Preparation method of alpha-Al2O3/mullite multiphase ceramic fiber

A technology of composite ceramics and mullite, which is applied in the direction of inorganic raw materials such as artificial filaments, can solve the problems of environmental pollution, high risk, and difficulty in large-scale preparation, and achieve high surface activity, low cost, and uniform microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

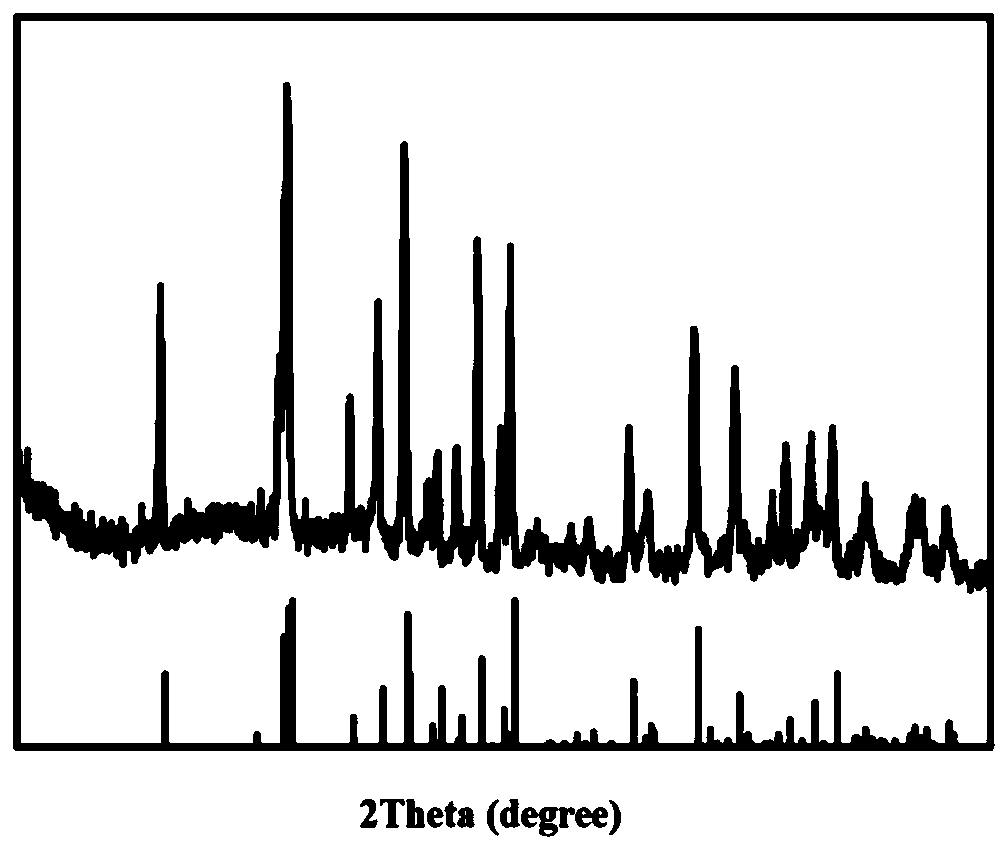

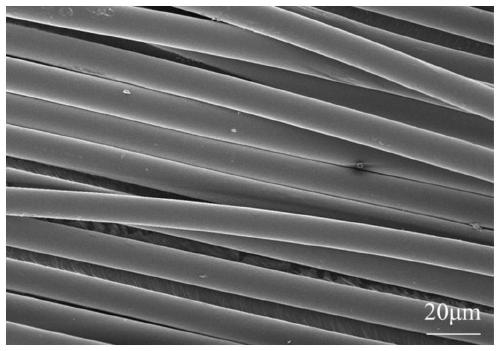

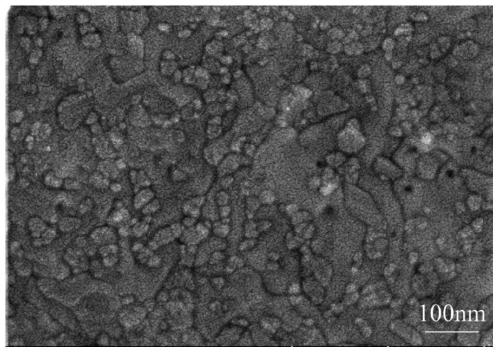

Image

Examples

Embodiment 1

[0044] an α-Al 2 o 3 The preparation method of / mullite multi-phase ceramic fiber comprises steps:

[0045] (1) Add 645g of aluminum sulfate hexadecahydrate and 9.0g of aluminum powder into 1000mL of deionized water and stir evenly, heat and reflux at 150°C for 10h until the aluminum powder reacts completely, cool and filter to obtain 13 Colloidal alumina sol, colloidal particle size 3nm, namely aluminum sol.

[0046] (2) Take 115.67g of aluminum sol obtained in step (1) and 10.0g of silica sol (the content of silicon dioxide is 30wt%) and mix evenly at 35°C, add 2.0g of α-Al 2 o 3 Dispersion (α-Al 2 o 3 content is 20wt%) and 10.0g polyvinylpyrrolidone, mix evenly, then aging and concentrating at 38°C and 0.095MPa vacuum conditions to a solid content of 35wt%, viscosity at 25°C is 1000Pa.s, can be obtained Spinable silica / aluminum sol.

[0047] (3) Utilize the above-mentioned spinnable silica / alumina sol to adopt dry spinning, and the gel fiber with a diameter of about 1...

Embodiment 2

[0056] an α-Al 2 o 3 The preparation method of / mullite multi-phase ceramic fiber comprises steps:

[0057] (1) The preparation of aluminum sol is as described in Example 1.

[0058] (2) Take 115.67g of aluminum sol obtained in step (1) and 5.0g of silica sol (the content of silicon dioxide is 30wt%) and mix evenly at 35°C, add 3.5g of γ-Al 2 o 3 Dispersion (γ-Al 2 o 3 content of 20wt%) and 3.0g of polyethylene oxide, mixed evenly, and then aged and concentrated at 38°C and 0.095MPa vacuum conditions to a solid content of 38wt%, and a viscosity of 830Pa.s at 25°C to obtain spinnable silicon / aluminum sol.

[0059] (3) Utilize the above-mentioned spinnable silicon / alumina sol to adopt dry spinning, and the gel fiber with a diameter of about 17 μm is prepared under the condition that the ambient temperature is 30° C. and the relative humidity is 30%, and the fiber is collected at a speed of 80 m / min. The speed winds the gel fiber on the take-up roll.

[0060] (4) Calcini...

Embodiment 3

[0063] an α-Al 2 o 3 The preparation method of / mullite multi-phase ceramic fiber comprises steps:

[0064] (1) Add 80.5g of aluminum chloride and 9.0g of aluminum powder into 1000mL of deionized water and stir evenly, heat and reflux at 180°C for 14h until the aluminum powder is completely reacted, cool and filter to obtain 13 Colloidal alumina sol, colloidal particle size 8nm, namely aluminum sol.

[0065] (2) Take 142.7g of aluminum sol obtained in step (1) and 10.0g of silica sol (the content of silicon dioxide is 30wt%) and mix uniformly at 35°C, add 3.0g of α-Fe 2 o 3 Dispersion (α-Fe 2 o 3 content is 20wt%) and 5.0g polyvinylpyrrolidone, mix evenly, then aging and concentrating at 38°C and 0.095MPa vacuum conditions to a solid content of 30wt%, viscosity at 25°C is 580Pa.s, can be obtained Spinable silica / aluminum sol.

[0066](3) Utilize the above-mentioned spinnable silica / alumina sol to adopt dry spinning, and the gel fiber with a diameter of about 16 μm is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com