Low-resistivity silicon carbide ceramic and preparation method thereof

A technology of silicon carbide ceramics and low resistivity, applied in the field of SiC ceramics, can solve problems such as short service life, performance change, uncontrollable volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

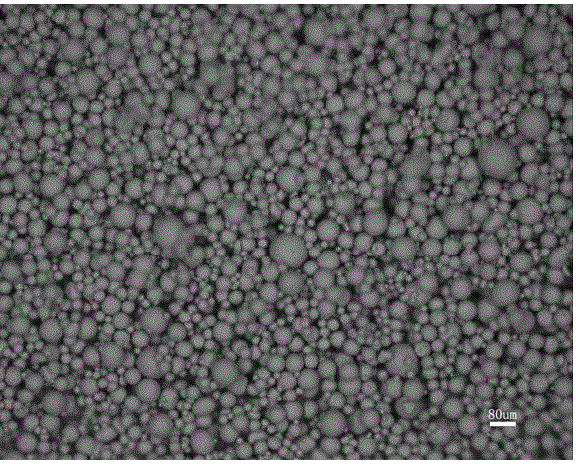

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing low-resistivity silicon carbide (SiC) ceramics. It includes the following steps:

[0022] 1) SiC powder, AlN powder, B 4 C powder and phenolic resin as raw materials;

[0023] 2) making the raw materials into a slurry with a solid content of 40-45wt%, and performing ball milling and mixing;

[0024] 3) Spray granulation of the slurry mixed by the ball mill, and dry press molding and isostatic pressing molding of the obtained powder;

[0025] 4) After the sample is debonded in vacuum, it is sintered under normal pressure inert atmosphere conditions, the sintering temperature is 1900-2300°C, and the holding time is 1-2h.

[0026] The prepared SiC ceramics have a density of 3.11-3.15 g cm -3 , The bending strength is: 280Mpa-350Mpa, the resistivity is 2330Ω·m~18140Ω·cm.

[0027] SiC powder, AlN powder, B 4 C powder and phenolic resin are raw materials, among which SiC powder is high-purity SiC powder (oxygen content ≤ 1.8...

Embodiment 1

[0039] SiC, AlN (1wt%), sintering aid B 4 C (0.5wt%) and phenolic resin (10wt%) totaled 100g, the powder was made into a slurry with a solid content of 45wt%, and 200g of SiC balls were used as the ball milling medium, mixed for 24h, and then spray granulated to obtain the powder It is formed under 16MPa pressure on a flat vulcanizer, and then isostatically pressed under 200MPa pressure. After debonding, it was sintered under normal pressure Ar gas atmosphere, the sintering temperature was 2200°C, and the holding time was 1h. The obtained SiC ceramics had a density of 3.14gcm -3 , the bending strength is 310MPa, and the resistivity is 2330Ω·cm.

Embodiment 2

[0041] SiC, AlN (5wt%), sintering aid B 4 C (0.6wt%), phenolic resin (10wt%) a total of 100g powder is made into a slurry with a solid content of 45wt%, with 200g of SiC balls as the ball milling medium, mixed for 24h, and then spray granulated, the obtained powder was in Forming under 16Mpa pressure on a flat vulcanizing machine, and then isostatic pressing under 200MPa pressure. After debonding, it was sintered under normal pressure Ar gas atmosphere, the sintering temperature was 2200°C, and the holding time was 1h. The obtained SiC ceramics had a density of 3.11gcm -3 , the bending strength is 350MPa, and the resistivity is 18140Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com