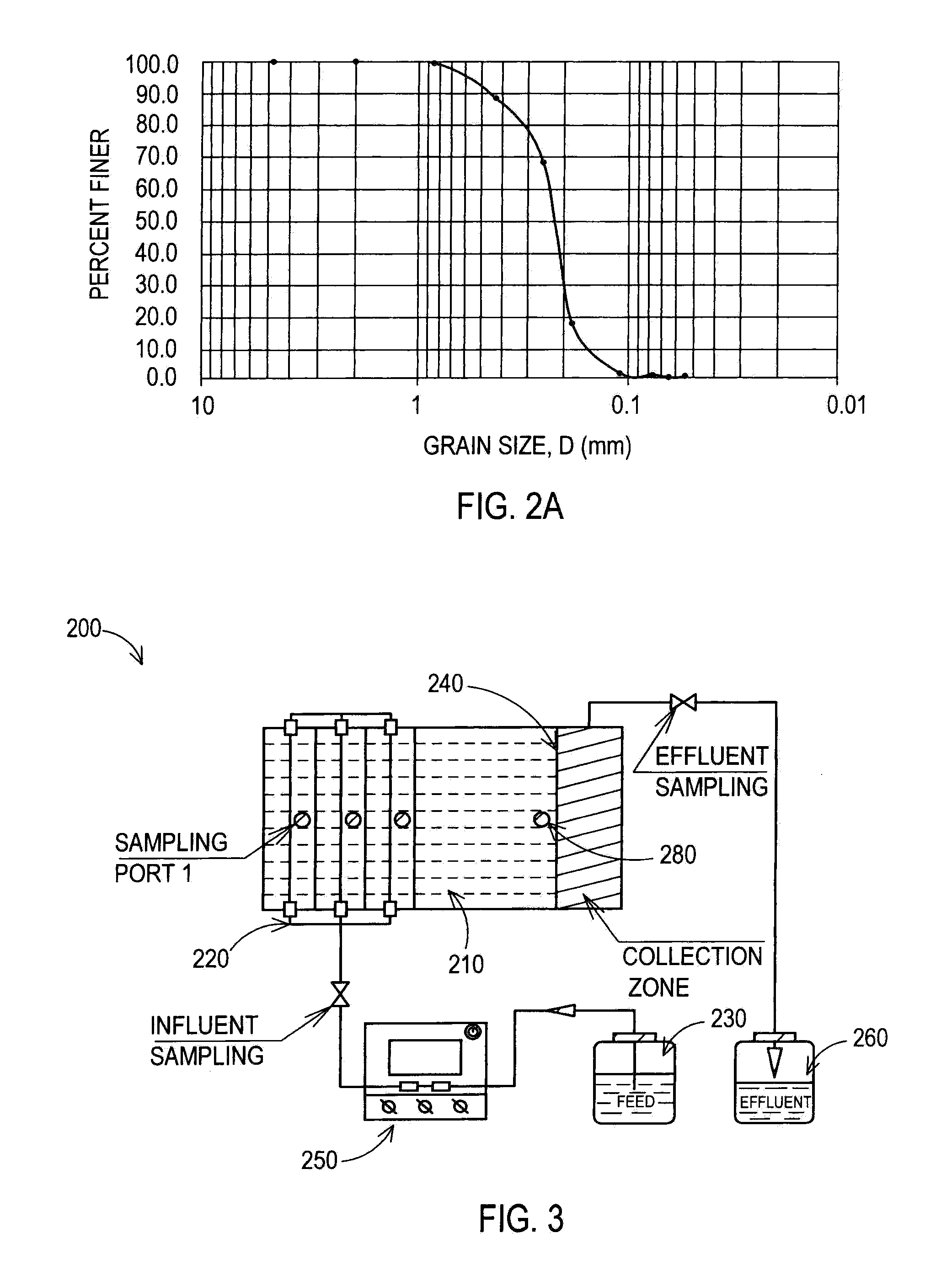

Passive Underground Drainfield For Septic Tank Nutrient Removal Using Functionalized Green Filtration Media

ActiveUS20100059437A1Improve sustainabilityImprove applicationWater cleaningContaminated soil reclamationSubsurface drainageOyster

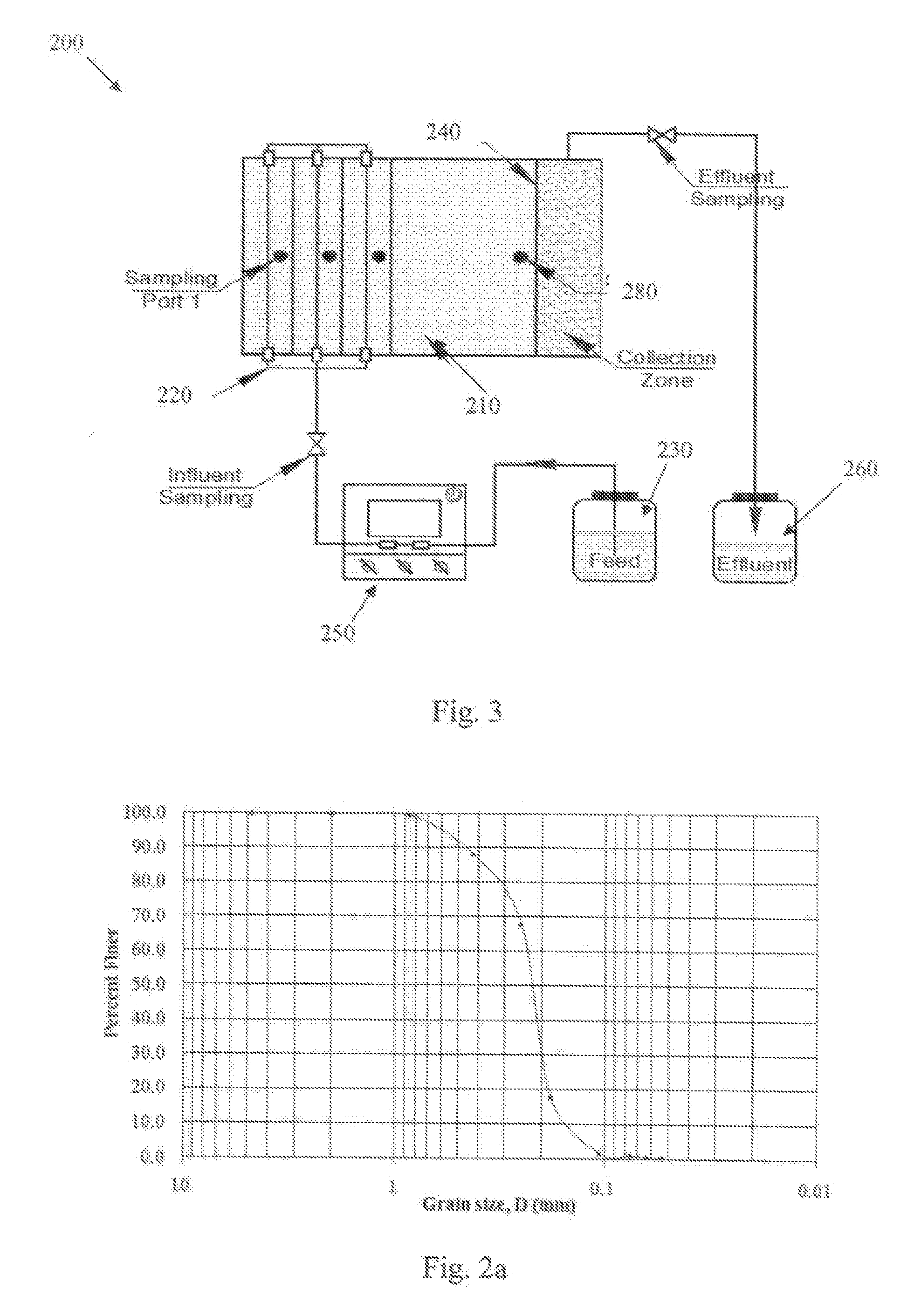

Methods, systems and compositions for a green sorption media for bioretention soil amendments in drainfields for on-site waste water systems filled with the green sorption media to foster an anaerobic or anoxic environment saturated. The green sorption media includes one or more recycled materials, including tire crumb, sawdust, orange peel, coconut husks, leaf compost, oyster shell, soy bean hulls and one or more naturally occurring materials including peat, sands, zeolites, and clay. The wastewater filtration system for a passive drainfield includes the green sorption material mixture, a cell including baffled compartments and a riser, the cell filled with green sorption material mixture to provide an alternating cycle of aerobic and anoxic environments, an influent distribution system to distribute the influent over the cell, and a piping system arranged for dosing the cell to sustain the functionality of the green sorption material mixture to remove nutrient content in wastewater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

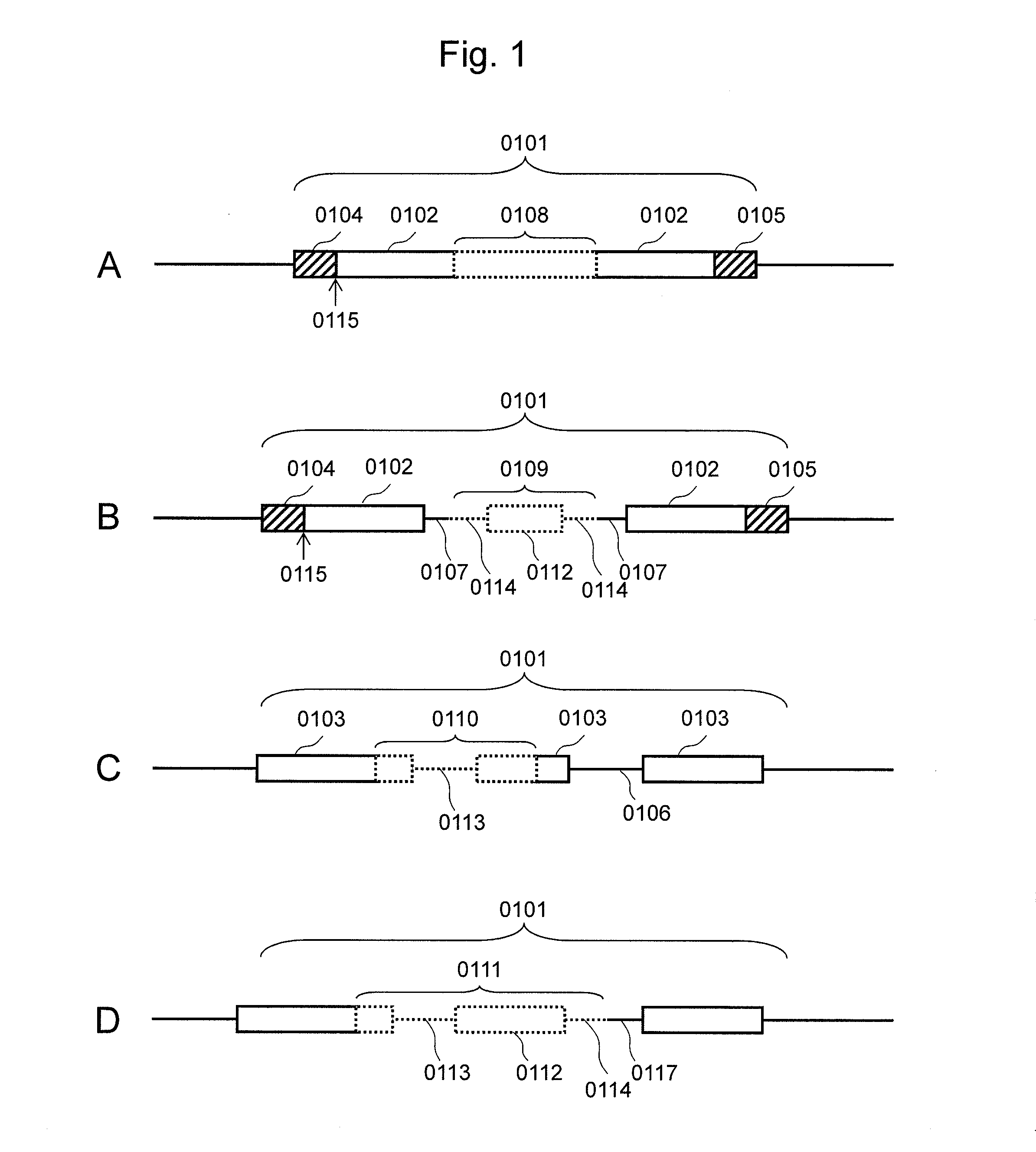

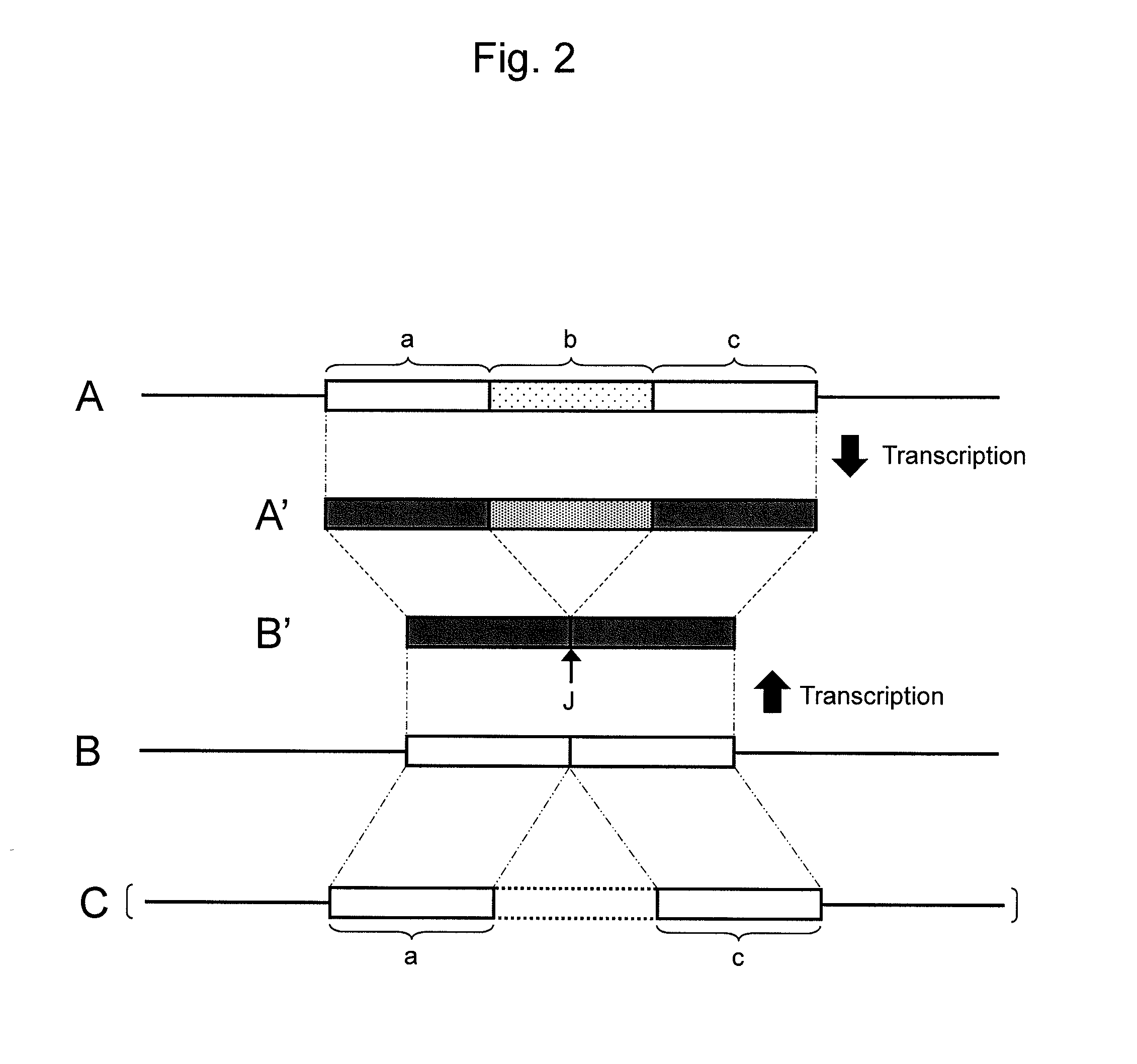

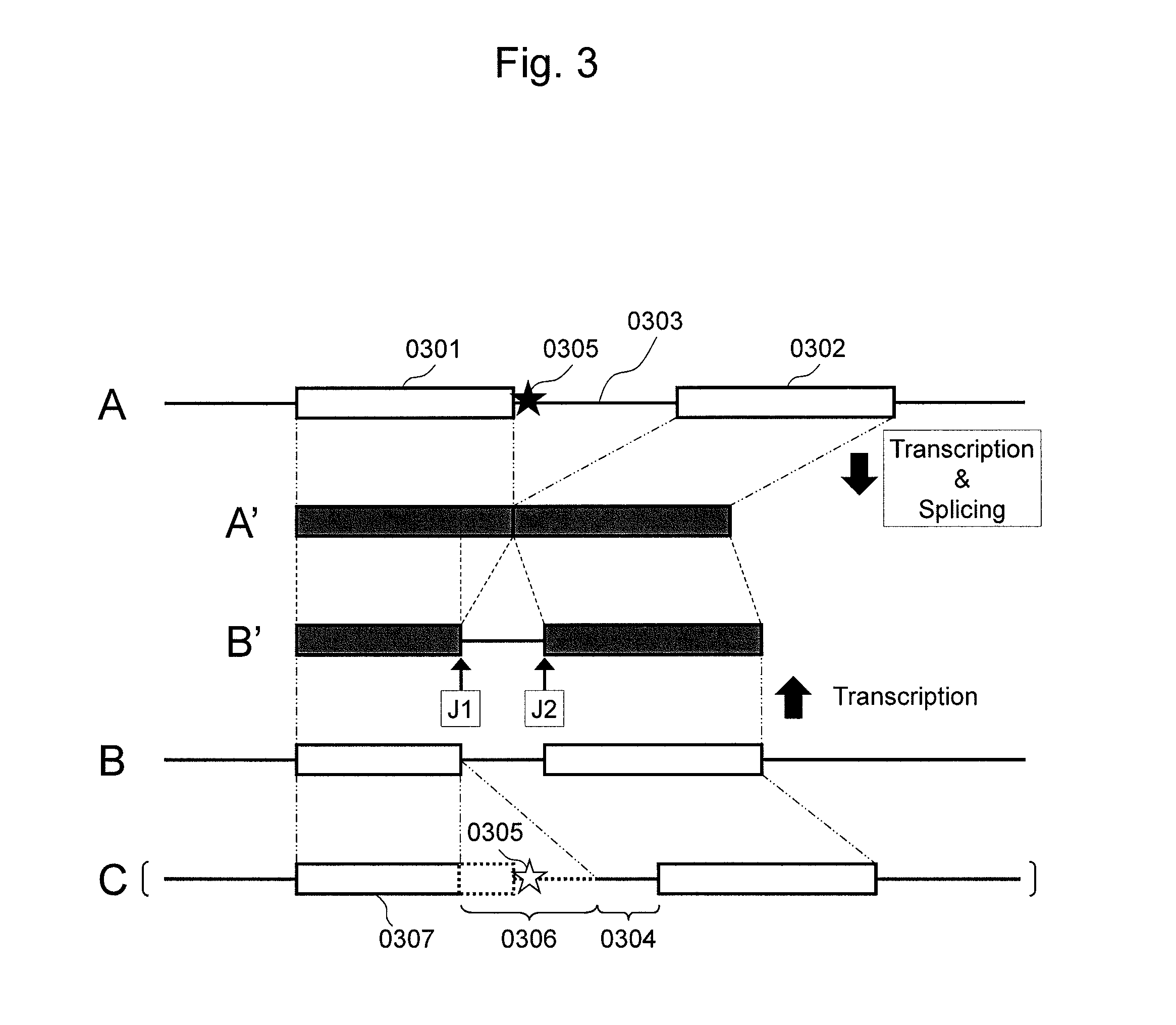

Agent for suppressing expression of dominant mutant gene

InactiveUS20130197061A1Inhibit expressionMaintain expressionOrganic active ingredientsSugar derivativesWild typeGene

Owner:LSIP

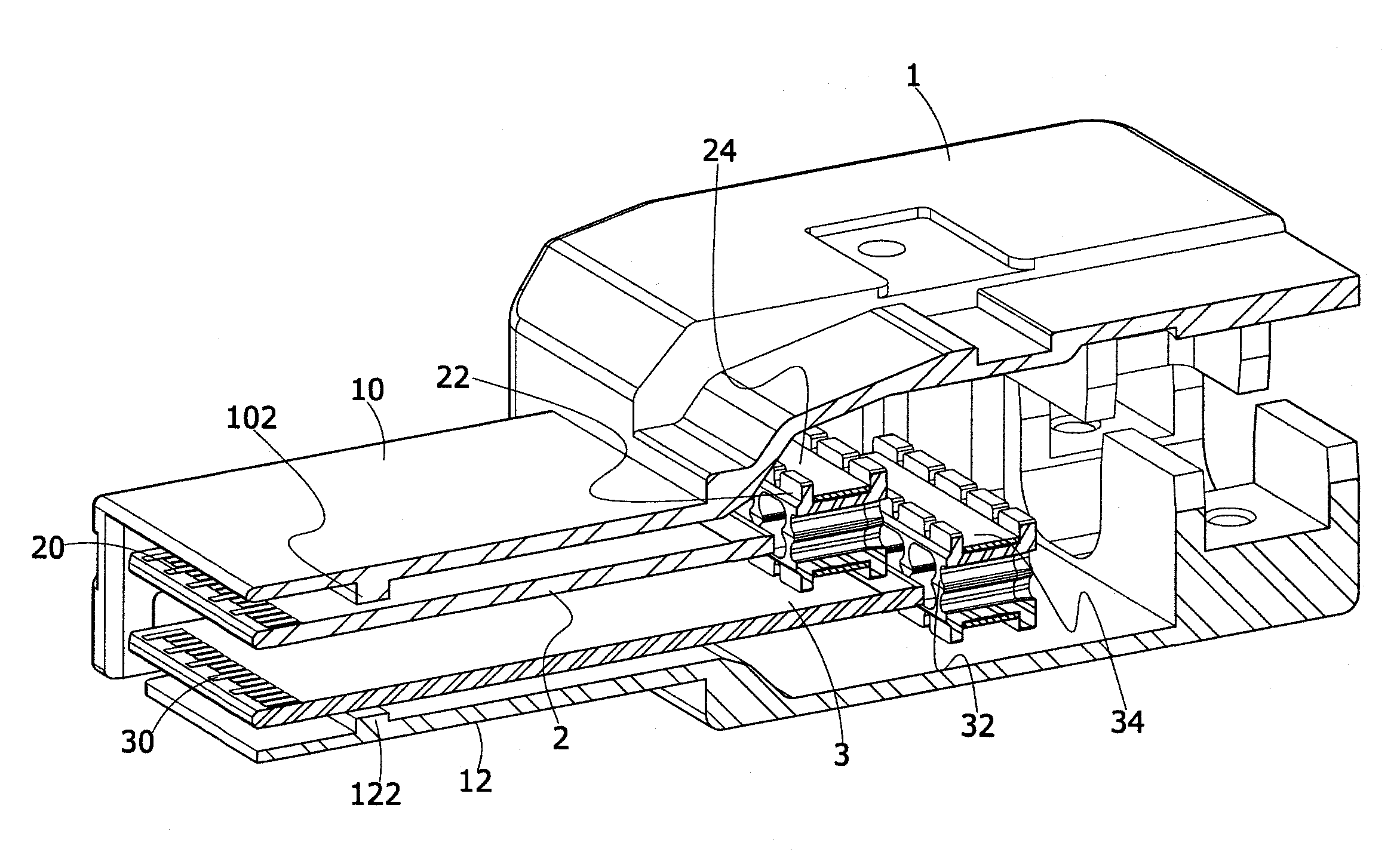

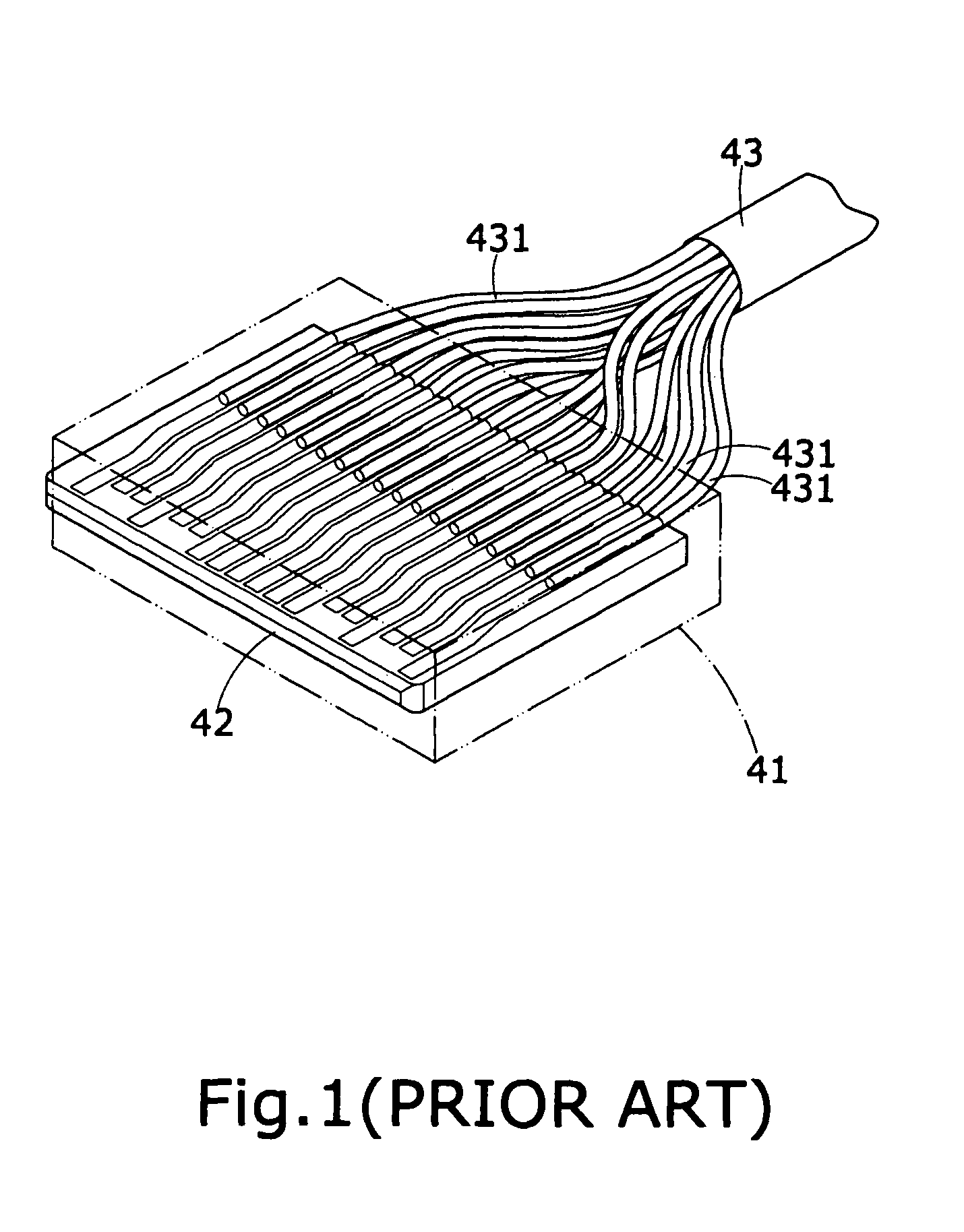

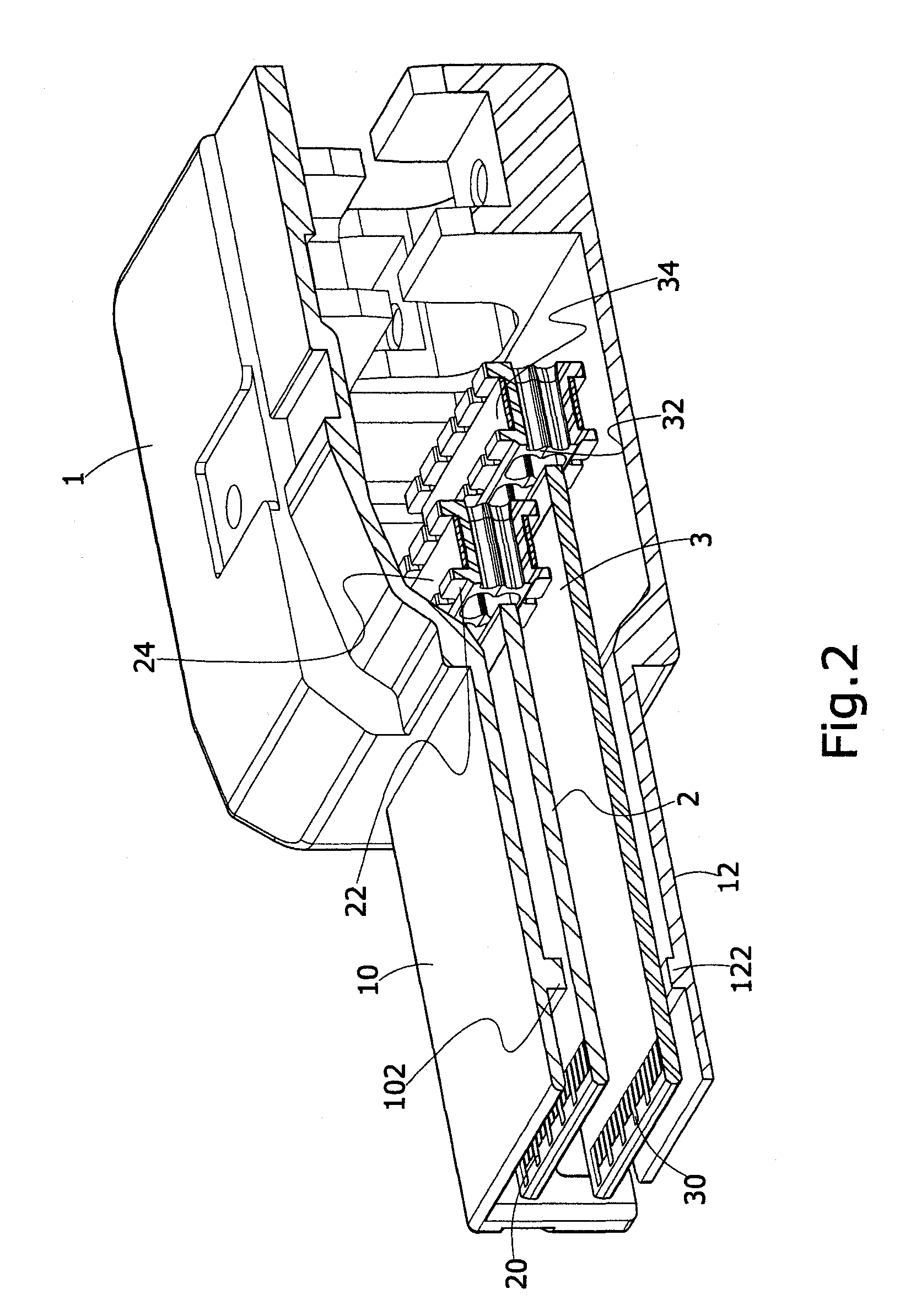

Signal line connector structure of computer system

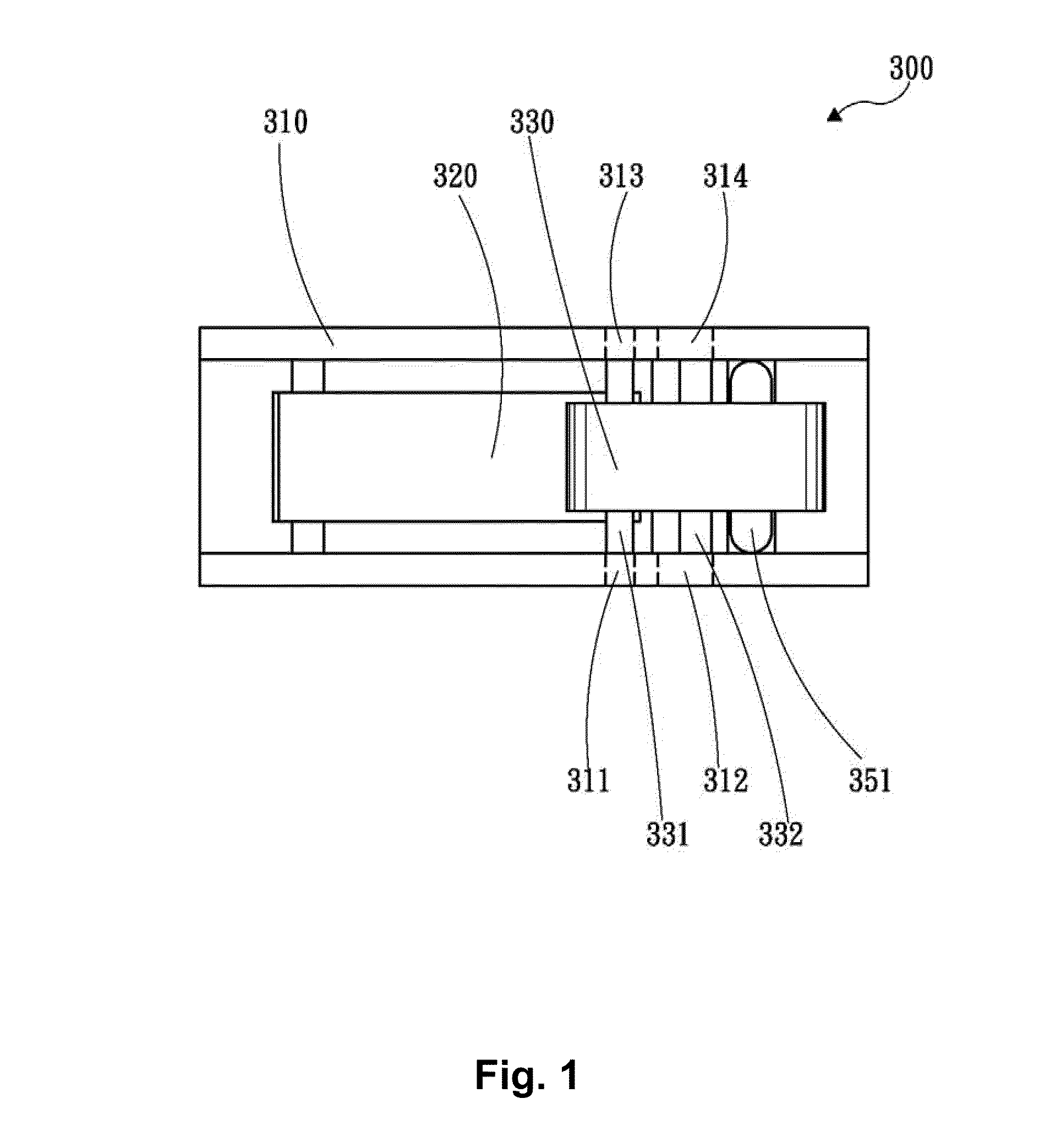

InactiveUS7803010B1Improve convenienceEasy to assembleElectrically conductive connectionsCoupling device detailsComputerized systemEngineering

A signal line connector structure of a computer system includes a casing, a first connecting module and a second connecting module. The casing consists of an upper casing and a lower casing. The upper casing includes a first positioning block having a first stop side, and the lower casing includes a second positioning block having a second stop side. The first connecting module and the second connecting module are installed in the casing and abutted and fixed by the first positioning block and the second positioning block respectively to enhance the stability and convenience of the connection. In addition, two connecting modules are used for improving the applicability.

Owner:HWANG MAO LIN

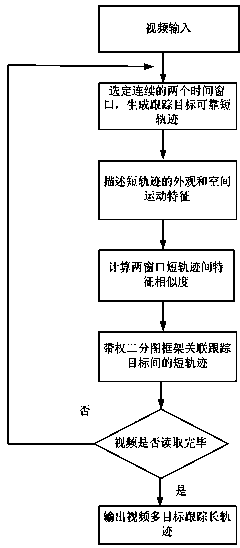

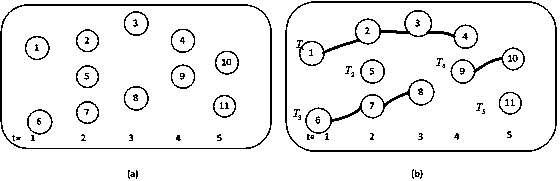

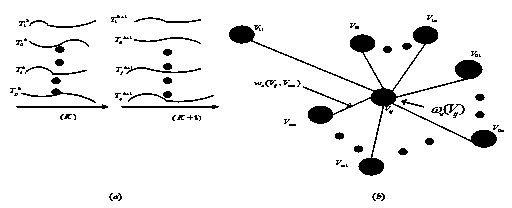

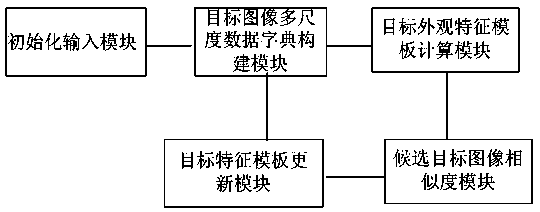

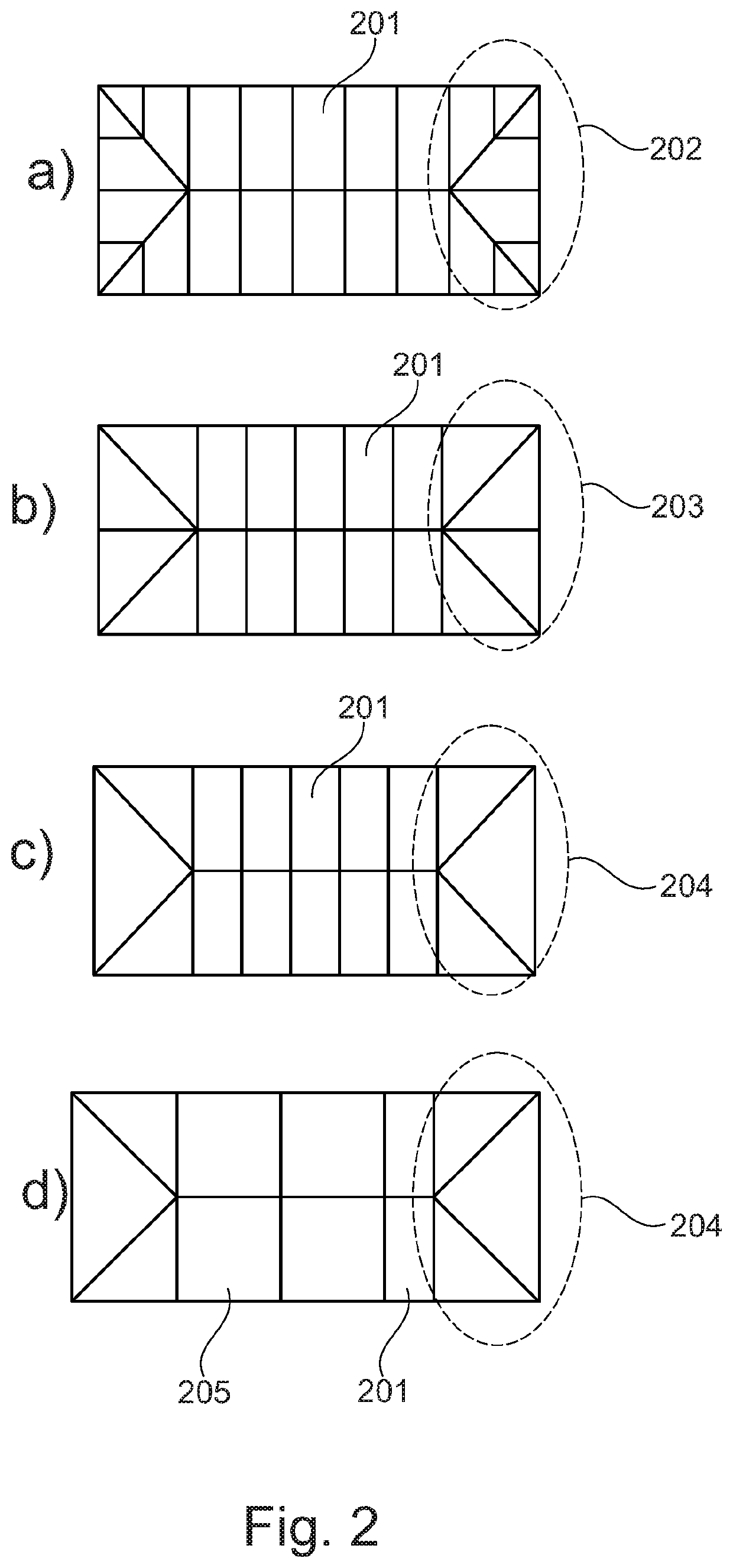

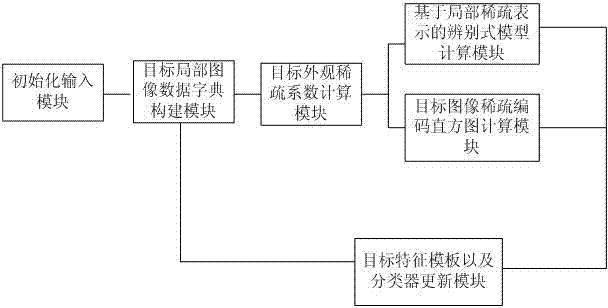

Multi-target tracking method based on graph representation and matching

InactiveCN104200488AImprove visibilitySimple calculationImage analysisPattern recognitionMulti target tracking

The invention discloses a multi-target tracking method based on graph representation and matching. Compared with the prior art, the method has the advantage that the defect of incapability of successfully tracking due to frequent interactive shielding of targets and similar appearance features in a video tracking technology is overcome. The multi-target tracking method comprises the following steps: inputting a tracking video, and generating target-reliable short tracks in adjacent time windows; building a spatial motion model which takes a graph as a framework and an appearance model which takes color and local two-value difference as features for the formed target short tracks; calculating the appearance feature and spatial motion similarity among the tracks; realizing relevant tracking of a target by using a weighted two-value graph matching framework; repeating the steps continually to obtain a motion track at all moments of each target. Through adoption of the multi-target tracking method, the target tracking accuracy and efficiency in a complicated scene are increased, and the application degree of a track tracking technology in various scenes is increased. Accurate tracking of the target in a complicated environment is realized by means of online learning of the appearance model and the spatial motion model.

Owner:HEFEI UNIV OF TECH

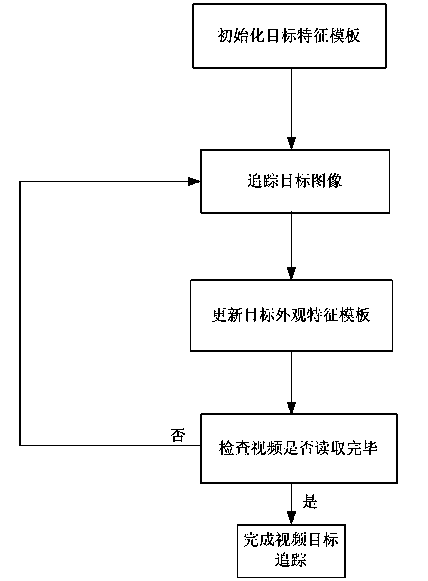

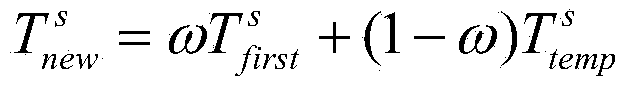

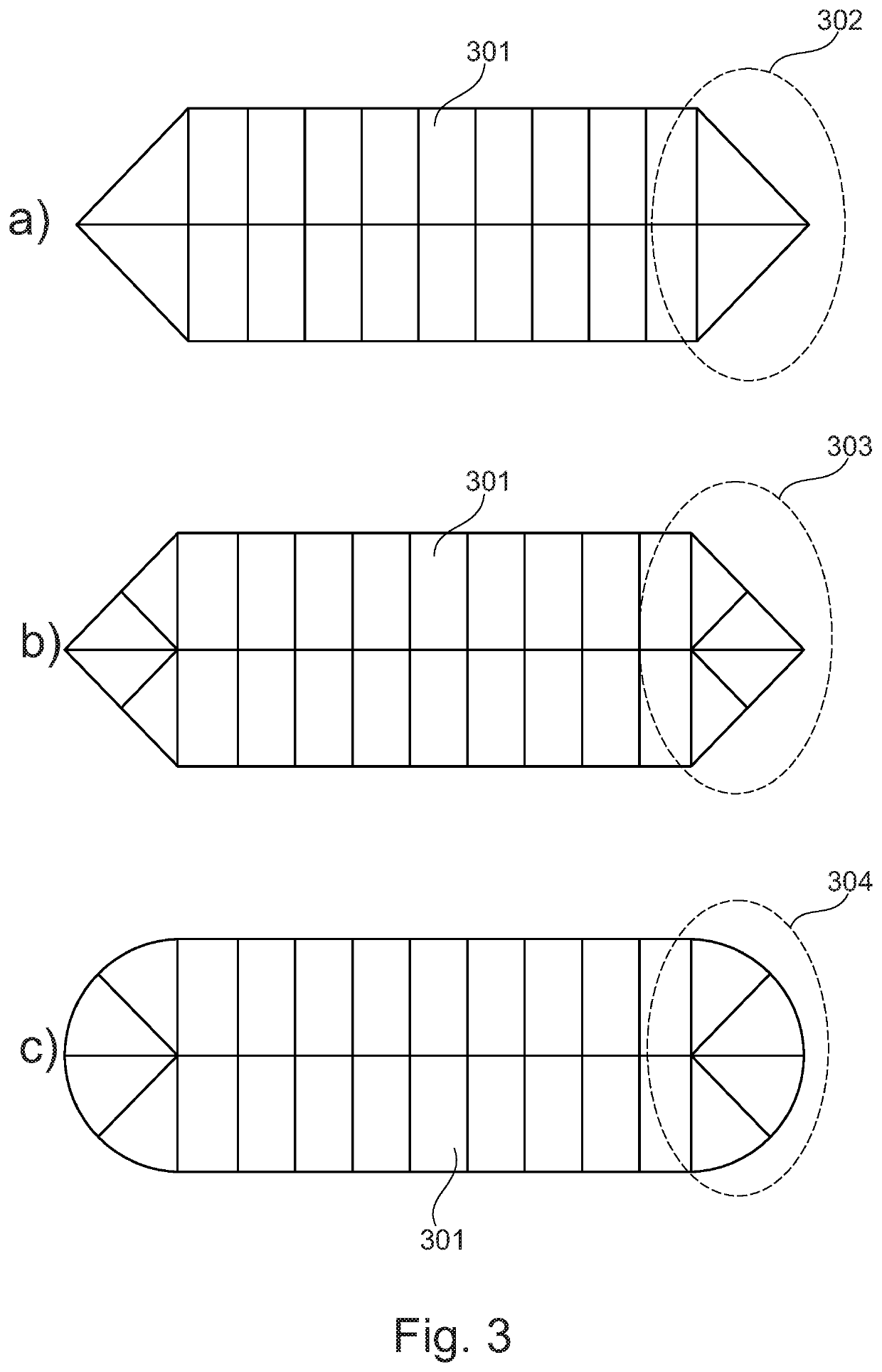

Video target tracking method based on multi-scale block sparse representation and system thereof

The invention relates to a video target tracking method based on multi-scale block sparse representation and a system thereof. Compared with the prior art, the invention solves the defect that the conventional target tracking method cannot achieve a better effect. The method comprises the following steps: initializing a target feature template; tracking a target image; updating a target appearance feature template; checking whether a video is read or not. Through the adoption of the method, target tracking precision and efficiency in complex scenes are improved, and the application degree of a target tracking technology in various scenes is improved.

Owner:HEFEI UNIV OF TECH

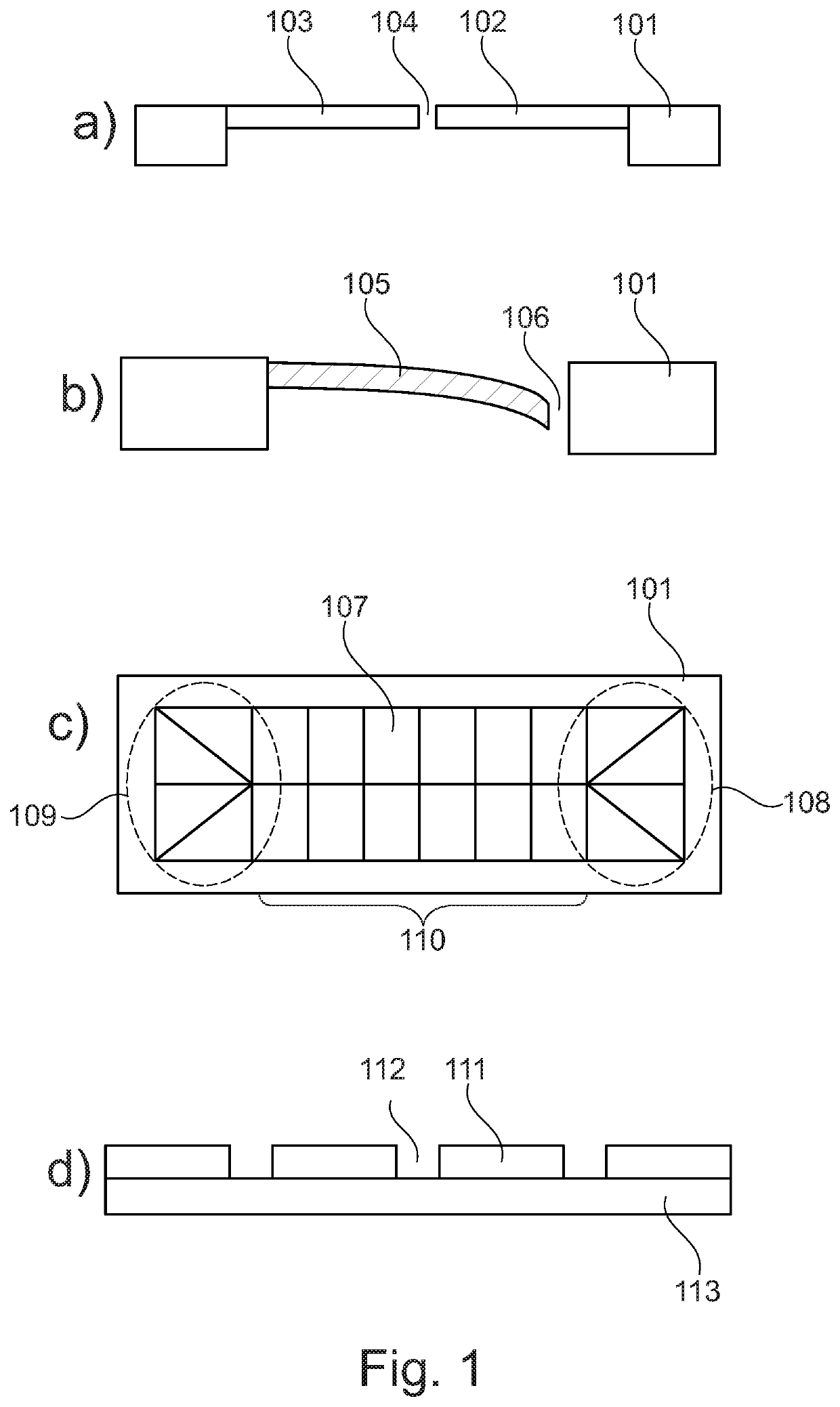

Scanning line point cloud based skin boundary feature reconstruction method

ActiveCN105868498AImprove assembly efficiencyImprove assembly qualityGeometric CADDesign optimisation/simulationAirplaneReconstruction method

A scanning line point cloud based skin boundary feature reconstruction method is characterized by including: extracting feature points from each scanning line, and adopting the feature points for construction of straight lines or B spline curves to reconstruct boundary features, wherein extraction of the feature points includes steps of neighborhood search, measurement point position recognition and linear fitting and intersection; in neighborhood search, ordering the points along the scanning lines, using the B spline curves for interpolation of an ordered point set, recognizing points on surfaces and chamfer points through curvatures, using points on the surfaces and lateral sides to fit the straight lines respectively, and taking intersection points of the straight lines as feature points; finally fitting the feature points into straight lines or B spline curves for expressing skin boundary features. By the scanning line point cloud based skin boundary feature reconstruction method, numerical control machining precision and application degree can be improved, and airplane skin assembly efficiency and assembly quality are improved accordingly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

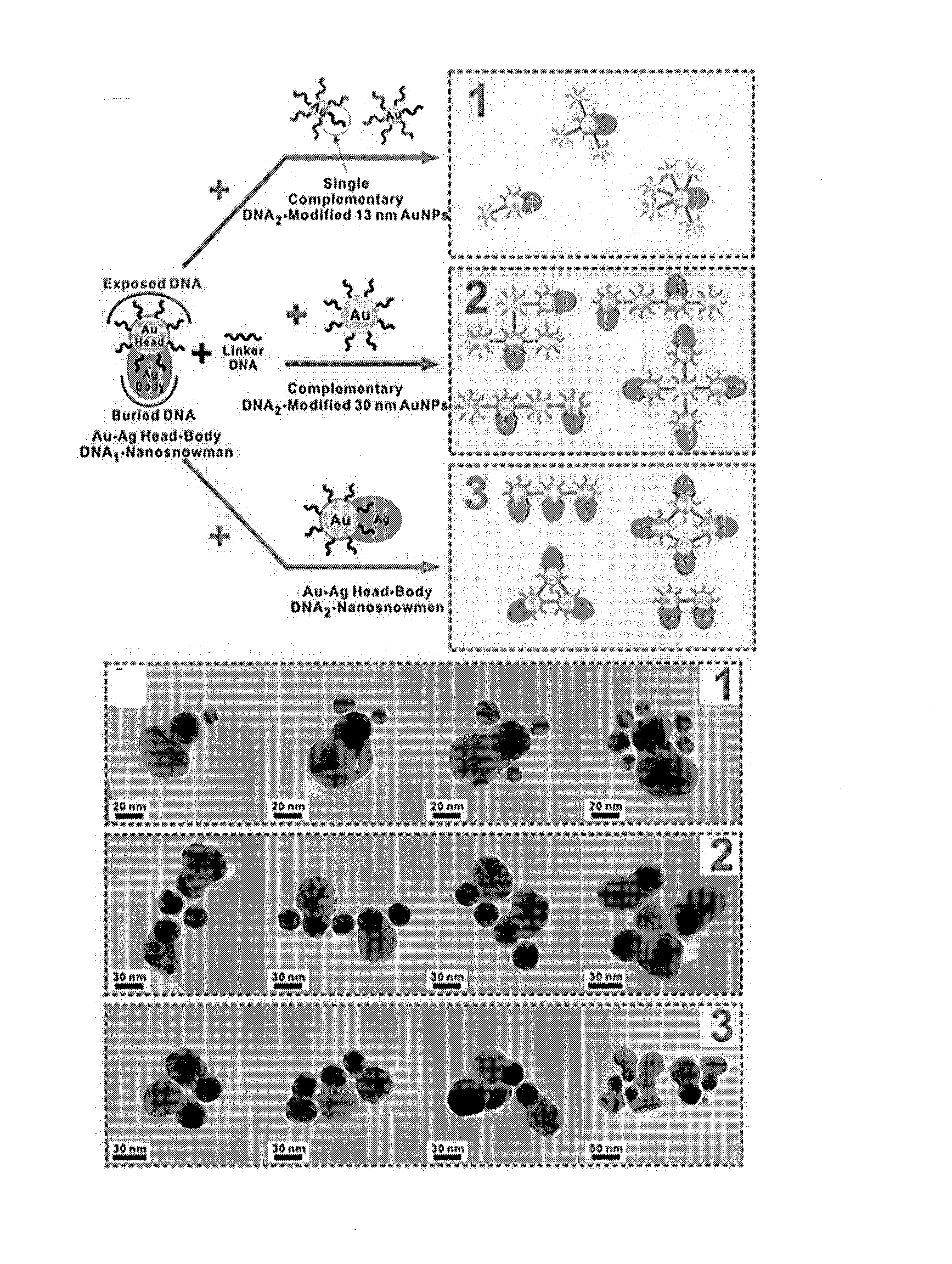

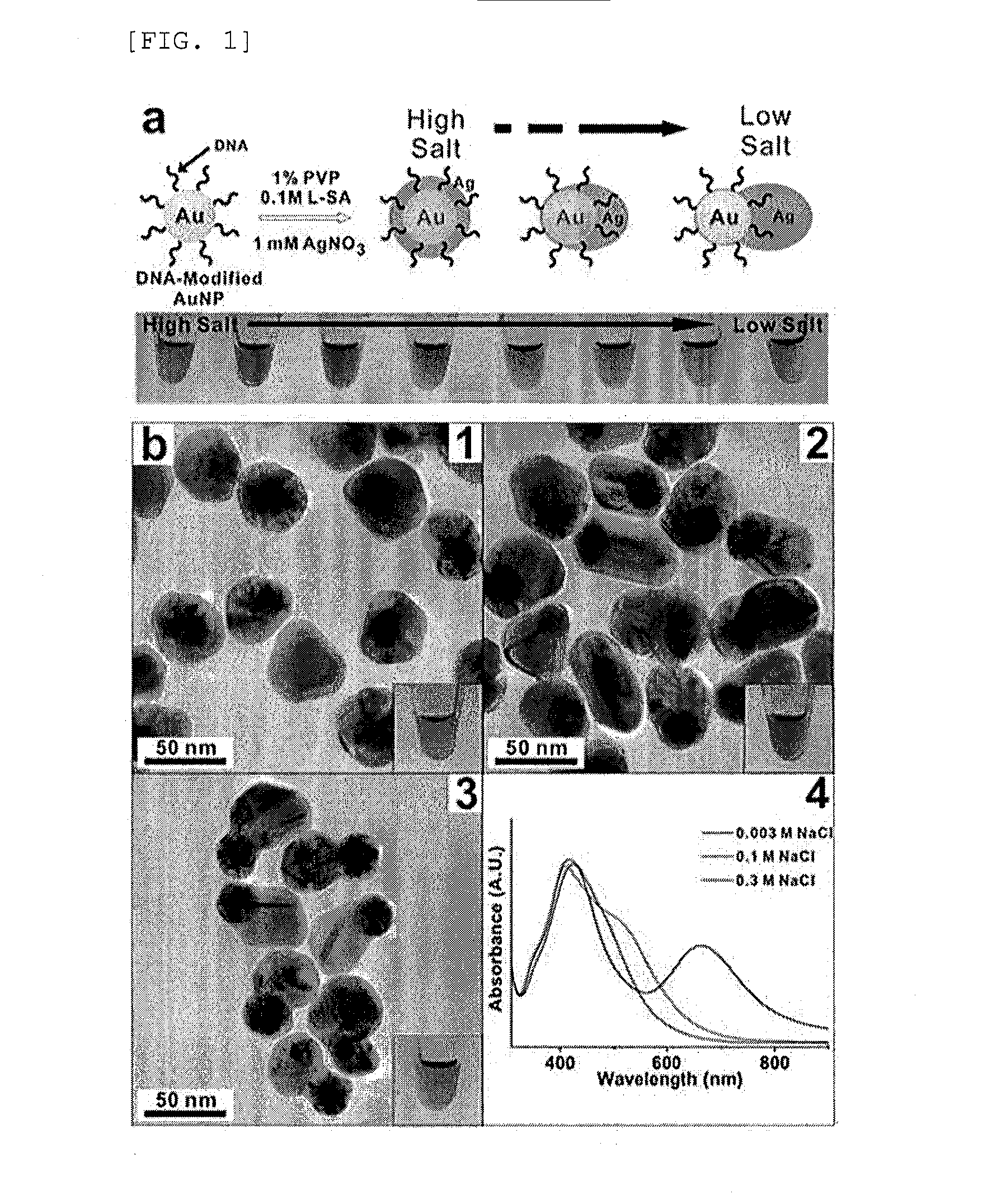

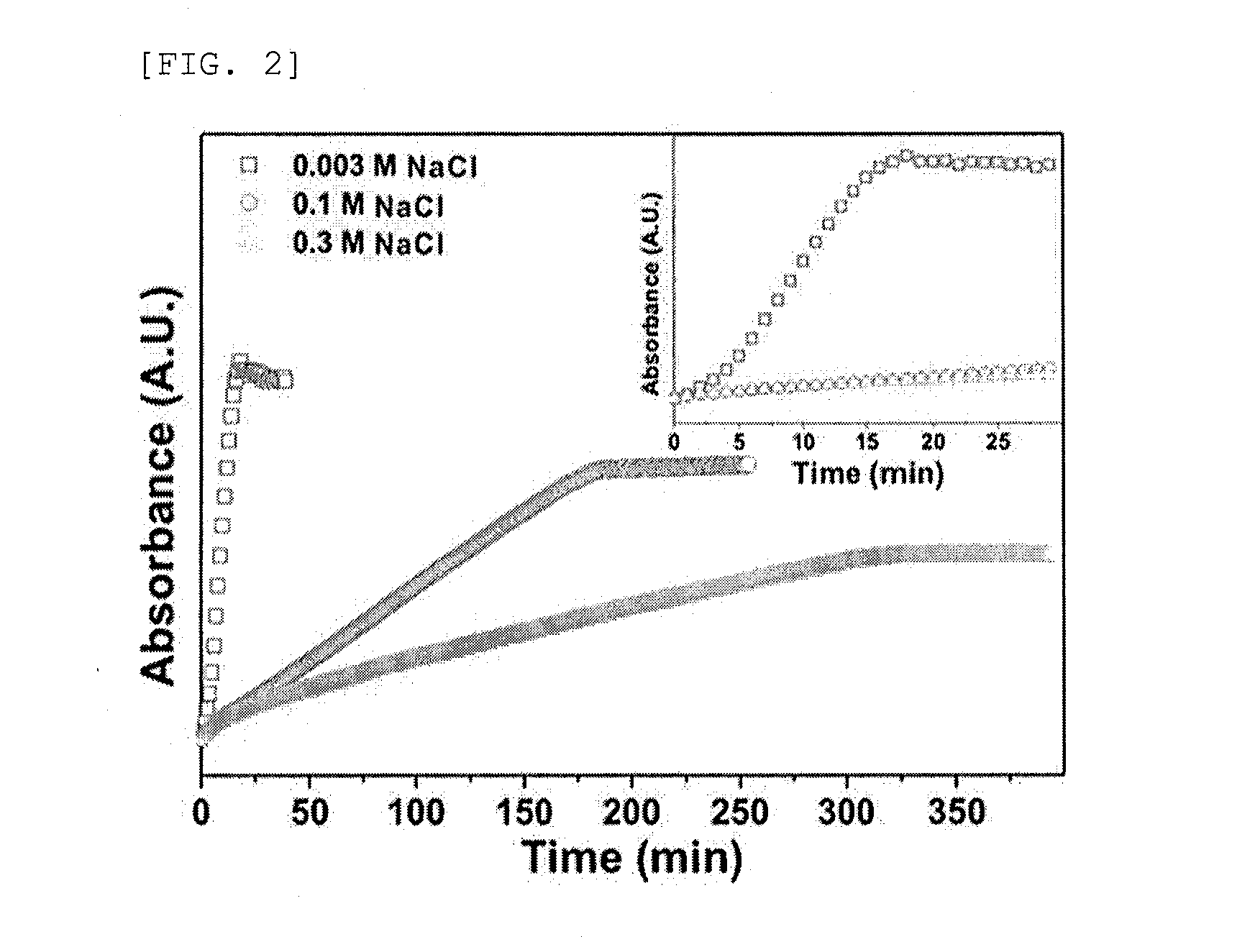

Nanoparticles in the shape of nanosnowman with a head part and a body part, a preparation method thereof and a detection method using the same

InactiveUS20130295563A1Improve applicationMicrobiological testing/measurementIndividual molecule manipulationBiophysicsBody segment

The present invention relates to nanoparticles in the shape of nanosnowman with a head part and a body part, a preparation method thereof, and a detection method using the same. More particularly, the present invention relates to nanoparticles in the shape of nanosnowman with head and body parts, which can offer platforms for DNA-based assembly of various aligned and unconventional nanostructures and is highly applicable to the detection of DNA and an analyte associated with the onset and progression of a particular disease, a preparation method thereof, and a detection method using the same.

Owner:SEOUL NAT UNIV R&DB FOUND

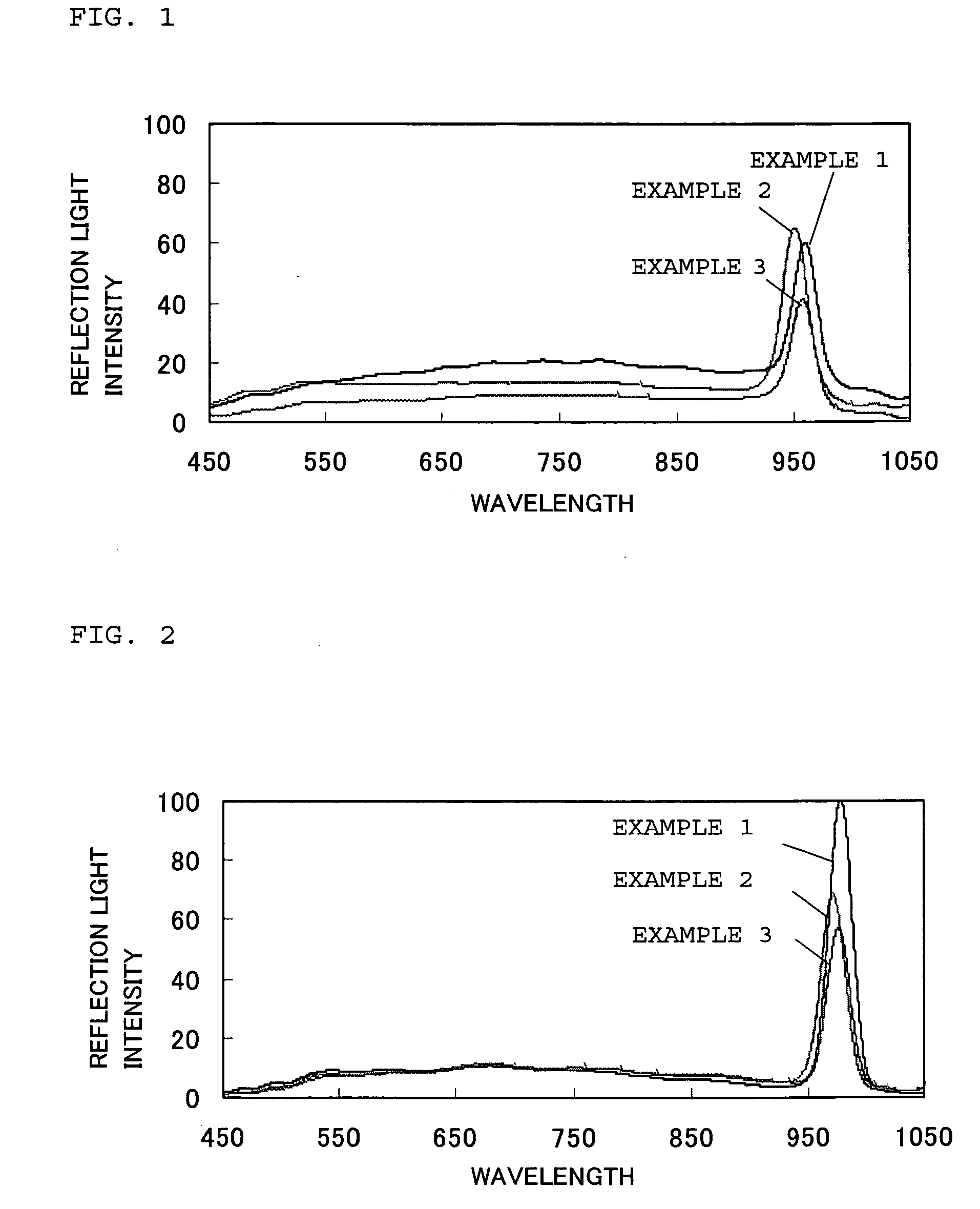

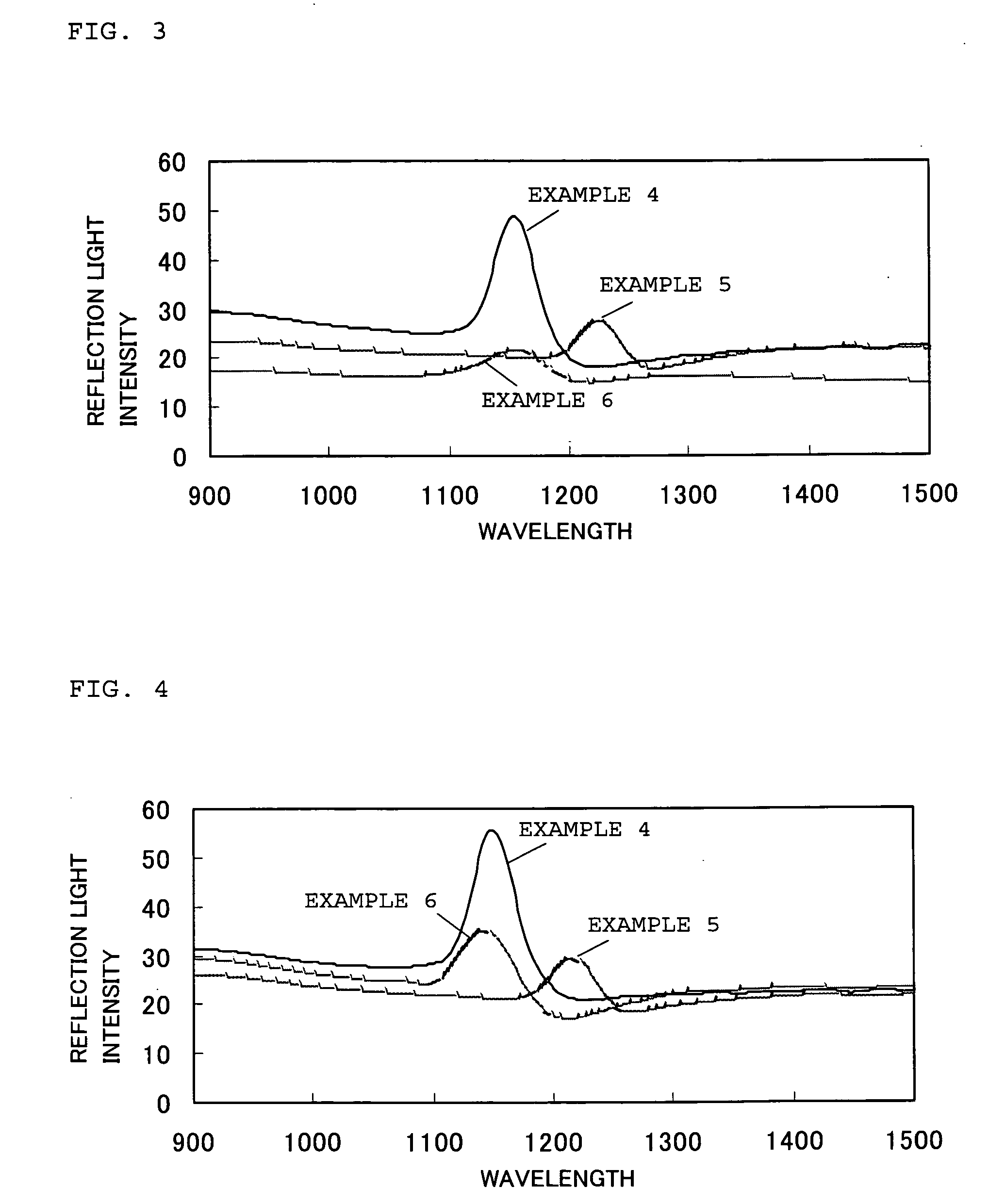

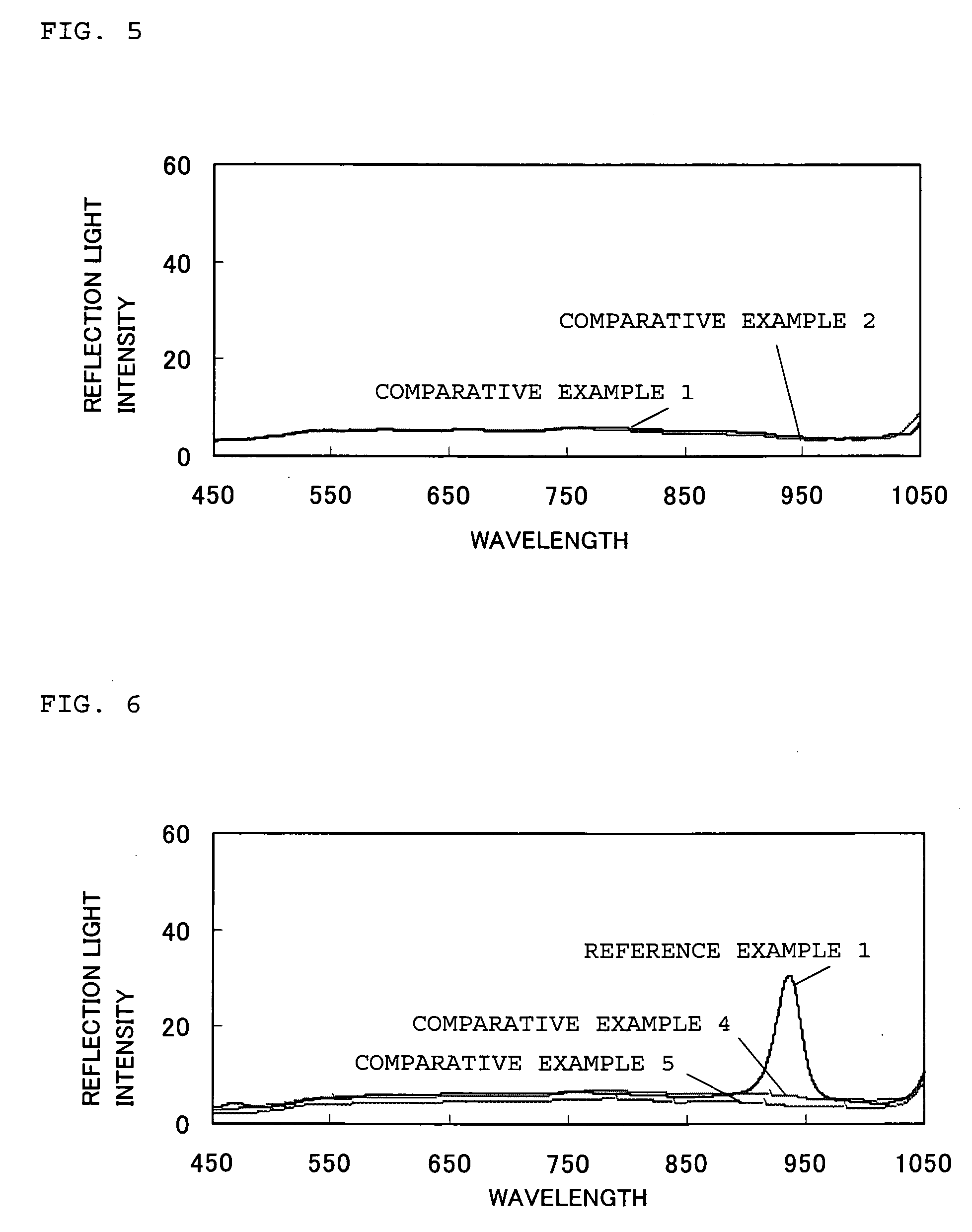

Process for producing colloidal crystals immobilized with a polymer and colloidal crystals immobilized with a polymer

InactiveUS20080305968A1Low degreeEasy to fixPolycrystalline material growthFrom normal temperature solutionsColloidal particleMonomer

A process for producing colloidal crystals immobilized with a polymer, comprising the steps of:preparing a monomer-dispersion in which colloidal crystals having a three-dimensionally ordered array state are formed by adding, to a monomer-containing liquid containing at least one kind of monomers, colloidal particles having an average particle size in a range from 0.01 μm to 10 μm and a degree of monodispersity expressed by a following equation (1) of 20% or below,[Degree of monodispersity (unit: %)]=([Standard deviation of particle size] / [Average particle size])×100 (1)and then by dispersing the colloidal particles so as to arrange the colloidal particles in a three-dimensionally ordered array state at which a reflection spectrum thereof exhibits a reflection peak; andobtaining the colloidal crystals immobilized with a polymer by polymerizing the monomers in the monomer-dispersion.

Owner:TOYOTA CENT RES & DEV LAB INC

Miniature speaker with essentially no acoustical leakage

ActiveUS20200211521A1Improve applicationMicrophonesLoudspeaker transducer fixingCantilevered beamHearing apparatus

The present invention relates to a miniature speaker comprising front and a rear volume, and one or more moveable diaphragms each comprising one or more cantilever beams, and associated one or more air gaps, arranged between the front and rear volumes, wherein the one or more cantilever beams are configured to bend or deflect in response to an applied drive signal, and wherein the one or more air gaps between the front and rear volumes remain essentially unaffected during bending or deflection of the one or more cantilever beams thus maintaining the acoustical leakage between the front and rear volumes at a minimum. The present invention further relates to a receiver assembly comprising such a miniature speaker, and to a hearing device, such as a receiver-in-canal hearing device, comprising such a receiver assembly.

Owner:SONION NEDERLAND

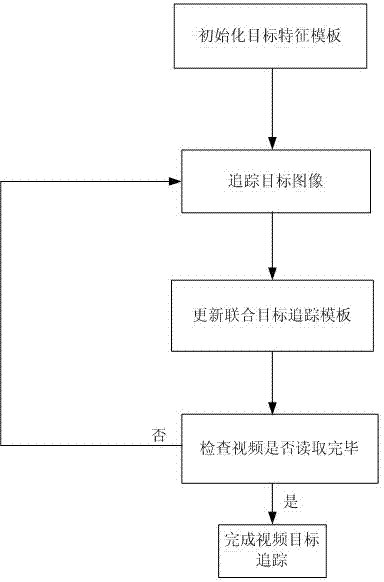

United target tracking method based on local sparse representation and system thereof

ActiveCN103544483AHigh precisionImprove efficiencyCharacter and pattern recognitionGoal attainmentVideo tracking

The invention relates to a united target tracking method based on local sparse representation and a system thereof. Compared with the prior art, the united target tracking method based on the local sparse representation and the system thereof overcome the defects that tracking cannot succeed when target images are shielded and the appearance characteristics change in the video tracking technology. The united target tracking method based on the local sparse representation comprises the following steps of initializing a template of the appearance characteristics of a target, tracking images of the target, updating a tracking template of a united target, and checking whether reading of a video is finished or not. The united target tracking method based on the local sparse representation and the system thereof improve the precision and efficiency of target tracking in complex scenes, and improve the application degree of the target tracking technology in various scenes. The effect that accurate tracking can be achieved when target images are shielded is achieved through classifier models in the comparing process and by adopting the self-learning technology in the tracking technology.

Owner:HEFEI UNIV OF TECH

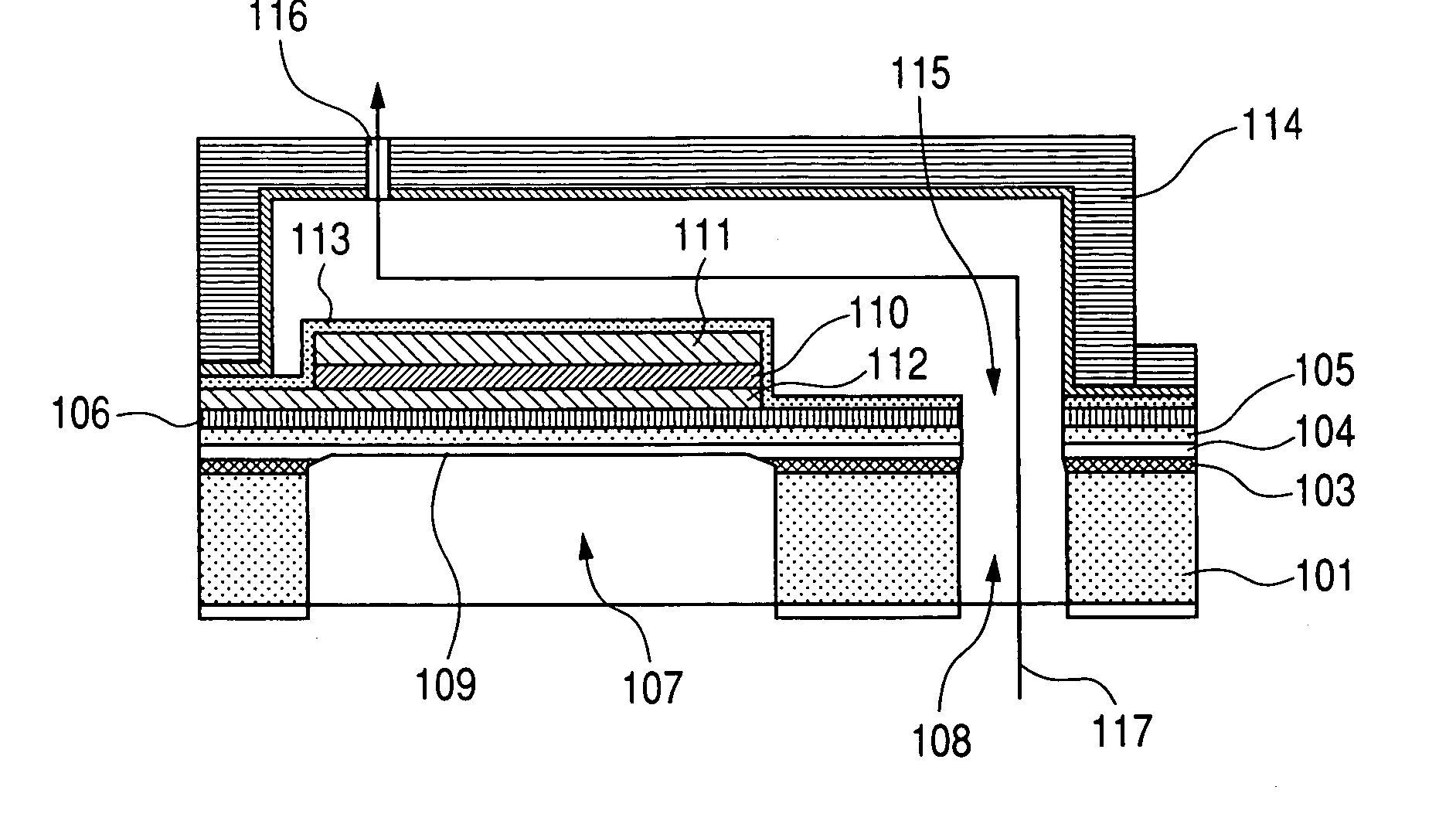

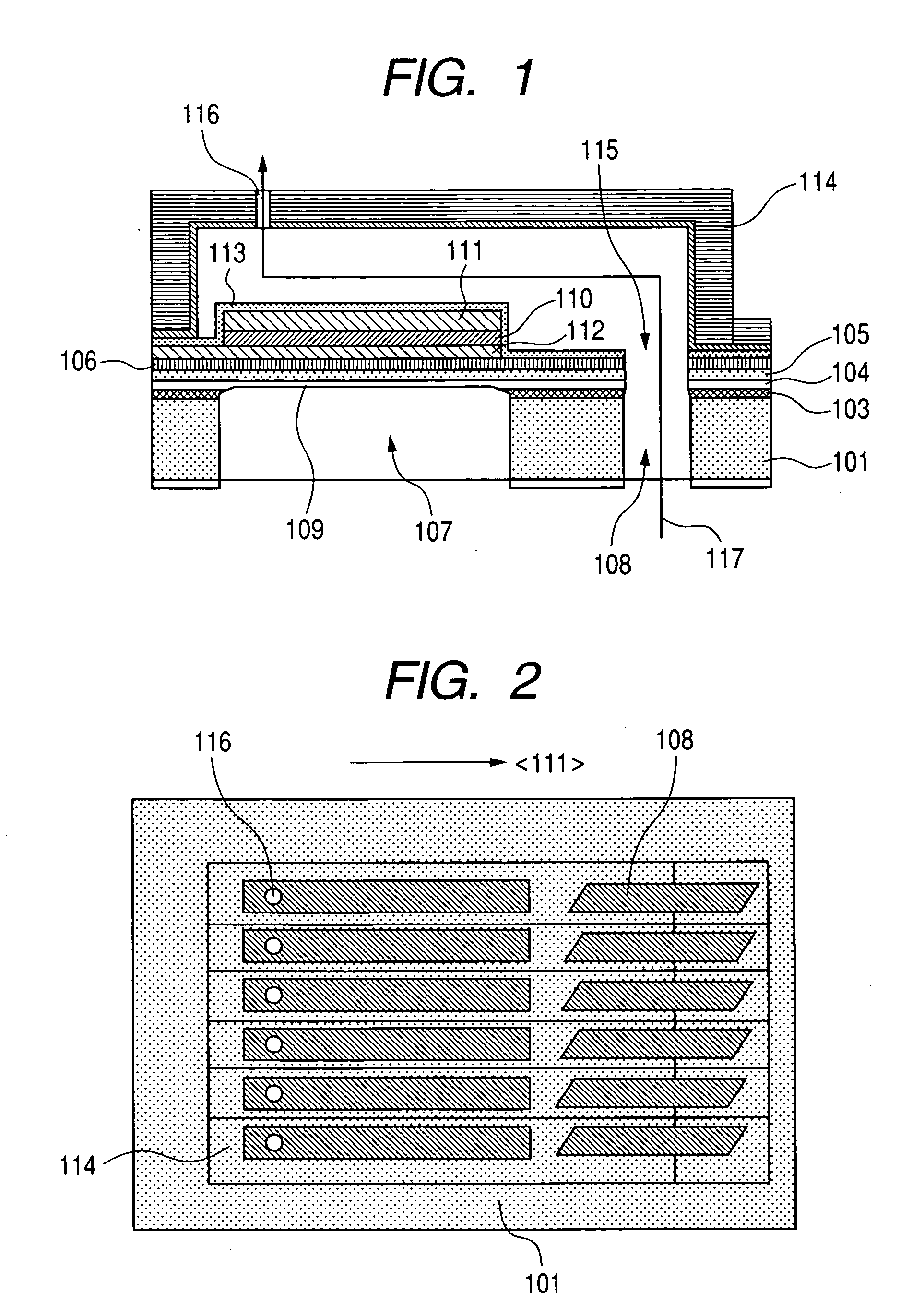

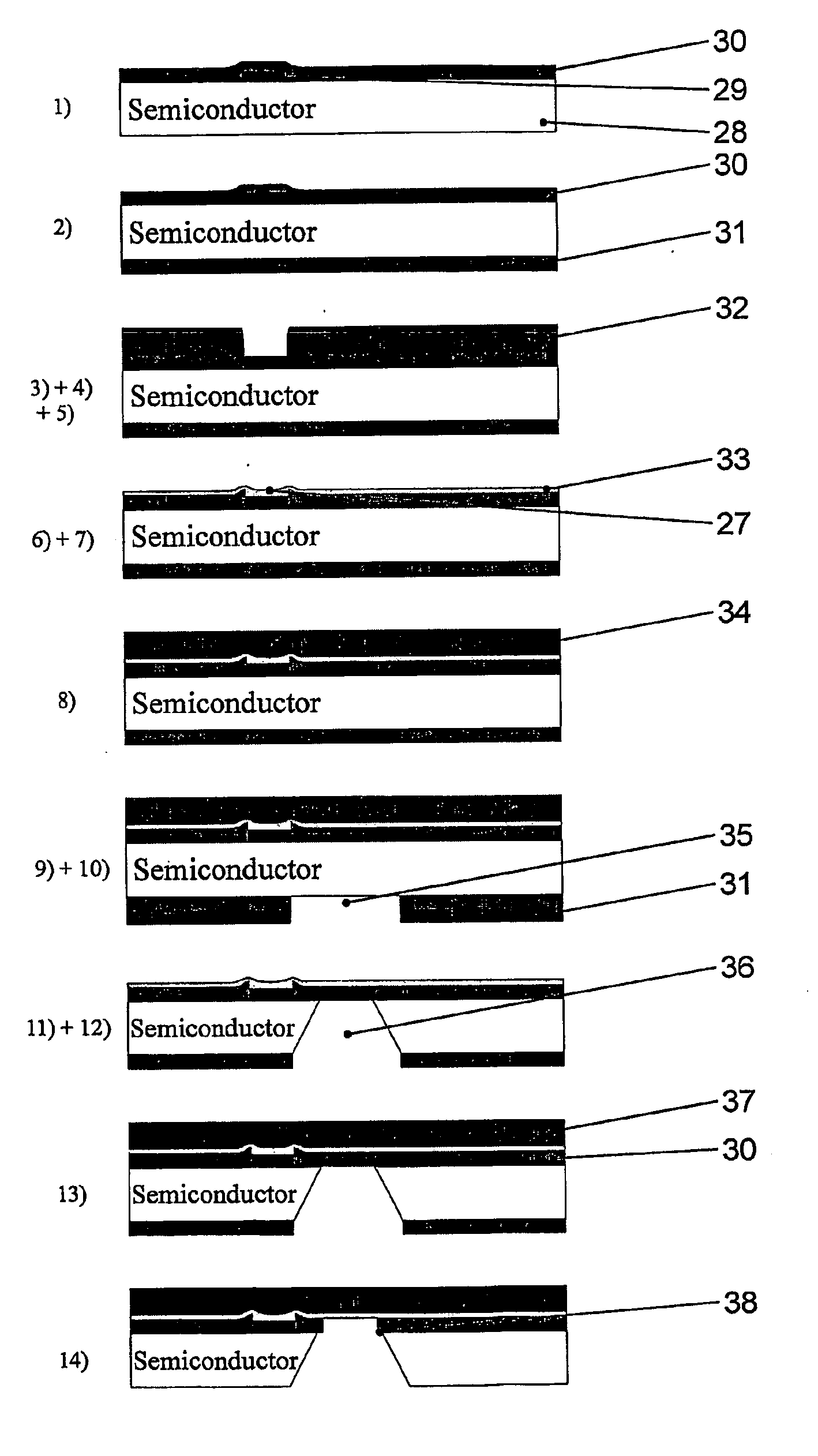

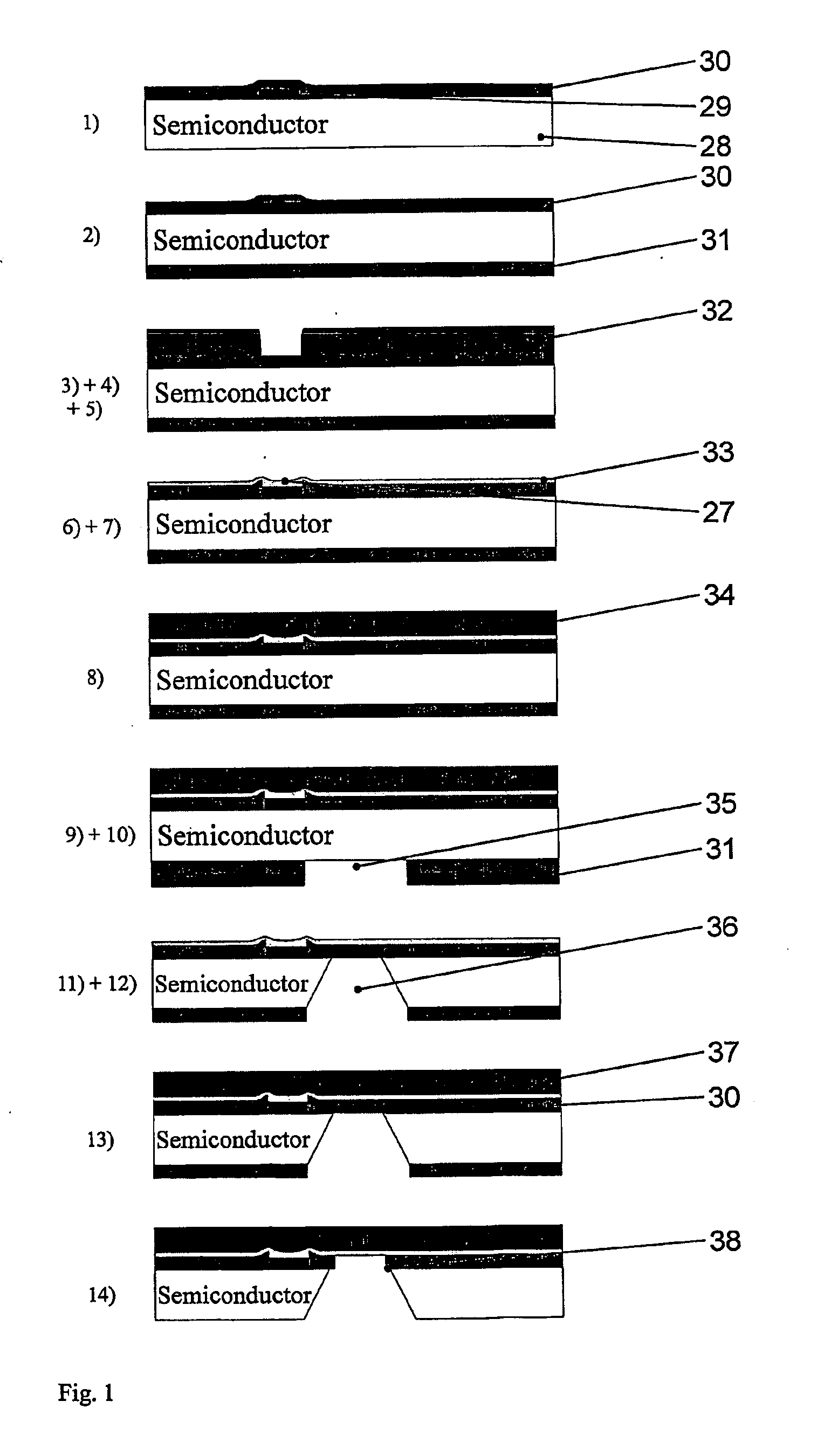

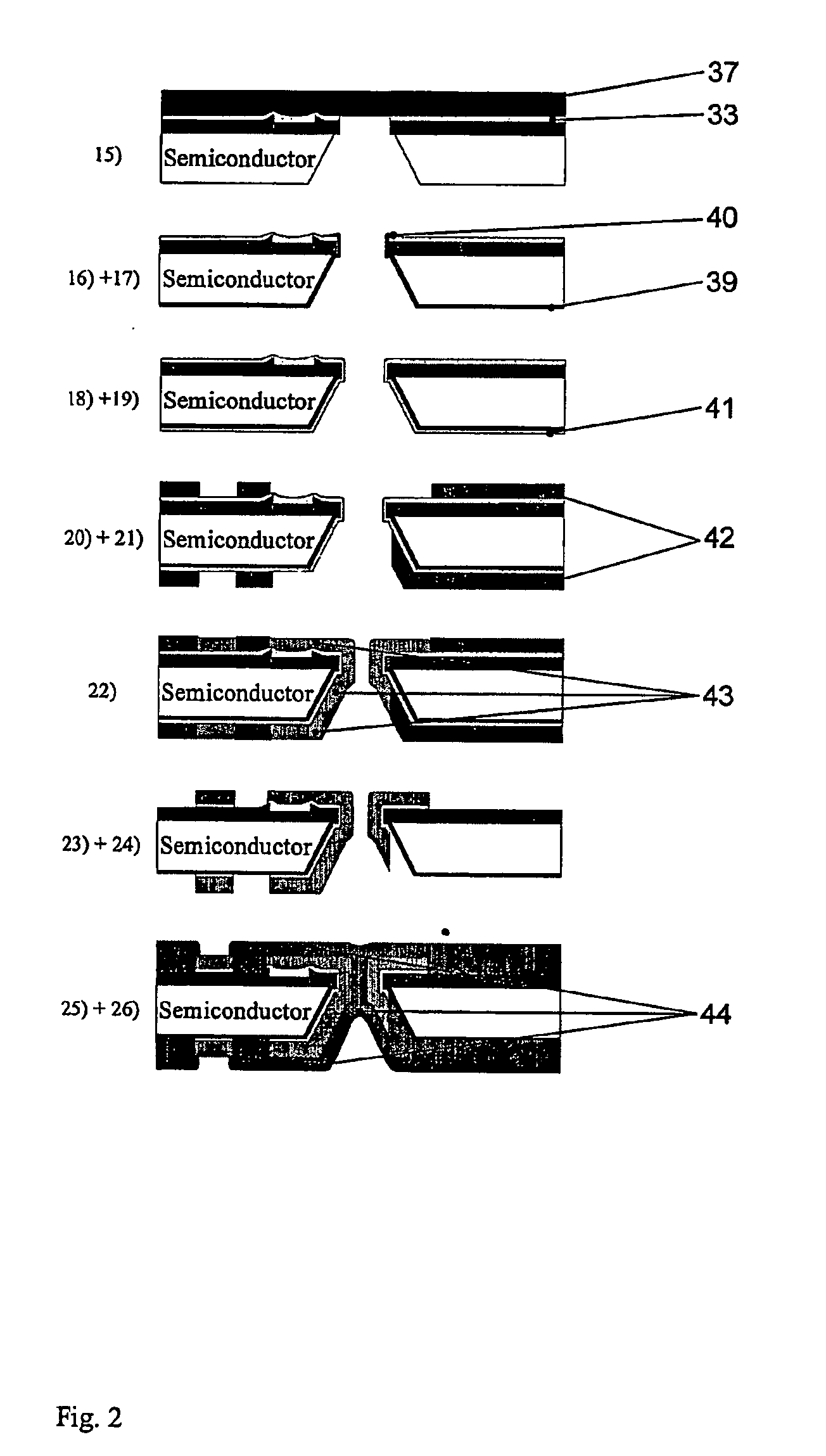

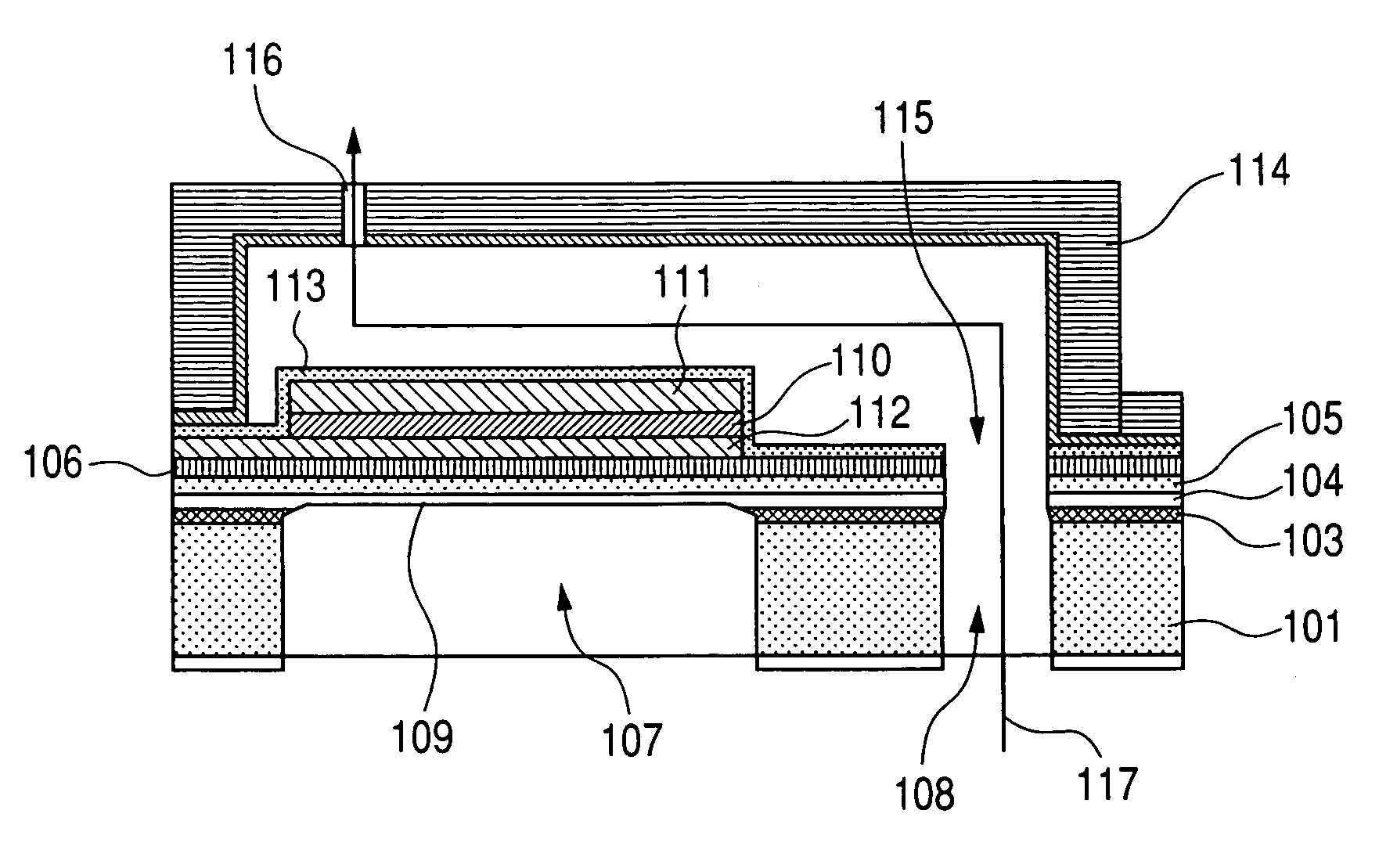

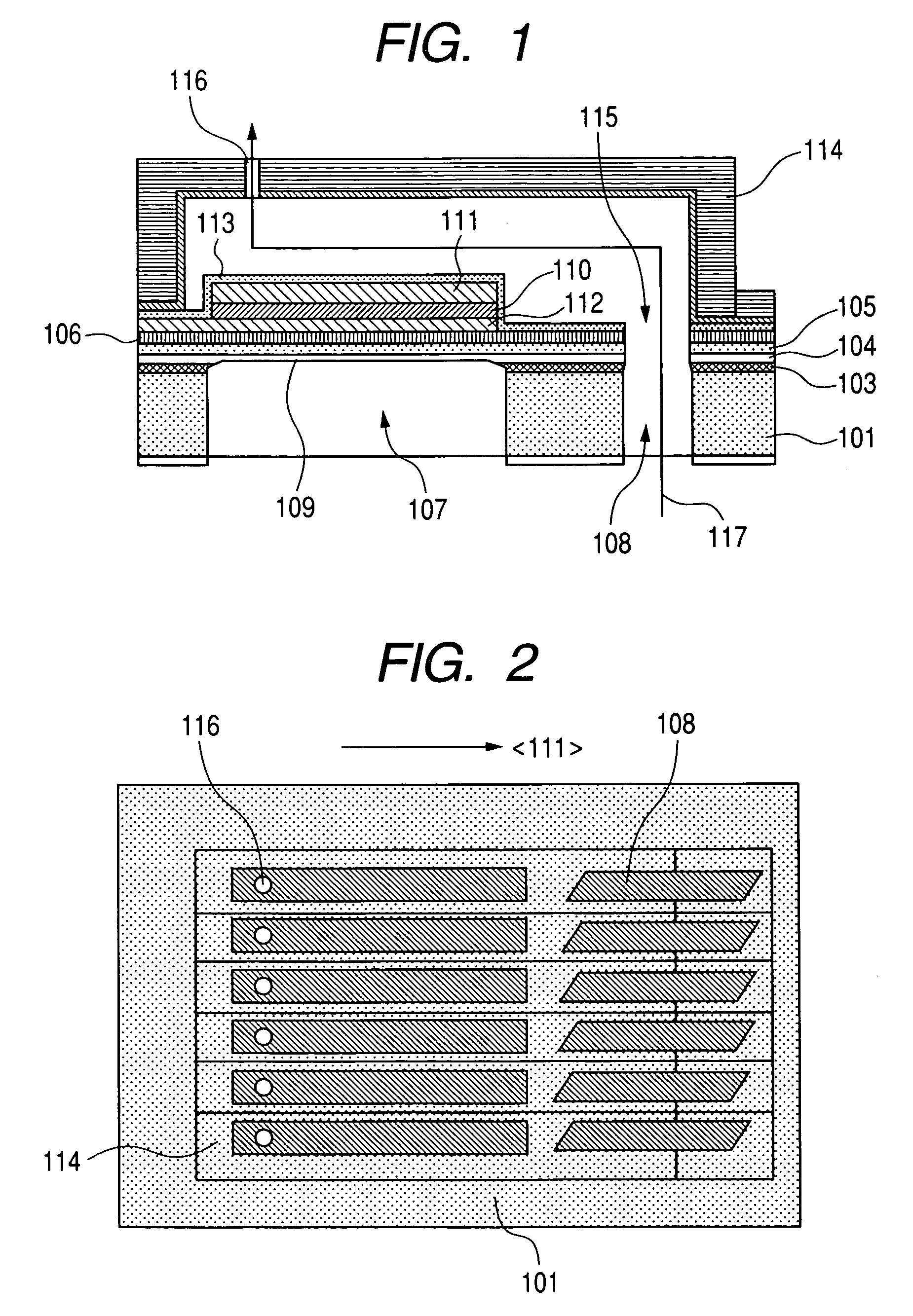

Method of manufacturing liquid discharge head and method of manufacturing substrate for liquid discharge head

InactiveUS20060027529A1High yieldDense highRecording apparatusRecord information storageEngineeringSingle crystal

A method of manufacturing a liquid discharge head including a pressure generating chamber communicated to a discharge port for discharging liquid and a piezoelectric element which is provided corresponding with the pressure generating chamber and includes a piezoelectric material film and a pair of electrode films sandwiching the piezoelectric material film, including: a step of preparing a structure with a single crystal Si layer being accumulated above a front surface of an Si substrate through an etching stop layer; a step of forming a buffer layer on the above described single crystal Si layer; a step of forming, above the above described buffer layer, the above described piezoelectric material film consisting of a single crystal thin film or a thin film which is directed in a preferential orientation to a direction of the polarization through one of the above described pair of electrode films; a step of forming the above described pressure generating chamber on the above described piezoelectric material film; and a step of etching a location corresponding with the above described piezoelectric material film of the above described Si substrate from a rear surface of the above described Si substrate to reach the above described etching stop layer.

Owner:CANON KK

Feed-through process and amplifier with feed-through

InactiveUS20050215054A1Improve applicationMounting of the sensitive wafer in an enclosure is avoidedSemiconductor/solid-state device manufacturingSemiconductor devicesAudio power amplifierEngineering

The invention concerns a process for generating a feed-through in a semiconductor wafer, which has electric circuitry embedded in a front surface whereby the hole for the feed-through is generated by the combined use of a front side protection layer and a wet KOH etch process etching the hole from the back side of the wafer, where a photomasking process is subsequently used do define the via followed by deposition of the via material.

Owner:OTICON

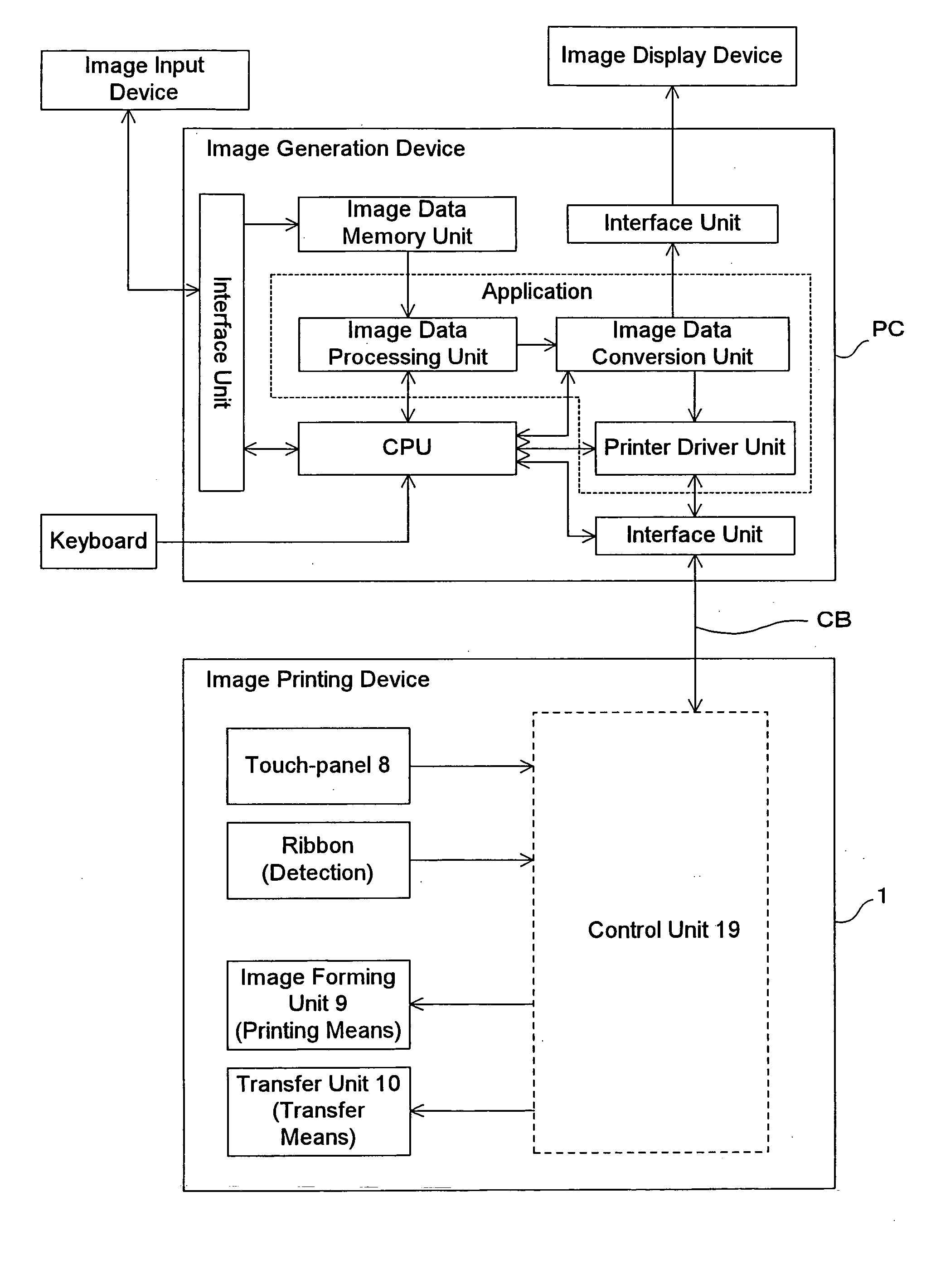

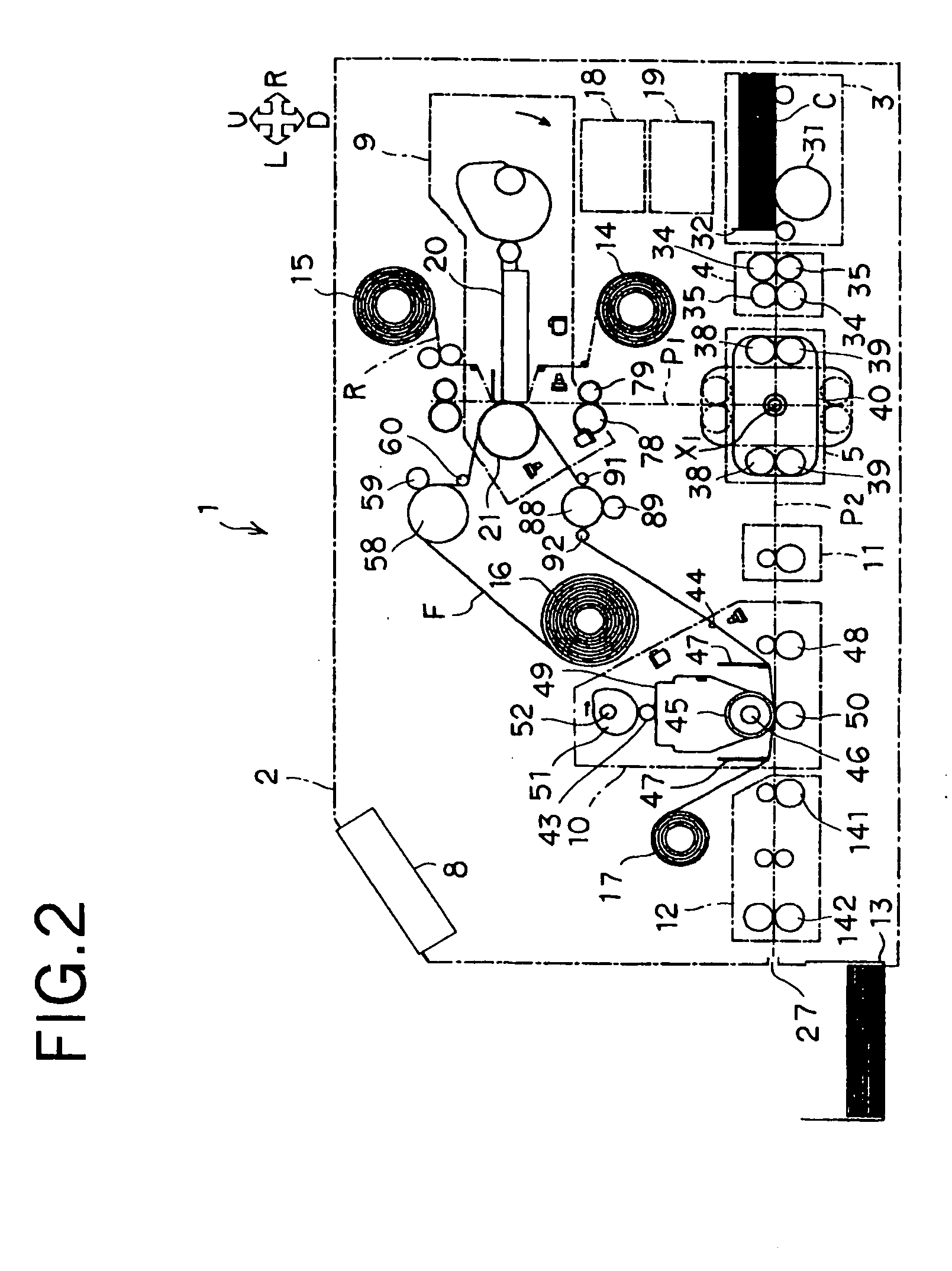

Printing method and printing system and printing apparatus

InactiveUS20050052524A1Improve convenienceLow running costRecording apparatusPrinting mechanismsImage formationImaging data

In direct transfer, a card is transported to an image forming portion, same size, reduced or gradation corrected image data is used for forming an image to the entire surface of at least one side of a card. In indirect transfer, intermediate transfer film is transported to an image forming portion, and same size, reduced or gradation corrected image data is used to form images on the intermediate transfer film, then while transporting the intermediate transfer film to a transfer portion, a card is also transported to the transfer portion where images formed on the intermediate transfer film are transferred to the entire area of at least one side of the card. Image data size is varied. By switching between a direct transfer method and an indirect transfer method makes either transfer method applicable thereby improving printer user convenience, enables the forming of beautiful printing to the entire print surface, lowers running costs and enables high applicability of the printing system.

Owner:NISCA KK

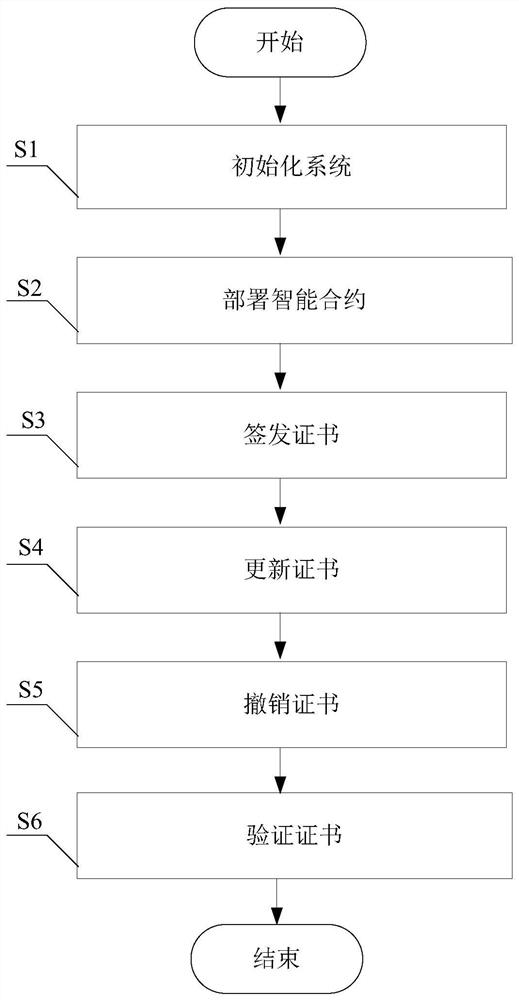

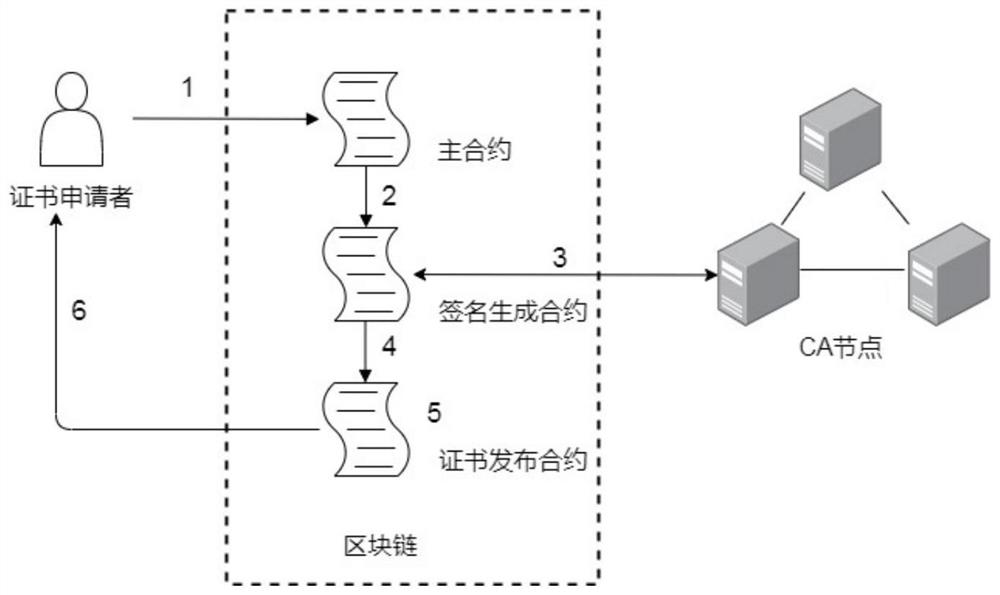

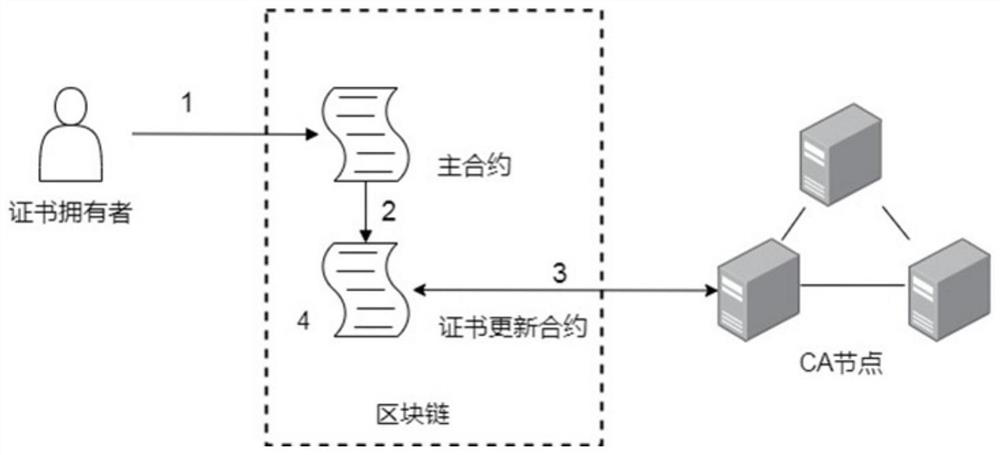

Distributed public key infrastructure construction method based on editable blockchain

ActiveCN112187455AReduce storage pressureReduce verification timeKey distribution for secure communicationUser identity/authority verificationEngineeringSmart contract

The invention provides a distributed public key infrastructure construction method based on an editable blockchain, and belongs to the technical field of public key infrastructure, and the method comprises the following steps: S1, initializing a system; S2, deploying an smart contract; S3, signing and issuing a certificate; S4, updating the certificate; S5, revoking the certificate; and S6, verifying the certificate. Compared with an existing PKI system based on a blockchain, an editable blockchain framework is creatively adopted, a new block does not need to be uploaded during certificate updating and revocation, the storage pressure of a blockchain network can be reduced, the certificate verification time can be shortened, a threshold ring is used for signing and issuing a certificate, and an authentication mechanism is composed of multiple CA nodes; the CA independently audits the operation request for the certificate, and the certificate can be operated only after the CA exceedingthe threshold number passes the auditing, so that the tolerance of the system to a Byzantine node is improved, and the security is relatively high.

Owner:SOUTHWEST JIAOTONG UNIV +1

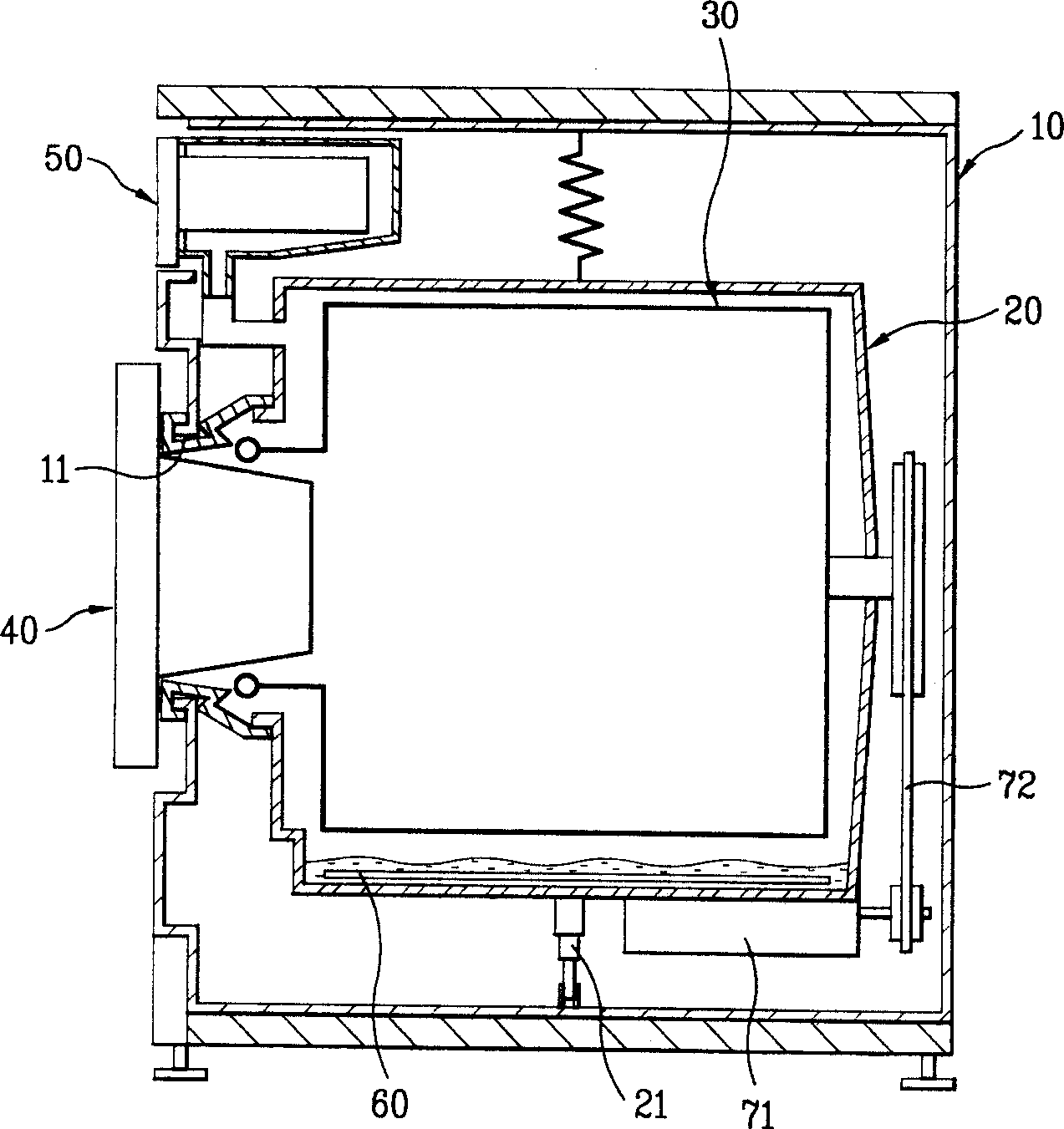

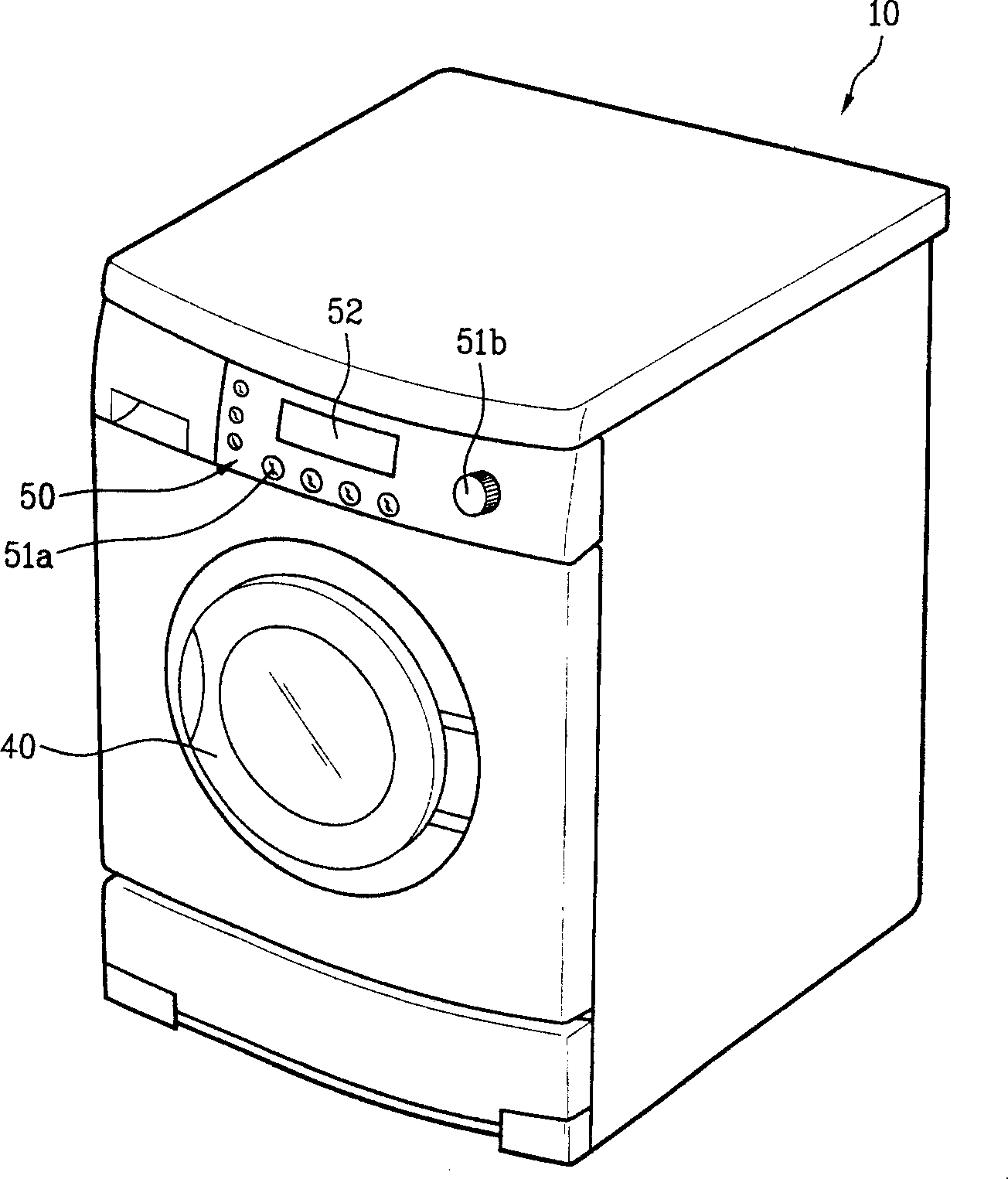

Scouring apparatus

InactiveCN101177890AImprove applicationAvoid destructionTelevision system detailsPulse modulation television signal transmissionAnimationImaging data

The invention discloses a washing device, comprising a main body forming the appearance, a control panel convenient for users to perform various washing-relevant operations, a data transceiving part for transceiving various content data, an image output part that is arranged on one surface of each external side of the main body and can form an unfolded state by turning over and is provided with a screen that receives and displays image data from various content data and a data transferring part that transfers the content data of the data transceiving part to the image output part. The invention is provided, on the washing device, with the image output part and a sound output part, through which the users can see and listen to various contents, ensuring users to watch TV or listen to broadcasting and watch cartoon during the washing process, thereby improving the product application by users. The image output part can be foldably stored up inside an accommodating part formed on the main body, thus avoiding, to the greatest extent, the damage caused by the exposure of the image output part.

Owner:NANJING LG PANDA APPLIANCES

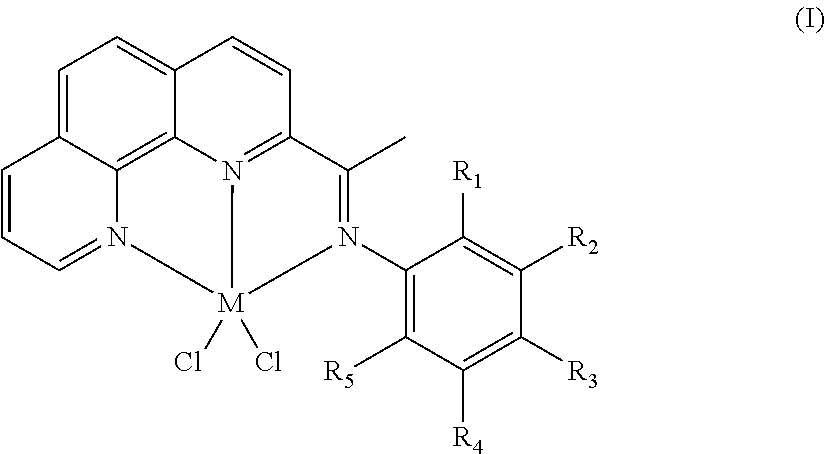

Catalyst composition for oligomerization of ethylene and processes of oligomerization

InactiveUS20130018214A1Low costReduce the amount requiredOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPhenanthrolineChloride

The present invention provides a catalyst composition for the ethylene oligomerization, which comprises 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst. The present invention also provides a process for oligomerization of ethylene is provided, wherein a catalyst composition comprising 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst is used, and the molar ratio of aluminum in the cocatalyst to central metal in the main catalyst ranges from 30 to less than 200. According to the present invention, another process for oligomerization of ethylene is also provided, wherein a catalyst composition comprising 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst is used, and the temperature of ethylene oligomerization ranges from −10 to 19° C. According to the present invention, the price of cocatalyst i.e. triethylaluminum, is low, just a fraction of that of methylaluminoxane, the amount of cocatalyst is therefore significantly reduced, with the catalytic activity is still acceptable, thus the cost of ethylene oligomerization is significantly reduced. In view of both the catalytic activity and the cost, the present invention is highly applicable in industry.

Owner:CHINA PETROCHEMICAL CORP +1

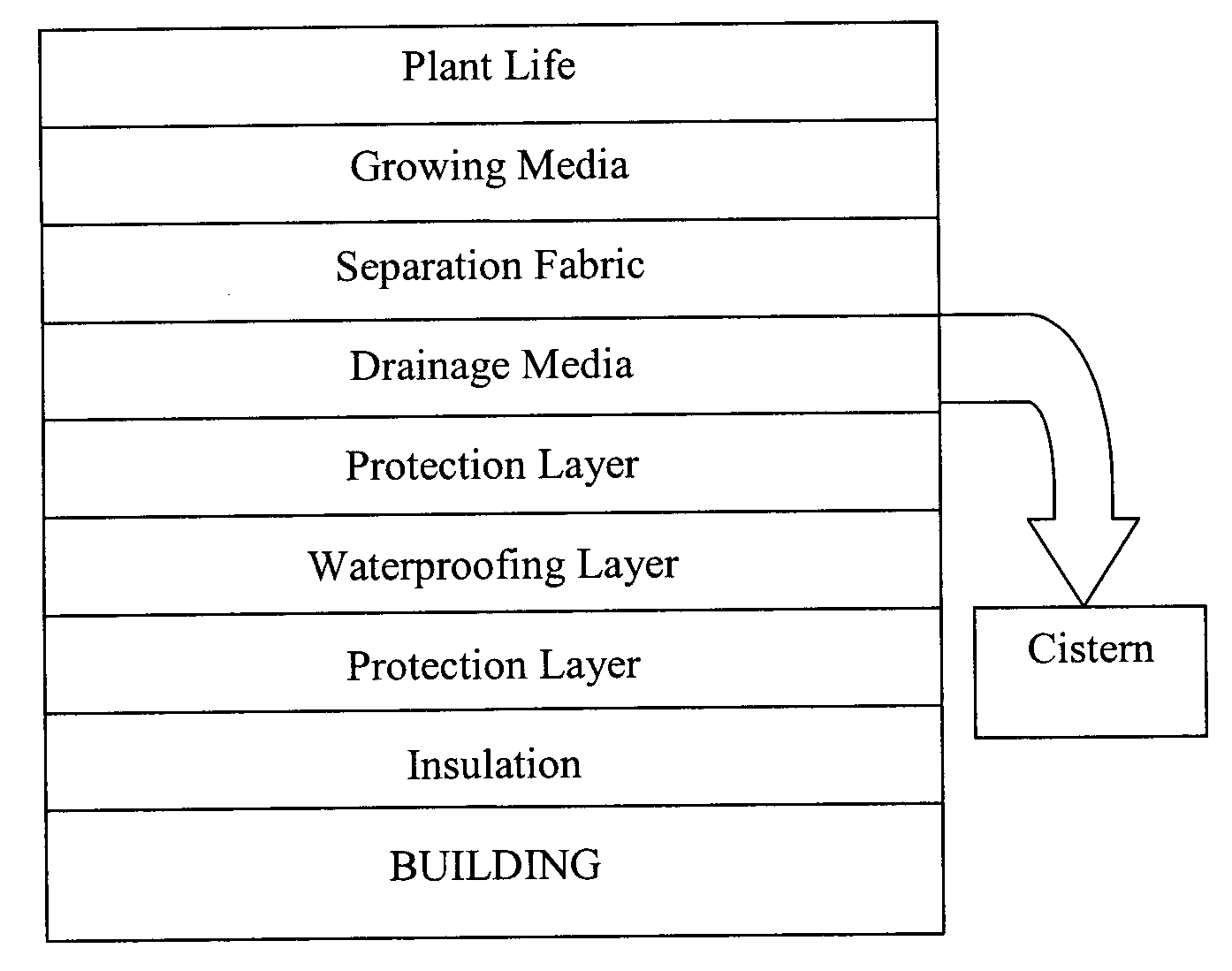

Retention/Detention Pond And Green Roof Passive Nutrient Removal Material Mixes

ActiveUS20100051540A1Improve sustainabilityIncrease flexibilityCalcareous fertilisersWater cleaningFiltrationEngineering

Materials, compositions, substances and methods and systems for stormwater treatment in wet ponds, dry ponds and a green roof system. A first embodiment provides in-situ treatment unit within the retention pond by withdrawing the stored stormwater to circulate the stored stormwater into the in-situ treatment unit to sorb nitrogen from the stored stormwater. A second embodiment provides uses a riprap apron, a perforated riser located at the bottom of the riprap apron and a goetextile media encased in a sorption media jacket around the perforated riser. A third embodiment provides a green roof stormwater treatment system that includes protection for waterproofing and insulating the roof, a pollution control media layer for filtration and sorption of solids and dissolved materials found in stormwater, a growing media for growing vegetation, and a cistern to store the runoff stormwater between irrigation events. The green roof system includes recycling runoff stormwater by irrigating the green roof with the stored stormwater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Method of manufacturing liquid discharge head and method of manufacturing substrate for liquid discharge head

InactiveUS7497962B2Simple processHighly dense piezoelectricRecording apparatusRecord information storageOptoelectronicsSingle crystal

A method of manufacturing a liquid discharge head, which includes a pressure generating chamber, a discharge port, and a piezoelectric element formed of a pair of electrode films sandwiching a piezoelectric material film, includes steps of preparing a structure with a single crystal Si layer accumulated above a front surface of an Si substrate through an etching stop layer; forming a buffer layer on the single crystal Si layer; forming, above the buffer layer, the piezoelectric material film which is directed in a preferential orientation to a direction of the polarization through one of the pair of electrode films; forming the pressure generating chamber on the piezoelectric material film; and etching a location corresponding to the piezoelectric material film of the Si substrate from a rear surface of the Si substrate to reach the etching stop layer.

Owner:CANON KK

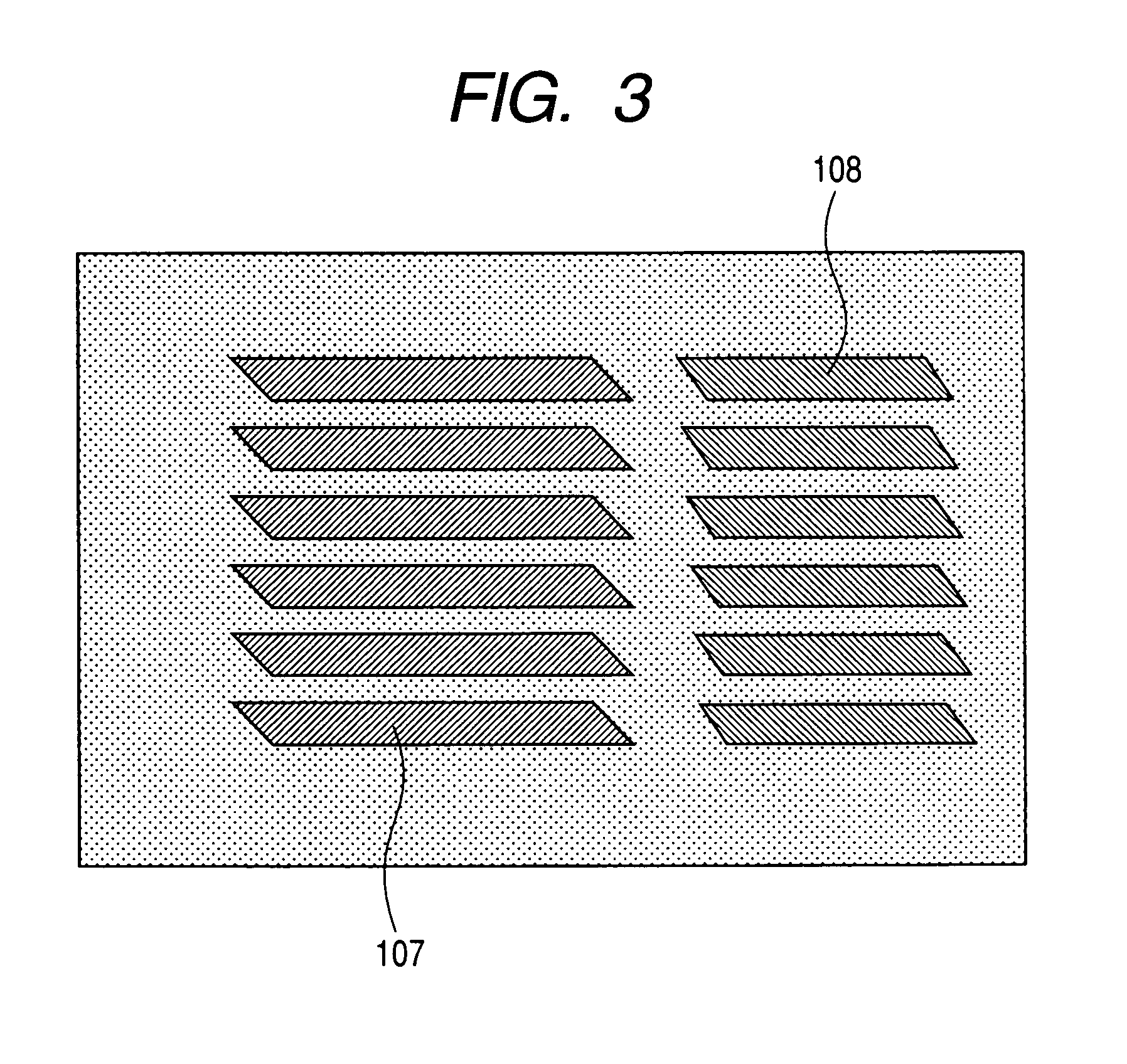

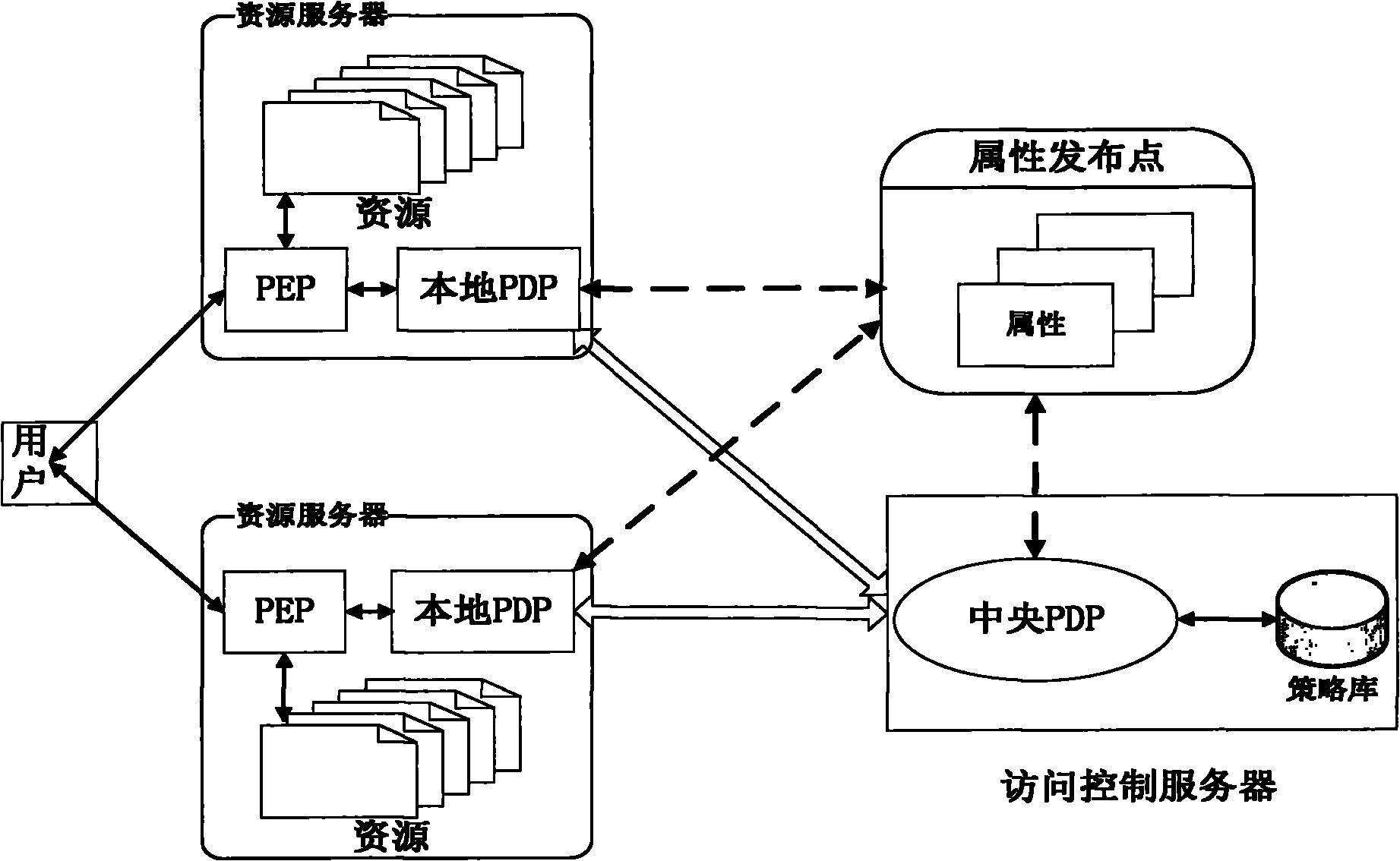

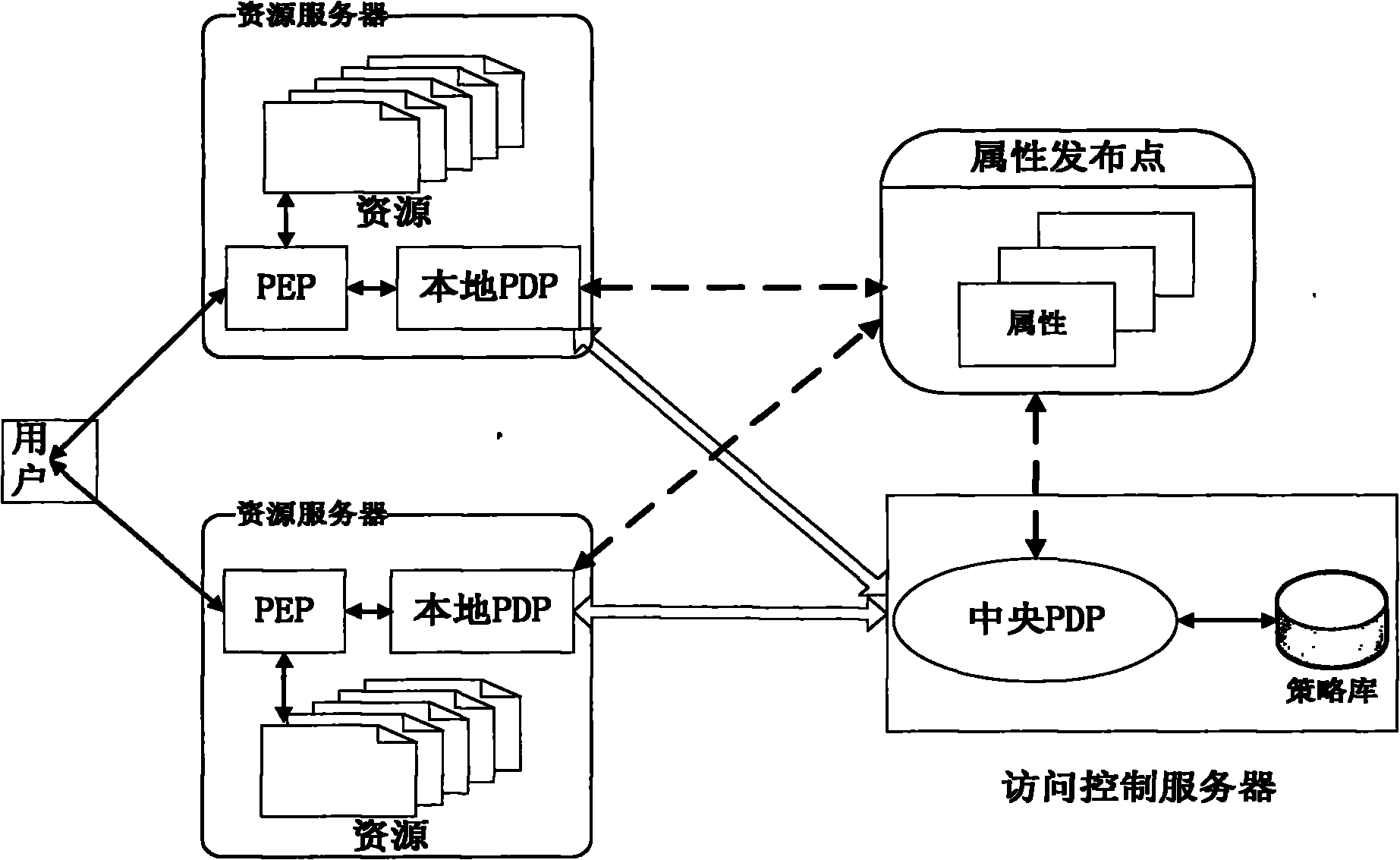

Two-level policy decision-based access control method and system

ActiveCN102006297AGuaranteed versatilityReduce the burden onTransmissionPolicy decisionAccess control matrix

The invention discloses a two-level policy decision-based access control method and a two-level policy decision-based access control system, and belongs to the field of access control in information safety. In the method, a local policy decision point (PDP) is deployed at a policy enforcement point (PEP) end, and the local PDP makes a decision for an access request according to a local policy cache, and if the local PDP cannot determine that the decision is a deterministic decision, a central PDP finally finishes the decision according to a system policy library. The system comprises a policydecision server, an attribute publishing point and a plurality of resource servers, wherein a policy enforcement point (PEP) and a local policy decision point (PDP) are deployed on each resource server; and a central policy decision point (PDP) is deployed on the policy decision server. The invention has a good dynamically adjusted elastic system framework, fully utilizes the computing resources of the PEP end, lightens the burden of the central PDP, reduces the network transmission overhead and effectively improves the access control efficiency at extremely low policy update cost.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

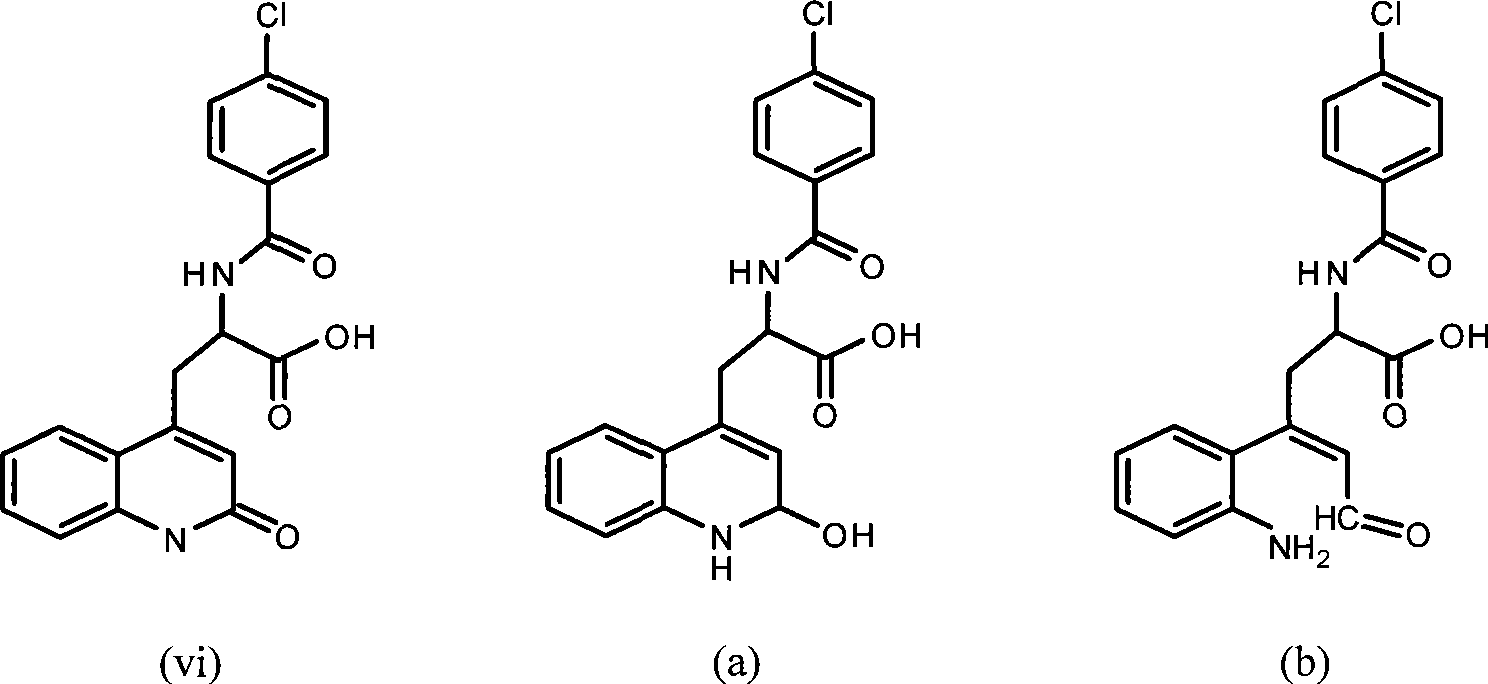

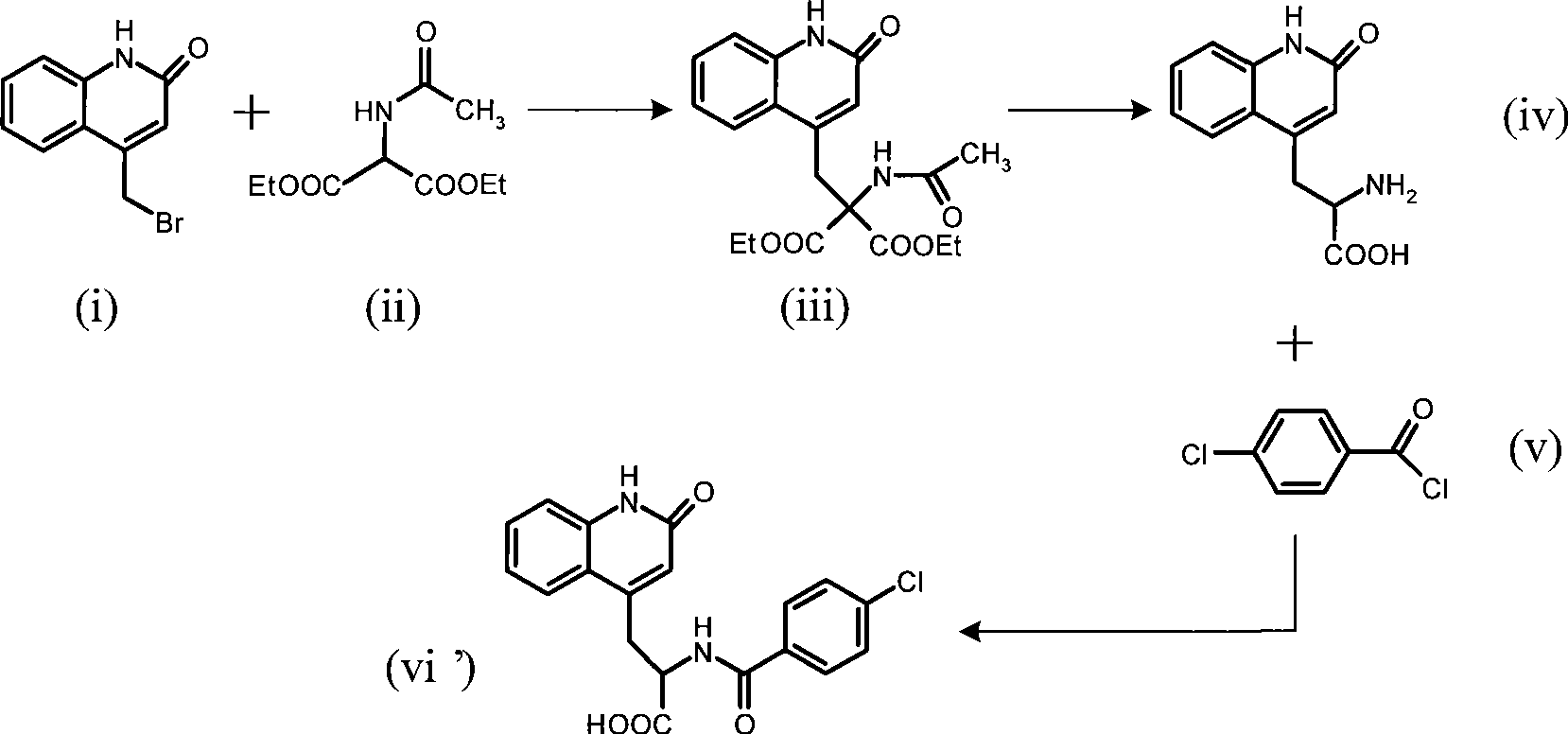

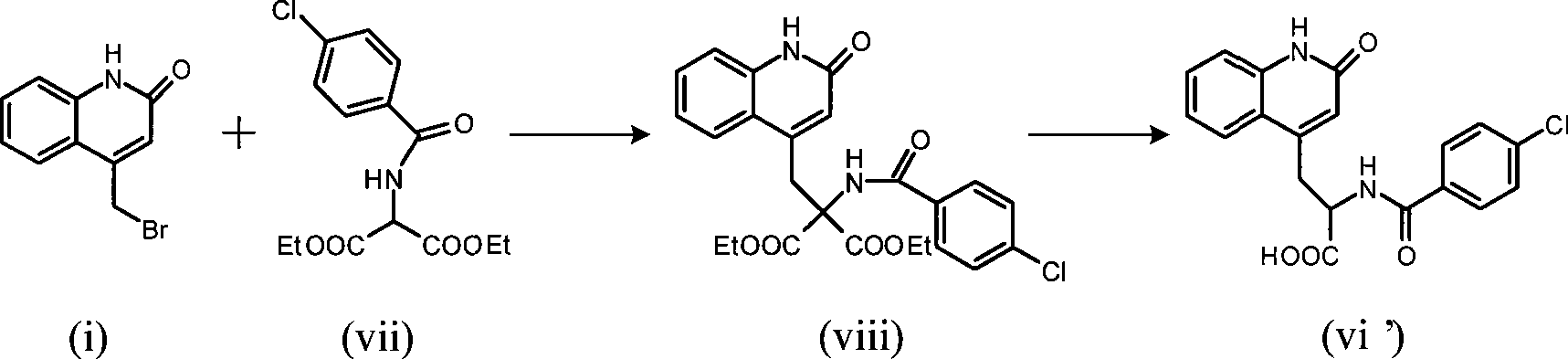

Method for purifying rebamipide crude product

InactiveCN101463005AImprove applicationInhibition of ring opening reactionOrganic chemistryDigestive systemActivated carbonProtective drugs

The invention relates to a purifying method for a Rebamipide crude product. Alkaline is added in alcohol-water mixed solvent to dissolve the Rebamipide crude product. Then, activated carbon is added for decolorizing. Concentrated hydrochloric acid is added dropwise, pH is regulated to 2-3, solids are precipitated, and purified Rebamipide is obtained after filtering and drying. During the process, the mol ratio of the added amount of alkaline to the Rebamipide is controlled to be less than 3 to 1. And the operational temperature during the alkaline adding for dissolution and the acid adding for crystallization is controlled at 150 DEG C; therefore; the ring cleavage reaction of quinolone is inhabited and the generation of two impurities which are similar in structure with Rebamipide is reduced. Rebamipide with the purity of higher than 99.5 percent is obtained. Conditions are provided for improving the application degree of Rebamipide in pharmaceutical aspects of gastric mucosal protective drugs, etc.

Owner:苏州天马医药集团天吉生物制药有限公司

Multifunctional plastic with anti-microbial effect, oxidation resistance and metal-chelating property and preparation method thereof

The invention provides a multifunctional plastic with an anti-microbial effect, an oxidation resistance and a metal-chelating property and a preparation method thereof. The plastic material is mainly prepared from the following raw materials in parts by weight: 6%-10% of active anti-microbial agent, 2%-6% of active antioxidant, 3%-8% of metal-chelating agent and the balance of macromolecule resin base membrane. The modified resin substrate has certain anti-microbial effect, oxidation resistance and metal-chelating property. A novel application material is supplied for the products, such as, electronic cigarette, and the fields, such as, food packaging. The plastic has certain various characteristic functions; on the basis of improvement for the inherent performance of the products, the plastic is endowed with a more practical characteristic; the guarantee period of the products is prolonged and the application thereof is improved, so that the market value is promoted; the original raw material cost is lowered; the market space is expanded and the incoming is increased.

Owner:CHINA TOBACCO GUANGXI IND

Passive nutrient removal material mixes

ActiveUS7824551B2Improve sustainabilityIncrease flexibilityCalcareous fertilisersSolid sorbent liquid separationFiltrationStormwater treatment

Materials, compositions, substances and methods and systems for stormwater treatment in wet ponds, dry ponds and a green roof system. A first embodiment provides in-situ treatment unit within the retention pond by withdrawing the stored stormwater to circulate the stored stormwater into the in-situ treatment unit to sorb nitrogen from the stored stormwater. A second embodiment provides uses a riprap apron, a perforated riser located at the bottom of the riprap apron and a geotextile media encased in a sorption media jacket around the perforated riser. A third embodiment provides a green roof stormwater treatment system that includes protection for waterproofing and insulating the roof, a pollution control media layer for filtration and sorption of solids and dissolved materials found in stormwater, a growing media for growing vegetation, and a cistern to store the runoff stormwater between irrigation events. The green roof system includes recycling runoff stormwater by irrigating the green roof with the stored stormwater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Latch assembly

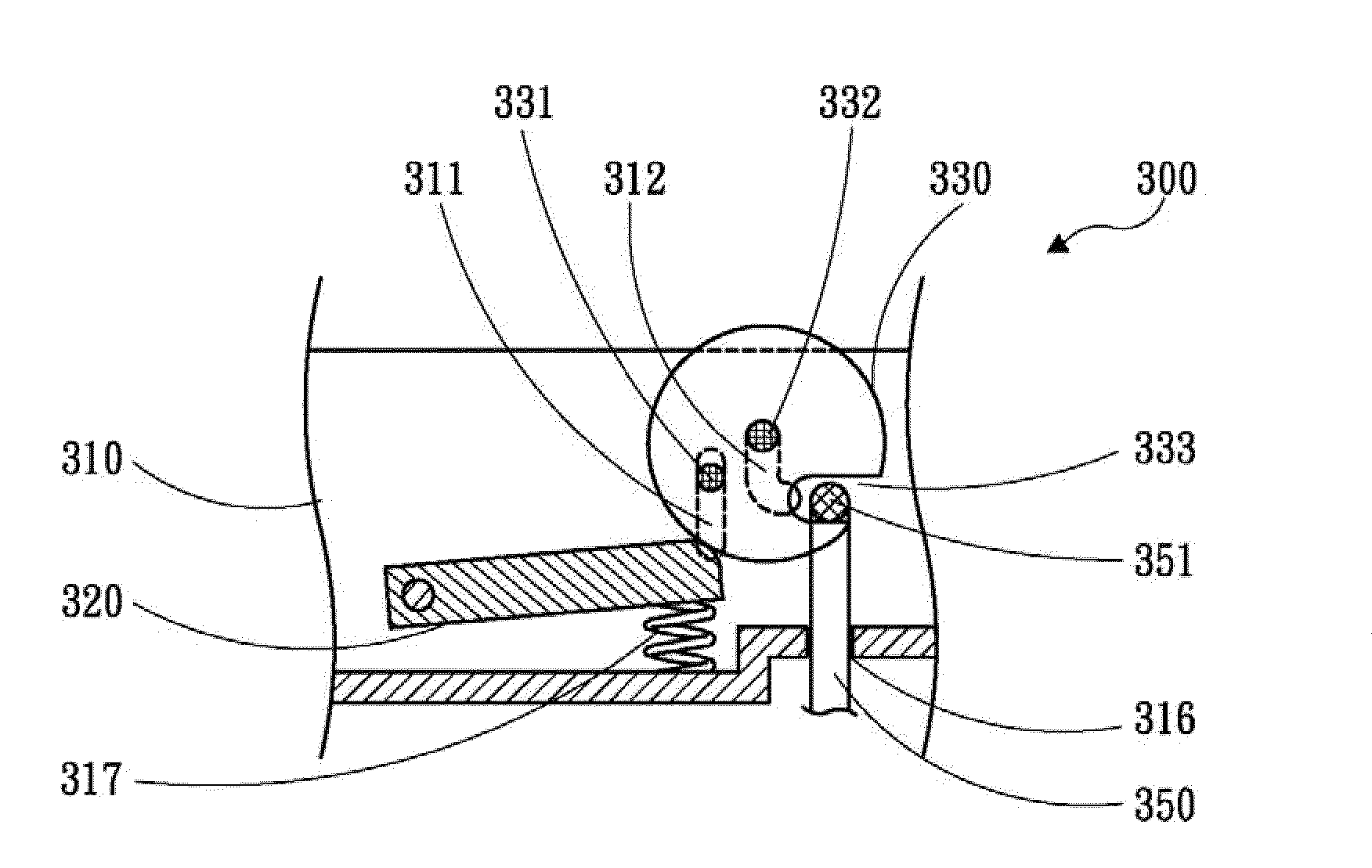

InactiveUS20100314889A1High stabilityCompact structureWing fastenersFastening meansEngineeringMechanical engineering

A latch assembly includes a body having an accommodating space, two pairs of retaining recesses, a window, and a resilient element; a carrier received in the accommodating space and having one end pivotally connected to the body and an opposite end abutting against the resilient element; a driven member received in the accommodating space and abutting against the carrier, the driven member including a main shaft, a guide post, and a notched portion corresponding in position to the window of the body; and a driving member having a connecting portion to be inserted into the window and coupled with the notched portion of the driven member so as to form a loose fit with the driven member. When the connecting portion is inserted into the window and coupled with the notched portion, the driven member is drawn by the driving member to move and rotate within the retaining recesses.

Owner:SOLTEAM ELECTRONICS

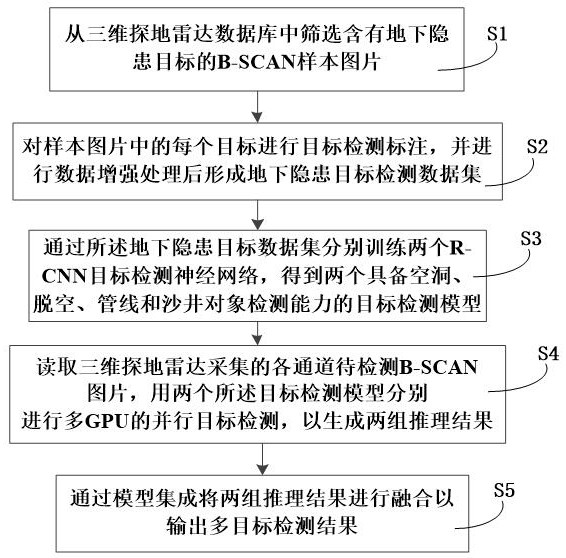

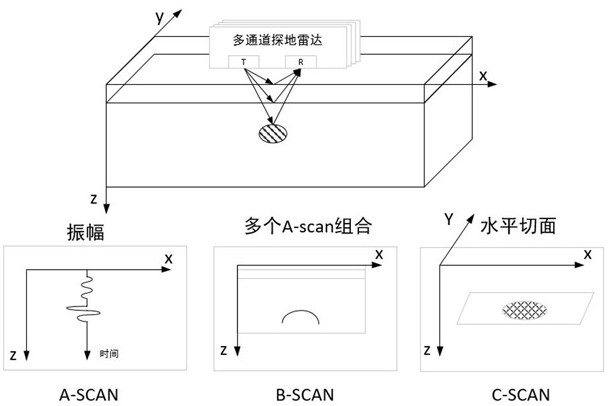

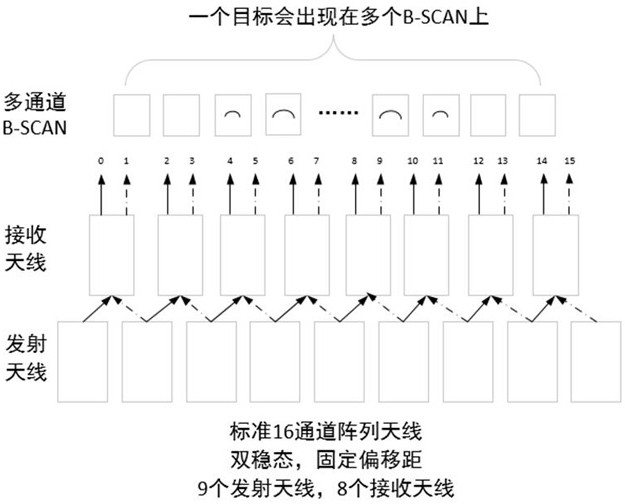

Road underground hidden danger detection method and system based on radar image and artificial intelligence

ActiveCN113256562AImprove applicationEasy to handleImage enhancementImage analysisData setEngineering

The invention provides a road underground hidden danger detection method and system based on radar images and artificial intelligence. The road underground hidden danger detection method comprises the steps of S1, screening the B-SCAN sample pictures containing underground hidden danger targets from a three-dimensional ground penetrating radar database; S2, performing target detection marking on each target of the sample picture, and performing data enhancement processing to form an underground hidden danger target detection data set; S3, respectively training the two R-CNN target detection neural networks to obtain two target detection models with cavity, void, pipeline and manhole object detection capabilities; S4, reading the to-be-detected B-SCAN pictures of each channel acquired by the three-dimensional ground penetrating radar, performing multi-GPU parallel target detection by using the two target detection models, and generating two groups of reasoning results; and S5, fusing and outputting the two groups of reasoning results through model integration. The method and the system are high in anti-interference performance, rich in target information and high in accuracy.

Owner:深圳安德空间技术有限公司

Aluminum or aluminum alloy material having surface treatment coating film, and method for treating a surface thereof

ActiveUS20130034743A1Improve applicationImprove heat exchanger efficiencyPretreated surfacesPaints with biocidesHydrophilic polymersSide chain

Provided is an aluminum or aluminum alloy material having a surface treatment coating film on a surface of a substrate formed by an aluminum or aluminum alloy. The aluminum or aluminum alloy material has: a substrate formed by an aluminum or aluminum alloy; and a first protective layer and a second protective layer in the order on a surface of the substrate, wherein the first protective layer is a conversion coating film including vanadium and at least one or more types of metals selected from titanium, zirconium, and hafnium, the second protective layer is an organic coating film having a composition that includes (1) a chitosan derivative and a solubilizing agent, (2) a modified polyvinyl alcohol formed by graft polymerization of a hydrophilic polymer to a side chain of polyvinyl alcohol, and (3) a water-soluble crosslinking agent.

Owner:NIHON PARKERIZING +1

Functionalized green filtration media for passive underground drainfield for septic tank nutrient removal

ActiveUS20100062933A1Improve sustainabilityImprove applicationMolecular sieve catalystsOther chemical processesFiltrationOyster

Methods, systems and compositions for a green sorption media for bioretention soil amendments in drainfields for on-site waste water systems filled with the green sorption media to foster an anaerobic or anoxic environment saturated. The green sorption media includes one or more recycled materials, including tire crumb, sawdust, orange peel, coconut husks, leaf compost, oyster shell, soy bean hulls and one or more naturally occurring materials including peat, sands, zeolites, and clay. The wastewater filtration system for a passive drainfield includes the green sorption material mixture, a cell including baffled compartments and a riser, the cell filled with green sorption material mixture to provide an alternating cycle of aerobic and anoxic environments, an influent distribution system to distribute the influent over the cell, and a piping system arranged for dosing the cell to sustain the functionality of the green sorption material mixture to remove nutrient content in wastewater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com