Method for hot-pressing and sintering alumina-based eutectic composite ceramic materials

A composite ceramic and hot pressing sintering technology, applied in the field of ultra-high temperature structural ceramics, can solve the problems of affecting material properties, poor organizational uniformity, etc., and achieve the effect of eliminating grain boundaries and interfacial amorphous phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

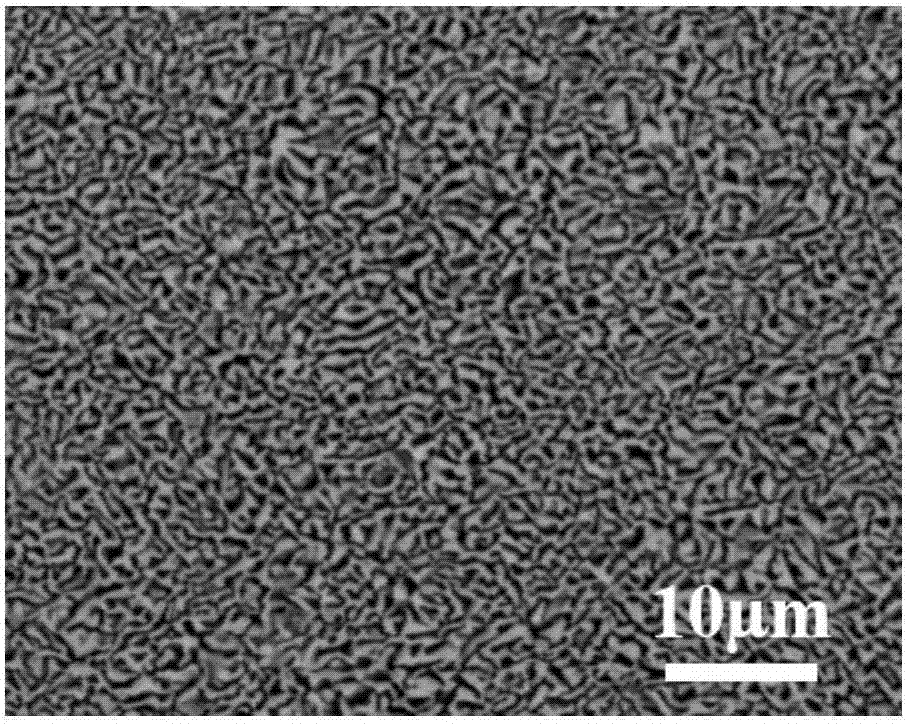

[0047] This implementation is a hot-pressed sintered Al 2 o 3 The method for the / YAG bulk eutectic composite ceramic material, the specific process comprises the following steps:

[0048] Step 1, Al 2 o 3 / YAG eutectic autogenous composite ceramic sample preform preparation. Al with a purity of 99.99% 2 o 3 and Y 2 o 3 Powder as raw material, according to Al 2 o 3 / Y 2 o 3 For the eutectic point ratio of the phase diagram, add polyvinyl alcohol solution and absolute ethanol to the weighed mixed powder and fully mix and stir; the speed of the ball mill is 550r / min, and the stirring time is 5h to obtain a well-mixed mixture. powder. The addition amount of the polyvinyl alcohol is 15ml of polyvinyl alcohol solution per 100g of the raw material; the addition of the absolute ethanol is 50ml per 100g of the raw material. The added polyvinyl alcohol solution is obtained after adding 5 g of polyvinyl alcohol into 100 ml of purified water and heating to dissolve the polyv...

Embodiment 2

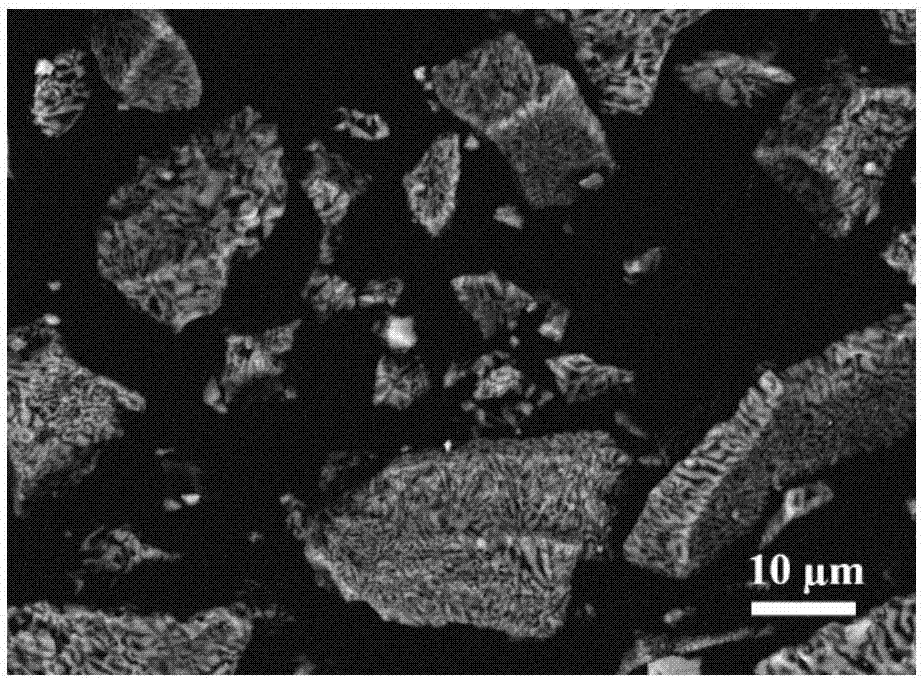

[0064] This implementation is a hot-pressed sintered Al 2 o 3 / YAG / ZrO 2 A method for a bulk eutectic composite ceramic material, the specific process comprising the following steps:

[0065] Step 1, Al 2 o 3 / YAG / ZrO 2 Preparation of eutectic autogenous composite ceramic sample preforms. Al with a purity of 99.99% 2 o 3 , Y 2 o 3 and ZrO 2 Powder as raw material, according to Al 2 o 3 / Y 2 o 3 / ZrO 2 Phase diagram eutectic point ratio.

[0066] Add polyvinyl alcohol solution and absolute ethanol to the weighed mixed powder and carry out thorough mixing and stirring; the rotating speed of the ball mill is 550r / min, and the stirring time is 5h to obtain a uniformly mixed mixed powder. The addition amount of the polyvinyl alcohol is 10ml of polyvinyl alcohol solution per 100g of the raw material; the addition of the absolute ethanol is 55ml per 100g of the raw material. The added polyvinyl alcohol solution is obtained after adding 5 g of polyvinyl alcohol into 1...

Embodiment 3

[0082] This implementation is a hot-pressed sintered Al 2 o 3 / YAG / ZrO 2 A method for a bulk eutectic composite ceramic material, the specific process comprising the following steps:

[0083] Step 1, Al 2 o 3 / YAG / ZrO 2 Preparation of eutectic autogenous composite ceramic sample preforms. Al with a purity of 99.99% 2 o 3 , Y 2 o 3 and ZrO 2 Powder as raw material, according to Al 2 o 3 / Y 2 o 3 / ZrO 2 Phase diagram eutectic point ratio.

[0084] Add polyvinyl alcohol solution and absolute ethanol to the weighed mixed powder and carry out thorough mixing and stirring; the rotating speed of the ball mill is 550r / min, and the stirring time is 5h to obtain a uniformly mixed mixed powder. The addition amount of the polyvinyl alcohol is 5ml of polyvinyl alcohol solution per 100g of the raw material; the addition of the absolute ethanol is 60ml per 100g of the raw material. The added polyvinyl alcohol solution is obtained after adding 5 g of polyvinyl alcohol into 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com