Insulating composite paint of nanometer inorganic matter and polymer and its prepn

A composite insulation and inorganic nanotechnology, applied in epoxy resin coatings, coatings, etc., can solve the problems of difficult dispersion of nanoparticles, poor dispersion efficiency, etc., achieve high breakdown strength and anti-flashover characteristics, and improve the dispersion effect , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

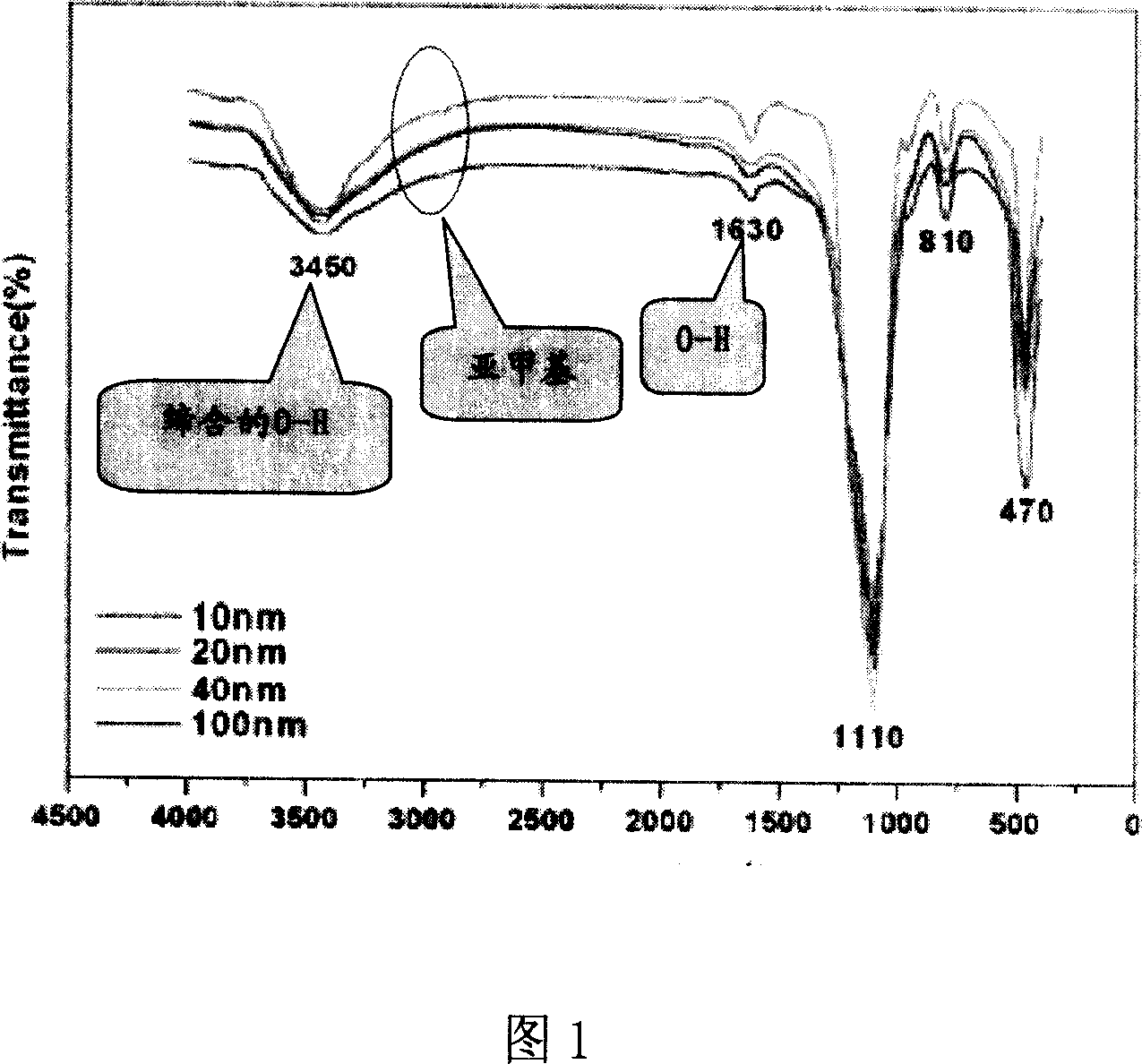

Image

Examples

Embodiment 1

[0019] With 8% (weight percentage) KH550 long carbon chain type modified amino silane coupling agent surface modification, particle diameter is the SiO of 10nm 2 Inorganic nanoparticles and epoxy resin E44 are mixed according to the mass ratio of nanoparticles and polymer precursors at 5:100, and after adding organic solvent acetone, disperse at 70°C for 60 minutes to obtain a stable suspension; vacuum at 100°C Process to remove solvent and gas; finally, cure at 220°C for 6 hours to obtain an insulating coating.

Embodiment 2

[0021] With 8% (percentage by weight) KH550 long carbon chain type modified aminosilane coupling agent surface modification, the TiO particle size is 10nm 2 Inorganic nanoparticles and epoxy resin E44 are mixed according to the mass ratio of nanoparticles and polymer precursors at 5:100, and after adding organic solvent acetone, disperse at 70°C for 60 minutes to obtain a stable suspension; vacuum at 100°C Process to remove solvent and gas; finally, cure at 220°C for 12 hours to obtain an insulating coating.

Embodiment 3

[0023] With 8% (percentage by weight) KH550 long carbon chain type modified aminosilane coupling agent surface modification, particle diameter is the Al of 10nm 2 o 3 Inorganic nanoparticles and epoxy resin E44 are mixed according to the mass ratio of nanoparticles and polymer precursors at 5:100, and after adding organic solvent acetone, disperse at 70°C for 60 minutes to obtain a stable suspension; vacuum at 100°C Process to remove solvent and gas; finally, cure at 220°C for 4 hours to obtain an insulating coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com