Patents

Literature

101results about How to "Dense high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

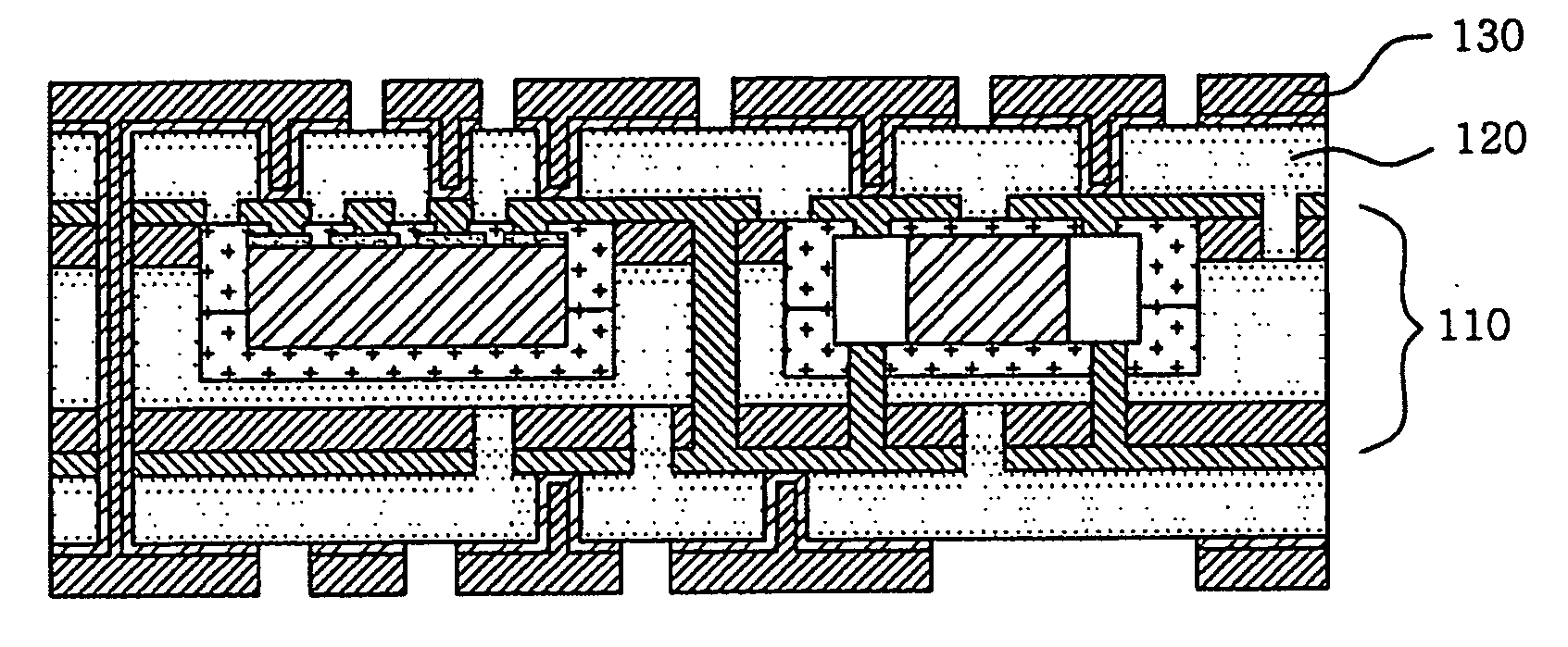

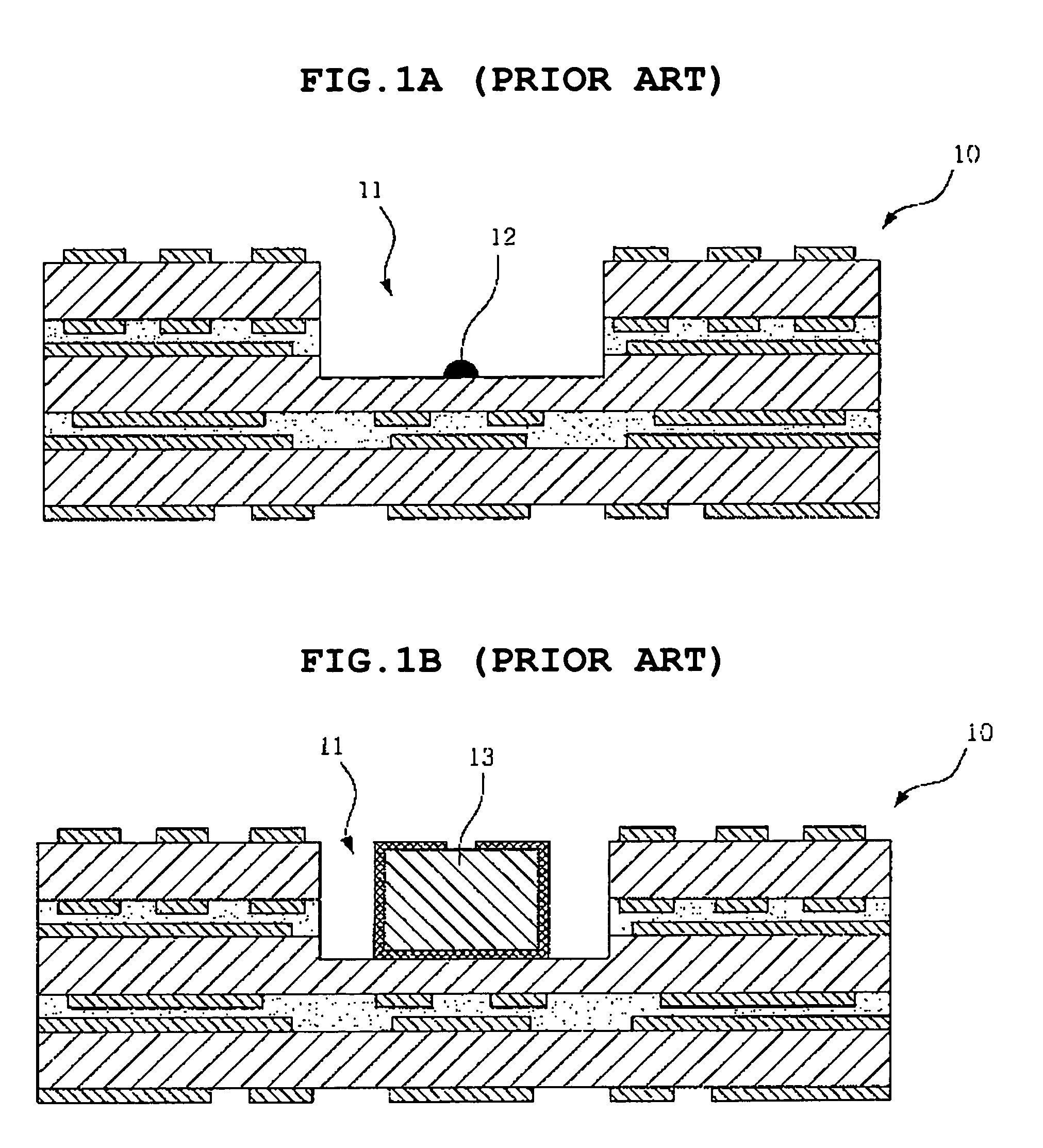

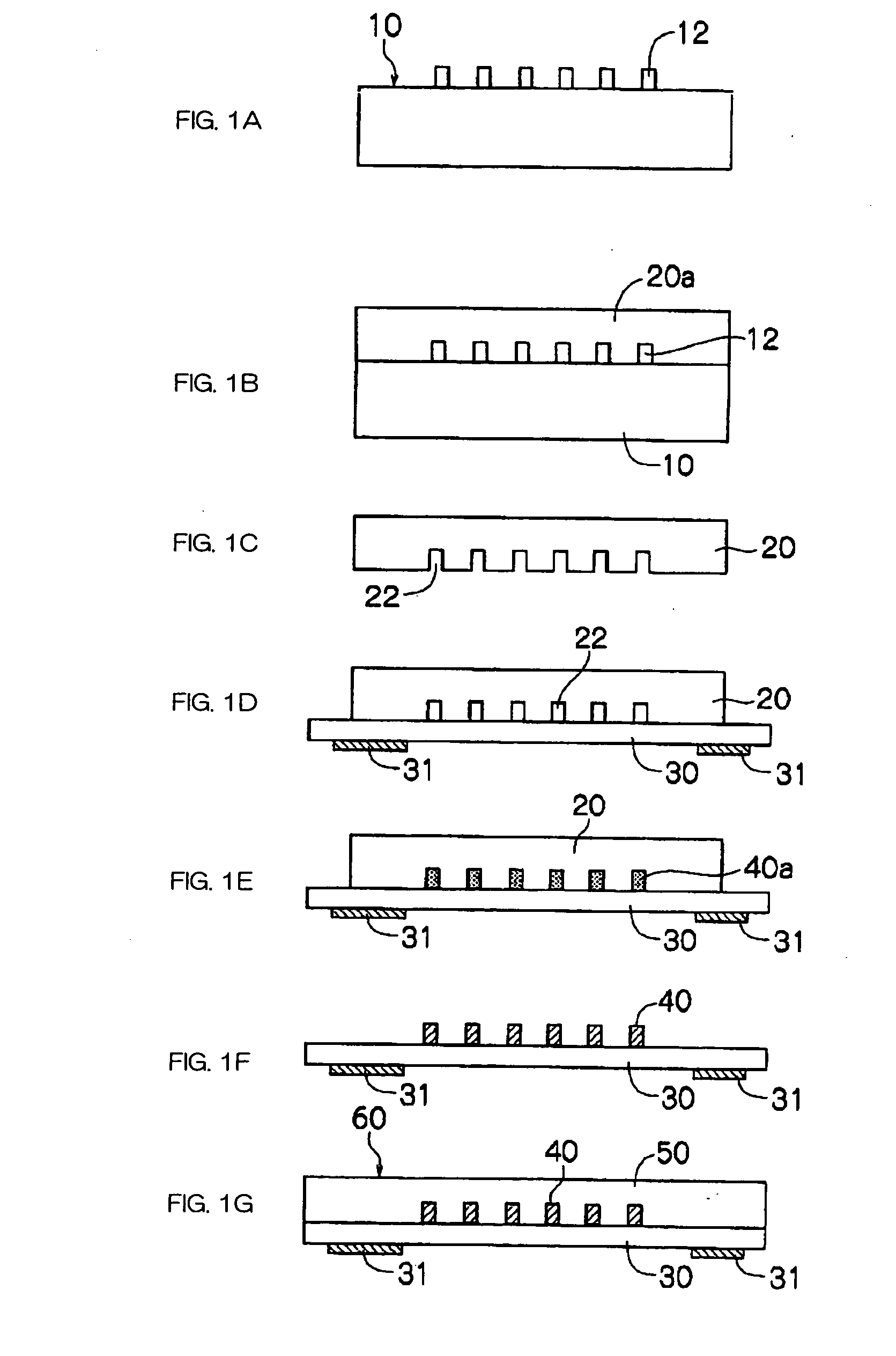

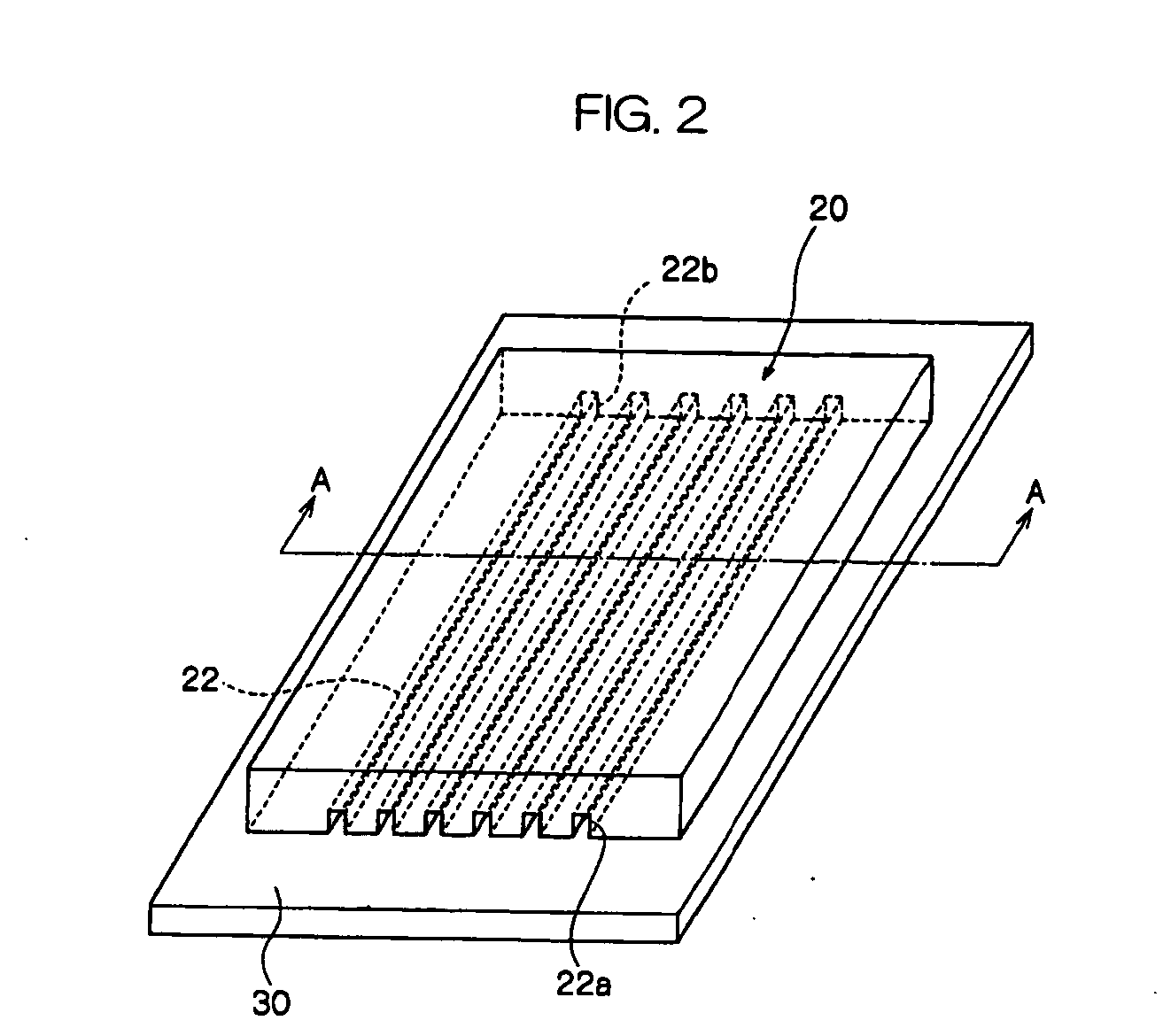

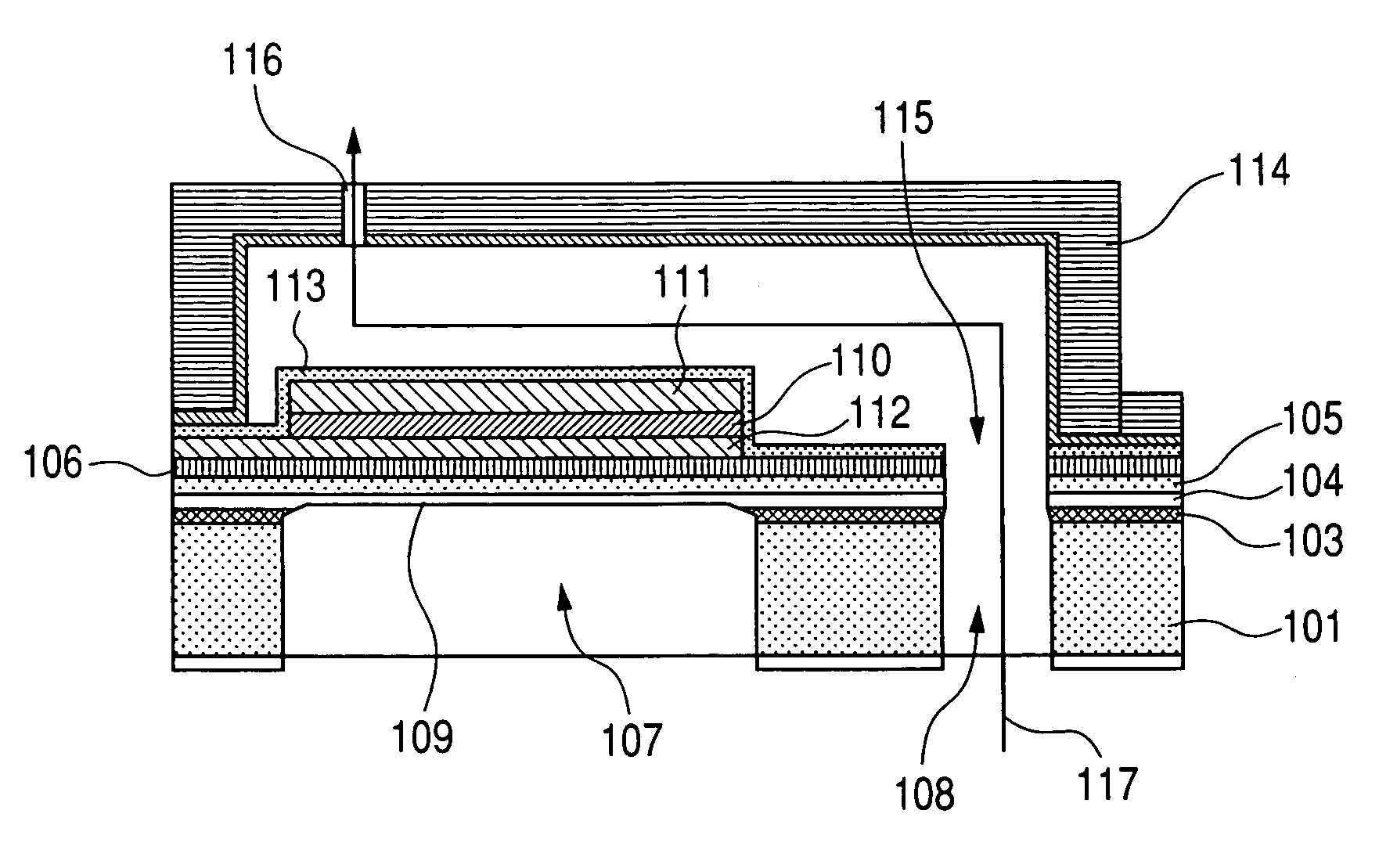

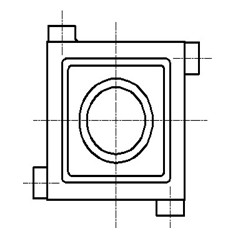

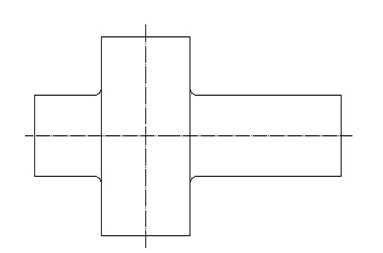

Embedded chip printed circuit board and method of manufacturing the same

InactiveUS20060191711A1Dense highLight and slim and shortPrinted circuit assemblingSemiconductor/solid-state device detailsElectricityElectrical connection

The present invention relates to an embedded chip printed circuit board in which a space required for embedding a chip is formed to a desired depth depending on various thicknesses of chips to be embedded, and thus, the circuit line for the electrical connection between the embedded chip and the circuit pattern layer can be formed to be relatively short, thereby maximizing space efficiency and decreasing inductance at high frequencies. In addition, a method of manufacturing such an embedded printed circuit board is also provided.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

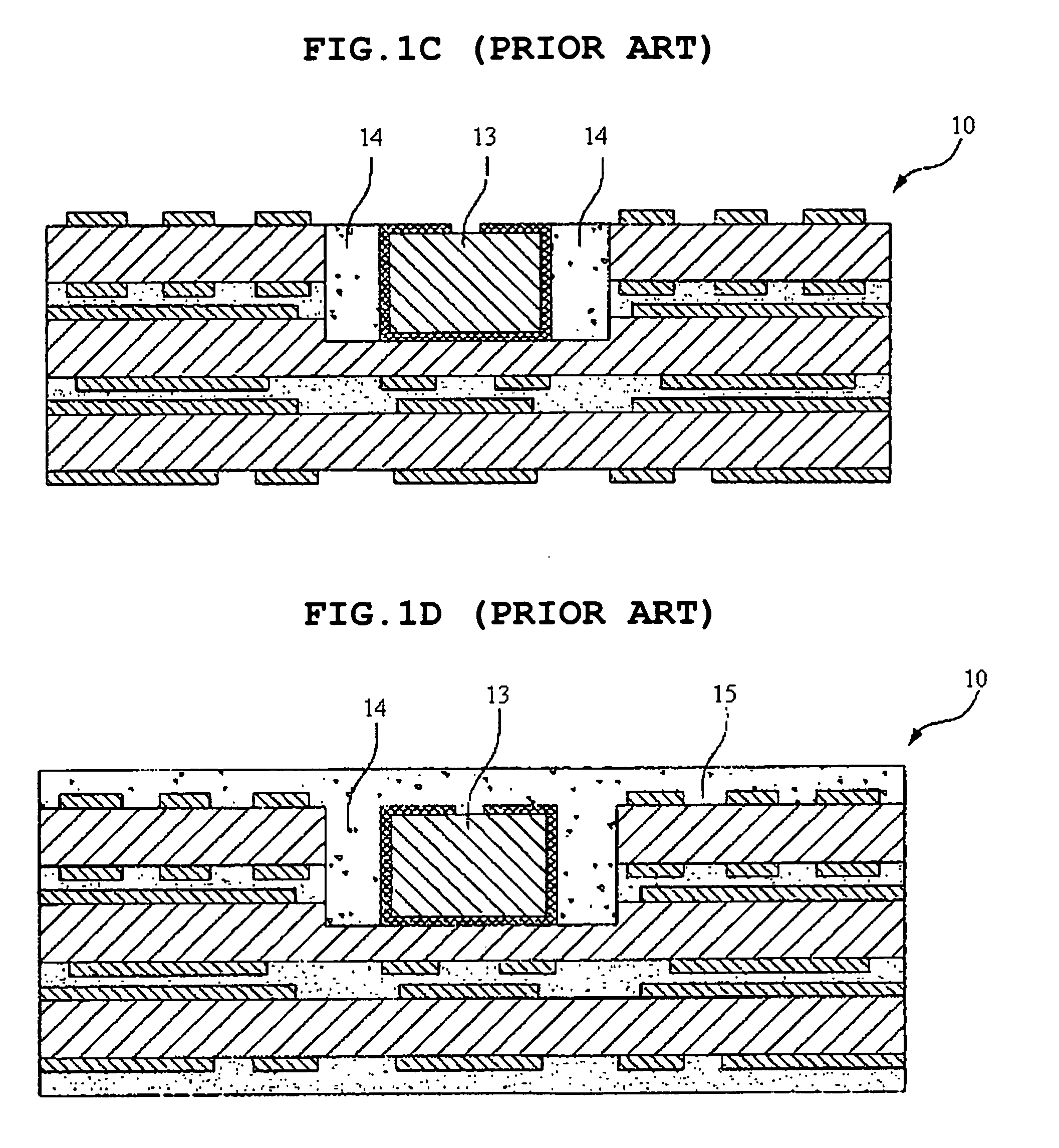

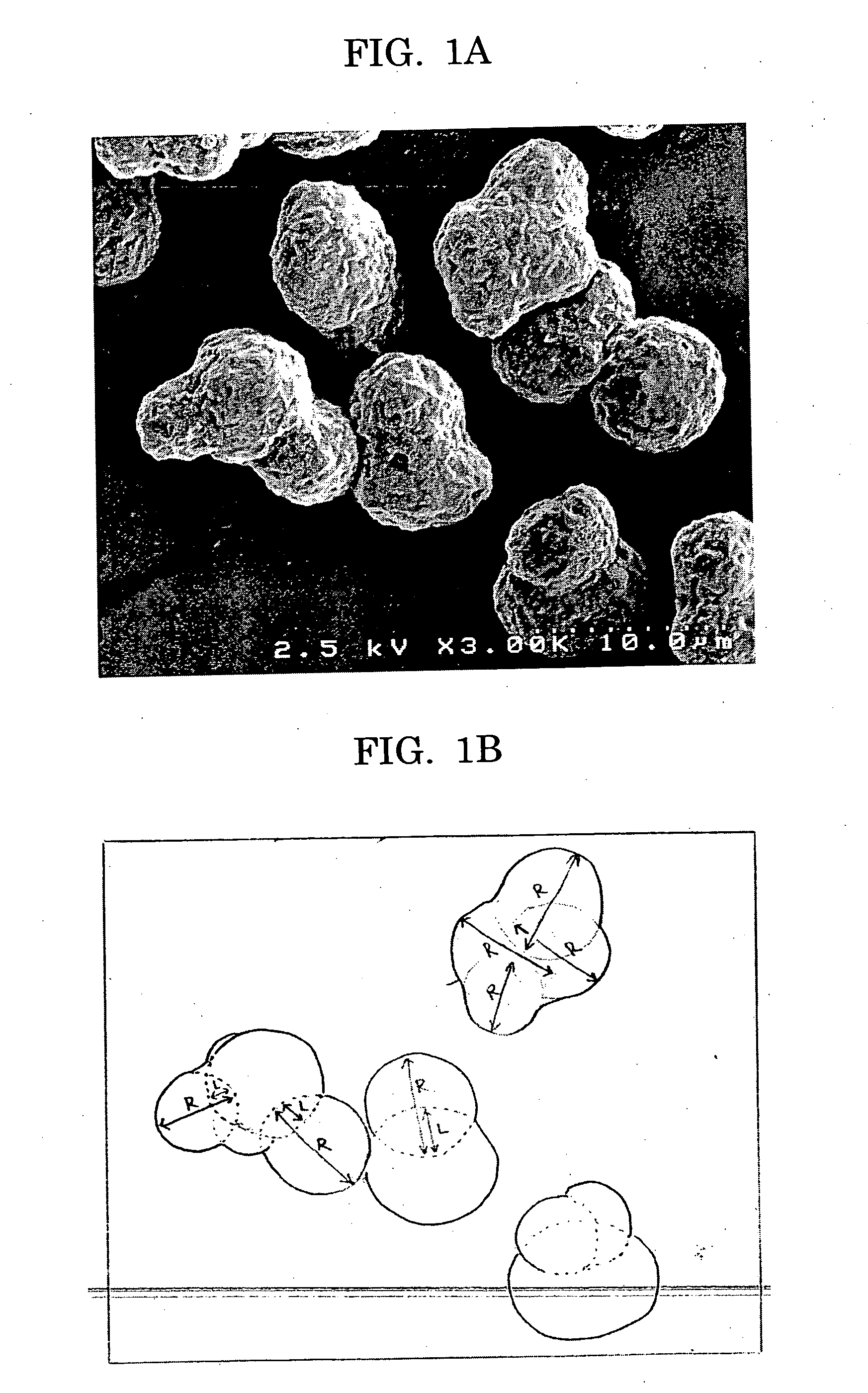

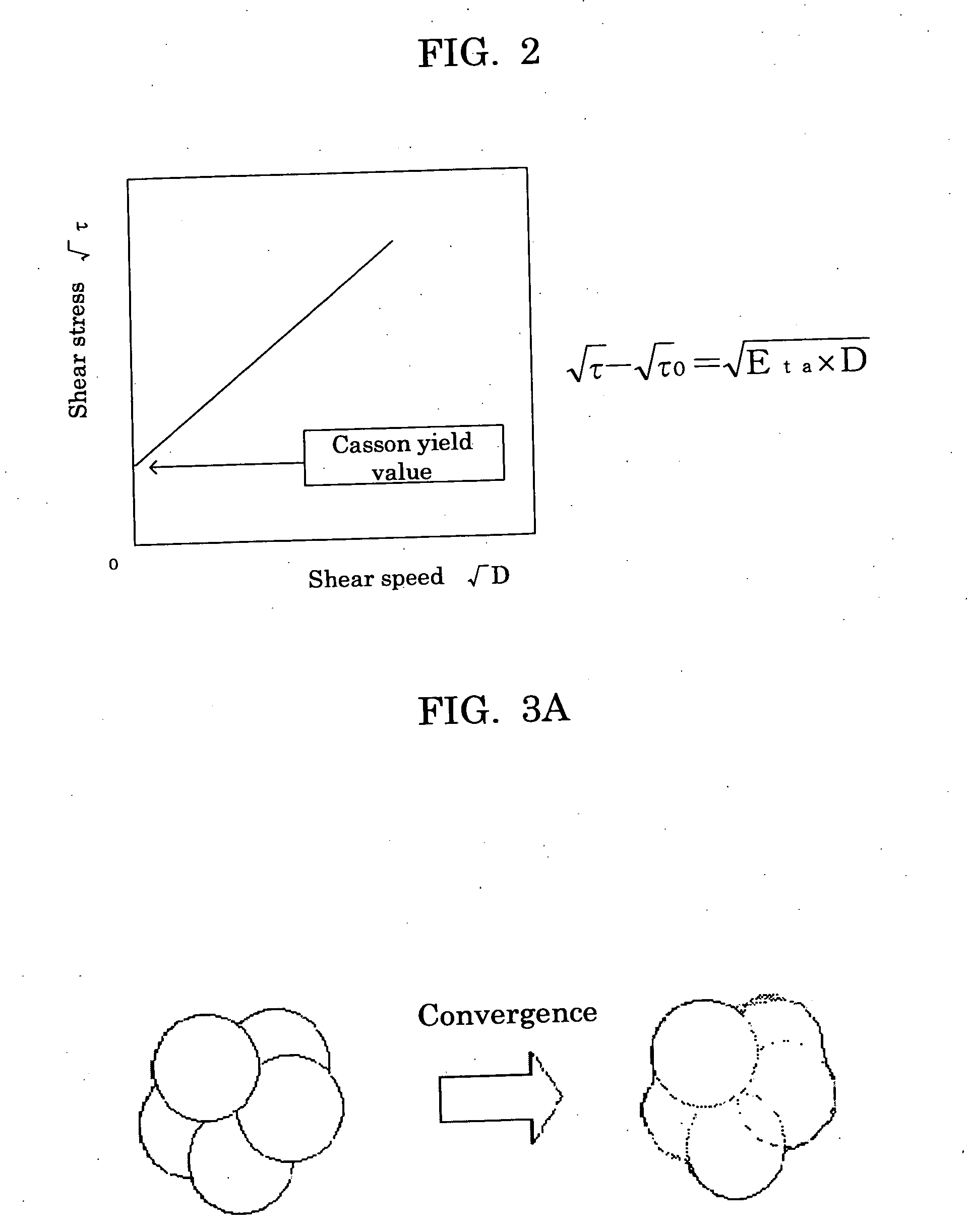

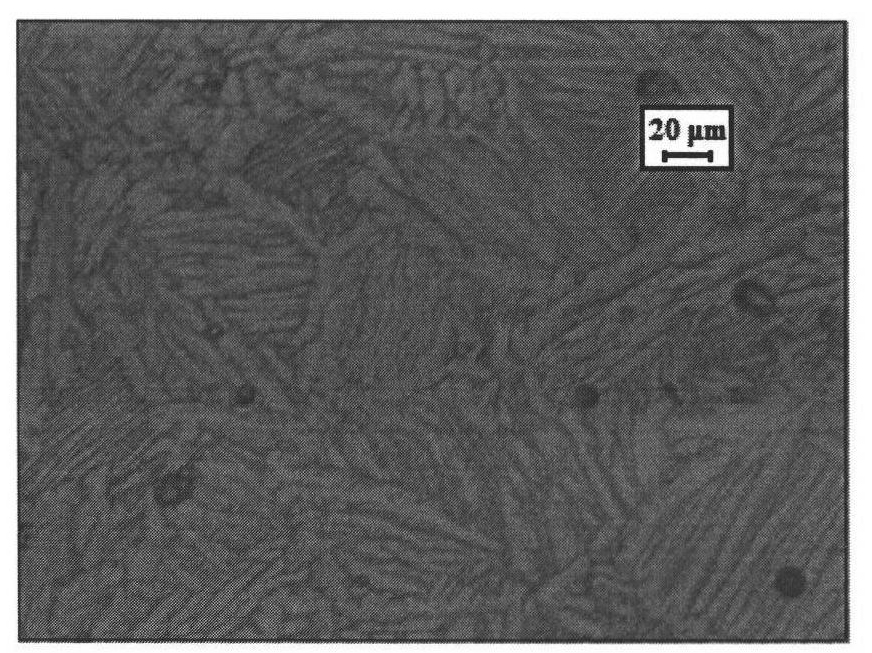

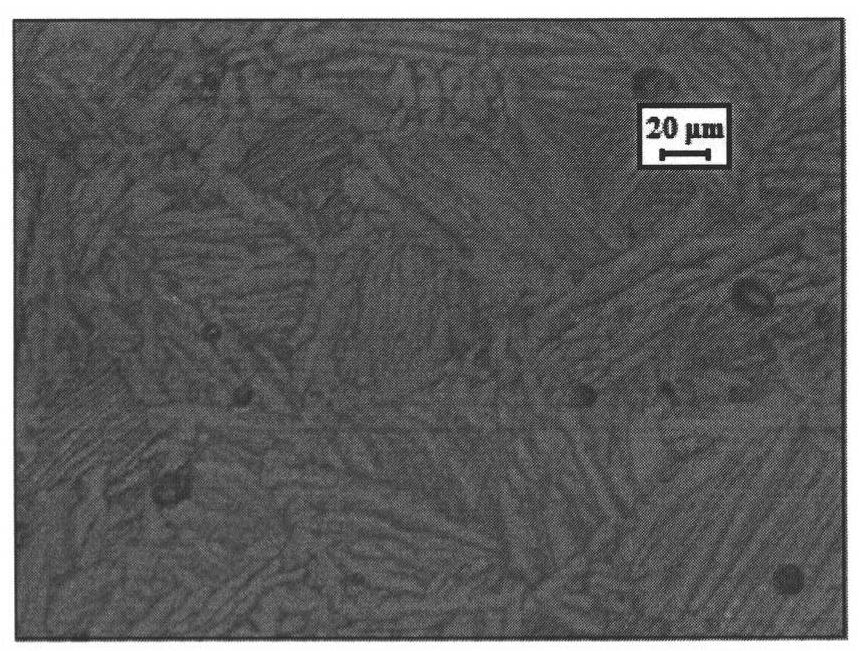

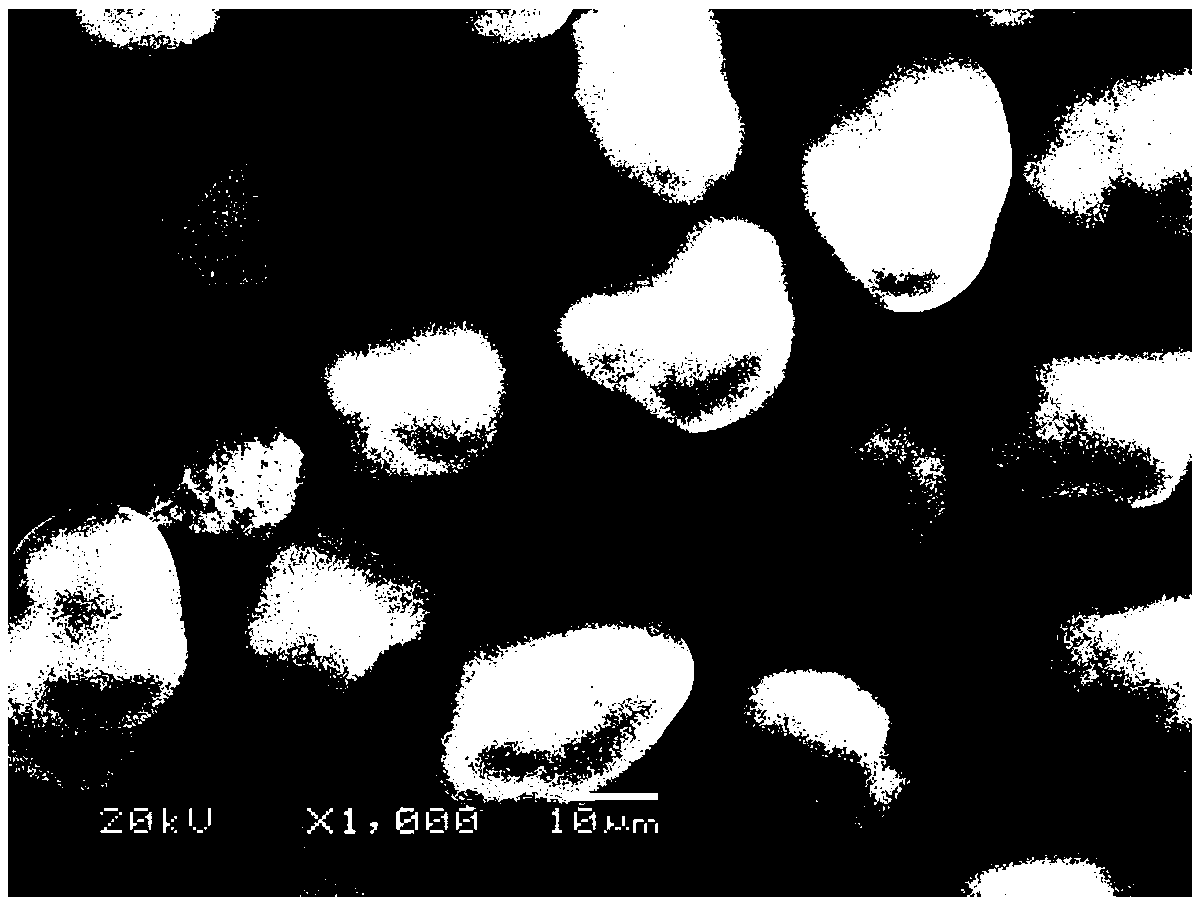

Toner and developer, toner container, process cartridge, image-forming apparatus, and image-forming method using the same

ActiveUS20060063089A1Dense highHigh quality imagingDevelopersElectrographic processes using charge patternImaging qualityImage formation

An object of the present invention is to provide a toner having small-sized and potato-shaped particles created from multiple coherent spherical particles for excellent cleaning ability and high image quality, an image-forming method that realizes high image quality using the toner, and the like. To this end, there is provided a toner, which is produced by granulating toner materials as an organic phase comprising at least a binder resin and a colorant in an aqueous medium and has potato-shaped particles created from multiple coherent primary oil droplets of the organic phase in the aqueous medium.

Owner:RICOH KK

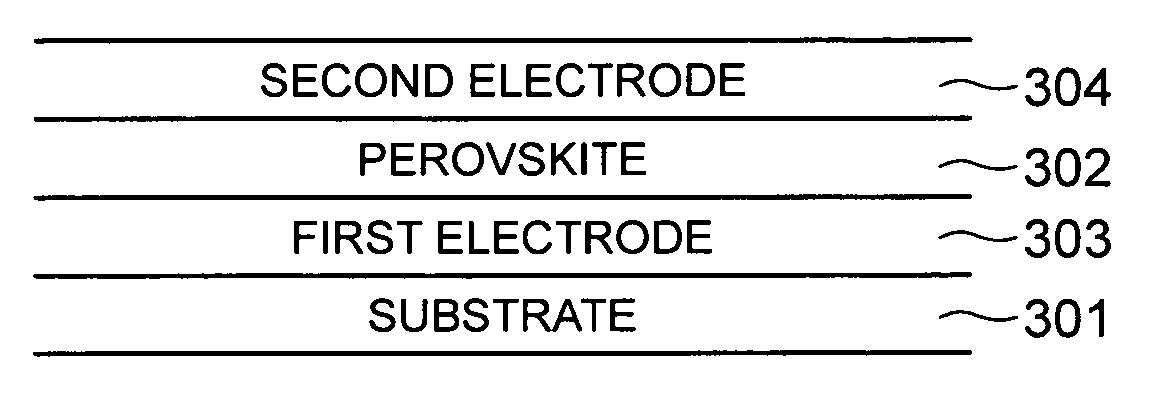

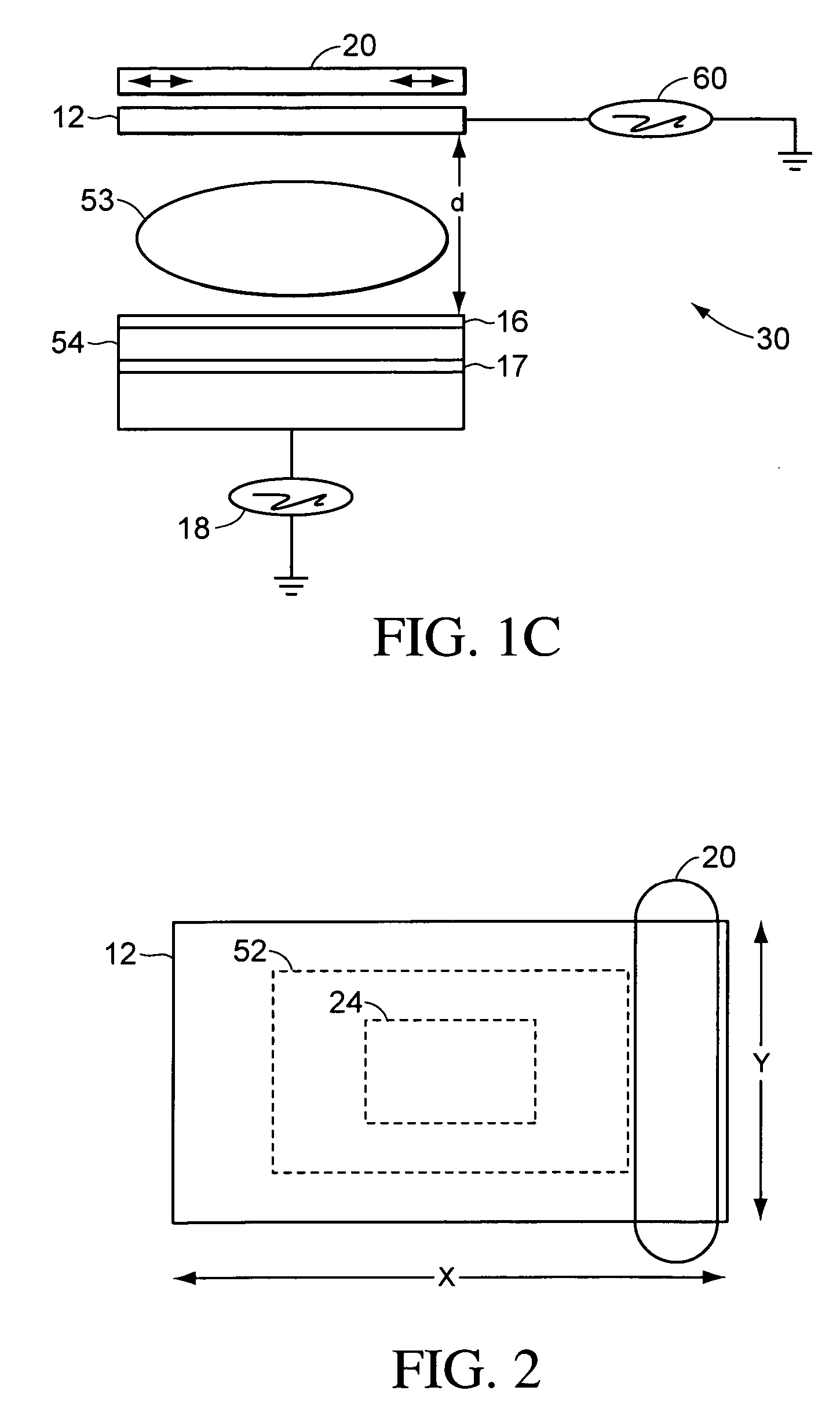

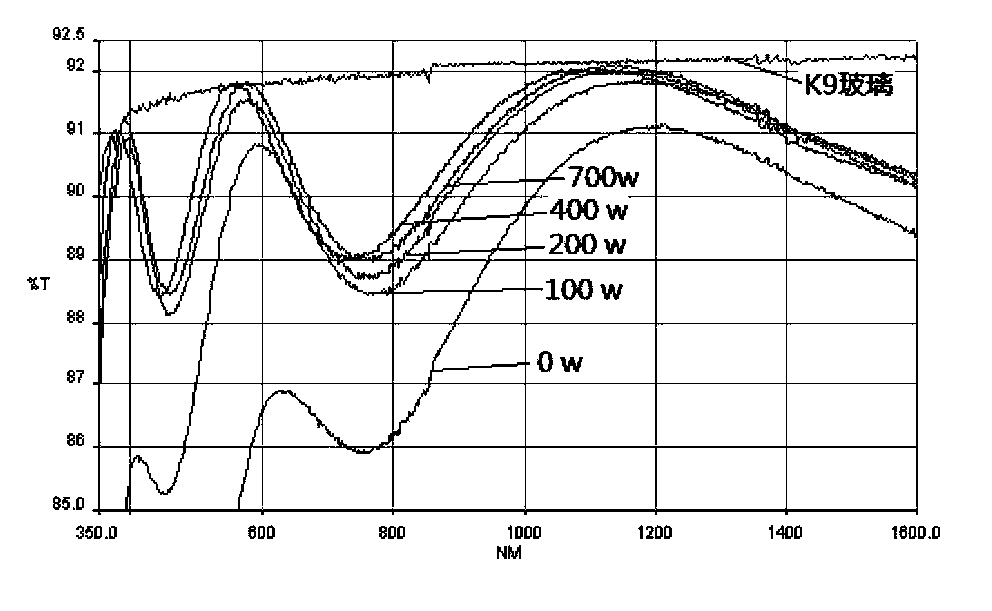

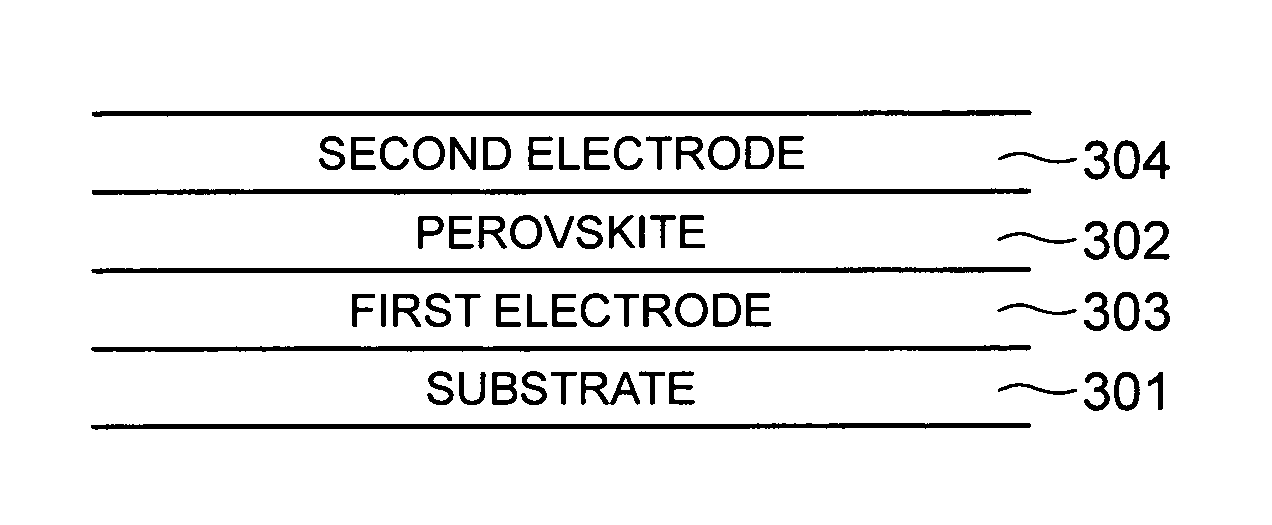

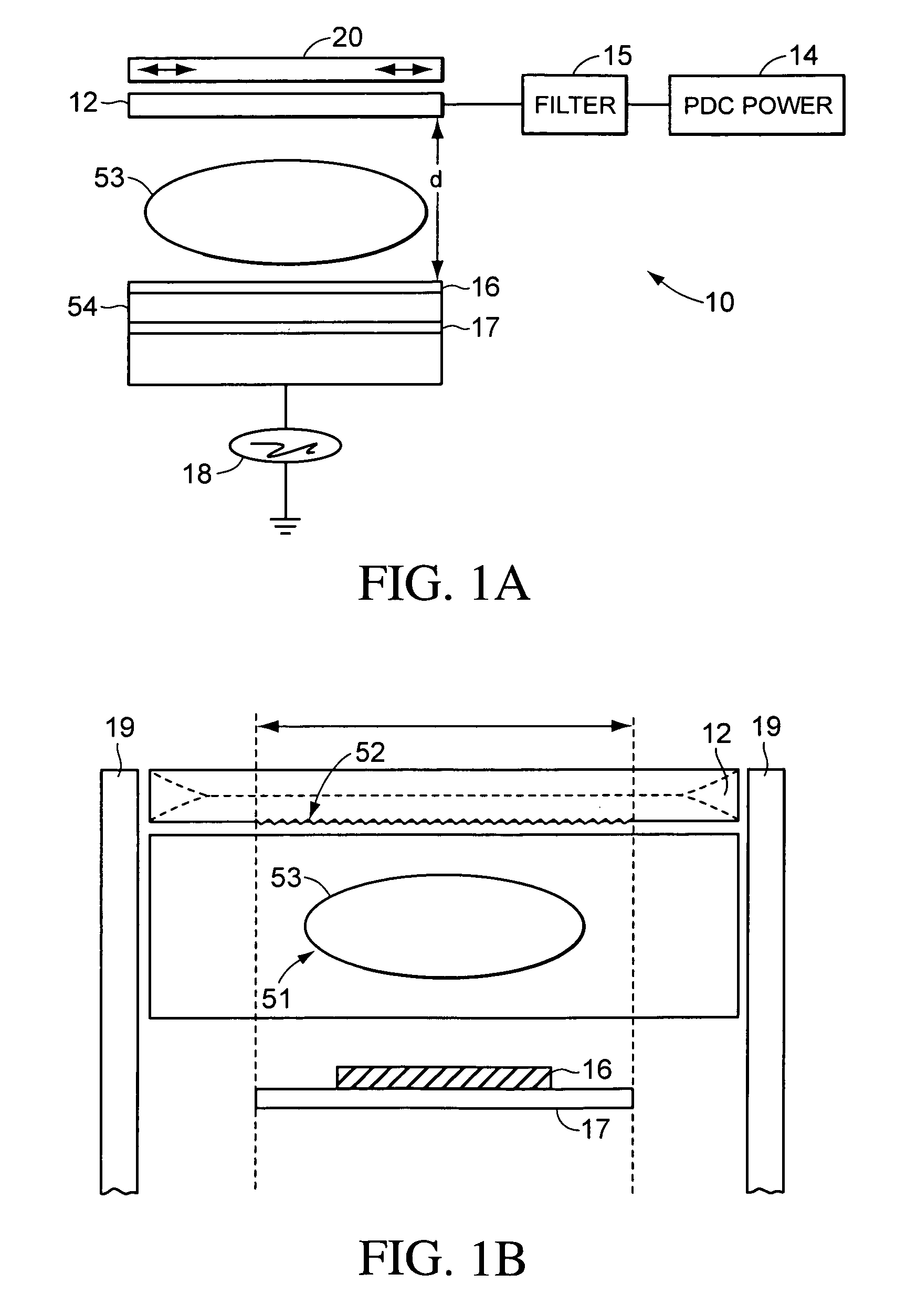

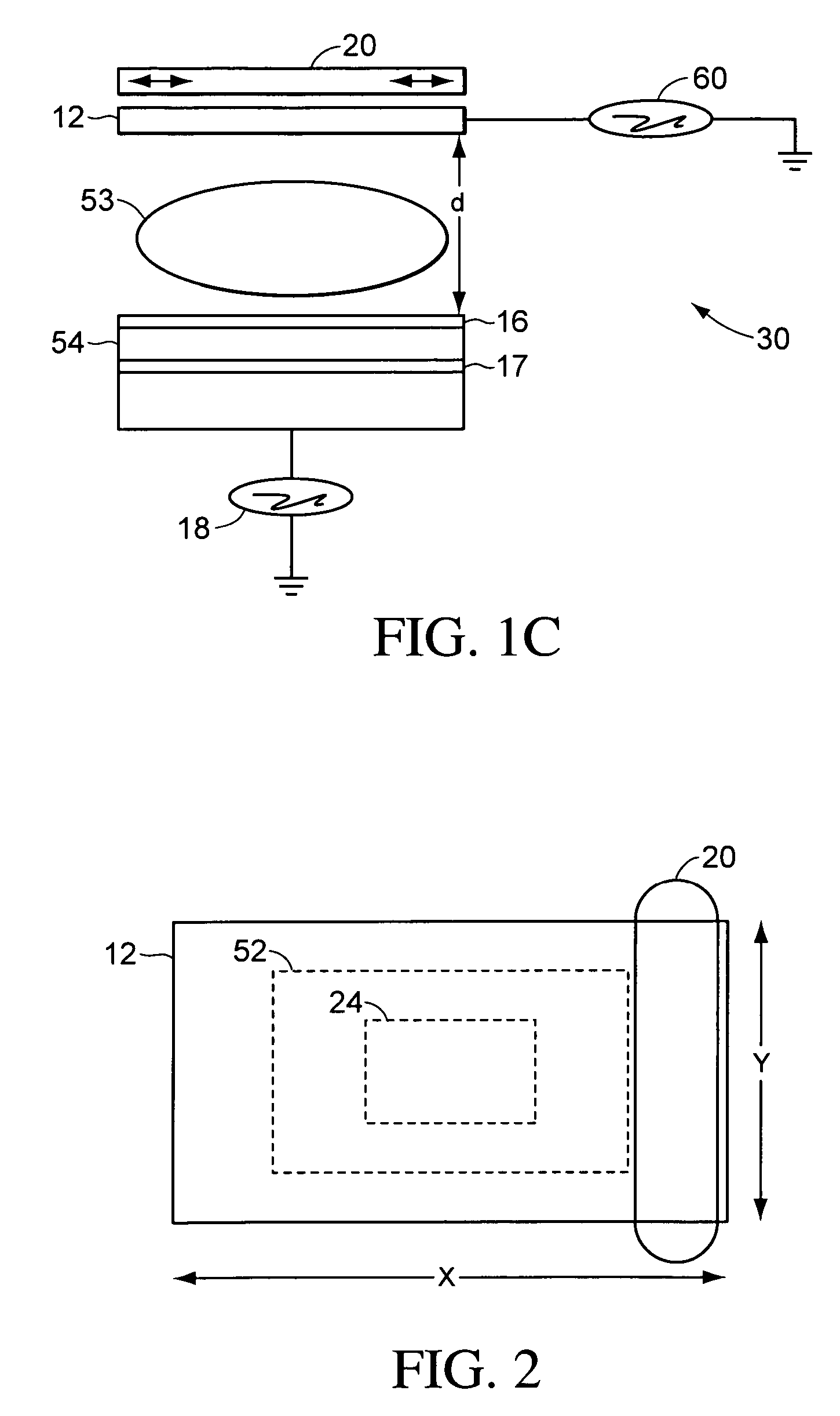

Deposition of perovskite and other compound ceramic films for dielectric applications

InactiveUS20070053139A1Increase capacitanceReduce the temperatureThin/thick film capacitorFixed capacitor dielectricHigh ratePulsed DC

In accordance with the present invention, deposition of perovskite material, for example barium strontium titanite (BST) film, by a pulsed-dc physical vapor deposition process or by an RF sputtering process is presented. Such a deposition can provide a high deposition rate deposition of a layer of perovskite. Some embodiments of the deposition address the need for high rate deposition of perovskite films, which can be utilized as a dielectric layer in capacitors, other energy storing devices and micro-electronic applications. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the BST layer.

Owner:DEMARAY

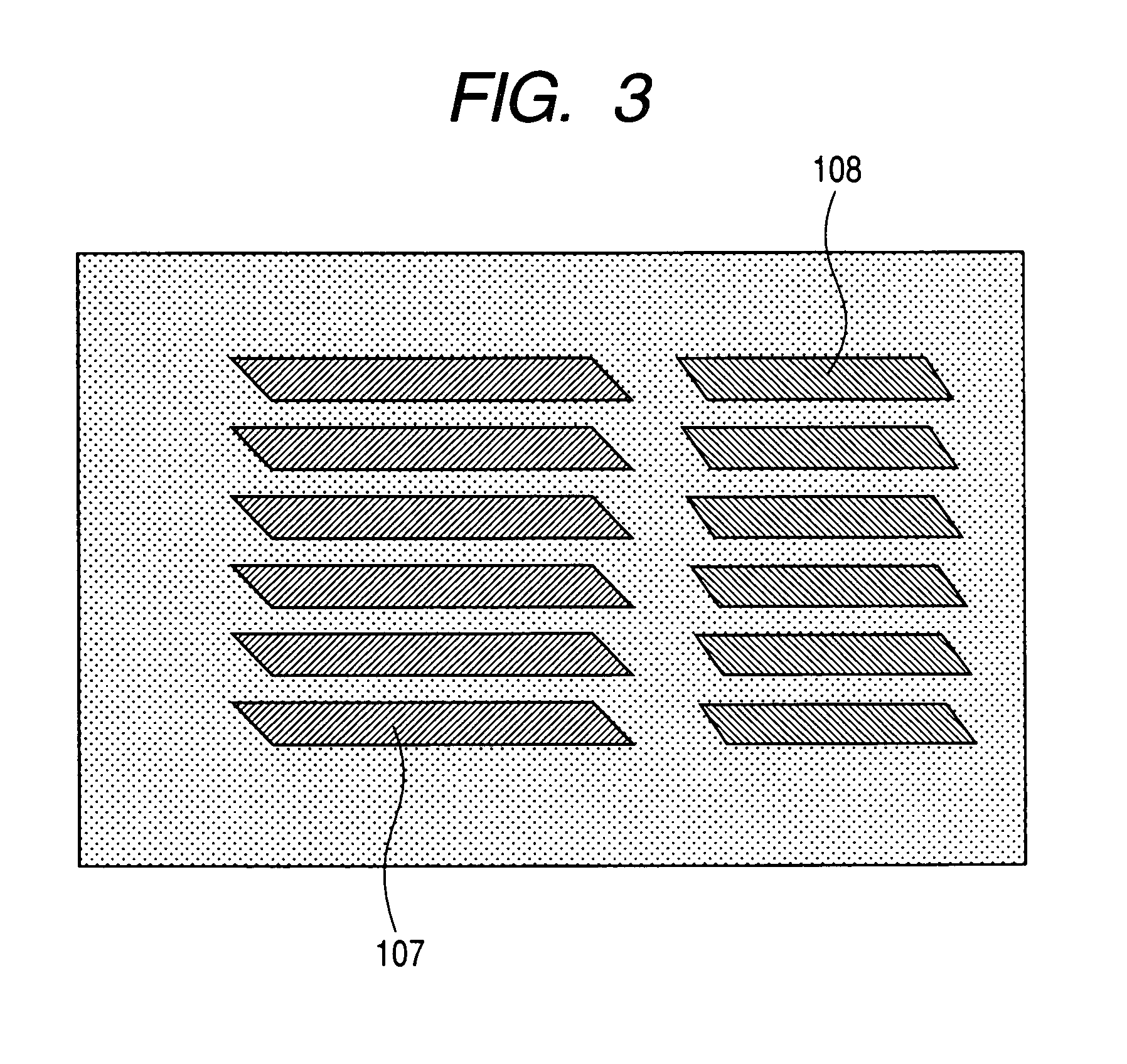

Method for fabricating polymer optical waveguide device

InactiveUS20060091571A1Easy to manufactureReduce light lossOptical articlesOptical waveguide light guideOptical bondingPolymer optical waveguide

The present invention provides a method for fabricating a polymer optical waveguide device, the method at least includes: preparing a mold including a cured resin layer of a mold forming curing resin and having a concave portion correspondent to a core portion of an optical waveguide formed therein; attaching the mold to a cladding base material; filling the concave portion of the mold with a core forming curing resin; hardening the core forming curing resin to form a cured core portion; forming a space or a groove for placing an optical device in a middle part in the waveguide direction of the core portion such that the optical device cuts across the core portion; inserting and positioning the optical device in a predetermined position of the space or groove; and conducting an optical bonding between an optical pathway portion of the optical device and the core portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

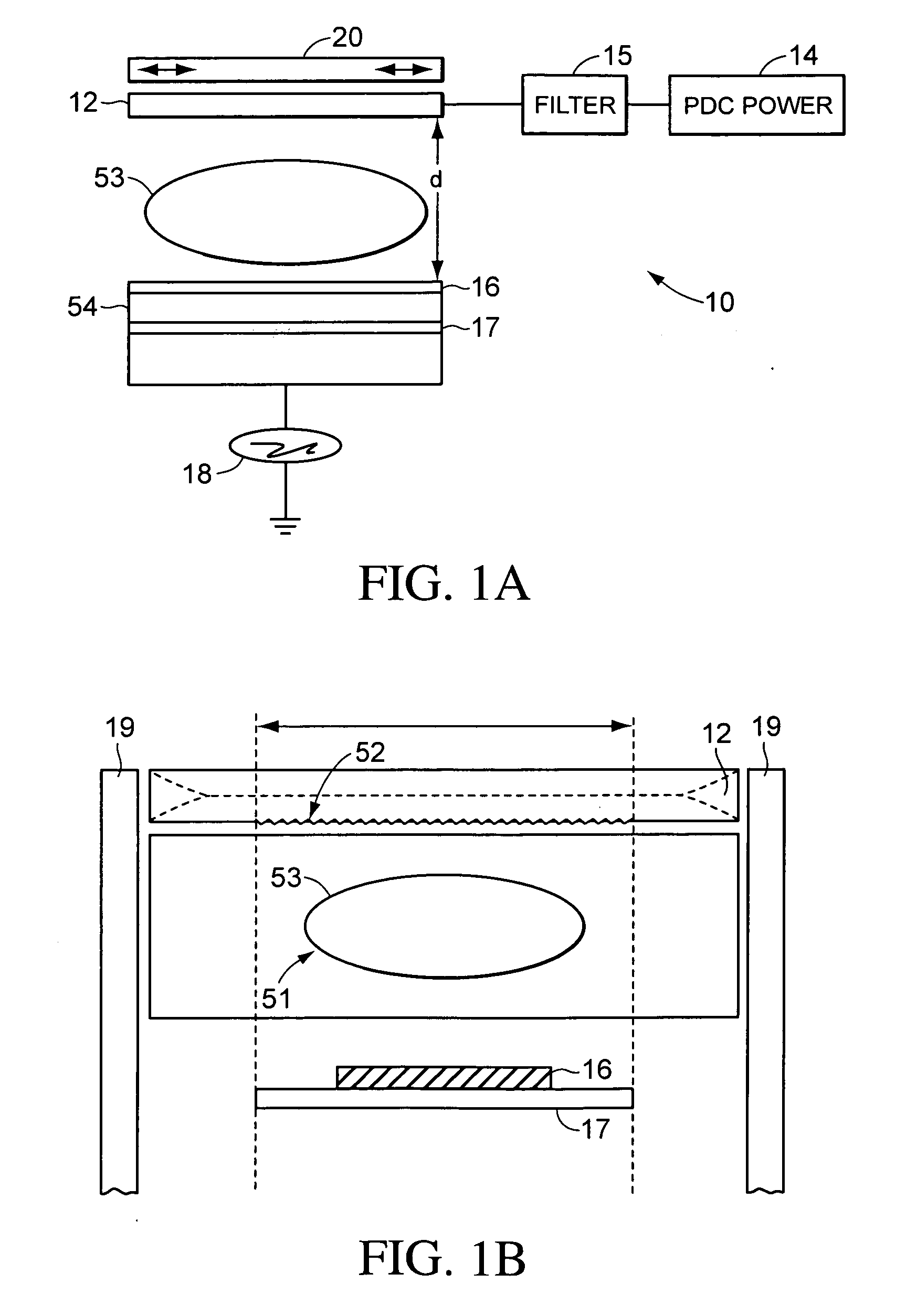

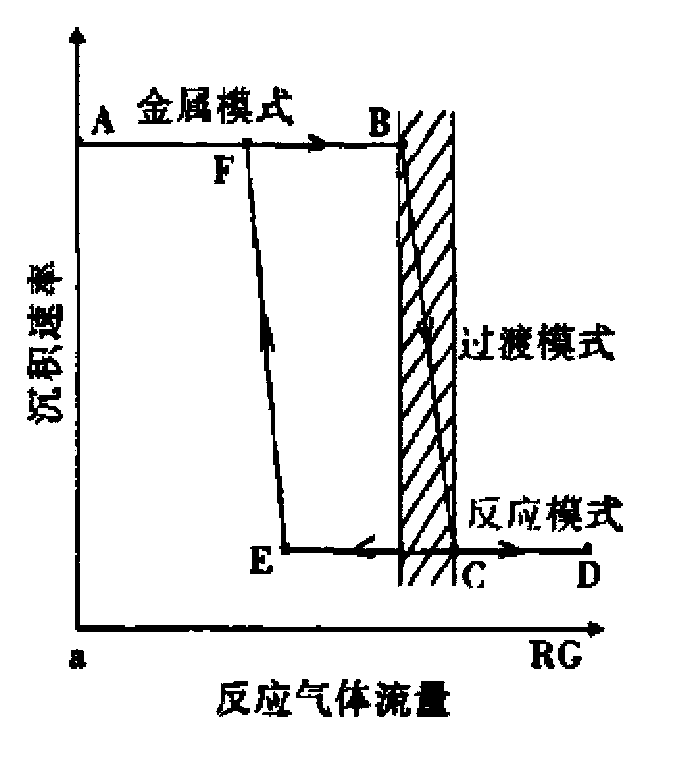

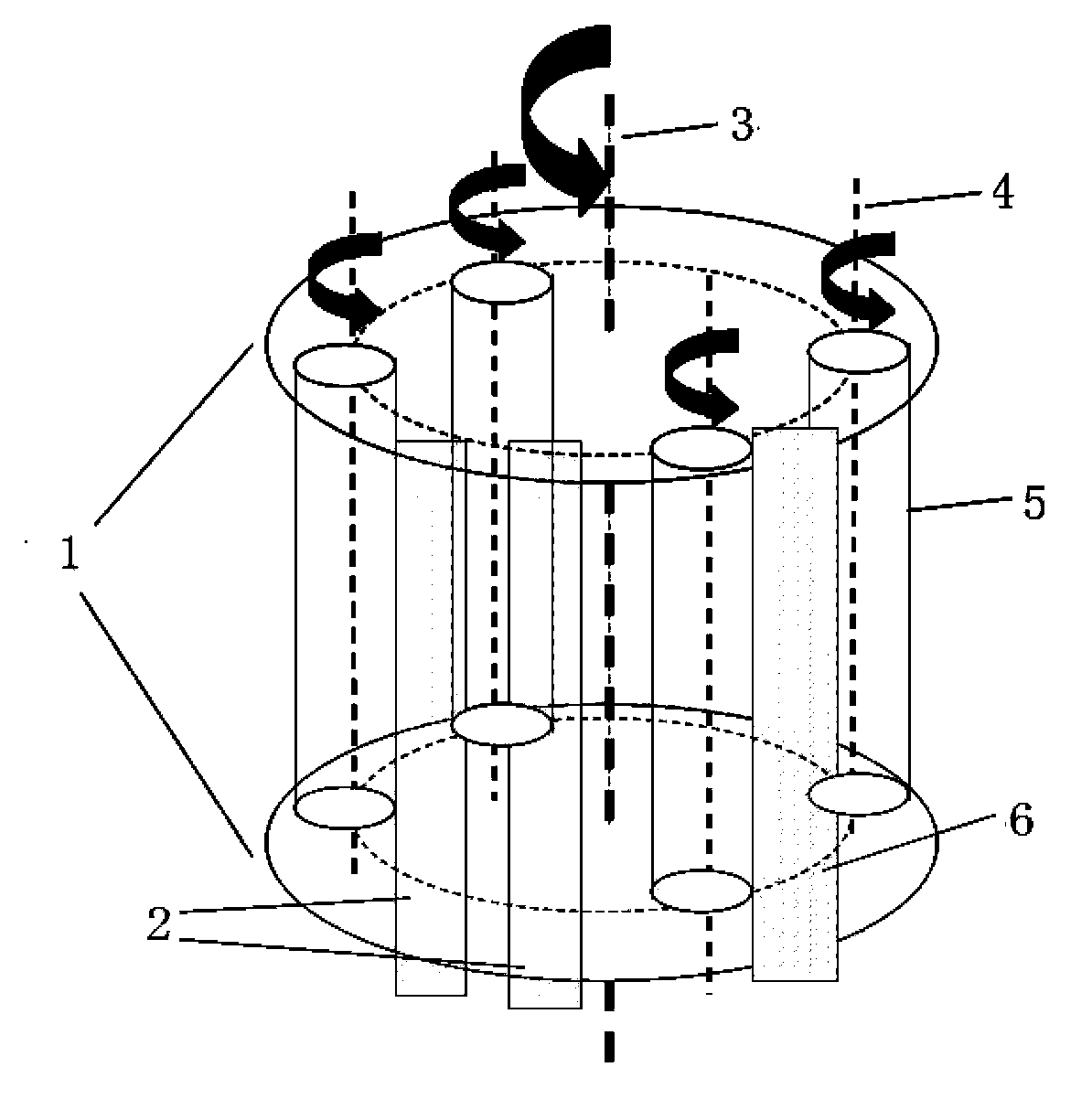

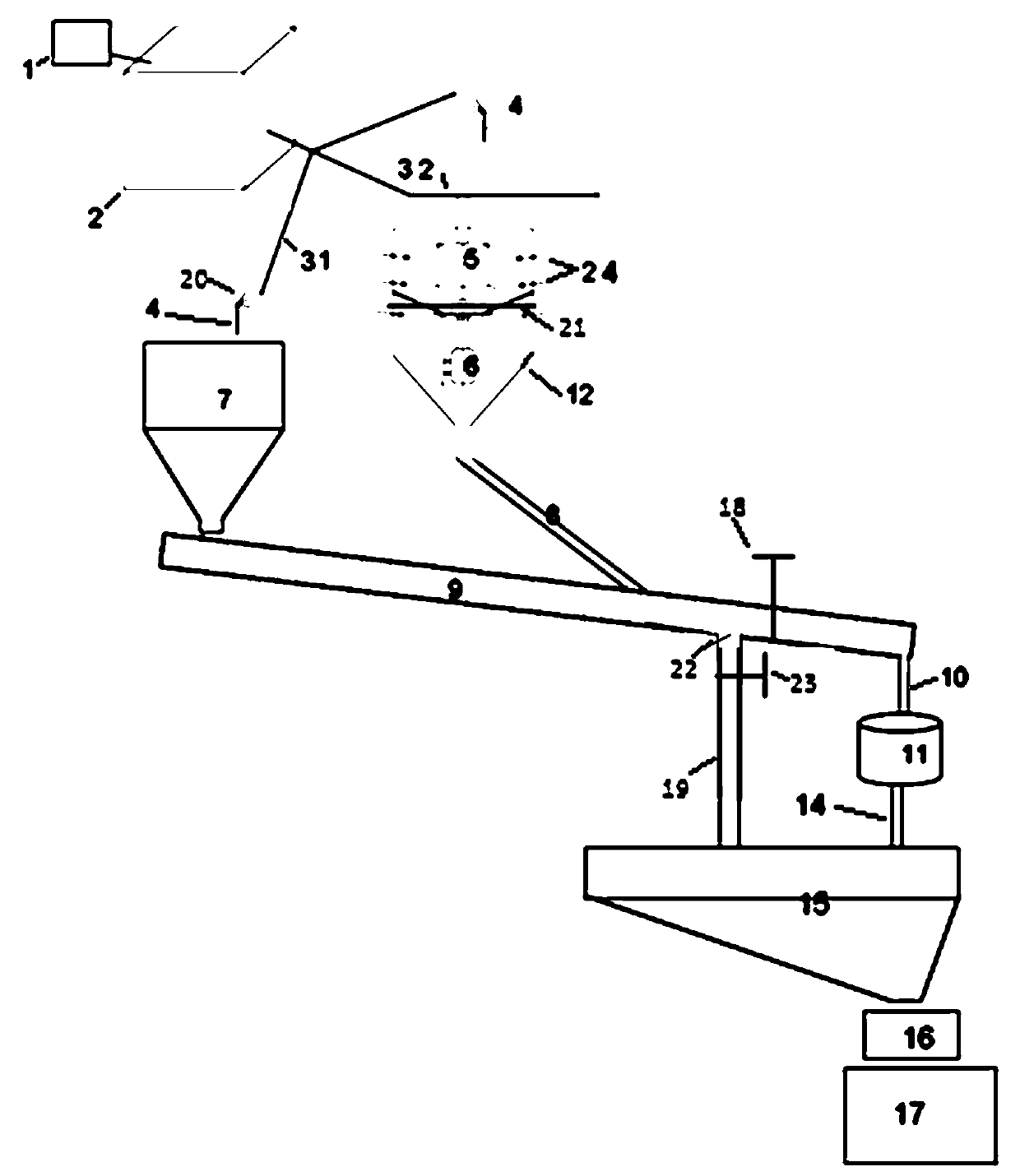

Plasma assisted magnetron sputtering depositing method

ActiveCN103668092ALow costStrong engineering magnificationVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

The invention relates to a plasma assisted magnetron sputtering depositing coating method. When a metal compound thin film is prepared by magnetron sputtering, in order to overcome target poisoning, anode disappearance and the like, an intermediate frequency or pulse direct current reaction magnetron sputtering method is common adopted. The invention provides a novel plasma assisted depositing method, wherein a plasma discharge area is additionally arranged in a vacuum chamber, a work rest rotates at a high speed along with a revolution plate which revolves at the same time, and when a workpiece rotates through the plasma discharge area, combination reaction is further carried out on the incompletely reacted ultrathin thin film and gas ions to obtain a compound thin film with a higher stoichiometric ratio, so that the depositing rate of the thin film is greatly improved. Compared with conventional plasma source assisted depositing technologies, the novel plasma generating technology provided by the invention is lower in cost and easy to amplify, can be used for the field of industrialized production on a large scale, and has an important application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

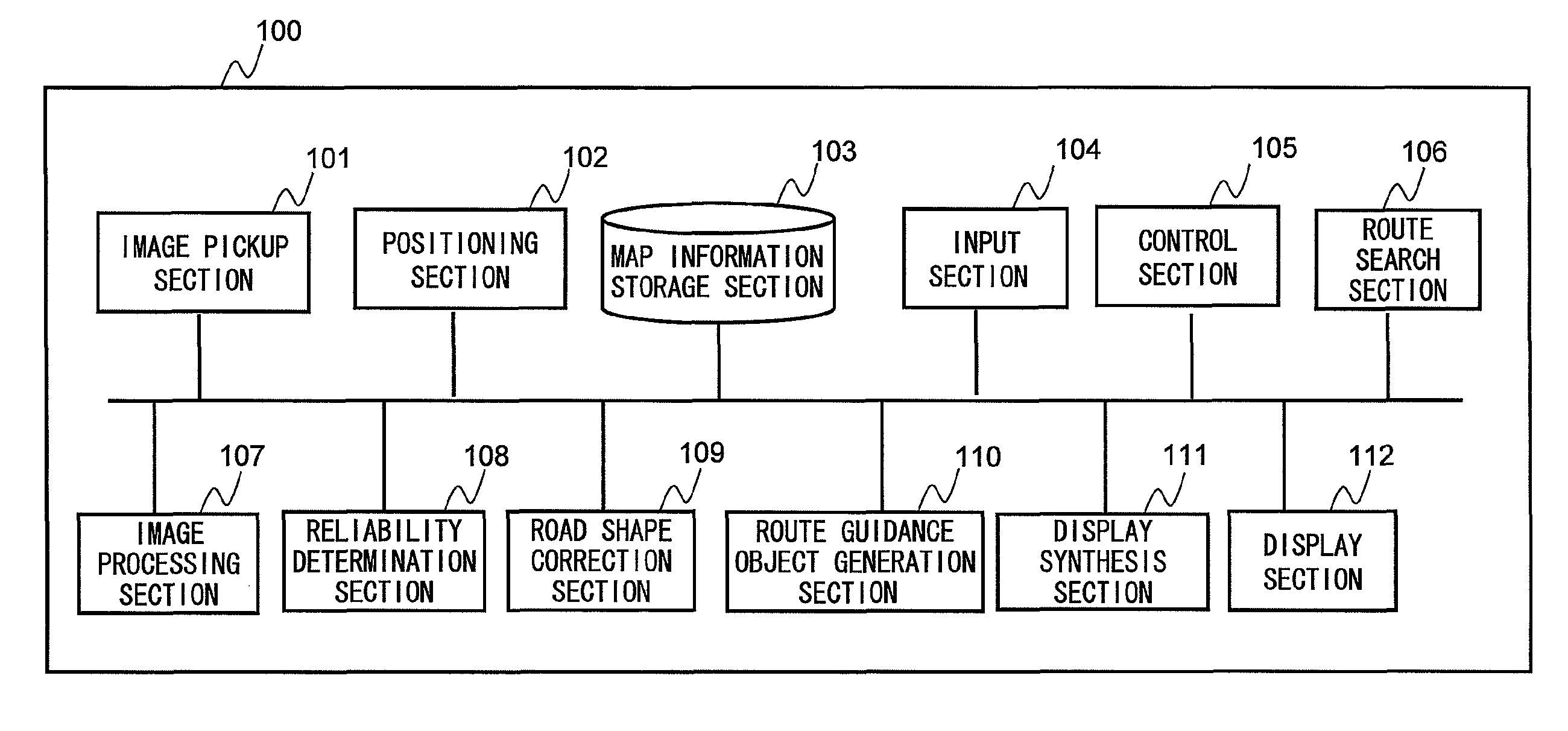

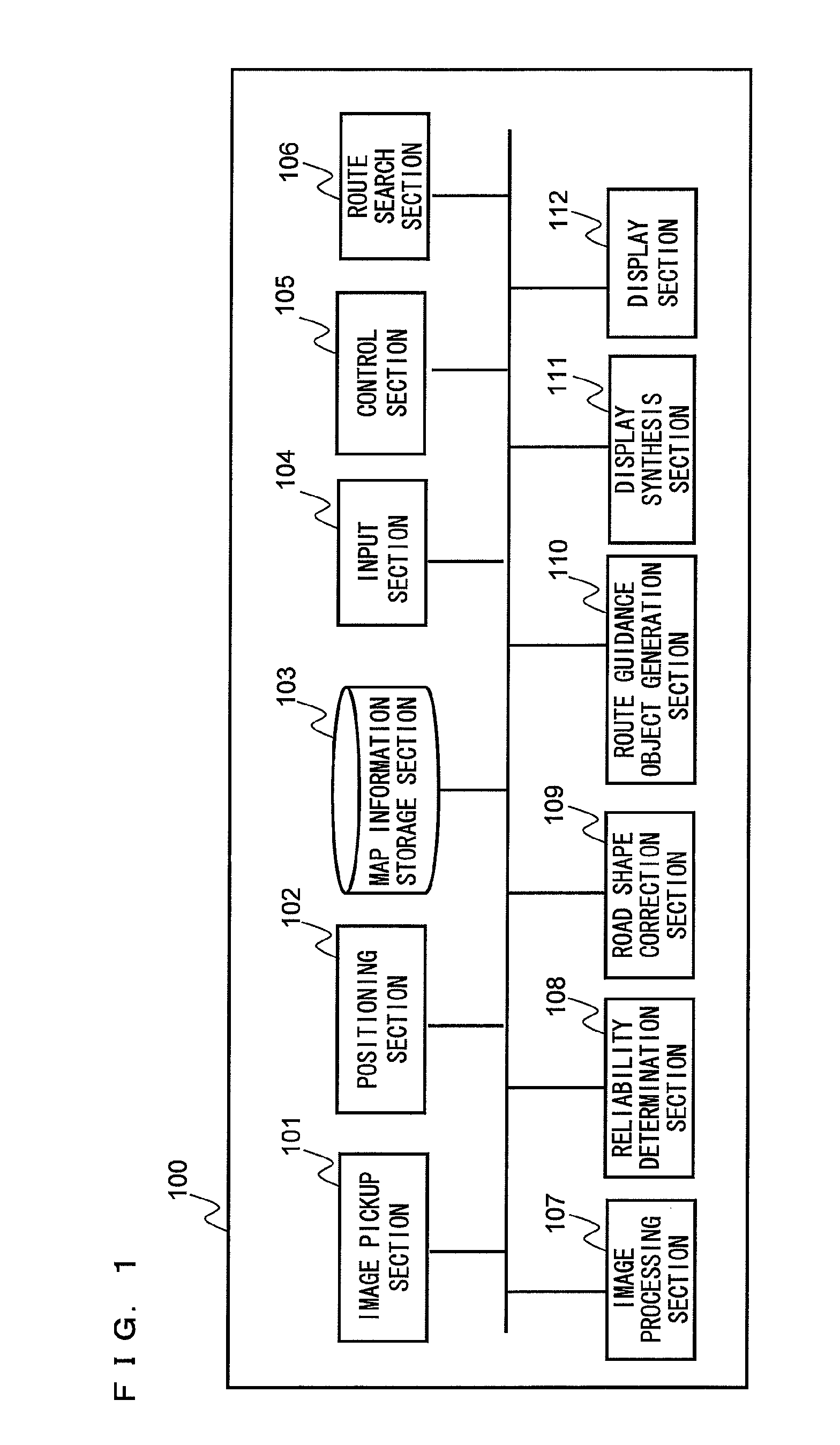

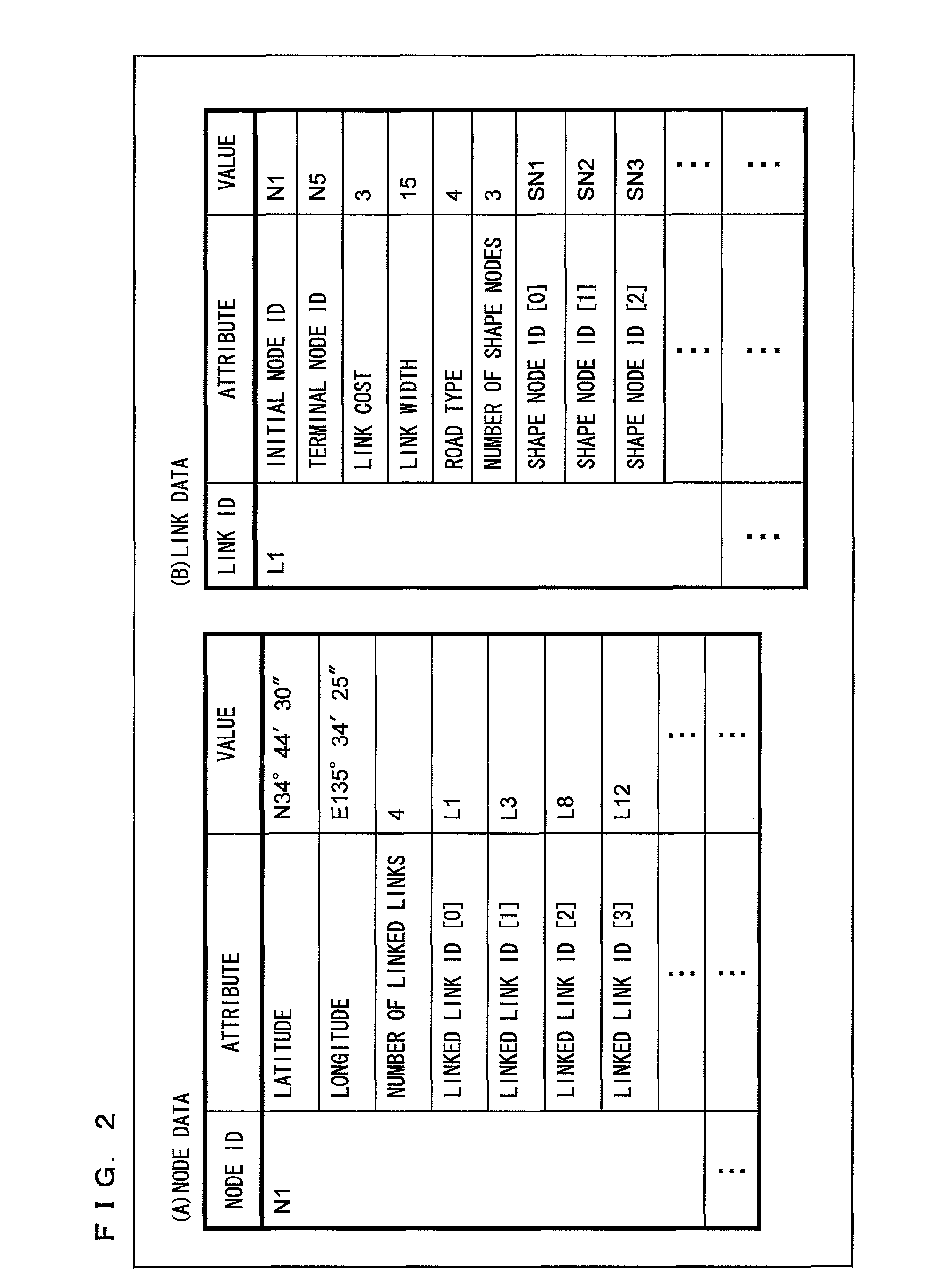

Navigation device, navigation method, and navigation program

ActiveUS8239131B2Not be changedEasy to compareInstruments for road network navigationRoad vehicles traffic controlWhite lineMarine navigation

A navigation device displays, on a screen, a route guidance object indicating a route along which the vehicle is to travel, and includes: an image pickup section that obtains a photographed image ahead of the vehicle; a white line detection section that detects a road white line in the photographed image; a map information storage section that stores map information including road shape data which represents the road shape; a road shape data correction section that corrects the road shape data, based on a detection result of the road white line, such that the route guidance object is displayed along the road white line; a route guidance object generation section that generates the route guidance object, based on the corrected road shape data; and the display section that displays the generated route guidance object on the screen.

Owner:PANASONIC CORP

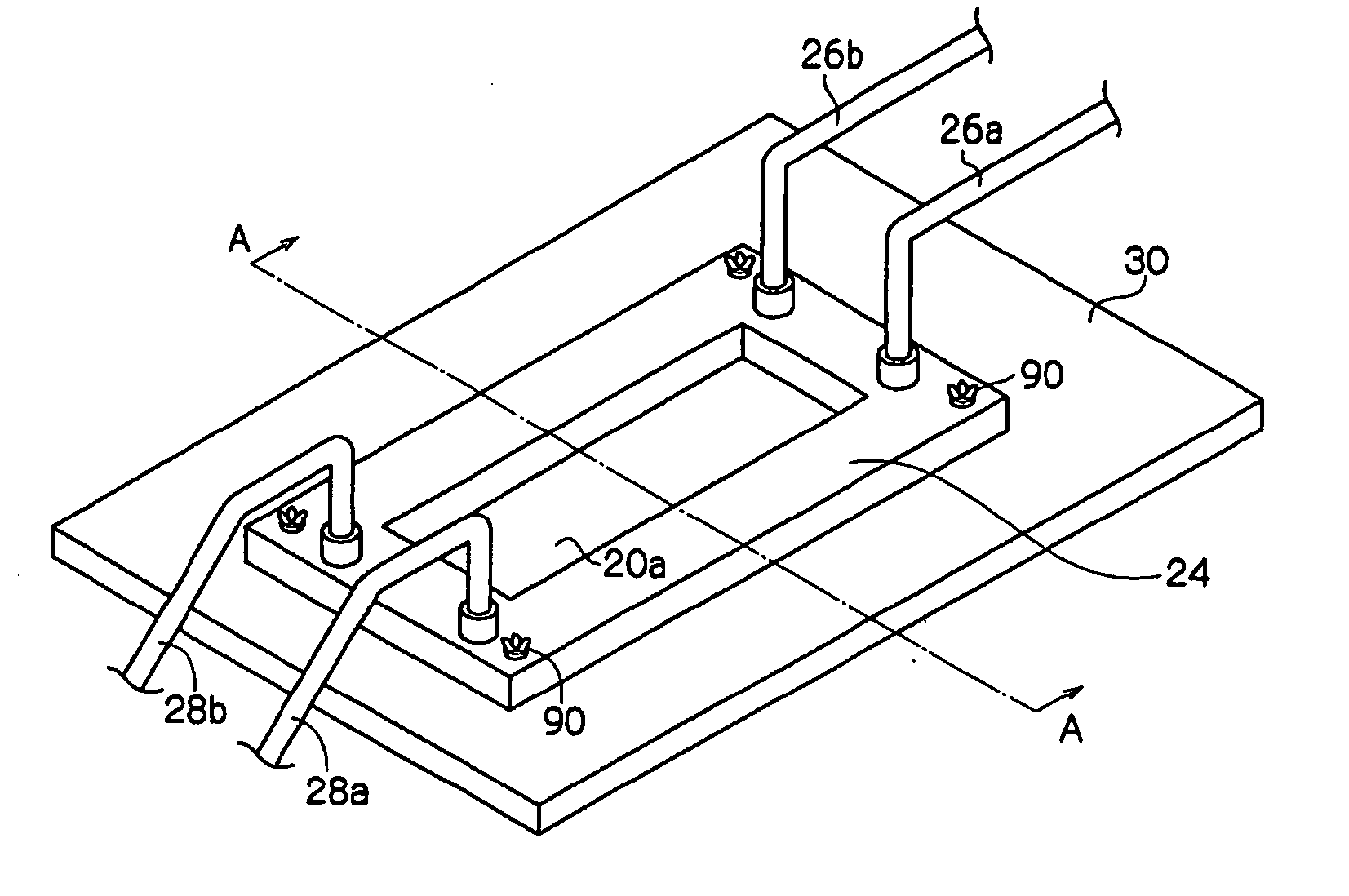

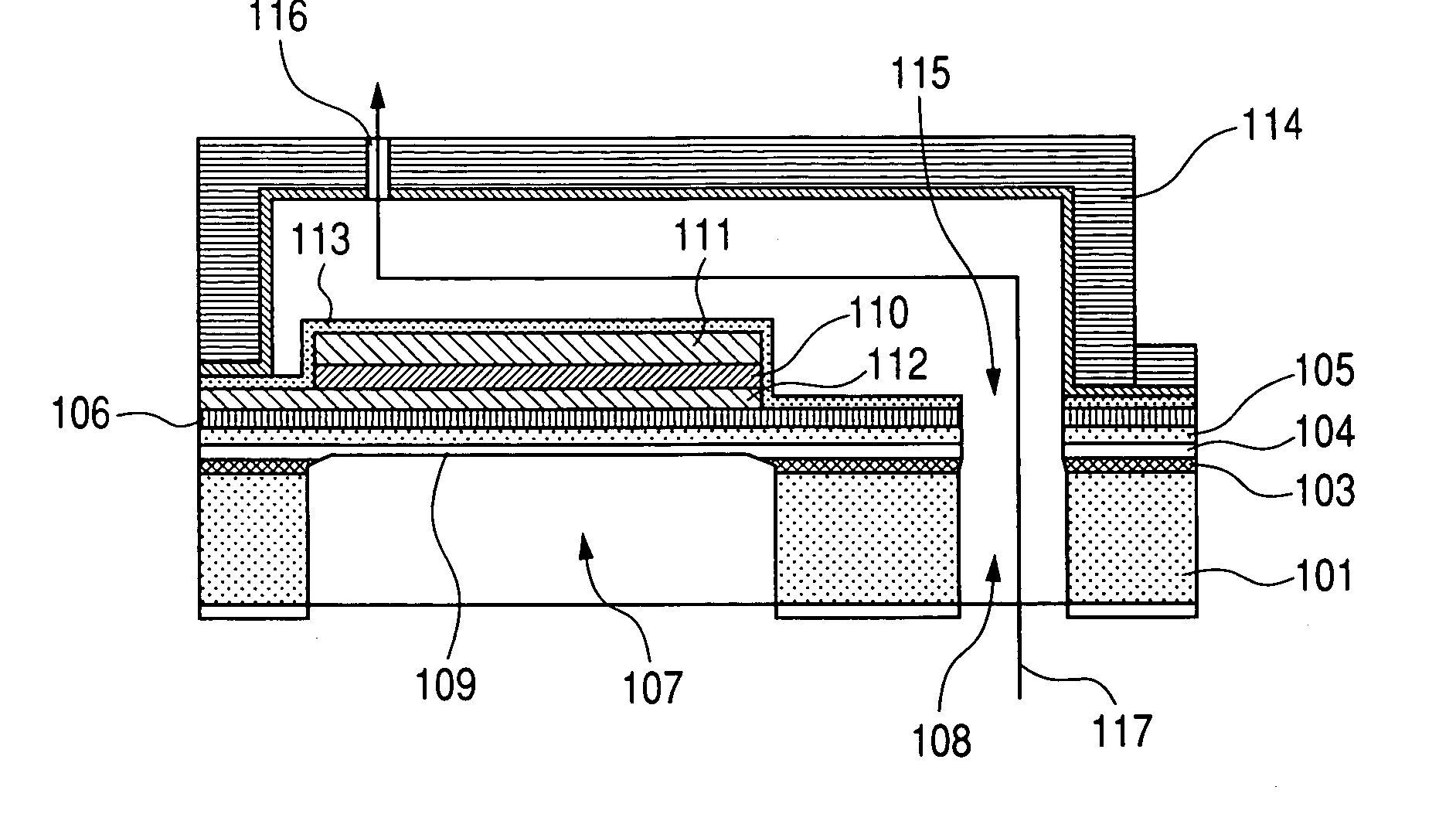

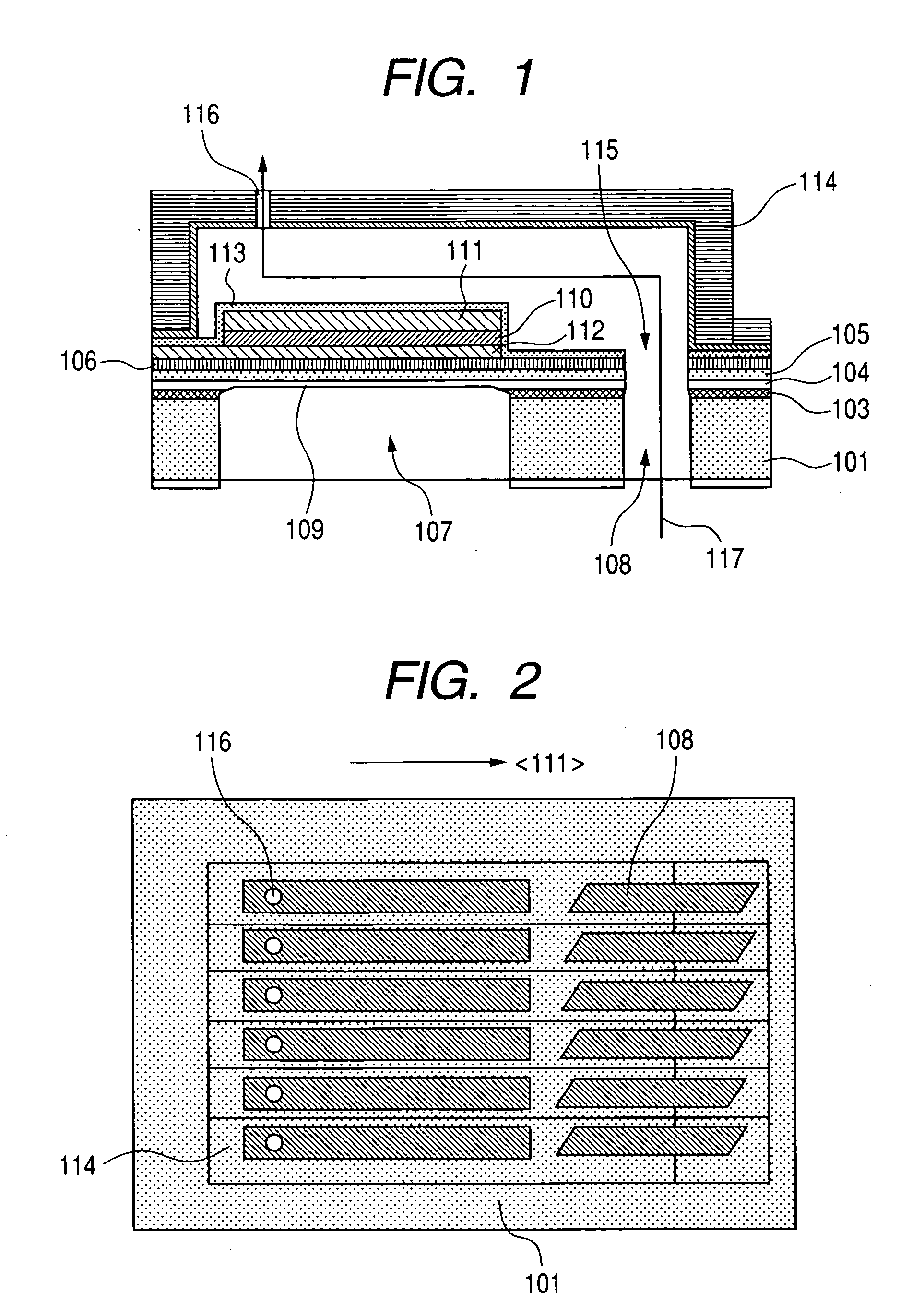

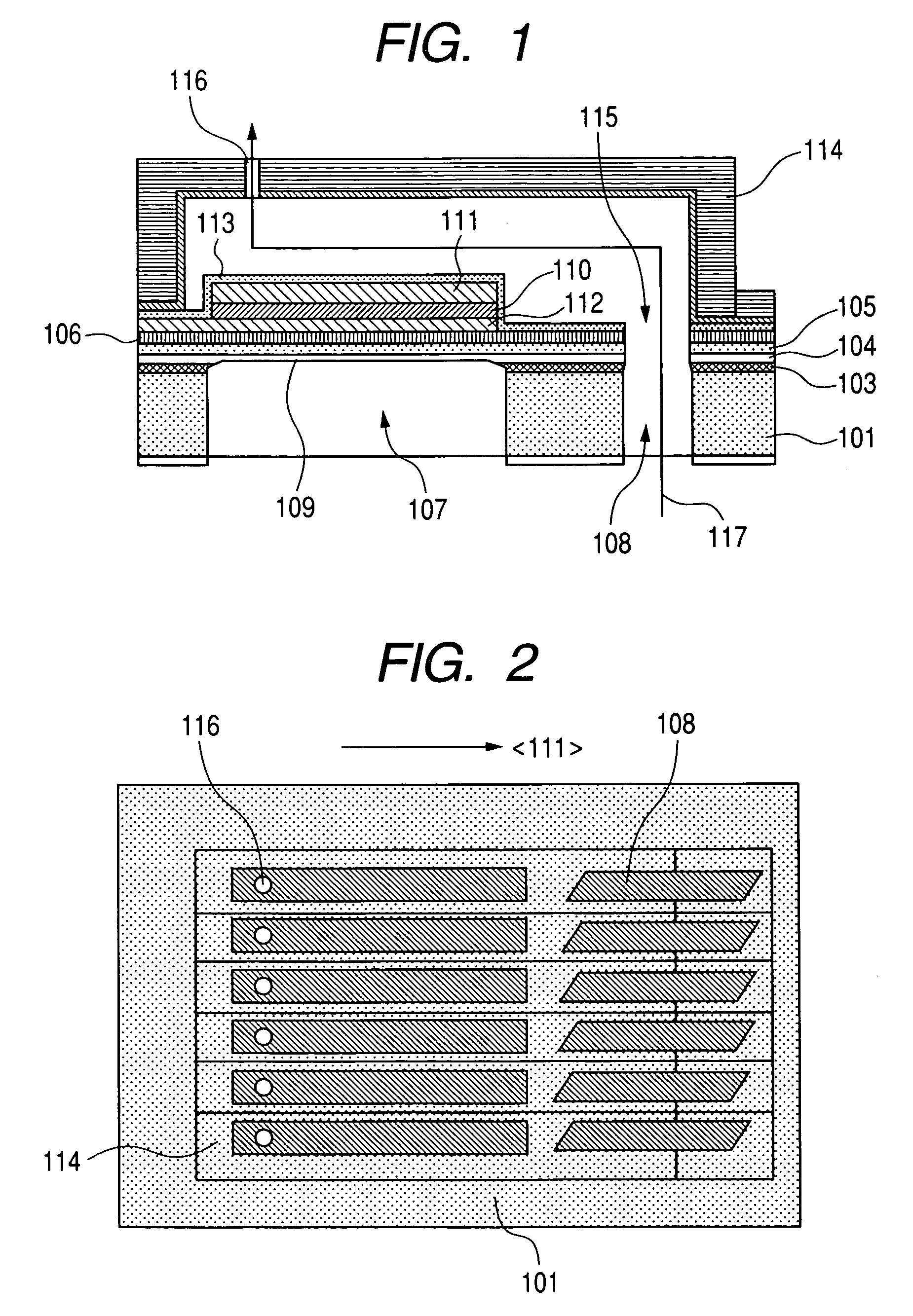

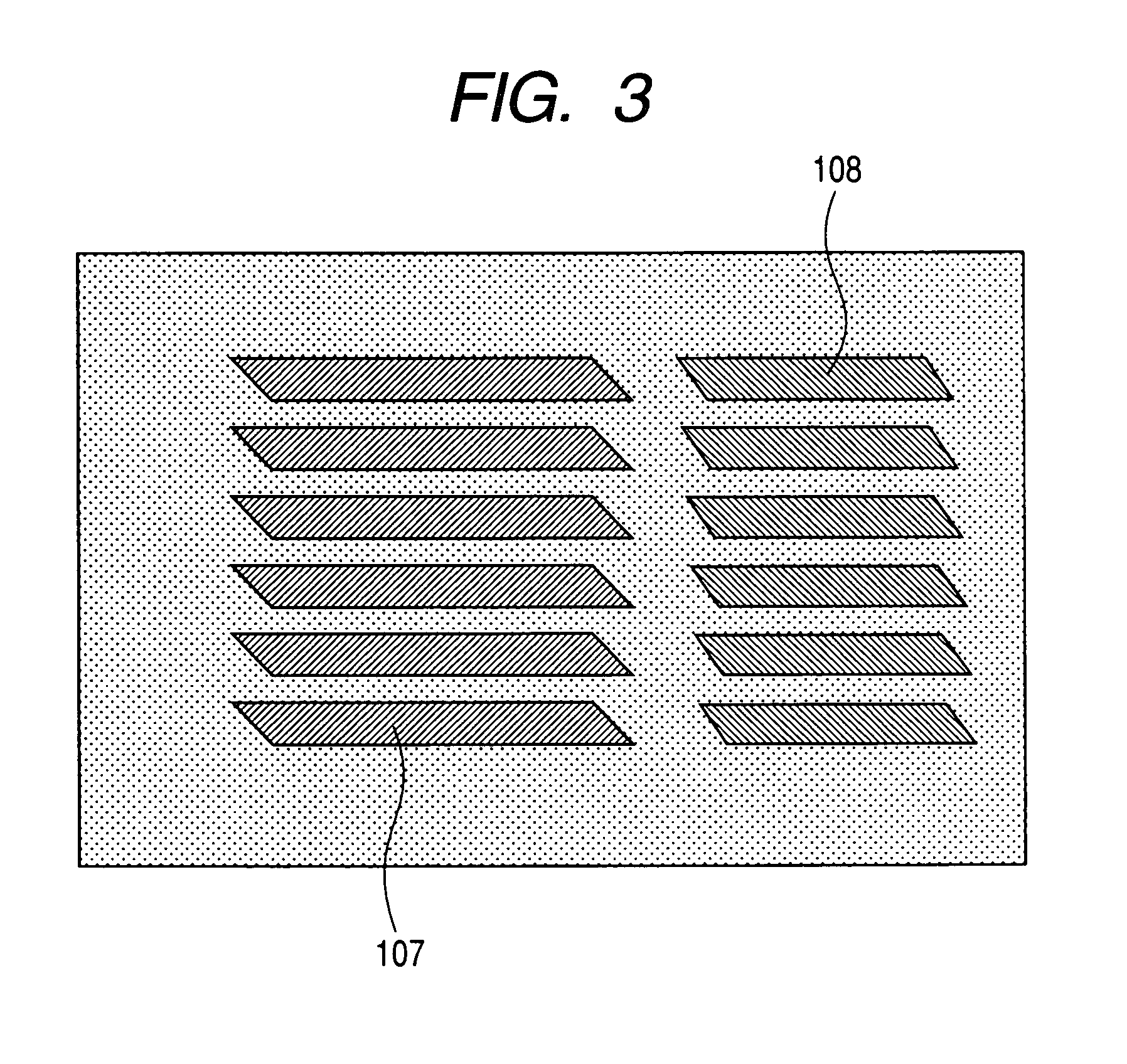

Method of manufacturing liquid discharge head and method of manufacturing substrate for liquid discharge head

InactiveUS20060027529A1High yieldDense highRecording apparatusRecord information storageEngineeringSingle crystal

A method of manufacturing a liquid discharge head including a pressure generating chamber communicated to a discharge port for discharging liquid and a piezoelectric element which is provided corresponding with the pressure generating chamber and includes a piezoelectric material film and a pair of electrode films sandwiching the piezoelectric material film, including: a step of preparing a structure with a single crystal Si layer being accumulated above a front surface of an Si substrate through an etching stop layer; a step of forming a buffer layer on the above described single crystal Si layer; a step of forming, above the above described buffer layer, the above described piezoelectric material film consisting of a single crystal thin film or a thin film which is directed in a preferential orientation to a direction of the polarization through one of the above described pair of electrode films; a step of forming the above described pressure generating chamber on the above described piezoelectric material film; and a step of etching a location corresponding with the above described piezoelectric material film of the above described Si substrate from a rear surface of the above described Si substrate to reach the above described etching stop layer.

Owner:CANON KK

Lithium ion conductive solid electrolyte and production process thereof

InactiveUS20110300451A1Increase battery capacitySimple and convenient for manufacture and handlingSolid electrolyte cellsSecondary cellsPorosityLithium metal

A lithium ion conductive solid electrolyte formed by sintering a molding product containing an inorganic powder and having a porosity of 10 vol % or less, which is obtained by preparing a molding product comprising an inorganic powder as a main ingredient and sintering the molding product after pressing and / or sintering the same while pressing, the lithium ion conductive solid electrolyte providing a solid electrolyte having high battery capacity without using a liquid electrolyte, usable stably for a long time and simple and convenient in manufacture and handling also in industrial manufacture in the application use of secondary lithium ion battery or primary lithium battery, a solid electrolyte having good charge / discharge cyclic characteristic in the application use of the secondary lithium ion battery a solid electrolyte with less water permeation and being safe when used for lithium metal-air battery in the application use of primary lithium battery, a manufacturing method of the solid electrolyte, and a secondary lithium ion battery and a primary lithium battery using the solid electrolyte.

Owner:OHARA

Deposition of perovskite and other compound ceramic films for dielectric applications

InactiveUS7838133B2Increase capacitanceReduce the temperatureThin/thick film capacitorFixed capacitor dielectricElectricityHigh rate

In accordance with the present invention, deposition of perovskite material, for example barium strontium titanite (BST) film, by a pulsed-dc physical vapor deposition process or by an RF sputtering process is presented. Such a deposition can provide a high deposition rate deposition of a layer of perovskite. Some embodiments of the deposition address the need for high rate deposition of perovskite films, which can be utilized as a dielectric layer in capacitors, other energy storing devices and micro-electronic applications. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the BST layer.

Owner:DEMARAY

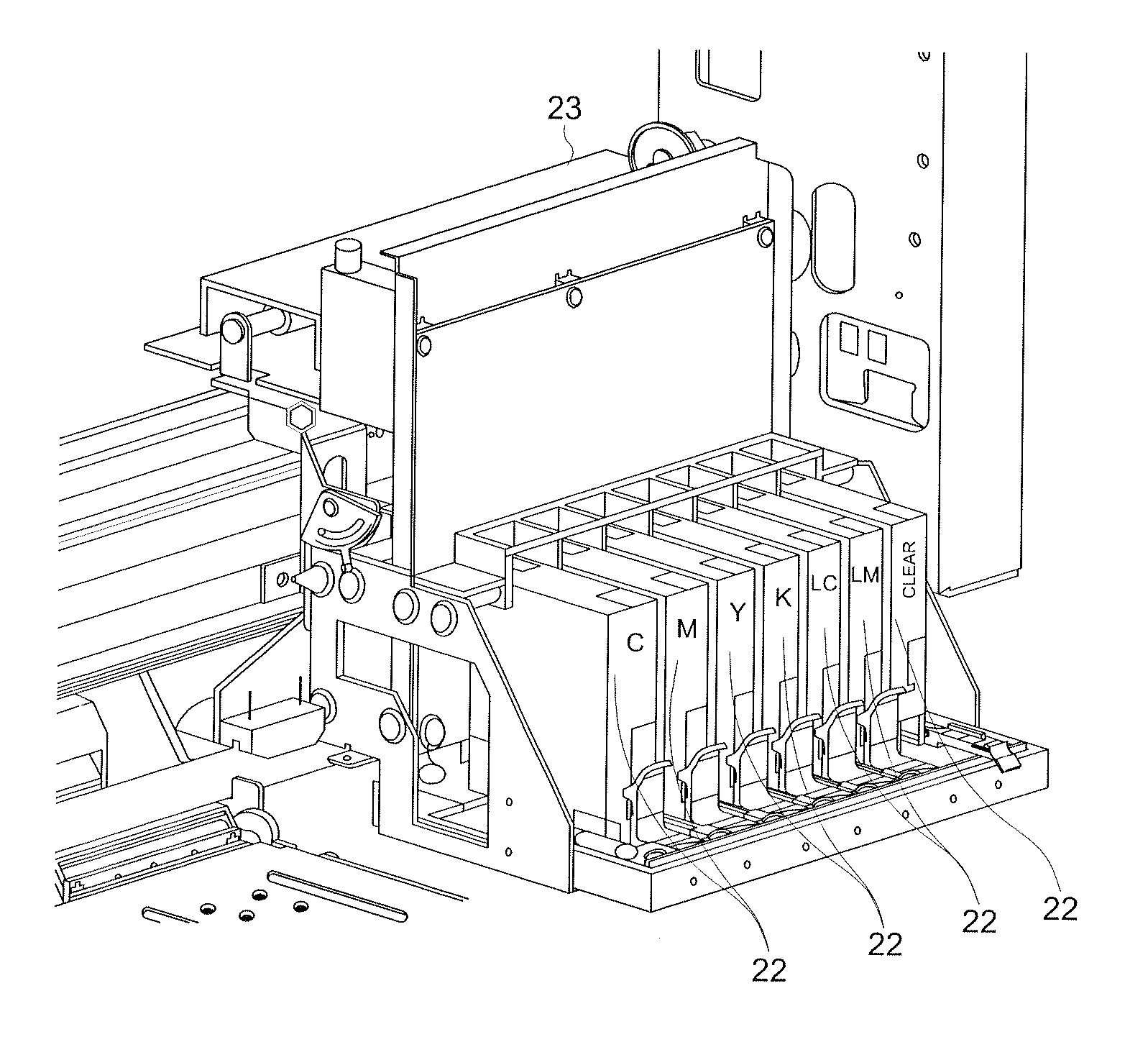

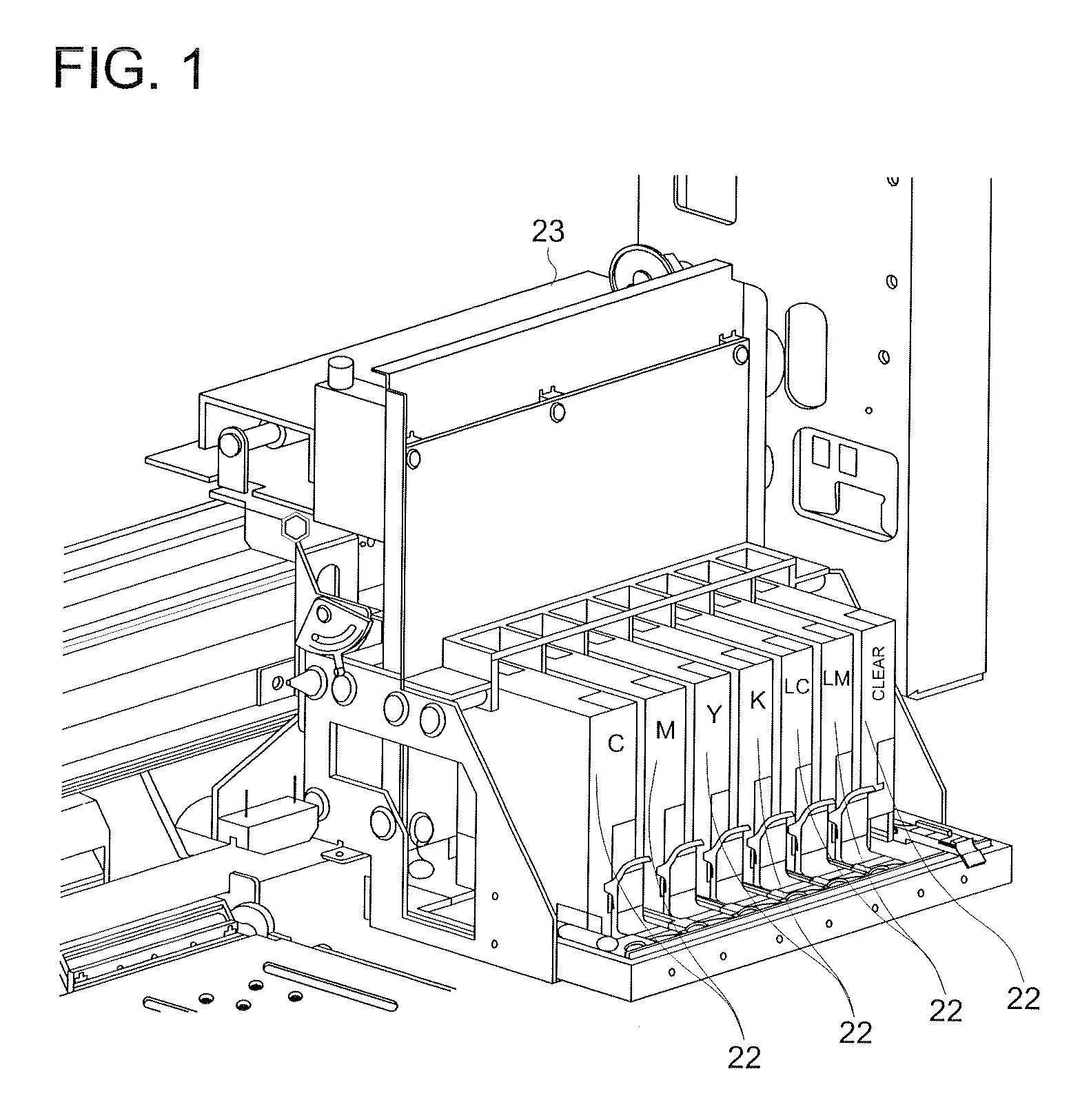

Ink-jet image forming method

InactiveUS20070052785A1Good weather resistanceHigh glossLiquid surface applicatorsMeasurement apparatus componentsWater dispersiblePolymer chemistry

A method of forming an ink-jet image comprising the steps of: i. ejecting ink compositions from an ink-jet head onto a recording medium; and ii. forming an image, wherein a) the recording medium is a porous type medium having a porous ink absorbing layer on a non-water absorptive support, b) the ink-jet head has a plurality of nozzles which eject more than two ink compositions respectively, and one ink composition is a clear ink, and one ink composition is a color ink, c) the clear ink contains water dispersible microscopic resin particles having an average diameter of 10-200 nm of more than 1 weight %, and d) pH of the ink compositions is 6.5-11.0, and an absolute value of a difference, between an ink composition pH and film surface pH of the recording medium, is less than 4.0.

Owner:KONICA MINOLTA PHOTO IMAGING

Powder metallurgy method of Ti-6Al-4V alloy

The invention provides a powder metallurgy method of a Ti-6Al-4V alloy. The method is characterized by comprising the following steps of: lubricating the inner wall of a die with a lubricant, filling Ti-6Al-4V powder between -100 meshes and -300 meshes into a die cavity, prepressing, exhausting, and pressing a green body in the ratio of impact energy to powder filling amount of (304-1,065J):(7.43-9.65)g; and sintering the green body at the temperature rise speed between 3 DEG C per minute and 4DEG C per minute and the vacuum degree between 1*10<-3> Pa and 1*10<-4> Pa and at the temperature between 1,250 DEG C and 1,300 DEG C for 2-3 hours, and cooling to obtain the Ti-6Al-4V alloy. The method has a simple technical process, can be used for preparing a powder metallurgy titanium alloy with high performance by near-net-shape forming and short flow at low cost, and is suitable for industrial production. The titanium alloy prepared by adopting the method has the density of 95.1-97.8 percent, the Vickers hardness (HV) of 261-358 and the compression strength of 1,600-2,100 MPa.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

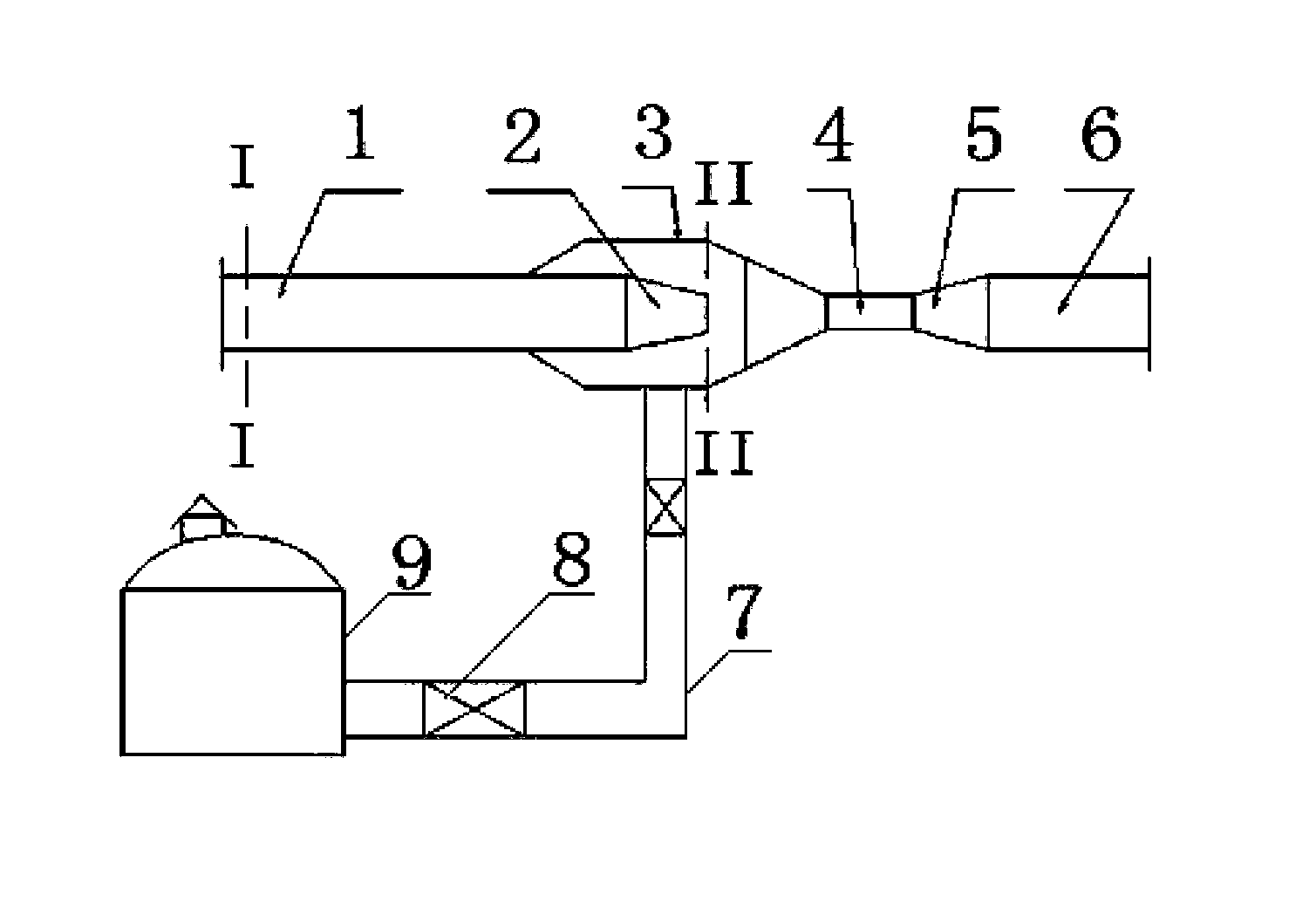

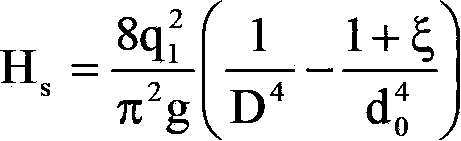

Wellhead high-pressure-spraying agentia adding method and device for water injection wells

The invention discloses a wellhead high-pressure-spraying agentia adding method and device for water injection wells. The wellhead high-pressure-spraying agentia adding method and device are designed for fixed-point agentia adding for the single water injection well and unpowered agentia adding at a high-pressure wellhead, namely, one end of a negative-pressure generating cavity is connected with a pressure pipeline with a nozzle, the other end of the negative-pressure generating cavity is sequentially connected with a throat pipe, a diffuser and a discharge pipe, and two ends of an agentia adding pipeline are respectively connected with an agentia storage tank and the negative-pressure generating cavity. The wellhead high-pressure-spraying agentia adding method includes that an anti-corrosion coating layer is surfaced on the inner wall of the nozzle at first, then a spraying device is arranged at the wellhead, high-pressure fluid is input so as to enable the negative-pressure generating cavity to generate negative pressure, and liquid agentia is sucked into the throat pipe and is injected into the water injection well through the discharge pipe after energy conversion. The wellhead high-pressure-spraying agentia adding method is simple to operate, energy-saving and lower in consumption. Technical process and the device are simplified. Since no motion parts are installed in the nozzle, the high-pressure-spraying agentia adding device is reliable to operate, leakproof and low in cost. The anti-corrosion coating layer of the nozzle has high density and uniformity, is resistant to washout and high pressure, can effectively protect the base body of the nozzle, and is easy to process and low in maintenance workload, and the service life of the device can be prolonged by 5-10 times of that of existing devices.

Owner:PETROCHINA CO LTD

Method of manufacturing liquid discharge head and method of manufacturing substrate for liquid discharge head

InactiveUS7497962B2Simple processHighly dense piezoelectricRecording apparatusRecord information storageOptoelectronicsSingle crystal

A method of manufacturing a liquid discharge head, which includes a pressure generating chamber, a discharge port, and a piezoelectric element formed of a pair of electrode films sandwiching a piezoelectric material film, includes steps of preparing a structure with a single crystal Si layer accumulated above a front surface of an Si substrate through an etching stop layer; forming a buffer layer on the single crystal Si layer; forming, above the buffer layer, the piezoelectric material film which is directed in a preferential orientation to a direction of the polarization through one of the pair of electrode films; forming the pressure generating chamber on the piezoelectric material film; and etching a location corresponding to the piezoelectric material film of the Si substrate from a rear surface of the Si substrate to reach the etching stop layer.

Owner:CANON KK

Production method of medical polyurethane antibacterial nano-silver coating

InactiveCN107583112AGood dispersionIncrease contentCatheterCoatingsVacuum dryingAntibacterial property

A production method of a medical polyurethane antibacterial nano-silver coating comprises the following steps: (1) dissolving dopamine in Tris-HCl buffer solution with the concentration being 0.015-0.025 mol / L and the pH value being 7.5-9, and carrying out a reaction at 20-30 DEG C in a dark environment for 25-35 min, wherein a dosage ratio of the dopamine to H2O is (800-1000) mg : 100 ml; (2) adding polyurethane to a solution obtained in the step (1), carrying out a reaction at 20-30 DEG C in a dark environment, taking out the polyurethane, flushing the polyurethane with plasma water, and drying the flushed polyurethan in a vacuum drying box; and (3) adding polyurethan obtained in step (2) into a silver ammonia solution, reducing silver nitrate with glucose as a reducing agent, and carrying out ultrasonic vibration cleaning to obtain the antibacterial polyurethane. The polyurethane nano-silver coating has the advantages of obvious antibacterial property, high content, high density, good dispersivity, no shedding and fast production speed.

Owner:NANCHANG UNIV

Organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion and coating thereof

InactiveCN105131263AImprove weather resistanceImprove hydrolysis resistancePolyester coatingsEmulsionOrganosilicon

The invention provides an organosilicon epoxy acrylic acid modified waterborne alkyd resin and a coating thereof; the formula of the coating comprises the components in parts by mass: 40-50 parts of an organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion comprising the components of 45-65 parts of tung oil, castor oil or linseed oil, 25-45 parts of phthalic anhydride, trimellitic anhydride or trimellitic anhydride, 3-10 parts of xylene, 5-10 parts of epoxy ester and 5-10 parts of organosilicon ester; 3-4 parts of a pigment; 6-26 parts of a packing; 10-20 parts of deionized water; 0.05-0.5 part of a dispersant; 0.1-0.3 part of a defoaming agent; and 0.9-2.5 parts of a drier. The preparation method of the emulsion comprises the steps: heating oil, glycerol, pentaerythritol and trimethylolpropane with nitrogen protection, adding an alcoholysis catalyst, heating up, keeping a reaction until the ethanol tolerance degree reaches 2.0-5.0 ml / 100 ml, and cooling; adding anhydride and xylene; adding organosilicon ester and epoxy ester, and modifying; and adding acrylate, and modifying; and cooling, and dispersing the mixture for two times. The coating has the advantages that easily-volatile organic compounds are reduced with water as a diluent.

Owner:盘锦辽河油田金宇生态环境有限公司

Joining method of SiC ceramic through combining nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as prepared ceramic connector

The invention belongs to the technical field of ceramic joining and discloses a joining method of SiC ceramic through combining a nano-impregnated transient co-crystal phase with chemical vapor infiltration as well as a prepared ceramic joining part. The method comprises the following steps: firstly, mixing SiC powder with Al2O3-Re2O3, adding a solvent and a ball milling medium for mixing and drying to obtain mixed powder; granulating the mixed powder and spreading the granulated powder between two pieces of polished SiC to form a sandwich structure; putting a sample with the sandwich structure into a heat treatment furnace, raising the temperature to 1000 to 1400 DEG C for heat treatment in a vacuum or protective atmosphere, adding organic carbon silane doped with filler and carrying outchemical vapor infiltration at 1300 to 1600 DEG C to obtain a joining part of the SiC ceramic. According to the joining method disclosed by the invention, low-temperature pressure-free joining of theSiC ceramic is realized by combining the nano-impregnated transient co-crystal phase with the chemical vapor infiltration and the leakage rate at the joint reaches 0 to 1*10<-10> Pa.L / s.

Owner:GUANGDONG UNIV OF TECH

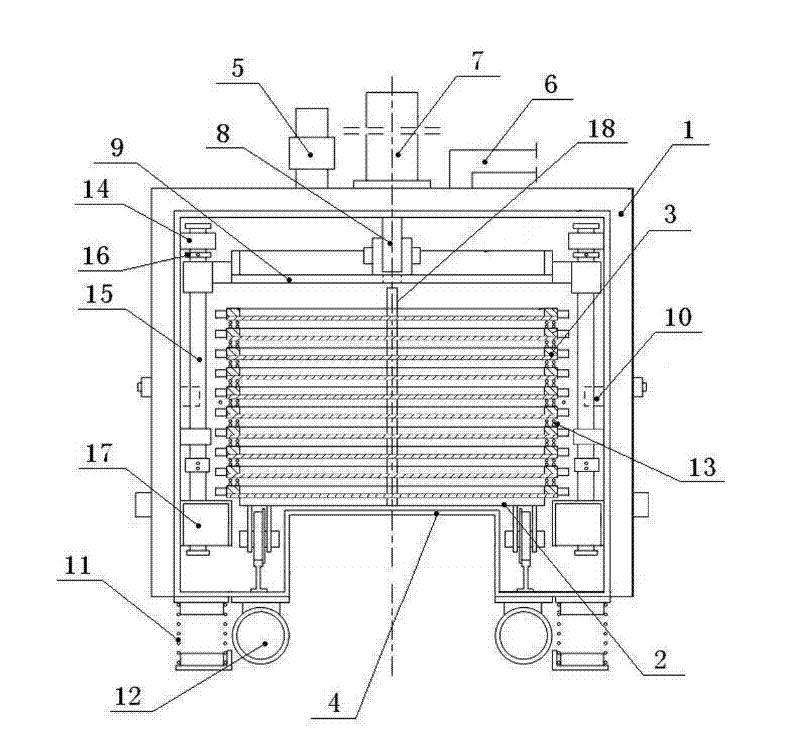

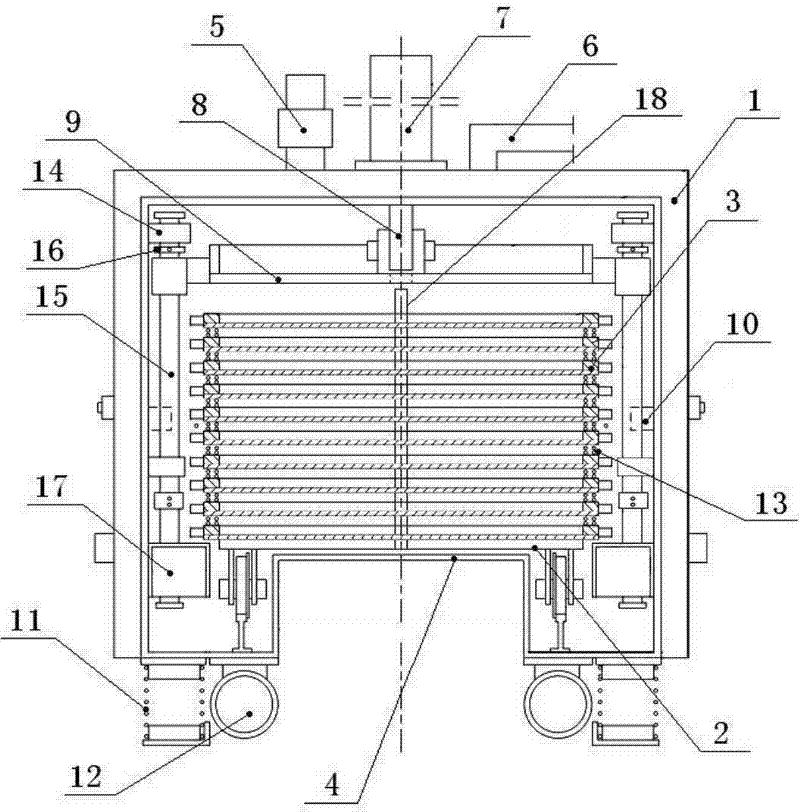

Multilayer combined type vacuum stone molding device

The invention relates to a multilayer combined type vacuum stone molding device which solves the problems that the traditional stone molding device only can mold stones piece by piece, the solidification is carried out in addition, molded composite boards are uncompacted, are easy to buckle and deform, and the like. The device is characterized in that an oil cylinder or an air cylinder with a hold-down device are arranged on the top of a vacuum tank; a supporting spring and 2 to 6 vibrators with 50-300Hz of frequency are arranged at the bottom of the vacuum tank; a plurality of layers of mold boards which are arranged in a stacked manner are also arranged in the vacuum tank; and a plurality of compression springs are arranged among each layer of the mold boards. The excitation force generated from the lower parts of the vibrators and the low-frequency excitation force generated from the upper part of the vacuum tank are matched with the compression springs among the mold boars and the supporting spring at the bottom of the vacuum tank to jointly form a vibration process of amplitude variation thereof, and the molding and the solidification are integrally carried out, thereby improving the working efficiency and restricting the problem that the composite boards buckle and deform in the solidification process. The multilayer combined type vacuum stone molding device is suitable for vacuum glue permeation of minerals such as quartz jade material and the like and the molding of spliced composite boards.

Owner:佛山市龙美达石业有限公司

A kind of synthetic magnesium calcium sand and preparation method thereof

InactiveCN102285806AHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

Nano water-based functional ceramic composite coating and preparation method thereof

ActiveCN103588443AGood physical and chemical stabilityExcellent abnormal temperature mechanical propertiesEmulsionPliability

The invention discloses a nano water-based functional ceramic composite coating which comprises raw materials in parts by weight as follows: 10-35 parts of silicate inorganic adhesives, 10-35 parts of main filler, 2-10 parts of stabilizing materials, 5-20 parts of toughness-enhancing emulsion type binding agents, 3-10 parts of film forming assistants and 5-25 parts of water. A preparation method comprises the steps as follows: the silicate inorganic adhesives and diluent are poured into a container and stirred at 350-400 r / min for 10-20 min, so that a mixed liquid is obtained; the main filler and the stabilizing materials are added to the mixed liquid, and the mixture is stirred at 350-400 r / min for 50-60 min; and the toughness-enhancing emulsion type binding agents and the film forming assistants are added sequentially, and the mixture is filtered by gauze with 400-600 meshes, so that the composite coating is obtained. A film of the coating is formed at the normal temperature, and the nano water-based functional ceramic composite coating has the characteristics of infiltration, large adhesive force, high density, stone hit resistance, impact resistance, high and low temperature resistance, superior abrasion resistance, washing resistance and good flexibility.

Owner:WUHAN ZHUOYI TECH DEV CO LTD

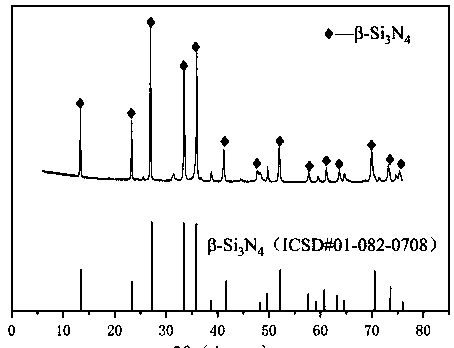

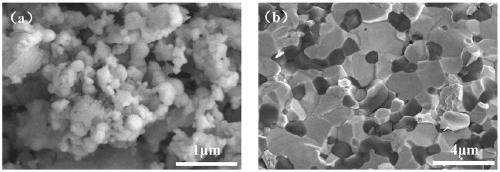

High-beta-phase compact silicon nitride ceramic and low-temperature preparation method

The invention belongs to the technical field of silicon nitride ceramics, and relates to a high-beta-phase compact silicon nitride ceramic, and a low-temperature preparation method. The preparation raw materials of the high-beta-phase compact silicon nitride ceramic comprise Si3N4 powder and a sintering aid; the sintering aid is a composite sintering aid consisting of LixMOy type lithium salt andone or more other oxides; wherein the LixMOy type lithium salt is one selected from LiAlO2, LiYO2, LiNbO3, Li2ZrO3, LiYbO2 and Li2SiO3, and the other oxides are one or more selected from rare earth oxide or metal oxide, Y2O3, CeO2, Yb2O3, MgO, CaO and MgAl2O4; the mass ratio of the LixMOy type lithium salt to other oxides in the composite sintering aid is (4-12): (0-8); the mass ratio of the Si3N4powder to the composite sintering aid is (85-94): (6-15). According to the method, the sintering temperature is greatly reduced, volatilization of the silicon nitride ceramic is reduced, and the excellent performance of the silicon nitride ceramic is better maintained.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

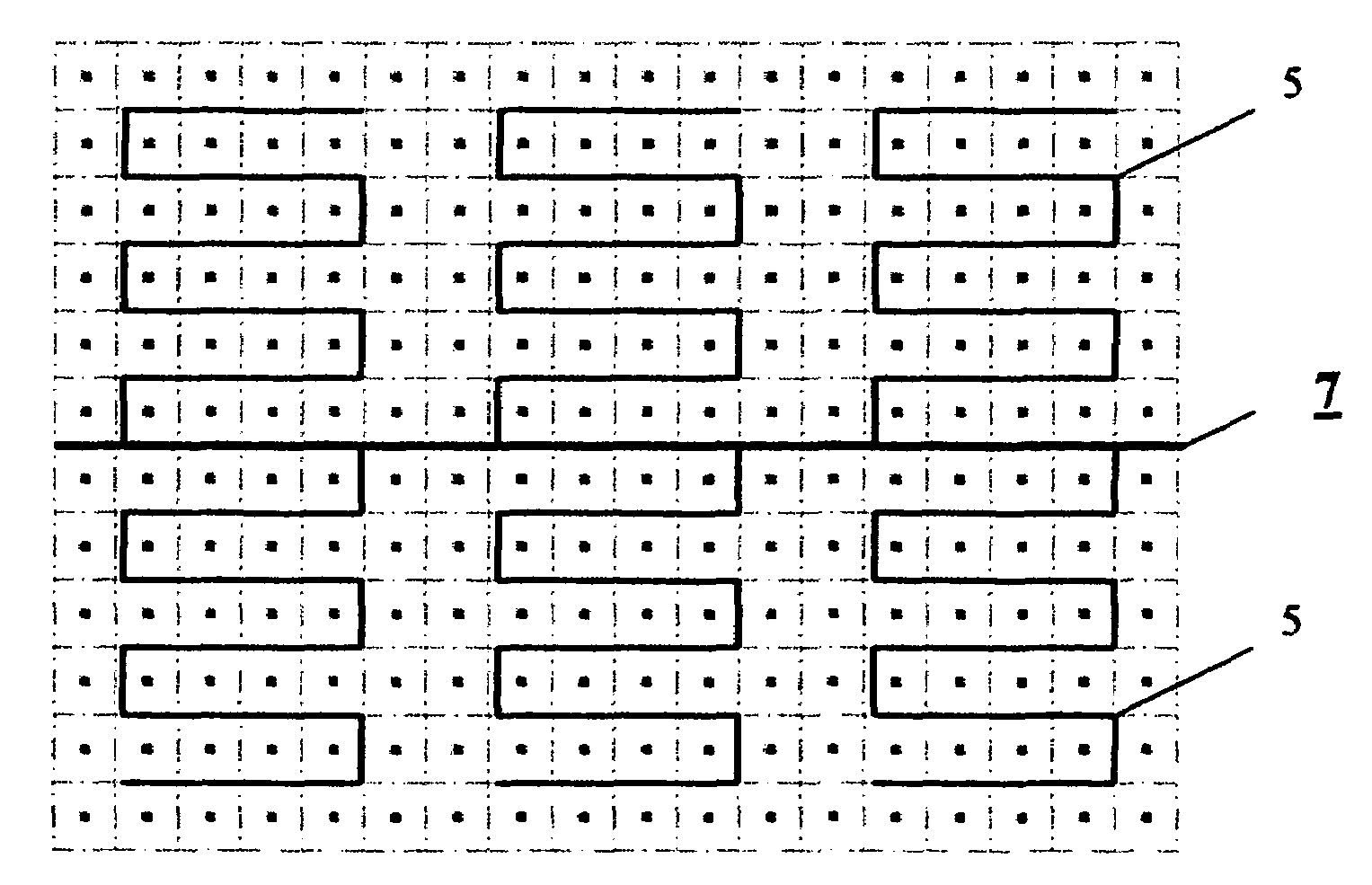

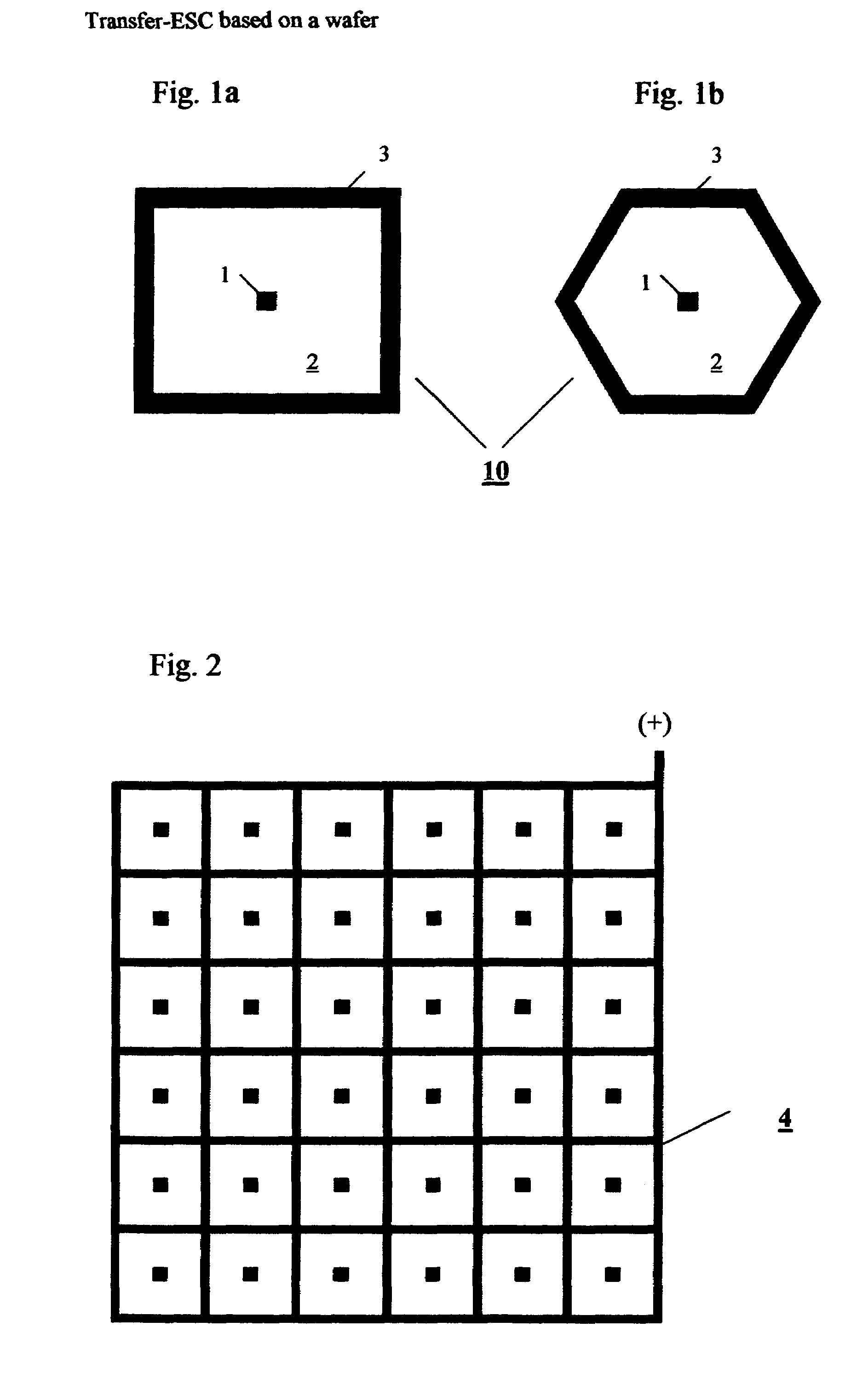

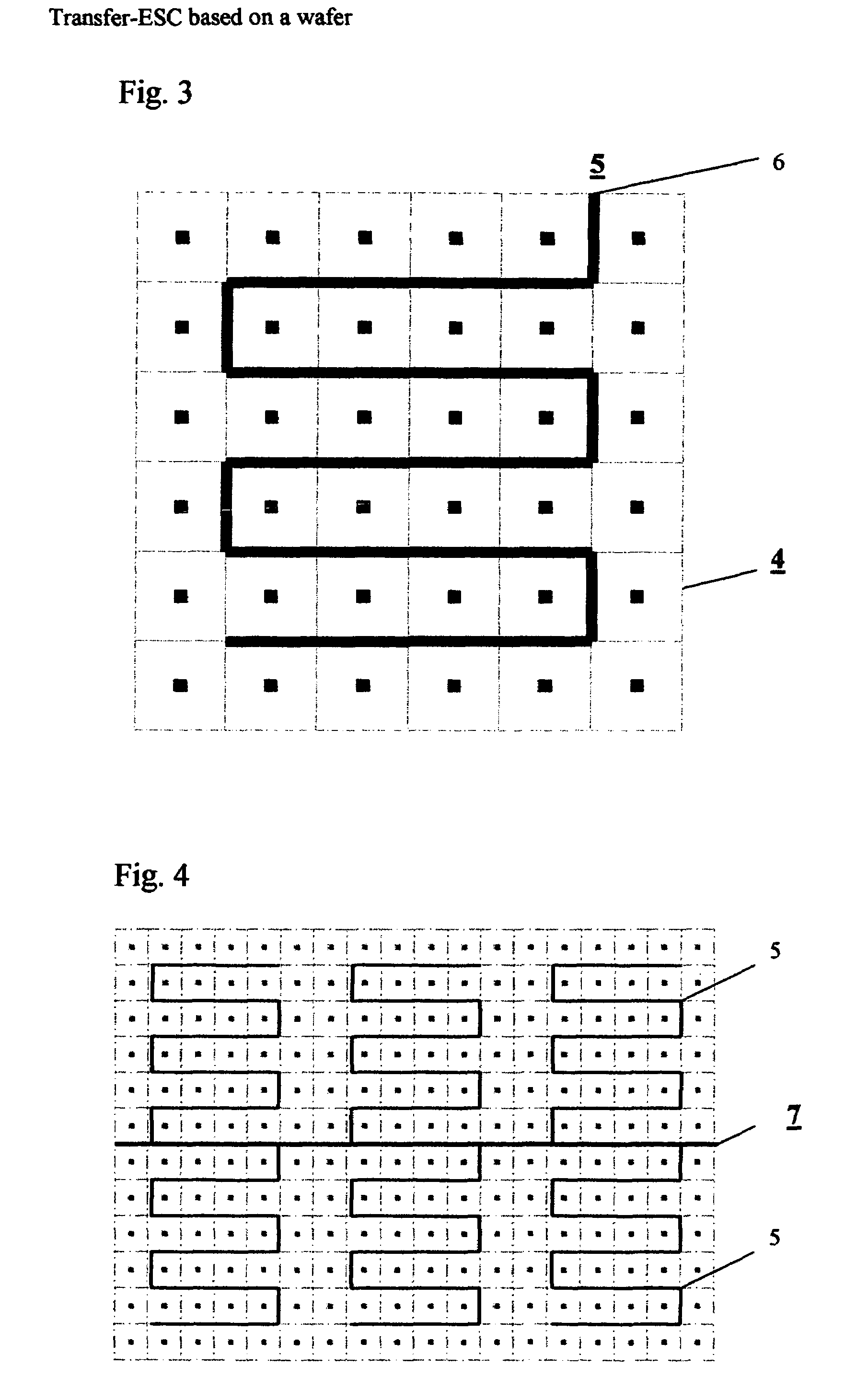

Transfer-ESC based on a wafer

InactiveUS7564672B2Reduce the amount of solutionCurrent densityTumbler/rocker switchesSemiconductor/solid-state device manufacturingPeak valueSafe handling

A mobile transportable electrostatic chuck for clamping thin wafers (12) without permanent connection to an external power supply unit is described. The mobile chuck allows a safe handling of thin substrates on existing production equipment because the size and thickness of the clamped substrate on the mobile chuck is similar to a standard wafer. The chuck is made from silicon wafers itself as base material (11) using an IC manufacturing processes. Bipolar electrode-unit-cells (10), combined into clusters (4) and linked to an integrated fuse (5), generate a non-uniform electric field with additional force components. Peak-electrodes (1) are introduced with the highest field density in the peak region and thus creating a three dimensional non-uniform electric field with each surrounding electrode (3). Quadratic or hexagonal electrode-unit-cells (10) enable the highest dense of unit cells, which effectively clamp wafers (12) in close proximity to the surface (8a) of the chuck at elevated temperatures.

Owner:RETZLAFF UDO HEINZ

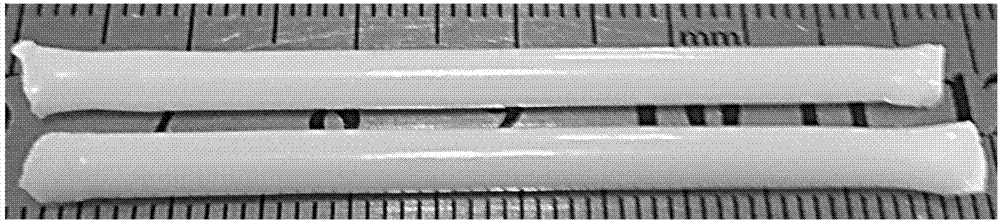

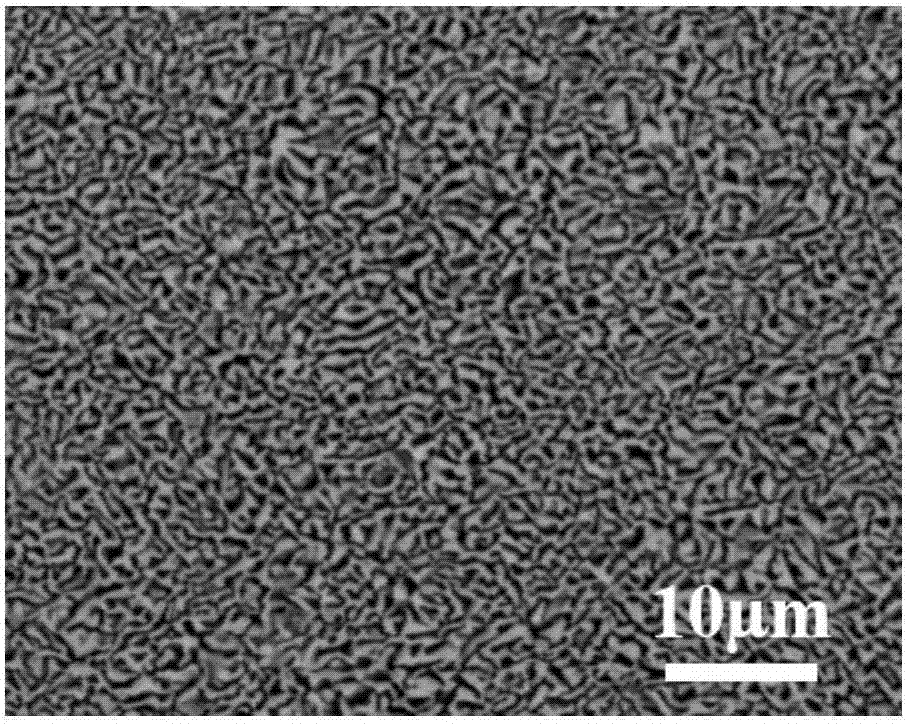

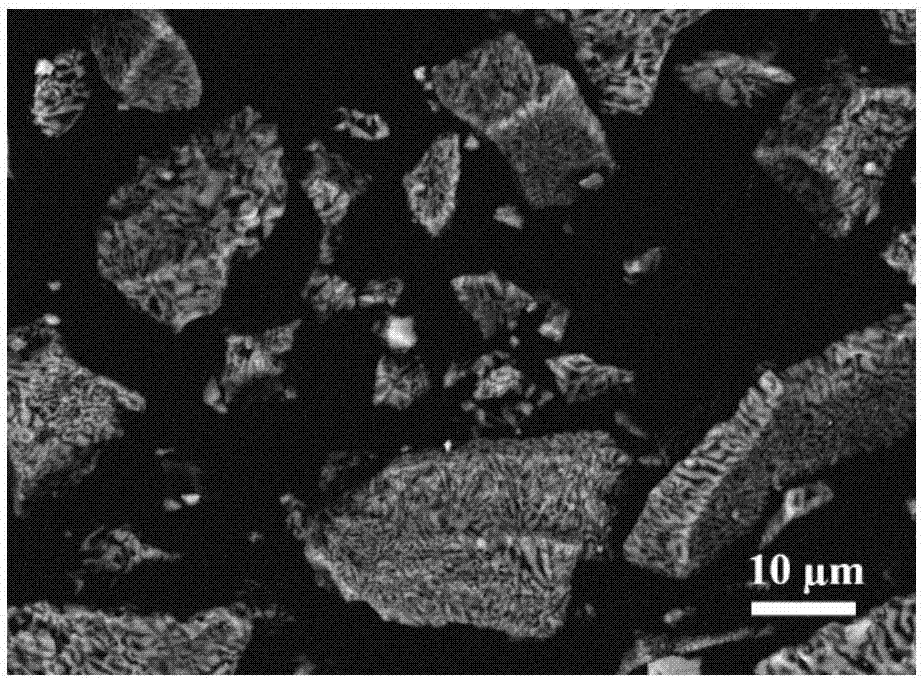

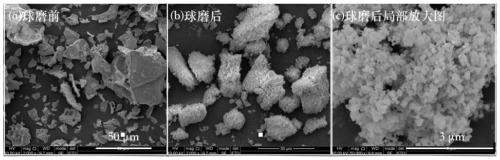

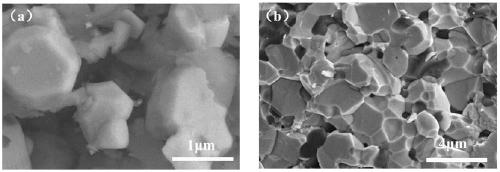

Method for hot-pressing and sintering alumina-based eutectic composite ceramic materials

InactiveCN107032767AEliminate grain boundariesElimination of interfacial amorphous phaseCeramic compositeGranularity

The invention discloses a method for hot-pressing and sintering alumina-based eutectic composite ceramic materials. The method includes the steps: preparing rod-like eutectic samples with small and uniform tissues by the aid of laser suspension zone melting-directional solidification technology; performing crushing and screening to obtain eutectic powder with inner eutectic structures; preparing the alumina-based eutectic composite ceramic materials with inner eutectic structures in a hot-pressing and sintering manner. The prepared sintering eutectic composite materials reserve eutectic structures in initial eutectic samples and eliminate most of crystal boundary and interface non-crystal phases, so that a new idea is provided for preparation of large alumina-based eutectic composite ceramic materials. According to the method, the tissues are typical 'hieroglyphic' eutectic morphologies, the particle size of eutectic particles ranges from 4mum to 25mum and larger than gaps between eutectic layer sheets, so that the eutectic particles effectively reserve eutectic structures, and the large-block eutectic composite ceramic materials are prepared, high in melting point, close to full density and provided with inner approximately full-eutectic structures.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

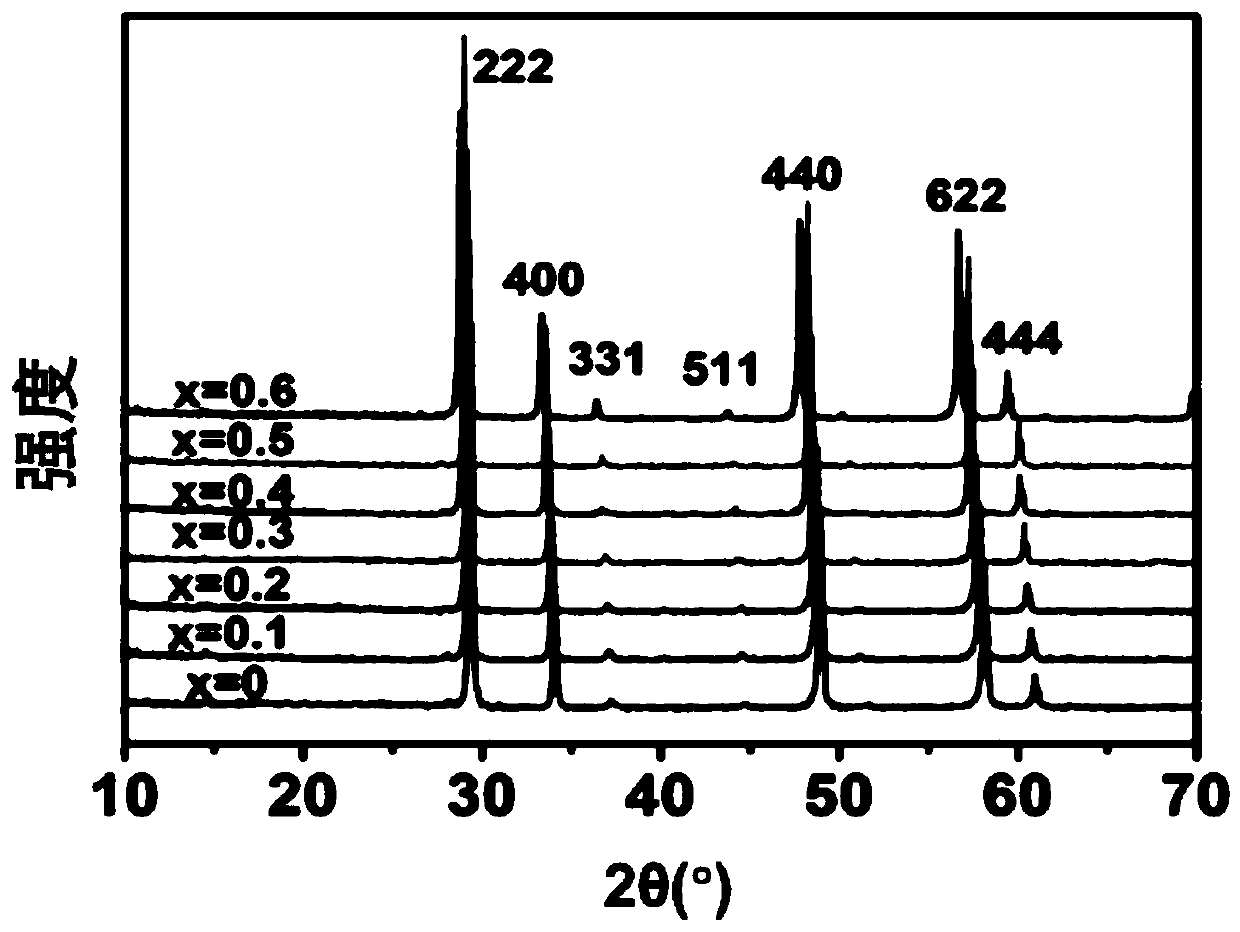

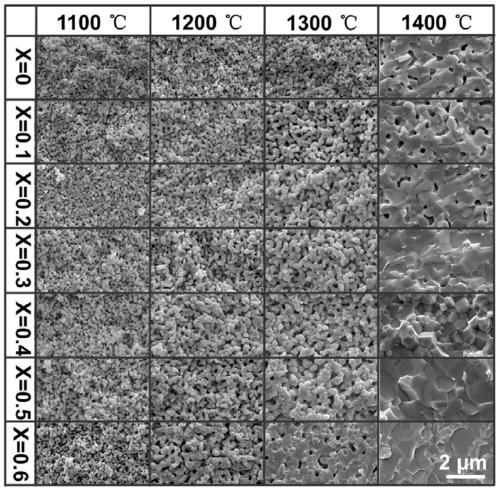

Gadolinium zirconate ceramic for curing TRPO simulated waste, and preparation method thereof

ActiveCN111039674AEasy to handleGood dispersionCeramic shaping apparatusRadioactive decontaminationZirconateGadolinium

The invention discloses a gadolinium zirconate ceramic for curing TRPO simulated waste, and a preparation method thereof. The preparation method comprises the following steps: (1) preparing precursorpowder by solid solution of radioactive elements in a liquid manner; (2) preparing a biscuit from the precursor powder obtained in step (1) by adopting dry pressing; and (3) preparing the gadolinium zirconate ceramic for curing the TRPO simulated waste by adopting a microwave sintering method. The prepared gadolinium zirconate ceramic for curing the TRPO waste has the advantages of no block cracking, high compactness and high hardness, and still keeps a single fluorite structure when the solid solution content reaches 60%. The preparation method provides a basic reference scheme for treating high-level radioactive waste liquids, especially curing actinide nuclides with long service life.

Owner:SICHUAN UNIV

System and method for producing fracturing propping agent by taking red mud as raw material

The invention discloses a system and a method for producing a fracturing propping agent by taking red mud as a raw material. The system comprises a charging machine, a high temperature furnace, a swing-out device, a blanking bin, a tempering furnace and screening equipment, wherein the high temperature furnace is connected with the blanking bin or the swing-out device; dosing is performed by taking inorganic solid wastes as raw materials; and the product is prepared by performing high-temperature melting in the high temperature furnace and molding in a molding device. The method comprises the following steps: (1) dosing, namely mixing pure red mud or red mud with one or more of fluorite, silica sand, potassium (or sodium) feldspar and dolomite; (2) mixing and performing wet grinding, namely mixing and performing wet grinding on the prepared materials; (3) drying and granulating; (4) melting the granulated materials in the high temperature furnace; (5) molding the granulated materials into propping agent granules by utilizing the molding device; and (6) screening, weighing and packaging the propping agent granules by virtue of the screening equipment. The system and the method are high in product yield, high in production efficiency and low in cost.

Owner:JINGANG NEW MATERIALS

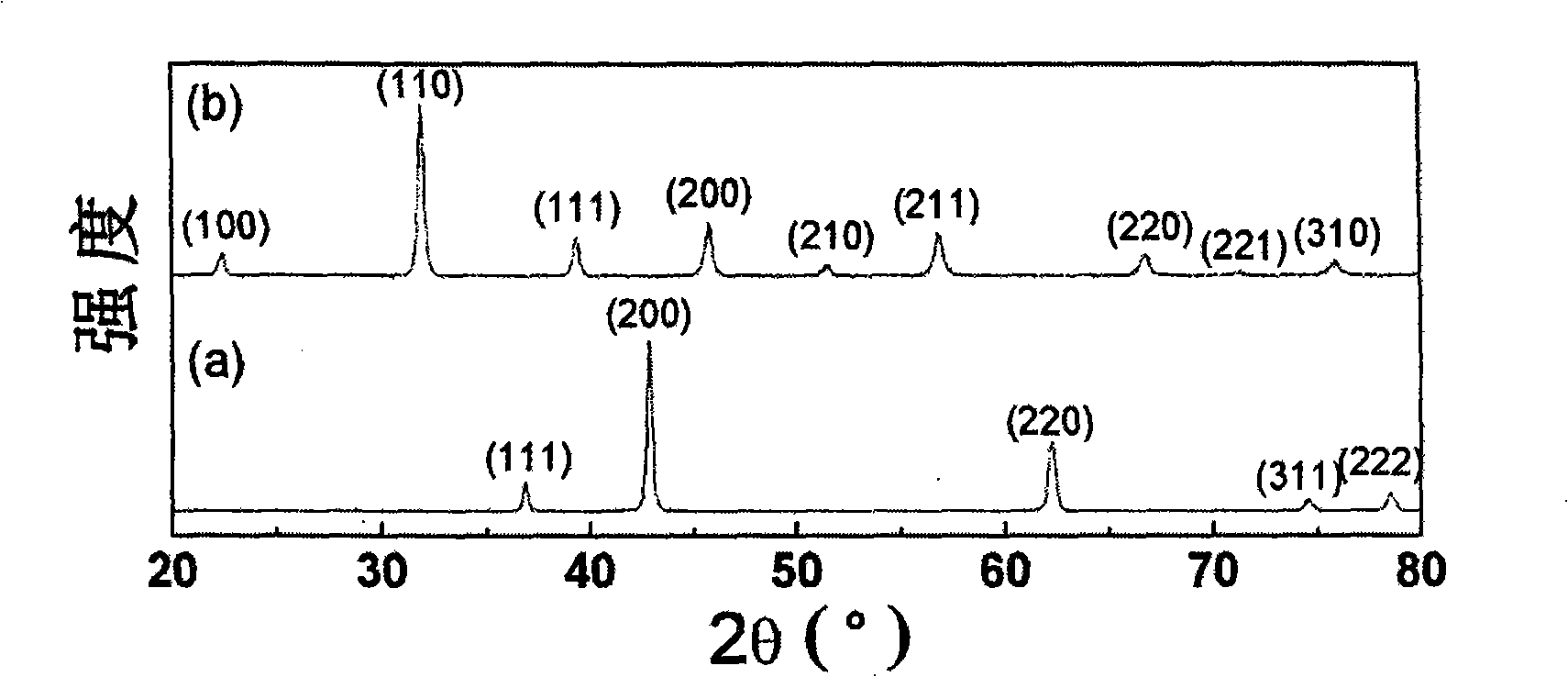

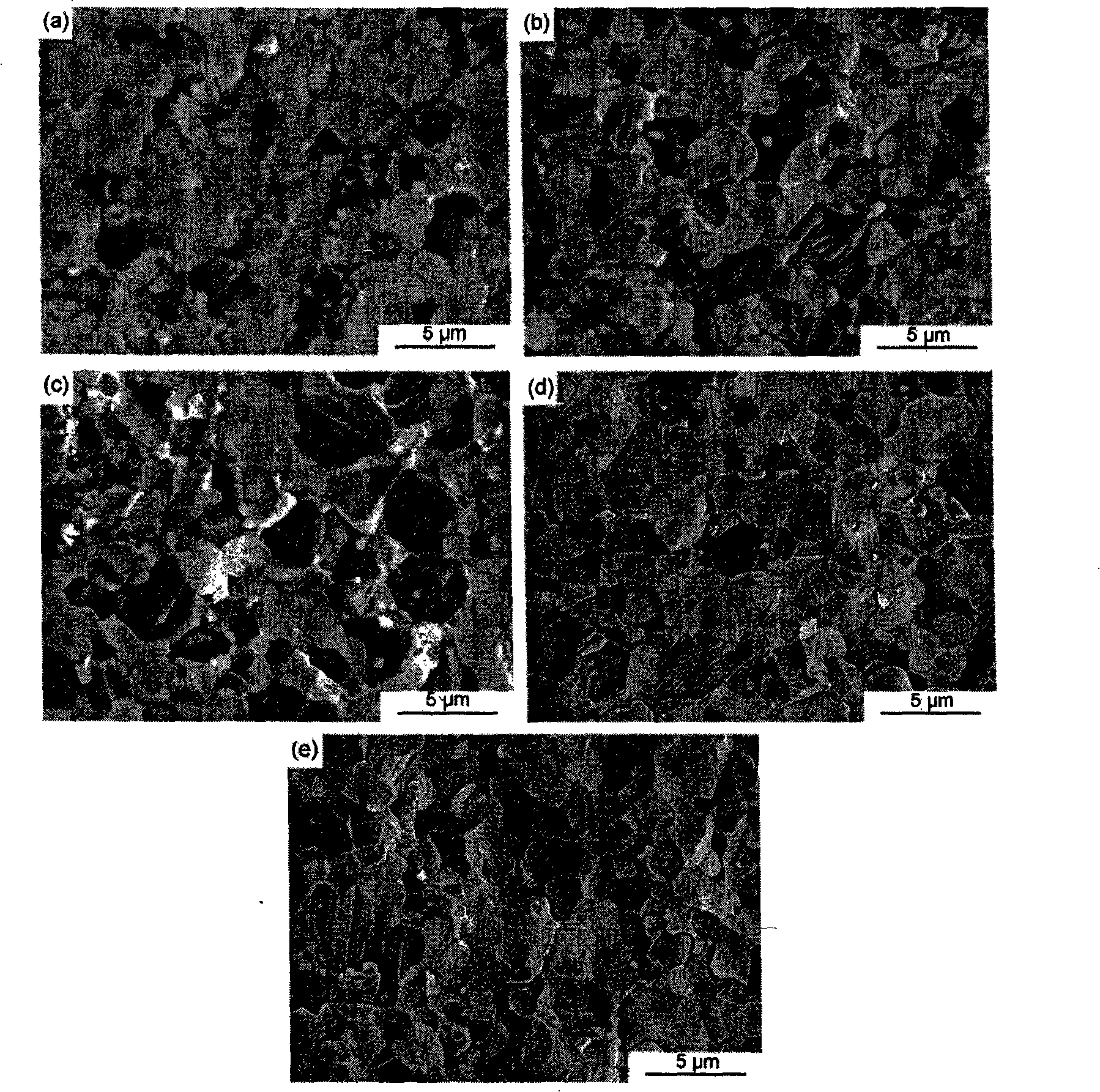

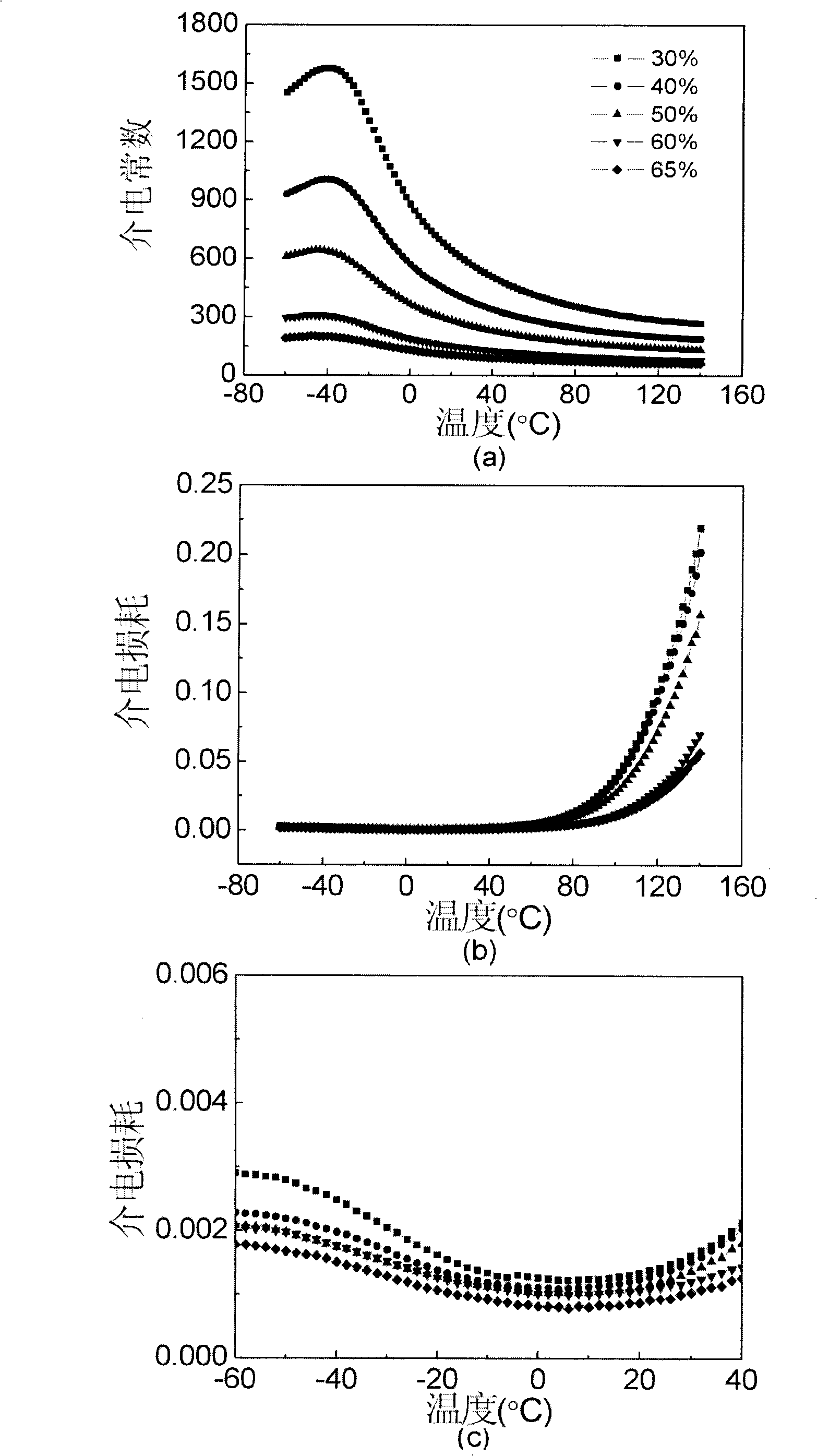

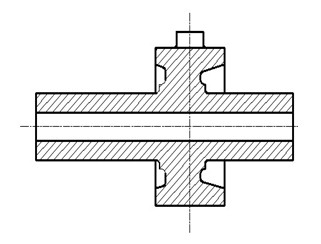

Pressure control adjustable strontium barium titanate-based composite ceramic materials and method for preparing same

ActiveCN101337812AImprove sintering performanceLow dielectric lossBarium strontium titanateComposite ceramic

The invention belongs to the technical field of preparation of microwave ceramics, in particular relates to a pressure control adjustable barium strontium titanate-base compound ceramic material and a preparation method thereof. The compound ceramic material is prepared as follows: Ba(1-x)SrxTiO3 is compounded with Mg(1-y)ZnyO with low dielectric constant and low dielectric loss; little Ta2O5 is added to modify the compound ceramics of (1-m)Ba(1-x)SrxTiO3-mMg(1-y)ZnyO so as to meet the performance requirements of pressure control adjustable microwave ceramics with proper dielectric constant, low microwave dielectric loss, high pressure control adjustability and so on. The barium strontium titanate-base compound ceramic material prepared by adopting the solid reaction process or the coprecipitation coating process is cold isostatic compacted without adding any forming agent and is sintered under atmospheric pressure, thus obtaining high density and high purity ceramic blocks. The pressure control adjustable barium strontium titanate-base compound ceramic material is applicable for such microwave devices as phased array phasers, adjustable filters, delay lines, oscillators, resonators and so on.

Owner:GRIMAT ENG INST CO LTD

Cast and formed blade guiding frame and casting forming method thereof

ActiveCN102001441ASimplify machining allowanceImprove mechanical propertiesPropellersFoundry mouldsChemical compositionMetallurgy

The invention relates to a casting forming method of a cast and formed blade guiding frame. The cast and formed blade guiding frame is prepared from the following chemical components (in percentage by mass): 0.38-0.44 percent of C, 0.20-0.35 percent of Si, 0.60-0.90 percent of Mn, 0.030 percent of S or less, 0.030 percent of P or less, 0.90-1.20 percent of Cr, 0.15-0.30 percent of Mo, 0.05-0.08 percent of V and 0.005-0.01 percent of Ti. The invention has the advantages that (1) the production process is simplified by changing forging forming into casting forming, the raw materials are saved, and the production cost is decreased; and (2) the aims of enhancing grain thinning and improving the compactness of the materials and further improving the comprehensive mechanical performance of the materials are reached by externally enhancing external cooling, internally optimizing material components and adding microalloy elements.

Owner:BAODING TECH CO LTD

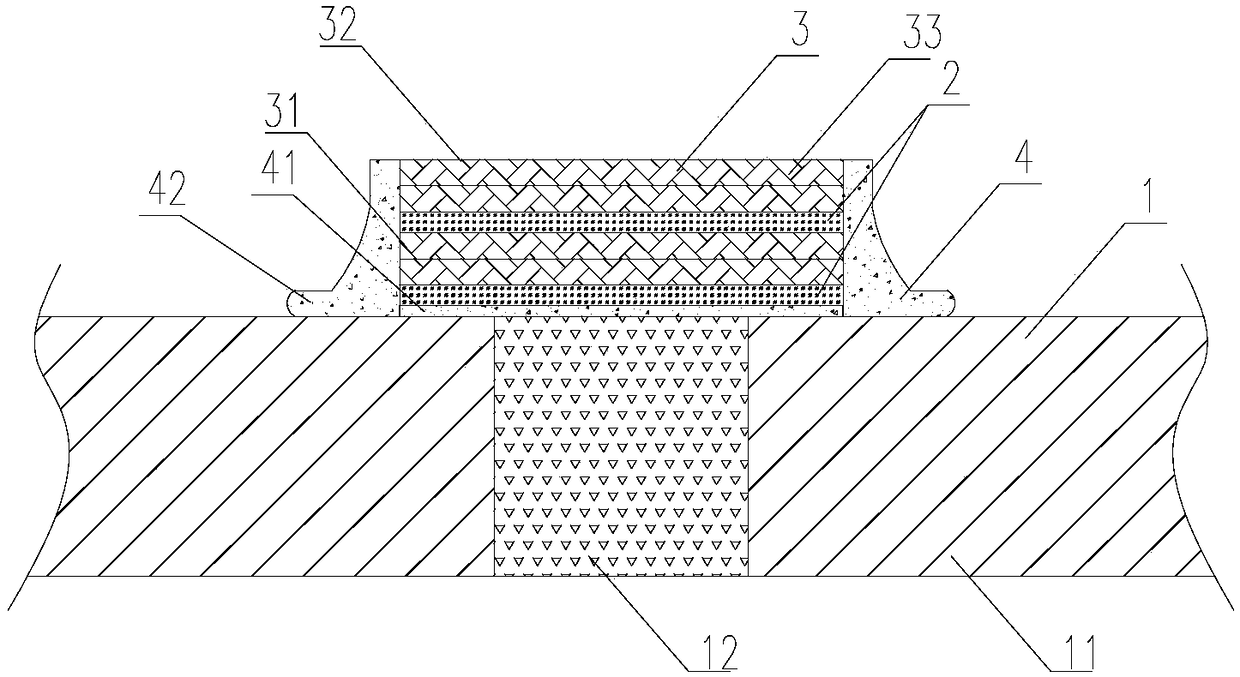

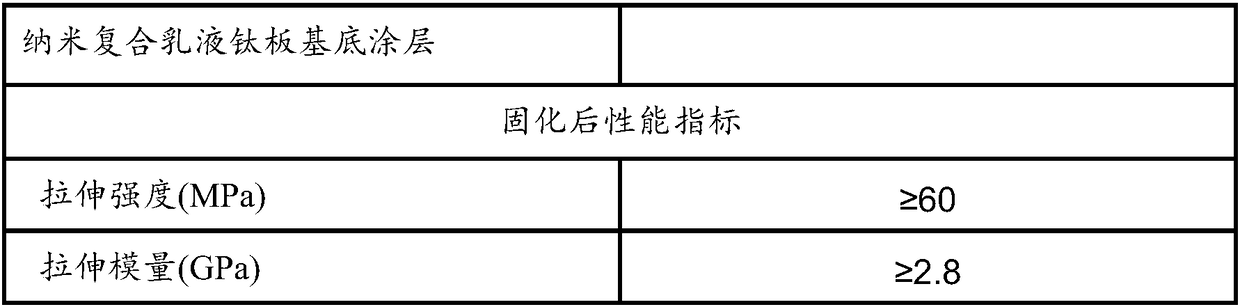

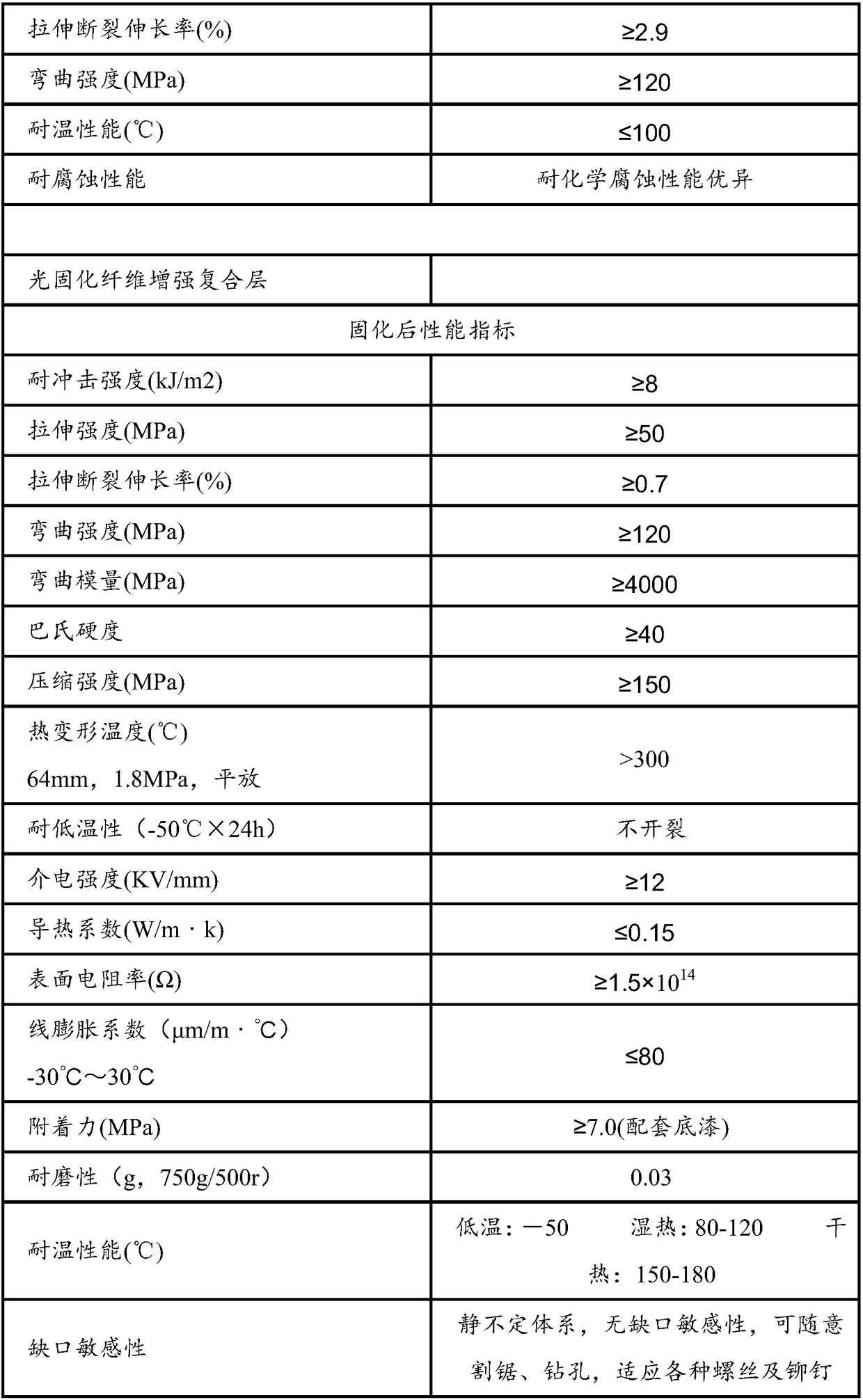

Composite heavy anti-corrosion structure for thermal power plant titanium plate chimney and construction technology

PendingCN108286358AFirmly connectedHigh mechanical strengthAnti-corrosive paintsTowersThermal insulationWeld seam

The invention belongs to the technical field of anti-corrosion materials, and particularly relates to a composite heavy anti-corrosion structure for a thermal power plant titanium plate chimney. The composite heavy anti-corrosion structure for the thermal power plant titanium plate chimney is arranged on a titanium plate chimney body, the titanium plate chimney body comprises multiple titanium plates which are welded together, a nano composite emulsion titanium plate substrate coating and at least one light curing fiber reinforcement composite layer, and the nano composite emulsion titanium plate substrate coating and the light curing fiber reinforcement composite layers are sequentially arranged on the welding seams of the multiple titanium plates and used for closing the welding seams. The composite heavy anti-corrosion titanium plate chimney has the advantages of being excellent in mechanical strength, high in electrical insulation and thermal insulation, high in temperature resistance, good in heat shock resistance, small in expansion coefficient and the like; chemosmosis can be well prevented, a base material is prevented from making contact with the outside world to the maximum extent, and the long-time stability of the base material is guaranteed; the construction time can be greatly shortened, and the construction difficulty and labor cost can be greatly lowered.

Owner:WELLABLE NEW MATERIALS ENG CO LTD SHISHI

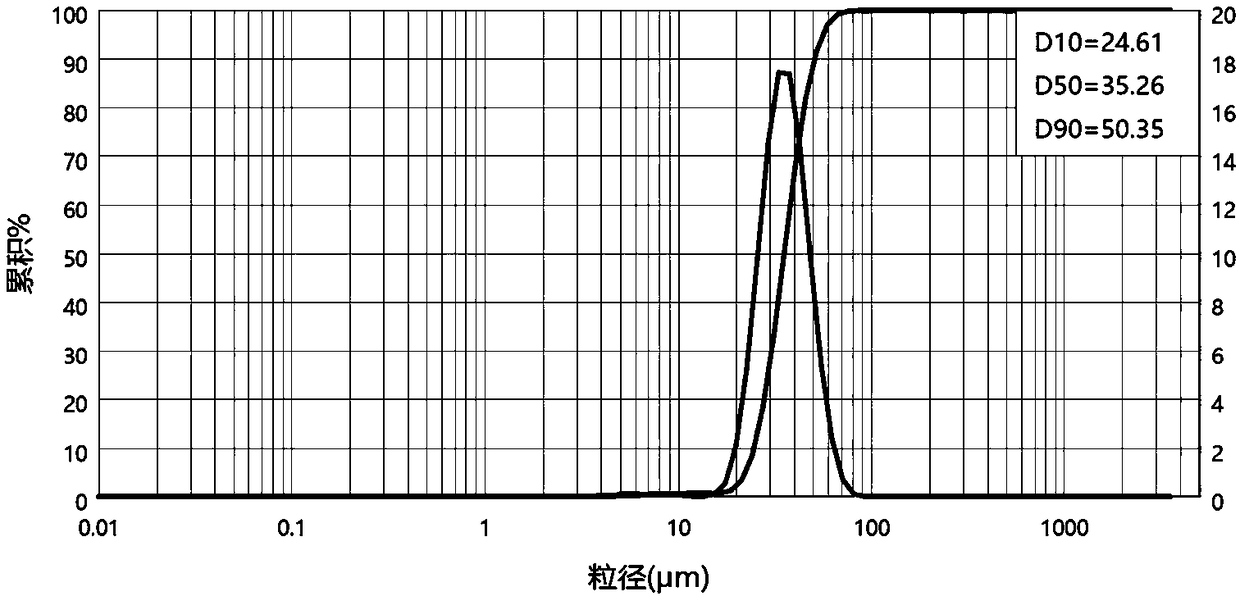

Carbonate precursor and preparation method and application thereof

ActiveCN108862406AUniform particle size distributionLarge particle sizeCell electrodesSecondary cellsRare-earth elementManganese

The invention discloses a carbonate precursor and a preparation method and application thereof. The precursor has a molecular formula of (NixCoyMz)(CO3)1-k(OH)2k, wherein M is one of Mn, Al, Ti, Cr, V, Sn, Zr, Fe, B and a rare earth element. The preparation method comprises the following three steps: 1) mixing nickel-cobalt-manganese salt or nickel-cobalt-aluminum with a growth promoting agent toobtain a solution a; 2) mixing the solution a with a precipitating agent to form a solid precipitate; 3) washing the solid precipitate obtained after reaction, and filtering and drying to obtain the precursor. The method has the characteristics of simple process, short process, low cost and environmental protection. The precursor obtained by the process has large particles and a narrow particle size distribution range and can be applied to preparation of positive electrode material of a lithium ion battery.

Owner:CENT SOUTH UNIV

Superhigh-temperature SiC-HfB2 composite ceramic and preparation method and application thereof

InactiveCN109665848AStable performance at high temperatureImprove antioxidant capacityComposite ceramicSolvent

The invention belongs to the technical field of ceramic materials and discloses superhigh-temperature SiC-HfB2 composite ceramic and a preparation method and application thereof. The superhigh-temperature SiC-HfB2 composite ceramic is prepared by: adding a solvent and a ball milling medium into SiC powder, HfO2 powder, Ta2O5 powder and amorphous boron powder, mixing, drying to obtain mixed powder,die-pressing the mixed powder to obtain a mixed powder blank, thermally treating in vacuum, heating to 900-1300 DEG C, carrying out temperature holding I, heating to 1500-1800 DEG C, carrying out temperature holding II, thermally treating in vacuum to obtain SiC-HfB2 powder, performing discharge plasma sintering to heat the SiC-HfB2 powder to 1000-1400 DEG C, injecting a protective atmosphere, heating to 1800-2200 DEG C, and calcining. The superhigh-temperature SiC-HfB2 composite ceramic has good resistance to high temperature.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com