Preparation method of two-dimensional boron nitride nanosheet

A technology of boron nitride and nanosheets, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem of low yield and quality of two-dimensional boron nitride nanosheets and too small size of two-dimensional boron nitride nanosheets , small size of two-dimensional boron nitride nanosheets, etc., to achieve the effect of easy promotion, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Using solid urea as the intercalation agent, according to the mass ratio of the boron nitride raw material and the intercalation agent being 1:5, pre-mix the boron nitride and the intercalation agent evenly, and set aside;

[0029] 2) Put the pre-mixed mixture in step 1) into a polytetrafluoroethylene ball mill tank, add 200g of zirconia grinding balls of different sizes according to the ball-to-material ratio (6-80): 1, and control the total charge It is 1 / 3~2 / 3 of the volume of the ball mill tank, stirred and milled in the ball mill for 4 hours at a speed of 300r / min to obtain a uniform white solid mixture;

[0030] 3) The white solid mixture obtained in step 2) is placed in a high-temperature-resistant porcelain boat, kept in a muffle furnace at a temperature of 600°C for 1 hour, taken out, and cooled to room temperature to obtain solid two-dimensional boron nitride nanosheets .

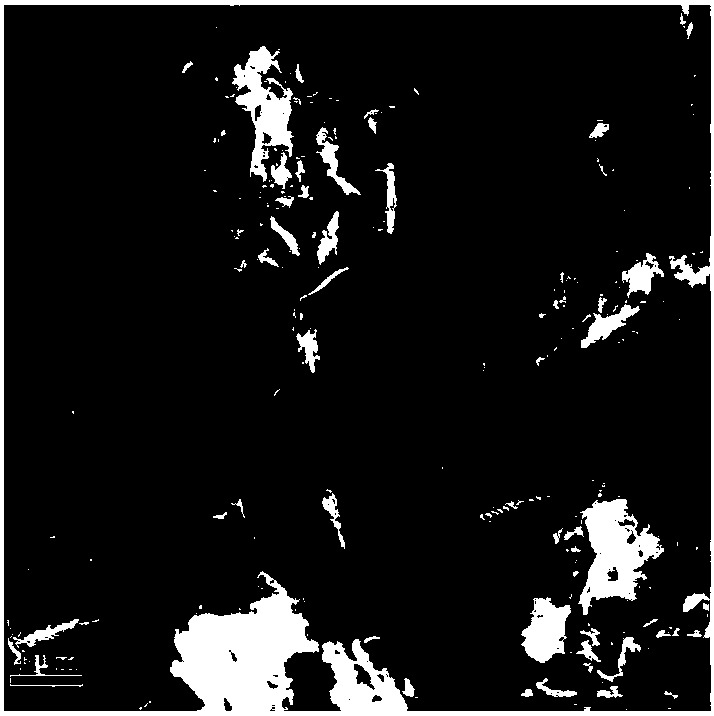

[0031] The scanning electron microscope (SEM) figure and the transmission electron ...

Embodiment 2

[0033] 1) Using solid ammonium bicarbonate as the intercalation agent, according to the mass ratio of the boron nitride raw material and the intercalation agent being 1:10, pre-mix the boron nitride and the intercalation agent evenly, and set aside;

[0034] 2) Put the pre-mixed mixture in step 1) into a polytetrafluoroethylene ball mill tank, add 200g of zirconia grinding balls of different sizes according to the ball-to-material ratio (6-80): 1, and control the total charge It is 1 / 3~2 / 3 of the volume of the ball mill tank, stirred and milled in a ball mill for 2 hours at a speed of 400r / min to obtain a uniform white solid mixture;

[0035] 3) The white solid mixture obtained in step 2) is placed in a high-temperature-resistant porcelain boat, kept in a muffle furnace at a temperature of 700°C for 5 minutes, taken out, and cooled to room temperature to obtain solid two-dimensional boron nitride nanosheets .

Embodiment 3

[0037] 1) using ammonium carbonate solid as the intercalation agent, according to the mass ratio of the boron nitride raw material and the intercalation agent being 1:50, pre-mixing the boron nitride and the intercalation agent evenly, and then set aside;

[0038] 2) Put the pre-mixed mixture in step 1) into a polytetrafluoroethylene ball mill tank, add 200g of zirconia grinding balls of different sizes according to the ball-to-material ratio (6-80): 1, and control the total charge It is 1 / 3~2 / 3 of the volume of the ball mill tank, stirred and ball milled in the ball mill at a speed of 100r / min for 12h, and a uniform white solid mixture is obtained;

[0039] 3) The white solid mixture obtained in step 2) is placed in a high-temperature-resistant porcelain boat, kept in a muffle furnace at a temperature of 700°C for 2 hours, taken out, and cooled to room temperature to obtain solid two-dimensional boron nitride nanosheets .

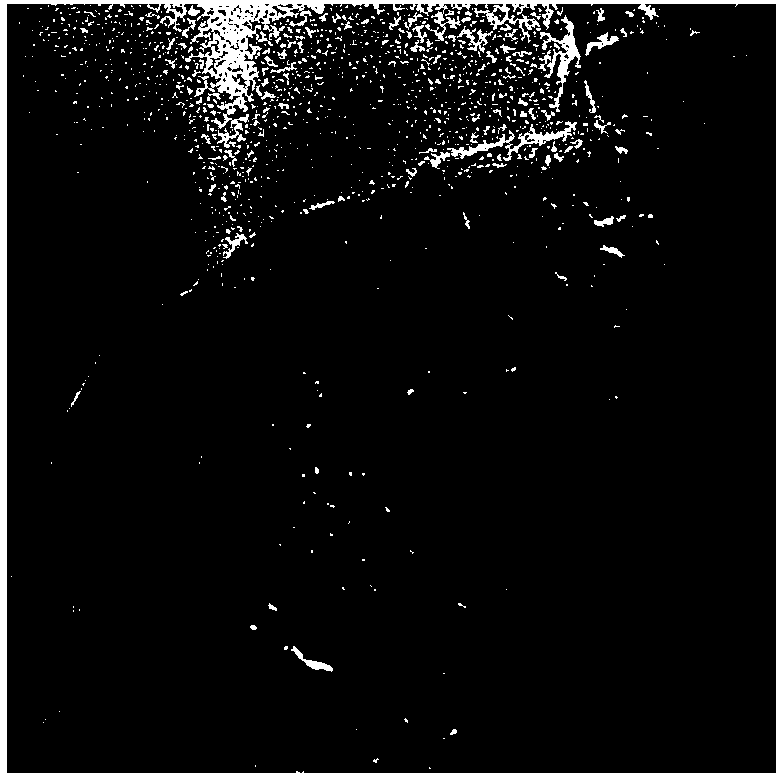

[0040] For the HRTEM image of the two-dimensional b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com