A kind of ni-co-cr series single crystal superalloy and preparation method thereof

A ni-co-cr, superalloy technology, applied in the field of nickel-based superalloys, can solve the problems of reducing γ' phase strengthening effect, incoherent interface stress concentration, consumption of γ' phase forming elements, etc., and achieve excellent microstructure stability. properties, increasing volume fraction, and excellent high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides the preparation method of the Ni-Co-Cr series single crystal superalloy according to the above scheme, comprising the following steps:

[0040] Corresponding to the elemental composition of the Ni-Co-Cr series single crystal superalloy, each prepared raw material is smelted and refined to obtain a master alloy ingot;

[0041] Using the seed crystal method to prepare the master alloy ingot into a single crystal alloy;

[0042] performing solution treatment on the single crystal alloy to obtain a solid solution alloy;

[0043] The solid solution alloy is subjected to aging treatment to obtain a Ni-Co-Cr-based single crystal superalloy.

[0044] According to the element composition of the Ni-Co-Cr series single crystal superalloy, in the present invention, each preparation raw material is smelted and refined to obtain a master alloy ingot.

[0045] In the present invention, the preparation raw materials preferably include elemental Ni, elem...

Embodiment 1

[0064] The Ni, Ti particles and Cr flakes (mass ratio of 15:2:4) with a purity of 99.9% are polished to remove the oxide scale, then weighed, cleaned, dried, and then smelted in a non-consumable arc melting furnace. Repeatedly Smelting 6 times to obtain Ni-Cr-Ti master alloy button ingots with uniform element distribution of Φ50*12mm;

[0065] According to the composition element ratio in Table 1, the selected raw materials are Ni-W master alloy ingots, Ni-Cr-Ti master alloy ingots, Ni, Co, and Al particles with a purity of 99.9%. Cleaning, drying, smelting in a vacuum induction melting furnace, refining at high temperature for 5 minutes, slowly cooling down until the alloy liquid solidifies, and then slowly heating up for the second high-temperature refining, repeated three times, after the third refining, when the temperature decreases When the temperature reaches 1550 °C, casting is performed to obtain a Φ30*100mm master alloy ingot with uniform element distribution;

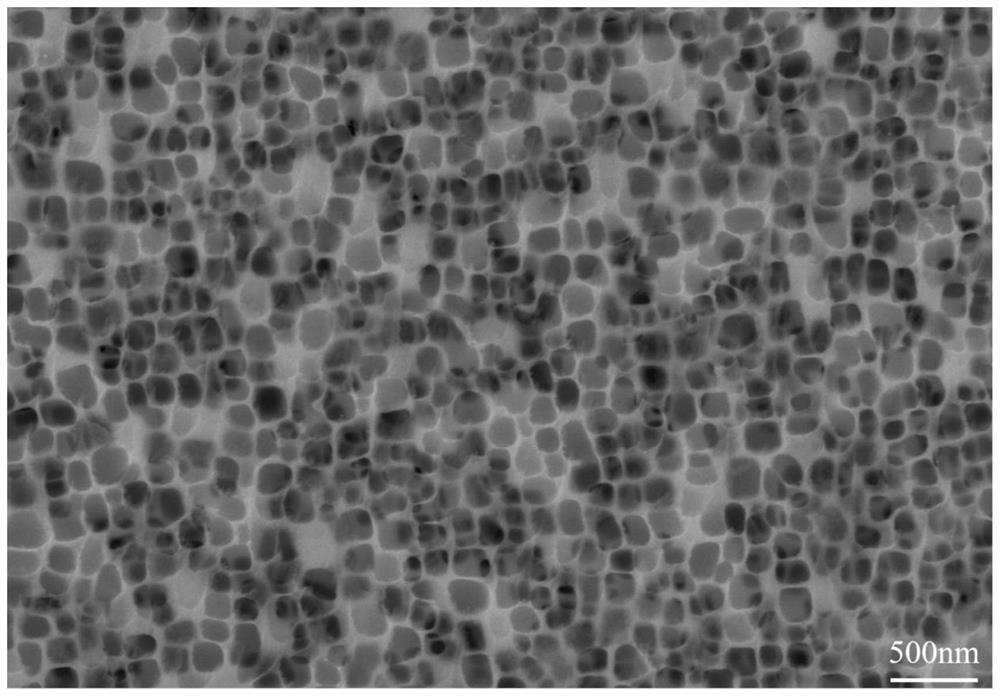

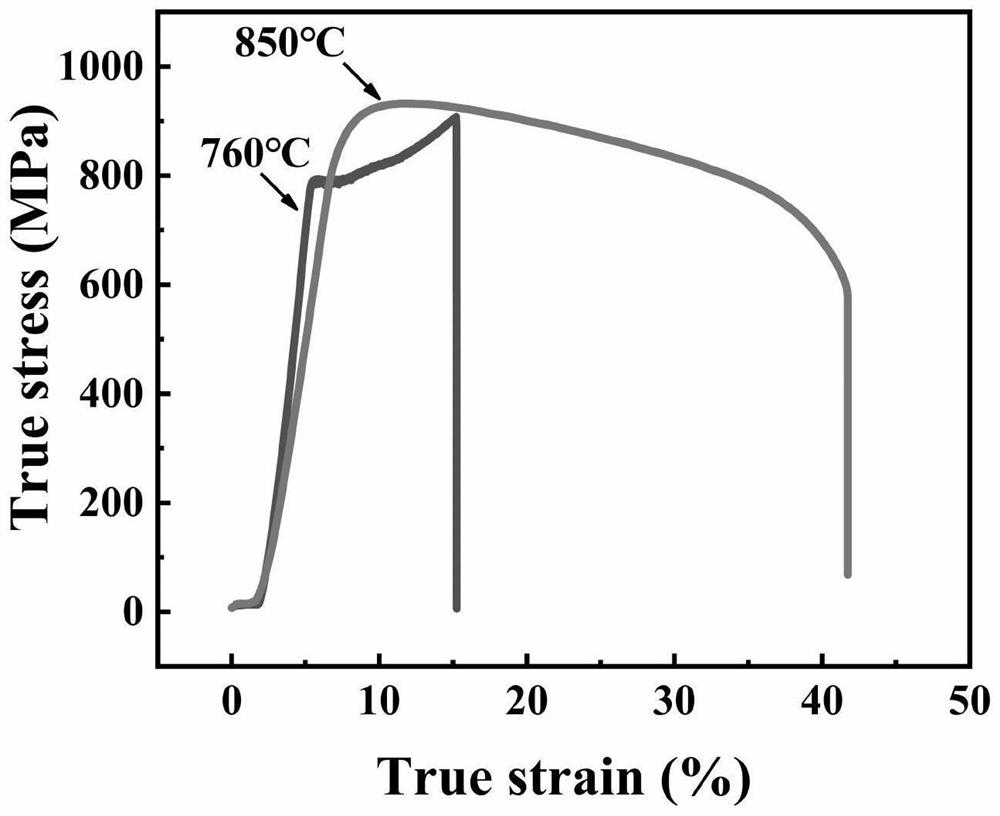

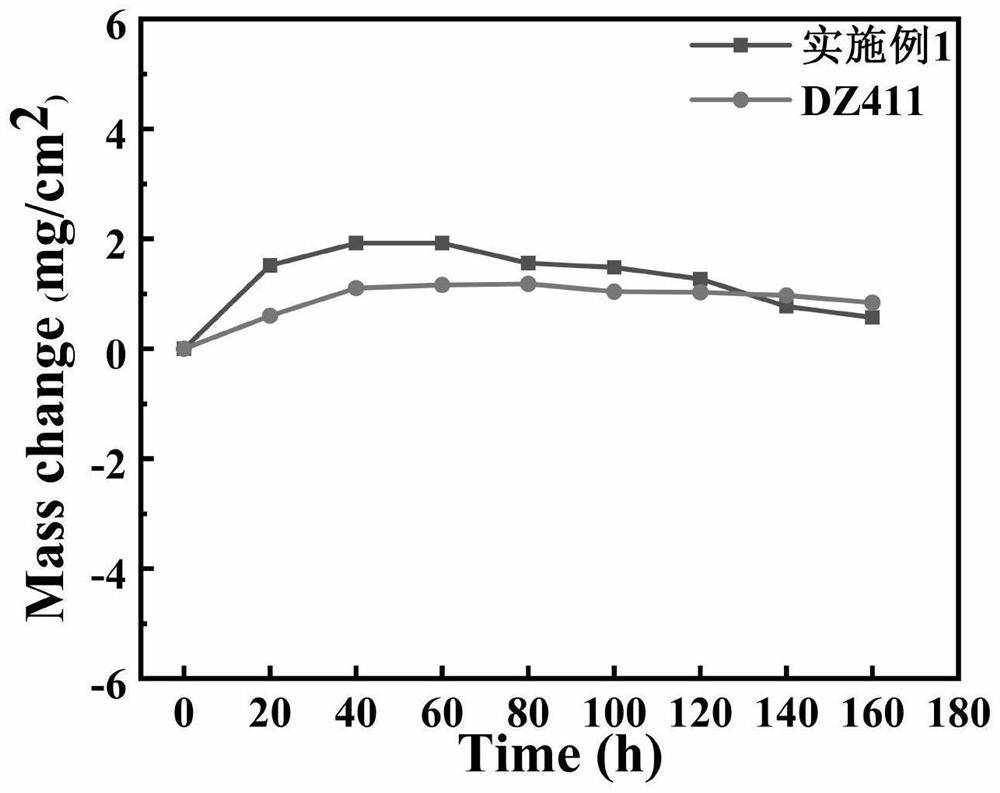

[00...

Embodiment 2~4 and comparative example 1

[0070] The elemental composition is shown in Table 1, and the preparation method is the same as that in Example 1 to obtain a superalloy.

[0071] Table 1 Elemental composition (at%) of Examples and Comparative Examples

[0072] alloy Ni Co Cr Al Ti W Fe Example 1 51.5 20 12 7.5 7.5 1.5 0 Example 2 44 20 15 7.5 7.5 2 0 Example 3 50.2 19 13 7 9 1.8 0 Example 4 47.5 20 15 7.5 8 2 0 Comparative Example 1 48 17 9 9 6 3 8

[0073] The configuration entropy of Example 1, Example 2, Example 3, Example 4 and Comparative Example 1 are 1.37R, 1.43R, 1.40R, 1.42R and 1.56R, respectively. Therefore, Examples 1 to 4 belong to the middle Entropy alloy, Comparative Example 1 belongs to high entropy alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com