Patents

Literature

124results about How to "Avoid secondary reunions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

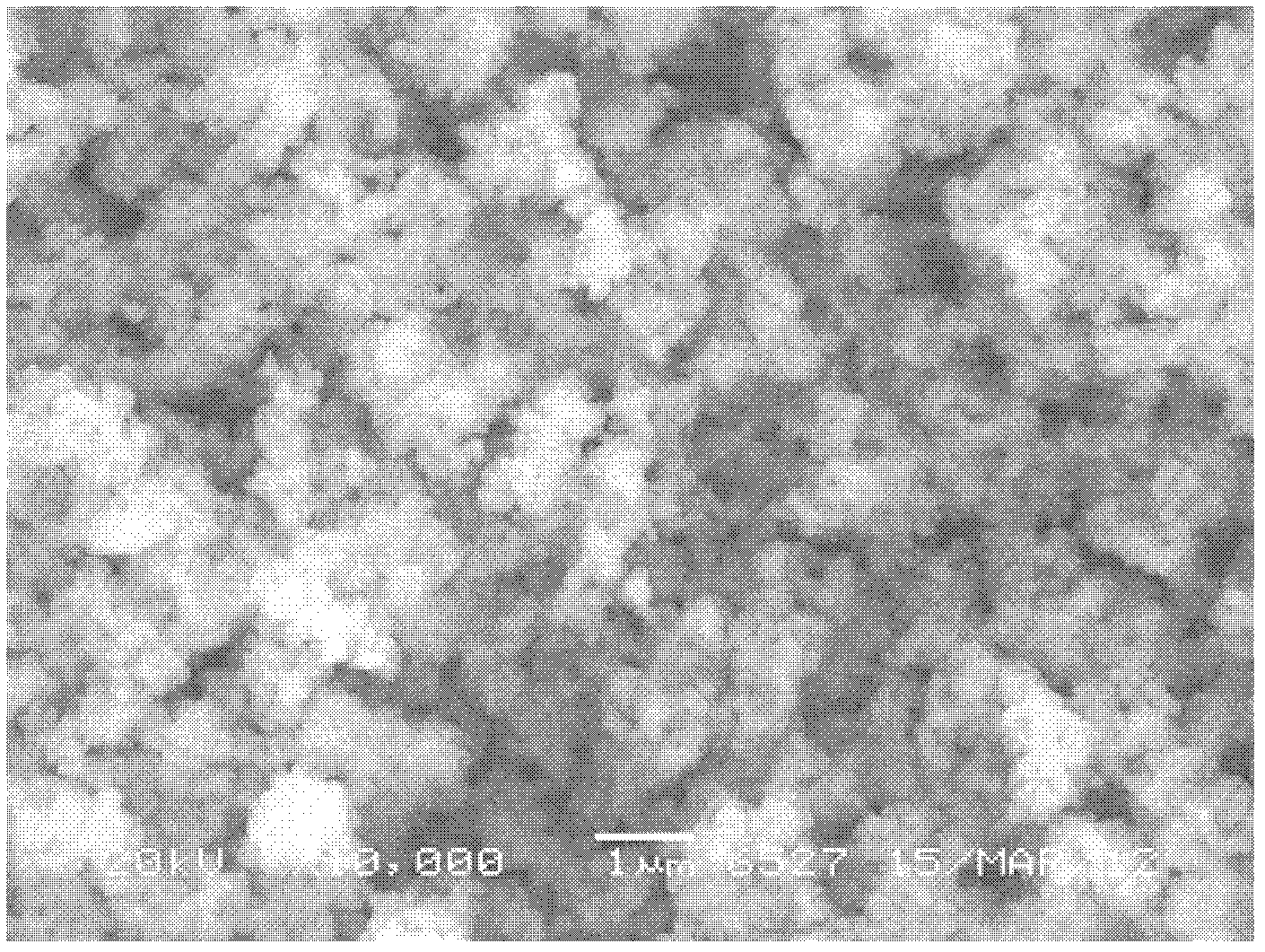

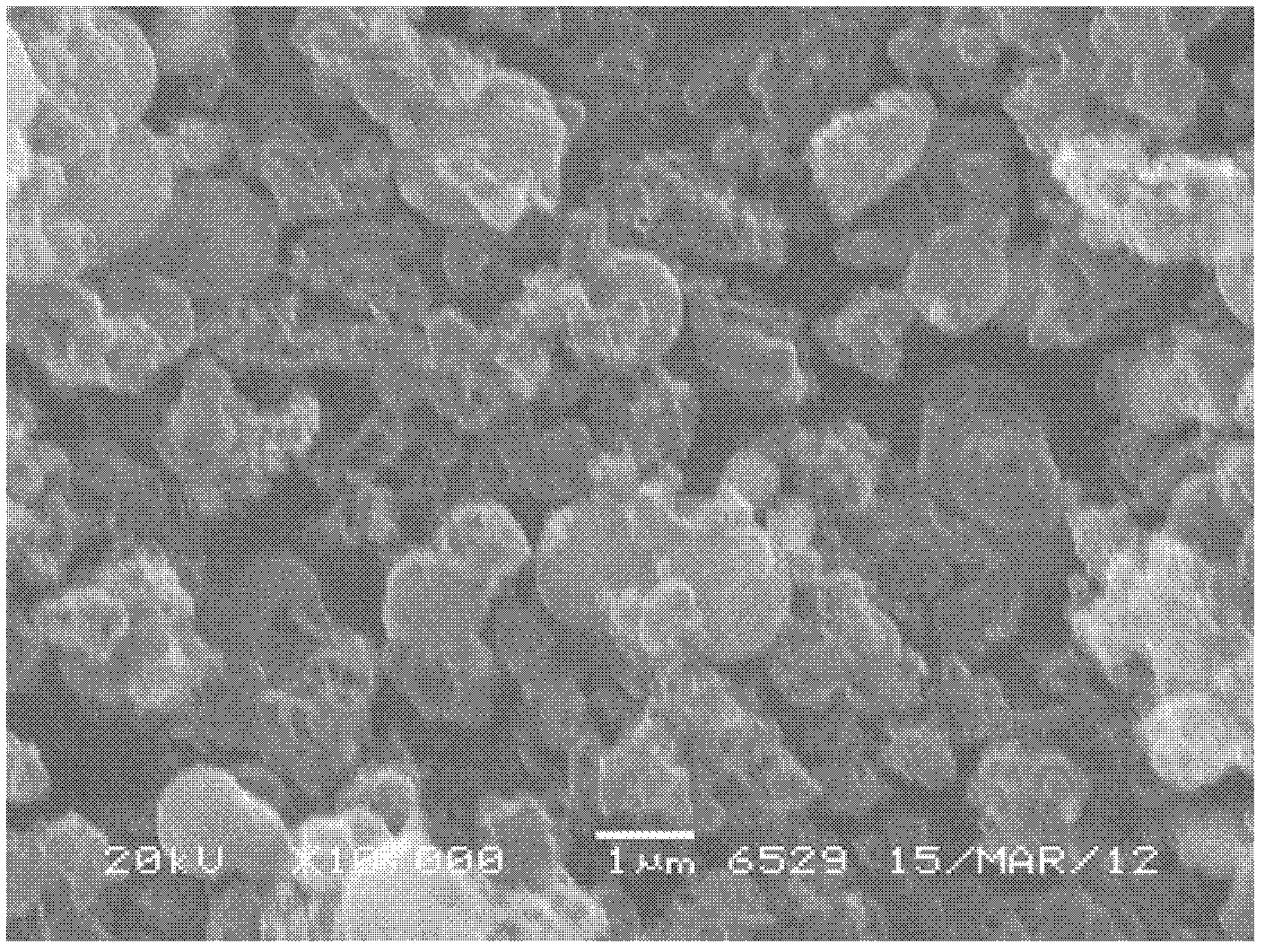

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

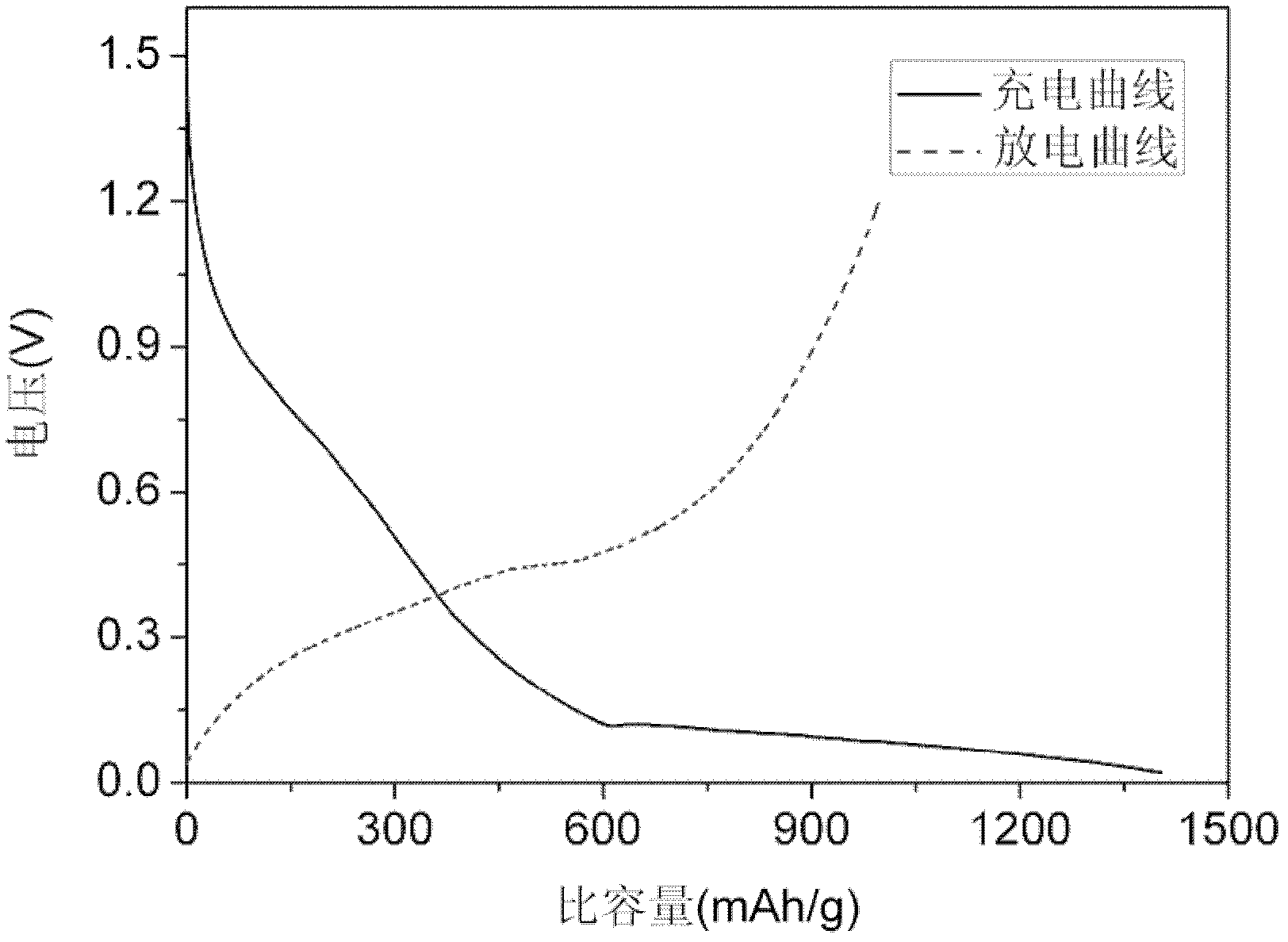

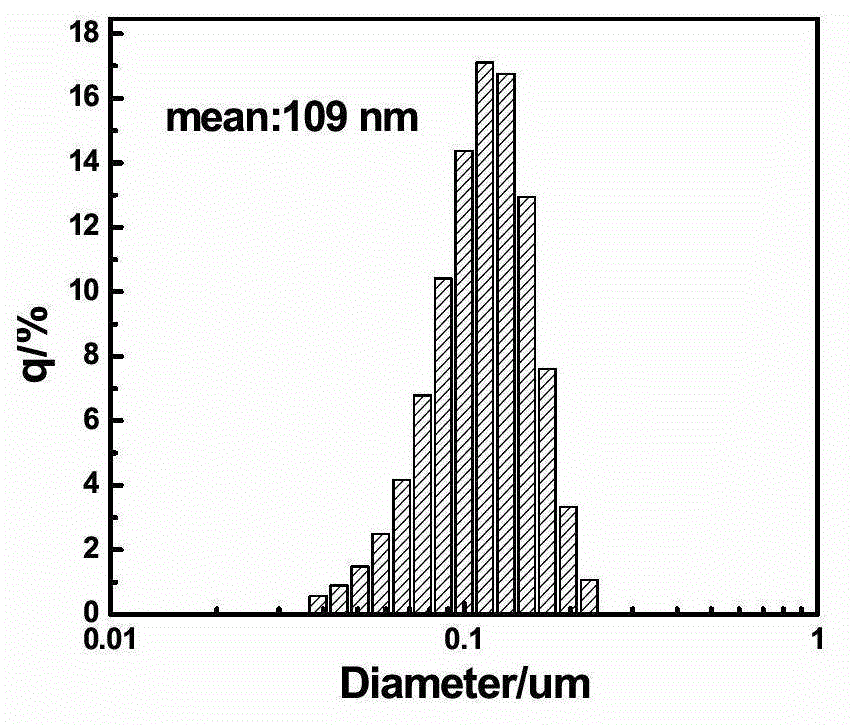

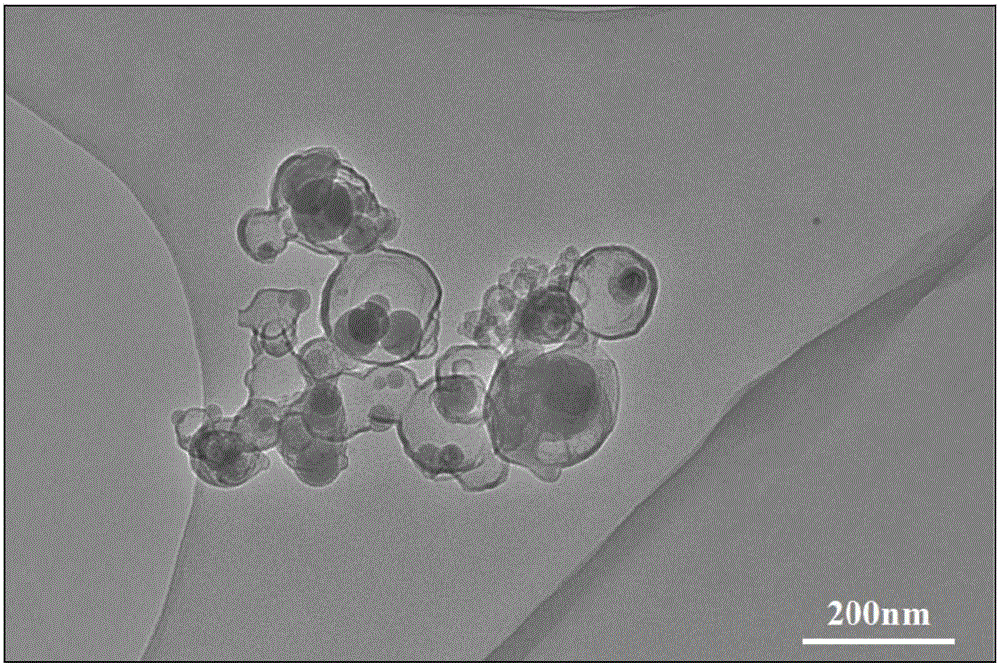

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

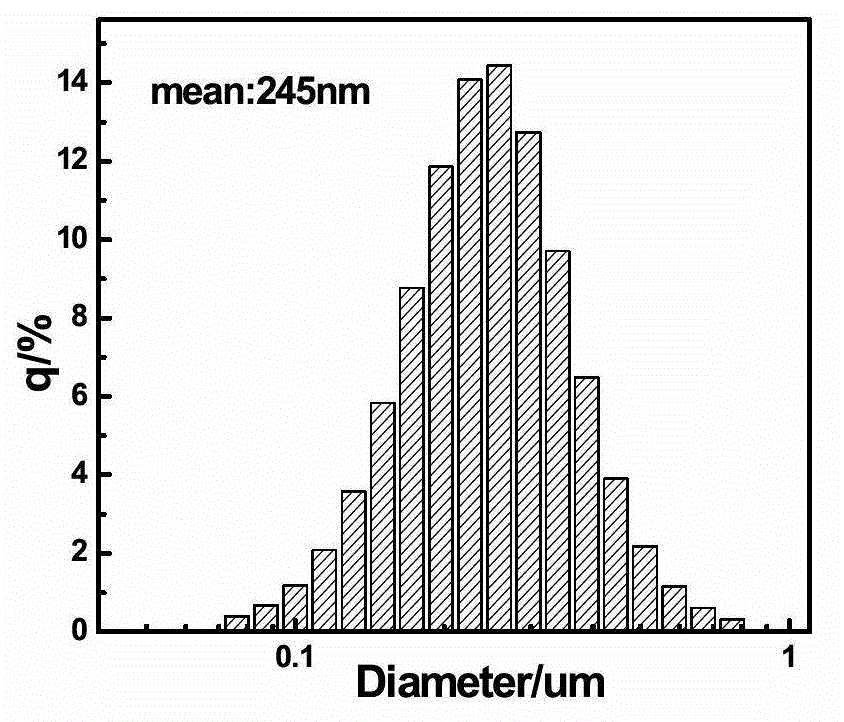

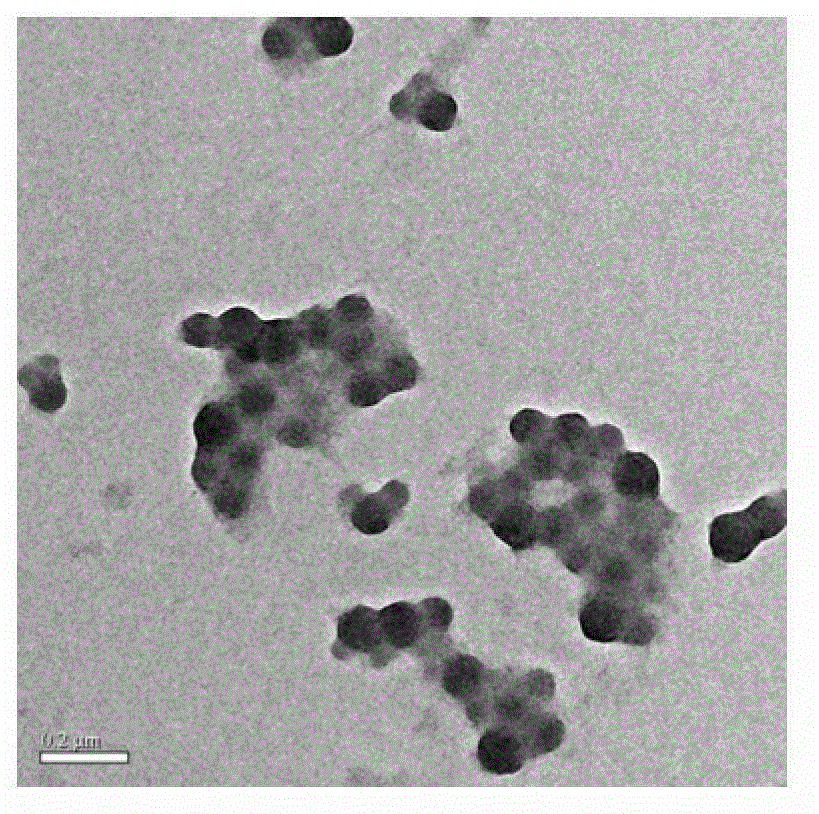

Preparing method of composite styrene-acrylic emulsion containing silicon dioxide

The invention aims at the shortcomings that inorganic nanometer particles are easy to conglomerate and poor in compatibility with a polymer, a polymer emulsion is unstable, and directional conglomerating of emulsion bundles is easy to appear and residues are easy to generate during the polymerization process in a traditional inorganic or organic composite emulsion, and provides a preparing method of a composite styrene-acrylic emulsion containing silicon dioxide. The preparing method includes: using an in situ sol-gel method to produce nanometer silicon dioxide particles which are uniformly dispersed in monomer, and controllable in particle morphology and particle diameters; then preparing a seed emulsion containing the silicon dioxide particles after obtaining a styrene-acrylic pre-emulsion by using mixed type emulsifiers; and finally preparing the composite styrene-acrylic emulsion by adopting a seed emulsion polymerization method. By adopting the preparing method, the styrene-acrylic emulsion of which silicon dioxide is high in filling volume, and uniformly and stable dispersed in the emulsion is obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Anode material and manufacturing method thereof as well as lithium ion battery and negative plate thereof

ActiveCN102332572AHigh specific capacityIncrease capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesMetal particleSodium-ion battery

The invention discloses an anode material which comprises a stack layer of graphene sheets and tin metal particles, wherein the tin metal particles are embedded into the graphene sheets or distributed among the graphene sheets. The invention also discloses a manufacturing method of the anode material, and the manufacturing method comprises the following steps of: directly reducing tin hydroxide on the graphene sheets by adopting a one-step total heating reduction method to obtain the tine metal particles; and baking to obtain a tin-graphene composite material. The invention also discloses a lithium ion battery, and the negative electrode of the lithium ion battery is manufactured by using the lithium ion battery anode material. The lithium ion battery anode material is high in specific capacity, the first-time discharge capacity can reach 600-900 mAh / g, and the capacity can reach 550-820 mAh / g when the discharge is stable; the cycle life of the lithium ion battery anode material is long, and the number of cycles can reach over 1,000; and the lithium ion battery anode material is simple in preparation process, and is suitable for industrial production.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

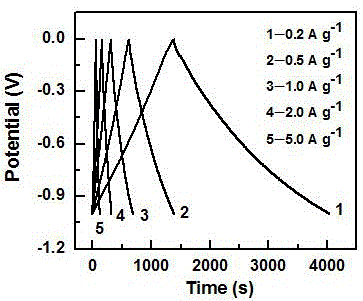

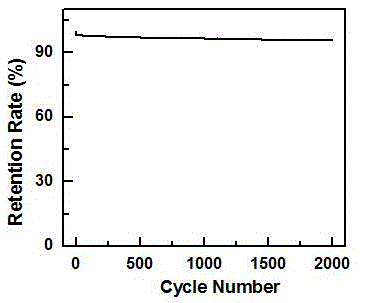

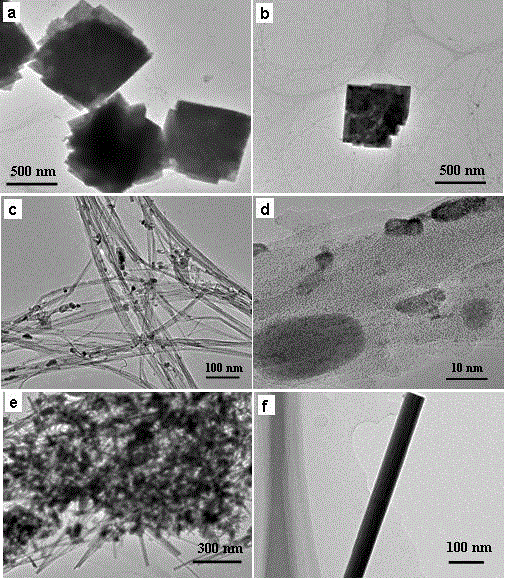

Preparation and application of nitrogen-doped graphene-carbon nanohorn composite material

InactiveCN105552371AMaintain specific surface areaAvoid reunionHybrid capacitor electrodesCell electrodesDispersityNitrogen doped graphene

The invention provides a preparation method and an application of a nitrogen-doped graphene-carbon nanohorn composite material, and belongs to the field of functional carbon materials. The preparation method of the nitrogen-doped graphene-carbon nanohorn composite material comprises the steps of ultrasonically dispersing graphene oxide to form a uniform solution in the presence of a biomass raw material, adding a nitrogen source substance and a carbon nanohorn, performing ultrasonic and uniform dispersion again to obtain a graphene oxide-biomass-nitrogen source substance-carbon nanohorn mixture solution, and drying the mixture to a constant weight, thereby obtaining a nitrogen precursor mixture; and performing normal-pressure high-temperature pyrolysis on the nitrogen precursor mixture to obtain the nitrogen-doped graphene-carbon nanohorn composite material. The prepared nitrogen-doped graphene-carbon nanohorn composite material can be used for electrode materials of lithium ion batteries and supercapacitors. The preparation method is simple; and the obtained composite material is loose in structure and good in nitrogen-doped graphene nanosheet dispersity. The method provides a new way for preparing a nitrogen-doped graphene based composite material.

Owner:FUZHOU UNIV

Lithium ion battery film cathode containing porous polymer elastomer and preparation method thereof

ActiveCN102130323AIncrease capacityReduce capacityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesElastomerPorosity

The invention discloses a lithium ion battery film cathode containing a porous polymer elastomer, which comprises a copper foil current collector and a surface coating, wherein the surface coating is uniformly coated on the surface of the copper foil current collector; and the surface coating is formed in a way that a high-capacity nano particle is compounded in a directional porous polymer elastomer. The high-capacity nano particle is loaded in a hole of the porous polymer elastomer through suction filtration, rolling and electrophoresis and coated on the copper foil current collector. The porous polymer elastomer is one of porous polythiophene, porous polypyrrole or porous polyaniline. The film cathode prepared in the invention can effectively prevent the high-capacity nano particle from causing pulverization due to volumetric expansion and causing capacity attenuation due to secondary agglomeration in charge and discharge processes, and improves the circulation property of the nanoparticle. Meanwhile, the porosity of the polymer can ensure rapid transmission of lithium ions in the cathode, thereby achieving the purpose of being rapidly charged and discharged. The cathode prepared in the invention can be directly used in battery assembly without tabletting or filming, and is suitable for industrialized production.

Owner:湖南宸宇富基新能源科技有限公司

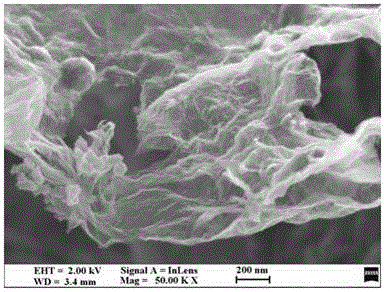

Wet-process method of preparing modified micron/nano-magnesium hydroxide flame retardant

InactiveCN108440995AAvoid secondary reunionsRegulating Surface ElectricityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPrillSlurry

The invention relates to a wet-process method of preparing a modified micron / nano-magnesium hydroxide flame retardant and belongs to the fields of non-metal mineral processing and environment-friendlymaterials. By means of a horizontal ball mill, a powder is subjected to impact, friction and shear in a cylinder body, which rotates at high frequency, with a milling medium, in order to complete ultrafine milling and surface modification to the powder; during the ball milling process, a milling additive is added to regulate the rheological properties of the ore slurry and surface electrical behavior of mineral granules so as to reduce the viscosity of the ore slurry and accelerate dispersion of the granules; meanwhile, a surfactant is added to perform surface modification to the powder, thusavoiding secondary aggregation of the powder. The method has reasonable processes and can effectively control the particle size of the powder, can reach micron / nano-scale and is high in fineness. Theproduct is concentrated in particle size distribution and is round and smooth in particle appearance, has good cladding modification effect and can satisfy use demands on flame retardants; especially, use demands with large addition quantity.

Owner:大连亚泰科技新材料股份有限公司

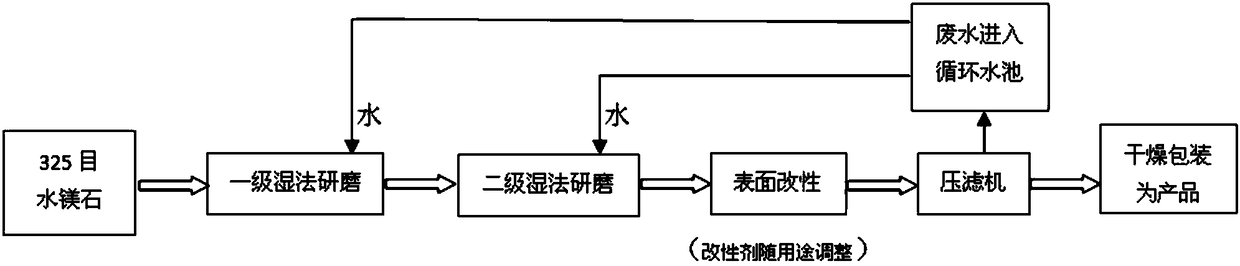

Breathable resin with high breathability and preparation method of breathable resin

ActiveCN104448514AAvoid the disadvantages of single natureAvoid secondary reunionsLow-density polyethyleneMasterbatch

The invention relates to breathable resin with high breathability and a preparation method of the breathable resin. The breathable resin with high breathability is prepared by the following components by weight percent: 35 to 55 percent of calcium carbonate powder, 0.2 to 0.5 percent of antioxidant, 0.5 to 2 percent of processing additive, 5 to 10 percent of color masterbatch, 20 to 30 percent of linear low-density polyethylene, 5 to 20 percent of low-density polyethylene and 5 to 20 percent of metallocene polyethylene. The breathable resin with high breathability is suitable for producing a breathable film with high breathability, the breathability can reach 5000g / m<2>.24h, the breathable resin is applicable to a high-speed production line in the process for manufacturing the breathable film, the production speed can reach 200m / min, and the production state of continuous production for 36 hours without stopping can be realized.

Owner:CHONGQING HETAI PLASTIC

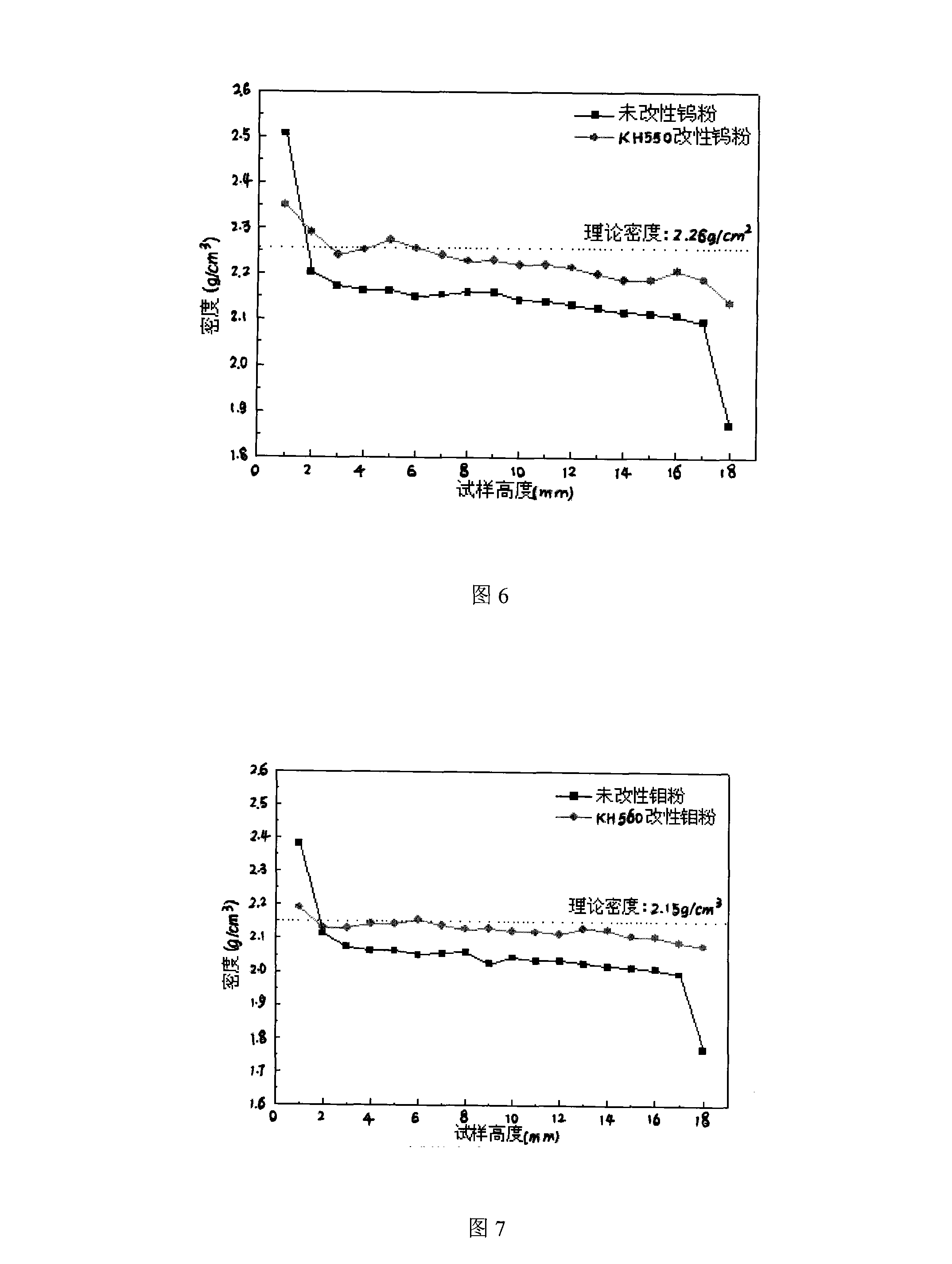

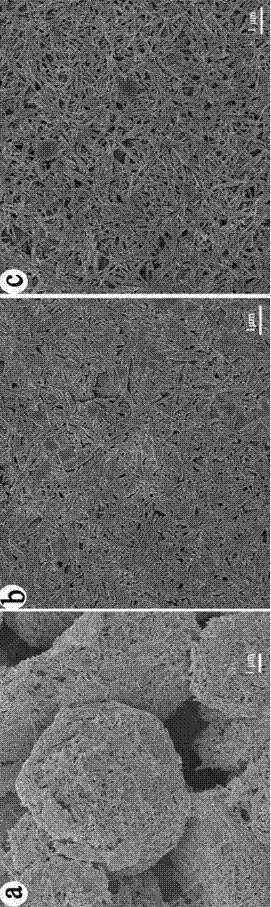

Method for adjusting morphology and size of tungsten oxide by using carbon nanotube

ActiveCN105600825AIncrease profitControl shapeMaterial nanotechnologyTungsten oxides/hydroxidesCarbon nanotubeIn process control

The invention discloses a method for adjusting the morphology and the size of a tungsten oxide by using carbon nanotubes, and belongs to the technical field of tungsten-based nano materials. The method comprises the following steps: by taking the carbon nanotubes as a template and a morphology adjusting agent, ethylene glycol as a dispersing agent and a tungsten metal salt as a tungsten source, adding an acid solution into a reaction system, enabling a tungstic acid to nucleate and grow up on the surface of a carbon nanotube bundle, so as to form a carbon nanotube / tungstic acid compound; putting the compound into a high-temperature reaction area, and performing thermal treatment in the presence of an inert atmosphere. The method is simple in preparation process, concise in process control and wide in application prospect, the raw materials are easy to obtain, and the morphology and the size of the prepared tungsten oxide can be regulated and controlled.

Owner:JIANGXI UNIV OF SCI & TECH

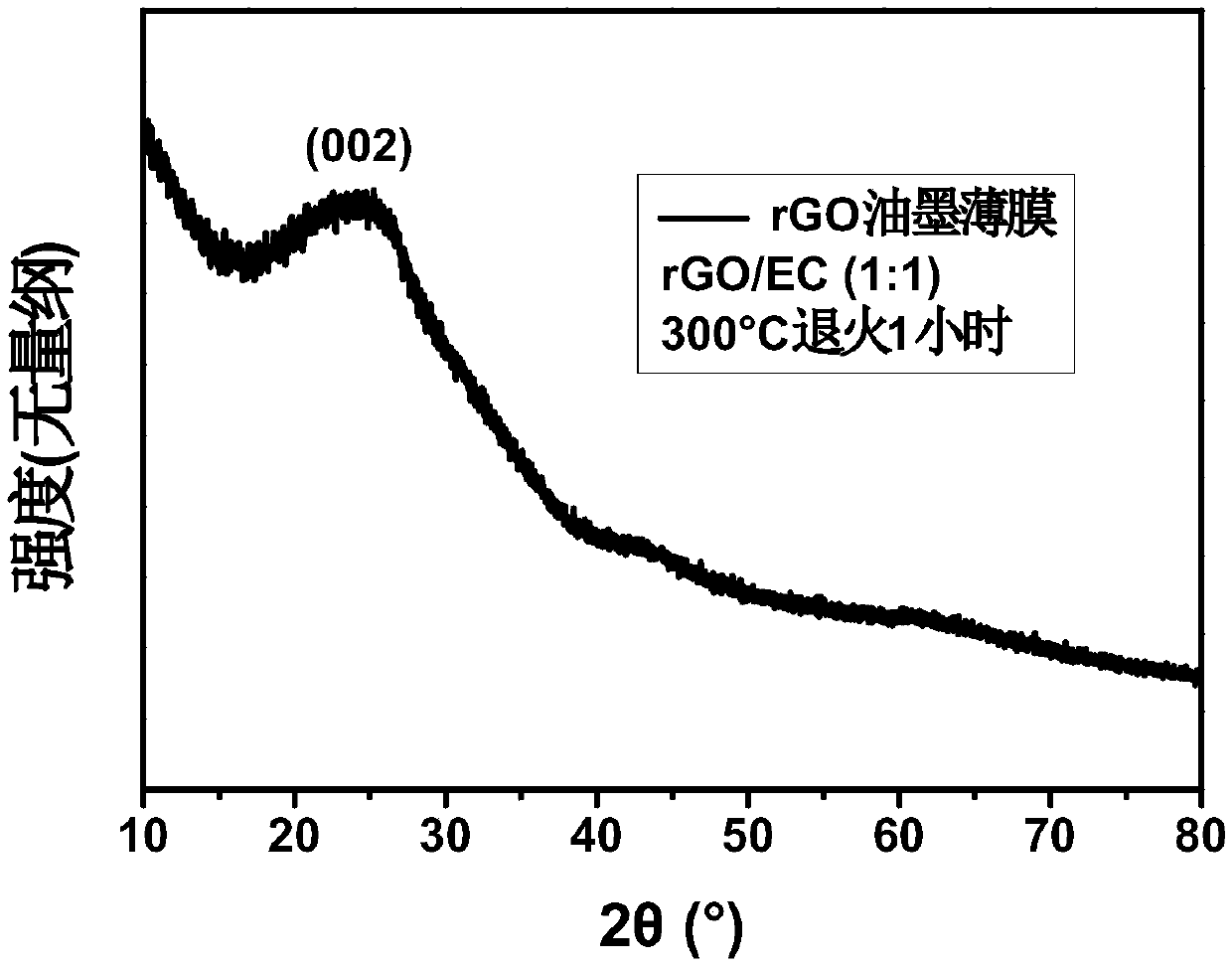

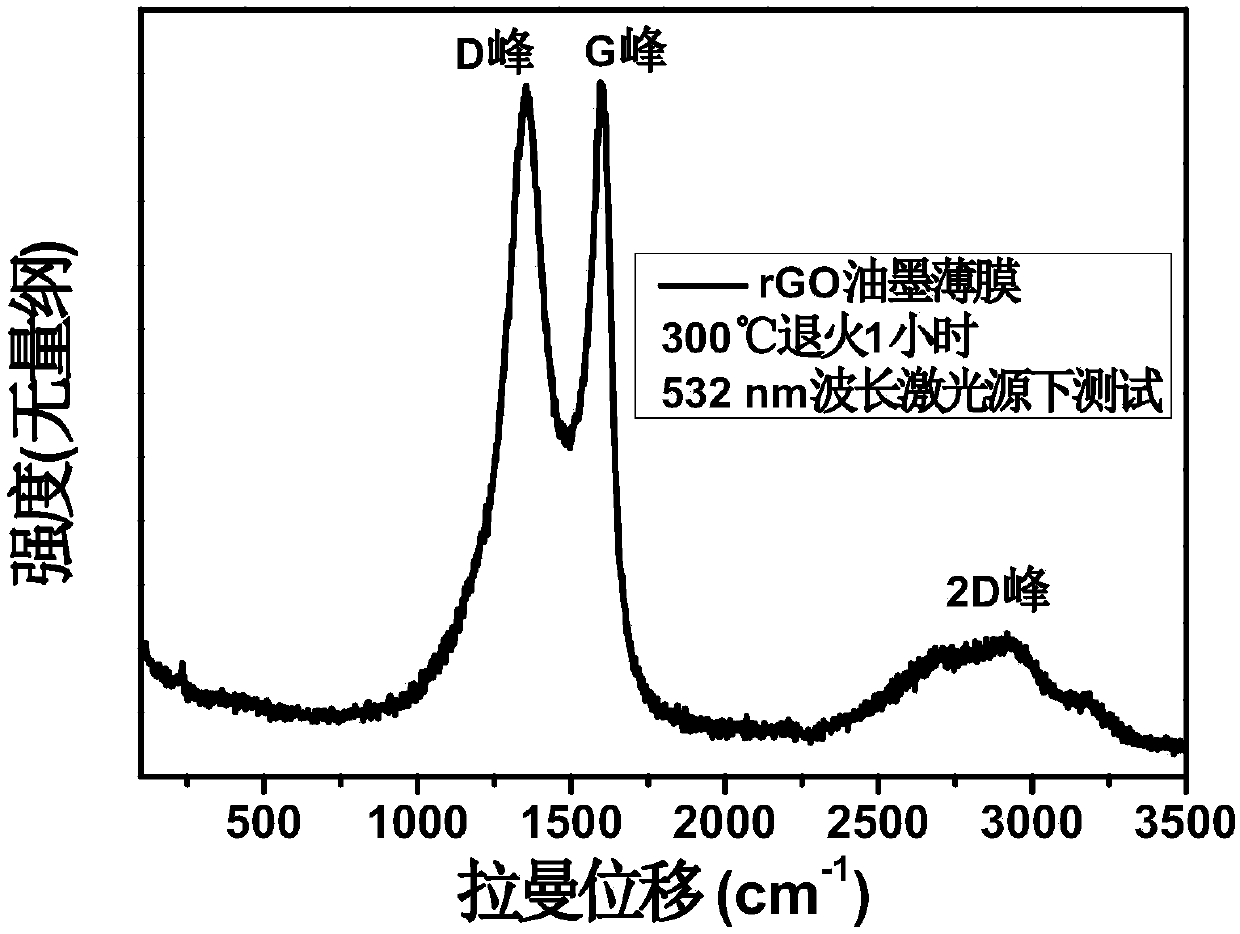

Graphene electric-conduction ink preparation method, graphene electric-conduction ink film and graphene electric-conduction ink film composite material film

The invention discloses a graphene electric-conduction ink preparation method, a graphene electric-conduction ink film and a graphene electric-conduction ink film composite material film. According tothe present invention, a graphene electric-conduction filler is uniformly dispersed in an alcohol / ketone / ester / ether solvent under the assisting of a cellulose-based dispersing agent through room-temperature stirring and ultrasonic dispersion to obtain high-quality high-stability high-conductivity graphene ink, and further the high-quality high-stability high-conductivity graphene ink is compounded with other functional materials to obtain graphene-based composite ink; the method has characteristics of simple formula, simple process, high efficiency, environment friendliness, low cost and thelike; and the graphene ink and the composite ink are suitable for scrape coating, screen printing, direct writing, ink-jet printing and other processes, and can firmly form pure graphene or graphenecomposite films and patterns on common hard / soft substrates.

Owner:XI AN JIAOTONG UNIV

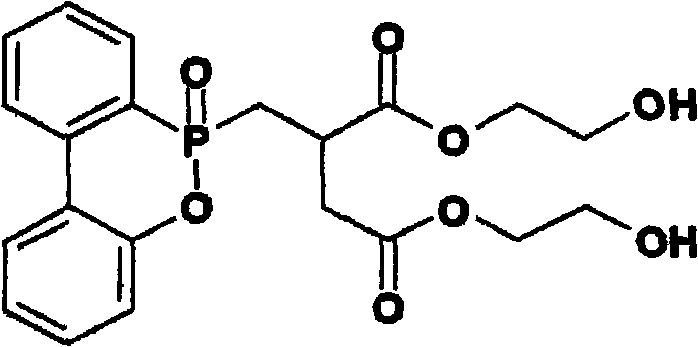

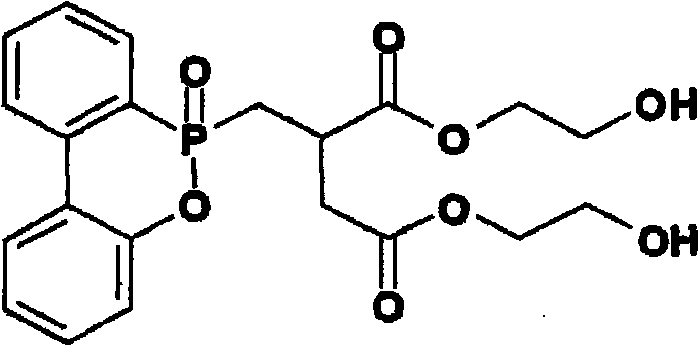

Bamboo charcoal, flame retardant and moisture conductive terylene fiber, preparation method and application thereof

InactiveCN101629333AImprove adsorption capacityImprove deodorizationFilament/thread formingMonocomponent copolyesters artificial filamentFire retardantMoisture

The invention discloses a bamboo charcoal, flame retardant and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 5-10 percent of active carbon parent granule and 90-95 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The terylene fiber has good functions of adsorption, deodorization, bactriostasis and rot resistance and flame retardance, and because the cross section of the fiber is the profile cross section, the moisture conductive function of the fiber is also excellent, thus the terylene fiber has wide range of application. The preparation method of the bamboo charcoal, flame retardant and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:苏州金辉纤维新材料有限公司

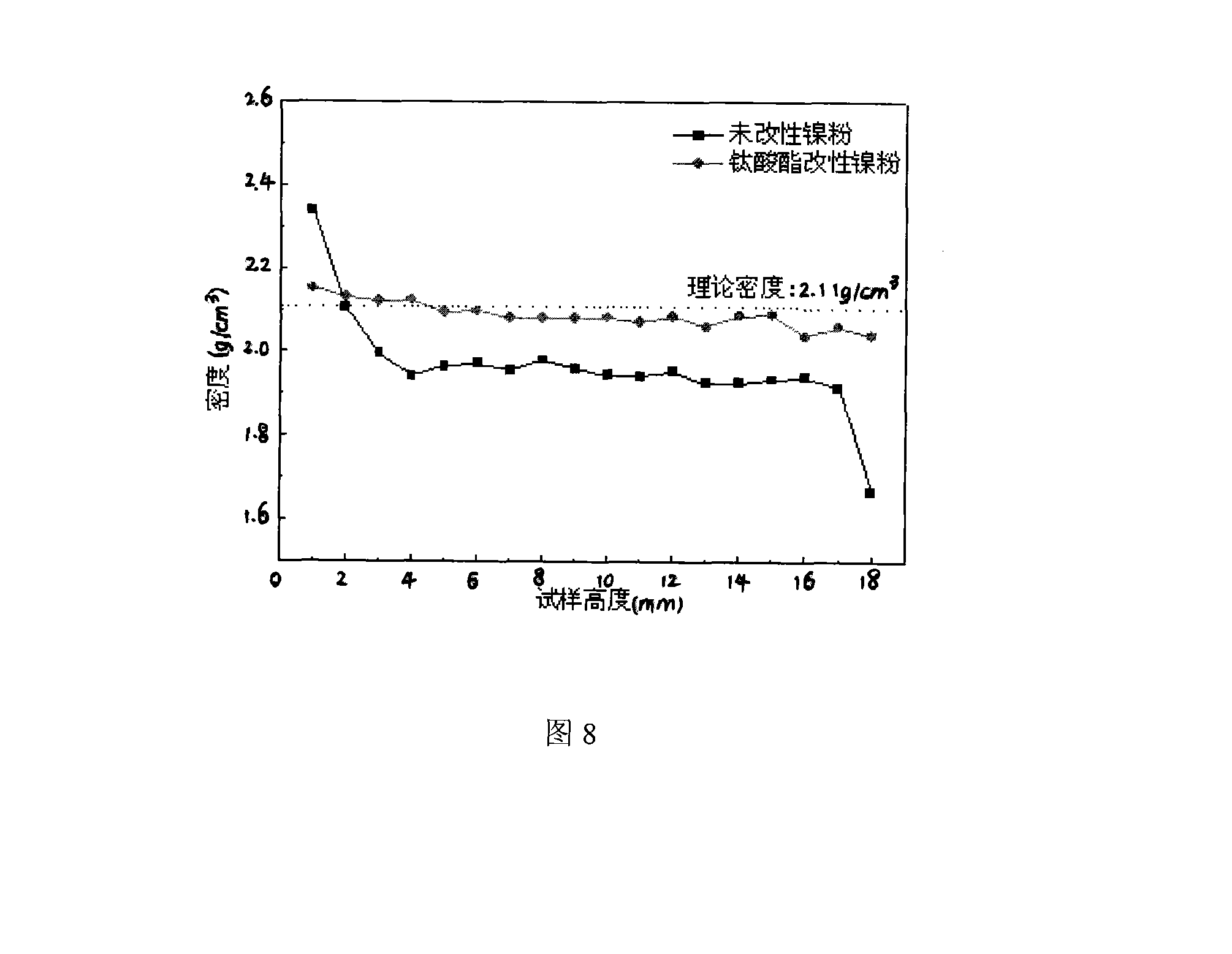

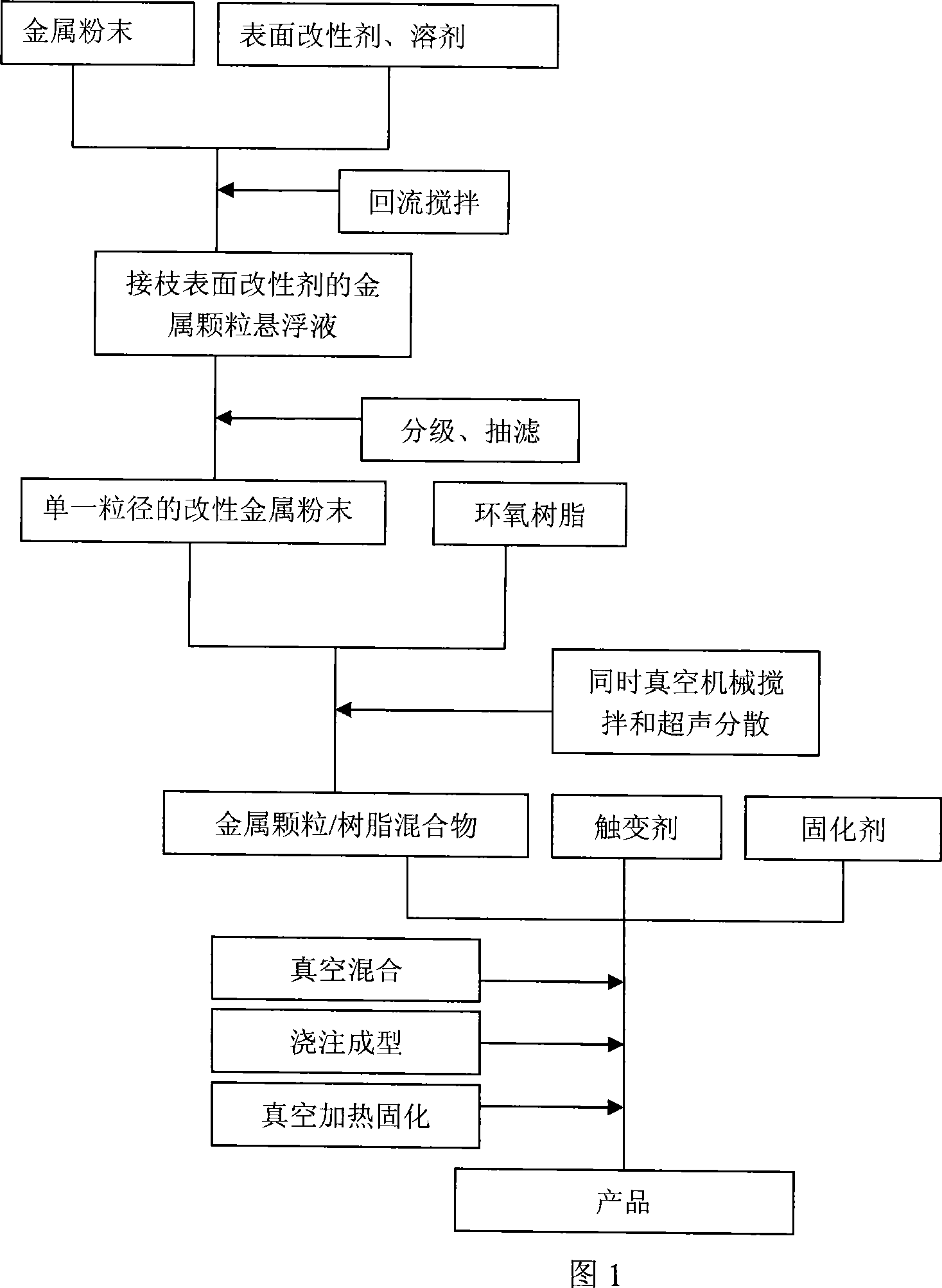

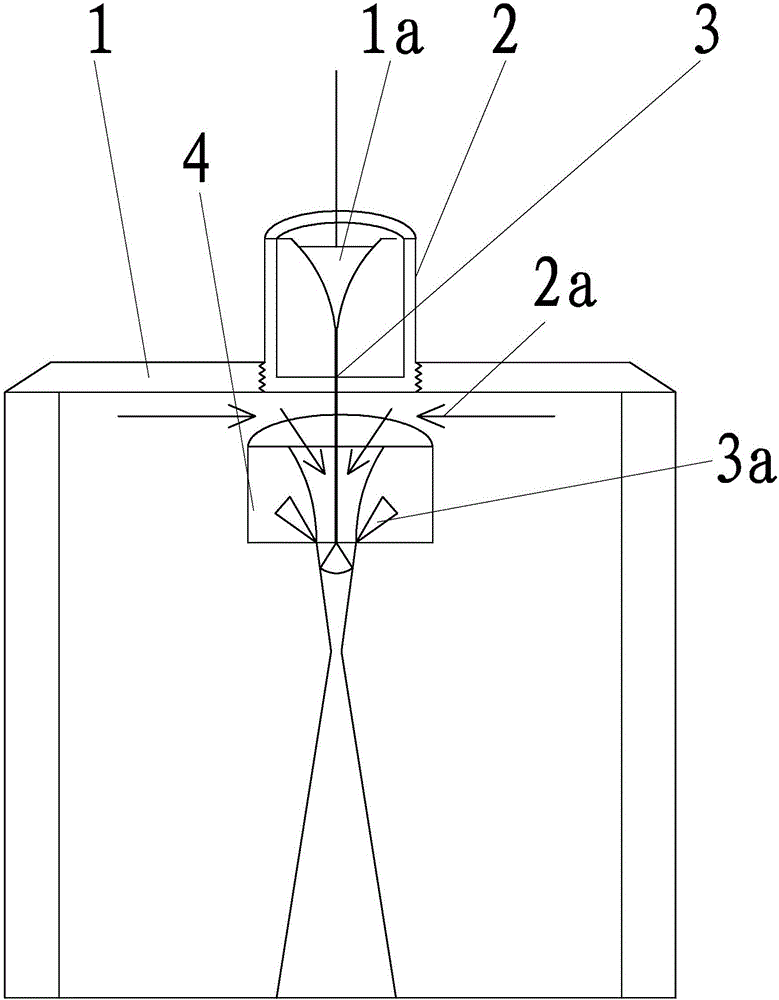

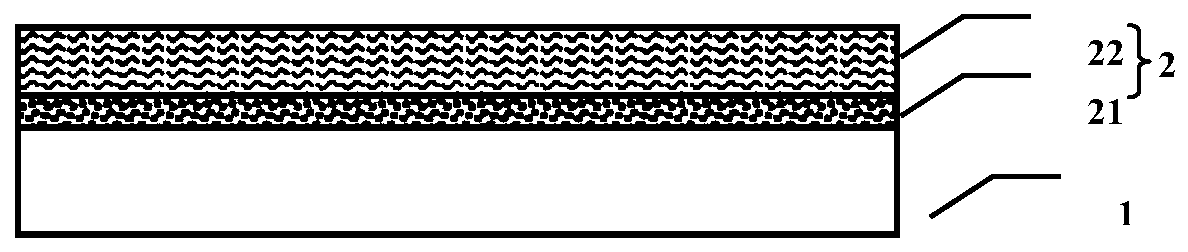

Method for preparing resin-base composite material containing metal particle

The invention relates to a preparation method of a resin matrix composite material filled with metal particles, in particular to a preparation method of a resin matrix composite material containing metal particles. The invention is characterized in that: the invention comprises the steps: 1) dried metal powder and surface modifier are mixed with solvent, and then the mixture obtained is heated and refluxed with the protection of inert gas under 80-150 DEG C, thus forming suspension; 2) the suspension is classified to obtain suspension with single particle-sized particles, which is then extracted and filtered, thus obtaining single particle-sized modified metal powder; 3) the modified metal powder obtained in the step 2) is added into the resin matrix, in which thixotropic agent and curing agent are added, and then a vacuum stirrer and a ultrasonic vibrating device are used together to stir and vibrate the mixture obtained; 4) the mixture obtained in the step 3) after mixed is poured into a die for casting moulding, thus obtaining the resin matrix composite material containing metal particles through curing technique. The method is characterized by good dispersion effective of the metal particles and preventing the metal particles from a secondary aggregation.

Owner:WUHAN UNIV OF TECH

High-magnetoconductivity soft magnetic alloy powder, inductance piece and preparation methods thereof

ActiveCN106205934AReduce power lossSolve the problem of low magnetic permeability and large power lossTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

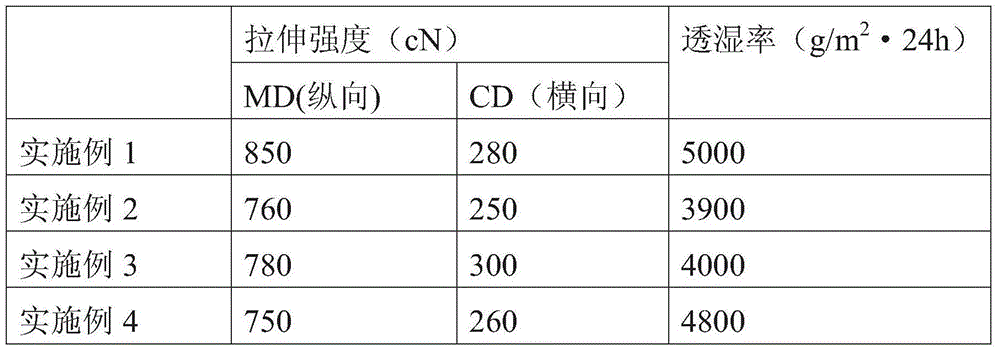

Preparation method of low-yellowness antibacterial calcium carbonate functional composite powder for ventilated membrane

ActiveCN102675918AEnsure maximum sizeMeet the control requirements of the distribution state below the maximum particle sizePigment physical treatmentPigment treatment with non-polymer organic compoundsCalciteUltimate tensile strength

The invention discloses a preparation method of low-yellowness antibacterial calcium carbonate functional composite powder for a ventilated membrane. The method comprises the following steps of: cleaning calcite raw ore, drying in the air and smashing; grading with a vibration sieve; mixing for preparing; coating; drying; and modifying. The composite powder has the beneficial effects: when added into the ventilated membrane, the composite powder plays a role in filling and increasing volume; the yellowness of the ventilated membrane is lowered by over 50 percent in comparison to a ventilated membrane into which an equal amount of ordinary calcium carbonate is added; the processing flowability, tensile strength and air permeability uniformity of a ventilated membrane product can be improved remarkably; and the ventilated membrane added with the calcium carbonate-based functional composite powder has antibacterial property.

Owner:ANHUI JIANGDONG TECH POWDER CO LTD

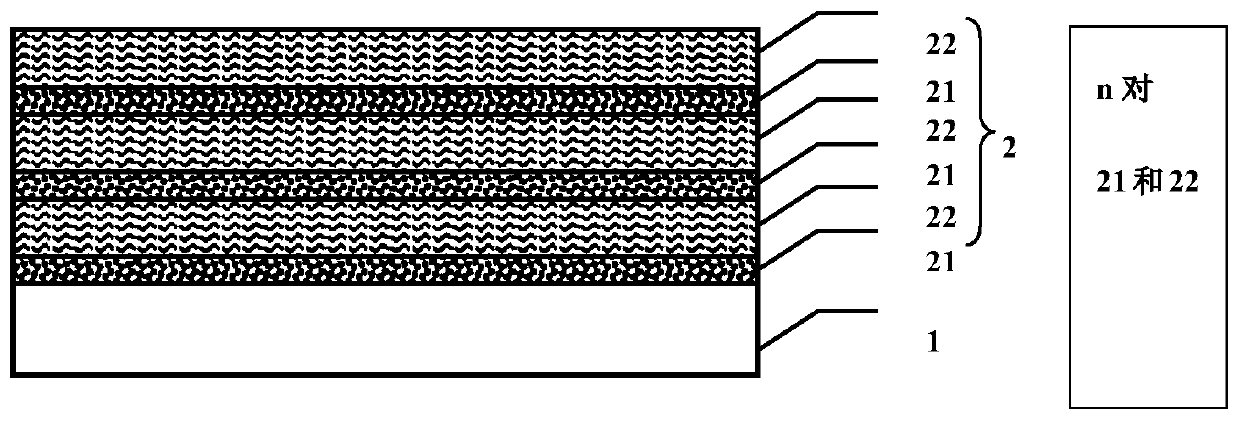

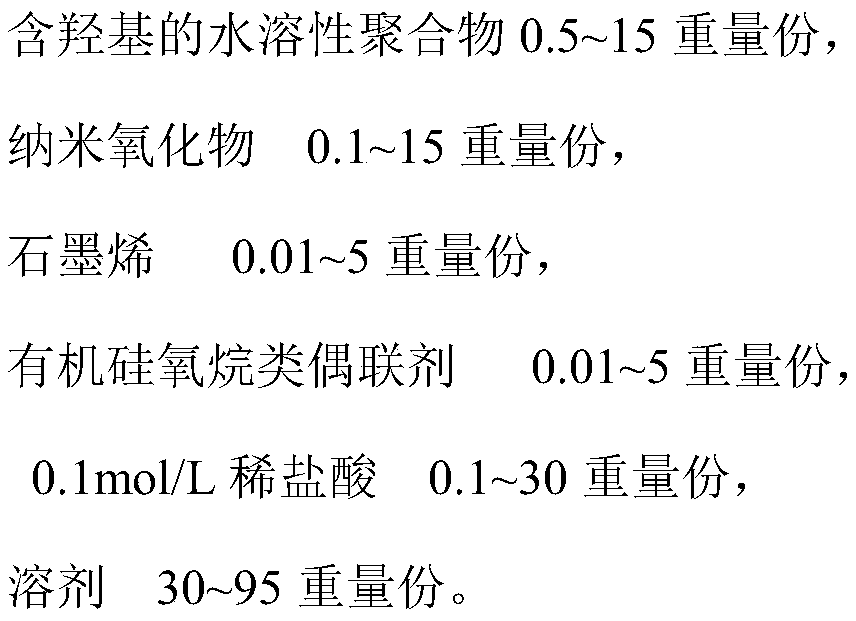

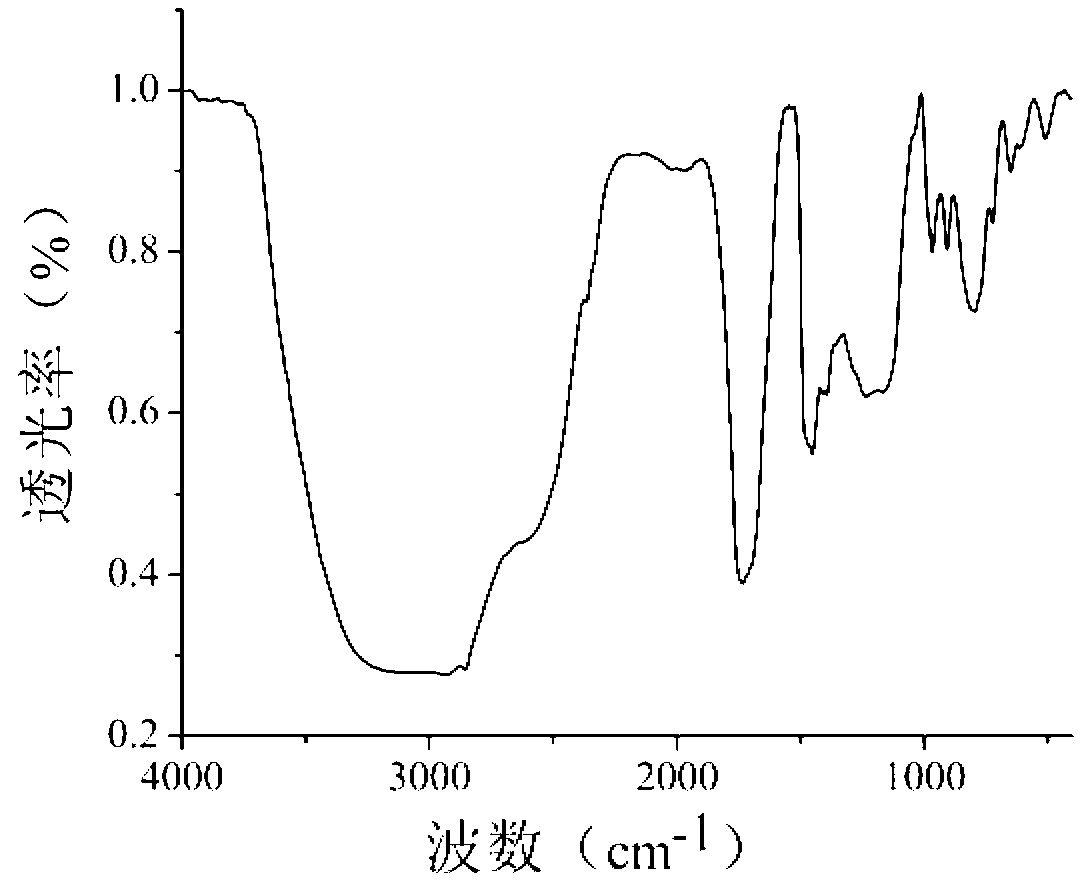

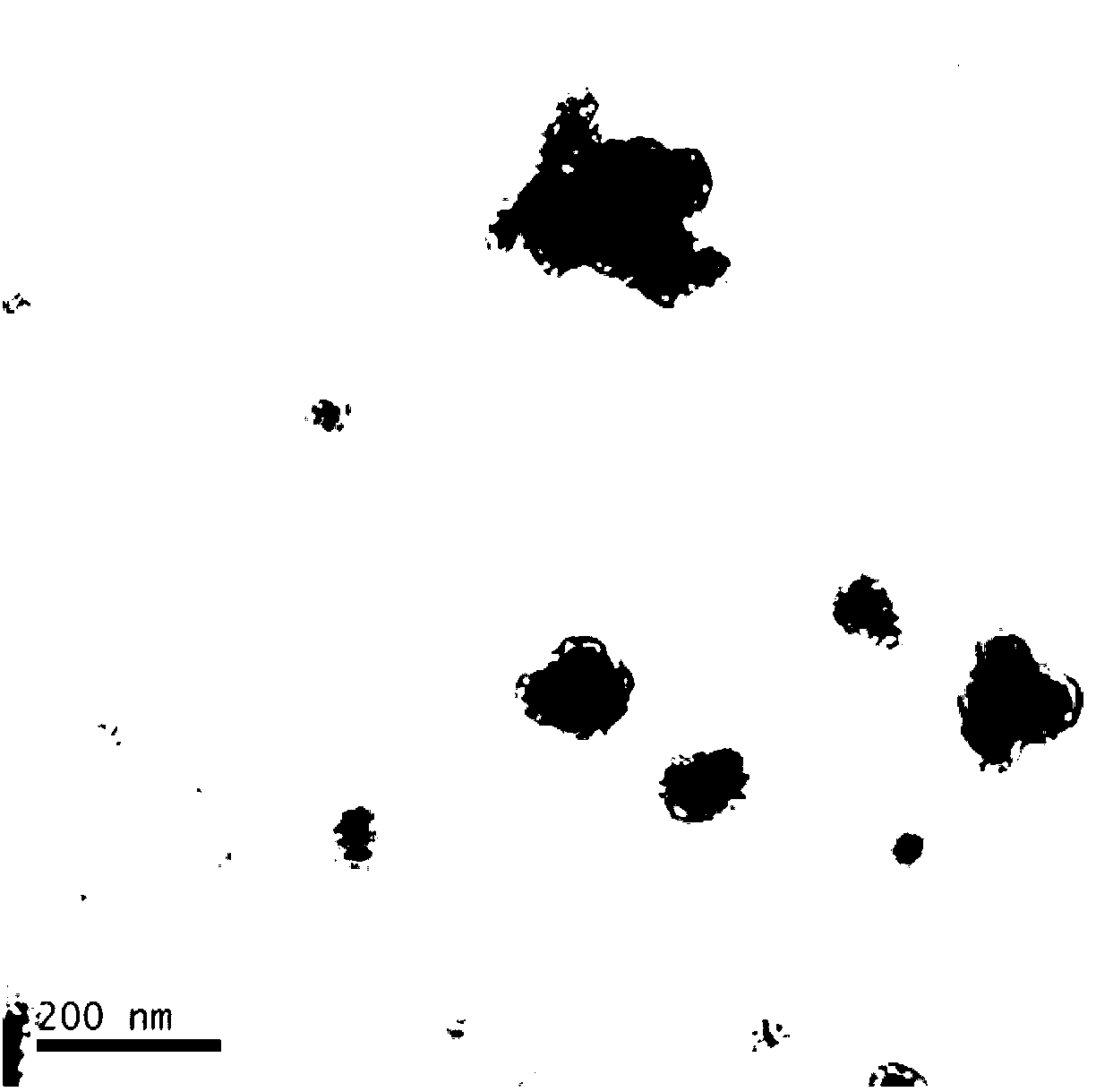

Water-based high-barrier coating liquid and production method thereof

The invention discloses water-based high-barrier coating liquid and a production method thereof. The water-based high-barrier coating liquid comprises 0.5-15 parts of a hydroxy group-containing water-soluble polymer, 0.1-15 parts of a nanometer oxide, 0.01-10 parts of graphene, 0.01-5 parts of an organic siloxane coupling agent, 0.1-30 parts of 0.1-mol / L diluted hydrochloric acid and 30-95 parts of a solvent. According to the water-based high-barrier coating liquid and the production method thereof, nanometer oxide particles produced through a sol-gel method are used as a small-size polymerization inhibitor, and are loaded onto the surfaces of the graphene by means of physical adsorption, and polymerization among the graphene can be inhibited, so that the problem of poor dispersity of thegraphene is solved; and by using cross linking of the nanometer oxide and the water-soluble polymer, the synergistic enhanced barrier action of the graphene / polymer on gas is given full play to. Moreover, a process of the production method of the water-based high-barrier coating liquid is simple and easy to implement, and a produced film material has good mechanical performance and package printing performance at the same time, and can be applied to a wide variety of fields of medicines, food, electronic product packaging, encapsulation and the like.

Owner:CHINA LUCKY FILM CORP

Preparation method of calcium carbonate based reinforcing agent for PVC (polyvinyl chloride) advertising film

ActiveCN102634240AEnsure maximum sizeMeet the control requirements of the distribution state below the maximum particle sizePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyvinyl chlorideUltimate tensile strength

The invention discloses a preparation method of a calcium carbonate based reinforcing agent for a PVC (polyvinyl chloride) advertising film. The preparation method fundamentally comprises the steps of carrying out clean-washing, air-drying and smashing on calcite raw ore; grading by a vibrating screen; mixing for preparation; coating; drying; and modification. The calcium carbonate based reinforcing agent has the beneficial effects that the tensile strength of the PVC advertising film added with the reinforcing agent prepared by the preparation method is improved by more than 10% compared with that of the PVC advertising film added with common heavy calcium carbonate with the same quantity as the reinforcing agent, both the elongation at break and the product glossiness are improved remarkably, an antibacterial characteristic is added, and the filling content can be improved 5% under the condition of the same product quality.

Owner:ANHUI JIANGDONG TECH POWDER CO LTD

Nano composite diatom ooze coating and preparation method thereof

The invention relates to a nano composite diatom ooze coating including a solvent and the following components with the total mass of 100%: 0.5-1.8% of cellulose, 5-18% of tourmaline, 5-15% of titanium dioxide, 4-18% of kaolin, 5-12% of a sepiolite powder, 35-55% of diatomite, 5-12% of a nano noble metal loaded type catalyst, 1-6% of nano activated carbon, 0.5-0.8% of a levelling agent, 1.5-5% of a thickener, 7-16% of a re-dispersible latex powder, and 0-5% of a pigment. The solvent is preferably water, and the amount of the water is 20-30%, preferably 25%, of the total mass of all the components. Nano noble metal particles are loaded on a carrier firstly and then mixed with other powders, so as to prevent an agglomeration effect of the nano noble metal particles. The prepared nano composite diatom ooze coating has extremely strong adsorption and ion exchange, can adsorb formaldehyde in air, and decomposes formaldehyde and other harmful gases under the action of the catalyst.

Owner:上海源由纳米科技有限公司

Method for preparing nano titanium dioxide/polyacrylate compound emulsion

The invention discloses a method for preparing a nano titanium dioxide / polyacrylate compound emulsion. The method comprises the steps as follows: at a room temperature, mixing 4-10 parts of hexadecyl trimethyl ammonium bromide, 6-14 parts of acrylic acid and 10-30 parts of an acrylate monomer in parts by mass uniformly and then dropwise adding deionized water until the system becomes clear; adding 2-6 parts of butyl titanate and 1-4 parts of a silane coupling agent, then adding 30-50 parts of deionized water, and performing ultrasonic dispersion; and adding deionized water and hexadecyl trimethyl ammonium bromide, raising the temperature, stirring, and dropwise adding a mixed solution of an initiator and deionized water, performing thermal reaction, raising the temperature to 80-90 DEG C, performing thermal reaction for 0.5-3h continuously, and lowering the temperature to the room temperature to obtain the nano titanium dioxide / polyacrylate compound emulsion. The method is simple in process, and avoids a problem of 'secondary agglomeration' of conventional nano titanium dioxide in a polymerization process of the emulsion effectively, so that a polymerization reaction can proceed smoothly. The prepared nano titanium dioxide / polyacrylate compound emulsion has good stability.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of two-dimensional boron nitride nanosheet

InactiveCN108069408AReduce usageNo pollution in the processNitrogen compoundsHexagonal boron nitrideBoron nitride

The invention relates to a boron nitride nanosheet, in particular to a preparation method of a two-dimensional boron nitride nanosheet. The preparation method comprises: subjecting blocky hexagonal boron nitride, as a raw material, and a solid intercalation agent, which may fully decompose into gas after being heated, to premixing according to their mass ratio of 1:(5-50) to obtain a mixture; adding the premixed mixture into a ball mill tank, adding milling balls different in size according to a ball-to-material ratio of (6-80):1, with total charge quantity 1 / 3-2 / 3 of the ball mill tank by volume, stirring at the speed of 100-400 r / m for ball milling for 2-12 h so that edge defects occur to the boron nitride and the intercalation agent is embedded in the boron nitride for intercalation toobtain a boron nitride mixture physically intercalated with the intercalation agent, which is a uniform white solid mixture; heating the white solid mixture to obtain solid two-dimensional boron nitride nanosheet powder; alternatively, dispersing the white solid mixture in isopropanol to obtain two-dimensional boron nitride nanosheet dispersion.

Owner:XIAMEN UNIV

Preparation method of organic modified graphene

The invention discloses a preparation method of organic modified graphene and belongs to the field of preparation of two-dimension nano material graphene. The method is characterized by taking low-cost raw graphite as the raw material, adding different masses of dry ice for creating high-pressure and high-energy environment, preparing graphene via a ball milling method, simultaneously introducing nitrogenous organic matters in the ball milling process, taking nitrogenous organic matters as friction agents and modifiers for simultaneously preparing graphene and carrying out in-situ modification to prepare a nitrogenous organic matter modified graphene structure. Through the preparation method of organic modified graphene, graphene with a circular microstructure is prepared by controlling reaction time, reaction pressure and the ratio of the raw graphite to the nitrogenous organic matters; a low-cost and high-efficiency method for preparing graphene with organic modified surface and complete body structure is developed; the problems of high cost, long preparation cycle, low dispersibility and poor interfacial adhesion caused in large-scale application of graphene are solved; the method has a great significance in industrial production and application of graphene.

Owner:BEIJING UNIV OF CHEM TECH

BOPET film high concentration matt masterbatch and preparation method thereof

The invention relates to the technical field of high molecular materials, more specifically, and relates to BOPET film high concentration matt masterbatch and a preparation method thereof. The main points of the technical schemes are as follows: the masterbatch includes, by weight ratio, 50-80 parts of PET, 5-25 parts of silicon dioxide, 1-3 parts of a hyper-dispersant, 3-15 parts of matting resin, 0.1-1 part of an anti-oxidant, and 3-15 parts of silicone microspheres. The masterbatch prepared through the above components and ratio is high in effective concentration, obvious in the cooperativeeffects of several matting components, good in matting effect and low in glossiness of matt BOPET films; and the masterbatch is only applied to the surface layers of the BOPET films, so that the advantage of costs can be obvious.

Owner:东莞市源丰高分子材料科技有限公司

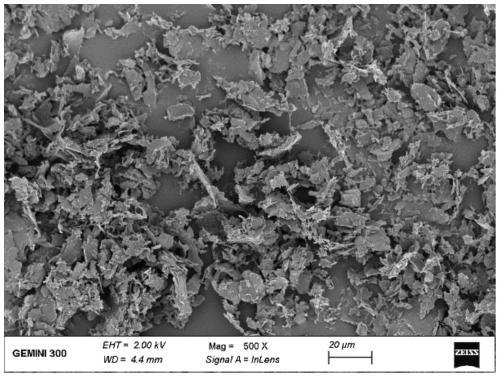

Preparation method of graphene modified polyester composite material based on liquid phase stripping

InactiveCN111592640AReinforcement stiffnessReinforced cross-linking degreeGrapheneOrganic solventGraphene

The invention relates to the technical field of graphene composite material preparation, aims at the problems in the prior art that graphene in a graphene modified polyester composite material is poorin integrity and prone to agglomeration, and discloses a preparation method of a graphene modified polyester composite material based on liquid phase stripping. The preparation method comprises the following steps: taking a graphite derivative as a raw material, dispersing the graphite derivative in an organic solvent, adding a dispersing agent, and preparing a graphene dispersion liquid under the ultrasonic-assisted action; mixing the graphene dispersion liquid with a polyester monomer and a catalyst, and performing esterification reaction and condensation polymerization to obtain the graphene polyester nano composite material. According to the method, a liquid-phase stripped graphene modified polyester composite material is adopted, the agglomeration phenomenon of the graphene after liquid phase stripping is reduced, the stability and integrity of the graphene are improved, the physical and chemical properties of the graphene are relatively strong, the uniform dispersity of the graphene in the modified polyester composite material is further improved, and the finally obtained product graphene polyester fiber is durable in performance and high in washing resistance.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

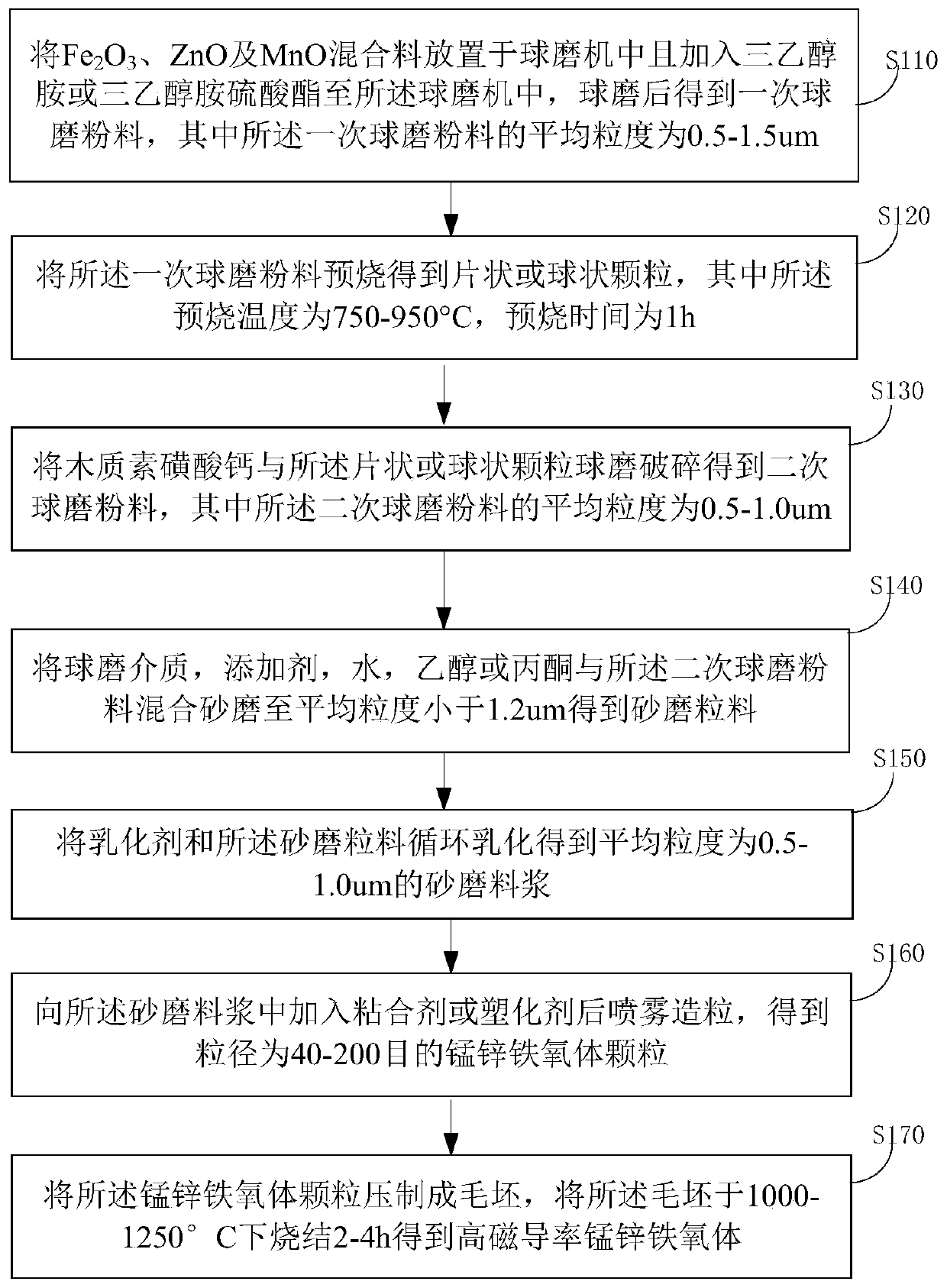

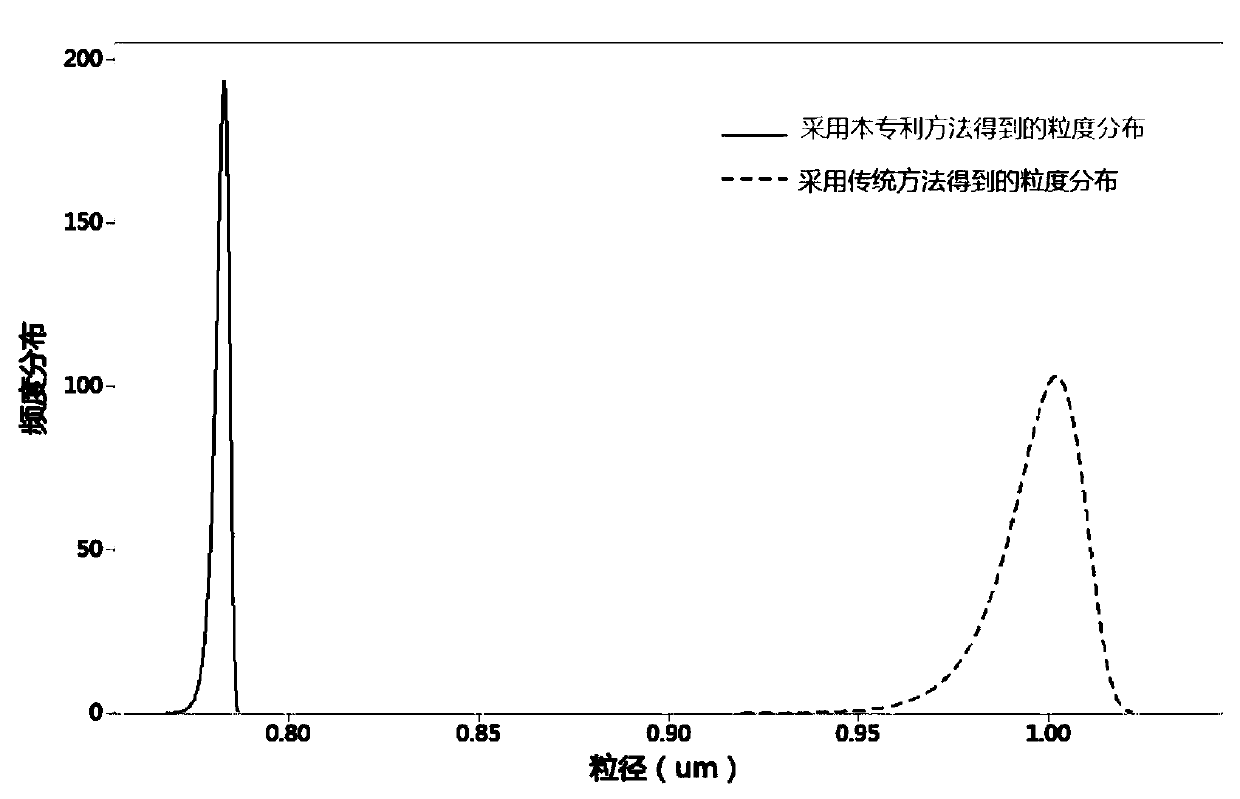

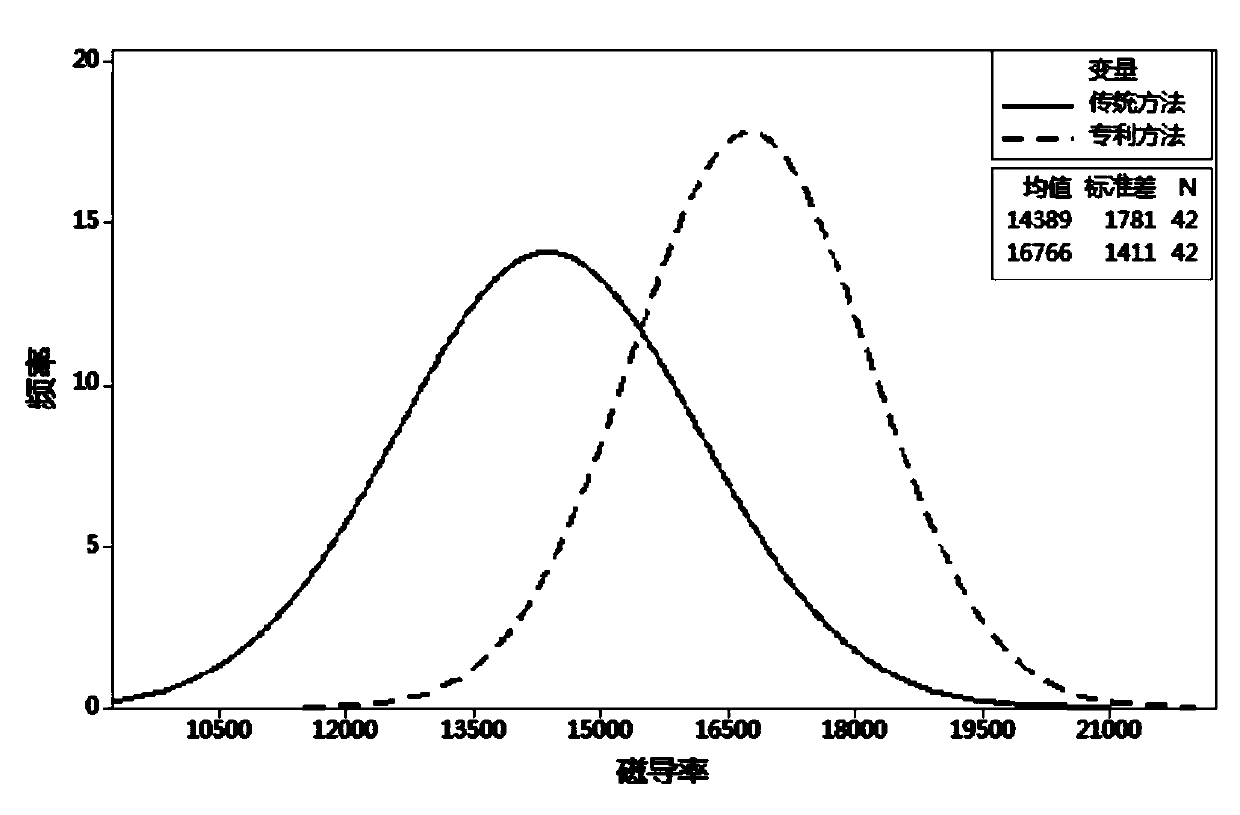

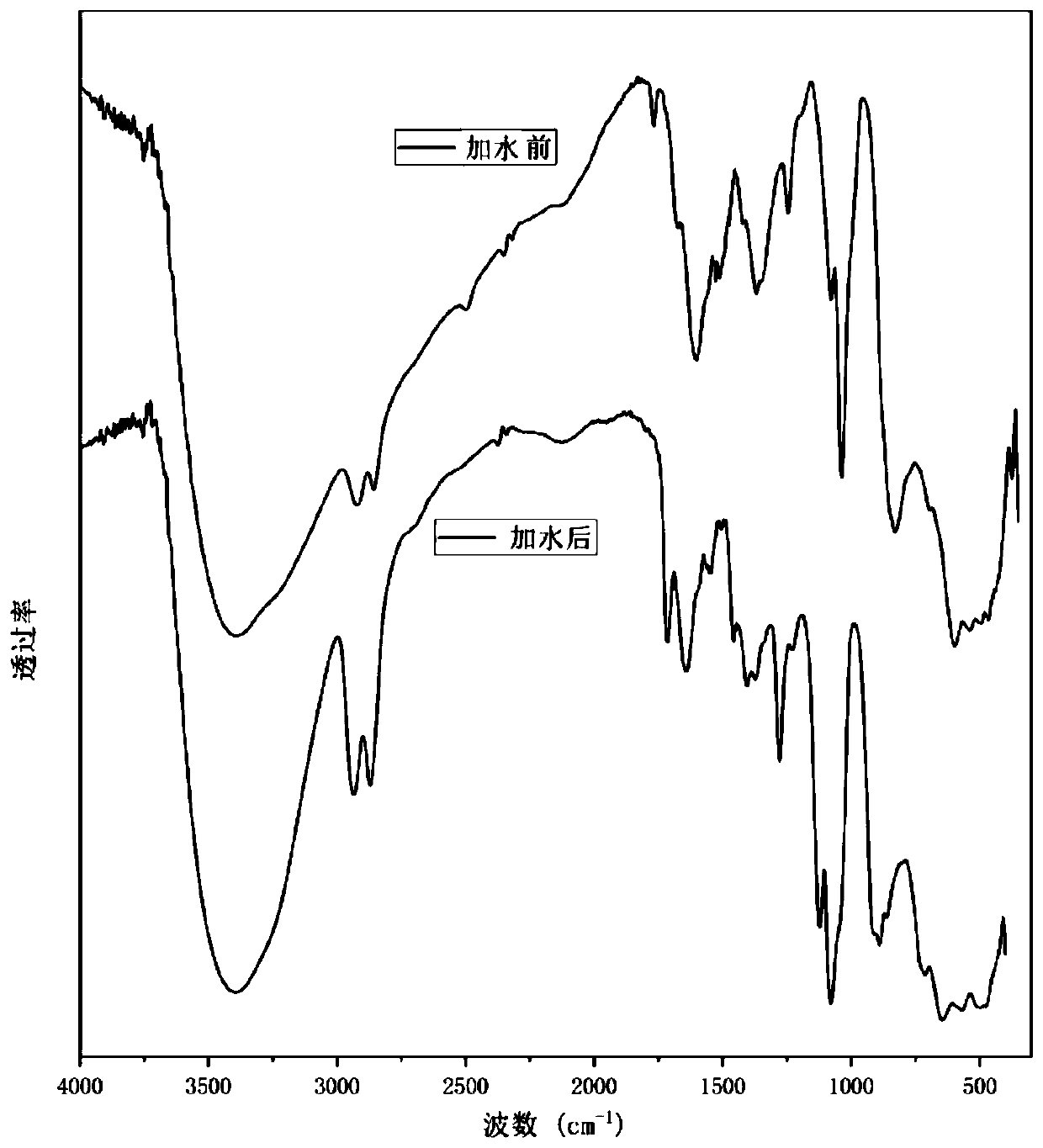

Preparation method of manganese-zinc ferrite with high magnetic conductivity

InactiveCN110577400ASmall particle sizeEffective surface propertiesInorganic material magnetismBall millLarge particle

The invention provides a preparation method of manganese-zinc ferrite with a high magnetic conductivity. Fe2O3, ZnO and MnO which are used as raw materials undergo primary ball-milling and presintering to realize primary ferritization, and then undergo secondary ball-milling crushing and granulation to obtain manganese-zinc ferrite particles, and the particles are molded and sintered to obtain a manganese-zinc ferrite powder. The Fe2O3, ZnO and MnO are mixed in a ball mill, triethanolamine or triethanolamine sulfate is added, large particles are broken by utilizing the mechanical force of theball mill to form small particles, the triethanolamine or triethanolamine sulfate can be effectively adsorbed on the surfaces of the particles in an electrostatic manner as a dispersant, so secondaryagglomeration of the particles is prevented, thereby the particle size of the ball-milled particles is small, and the magnetic conductivity of the obtained manganese-zinc ferrite powder is high; and calcium lignosulphonate is decomposed into CaO in the subsequent sintering process, and is deposited at the grain boundary, so the resistivity of the product is improved, thereby the magnetic conductivity of the manganese-zinc ferrite powder is improved.

Owner:山东春光磁电科技有限公司

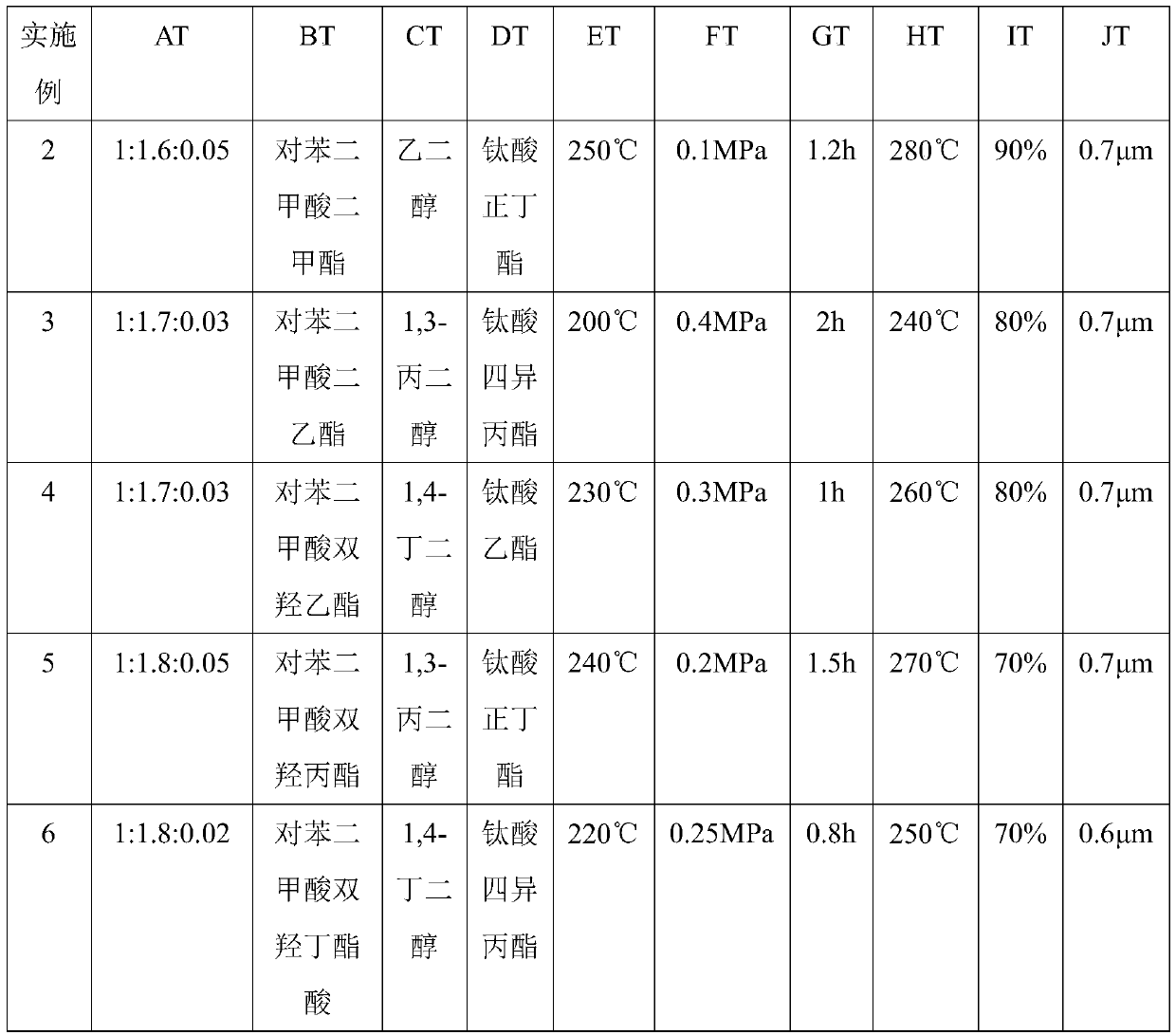

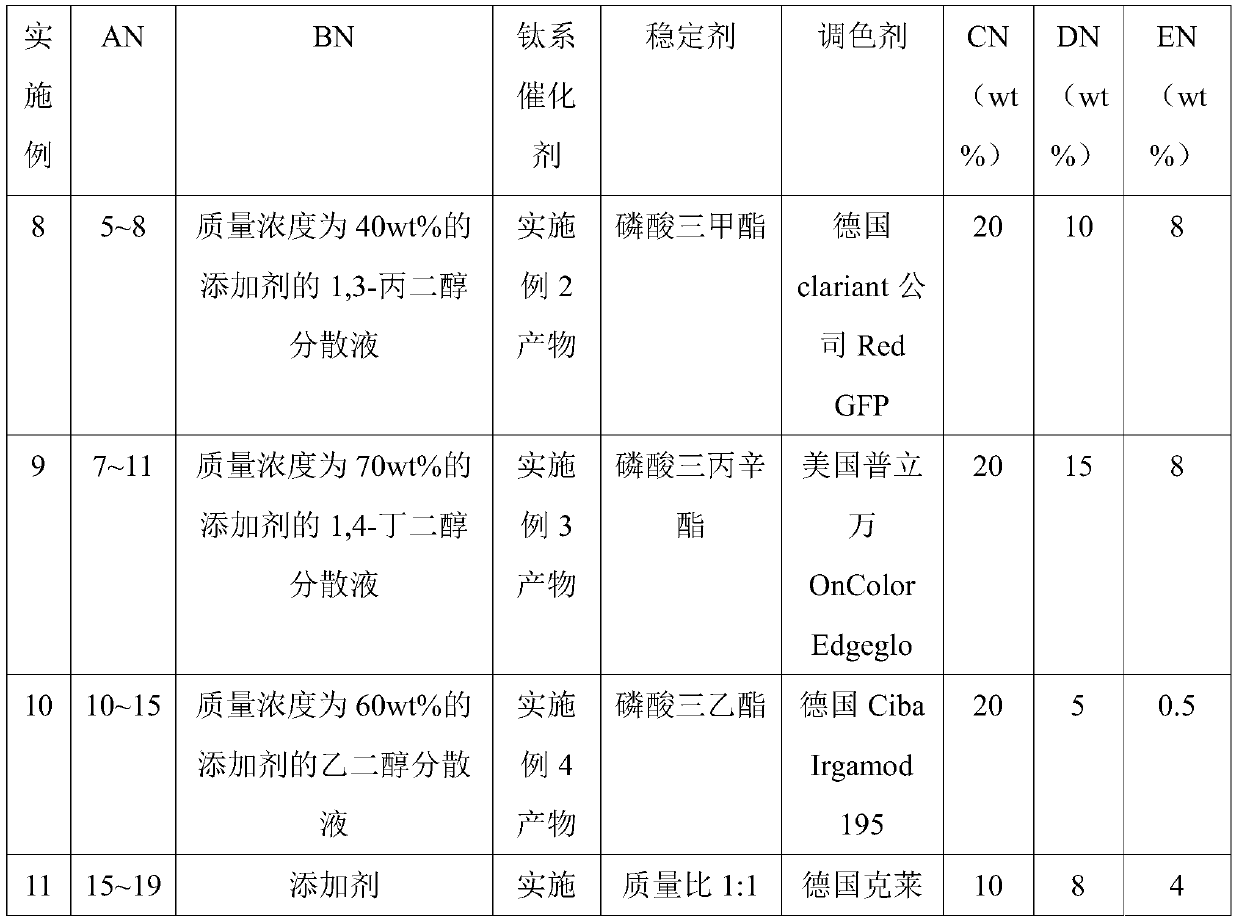

Method for preparing titanium-based polyester filaments by direct spinning of multi-kettle melt

PendingCN111088546AHigh melting pointAvoid reunionMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention relates to a method for preparing titanium-based polyester filaments by direct spinning of four-kettle melt. The preparation method comprises the following steps of preparing polyester melt by taking PTA, EG and a polyester titanium catalyst composite material system as raw materials and adopting a four-kettle polymerization process, and then performing melt direct spinning to prepare titanium-based polyester filaments; and adding the PTA, the EG and the polyester titanium catalyst composite material system into an esterification kettle 1 jointly, wherein the polyester titanium catalyst composite material system mainly comprises a polyester prepolymer with the polymerization degree of 5 -30 and a sheet-shaped titanium polyester catalyst dispersed in the polyester prepolymer.According to the method for preparing the polyester filaments by direct spinning of the four-kettle melt, the catalyst is wrapped with the polyester prepolymer with the polymerization degree of 5 -30,so that agglomeration is effectively avoided; the adopted catalyst has excellent hydrolysis resistance and can be added in any stage of esterification and pre-polycondensation; and the method for preparing the titanium-based polyester filaments by direct spinning of the four-kettle melt has the advantages of simple process, low cost and good application prospect.

Owner:上海慧翌新材料科技有限公司 +1

Superhigh-fineness calcium carbonate composite powder

InactiveCN103881417AEnsure maximum sizeMeet the control requirements of the distribution state below the maximum particle sizePigment physical treatmentCalciteMaterials science

The invention discloses a preparation method for a superhigh-fineness calcium carbonate composite powder. Simply, the preparation method comprises steps of cleaning of calcite raw ore, air drying, crushing, grading, mixing preparation, cladding, drying and modification. The beneficial effects comprise that the superhigh-fineness calcium carbonate composite powder has relatively high quality, the loading of calcium carbonate is improved, and secondary agglomeration of particles is avoided.

Owner:许峰

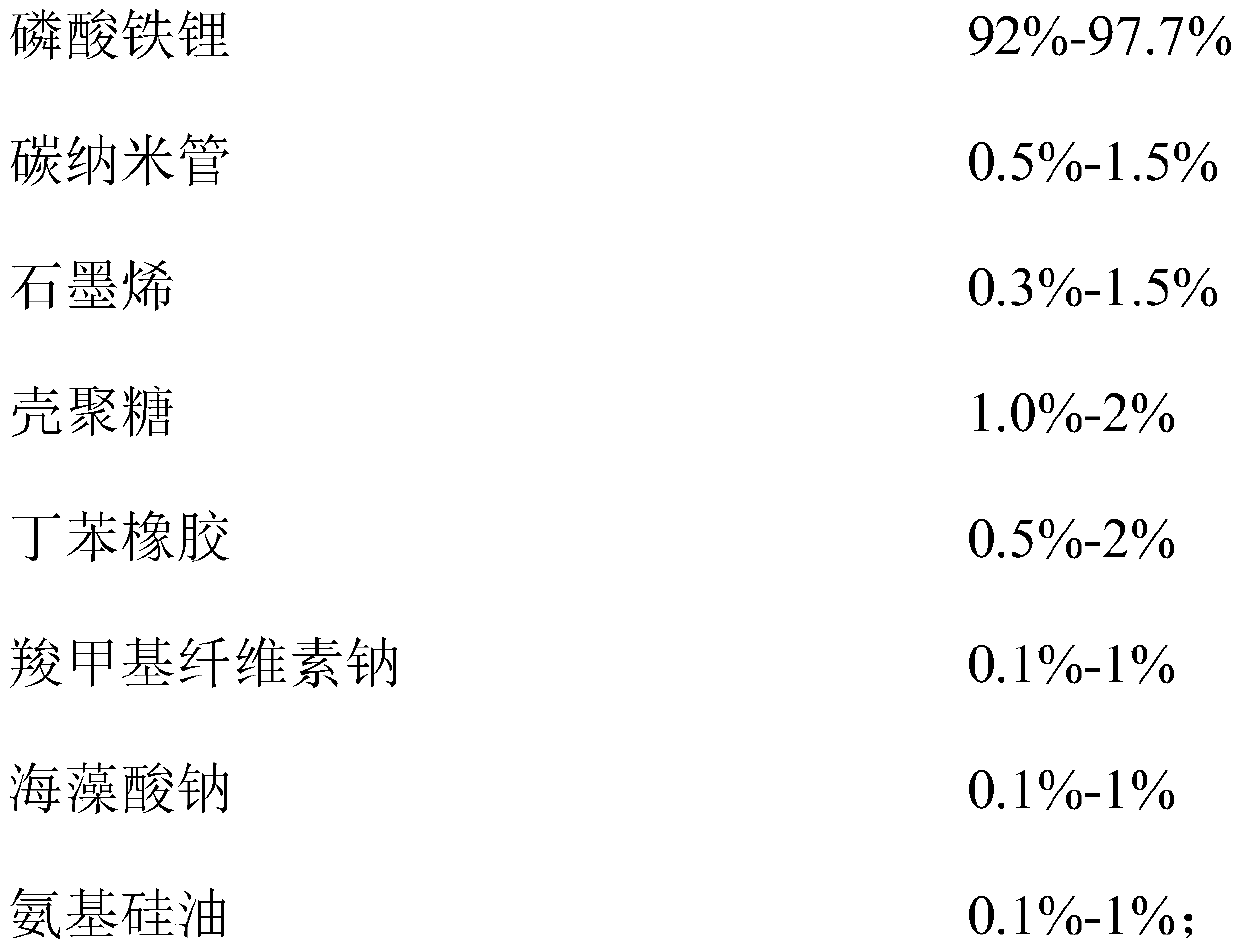

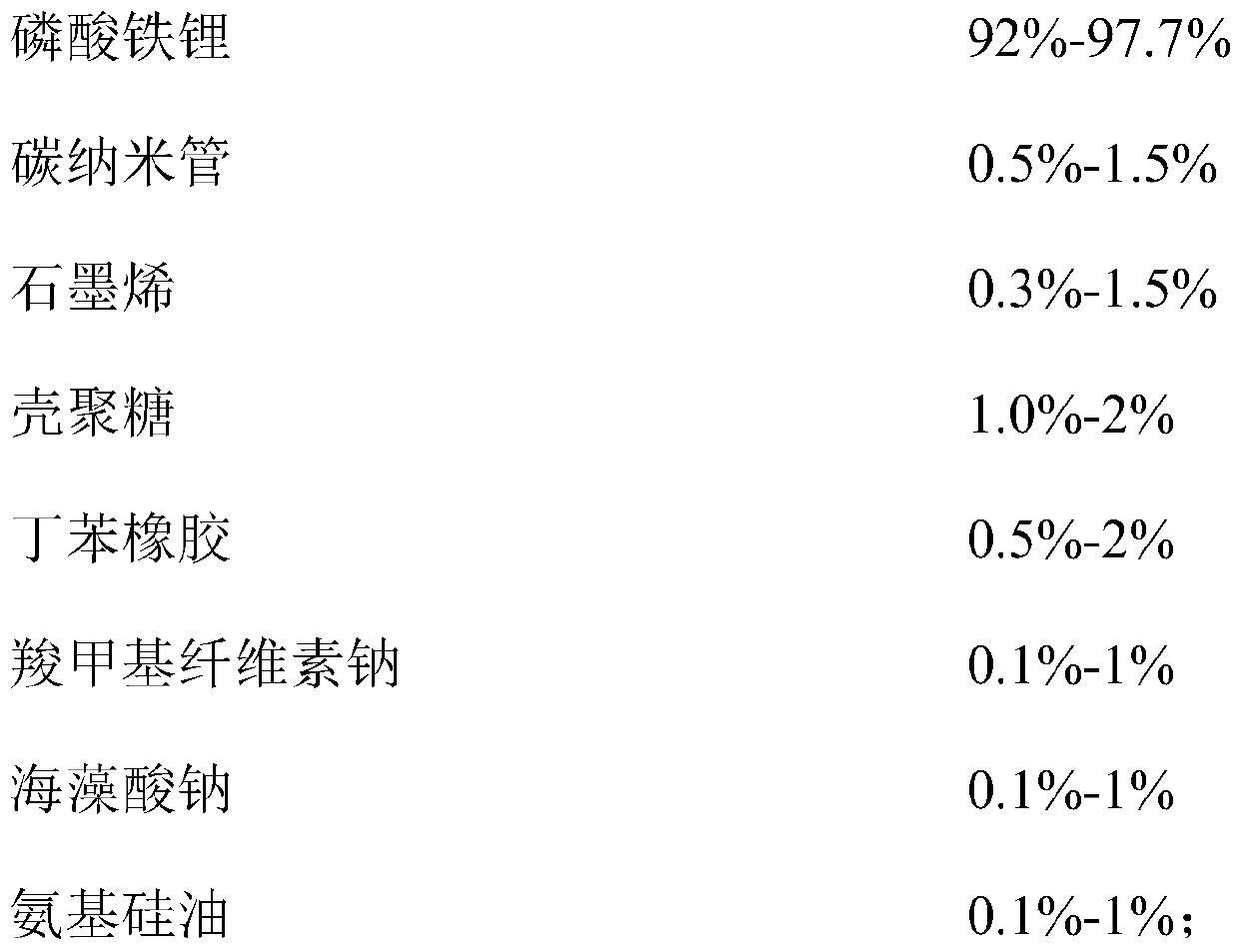

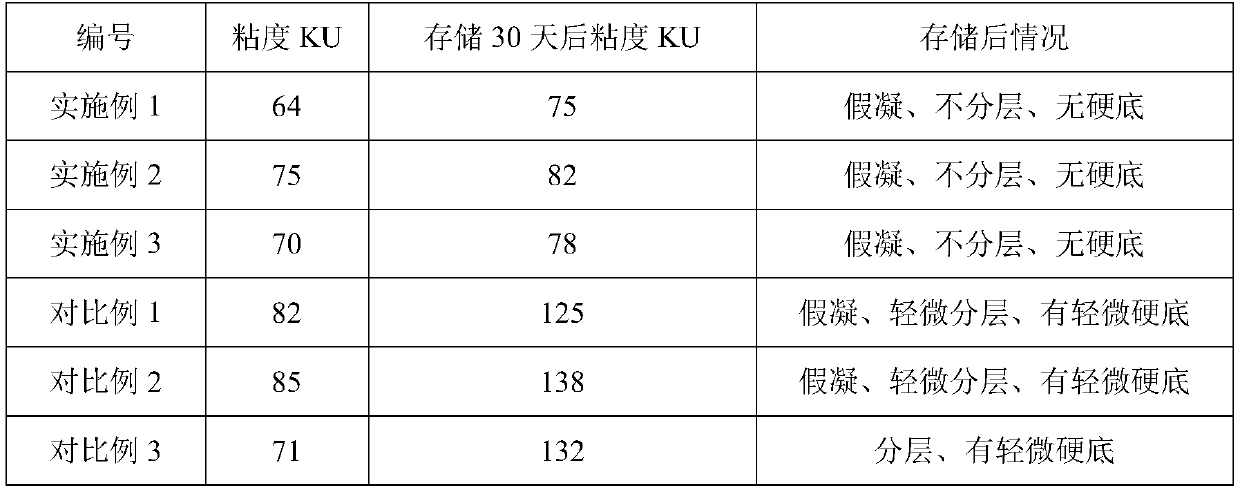

Lithium iron phosphate positive plate and environment-friendly low-temperature-resistant lithium battery comprising same

InactiveCN111261835AIncrease capacityAvoid secondary reunionsSecondary cellsPositive electrodesElectrical batteryButadiene-styrene rubber

The invention discloses a lithium iron phosphate positive plate. The lithium iron phosphate positive plate comprises an aluminum foil and water-based positive slurry which coats the aluminum foil; thewater-based positive slurry comprises lithium iron phosphate, carbon nanotubes, graphene, chitosan, butadiene styrene rubber, sodium carboxymethyl cellulose, sodium alginate and amino silicone oil; and the particle size of the lithium iron phosphate is 4-10 microns. According to the lithium iron phosphate positive plate of the invention, a positive electrode active substance with large particle size and small specific surface area is adopted, so that the low-temperature performance of the lithium iron phosphate positive plate is good; the environment-friendly water-based positive electrode slurry is adopted, so that the positive electrode plate is environment-friendly, non-toxic, good in processing environment adaptability and stable in processing performance, and the obtained positive electrode plate is high in compaction density, high in specific energy and excellent in low-temperature property. The invention further discloses an environment-friendly low-temperature-resistant lithium battery which comprises the lithium iron phosphate positive plate and is combined with a negative plate with high cost performance, large capacity and high activity, and the obtained lithium iron phosphate battery is good in safety performance, high in energy density, excellent in low-temperature performance, stable in processing performance, free of pollution in the production process and low in battery cost.

Owner:广西卓能新能源科技有限公司

Preparation method of universal titanium dioxide water slurry

The invention relates to a preparation method of a universal titanium dioxide water slurry. The method includes: adding an organic dispersing agent, an inorganic dispersing agent and water into an inorganic coated titanium dioxide filter cake, performing pulping and dispersing, and then carrying out sanding treatment to prepare a titanium dioxide dispersed water slurry; and adding cellulose into the dispersed water slurry, and conducting high speed dispersing to obtain the universal titanium dioxide water slurry. The method has the advantages of simple process and convenient operation. The mixed use of a cellulose thickening agent in cooperation with the inorganic dispersing agent and the organic dispersing agent can reduce layered settlement due to the adsorption and aggregation among particles in the titanium dioxide water slurry and formation of large particles finally, thus preventing the viscosity rise or serious layering of the water slurry from generating hard precipitates, andensuring the performance and normal use of the titanium dioxide water slurry. The method not only can reduce dust flying and material wasting for customers, and save the energy consumption for grinding and dispersion, but also can give full play to dispersity, covering power, high whiteness and other application performance of titanium dioxide, and the prepared universal titanium dioxide water slurry can be applied to paint, papermaking and other water-based fields.

Owner:中信钛业股份有限公司

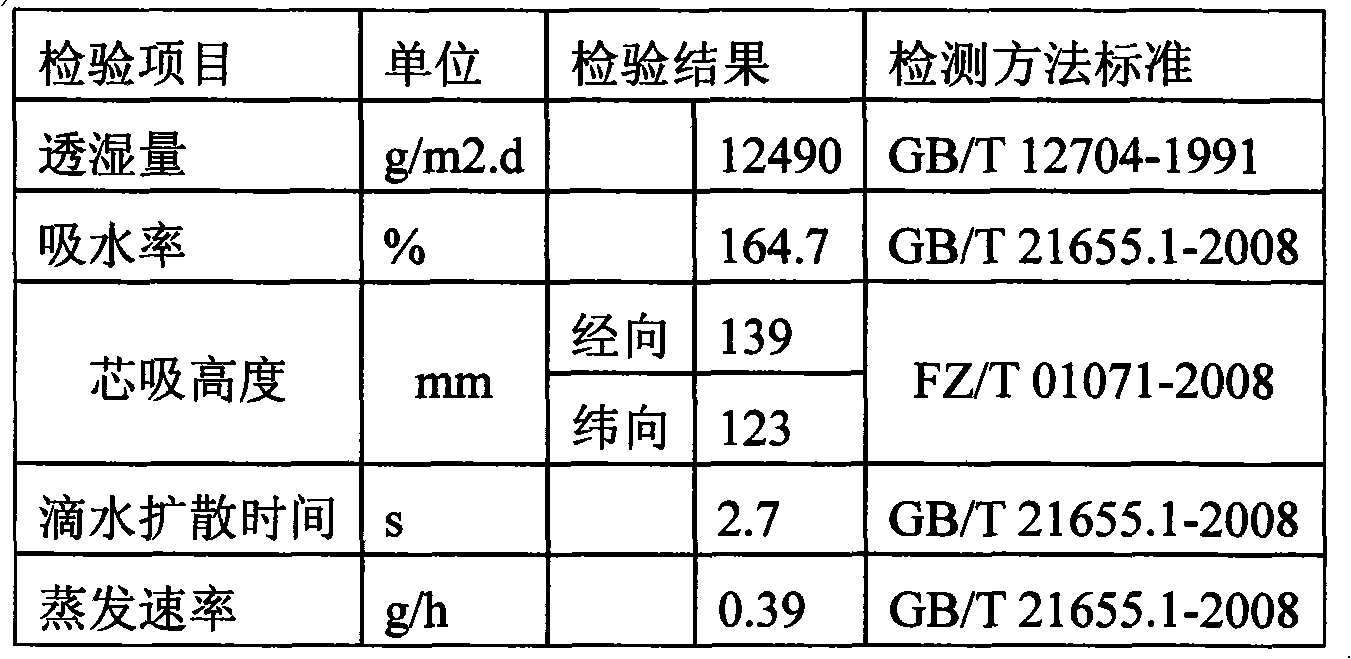

A sweat-absorbent polyester fiber pantyhose

ActiveCN109123821AEvenly dispersedAvoid secondary reunionsElectroconductive/antistatic filament manufactureWeft knittingPerspirationPolyester

The invention discloses a sweat-absorbent polyester fiber pantyhose including a pantyhose body. The pantyhose body is formed by interlacing a lining yarn and a veil. The lining yarn is made of a blended viscose fiber and a moisture wicking polyester fiber, and the veil is spandex, in terms of weight percent, the composition of each fiber raw material of the pantyhose body is: 12 to 13% of spandex,8 to 9% of modified viscose fiber, and 78 to 80% of moisture-absorbing and perspiration polyester fiber. The sweat-absorbent polyester fiber pantyhose has better moisture absorption and perspirationperformance, and has washing resistance, antibacterial, anti-ultraviolet, anti-static and other functions.

Owner:YIWU ZHISHANG SOCKS

Electric pole material of natural modified spherical mineral carbon load nano particle and preparation method thereof

InactiveCN101159323AInhibit growthAvoid secondary reunionsElectrode manufacturing processesActive material electrodesCyclic processLithium

The invention relates to a composite electrode material of natural modified spherical graphite (MSG)-loading nano-Cu6Sn5 and a fabrication method thereof. The main body of the electrode material is natural modified spherical graphite (MSG), and the particle surface of the main body material loads Cu6Sn5 alloy particles in the scale of nanometer. In the structure of the composite material, Cu6Sn5 nanoparticles are fixedly loaded on the surface of graphite, which buffers the volume expansion as well as ensures the conductivity in the process of recirculation, and the surface of graphite has Cu6Sn5 nanoparticles of high specific capacity, which enhances the capacity of entire electrode materials. By using the present composite material as negative materials of Li-ion batteries, the negative materials of Li-ion batteries can be obtained with high-capacity Li-storage, excellent security and good circulation.

Owner:FUDAN UNIV

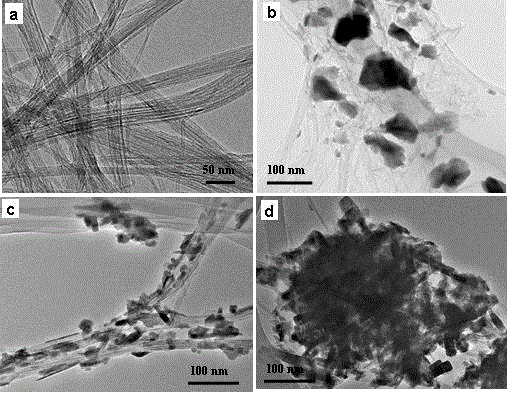

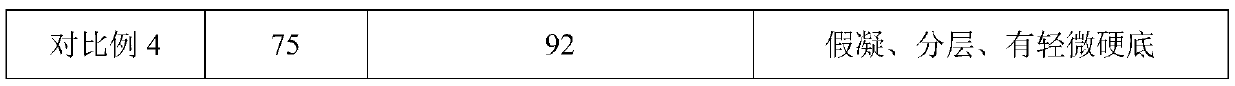

Method for preparing single crystal dispersed nanometer attapulgite through ion liquid synergetic high-pressure homogenizing treatment

ActiveCN107188192AAvoid secondary reunionsImprove performanceNanotechnologySilicon compoundsPhysical chemistrySingle crystal

The present invention discloses a method for preparing single crystal dispersed nanometer attapulgite through ion liquid synergetic high-pressure homogenizing treatment. The method comprises: carrying out breaking treatment on attapulgite crude ore, adding to the ethanol / methanol solution of an ion liquid, uniformly mixing, carrying out roller pressing treatment, transferring to a closed container, carrying out closed placing for 6-24 h so as to completely interact between the ion liquid and the attapulgite, directly dispersing the attapulgite and ion liquid mixture into water, completely stirring to form a suspension with a mass concentration of 5-20%, screening with a 400 mesh sieve, carrying out high-pressure homogenizing treatment, separating the obtained solid, drying, and crushing to obtain the nanometer attapulgite while recycling the liquid. According to the present invention, the method has advantages of simple production process, high efficiency and no waste liquid discharge, and the obtained product has advantages of excellent performance, high purity and stable quality, and can be used in a variety of fields such as polymer material reinforcement, thickening and suspending, functional carriers and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

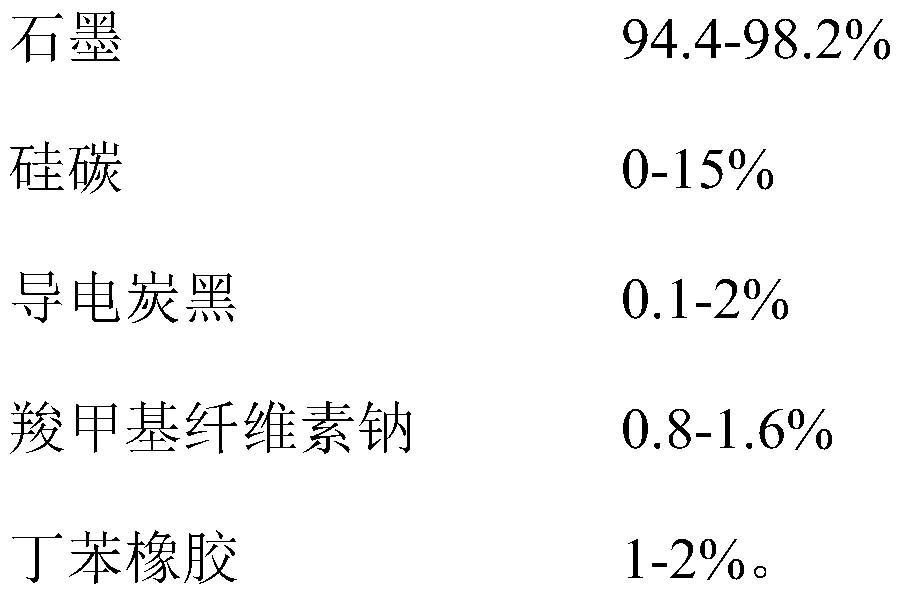

Silicon-carbon negative electrode material slurry and preparation method thereof

ActiveCN110854367AAvoid secondary reunionsGood dispersionSecondary cellsNegative electrodesGraphiteSlurry

The invention provides silicon-carbon negative electrode material slurry and a preparation method thereof. The method comprises steps of 1) dividing CMC glue solution into two parts, and mixing a first part of the CMC glue solution with conductive agent and a silicon carbon material to obtain slurry 1; 2) adding a graphite material into the slurry 1, and dispersing the material to obtain slurry 2;3) adding a second part of CMC glue solution and the water into the slurry 2, vacuumizing, and dispersing the material to obtain slurry 3; and 4) adding SBR binder into the slurry 3, dispersing, sieving the slurry, and discharging bubbles to obtain silicon-carbon negative electrode material slurry. The method is advantaged in that the agglomeration phenomenon of the silicon-carbon particles in the pulping process is eliminated, that the graphite material uniformly wraps the silicon-carbon particles is guaranteed, and the overall cycle life of a battery is improved.

Owner:SHAANXI COAL & CHEM TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com